- Offer Profile

- Our international company develops innovative permanent marking and automated identification solutions for the complete traceability of industrial components. We offer high quality systems in all marking technologies: our marking solutions include laser, dot peen and scribing machines that are especially robust and reliable and that are designed to increase productivity and offer unrivalled marking quality. Our product catalog ranges from standard machines to fully custom engineered marking solutions. Our engineers can customize any product to your needs: adjustment of the marking window size, custom clamping on portable machines, addition of automatic tag feeder... All our custom engraving machines are created with the most careful attention so as to bring functional design, quality, innovation, and the highest performance to your manufacturing lines.

WORKSHOP RANGE

- For standalone marking stations or portable marking machines, our Workshop offer covers all the marking configurations and constraints of production workshops.

Portable Dot peen marking machines

-

Our portable marking machines are designed for compatibility and durability in the most demanding industrial environments. They are easy to handle, robust, on battery or wired and without consumables.

They provide you with considerable freedom of movement, utilisation modes (optional columns) or marking configurations (interchangeable front panels, as a function of the parts being marked).

E-MARK

-

The E-MARK is a PORTABLE CORDLESS DOT PEEN marking machine that can mark all types of material, from plastic to treated steel with a hardness of up to 62 HRC.

It can operate for long periods on its INTEGRAL BATTERY. This mobile and portable marking machine is fully autonomous due to its integral 18V Li-Ion battery, giving up to 4 HOURS OF CONTINUOUS USE. The E-MARK comes with two batteries and a fast charger, in a convenient carrying case, which allows you to continue working with one battery while the other is being charged.

The robust E-MARK design is based on an aluminium alloy casting, which makes it particularly suitable for severe INDUSTRIAL ENVIRONMENTS.

E-MARK XL

-

The E-MARK XL is a cordless portable dot peen marking machine that features A VERY LARGE MARKING WINDOW: 120 x 40 mm.

It can operate for long periods on its integral battery. This MOBILE AND PORTABLE MARKING MACHINE is fully autonomous due to its integral 18V Li-Ion battery, giving up to 4 HOURS OF CONTINUOUS USE. The E-MARK XL comes with two batteries and a fast charger, in a convenient carrying case, which allows you to continue working with one battery while the other is being charged. The E-Mark XL is a robust design with a cast alloy base. It is particularly suitable for DEMANDING INDUSTRIAL ENVIRONMENTS. Its high striking force makes it especially suitable for marking heavy or very large parts.

The E-MARK XL is also ERGONOMIC AND VERY EASY TO USE.

E-TOUCH

-

The E-TOUCH is a PORTABLE MARKING MACHINE WITH A TOUCH SCREEN.

It is robust, compact and light.

It has 3 CONTACT FACES that are INTERCHANGEABLE without tools, that allow it to be set up in various marking configurations (piece shapes and marking conditions).

The E-TOUCH weighs LESS THAN 2 kg and is very compact, measuring 220 x 210 x 125 mm. It is the LIGHTEST AND MOST COMPACT PORTABLE DOT PEEN MARKING GUN ON THE MARKET.

Nevertheless, its internal metal structure makes it very robust. In addition, an ergonomic handle and excellent mass balancing make it VERY EASY TO HANDLE.

E-TOUCH XL

-

The E-TOUCH XL is a cordless portable touch screen marking machine with A VERY LARGE MARKING WINDOW: 120 x 50 mm.

It is robust, compact and light. It has 3 CONTACT FACES that allow it to be set up in various marking configurations (piece shapes and marking conditions).

The E-TOUCH XL WEIGHS LESS THAN 3 kg and has a large marking window. It can mark HEAVY OR BULKY PARTS while also being mobile. Nevertheless, its internal metal structure makes it very robust. In addition, an ergonomic handle and excellent mass balancing make it VERY EASY TO HANDLE.

The shape of the E-TOUCH XL allows programming with both hands. The TOUCH SCREEN is usable with or without gloves, which makes it particularly suitable for use in an industrial environment. Its full-size viewing window allows the MARKING TO BE PREVIEWED exactly as it will be applied on the piece.

P63

-

The P63 is a DOT PEEN MARKING GUN designed to mark all types of industrial parts. This mobile marking machine is suitable for the identification and traceability of heavy and bulky parts and can mark all types of material.

The P63 has a cast alloy body and a stainless steel front module that make it extremely strong.

The P63 marking gun is FAST AND POWERFUL and MARKS WITH CONSTANT QUALITY AND PRECISION.

The P63 has a tungsten carbide stylus that distorts the material and can make PERMANENT MARKINGS of all types: alphanumeric text, logos, 2D Datamatrix code or QR codes.

The P63 marking gun comes with AN INDEPENDENT E10 CONTROLLER THAT OFFERS MANY PROGRAMMING POSSIBILITIES. All marking files can be transferred through the USB port on the E10 controller.

P123

-

The P123 is a DOT PEEN MARKING GUN designed to mark all types of industrial parts. It features WIDE MARKING WINDOWS: 120×25 mm or 120×40 mm.

This mobile marking machine is suitable for the IDENTIFICATION AND TRACEABILITY OF HEAVY AND BULKY PARTS and can mark all types of material.

The P63 has a cast alloy body and a stainless steel front module that makes it EXTREMELY STRONG. The P63 marking gun is fast and powerful and marks with constant quality and precision.

Dot peen marking stations

- Our dot peen marking stations or marking “benches” are standalone stations that combine durability, precision and high marking rate, on all types of material.

EC1 DOT PEEN MARKING MACHINE

-

The EC1 is a COLUMN-MOUNTED DOT PEEN MARKING MACHINE – a machine that can be manually adjusted on the vertical axis to position the marking head according to the height of the part. It is ideal for marking small or medium sized parts, which are placed directly beneath the marking head.

