- Offer Profile

-

Laser Marking Machines

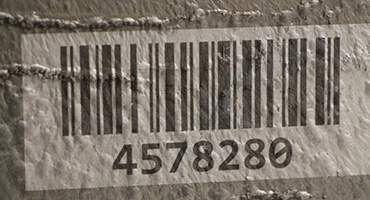

Our industrial laser markers are an integral part of a complete traceability system. They are used the world over to uniquely identify parts and bundles of parts with serial numbers, model number, batch number, date codes or any other useful information. Such identifiers may include barcode and Data Matrix Code - both of which can be scanned to release a wealth of information about the targeted product.

Laser Cleaning Machines

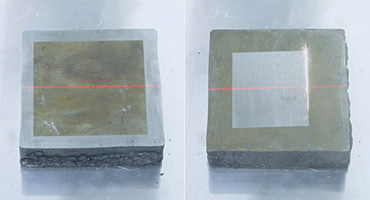

Automated industrial laser systems can remove rust, oil, oxidation and other contaminants from a variety of metals. When properly set, Laserax laser cleaners will remove the contaminants with close to zero effect on the base metal. It is an invaluable characteristic for laser mold cleaning, laser weld cleaning and laser surface preparation before welding and prior to many other surface treatments.

LASER MARKING AND CLEANING MODULAR SOLUTIONS

-

Lasers, enclosures and options are the building blocks of our laser systems. We offer CO2 and fiber laser machines — all of which come in different optical configurations, power levels and advanced features. We have enclosures that are affixed to conveyors and others that are free standing. You can also choose among our options to make your laser system even more adapted to your specific needs.

Customers receive a unique modular solution, safe and easy to install.

CHOOSING THE LASER

- Laser machines are the central core of a Laserax systems. We offer fiber laser machines known for their compatibility with various metals. Laserax has developed three distinct fiber laser series, each with their own optical capabilities. We also offer one series of CO2 laser machines to process plastics and other complex organic materials. Both laser types are available at different power levels.

CHOOSING THE ENCLOSURE

- Enclosures offer a safe industrial solution for laser applications. Laserax offers different types of enclosures. The standalone enclosure is a free standing laser workstation that works independently from your production line. While the laser enclosure for conveyors can be adapted to your conveyor system. Both enclosures can be automated.

CHOOSING THE OPTIONS

- The cabinet for laser sources, controllers and PLCs is a sturdy housing that provides ingress and mechanical protection, as well as a temperate environment for optimal performance of the laser system. The cabinet may also harbour Laserax’s HMI (Human-Machine Interface). The HMI’s main functions are to provide a means to give instructions to the laser system and to generate reports on its functioning.

LASER MACHINES PRODUCTS

- From our patent pending 3D autofocusing laser machines to the fastest air cooled laser marker on the market,

Laserax offers a complete range of unique industrial laser solutions that guarantee unmatched performance and reliability.

2D FIBER LASER MARKING MACHINE LXQ

OEM SYSTEM-

With an output power up to 200 W and certified IP67 class protection, the LXQ series is the most efficient and reliable industrial laser marking machine on the market.

- The fastest industrial fiber laser marker

- Withstands the most challenging environments (IP67 certified)

- Provides high definition and permanent identification

- Requires no consumables

- Capable of marking metal at high temperatures

- High speed on-the-fly marking capabilities

- Also capable of cleaning rust, varnish, paint and other contaminants on metals

Laserax LXQ 2D Fiber laser is the central element of our laser marking and cleaning systems

3D ADJUSTABLE FOCUS FIBER LASER MARKING MACHINE

LXQ 3D-

This 3D fiber laser system allows for industrial laser marking on various part geometries. This industrial laser marking machine will perform fast and reliable laser etching on various part geometries.

- Marks curved, tilted, multi-level surfaces

- The fastest industrial laser marker on the market

- Withstands the most challenging environments (IP67 certified)

- Provides high definition and permanent identification

- Requires no consumables

- Capable of marking metal at high temperatures

3D AUTOFOCUS FIBER LASER ENGRAVING MACHINE WITH 3D IMAGING

LXQ 3D VISION-

With the patent pending LXQ 3D Vision Series, Laserax brings to the market the first adaptative traceability laser engraver to offer the joint benefits of laser engraving and 3D imaging.

- Auto-focusing system that self-adjusts to part geometry and position within 5 inches range

- 3D vision provides surface data for quality control analysis

- Integrated camera for automated barcode validation

- Withstands the most challenging environments (IP 67)

- Provides high definition and permanent identification

- Requires no consumables

- Capable of marking metal at high temperature

- Also has the capabilities to remove rust, paint, oxydation and other contaminants from metalic surfaces

The LXQ 3D Vision can be embedded in laser safety enclosure creating the safest laser cleaning and marking systems.

2D CO2 LASER MARKING MACHINE

LXM SERIES (OEM SYSTEM)-

The LXM Series provides flexibility and durability without compromising on precision or speed.

- Direct integration on existing production lines

- Fully integrated unit

- Optimal contrast

- Modular system

- Compatible with most communication protocols

- Several wavelengths available

LASER MARKING, ENGRAVING, AND CLEANING SYSTEMS

- Laserax laser systems offer integrated solutions for specific industrial applications. Our systems are used in diverse industries such as: the aluminum and the steel industries, the die-casting, the extrusion and the converting industries and many other industries in the manufacturing sector.

MOBILE LASER CLEANING SYSTEM

-

A Laserax mobile laser system provides onsite laser marking and cleaning capability. This mobile workstation provides the flexibility needed for many repair and maintenance jobs. It can reduce the need to disassemble parts for cleaning, marking or general surface preparation.

Laserax’s mobile laser cleaning system is an ergonomic solution for onsite industrial cleaning, derusting and surface preparation. This solution includes a pneumatically balanced articulated arm to support the weight of the laser head. It does the heavy lifting for you. The three segments of the manipulator included in Laserax’s mobile laser cleaning solution provides a reach of up to 2.5 m (or 8’ 2”). The laser cleaner is installed on a wheeled cabinet.

LASERAX’S MOBILE LASER CLEANER :

- is designed to be ergonomic,

- requires no consumables,

- stores your library of tasks for different materials,

- is safe when used within the guidelines of the manufacturer,

- requires little to no maintenance

MOBILE LASER MARKING SYSTEM

-

With a mobile laser marking system from Laserax you will get the capacity to mark metallic parts on site. This mobile workstation provides the flexibility needed for many unique identification jobs. Combine our mobile laser marking solutions with Data Matrix and you get a highly reliable identification and traceability system.

Laserax proposes the mobile laser marking system as a solution for your on-site marking needs. It uses a lift assist articulated arm. The pneumatically balanced articulated arm supports the weight of the laser head, reducing the risk of musculoskeletal injuries. The three segments of the manipulator provide a reach of up to 2.5 m (8’ 2”). The mobile laser marking solution can be installed on a wheeled cabinet.

LASERAX’S MOBILE LASER MARKER:

- is designed to be ergonomic,

- requires no consumables,

- stores a library of tasks for laser parameters, label layout, etc. and

- requires little to no maintenance.

LASER MARKING SYSTEM

- With multiple wavelengths, optical configurations, power levels and advanced features, we provide the most efficient laser marking systems for your needs.

LASER CLEANING

- Lasers can deliver large quantities of energy on very small surface areas by laser beams. That energy can be used to remove rust, adhesives, paint or otherwise prepare materials for other surface treatments.