- Offer Profile

-

Your partner for laser marking and laser systems

Whether as contract manufacturing in-house or laser integration in your own production. We support you competently from the first idea up to implementation.

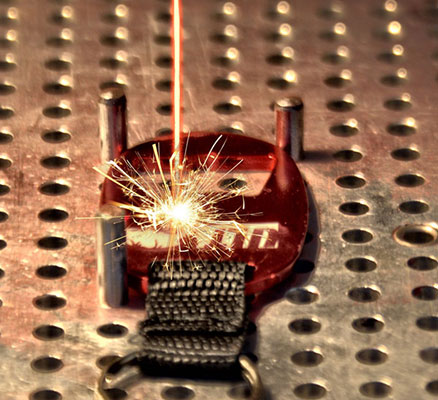

Laser marking

We process both single parts as well as large series. When processing, you can always count on our expertise, speed and reliability.

Laser marking in particular has become one of the most important marking methods in recent years. Due to the continuous development of laser technology since the 1960s, today materials of various kinds can be marked, labelled, engraved or changed.

Advantages of laser marking:

- High flexibility even with constantly changing markings

- Contactless

- No mechanical stress

- High throughput rates

- Permanent readability, as water, wipe and abrasion-proof

- High quality of laser marking

- Applicable for almost all materials

- Cost-effective even in small quantities

- Acid-resistant

- Environmentally friendly

Variants of a laser marking: With this laser one has the possibility to process the most different products, consisting of most different materials with different procedures. When it comes to laser marking, only the surface of the material is processed by the laser. However, laser engraving removes the material by evaporation in the depth.

What materials can be engraved with the laser?

- Wood

- Coatings

- Plastic

- Glass

- Metal

- Textiles

Day/Night design

-

Colour removal in the day/night design describes the process in which paint layers of parts are selectively removed and the underlying material comes visible. In a later backlighting only the cleared symbols are visible at night. Material basis of the day/night design are translucent or transparent plastics.

In this case, complete switch consoles as well as individual controls can be edited. That is why laser marking in the day/night design is often used in the automotive industry for marking control elements. Here, these elements should be light up white during the day and the brand of the car should light up in specific colours at night.

Examples for laser marking in the day/night design:

- Automobile: Various operational controls in the car such as buttons for the windows or also the button for operating the hazard warning lights.

- Coffee machines: Buttons from coffee machines

- Telecommunications: Keyboards of telephones or computers

When working in the day/night design, the laser represents the most rational and process-reliable option. Mostly it is the only option.

Examples for laser marking in the day/night design:

With a conventional print, no day/night design can be created because the luminous area would still be covered with colour. Another advantage of laser marking over printing is durability. Straight controls which are often used show signs of wear very quickly. The laser marking in the day/night design is almost indestructible. Laser engraving

