- Offer Profile

- Metrolux is a renowned provider of optical mesurement technology for the characterization of laser beams and optical systems. Metrolux has been developing, producing and marketing intelligent measurement technology for over 20 years.

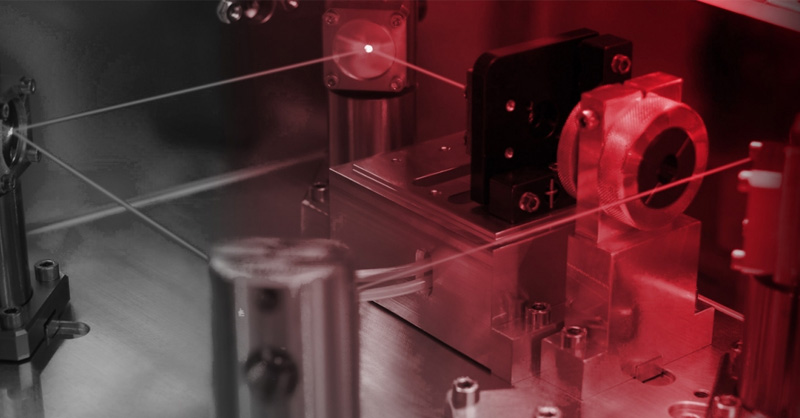

Optical measurement technology - Analysis of laser beams

- The laser has established itself as a valuable tool in many markets. The characterization and inspection of this tool impose high demands on the measurement technology. Different measurement methods can be used to cover the variety of necessary functions.

Beam profiling

-

Beam profiling is a tool for speeding up processes by providing an optimized laser spot. Control of beam shape and position using a beam profiler ensures the continued high quality of the process.

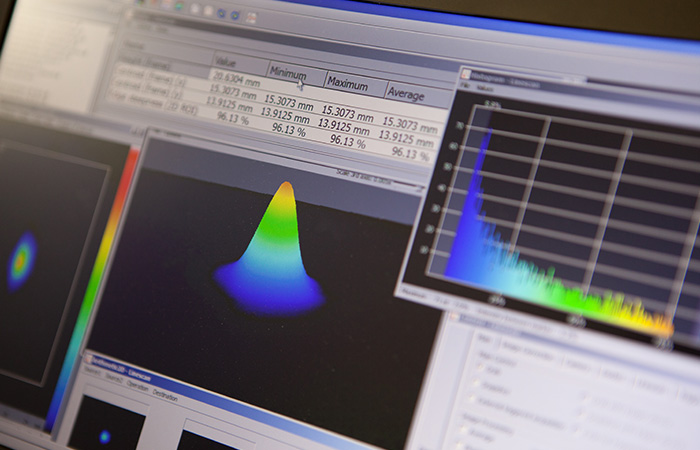

This fundamental function of laser beam analysis is provided by the Beamlux software. The contained software tools such as 2D-zoom and spot tracking or the time-dependent plotting of many calculated results are ideal tools for quality control. They are employed wherever a precise positioning or monitoring of laser beams is relevant.

Metrolux measurement systems are set up for the many requirements in Laser systems and related applications. They are employed worldwide in many systems even for UV and IR wavelengths that are normally inaccessible by CCD or CMOS sensor technology.

Products:

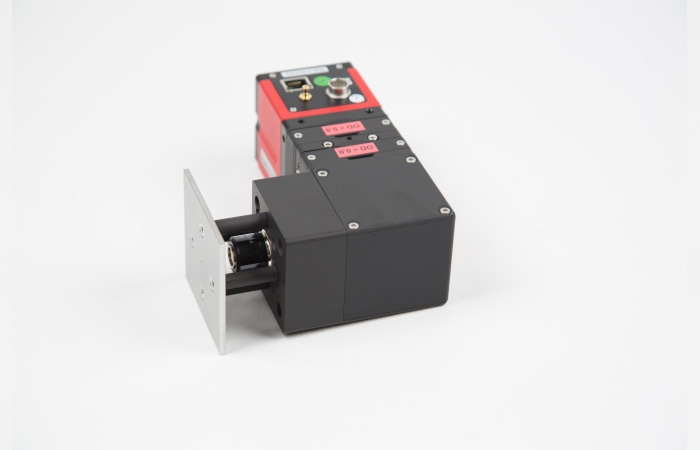

- LBM2.0 - Laser Beam Monitor

The LBM2.0 is a low form factor beam profiler that measures the important beam parameters quickly and precisely. The employed Sony Pregius CMOS sensor provides a 2 megapixel resolution. - BM8304 - Beam Monitor 8304

