- Offer Profile

- Easy-Laser® is one of the world’s leading manufacturers and suppliers of laser based measurement and alignment systems. We develop straightforward products made to quickly and accurately perform measurements and align machines for assignments in all types of industry.

LASER BASED MEASUREMENT SYSTEMS: SHAFT ALIGNMENT FOR ALL YOUR ROTATING MACHINERY

- There is an Easy-Laser® shaft alignment system for every situation and industry, from the most simple to the most advanced, and for use in potentially explosive environments. All systems are designed to be easy to mount on the machines. Vital components are made of aluminium and stainless steel to guarantee reliable measurement values and the highest reliability in even the toughest of environments.

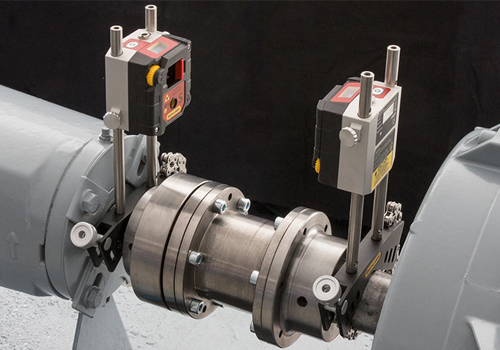

XT770 SHAFT ALIGNMENT

-

THE COMPLETE ALIGNMENT SYSTEM

With Easy-Laser XT770 you can perform shaft alignment of horizontal and vertically/flange mounted machines, but also align machine trains, measure twist of foundation, soft foot, bearing clearance, and more. The EasyTrend program allows you to keep track of machine movement over time. That is useful when checking for thermal expansion and pipe strain issues for example.

2 axis PSDs (position sensitive detectors) permit adjustment of your machine both vertically and horizontally at the same time, with measuring units in any position. We call it 360° Live adjustment. With the XT770 you have a choice of several different measurement methods, e.g. continuous sweep and multipoint. This gives you the flexibility you need to achieve the perfect measurement result.

Easy-Laser XT measuring units and display unit are shock proof and rated both IP66 and IP67 water and dust proof. Along with long operating times, this guarantees you will be able to take on and finish even the toughest jobs.

USER-FRIENDLYUse the rugged Easy-Laser XT11 display unit, or install the free XT Alignment app on your iOS or Android device*. The intuitive user interface guides your through the measurement process.

UNIQUE DOCUMENTATION POSSIBILITIESThe XT11 display unit has a 13MP camera. You can also get the XT11 display unit with a built-in IR camera**! This means you can add a thermal image of the machine before and after alignment. You can easily create and share a PDF report containing all measurement data and images.

GEOMETRIC MEASUREMENTS KITWith this kit added to your XT770, using the Values program, you will be able to take flatness and straightness measurements with the highest reliability and precision. The kit includes the very versatile and long proven laser transmitter D22 plus geo brackets.

Easy-Laser® XT770 is the most powerful of our Generation XT alignment systems. The 360° Live feature gives you even more possibilities to perform advanced adjustments. With XT770 you can carry out the following:

- Align the machine

- Check base twist

- Check bearing play

- Check soft foot

- Measure machine movement over time

- Document and share the results

XT660 SHAFT ALIGNMENT

-

MORE POSSIBILITIES WITH DOT LASER

The XT660 measuring units utilize dot laser technology. This makes it possible to measure larger machines and longer spans than line laser systems. It also provides higher accuracy when backlash in the coupling is present. In addition, dot laser allows you to check more things when installing a machine, e.g. twist of foundation and bearing clearance.

With the XT660 you have a choice of several different measurement methods, e.g. continuous sweep and multipoint. This gives you the flexibility you need to achieve the perfect measurement result.

The XT products are rugged, rated both IP66 and IP67 water and dust proof. Along with long operating times, this guarantees you will be able to take on and finish even the tougher jobs.

USER-FRIENDLY

Use the rugged Easy-Laser XT11 display unit, or install the free XT Alignment app on your iOS or Android device*. The intuitive user interface guides your through the measurement process.

UNIQUE DOCUMENTATION POSSIBILITIES

The XT11 display unit has a 13MP camera. You can also get the XT11 display unit with a built-in IR camera**! This means you can add a thermal image of the machine before and after alignment. You can easily create and share a PDF report containing all measurement data and images. XT550 SHAFT ALIGNMENT

-

INTRINSICALLY SAFE FOR POTENTIALLY EXPLOSIVE AREAS

The Ex-approved XT550 system is developed for hazardous areas and is easily operated through our XT Alignment app. It is an advanced measurement system for alignment of horizontal and vertical/flange mounted rotating machinery.

