- Offer Profile

-

Metzner Maschinenbau GmbH is an internationally active, medium-sized company and one of the leading manufacturers of cutting and assembly machines for cable and plastics processing as well as automation solutions for the hard metal industry, medical technology and e-mobility. For more than 30 years, Metzner machines and solutions have been convincing through patented and innovative processes. This applies to the wide range of cutting technologies in rubber and plastics processing as well as pioneering solutions for the processing of cables, strands and corrugated pipes. In addition, Metzner has supplemented its product range in recent years with automation solutions for powder presses and other industrial applications.

As a system provider, Metzner develops and produces both series machines and customer-specific systems for each product area. Various patents and utility models underline the company's know-how.

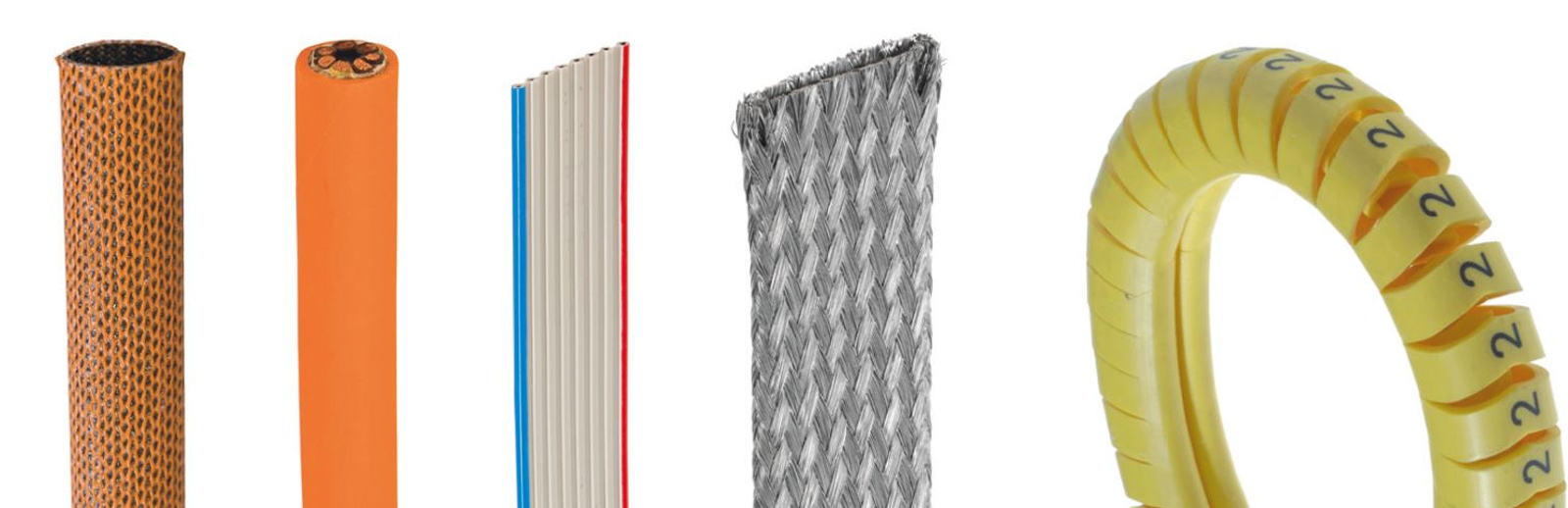

Cable Processing

CUT & STRIP

- With its standard machines, Metzner offers numerous possibilities for the precise cutting and stripping of cables of various types. The range includes semi-automatic table machines, fully automatic processing lines and precise rotary processing for coaxial cables and shielded cables. Metzner machines and their accessories are consistently designed to meet the high demands that new materials and designs place on successful and high-quality cable processing. Wherever standard solutions do not optimally meet your requirements, we offer individual extensions.