The Beam MonitorBM8304 consists of the robust and compact beam profiler camera BPC8304ML and the image processing software Beamlux: it is a standard beam profiler suitable for all markets. - Software

The perfect combination of hard- and software is essential for the exact measurement and analysis of laser beams.

- LBM2.0 - Laser Beam Monitor

Focus measurement

-

Focus measurement helps to increase process speeds by helping to optimize the laser spot. Distortion-free attenuation and magnified imaging enable control over the intensity distribution and position of a laser focus. This is an important tool in process monitoring.

Metrolux provides Measurement systems that are optimized for very different requirements for a focused laser beam such as wavelength, power density, numerical aperture and spot size. The tools contained in the Beamlux software such as 2D-zoom and spot tracking or the time-dependent plotting of many calculated results are ideal for the analysis and optimization of the intensity distribution in the laser focus.

The laser focus has been recognized as a valuable tool in many areas of materials processing. The automotive industry uses focused laser beams for remote welding of vehicle body parts, the display industry for cutting glasses and the separation of layers while the solar industry uses them for cutting and scribing silicon wafers.

Products:

- FM100 – Focus Monitor 100

The Focus Monitor 100 (FM100) is a robust and compact beam profiler for the analysis of of focused laser beams. It is employed for the regular quality control of laser beams in many industrial applications due to its versatility. - Software

The perfect combination of hard- and software is essential for the exact measurement and analysis of laser beams.

- FM100 – Focus Monitor 100

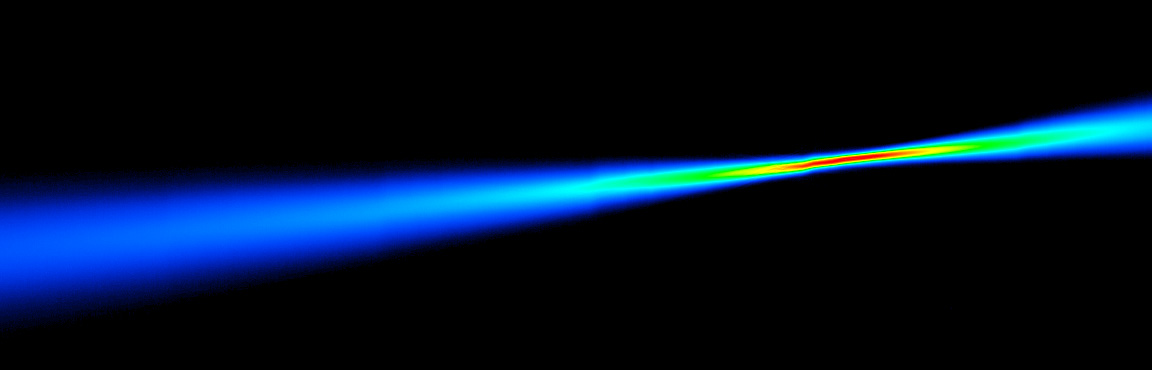

Caustic measurement

-

The measurement of a laser's caustic allows a precise characterization of the beam's quality. The M2-Tool within the Beamlux software is optimized for measurements of the intensity distribution along the laser beam caustic conforming to the ISO 11146 standard and provides this at a high speed and with the highest level of reproducibility

The characterizatoin of laser sources is of paramount importance in the production process of high quality laser systems. The choice of beam sources for integratd systems can be made and the systems can be planned based on the parameters defined in the standard. Metrolux Measurement systems are dsigned for a quick high-precision measurement of the laser's beam parameters according to ISO11146. They can be easily integrated into production processes due to the included remote control features.

This type of measurement is predominantly used by laser manufacturers and systems integrators to precisely specify lasers and laser beams. To this end the Metrolux software provides conclusive measurement reports.

