- Offer Profile

Your partner for compressed air system solutions

Kaeser Kompressoren has been providing compressed air systems solutions since 1919 and currently employs approximately 6600 people throughout the world. We consider ourselves as a partner to our customers and develop tailor-made, energy-efficient and reliable compressed air solutions. With our philosophy of "more compressed air for less energy", we have become a leading key global player in our industry.

KAESER Products – Innovation meets efficiency

- From the workshop to industrial plants, from the mine

to the petroleum refinery: More and more customers throughout the world rely

on Kaeser quality compressed air systems "Made in Germany" and benefit from

optimum compressed air availability combined with low life-cycle costs.

- Exceptional energy balance true to the KAESER motto of "More air, more savings..."

- Time-saving maintenance and operation

- Exceptional material quality and durability

SIGMA AIR UTILITY

-

"It's right there" – Compressed air at a fixed price

With the SIGMA AIR UTILITY operator model, you will secure a reliable supply of compressed air tailored to your needs – practically at the push of a button: You simply give us a few square metres of floor space, and we'll take care of the rest. Instead of investing in a complete compressed air station, all you pay for is the compressed air you actually use.

Here's how Kaeser's SIGMA AIR UTILITY operator model works:

- We'll analyse your compressed air needs and draw up an individual concept – based on what is required.

- Next we will build, install and operate the compressed air system.

- Our Kaeser Teleservice, the logistics centre and our extensive global service network ensure that compressed air is available at all times.

With the SIGMA AIR UTILITY operator model, you pay a fixed basic price that covers an agreed quantity of compressed air. When larger amounts are needed, a fixed contractual price applies for the additional quantities used.

All prices remain in effect for the entire duration of the contract, which means no price increases.Your advantages

- No compressed air worries:

We offer everything from a single expert source: from the analysis of your compressed air needs to the machines and service. That lets you and your personnel concentrate fully on your core tasks. - From fixed costs to variable costs:

Investments in a compressed air system are no longer needed. Your employees will have time for other tasks. That means: You have more liquidity, are saved from tapping into your working capital and have greater flexibility in deploying your personnel. - A system scaled to your needs:

A competitive market brings ups and downs. Are you cutting back your output, or perhaps stepping it up? Are you relocating your operations? With SIGMA AIR UTILITY you can remain flexible. We will adjust your compressed air supply to your needs.

Rotary screw compressors

Keep up the pressure

Rotary screw compressors supply production processes in industry, trade and workshop applications with a reliable supply of quality compressed air. They are the preferred choice for users requiring constant pressure over prolonged periods.

To ensure that our rotary screw compressors operate as efficiently as possible, we developed our own special rotor profile. Our SIGMA profile rotors provide you with energy savings of up to 15 % compared with conventional rotor profile designs.

Furthermore, our airends with SIGMA profile rotors boast an exceptionally long service life. This is in no small part due to the roller bearings we choose to use: they are precision adjusted and generously sized. Combine this with our in-house high-end manufacturing processes with lowest possible manufacturing tolerances and you have an exceptional product.

Rotary screw compressors with fluid cooling

- No matter whether a complete compressed air station or a

single compressor: our fluid-injected rotary screw compressors deliver

exceptional efficiency throughout their entire service life.

- Low life-cycle costs

- From 2.2 to 515 kW

- For reliable operation in ambient temperatures up to 45 °C

Oil-free compression rotary screw compressors

- Process-sure air purity – produced reliably and

efficiently

- Uncompromising efficiency

- Service-friendly design

- Optionally available with innovative i.HOC drying technology or energy-saving refrigeration dryer

Rotary screw vacuum pumps

- Our energy-saving complete solution for generating low

vacuum

- Connect and go

- With efficient IE3 motors

- Intake capacity: 4.75 to 15.70 m³/min – 99 % final vacuum

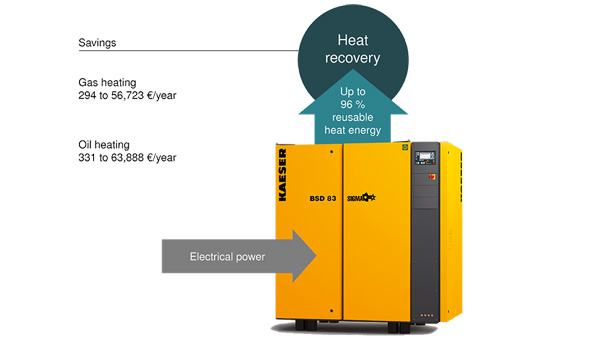

Heat recovery

- A rotary screw compressor converts 100 % of the drawn

electrical energy into heat. Up to 96 % of this energy can be recovered.

