- Offer Profile

- In the constant further development of our products, we at HECKL are constantly on the lookout for improvements and innovative solutions based on many years of experience. Quality, reliability and economic efficiency are always our top priorities in the manufacture and application of HECKL products.

Installation fittings

- The installation fittings manufactured by HECKL in its own production are characterised by tool-free assembly, long service life, simple operation and reliability in handling. The HECKL installation fittings are available in both rigid and telescopic form in the galvanised steel versions HECKL RENKO or HECKL PREMIUM as well as the stainless steel version HECKL PREMIUM PLUS.

Rigid installation fittings - stubborn head

-

The rigid installation set is a simple version, in which the removable protection tube enables the length of the installation set to be adapted directly on site. The RENKO installation fitting is suitable for connection to gate valves as well as valve tapping clamps.

The RENKO telescopic installation set enables the operating element to be individually adapted to the respective installation depth of valves already installed in the ground. This telescopic installation set is a simple version manufactured in the proven HECKL quality. The assembly of the set is simple and does not require any additional tools. The connection to the valve spindle of the valve to be connected is made by means of a coupling sleeve and clip pin.

PREMIUM Installation fittings - Resistant

-

These installation fittings of the HECKL PREMIUM series meet the highest requirements and are tested according to DVGW GW336. The sleeve tube is made of extremely resistant high-density polyethylene and reliably protects the internal surface-galvanised steel square bar with an additional sleeve on both the coupling and operator sides from dirt ingress. Even premature corrosion of the coupling sleeves and square caps made of spheroidal graphite cast iron is virtually impossible due to galvanic zinc plating. Possible impact and vibration effects on the valve or its pipelines are dampened by an integrated compensator. This ensures a long service life and reliable handling.

The telescopic installation set of the "PREMIUM" series is a genuine all-purpose weapon for the manual operation of earth-mounted shut-off valves. Thanks to the universally available lower part of the protection tube, the installation set can be used for all commercially available fittings and allows the operators of gas and water pipe networks to use only one connection variant in their maintenance areas. The coupling sleeves and square caps made of spheroidal graphite iron are protected against premature corrosion by galvanisation. The sleeve pipe is made of extremely resistant PE-HD and reliably protects the internal galvanised steel square bar from dirt penetration with an additional sleeve on both the coupling and operator sides. Reliable handling is thus guaranteed even with a long service life. In addition, a built-in compensator dampens possible shock and vibration effects on the valve or its pipelines.

PREMIUM PLUS Installation fittings - stainless steel

-

The rigid installation fittings of the HECKL PREMIUM PLUS series are suitable for operating all common gate valves, house connection valves and valve tapping clamps. The internal square rod is completely immune to rust due to the use of stainless steel. Galvanised zinc plating also protects the coupling sleeves and square caps made of nodular graphite cast iron against premature corrosion.The sleeve pipe is made of extremely resistant high-density polyethylene and reliably protects the internal stainless steel square rod from dirt ingress with an additional sleeve on both the coupling and operator sides. Reliable handling is thus guaranteed even with a long service life. Possible shock and vibration effects on the valve or its pipes are also dampened by a compensator built into the sleeve pipe.

The telescopic design of the HECKL PREMIUM PLUS installation set allows individual adaptation of the operating element to the respective installation depth of valves already installed in the ground. No additional tools are required for simple installation. The use of the telescopic installation set PREMIUM PLUS in connection with all types of HECKL road caps is possible and recommended at any time. This applies when using a HECKL support plate.

The square bar made of stainless steel and the galvanic zinc coating of the coupling sleeves and square protectors made of spheroidal graphite cast iron guarantee absolute protection against corrosion. In addition, sleeves reliably protect the operator and coupling sides of the sleeve tube made of extremely resistant high-density polyethylene from dirt ingress. Reliable handling is thus guaranteed even with a long service life. Possible shock and vibration effects on the valve or its pipes are also dampened by a compensator installed in the sleeve pipe.