-

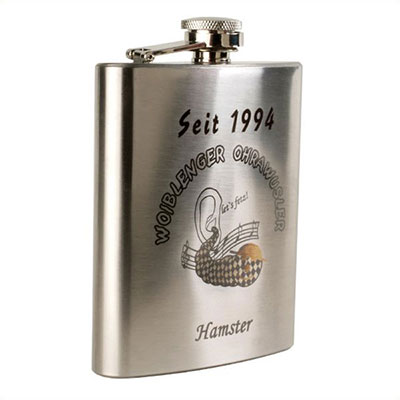

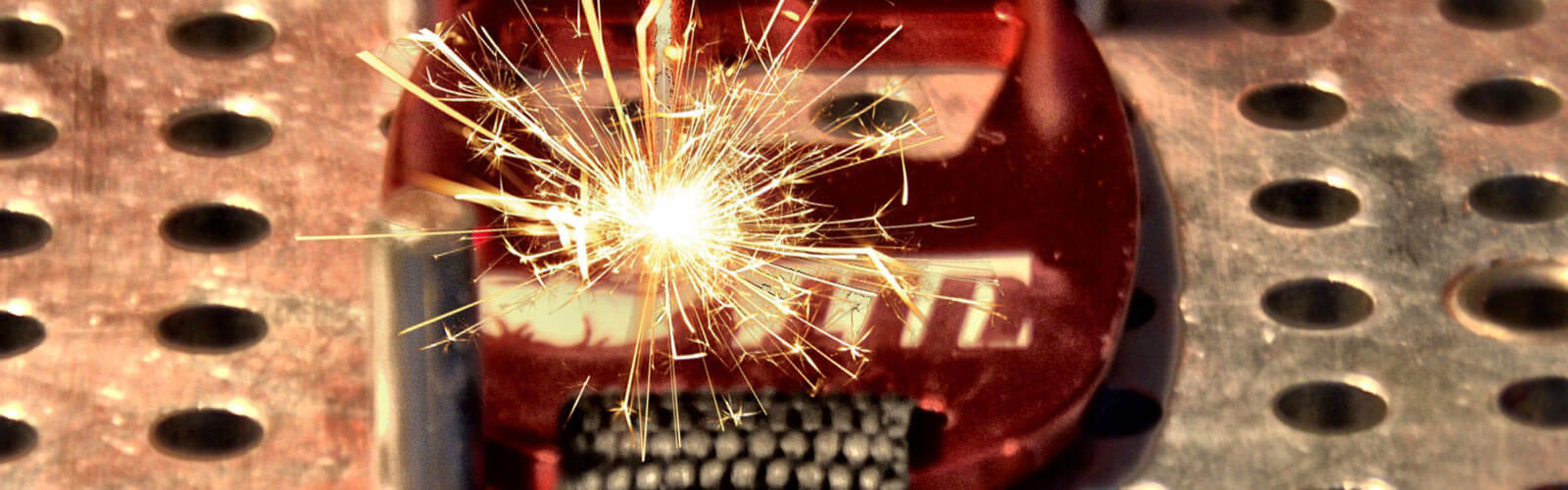

Laser engraving of various materials

Laser engraving on wood, metals or other materials is a variant of laser inscription in which the respective material to be engraved is removed from the work piece. The laser engraving serves a simple, flexible production of a forgery-proof and durable marking on the respective product. The engraving with the laser is done mainly on metals, wood or materials consisting of basically harder coatings. Especially in tool and mould making, engraving of typefaces, logos or other markings moulds or tools are engraved directly with the laser.

For example, laser engraving on a silver anodised aluminium flashlight. The anodised coating was removed and the aluminium was exposed. Aluminium usually turns white during laser engraving. Especially with coloured anodised or coated metals, the engraving is very beautiful. A laser engraving on steel turns brown to golden brown in most cases. By normal markings or by engraving promotional items usually a depth in the μ range is sufficient. In the case of very heavy-duty tools, deep engraving in the mm range is used with powerful lasers.

A laser engraving always uses a pulsed laser beam which acts accordingly to the respective material and thus removes it or deliberately breaks it.

Examples for Laser engraving:

Annealing marking

-

One form of laser marking is called annealing marking. In this case, only the surface of the material to be processed is edited by the laser. Metallic surfaces (precious metals) are specifically heated with the laser beam and thus obtain a discolouration that can be represented with different parameters as a colour spectrum. You can also observe this phenomenon in your car's exhaust system.

The achievable result depends on the carbon content of the material and the temperature of the laser. Because, depending on the material, the annealing marking will produce oxidations that differ in their colour.

Marking by annealing is ideal for all types of metals that change their colour under heat and the effect of oxygen. The outward layer of the material is only selectively heated by the laser beam and thus discoloured. That obtains an extremely high contrast and a very readable labelling.

Examples for annealing marking: Laser marking of plastics / laser foaming

-

Editing a material by foaming or recolouring with a laser is also a special type of laser marking in which the laser only processes the surface of the material.

Plastics often consist of different materials that react differently when processed with a laser. Not only the raw material plays a role, but also individual colour pigments or other mixed components contained in the material e.g. additives, fillers or protective substances influence the laser result.

If you want to apply permanently durable markings on plastics, engraving by laser is the most popular alternative. In contrast to traditional methods such as printing or embossing, laser engraving is extremely durable and high-contrast markings can be applied.

Most plastics can be marked very well with the laser but some only with the addition of certain additives. Here, the polymer is melted and it forms a foam-like structure. That is why this process is called foaming. In this way, bright plastics can be marked dark and dark plastics can be marked brightly. With certain additives, laser marking is even possible in colour.

Plastics can be processed by colour change when marking. In this case, the power of the laser beam changes pigments of the work piece to be processed in their optical property and the surface of the work piece remains virtually undamaged. The plastic material is processed only at a depth in the μ range.

- Foaming: When foaming, the surface is caused to melt by the action of heat by means of laser. As a result, gas bubbles form on the material and the volume is increased. The carbon contains and the plastic oxidizes to carbon dioxide which escapes and forms a foam layer (elevation). This achieves the desired contrast and creates a "raised" mark.