Products:

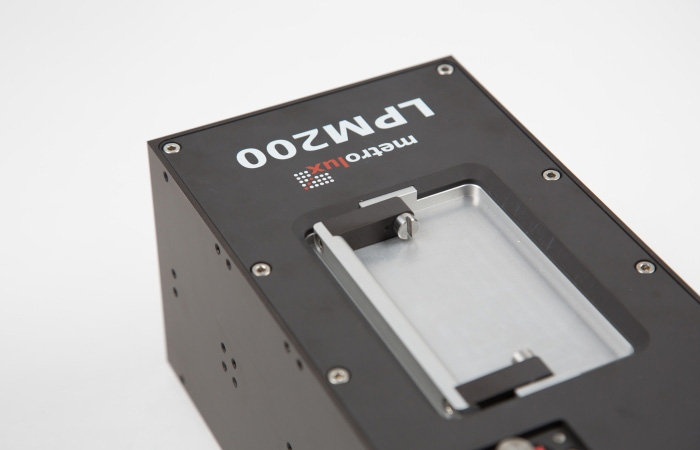

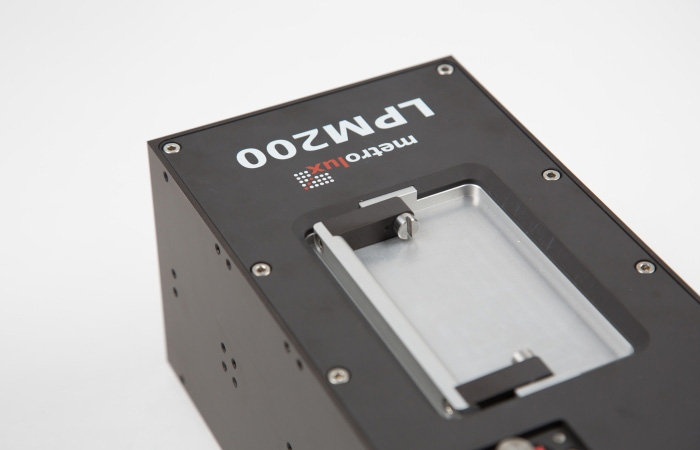

- LPM200 – Laser Propagation Monitor 200

The Laser Propagation Monitor 200 (LPM200) is a compact measurement system for rapid, automated analysis of a laser beam's quality. The measurement of M2 and the laser caustic takes as little as 10 seconds. - Software

The perfect combination of hard- and software is essential for the exact measurement and analysis of laser beams.

- LPM200 – Laser Propagation Monitor 200

Line focus measurement

-

Line focus measurement serves to enhance the process speed by providing an optimized laser line focus. To ensure a lasting high quality of productoin processes one must continuously monitor the line width, intensity distribution and homogeneity. This requires a quick measurement at high resolutions.

Line shaped laser foci with lengths of up to 3000 mm enable large area processin of many materials. Especially in large scale mass production settings this requires the constant monitoring of the employed laser tool. One instance of the efficient use of laser line foci is the OLED and LED display production. Lasers of vaying wavelength, line lengths and widths and intensity homogeneities are employed here. Metrolux provides measurement systems with the specialized Beamscan or Linescan software bundles that are optimized for the line focus anaysis to monitor the continously high quality. Some Metrolux UV systems are available for extended line focus or area scan measurements even at UV wavelengths such as 193 nm.

This method is predominantly employed in the display and semiconductor industries.

Products:

- FM100 – Focus Monitor 100

The Focus Monitor 100 (FM100) is a robust and compact beam profiler for the analysis of of focused laser beams. It is employed for the regular quality control of laser beams in many industrial applications due to its versatility. - Software

The perfect combination of hard- and software is essential for the exact measurement and analysis of laser beams.

- FM100 – Focus Monitor 100

Applications

- Optical metrology is used for the analysis of laser raw beams, foci, line foci, wave fronts and caustics. Metrolux measurement systems set the benchmarks internationally and are widely used in the display, automotive and laser industries as well as by systems integrators.

Laser manufacturers - Reliable and steady

-

Metrolux systems measure and characterize a laser's beam quality and output power along with beam properties such as beam size, focusability and beam profile. Reliable high precision measurement equipment is very important for manufacturers in both quality control and marketing. Reproducibility also plays an important role.