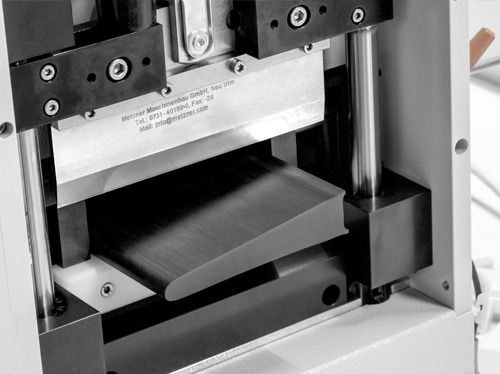

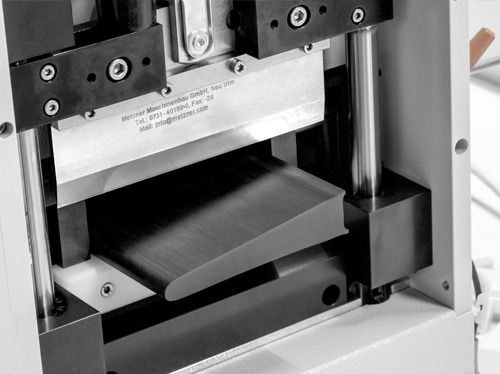

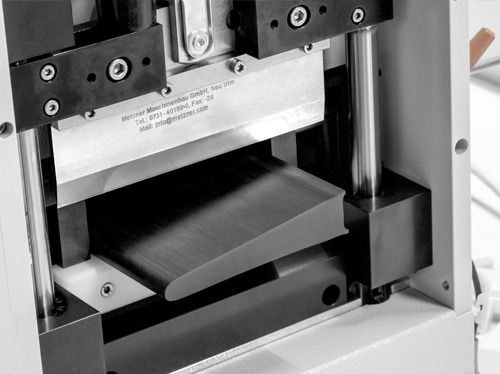

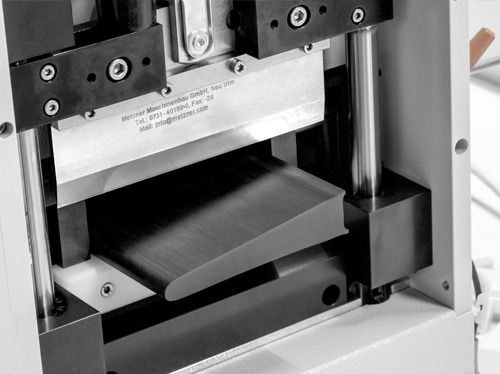

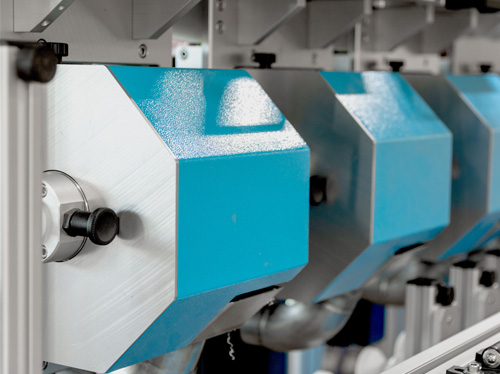

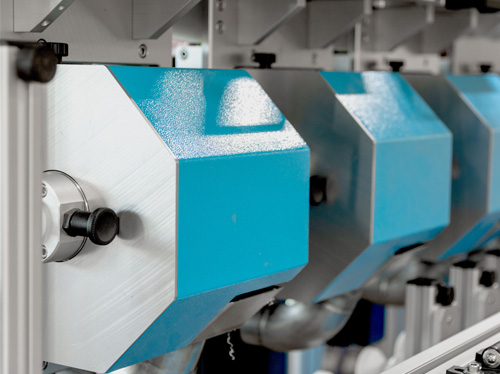

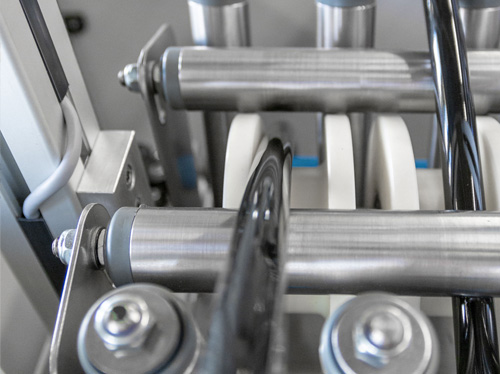

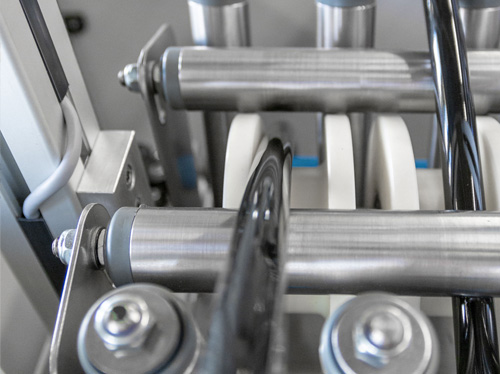

METZNER AM-RANGE- Processing of shielded cables

- Multi-stage stripping of multicore cables

- Outstanding cutting and pull-off force

- With or without rotary cut

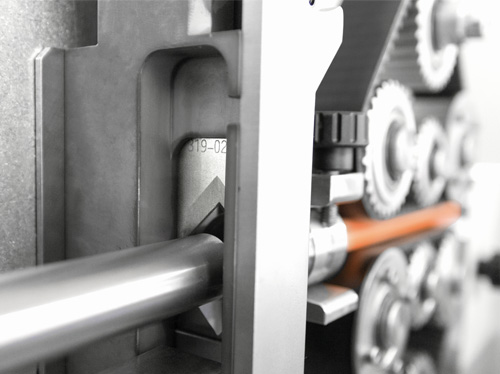

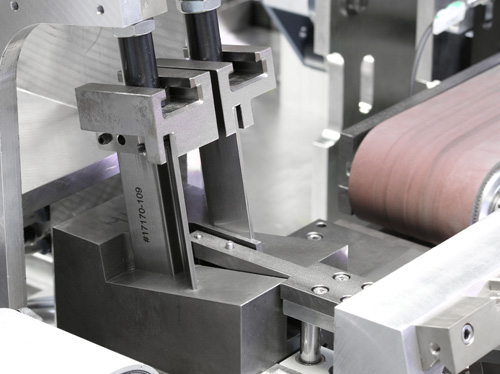

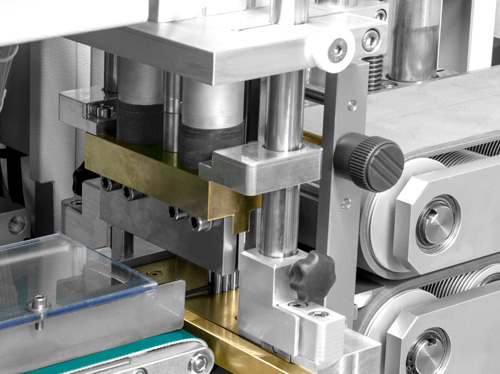

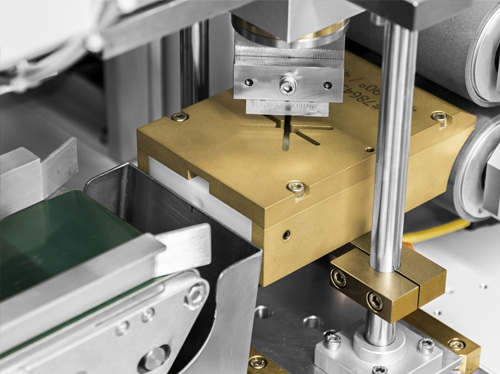

- Patented "double knife cutting system"

METZNER AM 1000

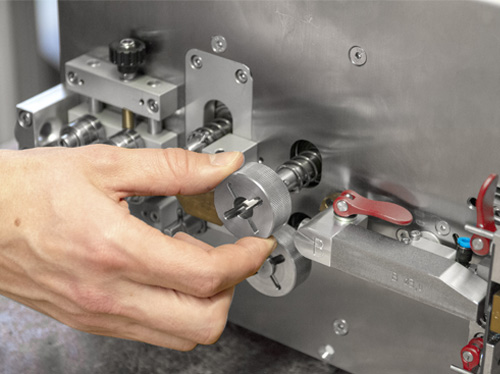

- The Metzner AM 1000 is a sensation among the tabletop units. The automatic cutting and stripping machine processes cables, strands and wires up to 10 mm diameter and 10 mm2 cable cross-section with a special cutting and pull-off force. The presettings are conveniently made via the modern 12" touch panel, where the operator can define all processes. Thanks to the sensors for diameter and material recognition, the AM 1000 works extremely precisely. Another special feature is the tool-free replacement of wear parts and cutting blades. This means that the AM 100 can be changed over in just one minute. With the extensive interface preparation, the machine can be optimally expanded with peripheral devices and adapts to all customer requirements. The compact design with retractable touch-screen and the low weight of only 28 kg also offer special comfort. This makes the AM 1000 especially easy to transport.

METZNER AM 5000

-

High power and versatility for large cross-sections

The Metzner AM 5000 range includes the flagship models for precise processing of thick cables up to 240 mm² section and 35 mm diameter. Even the basic specification models, with their high torque and powerful three-stage step motors offer the highest level of cutting and haul-off power. All models are equipped with as standard with the Metzner double-knife system that enables very varied and multi-stage processes to be performed. Moreover, with convincing operator-friendliness and long service life. Metzner AM 5000 models are also suited to processing thinner braided cables from 1.5 mm² The stripping full haul-off 1side/2nd side amount to 270-450 mm and 90-270 mm, for partial haul-off 450 mm and 270 mm. For interuption-free automatic production, a number of sensors monitor the material feeding Für einen unterbrechungsfreien, automatischen Produktionsablauf überwachen mehrere Sensoren die Materialzufuhr. If a material blockage occurs, the production stops automatically and the operator is informed about the cause of the fault.

METZNER AM 3800

-

Convincing Power and Versatility

The cable processing machines in the AM 3800 range are characterised by their outstanding cutting and haul-off power and their modular, robust and long-life construction for continuous use in industrial applications. These machines outstandingly combine power and versatility. Equipped with cutting power for cables up to 70 mm sectionand 20 mm diameter, they are the ideal solution for an unusually wide spectrum of applications. Depending o the processing demands, numerous knife contours and technologies are available: the patented double-knife system allows different processes to be performed in a single working pass. The circumferential rotary cut offers an exact cutting round cables with very thin or tough insulation outer cover.