The EC1 has a WIDE MARKING WINDOW (120×100 mm) and a column stroke of up to 300 mm, which allows it to mark parts of various shapes and sizes. This machine also has a CONTROL SYSTEM, including a graduated column for adapting the position of the stylus in relation to the marking area. The EC1 is able to mark ALL TYPES OF MATERIALS from plastic to metal up to a hardness of 62 HRC with CONSISTENT QUALITY AND PRECISION.

It only needs connecting to a POWER SUPPLY. Dot peen marking technology with electromagnetic control enables parts with a variety of shapes and surface finishes to be marked: flat, concave, convex, circular, raw and machined surfaces. Thanks to the tungsten carbide stylus, which displaces the material by creating a series of indents in the surface to be marked, the EC1 is equally capable of engraving alphanumeric text, logos, 2D Data Matrix codes or QR codes.

E10 C153 DOT PEEN MARKING MACHINE

-

The C153 is a COLUMN-MOUNTED DOT PEEN MARKING MACHINE, i.e. a machine that slides on a vertical axis to adjust the position of the marking head.

It is particularly suitable for marking SMALL AND MEDIUM SIZE PARTS that are placed directly under the marking head.

The C153 is a FAST MACHINE DESIGNED FOR INTENSIVE USE. THE MACHINE IS PARTICULARLY ROBUST WITH A CAST ALLOY BASE AND A STRENGTHENED COLUMN. It has an integral meter that facilitates the setting of the marking distance when parts are changed.The wide marking window of 160 x 100 mm, allows this machine to mark on a large surface. The LED lighting system facilitates marking when indoor light is insufficient. It only needs an electrical power supply.

Dot peen marking technology with electromagnetic control enables parts with various shapes and surface finishes to be marked: plane, concave, convex, circular, raw and machined surfaces. The tungsten carbide stylus deforms the material by executing a series of indents in the surface to be marked. The C153 can engrave alphanumeric text, logos, 2D Data Matrix codes or QR codes. It only needs an electrical power supply.

C153 ZA DOT PEEN BENCHTOP MARKING MACHINE

-

The C153 ZA is a COLUMN-MOUNTED DOT PEEN MARKING MACHINE, i.e. a machine that slides on a vertical axis to adjust the position of the marking head. It is ideal for marking small or medium sized parts, which are placed directly beneath the marking head. The C153 ZA is a fast machine, designed for intensive use.

This machine is particularly robust with a cast alloy base and a strengthened column. The C153 ZA has a LARGE MARKING WINDOW (160x100mm) and can precisely mark ALL TYPES OF MATERIAL, from plastic to steel hardened to 62HRC. The E10 CONTROLLER that controls the C153 ZA has a Qwerty keyboard covered by a waterproof membrane and a backlit colour screen that provides the user with a simple and intuitive interface. Marking files can be uploaded/downloaded to/from the controller, to/from a PC, using a USB memory stick.

C303 DOT PEEN MARKING MACHINE

-

The C303 is a COLUMN-MOUNTED DOT PEEN MARKING MACHINE, i.e. a machine that slides on a vertical axis to adjust the position of the marking head.

It is ideal for marking small or medium sized parts, which are placed directly beneath the marking head. It differs from other machines by its VERY LARGE MARKING WINDOW: 300×150 mm The C303 is a fast machine, designed for INTENSIVE USE. This machine is PARTICULARLY ROBUST with a cast alloy base and a strengthened column. It has an INTEGRAL METER that records the piece heights, to facilitate the setting of the marking distance when parts are changed.

Laser stations

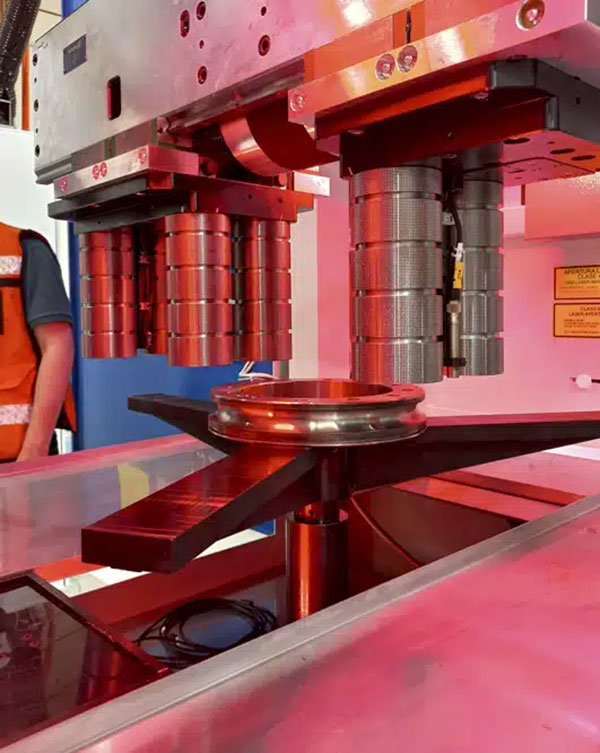

L-BOX LASER SYSTEM

-

SIC Marking's L-Box Laser Marking System was engineered with the energetic bustle of industrial environments in mind. It is equipped with a high powered, pulsed wave ytterbium-doped fiber laser that is easy to operate, even for users with minimal training in laser technology. Its robust and 100% solid steel construction are a clever contrast to its compact and eye-catchingly sleek design. The retractable cover is a solid steel construction that opens on all three sides, and its handle has been ergonomically designed to maximize user comfort and minimize fatigue.

Its Class 1 rated security features an integrated safety loop that automatically terminates the laser when the door is opened. The marking window is a full 100 mm x 100 mm (3.9" x 3.9"), with an option for 170 mm x 170 mm, and will mark components with heights of up to 235 mm (9.3"), and lengths of up to 450 mm (17.7"). SIC Marking's L-BOX is a durable, long-lasting benchtop marking machine with an extended component life expectancy of up to 100,000 operating hours.