Products:

- LPM200 – Laser Propagation Monitor 200

The Laser Propagation Monitor 200 (LPM200) is a compact measurement system for rapid, automated analysis of a laser beam's quality. The measurement of M2 and the laser caustic takes as little as 10 seconds. - Software

The perfect combination of hard- and software is essential for the exact measurement and analysis of laser beams.

- LPM200 – Laser Propagation Monitor 200

Display industry - A good picture

-

The homogeneity of the line focus emloyed in display production is directly responsible for the display quality. Metrolux measurement systems image and analyze this line using the Beamscan software.

Products:

- FM100 – Focus Monitor 100

The Focus Monitor 100 (FM100) is a robust and compact beam profiler for the analysis of of focused laser beams. It is employed for the regular quality control of laser beams in many industrial applications due to its versatility. - VA – Variable Attenuator

The Variable Attenuators (VA) are designed for precise precision adjustment and stabilization of laser powers. They provide the highest degree of reproducibility for laser processes. - Software

The perfect combination of hard- and software is essential for the exact measurement and analysis of laser beams.

- FM100 – Focus Monitor 100

Systems integration - Process safety

-

Systems integration covers a variety of technical aspects. Metrolux is a flexible and competent partner for all markets that rely on the quality of the laser as a tool.

Products:

- FM100 – Focus Monitor 100

The Focus Monitor 100 (FM100) is a robust and compact beam profiler for the analysis of of focused laser beams. It is employed for the regular quality control of laser beams in many industrial applications due to its versatility. - VA – Variable Attenuator

The Variable Attenuators (VA) are designed for precise precision adjustment and stabilization of laser powers. They provide the highest degree of reproducibility for laser processes. - LBM2.0 - Laser Beam Monitor

The LBM2.0 is a low form factor beam profiler that measures the important beam parameters quickly and precisely. The employed Sony Pregius CMOS sensor provides a 2 megapixel resolution. - BM8304 - Beam Monitor 8304

The Beam MonitorBM8304 consists of the robust and compact beam profiler camera BPC8304ML and the image processing software Beamlux: it is a standard beam profiler suitable for all markets. - Software

The perfect combination of hard- and software is essential for the exact measurement and analysis of laser beams.

- FM100 – Focus Monitor 100

Automotive - Light in the focus

-

The laser has established itself as an important tool for the automotive industry. It is ideally suited for welding, brazing and drilling. Metrolux offers solutions for reliable monitoring of single processes that allow keeping the parameters of the focused laser beam in the optimum range.

Products:

- FM100 – Focus Monitor 100

The Focus Monitor 100 (FM100) is a robust and compact beam profiler for the analysis of of focused laser beams. It is employed for the regular quality control of laser beams in many industrial applications due to its versatility. - Software

The perfect combination of hard- and software is essential for the exact measurement and analysis of laser beams.

- FM100 – Focus Monitor 100

Products

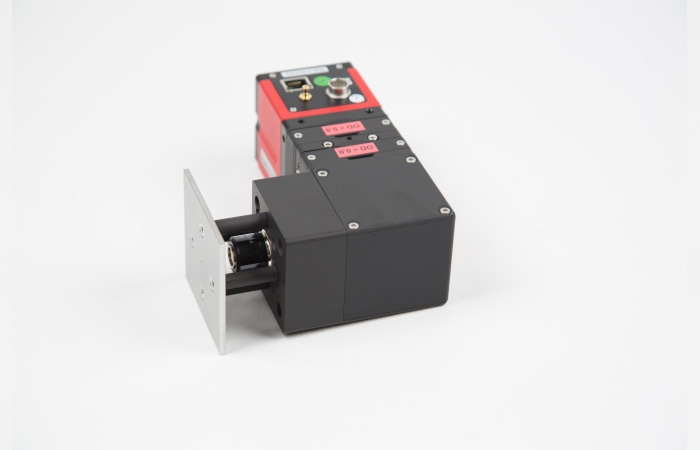

FM100 – Focus Monitor 100 - Laser focus analysis

-

The Focus Monitor 100 (FM100) is a beam profiler for the analyisis of focused laser beams. It is optimized for industrial use. The compact design ensures reliability and quality in the production.