METZNER AM 3000

- The AM 3000 range of cable processing machines are distinguished by cutting and haul-off power and their convincing modular, robust and long-life construction for continuous industrial working. There are different models with different cutting powers and specifications. To match the processing requirements, numerous knife contours and technologies are available: The patented double-knife system facilitates different processing in a single working pass, the circumferential rotary technology offers exact circular cutting for cables with very thin or rigid outer insulation cover and for co-axial cables. Every model is equipped as standard with a full set of interfaces for peripheral equipment and IT integration. The machines can easily be converted into complete production lines, thus further increasing the process automation.

METZNER AM 2000

-

Convincing Speed and Precision

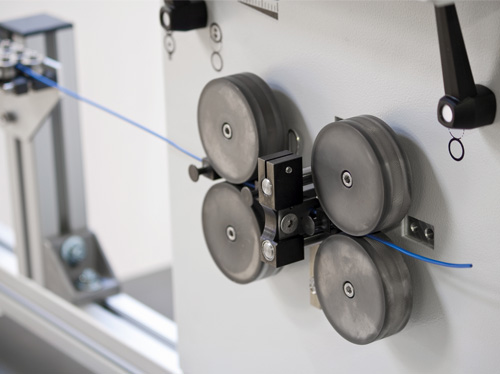

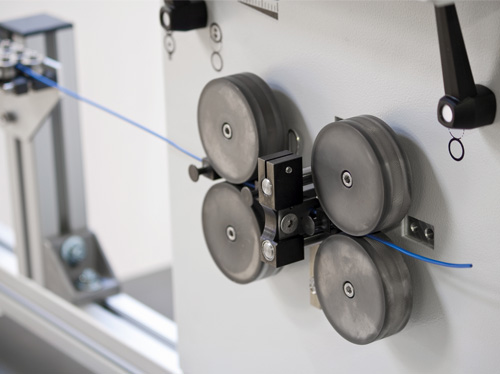

The Metzner AM 2000 automatic machine for cut-to-length and insulation removal processes of braided cables up to 6 mm² and r up to 6 mm diameter with precision and repeatability For industrial cable processing sectors where secure working, versatility and rapid production are required, the AM 2000 is a uniquely equipped machine in its price class. All cut-to-length and insulation stripping processes are programmed by the operator via the machine controls with just a few settings. Many pre-defined functions facilitate the access to a wide range of processing possibilities Further notable characteristics are the standard RS-232 interface, which enables to be used in PC-supported processing as well as for printing. A standard high-performance cable straightener ensures that all braided cables and wires – which often come from tightly wound spools - are straightened out.

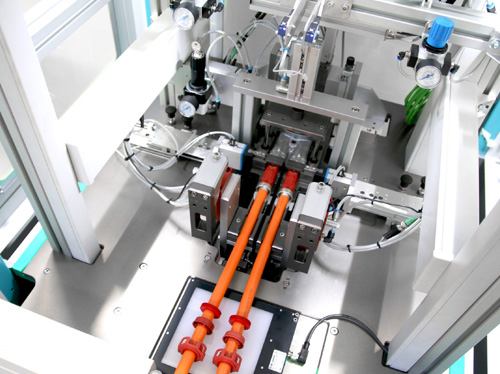

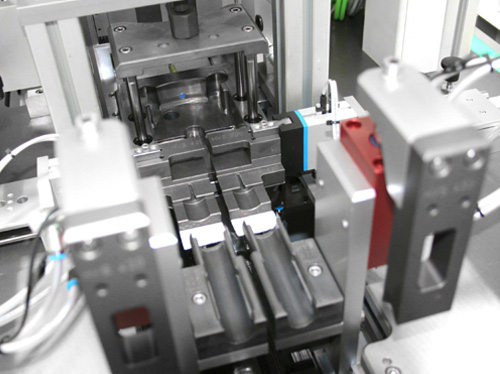

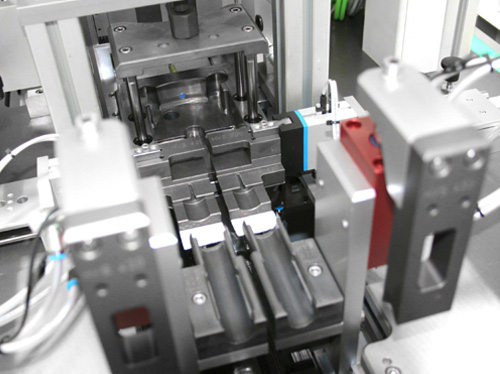

HIGH-VOLTAGE CABLE PROCESSING

- Electromobility is of great importance in the realisation of new mobility concepts. Metzner founded Metzner E-Mobility GmbH in 2018. Here, a team of experienced Metzner mechanical engineering developers and young talents are working together to cover the entire process chain from cutting cables to length to complex connector assembly and to offer customers a wide range of automation solutions for high voltage cable processing. With its efficient automation systems for the production of high-voltage cable harnesses, Metzner E-Mobility GmbH is making a significant contribution to making electric vehicles affordable for the mass market.

CUTSOMISED SOLUTIONS THANKS TO MODULAR SCALABILITY Metzner E-Mobility develops customised machines for the processing of high-voltage cables for every customer requirement. The platforms differ in the degree of automation and personnel requirements. The common feature of each platform is its modular design, which makes flexible and scalable expansion of production possible at any time. Flexible and modular in this case means: our process tools can be converted from one platform to another within a short time or can also be changed within the same platform for the production of other cables or contact systems.