- Recolour: This method, for example, is used in marking of computer keyboards and electronic components application. Additions of additives in plastics enhance this effect and even produce certain colour shades. Depending on the composition, the discolouration is lighter.

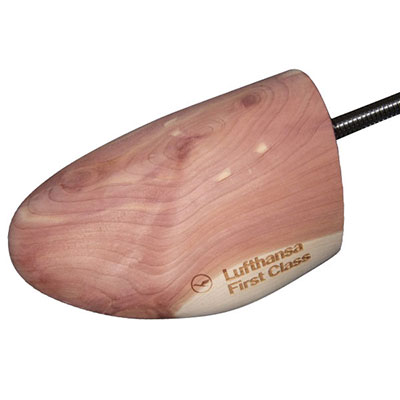

Branding

-

Branding is a laser marking method that “brands” organic materials such as wood, paper, cardboard or leather by means of a bundled beam of light. Similar to a brand, the material is intentionally burned by the impact of the light beam and preserves the typical appearance of a branding.

Thus, ladles made of wood, cardboard or wooden boards with your desired logo and lettering can be refined. Let us know your engraving request! Branding not only gives you a beautiful but also a long-lasting look. Further examples of laser engraving on organic materials can be found here.

Examples for branding:

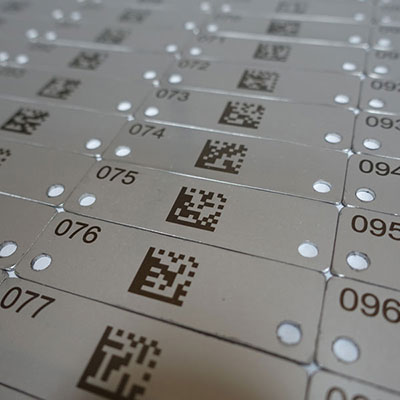

Product labelling / Industry labelling

-

Product labelling / Industry labelling Especially when marking industrial products, the laser is a well-chosen "tool" and the ideal alternative to printing, etching or embossing because the laser stitches with an extremely high performance and precision. Using laser marking, almost all common materials can be processed.

Advantages of laser marking:

- Non-contact marking of the product

- Personalized e.g. for barcodes or serial numbers

- Permanently water, scratch and abrasion resistant

- Sustainable lettering without printing ink or solvent

- Forgery-proof

- Acid-resistant and chemical-resistant marking

- Precise

- Cost-effective even with low quantities

- Traceability e.g. UDI and CE labelling

Our range of services in product labelling:

- Individual marking of your products

- Product identification with consecutive or different numbers, serial numbers and batch numbers

- Marking with barcodes e.g. data matrix and barcode

- Round labels (360° degrees)

- Engravings, annealing marking, colour removal and colour change

- Marking in day/night design

- Assembly and completion of small and large series

- Consultation for development, application and products

- Industry-specific project planning and process optimization

We work with very high quality standards. Our QM system works according to DIN EN ISO 9001: 2015. Great benefits are our know-how and our experience of over 25 years in laser marking and laser engraving, as well as our machinery from highly professional industrial plants. You also benefit from our network. We are at your side, from product design to construction, from injection moulding to surface finishing up to completion of assembly. Professionally and competently!

We offer you:

- Short processing, reaction and delivery time

- Economically even with small series or prototypes

- Marking of almost all materials (for example stainless steel, metal, plastic, wood)

- Storage area

- Absolute flexibility through the use of Nd-Yag, CO2 and green lasers.

Consulting & development

-

Our experienced team develops innovative solutions with you. Individually according to your wishes!

Innovative solutions with competence and experience

We have been dealing exclusively with laser marking, laser labelling and laser engraving since 2001. We support customers from the first idea up to the implementation, sample creation and up to series production. It does not matter whether your project runs on our behalf or if it is integrated into your processes at your local facility.

Independent and production-oriented! We know the market and we know which system is economically and effectively suitable for your project.

Well-known sporting goods manufacturers trust us in the implementation of their ideas as well as customers from the automotive industry.

An example from the field of cosmetics

Creation of a wood effect on a flip top closure with a haptic effect is not possible with conventional methods. Films are also reaching their limits quickly. The laser decoration is done directly on the plastic without being painted, coated or foiled.