It comes with Easy-Laser’s dot laser technology, allowing you to measure large machinery and long spans. The measuring units are approved in accordance with the latest ATEX directive, and are rated both IP66 and IP67 water and dust proof.

CHOOSE YOUR OWN DISPLAY UNIT

System XT550 comes in two configurations; with or without the ATEX approved ecom Tab-Ex® display unit. The XT Alignment app runs on most iOS and Android units, as well as our own display unit XT11. However, those are not allowed in potentially explosive areas, but makes for a perfect complement for use in other places.

Note. For use in Ex-classed areas, the mobile device you’re using must be approved for these areas. Always check for approval labels before entering potentially explosive areas. The XT11 is not Ex/ATEX approved. XT440 SHAFT ALIGNMENT

-

GENERATION XT – THE AGE OF MEASUREMENT INDEPENDENCE IS HERE!

Thanks to groundbreaking cross-platform technology, XT lets you display data on a multitude of different handheld devices, giving you the freedom to work with the gear that suits you and your company the best. To make this new generation as straightforward as possible we have included all XT measurement programs in a user-friendly application you can download for free.

NO LOCK-INS

Easy-Laser® XT440 shaft alignment system

With Generation XT we let you decide if you want the rugged and user-friendly Easy-Laser XT11 display unit to be included or not. The app also runs on your iOS or Android device*, be it a tablet or a phone, meaning you are never locked in to a specific way of working.

NO LICENSE HASSLE

With Generation XT the measuring units run the show! What they can do, the XT Alignment app will allow you to do too. No hassle with licenses to unlock new features in the app. If you have the hardware, you can use all of its capacity. That is straightforward!

RUGGED DESIGN AND LONG OPERATING TIMES

The XT products are rugged, rated both IP66 and IP67 water and dust proof. Along with the very long operating times of 16 hours, this guarantees you will be able to take on and finish also the tougher jobs.

UNIQUE DOCUMENTATION POSSIBILITIES

The XT11 display unit has a 13MP camera. You can also get the XT11 display unit with a built-in IR camera**! This means you can add a thermal image of the machine before and after alignment. XT190 BELT ALIGNMENT

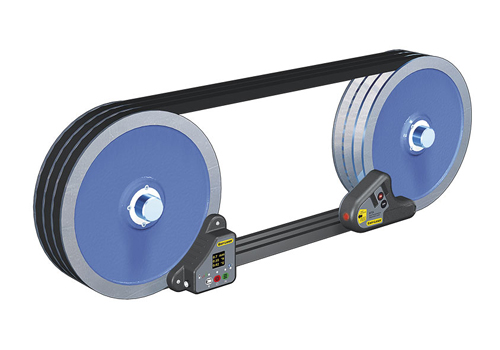

-

WIRELESS AND DIGITAL TOOL FOR ALIGNMENT OF SHEAVES/PULLEYS

The Easy-Laser® XT190 allows even more accurate and efficient alignment of sheaves/pulleys. Easy-Laser® is unique to the market in being able to offer digital read off.

The transmitter generates a laser plane parallel to the reference sheave. The detector reads the position in relation to the laser plane and provides a live digital display of both offset and angular value. This makes the alignment of the adjustable machine very simple. The accuracy of the digital readout also means that you can align within prescribed tolerances and rely on the result.

MANY READ-OUT OPTIONS

Follow the adjustment on the integrated OLED display, in the free XT Alignment app on your phone or tablet, or on a separate Easy-Laser® display unit*. The machine's shim and adjustment values are automatically calculated. It is also possible to read off visually on targets (included).

With the XT11 display unit or mobile device, it is easy to save the data and create a PDF report.

ACCURATE AND EASY TO USE

Compared with old methods such as rulers, the alignment is more accurate and efficient when both horizontal and vertical adjustment is carried out at the same time. In addition, the work can be performed by one person alone, in a significantly shorter time.

FITS ALL TYPES OF SHEAVES/PULLEYS

The XT190 is mounted on the sheave/pulley using super magnets. It can be used on all types of sheaves/pulleys, such as v-belt, timing belt, flat belt and chain drives. If you have aluminum sheaves/pulleys, the low weight of the tool means that it can be attached using strong double-sided tape.