XL-BOX LASER SYSTEM

-

PREMIUM LASER MARKING WORKSTATION As its name suggests, SIC’s XL-BOX is the flagship among a range of laser workstations, with features and dimensions designed to increase productivity and adapt to the evolving needs of manufacturing and production lines. Modeled after the ever popular L-BOX, XL-BOX has larger internal dimensions, with a 570 x 564 mm work area that more comfortably accommodates larger sized components. Constructed of solid steel, it’s a compact 655 mm wide enabling its user to work comfortably when loading/unloading parts to be marked. Much larger than its predecessor, XL-BOX is equipped with a pneumatically-powered, intuitively secure door that automatically locks when the cycle starts and opens when the marking is finished.

Operated with the push of a button, it’s a smooth action entry that allows access on all three sides and is equipped with a large viewing window. The “smart” Z-axis operates on a 235 mm (9-1/4”) motorized system; with the additional help of two red focal pointers, focusing a precise mark is simple. XL-BOX is equipped with a high powered, pulsed wave ytterbium-doped fiber laser which allows shallow or deep markings of alphanumeric codes, barcodes, and 2D Data Matric codes, and on all metals and some plastics. It is easy to operate, even for users with minimal training in laser technology. This versatile laser marking workstation is operated via SIC’s proprietary, user-friendly software: SIC LASER PC. This software – included with the package – can be run using Windows on any PC, and offers multiple configuration options.

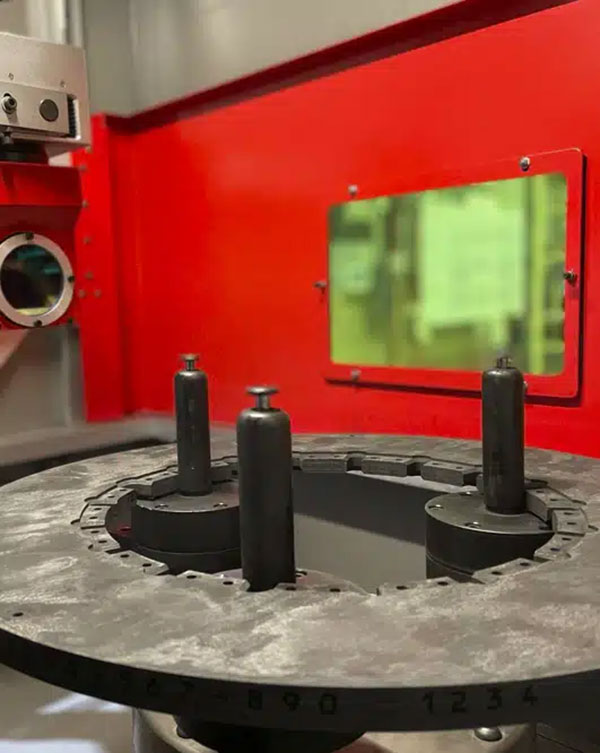

XXL-BOX LASER SYSTEM

- THE LARGEST MARKING STATION ON THE MARKET

The XXL-Box allows the marking of large parts. With a 820 mm depth and the ability to mark 520 mm parts high, this marking station has the largest volume on the market.

In order to meet different needs, the XXL-Box is available in 3 width (800, 1200 or 1600 mm) and can be equipped with an unlimited number of standard and customized options, making it a particularly modular machine :

- Control by the automation of a robotized cell

- Manual or motorized horizontal movement of the column

- Divider axis

- Drawer for heavy parts

- Suction and filtration system

- 3D marking or integrated reading system can be added at any time

- Etc.

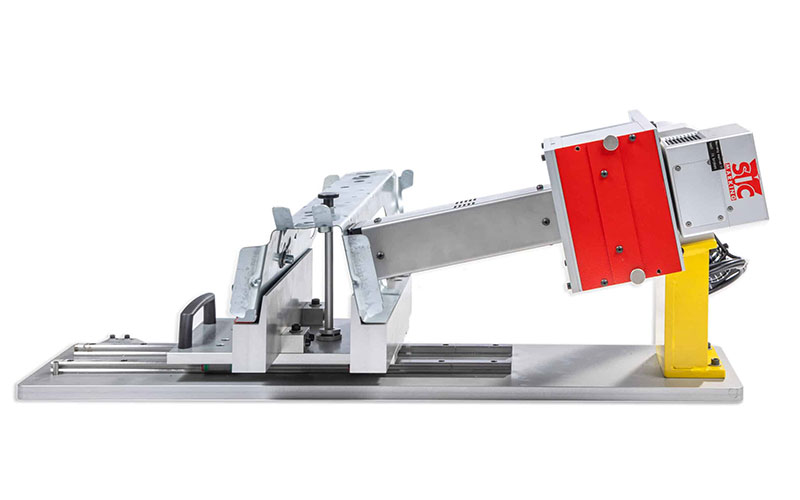

TAGMARK LASER

-

The LASERTAGMARK is a FULLY AUTOMATED LASER MARKING STATION that will allow you to simultaneously manage the marking of your plates, on a SINGLE, SAFE AND SYNCHRONISED WORK STATION with your own data.

PLATES ARE MARKED IN SERIES, AUTOMATICALLY. Operator presence is not necessary.

The TAGMARK LASER can be equipped with lasers of VARIOUS POWER RATINGS, for deeper marking or marking at higher rates. The ytterbium-enhanced SIC Marking fibre laser is a latest generation technology that enables high quality marking without affecting the piece, and with a shorter cycle time.

Production line range

-

This broad range of equipment meets production line constraints and performance requirements. Compact, efficient, robust and easily connected to your communication network, we offer the equipment in the form of modules or standalone stations, easily integrated into production lines or islands.

Production line integration can be handled by the customer directly, if they have a methods department, or can be carried out by an integrator. Irrespective of the customer, we support the teams through the installation, start-up and maintenance of our solutions.