The fully-enclosed design of modern rotary screw compressors makes them especially suitable for heat recovery. This fact applies to both fluid-injected as well as to oil-free compressors.- Reduce your

energy costs:

Energy costs account for up to 80 percent of life-cycle costs. By using heat recovery, you can significantly lower these costs. - You also reduce your CO2 footprint:

Heat recovery lowers the CO2 emissions of your organisation because you utilise energy more efficiently.

- Reduce your

energy costs:

Reciprocating compressors

-

Ideal for fluctuating air demand

The optimal duty cycle for reciprocating compressors is between 60 and 70 %. As such, they're the best choice for high-fluctuation operation with load peaks – especially for trades, workshops and small industry.

When used as boosters, reciprocating compressors can augment existing system pressure, raising it to 45 bar in specific locations.

Portable reciprocating compressors

-

Making your work easier

Portable reciprocating compressors from KAESER augment the quality and cost-effectiveness of your trades work. Our range includes numerous sizes to cover a wide spectrum of application areas:

- Compressed air supply for small and growing workshops and trades businesses

- Continuous use on construction sites, for associated building trades or in larger workshops

Stationary reciprocating compressors

-

Always at hand for the widest range of applications

From filling tyres in the workshop to transporting bulk materials in industry – our stationary reciprocating compressors offer exceptional versatility. We would be pleased to offer you a consultation to determine which solution is best suited to meet your specific application‘s needs.

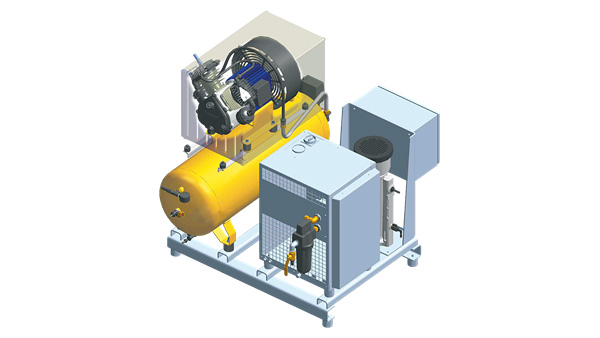

Complete packages

-

Quiet and ready for connection - the right solution for every application

Equipped with a reciprocating compressor, air receiver, refrigeration dryer and optional filters, our complete systems produce oil-free compressed air matched exactly to your needs.

Boosters

-

Targeted operation in high-pressure applications for enhanced efficiency

Do you need high pressure process air only for certain points in your production process? If so, installing boosters is a far more efficient solution than designing the entire system to deliver high pressure compressed air.

Select from individual components or a complete, turnkey system.

OEM

-

Customised for every compressed air user

Do you have special compressed air supply requirements? Kaeser will put together a complete, turnkey compressed air station for you – with custom compressed air quality, flow rate and pressure requirement specifications.

- Flow rate 60 to 1400 l/min

- Pressure from 7 to 35 bar

Naturally we use only the highest quality, industrial-grade Kaeser components. In special circumstances, Kaeser can also construct a completely custom machine to meet your individual needs.

Blowers

-

Quiet, yet phenomenally powerful – from vacuum to low-pressure operation

Low-maintenance, quiet and efficient, Kaeser blowers generate compressed air for a wide range of different applications:

- Pneumatic conveying of bulk materials

- Water management – e.g. for sedimentation tank aeration and filter flushing

- Process and cooling air for industrial purposes

- Mobile applications – e.g. mixing, tanker and suction vehicles

We offer three different design concepts for your compressed air application:

- Rotary lobe blowers featuring our efficient, three-lobe OMEGA rotors for minimising pulses

- Rotary screw blowers with the energy-saving SIGMA profile – specially designed by KAESER for optimal pressure and air delivery

- Turbo blowers with high-speed, permanent magnet motors featuring wear-proof, magnetic bearings.