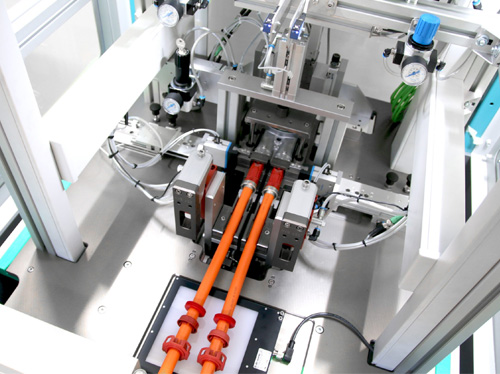

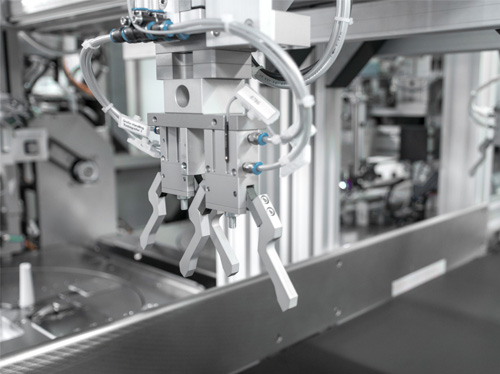

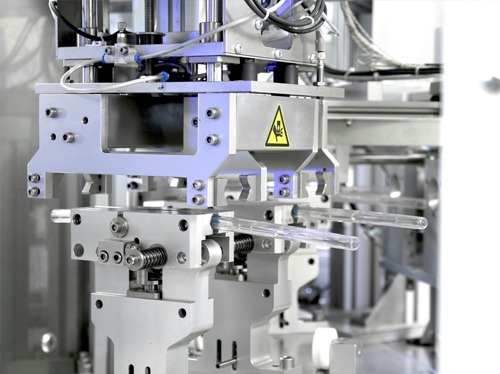

METZNER EM 100

-

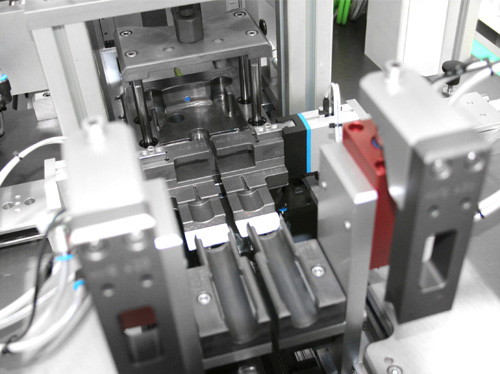

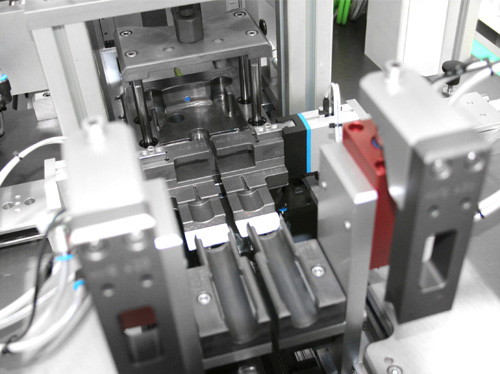

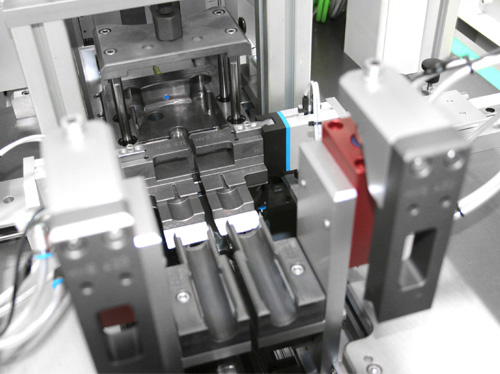

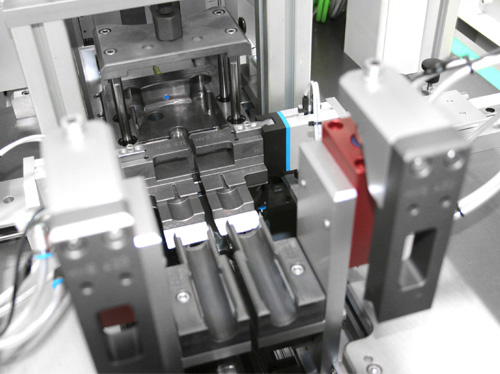

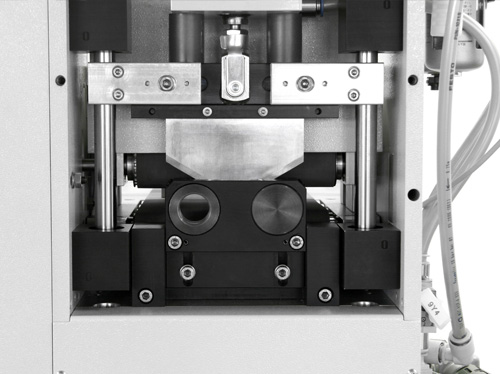

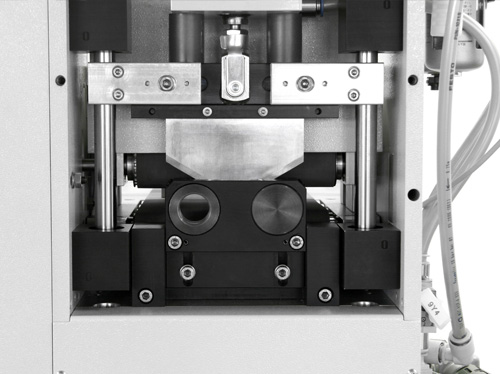

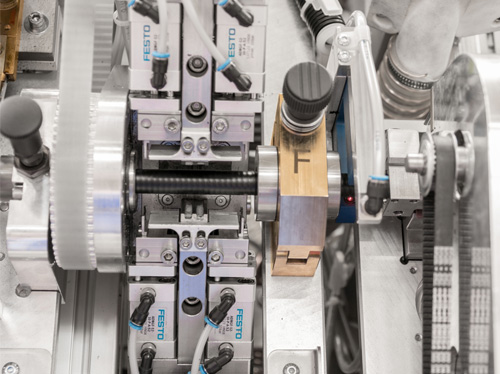

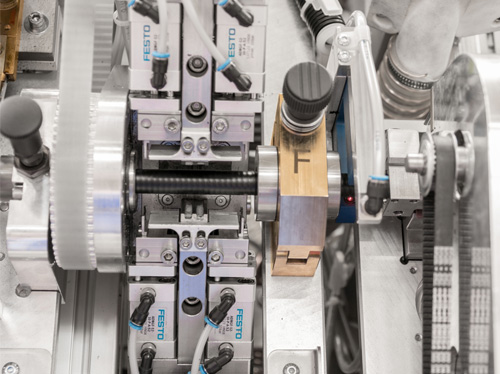

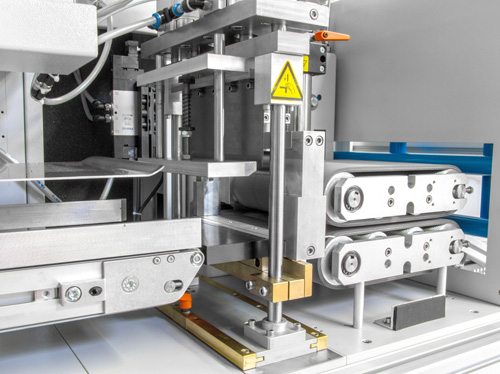

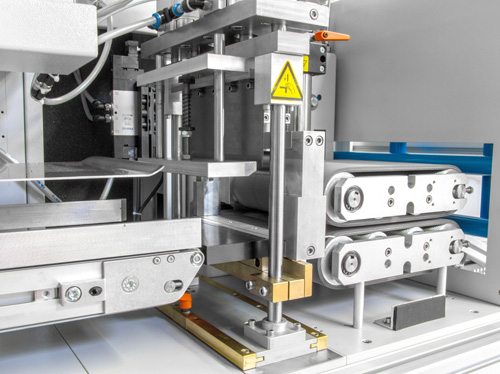

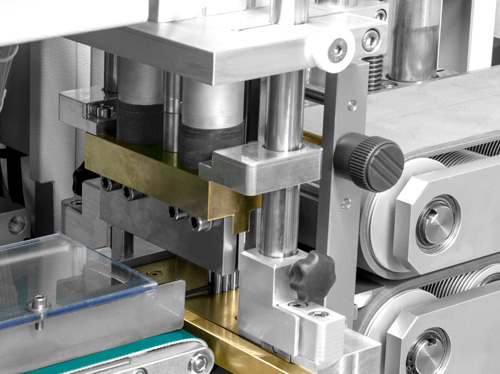

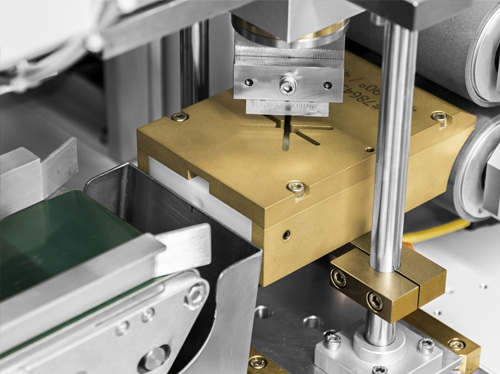

Patented method for automatic processing of cable shields

Metzner offers low-cost individual stations in the field of e-mobility for the entry into high-voltage cable processing. For the first time, the EM 101 module offers a solution for removing the cable foil without affecting the cable shield. The automatic processing of high-voltage cable wires also necessitates the connection of various components of the connector system. The Metzner EM 102 takes care of this. The EM 103 allows the cable shield to be opened and cut using a patented process which ensures that there is absolutely no contact with the inner insulation. The EM 103S offers the functionality of the proven EM 103 to meet the requirements of smaller cable wires of up to 8 mm diameter. These cost-effective models cannot be integrated into an automation line and are equipped with only limited traceability functions.

METZNER EM 300

-

Quick Changeovers and Fast Cycle Times

In addition to the EM 100, the Metzner EM 300 platform offers quick change of process tools and faster cycle times for a wide range of processes. With the EM 300, we protect your investment by providing improved expandability which enables the plug and play integration of future new applications.