Integrated Dot peen marking stations

Marking machine I 53

-

The I 53 is a DOT PEEN MARKING MACHINE designed for EASY INTEGRATION ON AUTOMATIC LINES in an industrial environment, due to its compact size and 4 mounting faces. It is suitable for a great majority of applications.

This integrable machine can be used in a production line IRRESPECTIVE OF THE DESIRED POSITION. The ROBUST CAST ALLOY STRUCTURE is protected by LEATHER BELLOWS, designed to resist projections and fine particles.

In addition, the I 53 connector can be moved onto the side face if needed for integration into a production line.

The tungsten carbide stylus deforms the material by creating a series of indents in the surface to be marked. The EC1 can engrave alphanumeric text, logos, 2D Data Matrix codes or QR codes. Dot peen marking technology with electromagnetic control enables parts with various shapes and surface finishes to be marked: plane, concave, convex, circular, raw and machined surfaces. It only needs an electrical power supply.

Marking machine I 83

-

The I 83 is a DOT PEEN MARKING MACHINE designed for easy integration on automated lines in an industrial environment. The precision of its electro-magnetic control and its crossed table make it THE BEST FOR MARKING VERY HIGH QUALITY 2D CODES (Datamatrix, QR codes, etc.)

This integrable machine can be used in a production line IRRESPECTIVE OF THE DESIRED POSITION. The I 83 connector can also be positioned on the side face, if necessary for production line considerations. Its robust structure is protected from oil or dust projections by bellows, which also give simpler utilisation in an industrial environment.

The i83 has two specific options. The first one is the I 83V, an INTEGRAL VIEWING SYSTEM that allows the codes marked to be read at the end of each marking cycle.

The second one is the I 83A, with an AUTO-SENSING SYSTEM that automatically positions the machine at the correct distance from the piece being marked, through an integral sensor. I 83 marking may be alphanumeric text, a logo, a 2D Datamatrix code or a QR Code. Dot peen technology provides reliable and permanent marking directly in the material, through a tungsten carbide stylus that strikes a series of dots at a very high rate.

Dot peen marking technology with electromagnetic control enables parts with various shapes and surface finishes to be marked: plane, concave, convex, circular, raw and machined surfaces. It only needs an electrical power supply.

Marking machine I 143

-

The I 143 is an electro-magnetic dot peen marking machine that can mark all types of industrial parts with its large marking field: 150×100 mm.

The I 143 is a dot peen marking machine designed for easy integration on automated lines in an industrial environment. The precision of its electro-magnetic control and its crossed table make it the best for marking very high quality 2D codes (Datamatrix, QR codes, etc.)

This integrable machine can be used in a production line irrespective of the desired position. Also, the I 143 connector can be moved onto the side face if needed, to meet any production line requirements.

Marking machine E-SMART

-

The E-SMART is an electro-magnetic dot peen marking machine that can be integrated into a production line.

The E-SMART marking machine is ALL-IN-ONE. It is designed to be easily integrated in an industrial environment, with its electronic controller integrated to the marking head. It can be installed in A PRODUCTION LINE, in A ROBOTISED CELL OR CNC MACHINE.

Its cast alloy ROBUST STRUCTURE is protected by leather bellows, designed to resist projections and metal particles, etc.

It provides VERY FAST PERMANENT MARKING ON ALL TYPES OF MATERIAL, from plastic to hardened steel up to 62 HRC. It is easy to use and can mark parts of various shapes and different surface conditions.

The E-SMART has a BATTERY OPTION that makes it fully standalone. An ADAPTER PLATE then allows any type of tool holder to be installed, for availability in the tool store of a numerical control machining centre.

E-SMART marking may be alphanumeric text, a logo, a 2D Datamatrix code or a QR Code. Dot peen technology provides reliable and permanent marking directly in the material, through a tungsten carbide stylus that strikes a series of dots at a very high rate.

Markiergerät i-SPEED

-

Der PNEUMATISCHE NADELPRÄGER i-SPEED kann in eine PRODUKTIONSANLAGE INTEGRIERT werden.

Das Gerät verwendet die OSZILLATIONSTECHNOLOGIE. Bei dieser besonderen Art der Nadelmarkiertechnologie vibriert die druckluftunterstützte Nadel während ihrer Bewegung über das Material, um besonders schnelle und fortlaufende Markierungen zu erstellen. Die pneumatische Prägeeinheit ist besonders für einfache Markierungen geeignet, die in kurzen Taktzeiten ausgeführt werden müssen.

Der Nadelpräger i-SPEED ist perfekt für Produktionsanlagen mit sehr hohen Produktionstakten und erreicht eine Markiergeschwindigkeit von BIS ZU 10 ZEICHEN pro Sekunde.

Marking machine I 124D

-

The I 124D is a DOT PEEN MARKING MACHINE designed for EASY INTEGRATION ON AUTOMATED LINES in an industrial environment.

The I 124D is probably the deepest dot peen marking machine on the market. It differs from other dot peening marking machines by its SPECIFIC STYLUS AND PNEUMATIC STRIKER , designed for DEEP MARKING, UP TO 0.8 mm on standard steel.

With powerful motors and a HEAVY DUTY STRUCTURE, the I 124D can mark ALL TYPES OF MATERIAL very fast. The tungsten carbide stylus deforms the material by creating a series of indents in the surface to be marked and can engrave alphanumeric text, logos, 2D Data Matrix codes or QR codes.

Integrated Laser solutions

-

Our integrated modules manage marking configurations and requirements; production lines. They are compact, ultra-fast and precise, and they guarantee high quality markings in the flow of your industrial processes.

Our integrated lasers are designed to operate at high rates and to connect easily to your communication networks. They provide precise answers to your online marking problems such as cycle time, communication or security.