A plant has been designed to produce 5 million (full area) closures per year. Almost all designs and optics can be created and the laser effortlessly even reaches the most difficult spots.We support special machine manufacturer in the integration and programming of the laser system to be integrated into the production line with selection, commissioning, setup and customer acceptance. Our mobile measuring microscope is used to set up projects with tight tolerances in line size and positional accuracy. Manufacturing companies also trust us as an external laser department. We commission new plants and optimize existing projects.

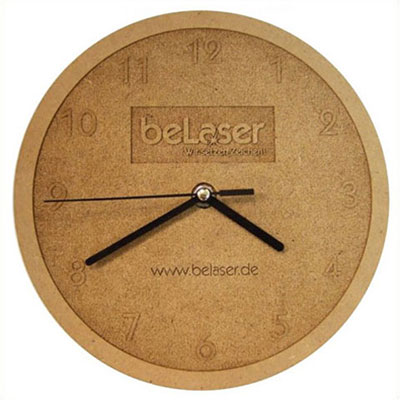

Laser systems & labelling lasers

-

The right laser marking machine

We offer special and custom laser for the labelling of plastics and metal engravings. Laser cells and compact tabletop lasers to be integrated in your production lines.

"Marking on the Fly" systems or camera-supported lasers

Fiber laser, Nd:YAG solid state laser, Co2 laser, UV laser and 512nm green laser

- For each laser marking or laser engraving application the optimal laser system.

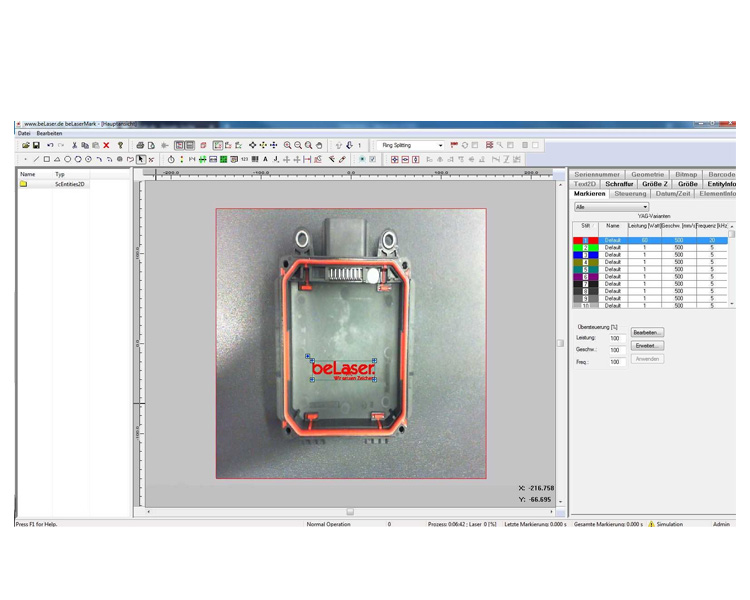

We offer you individual software solutions with our in-house programming service both for various connections or the operation of the laser marking devices via your own touch screen interface (e.g. tablet / smartphone) and for further options. Of course you are also welcome to use our powerful beLaserMark operating software, which can be individually adapted to your needs.

Kameraview now makes positioning even easier!

-

- Kameraview now makes positioning even easier!

- Up to 6 lasers can be controled simultaneously through one software interface!

- 2D and 3D high speed and low drift scanner technology.

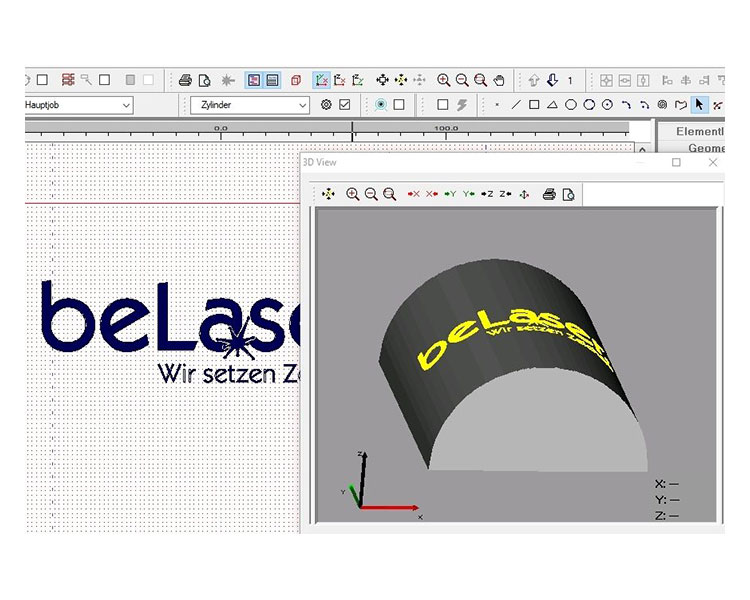

3D laser system

-

- Curves or objects with extreme geometries are no challenge for our 3D laser systems.