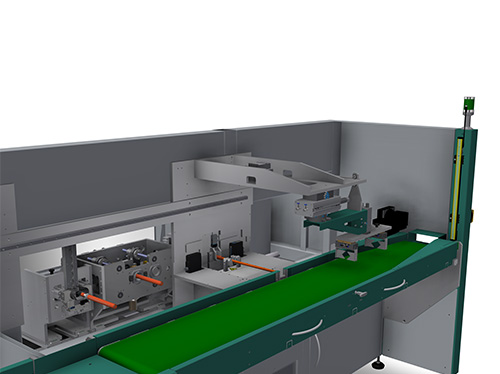

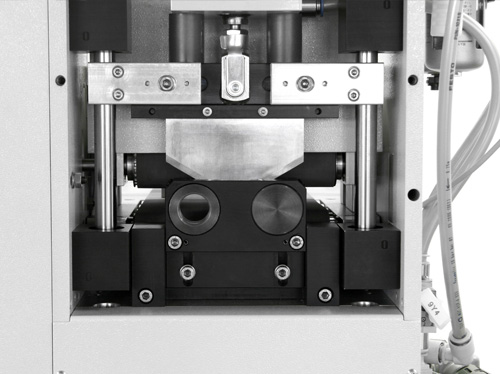

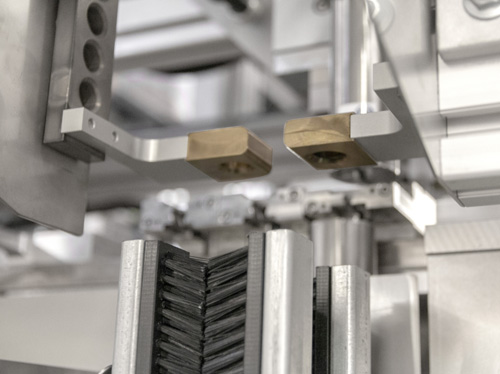

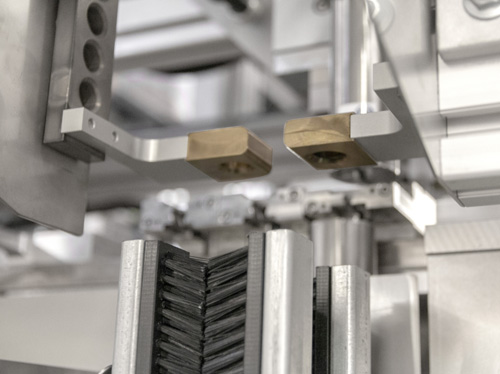

METZNER EM 600

-

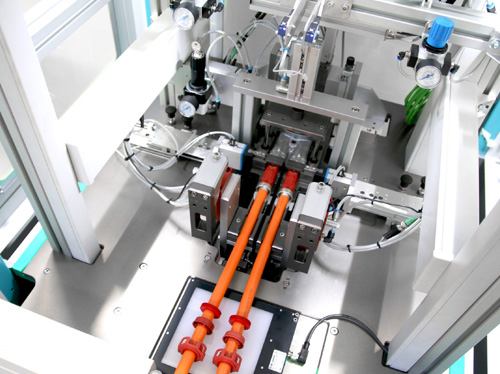

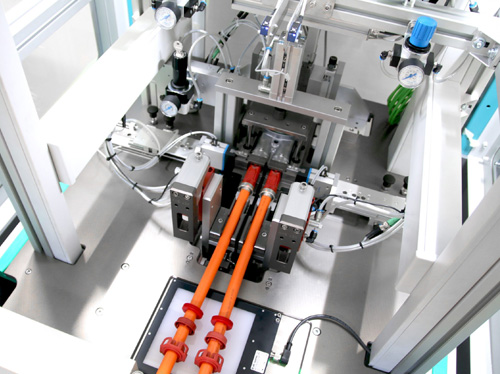

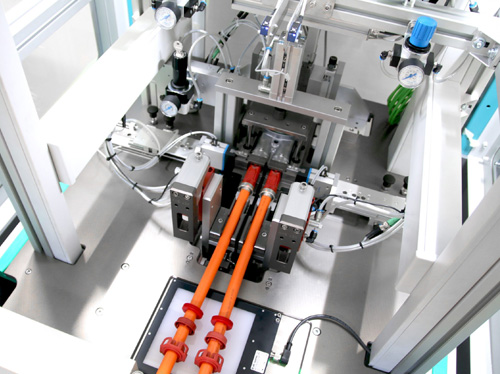

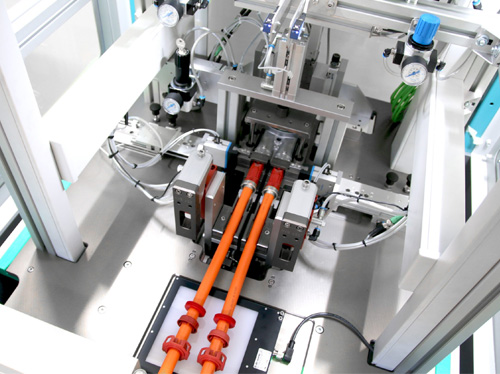

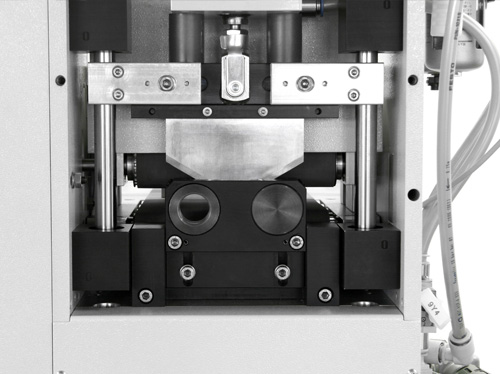

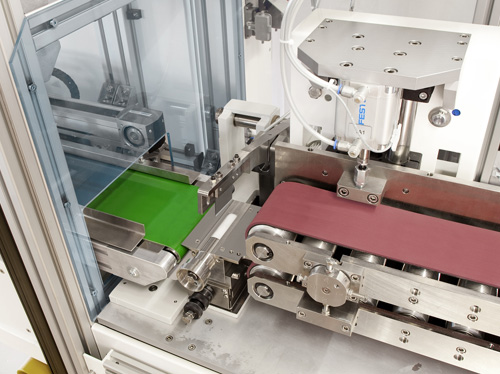

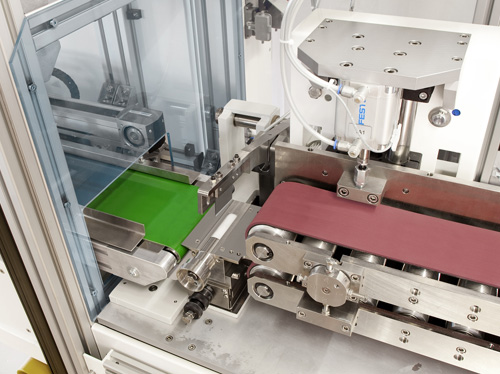

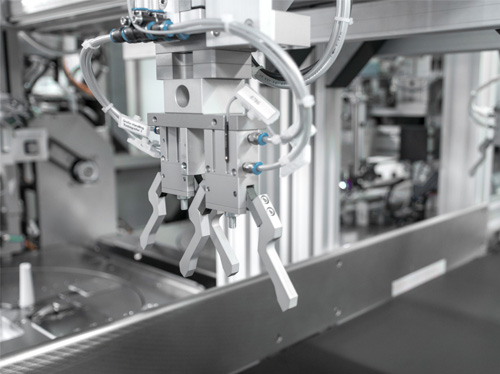

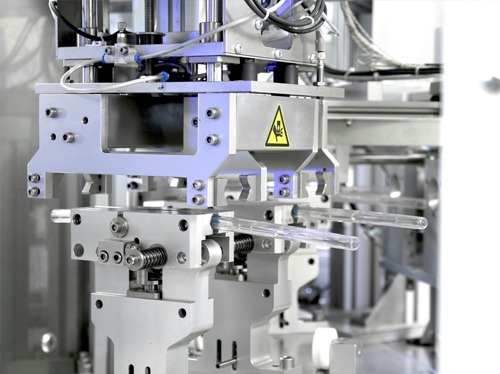

One station Six machining tools

The EM 600 can integrate up to six successive process tools in one single station. After insertion, the cable remains in a fixed position while the tools move towards the cable to provide optimum protection for the HV cable wires. The total cycle time of an EM 600 station is approx. 35 seconds for all operations of this station, with a total capacity of approx. 400,000 cable ends per year.