I 104 HIGH POWER marking head

-

In order to meet the need for shorter cycle times or deeper marking, SIC MARKING has developed a range of high power lasers. Our high power fibre lasers have power ratings up to 500W. They can be supplied in integrable laser format, or integrated in our class 1 security marking cells, or in our F.I.T LASER. Connecting a high power laser to your PLC is extremely simple. A single Profinet, Profibus or Ethernet IP type connection provides quick and easy integration. To guarantee both performance and life cycle in demanding production environments, SIC MARKING also supplies specific accessories, such as, for example, an efficient fume evacuation system that is essential for this type of laser. This type of laser has many applications:

- deep marking, that remains readable after shot blasting, surface treatment or the application of a coating (paint, anti-corrosion protection, etc.).

- texturing, which voluntarily changes or roughens the surface of a metal or plastic piece in order to change its appearance or properties like, for example, to clean a battery cell, roughen a surface to prevent unscrewing, remove the coating from a metal part to ensure conductivity, etc.

- regulatory marking of the VIN (Vehicle Identification Number) on the chassis of motor vehicles, to a minimum depth of 0.2 mm and in a cycle time that is often around 20 seconds.

- finally, the stripping of electrical wires, which is becoming increasingly used with the development of electric motors. This involves removing various insulation materials from part of the wire, to enable connection.

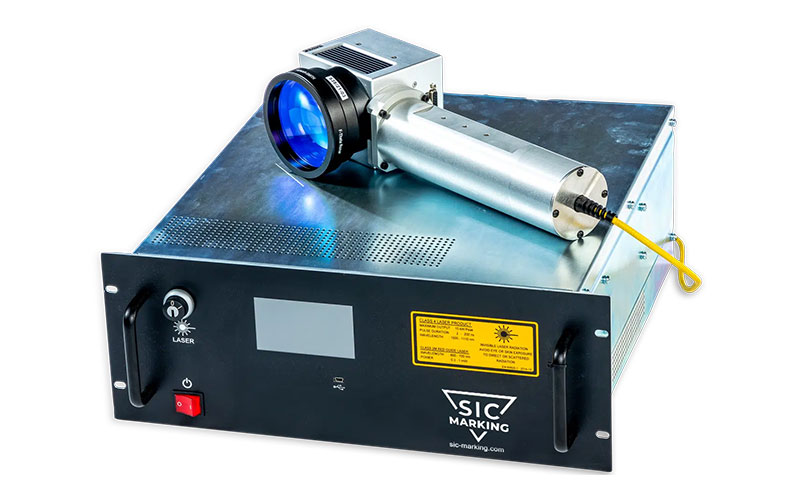

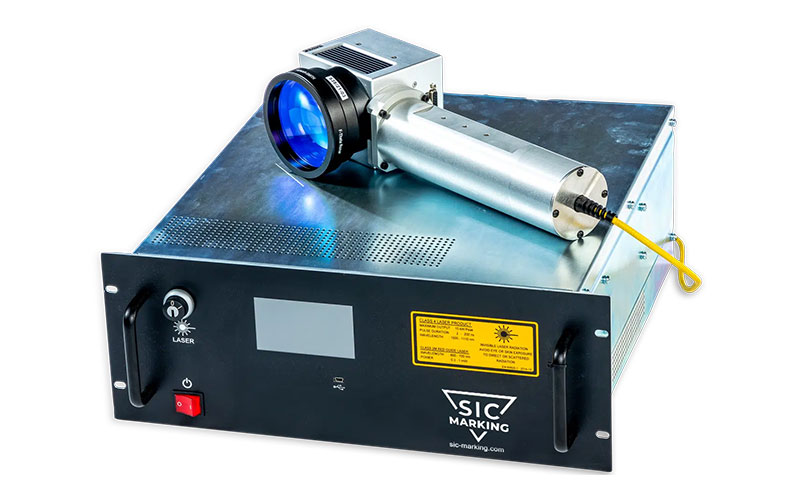

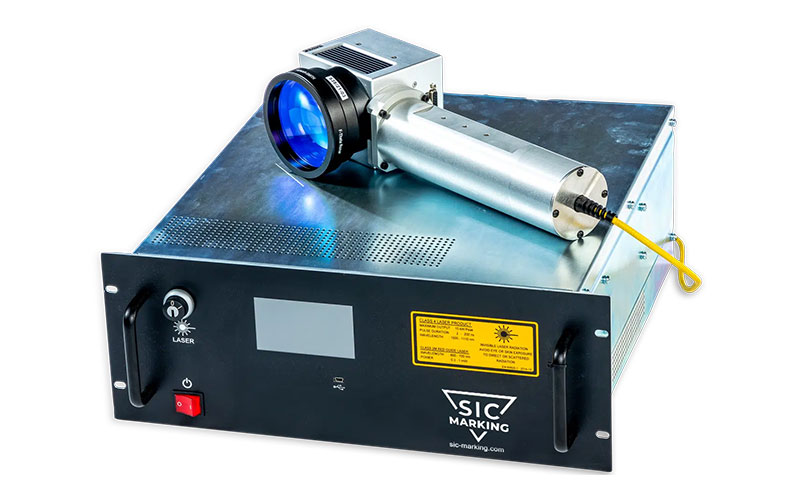

Integrable laser i104 EASY

-

The I-104 EASY is a FIBRE LASER marking head, THAT CAN BE INTEGRATED INTO YOUR PRODUCTION LINES. Our EASY laser marking systems are equipped with proven technology, with an ytterbium-enhanced fibre laser source and SEVERAL POWER RATINGS AVAILABLE to meet your needs.

The I-104 EASY marking laser is designed to mark parts at HIGH RATES in any industrial environment. It provides HIGH QUALITY MARKING on many materials (steel, aluminium alloy, stainless steel, titanium, plastics, etc.). The I-104 EASY laser marking head marks high definition logos, alphanumeric codes, and 1D, 2D and datamatrix codes, with precision and contrast.