Thanks to its versatility the FM100 is already in use for regular quality control of the laser beam in the display and semiconductor industries as well as in the processing of materials in the automotive industry. In addition to the integrated high power attenuator the FM100 has two filter slots for flexible attenuation of laser power. The configuration can be optimized for all laser wavelengths to guarantee the best possible measurement results.

Technical specifications:

- Wavelength 248–1100 nm or 9300-9600 nm

- Laser Power up to 100 W

- Sensor type CCD 2/3''

- Beam size 10-250 µm

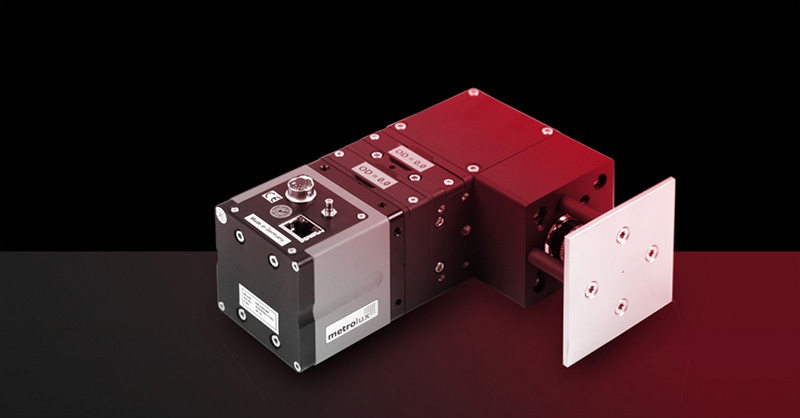

LPM200 – Laser Propagation Monitor 200 - Laser beam quality measuremen

-

The Laser Propagation Monitor 200 (LPM200) is a compact measurement system for rapid, automated analysis of a laser beam's quality. The measurement of M2 and the laser caustic takes as little as 10 seconds. Comprehensive accessories for attenuation and absorption of laser beams are available.

LPM200 – Laser Propagation Monitor 200

The exact characterization and specification of laser beam sources is crucial to provide and maintain a high product quality in the laser production. Systems integrators can choose the beam sources to use and integrate according to the parameters defined in the international standard. Metrolux Measurement systems are designed for a quick high precision measurement of laser beam parameters. The image processing software's remote controllability simplifies the integration into production processes.Technical specifications

Wavelength 340–1100 nm

Laser Power < 10 W without additional modules

Sensor type CCD 2/3"

Beam size, collimated 250 µm – 15 mm

VA – Variable Attenuator - Adjustment and stabilization of laser powers

-

The variable laser attenuators (VA) are designed for precise precision adjustment and stabilization of laser powers. They provide the highest degree of reproducibility for laser processes. Tye are typically used for Excimer and YAG laser wavelengths. They are suitable for cw lasers.

Variable Attenuator

The Variable attenuators provide highest reproducibility for laser processes. The stabilization of pulse energies in production processes is their main use. To compensate the beam displacement generated by the dielectric filter a transparent second optic is also employed. The transmitted laser beam's attenuation can be regulated contiuously by changing the filter's angle of incidence between 0° and 45°.

Technical specifications

For cw and pulsed lasers of high output power and pulse energy

Available for all excimer and YAG laser wavelengths

Clear aperture (W x H) 45 x 20 mm

Max. Beam Size ca. 43 x 18 mm

Dimensions (L x H x W) ca. 80 x 174 x 100 mm

Weight ca. 1.4 kg

Software

Measurement of beam profiles-

The perfect combination of hard- and software is essential for the exact measurement and analysis of laser beams. Metrolux has developed four software bundles for the analysis of laser and wave front parameters in accordance with the international ISO standard: Beamlux, Beamscan, Linescan and Raylux.

Frequently measurement systems are integrated into other systems or processes. This leads to a high importance of the compatibility of the data acquisition to other user interfaces. The remote control interface included with the Metrolux software bundles allows a straightforward integration into production processes as well as the generation of customer-specific GUIs. A variety of functions for data processing and report generation are already available.