Rotary screw blowers up to 250 kW

-

Efficiency at the touch of a button

When it comes to KAESER rotary screw blowers with the SIGMA Profile, efficiency is more than just a promise. As operation-ready, “Plug-and-play” complete solutions, low-maintenance blower systems offer exceptional efficiency at the touch of a button. What is more, KAESER rotary screw blowers are designed to be especially compact, can be controlled remotely or automatically for trouble-free operation and are compatible with Industrie 4.0 systems.

Low energy consumption, coupled with the ability to operate at 100% duty cycles, ensures that KAESER rotary screw technology pays off handsomely when it comes to municipal and industrial wastewater treatment, flotation, fluidisation and fermentation applications.

Performance data:

- 7.5 kW to 250 kW

- Flow rate from 3 to 160 m³/min

- Pressure differential 300 to 1100 mbar

Magnetic bearing turbo blowers 150 and 300 kW

-

Turbo blowers for aeration applications

Are you looking for a reliable and energy-efficient supply of compressed air in the low pressure range?

PillAerator turbo blowers from Kaeser Kompressoren are compact turbo compressors developed specifically with aeration applications in mind. Thanks to innovative magnetic bearings, the drive motor operates completely wear-free.

Our turbo blowers are used wherever process air is required in the low pressure range – such as aerobic, biological wastewater treatment, fermentation and flotation applications.

Performance data:

- 150 kW and 300 kW

- Flow rate up to 16,000 m³/h

- 0.3 to 1.3 bar

Rotary lobe blowers up to 250 kW

-

Rotary lobe blowers – Impressive reliability

Rotary lobe blowers from KAESER with the OMEGA Profile impress with their exceptionally durable construction. Thanks to a universal design concept, these blower systems are not only individually configurable and simple to expand - they also stand out for their ease of maintenance and handling.

When specified with the optional control cabinet, KAESER rotary lobe blowers are transformed into ready-to-run, “Plug and Play” complete solutions, thus ensuring simple commissioning and reliable, economical operation.

KAESER’s tried-and-tested rotary lobe technology is ideal for applications such as the pneumatic conveying of bulk materials, filter backwashing at drinking water installations, the aeration of biofilters and pools in the aquaculture sector, municipal and industrial wastewater treatment plants and the conveyance of nitrogen.

Performance data:

- 1.5 kW and 250 kW

- Gauge pressure flow rate from 0.8 to 156 m³/min

- Gauge pressure differential up to 1000 mbar

Rotary blowers (single block): OMEGA series

-

Tough and ready for anything

Our single-block blowers provide maximum flexibility. The OMEGA series blowers with their three-lobe rotors minimise pulsation and include a wide range of rotary lobe blowers for stationary and mobile applications. They are manufactured in state-of-the-art, climate-controlled CNC production facilities and are rigorously tested at full load.

- Highly versatile rotary lobe blowers – in stationary and mobile versions, suitable for both vacuum and pressure operation – for air and nitrogen conveying applications (OMEGA P and PN)

- Blower with primary components made from chromium-nickel alloy for vacuum distillation / process water recycling (OMEGA B)

- Vacuum blowers with pre-inlet cooling – suitable for alternating vacuum and pressure operation in tanker trucks and suction vehicles (OMEGA PV)

- Rotary lobe vacuum pumps for fine vacuum applications (OMEGA WVC) in combination with a booster pump

Aftercoolers / heat exchangers for blowers

-

The perfect fit: Aftercoolers / heat exchangers for Kaeser blowers

Kaeser aftercoolers / heat exchangers are specifically designed for use with Kaeser blowers. They are designed for all applications requiring an upper limit on the process air temperature. In addition, it is possible to recover heat energy with aftercoolers / heat exchangers.

Kaeser offers two cooling concepts for aftercooling:

- For use when the ambient air is cool enough and without a water source: Air cooling (cross-flow heat exchanger, ACA series).

- For achieving very low temperatures: Water cooling (shell and tube heat exchanger, WRN series).