The I-104 EASY laser is extremely COMPACT and is therefore very EASY TO INSTALL in a box or on a production line. It can operate with or without a PC. Without a PC, a single connection can fully control the laser from your PLC.

Marking laser i104 HD

-

The I-104 HD is a FIBRE LASER marking head that can be integrated into production lines. Fibre laser is a LATEST GENERATION, ULTRA-HIGH PERFORMANCE AND DURABLE technology. Our HD laser marking systems are equipped with a particularly efficient ytterbium-enhanced MOPA (Master-Oscillator Power-Amplifier) fibre laser source.

The power of the I-104 HD laser marking head allows it to MARK WITH CONTRAST ON ALL TYPES OF MATERIAL (steel, aluminium alloy, stainless steel, titanium, plastics, etc.). The marking of logos, alphanumeric codes and standard 1D, 2D and Datamatrix codes is particularly precise. The cycle time is shorter on materials such as aluminium alloy and the contrast is greater on plastics.

LASER F.I.T. marking machine

-

The LASER F.I.T. is A LASER MARKING UNIT WITH A SAFETY SLEEVE, designed for integration into production lines.

This all-in-one integrable solution includes the supply and the protections required to efficiently and safely mark parts on a production line. The marking unit is particularly COMPACT AND LIGHT (13 kg), for easy integration.

The LASER F.I.T. is actually READY FOR INTEGRATION AS CLASS 1. For the protection of persons close by, the beam is enclosed in a sleeve that contains the radiation. Various sizes of sleeve are available, to match your marking sizes and surfaces: 34 mm x 32 mm, 100 mm x 32 mm, 100 mm x 100 mm. Other sizes are possible on request. Connecting the LASER F.I.T. to your PLC is extremely simple.

Integrated scribing

-

Our scribe marking ranges are quiet, fast & accurate and available in two window sizes.

Discover our solutions for simple and efficient integration.

Marking machine i124S

-

The I 124S is a scribe marking machine that can easily be integrated into a production line. It differs from the I 63S by its wide marking window (120 mm x 60 mm).

Scribing is a marking technology that is quieter than dot peening. The E10R I 124S is powerful and is therefore ideal for deep scribing on all types of material.

The robust structure of the I 124s is protected against projections by stainless steel bellows and a full cowling. The machine can therefore be integrated into difficult environments and operate at high rates.

Marking machine I 63S

-

The E10R I 63S is a particularly compact scribe marking machine that can easily be integrated into a production line. Scribing is a marking technology that is quieter than dot peening. The I63S is powerful and is therefore ideal for DEEP SCRIBING ON ALL TYPES OF MATERIAL. The robust structure of the I63S is protected against projections by stainless steel bellows and a full cowling.

The machine can therefore be integrated into DIFFICULT ENVIRONMENTS and operate at HIGH RATES. Its easy integration and programming make it very simple to use. Utilisation cost is low as no maintenance or consumables are needed. The power of the integral software makes it a high performance unit.

Our custom machines

- Our custom marking and traceability solutions are developed based on our standard equipment, to which we apply all the expertise developed on specific projects and sectors by our dedicated team. Our custom marking solutions are modular: we can adapt 3D marking functions, integrated viewing systems, specific marking window sizes, PLCs, etc. We offer you 30 years of expertise and experience!

Our design department is at your service

-

Before each project, our experts conduct an individual analysis of your needs.

This first step enables us to draft specifications, from which we shall be able to determine the best marking or reading solution.

Testing in test laboratory

-

We have several test laboratories in which we can conduct marking tests on your parts, free of charge.

Marking depth, engraving contrast, post-engraving treatment of parts. All these parameters will be assessed and marking tests will be conducted, in order to recommend the right equipment, settings and the best options.

Design and development

-

Our design office will then prepare an offer that will include all the specific aspects of the project: functional analysis, preliminary design, cost, completion time, training and installation supervision.

Following your approval, a project will be initiated and the implementation of your project will be managed by a single contact.

Your custom equipment will then be manufactured by a dedicated and specialised team. Our production teams combine skills in Assembly, Mechanical engineering, Wiring, Software Programming and Automation.

Your custom machine is manufactured in our 1400m² production workshop, followed by functional tests. A preliminary acceptance is conducted in your presence, before your equipment is shipped.

MARKING APPLICATIONS

- For over 20 years, leading players from various global industrial sectors have placed their trust in the marking and traceability solutions developed by SIC Marking's engineering teams. Our highly skilled sales representatives, supported by our technical centers, respond to every industry's need in terms of direct part marking. Our permanent industrial engraving solutions are developed especially for all industrial sectors.

AEROSPACE

- Aircraft industry standards and specifications are very specific to this sector. They require perfect marking quality while respecting the integrity of the parts, that must not be affected by the marking. The traceability of parts and components meets the safety, quality and continuous improvement requirements of the aircraft industry. We have been working with industry leaders and their suppliers for many years.

AUTOMOTIVE

- SIC Marking has developed considerable expertise in the deployment of marking machines and in the implementation of traceability solutions in the automotive sector. Our applications in the direct and permanent marking of automotive parts or components are very varied: steel engine parts, plastic interior trim parts, exhaust modules, tyres, VIN marking on chassis, etc.

Marking for metallurgy &mechanics industry

-

We have many references in the implementation of traceability systems in metallurgy sectors such as forging, forming, stamping, cutting or machining… Depending on the material concerned, the expected rendering, your production conditions and traceability requirements, one of our laser engraving, dot peen marking or scribing solutions will be more appropriate.

Our experts are here to advise you according to your needs, do not hesitate to contact us!

Machinery & Transport

-

The construction sector is producing increasingly sophisticated equipment: quality standards are high and manufacturing processes are automated.

In this context, the traceability of parts and components is also incorporated at all stages of manufacture. Trains, buses, professional or private vehicles, construction site vehicles, etc., must bear permanent traceability markings throughout their life.