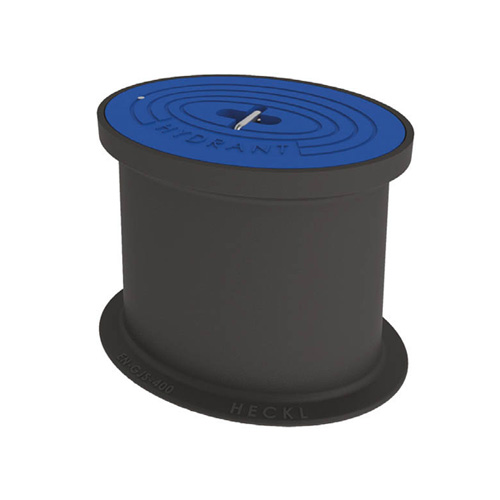

Street caps

-

HECKL's road caps enable easy access to fittings installed in the ground and their simple operation. This applies to both water and gas pipes or district heating networks. At the same time, the road caps provide reliable protection against dirt and fill. Mechanical damage is therefore virtually impossible.

HECKL road caps are available in various designs. Both rigid and self-levelling. They are therefore suitable for various areas of application. The road caps are suitable for house connections as well as gate valves and hydrants.

The conservative rigid design made of heavy cast metal has proven itself for decades and convinces with a high load capacity as well as a very long service life.

The same applies to the modern rigid plastic road cap. Thanks to its low weight, it is easy to handle during installation. In addition, the housing is absolutely resistant to rust thanks to its material. The dimensional stability when paving in hot asphalt is DVGW-certified.

The KOMPAKTUS® self-levelling road cap is a real innovation for road construction. This enables simple and cost-saving handling during installation or conversion, where only the inner housing has to be pulled out higher and rolled in again. As a hybrid solution (outer housing made of glass fibre polyamide, inner housing made of ductile cast iron), high dimensional stability and a long service life are also guaranteed.

Rigid road caps made of cast metal - heavyweight

- The rigid road caps made of high-quality grey cast iron convince with their high strength and durability. Lid and body are connected with a bolt. The cast metal road caps are tested and certified according to D 400 and are therefore suitable for roads that are approved for all types of road vehicles with a total weight up to 40t.

Rigid plastic road caps - dimensionally stable

- The housing of the rigid plastic road caps is manufactured at HECKL from resistant glass fibre polyamide and remains absolutely dimensionally stable due to the higher hot forming temperature when installed in asphalt surfaces. The covers are made of cast metal, all road caps are certified according to DIN 4055, DIN 4056 and DIN 4057 DVGW.

Self-levelling road caps KOMPAKTUS® - Adaptable

- The new self-levelling road caps from HECKL are a consistent further development of all common protective shafts used according to DIN 4055 (underground hydrants), DIN 4056 (sliders) and DIN 4057 (valves). Numerous innovations in the area of the cover and the inner housing improve the load capacity and service life of the road caps.

Support plates - Safe standing

- The support and centering plates from HECKL represent a universal solution for fixing the control element of a telescopic installation set and at the same time ensure the centric positioning of a road cap above the control element. In addition, the plate prevents the road cap from sinking into the ground, especially in loose soils.

Universal cast iron support plate P30

- The support plate P30 for the installation of telescopic fittings is made of spheroidal graphite iron according to EN-GJS 400. Due to its ductile properties, this cast iron plate is particularly suitable for use in areas with very high tensile and compressive loads. Due to the plastic deformability of its material, the support plate is extremely resistant to damage. Surface treatment with bitumen penetration varnish also provides high-quality corrosion protection.

VARIO universal support plate

-

The two-part VARIO support plate, consisting of a main part and an insert, can be connected without tools to almost all common installation fittings. For this purpose, the installation fittings are simply inserted through the opening in the support plate and locked by a 90° turn. The insert ensures that the fitting fits perfectly at all times and that the axes are aligned with the valve or slider cap.

The VARIO support plate is made of polypropylene, which gives the plate its high strength and temperature resistance. This ensures that the cap and installation set are securely held in the ground, even under high weight loads and extreme weather conditions.

Thanks to its low weight, it is easy to handle both during transport and installation.

Universal support plate VARIO 15

-

The one-piece VARIO 15 support plate is a further development of the VARIO support plate. It ensures the perfect fit of all common telescopic installation fittings in the ground. These are connected to the support plate by means of a 90° locking device, which simultaneously ensures exact axis alignment with the valve or slider cap.