The heated cooling air can be used for hall-heating purposes, whilst the heated cooling water can be used in water treatment systems, for example, for drying sludge.

Controller

-

The control centre for your compressed air supply and key technology for Industrie 4.0

The SIGMA CONTROL 2 (local intelligence) and SIGMA AIR MANAGER 4.0 (central intelligence) controllers ensure efficient interplay between all components in your compressed air system. This is where you can achieve the biggest energy savings. The capabilities of an intelligent computer are needed to perform such a complex task. Its tasks:

- Ongoing reduction of energy consumption throughout the entire life cycle of the system (simulation-based calculation of the most efficient operation scenario)

- Control of individual components within a station

- Compressed air and compressed air cost management

- Communication between a wide range of system components

Compressor controller: SIGMA CONTROL 2

-

Integrated intelligence

The SIGMA CONTROL 2 unit coordinates compressed air generation and consumption. With its intelligent control, this advanced system prevents inefficient energy usage, especially in partial load operation. Kaeser offers various compressor controllers suited according to particular requirement.

SIGMA CONTROL 2: for all KAESER rotary screw compressors, rotary screw blowers, reciprocating compressors, boosters and rotary lobe blowers

The SIGMA CONTROL 2 fulfils the highest requirements for an internal compressor controller and is based on advanced industrial computing technology. The control unit is linked with interchangeable input and output modules, allowing flexible matching to all available Kaeser rotary screw compressors, screw blowers, reciprocating compressors and rotary blower systems, as well as to external communications systems.

Master controller: SIGMA AIR MANAGER 4.0

-

Key technology for Industrie 4.0

The next generation of compressed air management master system, the SIGMA AIR MANAGER 4.0 utilises adaptive 3-Dadvanced Control to make air generation and treatment even more intelligent, reliable and efficient.

- The 3-Dadvanced Control analyses all operating data on an ongoing basis, simulates alternative actions and calculates the perfect compressor combination. The result: Unprecedented energy efficiency.

- Maintain an overview at all times thanks to easy operation, visualisation and analysis. With secure network technology – conveniently from any PC.

- Predictive Maintenance by Kaeser specialists prevents unplanned downtime.

And if you have big plans for the future: The SIGMA AIR MANAGER 4.0 is designed to grow with your air station. A simple software upgrade allows expansion of the master controller without the need for additional investment in new hardware.

Air treatment and condensate technology

Treatment components give no quarter to dirt and corrosion

Water, oil, dust: Kaeser offers a complete product portfolio for combating the enemies of your compressed air application – one which makes no compromises when it comes to dry and pure air – from straightforward construction site use to highly complex electronics production:- for high product quality

- for faultless and low-maintenance processes

- for regular sewage system disposal of your condensate

Centrifugal separator

-

Maintenance-free whirlwinds

Kaeser KC centrifugal separators remove condensate at the compressor's compressed air discharge point. They're a must for faultless and energy-efficient functioning of downstream dryers and filters. KC centrifugal separators are equipped with the economical and extremely reliable ECO-DRAIN 31 condensate drain – naturally, with test button and alarm contact included. They're also very easy to combine with KAESER FILTERS and can be wall-mounted using optional wall mounts – for highly straightforward installation.

- Separation rates up to 99 % in the flow rate range of 0.9 to 14.2 m³/min

- designed for working pressures up to 16 bar

- with ECO-DRAIN 31 electronic condensate drain

- with optional wall mounts

Models with flow rates up to 88.5 m³/min, special product variants available in silicon-free design, for working pressure of 45 bar.

Dryers

-

Reliability and efficiency for all drying levels

Kaeser compressed air dryers ensure perfect drying of compressed air for the intended application and all flow rates. Since they're designed to be high-quality industrial machines, you'll be providing reliable protection against condensate damage for your systems and processes, even under the harshest conditions.

And to ensure the balance of costs remains advantageous for you over the long-term, we offer intelligent energy-saving control for all drying processes and will work with you to identify the optimal unit size and configuration. Just get in touch!

Compressed air filters and activated carbon adsorbers

-

Reliable and profitable, pure compressed air

Kaeser compressed air filters and activated carbon adsorbers provide your systems and processes reliable, highly efficient protection against dust, aerosols and oil vapours – for all purity classes as per ISO 8573-1, perfectly compatible with our range of compressors and other compressed air treatment options.