- Up to 80mm height difference can be compensated without moving the component or the laser head.

- High speed and low drift scanner technology - 2D and 3D.

- Fast - Flexible - Precise

- Scan heads for highest throughput rates and precision.

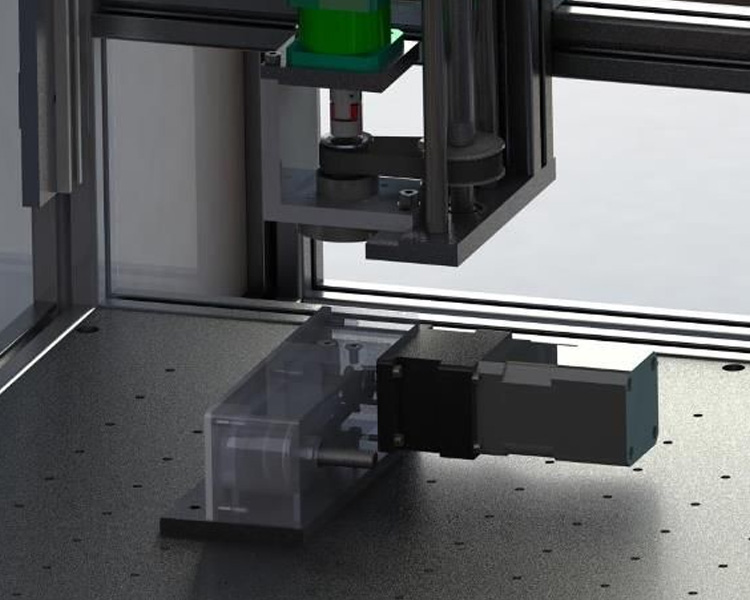

beLaser LMG Laser Workstation

- Workstation for small- and large series production

- Ergonomic design

- Footrest

- Automatic door opening

- Z-axis manually or automatically

- Focus laser + positioning laserOptional:

- Background camera

- Automatic item positioning

- Side door adjustments for large parts

- Rotation unit

- X/Y ProtalFor all performance classes 5 - 100Watt

- Fiber laser1064nm

- Green laser 532nm

- CO2 laser 10600nm

- UV laser 355nm

beLaser LMF compact series

-

Compact design - highest flexibility

Simple operation as well as high marking speeds characterize our LMF series. No compromises are made with regard to quality and flexibility. Both positioning aid and focus finder are part of the basic equipment as well as a protective housing according to laser class 1.

Optionally, the series is also available with a rotation unit and/or X/Y traversing table.Suitable among others for:

Texts, logos, vector data, QR codes, DMC codes, 2D codes, variable data sets and image engraving.

Accessories and options

-

- Rotation unit

- X/Y Portal

- Suction unit

- Protective gear

- Interchangeable lenses

- Workpiece holder (jig)

- Marking on the fly

- Promotion solutions / operation via smartphone or tablet

- Interface solution for automation and data transmission (for example UDI marking)

Laser for rent

-

Fair & Event Highlight Live Engraving: Impressive and highly effective advertising

Applications of the personalized live engraving as a unique experience

-

Impressive and highly effective at the same time

The highlight for your exhibition stand! We engrave your products or promotional items live at your stand and we make an event out of your customers´ visit. Personalized advertising does not just end up in the drawer, with an individual engraving you increase the advertising effect. We laser a variety of products, such as pens, business card cases and much more - and of course your own product. Talk to us, we will find a perfect solution for your appearance. Of course, visitors can follow up the laser engraving process live through a special sight glass.

We offer extensive services from the stand-alone devices to table lasers and integration in the trade fair stand.

Capacity bottleneck or temporary order?

- No problem! With our rental lasers, we can support you optimally. If in-house contract manufacturing does not make sense to you we will visit you with our laser systems. Whether diode-pumped Nd: YAG solid-state lasers, fibre or carbon dioxide lasers. Our rental lasers are all class 1in laser protection and can be operated by you after a short instruction.