The VARIO 15 support plate made of polypropylene is characterised by its high strength and resistance to mechanical damage. Therefore, when installing a road cap, it is not necessary to install an additional support. Caps and installation fittings are protected against slipping in the ground at all times if laid correctly.

Thanks to its low weight, it is easy to handle both during transport and installation.

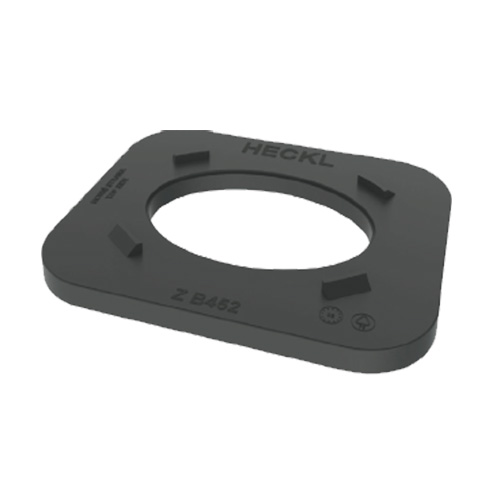

Hydrant support plate HECKL

-

The hydrant support plate is designed for the installation of all hydrant caps made of cast iron or plastic. The caps can be fixed and fitted directly to the support plate.

The HECKL hydrant support plate is made of polypropylene. This material gives the plate high strength and heat resistance, so that the installation position of the hydrant cap is guaranteed even under high weight loads and extreme weather conditions.

Repair clamps

Repair clamps IVE - Quick problem solution

- The repair clamp including its clamping system is made of stainless steel, which guarantees an almost unlimited service life. The labyrinth rubber seal fulfils the hygienic standards for contact with drinking water according to DVGW W 270 and ensures reliable sealing of the damaged connection point. The sealing clamps can be used to close holes and cracks, including transverse fractures, or to connect two pipes. The repair clamps are manufactured for DN 40 up to DN 2000 in various lengths. The repair clamp, including its clamping system, is made of stainless steel, which guarantees an almost unlimited service life. The labyrinth rubber seal meets the hygienic standards for contact with drinking water according to DVGW W 270 and ensures reliable sealing of the damaged joint. The sealing clamps can be used to close holes and cracks, including transverse fractures, or to connect two pipes. The repair clamps are manufactured for DN 40 up to DN 2000 in various lengths. We can also supply individual dimensions upon customer request.

Threaded Fittings - Secure Connection

- HECKL fittings ensure a safe connection when laying water, drinking water and gas pipeline networks. All connectors comply with the regulations of the German Gas and Water Association.

Brass fittings - on the safe side

- All pipe couplings are manufactured by HECKL itself from brass CW617N and are available in inch sizes from ½" to 2". They are designed for an operating pressure of up to 10 bar and for temperatures from 0 to 110° Celsius. The DVGW-certified fittings ensure a reliable solution in all networks.

Gunmetal fittings - demanding

- All fittings are manufactured by HECKL from gunmetal CC499K and are available in inch sizes from ½" to 2". They are designed for an operating pressure of up to 10 bar and for temperatures from 0 to 110° Celsius. The almost lead-free connectors meet even the most demanding DVGW requirements.

Mud bucket - a clean thing

Sludge bucket for road inlets - form A4

-

- Polyethylene hanging bucket (corrosion-free)

- Holder made of hot-dip galvanised 10 mm thick round steel

- DIN 4052 similar

- Form A4

- Nominal size 450mm, round, long, with four slot rows

- Outer diameter 385 mm; height 596 mm

- Weight: 2,2 kg

- Replaces all common sludge buckets according to DIN 4052 made of galvanized steel

Sludge bucket for road inlets - form B1

-

- Polyethylene hanging bucket (corrosion-free)

- Holder made of hot-dip galvanised 10 mm thick round steel

- DIN 4052 similar

- Shape B1

- Nominal size 450mm, round, short, with one slot row

- Outer diameter 385 mm; height 250 mm

- Weight: 1,4 kg

- Replaces all common sludge buckets according to DIN 4052 made of galvanized steel