The beam profiling and image processing software Beamlux is designed for the analysis of cw and pulsed laser beams. Parallel to each image acquisition the parameters derived from the beam’s intensity distribution are evaluated. The analysis conforming to the international ISO standards provides all essential functionalities of beam profile analysis. Further functions such as spot tracking and various zoom and display options make this software bundle ideally suited for focus measurement. Optional modules such as the M²-Tool or Power Tool provide optimized solutions for caustic measurement or relative power measurement.

The software bundles Linescan and Beamscan provide a tool for the analysis of extensive beam profiles such as line foci. These can extend to lengths of multiple meters combined with high resolution line widths. The optimized algorithms in these software bundles allow a high precision measurement of the beam homogeneity. The integrated motor control facilitates the scanning of long laser line foci.

The Raylux software is Metrolux’ tool for wave front analysis. It is designed for the evaluation of Shack-Hartmann data and the fit of all Zernike coefficients. This way the characterization of optics and beam quality monitoring can be easily achieved.

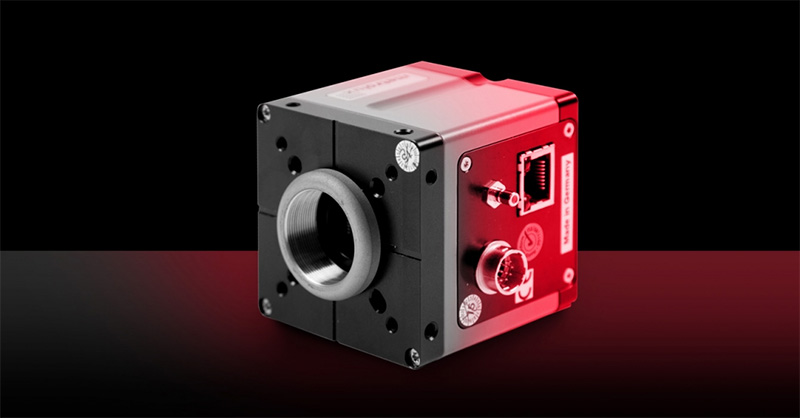

BM8304 - Beam Monitor 8304 Laser beam profile analysis

-

The Beam MonitorBM8304 consists of the robust and compact beam profiler camera BPC8304ML and the image processing software Beamlux it is a standard beam profiler usable for all markets.

BM8304 - Beam Monitor 8304

Low S/N ratios and a high sensor response linearity are prime attributes of the sensor employed in this Metrolux beam profiler. The Software provides the functions required for the international standards EN-ISO 11145, 11146, 11670 and 13694 that cover aspects of laser light characterization. The beam profiler camera BPC8304 uses a 1.4 MPixel CCD sensor with square pixels of 6.45 µm size. The wavelength range of 340 to 1100 nm allows the analysis of all common laser wavelengths. The data interface is Gigabit Ethernet (GigE). As most computers already provide a GigE interface (as opposed to Firewire) there is generally no need to add separate inteface cards. The cable length can easily reach up to 100 m, facilitating the integration into production systems.

Technical specifications:

- Wavelength 340–1100 nm

- Sensor type CCD 2/3"

- Beam size 70 μm – 6.5 mm

- Interface GigE Vision, GenICam compatible

focuslux high power

-

The focuslux high power is used to measure beam profi les of the focussed laser beam in the high power range, in situations such as directly in material processing systems.

Focus monitor

Beam profiler for quick measurement of laser spots in the high power range.You’ll benefi t from:

- Quick measurement of laser beams of the highest power levels

- Compact design: Assembly directly on the manufacturing system and on industrial robots

Design & technology

- Compact solution: Robust housing, imaging optics, attenuator, absorber module (for longer measurements)

- Large diameter of the optics guiding the beam

- Filter modules open up a wide range of dynamics on the power densities to be measured

- Coatings optimized for aberration-free imaging

- Motorized protective lid for process-controlled opening

- Integrated measurement system for working temperature and protective lid

Use

- Measurement of laser spots of the highest power levels (up to 6 000 W)

- Working spectral range: 1 030 nm – 1 070 nm (can be optionally expanded)

- Use in the immediate area around the production facility

- Intended for all industrial production systems