Kaeser compressed air filters are available with a pressure of 16 bar, whilst high-pressure filters range up to 45 bar; filters are also available in a silicon-free version, such as for use in painting processes.

ECO-DRAIN electronic condensate drain

-

Zero compressed air losses

Condensate drains remove condensate separated in centrifugal separators, air receivers, refrigeration dryers and filters from the compressed air system. They are therefore indispensable components for efficient compressed air treatment and disruption-free compressed air supply.

ECO-DRAIN electronic condensate drains from Kaeser are highly cost-effective and reliable. This is attributable to a control concept that works independently of condensate volume, dirt-resistant valve mechanics and a network-capable alarm contact (from model 31 and higher).

ECO-DRAIN condensate drains are available for compressor flow rates up to 1700 m³/min. Kaeser also offers suitable product versions for special applications, such as aggressive condensate, working pressures up to 63 bar, as well as in vacuums or frost regions.

Condensate treatment: AQUAMAT

-

Clean waste water – without the fuss

All compressor condensate usually contains trace amounts of oil. Accordingly, it's common in most cases for official regulations to apply which require compliance with a maximum oil content before condensate can be fed into the regular sewer system.

AQUAMAT oil-water separators remove dispersed oil – with type approval from Deutsche Institut für Bautechnik (DIBt). They enable legally compliant treatment of condensate – directly where it arises and with no energy consumption.

To meet specialised installation requirements, we offer electronic level sensors, tested oil pans and frost protection heaters. Special condensate distributors are available for a parallel hook up multiple separators with equivalent condensate load.

Compressed air storage and pressure maintenance

That's how you deal with pressure

Storage media and distribution and pressure maintenance systems are key components of any compressed air station. Efficient operation is assured only if network pressure is stable at all points and if the compressed air quality is high.

The Kaeser advantages:

- for high product quality

- for faultless and low-maintenance processes

- for regular sewage system disposal of your condensate

Air receivers

-

Vertical or horizontal air storage – up to 50 bar

Air receivers are an important link in the compressed air chain: as storage media or buffers for peak load demand.

With Kaeser air receivers, you are always on the safe side technically: because we look at the overall system, we focus on perfectly matched easy installation and a comprehensive range of accessories.

- Receiver sizes: 90 – 10,000 litres

- Maximum permissible gauge pressure: 11, 16, 45 or 50 bar

- Fittings, valves and instruments for every application

- Complete sets for condensate separation

DHS 4.0 air-main charging systems

-

Air-main charging systems - compact assistants that make a big difference

DHS 4.0 series electronic air-main charging systems from KAESER not only provide protection for your compressed air treatment components, but also help ensure reliable compressed air quality - even following a complete shutdown of your compressed air supply system.

With dropping pressure, the flow velocity in the pipework quickly increases and can potentially overwhelm all of the components in the compressed air system. Installation of a KAESER DHS 4.0 air-main charging system guarantees the required minimum pressure and thereby ensures reliable operation, especially when re-starting the system following a shutdown.

Thanks to a patented pulse width modulation control concept, each air-main charging system is prepared for every eventuality and, as is KAESER’s way, combines exceptional operational reliability with simple and straightforward operation.

- Connection diameters from G ½ to G 3 and DN 40 to DN 400

- for systems with one or more treatment lines

- Perfect integration thanks to numerous interfaces and configuration options

MOBILAIR portable compressors

Construction site masters - Made in Germany: powerful and efficient with long-term value retention

Compressed air wherever you need it – even under the toughest conditions: The main Kaeser plant in Coburg produces powerful machines with advanced, fuel-saving motors and heavy-duty chassis in a wide range of models – from the smallest portable units to large compressors.- Many models feature a rotational moulded PE enclosure (tension-free for extreme dent resistance)

- Simple and intuitive operation

- Optimal maintenance point accessibility prevents unnecessary downtime

MOBILAIR e-power

-

Electric portable compressors

Electric portable compressors from KAESER truly come into their own wherever an electrical power connection is available. Their whisper-quiet electric drive makes them the perfect choice for use in low emission and noise protection zones. The emissions-free drive also means they are ideal for operating in tunnels, excavation pits and buildings.