ENERGY

-

The energy sector covers many applications that require industrial marking: heating, solar panels, oil equipment, gas transport, etc.

The robustness, portability and power of our marking equipment will allow you to find the solution that meets your technical and environmental requirements, often extreme in these sectors.

OTHER SECTORS

-

Direct and permanent marking on parts provides better traceability and facilitates production automation, stock management, batch control, quality control, storage defects and eliminates reading errors.

We develop traceability systems for all types of sector, such as medical, military, electrical or electronic equipment, construction or consumer products…

Consult us for a study of an appropriate solution for your sector.

Materials

- In addition to the conditions and requirements for marking a part, its inherent characteristics will determine the choice of the most suitable marking technology (laser, dot peen marking or scribing) and the right marking machine (power, speed, portability, etc.).

The material, as well as the finish of the surface to be engraved, play a decisive role in making the right choice.

Aluminium

- Lightweight, resistant to oxidation and corrosion, aluminium alloy is a metal widely used in various industrial sectors.

In terms of marking and traceability, SIC MARKING has developed technologies perfectly suited to this versatile alloy.

Excellent engraving results are obtained with our laser, dot peen marking and scribing systems, whether the aluminium alloy be raw or treated.

Copper

- Copper is an excellent conductor of electricity and heat. It is durable and easy to treat.

Copper is used in many sectors: energy, building (plumbing), automotive, telecommunications, construction and transport.

SIC MARKING dot peen marking machines give excellent results on copper.

We are also developing innovative laser applications, such as the stripping of copper wire insulators for new energy vehicles (NEVs).

Stainless steel

- Stainless steel is one of the most used materials in industry.

Its anti-corrosion properties, its high strength and its attractive finish make stainless steel a preferred solution in terms of marking and traceability.

SIC MARKING engraving machines give high-quality results in laser technology, dot peen marking and scribing.

Plastic

- There is a wide variety of plastics, the choice of marking technology depends on the type of plastic and also on all the additives/pigments contained in the plastics.

Each project is unique and the richness of the SIC MARKING offer makes it possible to identify the marking machine that will give the best results, in dot peen technology, fibre laser (in particular HD because it limits the heating of the material) or green laser.

Steel

- Steel is a metal alloy consisting mainly of iron and a small quantity of carbon. Its composition gives it specific properties such as hardness and it remains one of the most used materials in an industrial environment.

Other materials

- SIC MARKING specialises in permanent marking and traceability, and provides its expertise for your projects, irrespective of the material being worked.

We are experts in steel, stainless steel, aluminium, plastic and copper, and can meet your more specific needs, such as engraving on carbon, titanium, ceramic, rubbers or on alloys such as Inconel, brass, bronze…

Marking types

- In addition to the conditions and requirements for marking a part, its inherent characteristics will determine the choice of the most suitable marking technology (laser, dot peen marking or scribing) and the right marking machine (power, speed, portability, etc.).

The material, as well as the finish of the surface to be engraved, play a decisive role in making the right choice.

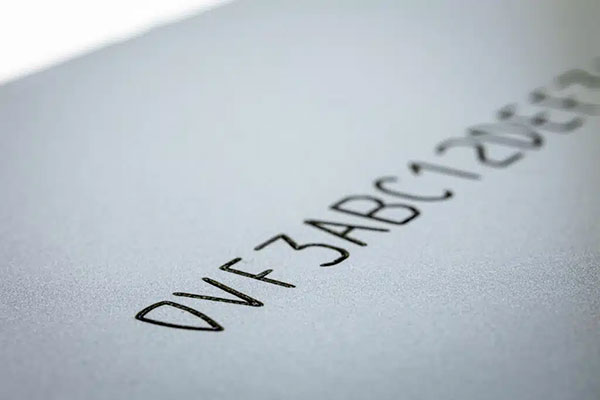

Alphanumeric Marking

-

Alphanumeric marking consists of marking a series of digits or letters.

This sequence of characters is used to identify parts when there is no automatic check and the marking is used by simple direct reading by the operator during the manufacturing process.This type of marking is possible with the 3 marking technologies we offer: laser, dot peen marking, scribing.

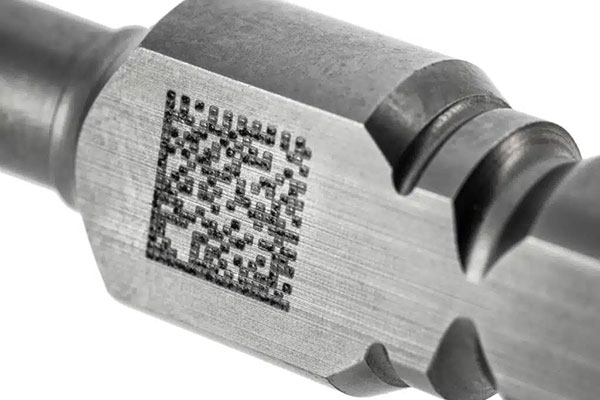

Datamatrix Marking

- Traceability management through the datamatrix code simplifies the tracking of your parts or products throughout your manufacturing, control and storage processes. The marking of a 2D datamatrix code is commonly used for Direct Marking on a part in cases of automatic reading.

Logo marking

- Logos can be marked using dot peen, laser or scribing technology.

Dot peen technology is possible for simple logos. Laser marking, with its finesse and clean appearance, is the best solution for HD logos and more complex designs.

This type of marking requires vector files.

QR code & barcode marking

-

The bar code or 1D code represents data by displaying a series of vertical bars of various widths.

Laser technology is perfect for marking such a code due to its precision and perfect appearance, which guarantees excellent reading.

The QR code is an alternative to the datamatrix.

We offer laser technology for this application.