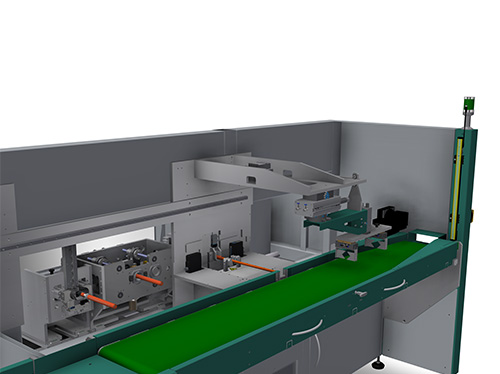

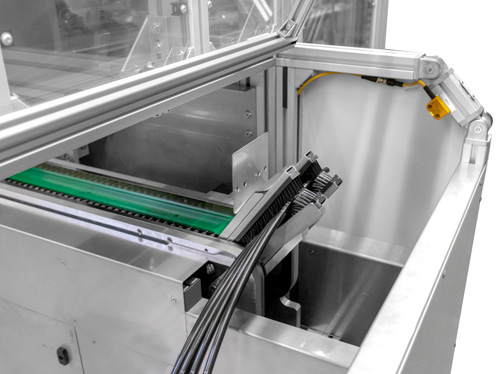

METZNER EM 700

-

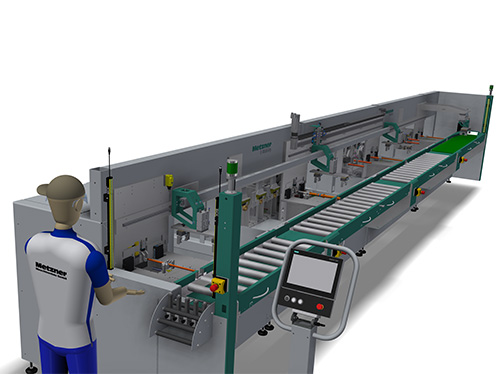

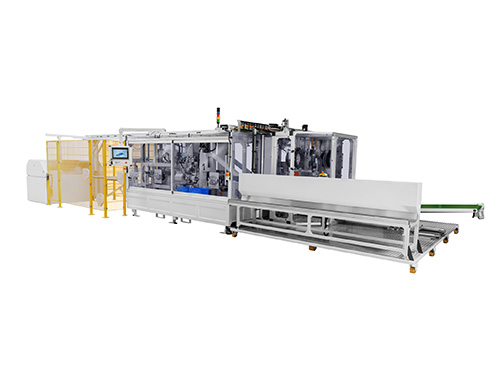

Several process stations combined Complete wire harness processing Cost-effective automation

Multiple EM 600 stations in combination with a cost-effective transfer system provide the additional benefits of the EM 700 series: higher degree of automation, no limit to the number of stations, modular and scalable, single- or double-sided processing

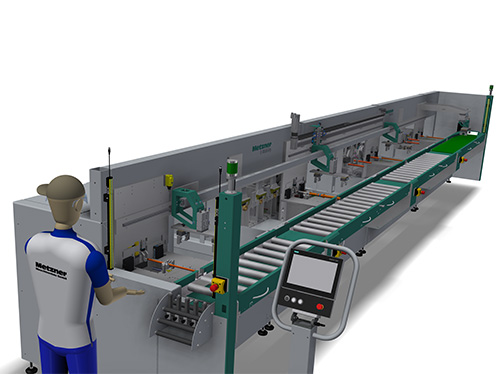

METZNER EM 900

-

Fully automatic with transfer system

Metzner has a clear understanding of the future and transforms existing processes into fully automated system solutions. Workstations that were previously operated separately are now combined into fully automatic production lines. The starting point of an automatic processing line is the cable that is wound on a reel. The end result is a finished cable with a completely assembled plug system