Electric portable compressors are perfectly equipped for every application, no matter how challenging. These portable powerhouses are incredibly durable, compact and energy-efficient. e-power makes them particularly simple to handle and exceptionally maintenance-free, thereby saving you time and costs.

MOBILAIR e-power compressors are extremely versatile when it comes to their application. The chassis can be equipped with or without an overrun brake and is available with a fixed or height-adjustable tow bar, meaning that this electric all-rounder can easily be transported to wherever it may be needed. Because they operate so cleanly, they are also well suited to bridging operations when maintenance is required at industrial facilities.

Performance data:

- Flow rate up to 24.7 m³/min (885 cfm)

- Gauge working pressure up to 15 bar (215 psi)

Your benefits:

- Quiet and emissions-free

- Can operate in low emission and noise protection zones

- Reduces operating and maintenance costs

Small portable compressors up to 1.6 m³/min (57 cfm)

-

Compact compressors, ideal for trades applications

Versatile, dependable and easy to manoeuvre – compact and convenient MOBILAIR compressors from KAESER can fit into the smallest loading spaces. With their high-quality motors and extremely impact-resistant PE housings, they are capable of mastering any application.

KAESER's small portable compressors with petrol engine keep a cool head, even at temperatures as high as +40 °C / 104 °F. This makes them ideally suited to the tough everyday conditions found on construction sites, for such applications as powering impact moles and sewer robots. Other possible applications range from operating air hammers and spades, to use as a trades compressor for powering drills, saws, screwdrivers and grinders.

The 15-bar version (M17 model) is ideal for trenchless fibre-optic cable laying.Performance data:

- Flow rate up to 1.6 m³/min (57 cfm)

- Gauge working pressure up to 15 bar (215 psi)

Compact compressors up to 6.6 m³/min (230 cfm)

-

Durable, compact portable compressors under 750 kg

Compact, service-friendly and powerful, MOBILAIR portable compressors with diesel engine impress not only on account of their high delivery volumes – a multitude of equipment options make these efficient machines into multi-talented compressed air powerhouses.

Robust construction ensures trouble-free operation in ambient temperatures ranging from -10 °C to +45 °C, whilst roto-moulded PE enclosures (optional) provide excellent impact protection and value retention. This makes them ideally equipped to face the tough everyday conditions found on construction sites. All model variants weigh well under 750 kg (except the models M59 & M65), making them suitable even for smaller towing vehicles.

They also demonstrate their versatility when it comes to their areas of application. Whether it's for sandblasting, blowing out formwork, or powering impact moles and breakers, these high-performance powerhouses always cut an impressive figure. What's more, when specified with the optional generator, they are transformed into portable power plants, capable of providing compressed air and/or electricity as required.

Performance data:

- Flow rate up to 6.6 m³/min (230 cfm)

- Gauge working pressure up to 14 bar (200 psi)

Versatile portable compressors up to 10.6 m³/min (375 cfm)

-

Powerful all-rounders for your construction site

The MOBILAIR portable compressors in this series are exceptionally versatile. Optionally available with synchronous generators and/or compressed air treatment components, they are also offered in a variety of maximum pressure variants, thereby ensuring that the perfect model is always available for every application.

What's more, transporting these powerful all-rounders is a simple and convenient matter. KAESER portable compressors are equipped with lifting eyes as standard; they can also be specified as stationary versions equipped with skids or machine feet, making them the perfect choice for any operating location.

MOBILAIR portable compressors can be used wherever the key requirements are efficiency and durability. These powerful all-rounders excel when working on blasting applications and crash barrier construction. The optional generator transforms these machines into a portable power plant for the whole construction site.

Performance data:

- Flow rate up to 10.6 m³/min (375 cfm)

- Gauge working pressure up to 14 bar (200 psi)

Portable compressors with diesel engine up to 48.1 m³/min (1700 cfm)

-

Diesel-driven compressors up to 48.1 m³/min (1700 cfm)

Compact, powerful and versatile – Performance is more than a promise with diesel-driven MOBILAIR portable compressors from KAESER. As true powerhouses of the MOBILAIR range, these oil-injected portable compressors combine exceptional performance with compact design. The necessary power is provided by EU emission level V engines to ensure dependable and environmentally-friendly operation.