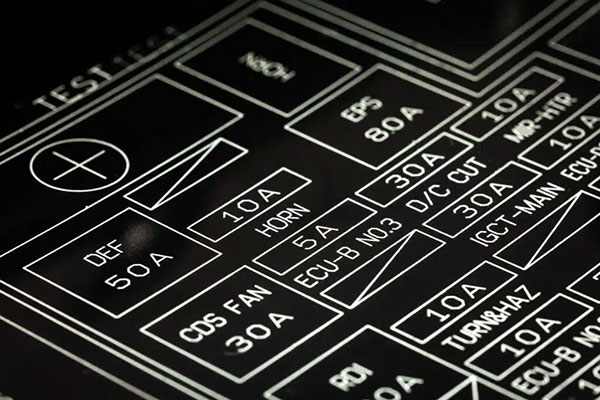

VIN marking

- VIN, Vehicle Identification Number: 3 letters for an acronym that has an essential place in automotive traceability and marking of parts. This marking is regulated and its traceability must be ensured for 30 years. This standard serial number of 17 characters is marked on the vehicle chassis and is unique, thus ensuring traceability throughout the manufacturing process and also after leaving the factory.

Our technologies

- With 30 years’ experience, we are experts in a number of marking technologies: Dot Peen marking, Laser marking and Scribe marking. Our solutions are robust, technically advanced and tailored to our customers’ challenging industrial environments.

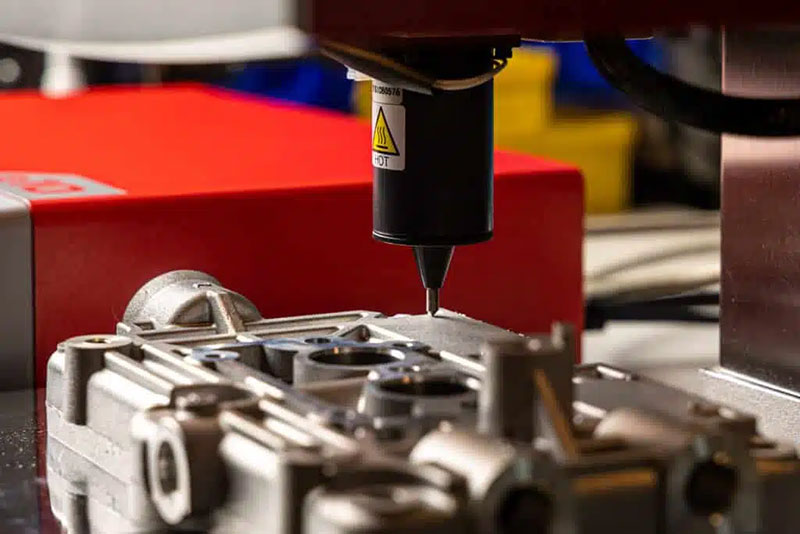

Dot peen marking

- Dot peen marking or engraving makes it possible to generate permanent, tamper-proof and perennial markings on all types of parts and materials. Dot peen marking or indented marking is widely used in the automotive industry, pioneering in its overall approach to quality via single component identification systems. Today, it is present in most industrial sectors. Our dot peen marking systems are designed to be installed in workshops, for fixed or mobile operation, or for integration into production lines.

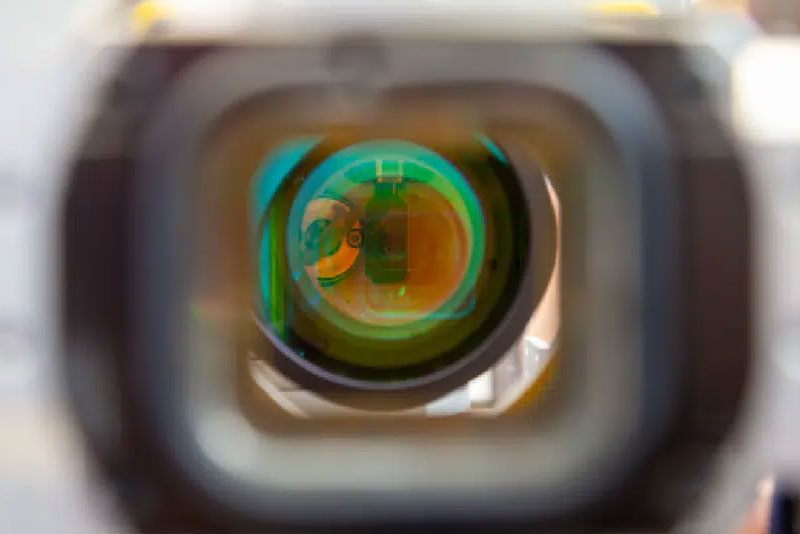

Laser

- Product traceability is essential to meet the high quality requirements of industry. For this reason, laser marking is used by manufacturers to automate marking operations and thus guarantee 100% control of their processes. Laser marking technology is particularly used for direct and permanent marking of metal or plastic parts depending on the hardness and their surface condition. Industrial laser marking is recommended for mass production, where speed and accuracy are required.

Scribing

- Scribe marking is powerful and fast, and gives aesthetic and precise markings. This direct marking technology is particularly suitable for hard steels as it allows very deep markings or hollow parts, with limited noise pollution. Our scribe marking machines are designed to withstand considerable mechanical loads and give contrasting and perfectly legible marking.

Traceability solutions

- Quality and safety mobilise the industrial world on a daily basis. At a time of globalisation, product traceability is a core issue for production sites, and similarly for communication between manufacturers and their suppliers or customers. This system of product tracking throughout the life cycle, from provisioning to end-of-life, including manufacture, sale or utilisation, enables data to be collected and analysed that can then be used for quality management, the identification and resolution of problems or the prevention of recalls. SIC MARKING guarantees the complete traceability of your production by combining a marking machine with one or more reading and identification systems. Do not hesitate to ask our experts to advise you on the choice of marking and viewing solutions best suited to your processes.