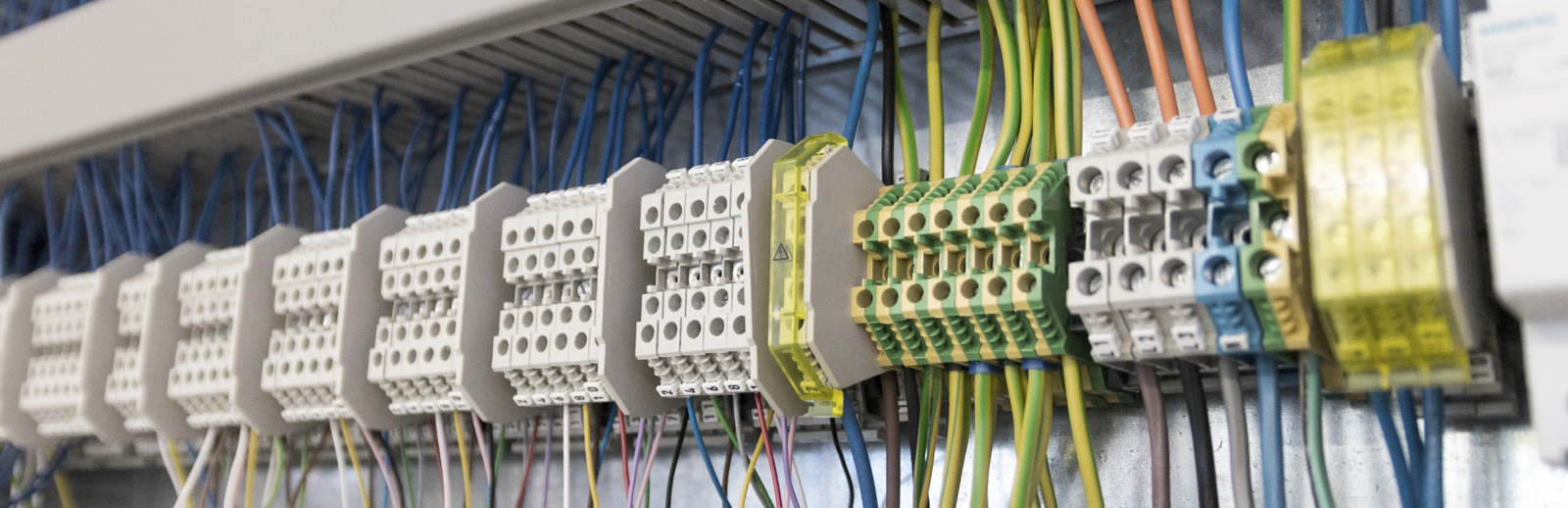

SWITCH CABINET CONSTRUCTION

- Electrical cabinets contain the electrical and electronic components of a process engineering system, a machine tool, or production equipment that is not directly located in the machine. They are manufactured by special switch cabinet builders or by the machine manufacturers themselves. To save costs, there are automation solutions that are not only worthwhile for large production series, but are also suitable for the more efficient and economical production of individual and small series. Metzner offers a unique and comprehensive system solution to reduce your expenses in switchgear construction. Depending on your requirements, different stripping and crimping machines are available, which differ in terms of design, performance and degree of automation.

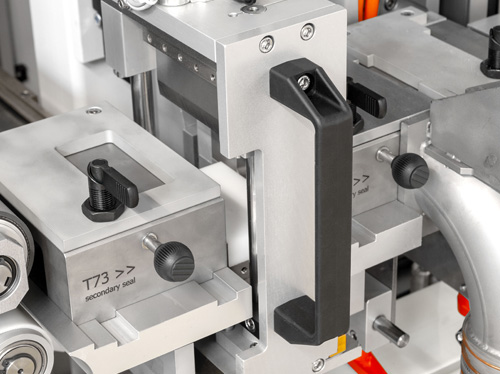

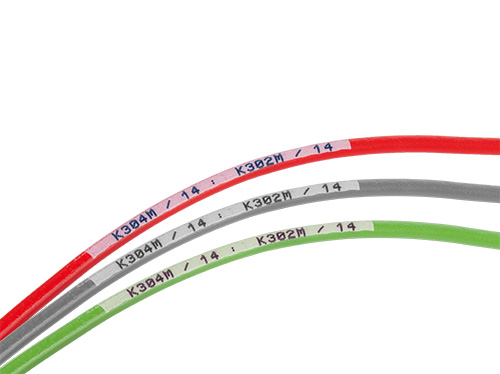

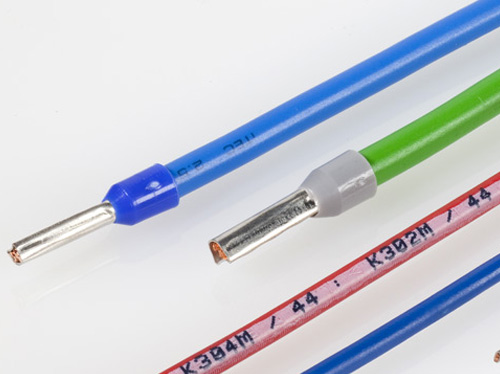

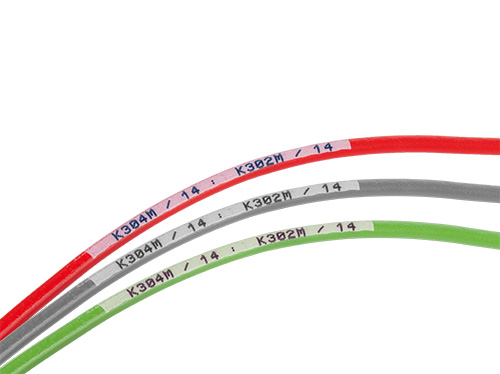

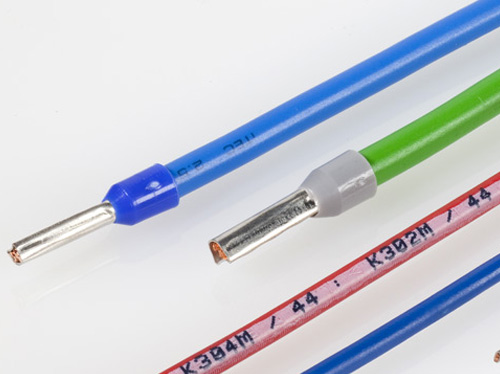

METZNER TRIATHLON SERIES- for precise cutting to length and one- or two-sided stripping at the exact position

- for crimping the ferrules (single- and double-sided)

- for individual labelling of strands with different printing methods

- for sorting the strands according to assembly groups

TRIATHLON 2000

- Inexpensive entry-level model for cutting to length and stripping strands with a cross section from 0.14 to 6 mm² and crimping ferrules of up to 4 mm² as well as for automatic individual wire marking.

TRIATHLON 3000

- Enables crimping of ferrules of up to 4 mm² cross-section, cable processing of up to 35 mm² and 15 mm diameter as well as automatic labelling of all cable wires with inkjet or thermal transfer printing.

TRIATHLON 3000+

- The most flexible model with modular crimping unit, which allows automatic crimping of up to 6 mm² wire cross section for quick expansion of processing possibilities.

TRIATHLON SOFT®

- Software compatible with all Triathlon models for creating digital switch cabinet layouts with automatic length calculation for all strands, cable ducts and top-hat rails.