These versatile machines can be perfectly adapted to meet the needs of the specific application thanks to a wide range of optional treatment components that always deliver the required compressed air quality. Furthermore, the generously-sized fuel tank ensures impressive construction site staying power. When full, the fuel tank has sufficient capacity to last an entire work shift.

These diesel-driven compressors also feature dynamic ‘pV control’ to provide incredible flexibility, meaning that one and the same system can deliver pressures between 6 and 14 bar. This makes them ideal for cable blowing and drilling, for blasting work and concrete processing, as well as for providing backup air in opencast mining and industrial applications.

Performance data:

- Flow rate up to 48.1 m³/min (1700 cfm)

- Working pressure up to 14 bar (200 psi)

Portable oil-free compression up to 45.8 m³/min (1600 cfm)

-

The new standard for the 50 cubic metre class

Our flagship M500-2 combines all the advantages of a two-stage oil-free compression rotary screw compressor with those of a portable unit: maximum compressed air delivery volumes and quality, coupled with unrivalled flexibility.

- Compressed air aftercooler fitted as standard

- Fleet Management via modem as standard

- Optional skids version for stationary applications

- Refinery equipment as standard – including certified spark arrester, engine shut-off valve and closed floor pan

- Numerous features to facilitate set-up (chassis with parking brake, lifting and lashing eyes, forklift pockets)

The MOBILAIR M500-2 excels when operating in industrial applications. This compressed air titan is ideal for providing compressed air bridging operations when maintenance or repairs are required, for operating as a backup system when compressed air demand is high, or for refinery applications. Even automated production processes, such as connection to a control centre, pose no problem at all. The M500-2 can easily be controlled from there and integrated into any existing compressed air system. In the event of a drop in the compressed air supply, this oil-free compression rotary screw compressor jumps automatically to the rescue.

Performance data:

- Flow rate up to 45.8 m³/min (1600 cfm)

- Gauge working pressure up to 10.3 bar (150 psi)

Tools and accessories

-

Durable and powerful with perfect ergonomics

Even better from a single source: Kaeser compressed air tools and portable compressor accessories are perfectly tailored to work together and are manufactured to the same stringent quality standards in terms of performance, durability and ergonomics.

- Breakers

- Hammer drills

- Condensate separators

- Tool lubricators

- Hose reels

- Hoses, connectors, lighting cables, lubricants

Your advantages

- Long-term savings:

High-quality tools perfectly tailored to the compressor are a key factor for cost-effective use of compressed air tools. - Increased productivity:

Ergonomic details such as shock-absorbing handles make tools easier on the user and therefore improve productivity. - Less damage, fewer accidents:

Hoses left lying about are trip hazards and are easily damaged: Kaeser hose reels are a reliable solution for preventing this.

KAESER life cycle management

-

A Kaeser compressor is a purchase for life – and a decision that we always want you to look back on with satisfaction. To make sure of that, we put all of our energy and passion into the development of our machines as well as excellent customer advice and service.

Energy efficiency is a top priority.

The purchase price and service costs account for just a fraction of the total lifetime cost of a compressor. The biggest item by far is the cost of energy.

We have been striving for more than 40 years to reduce your energy expenses from compressed air production – but not only that. We also never lose sight of the service and maintenance costs and the constant availability of the compressed air supply.

Customer satisfaction starts with good advice

That's why we take a close look at your production set-up and your needs. We've developed systems that permit a precise assessment of how much compressed air you need – and at which quality standards. That's because we need a clear understanding of your requirements to develop solutions that will save you time and money.

"You can't do that with compressor vendors. This is possible only with a compressed air system provider whose specialised staff – despite their detailed knowledge – do not get lost in the details. They see the big picture, and instead of talking customers into things, can make a convincing argument for the best solution."

Dieter Markowiak, Facility Maintenance/Energy Supply Specialist, Airbus plant, BremenCompressors for these solutions are not one-size-fits-all products. Amongst the numerous design options with a wide power output range, we'll find the right model for you.