UNIVERSAL CUTTING MACHINES

- Metzner universal cutting machines are robust and reliable basic models. Adapted to the processing requirements, the machines are equipped with the optimal cutting technology (punch cut, shear cut, tube cut), which can be quickly changed if necessary. The equipment lines »Red«, »Green« und »Blue« are available depending on the requirements.

METZNER UNIVERSAL CUTTING MACHINES- Quick-change cutting tools

- Available in three equipment lines: Red, Green and Blue

- Programmable logic controller

- Standard stepping motor for exact positioning and variable speeds

- Sensitive contact pressure

METZNER KL-BV

-

Outstanding value for money

The tubing specialist with unique precision and working speed for very thin, tension-elastic and pressure-sensitive materials. KL-BV is available in the equipment line Green and as KL-BV Gasket.ESPECIALLY MATERIAL-FRIENDLY

The Metzner KL-BV cutting machine stands out for its precision, compact design, and the wide range of processing options such as silicone tubes, flexible profiles and gaskets.

METZNER ST-OB

-

COMPACT, PRECISE AND EFFICIENT

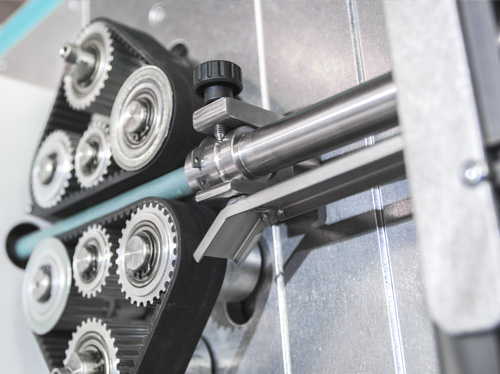

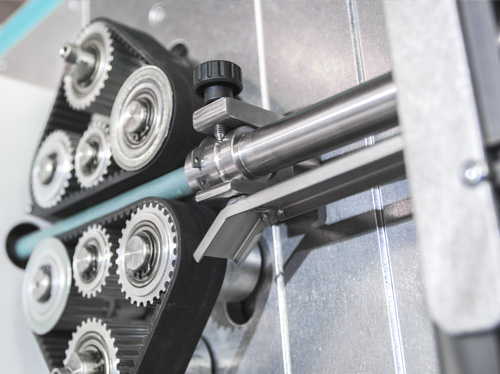

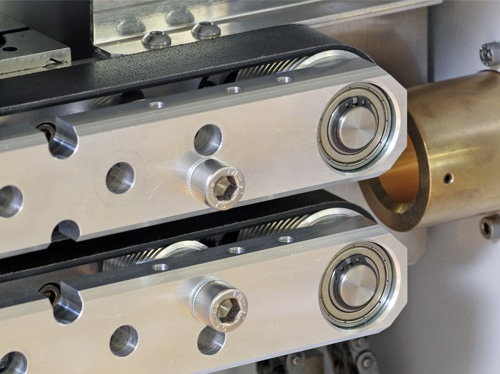

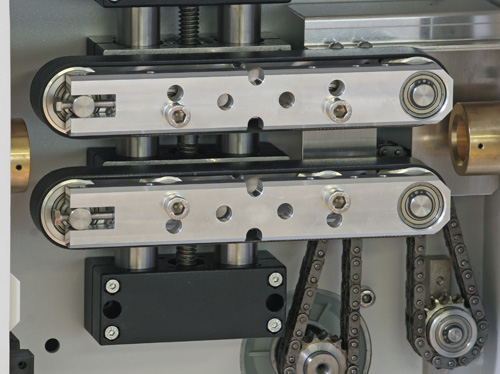

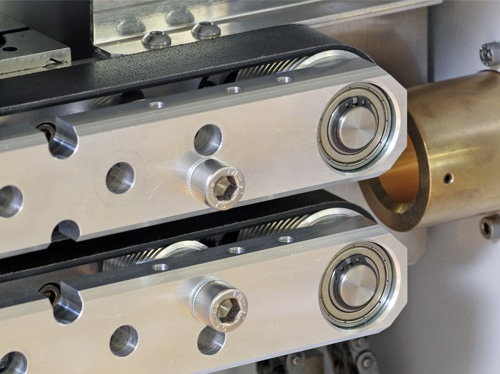

The »All-rounder« with particularly gentle and fine adjustment of the pressure between the transport belts. Ideal for soft and elastic material. The ST-OB is available in Red or Green versions.

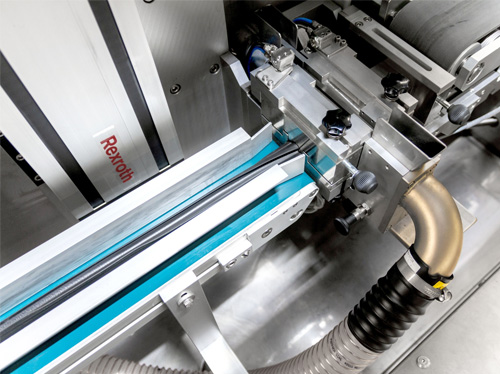

METZNER VARIOCUT

-

Outstanding Pulling and Cutting Force

The powerful "universal cutting machine" with superior pulling and cutting strength. The contact pressure between the conveyor belts is pneumatically controlled and opens and closes automatically when the cover is opened and closed. Ideal for solid and dimensionally stable materials.

Metzner also offers the Variocut in three “Red – Green – Blue" equipment lines. Each equipment variant is based on the same basic model with the same high-quality mechanical components. The individual models differ in speed, control and the interfaces for peripherals.

CUSTOMER SPECIFIC PROJECTS

- Complex processing lines for rail vehicles or challenging solutions for cutting sensor cable wires in the automotive sector Metzner also excels here with competent solutions for customer-specific requirements.

For all applications that go beyond the functions of the standard machines we plan, develop and manufacture individual solutions according to customer requirements. As a result, our many years of experience as a machine manufacturer for cable processing yields mature and application-specific solutions which are used under the most demanding conditions.

Metzner handles the entire development process, from analysis and consulting to design and successful delivery. The following pages present some customer-specific solutions and production lines. Discover some interesting approaches for your requirements!

Automatic cutting to length of insulated/non-insulated steel tubes without untwisting the wires and thickening the tube start/end

-

A supplier of Bowden cable wires and preassembled wire ropes of high quality had a special requirement for a new machine: It should be able to cut and strip insulated steel strands as well as to cut to length non-insulated steel ropes without the individual wires jumping up or the end or beginning of the rope thickening during the cutting process. Metzner Maschinenbau has responded to this demand by developing an automatic program-controlled production line: For this purpose an AM 3500 was modified and extended to form a complete production line with a driven reel unwinder, a special cutting module, and a material stacker. The latter are mobile and can be attached to the AM 3500 as required. The production line can process material with diameters from 0.5 to 5 mm.

Plastic-coated steel cable wires/strands are cut to length using a special shear cut module and then stripped with the cutting module of the AM3500 without the wires "jumping open".

Bare steel cable wires are transported by the modified AM 3500 directly to the special cutting machine, which is coupled between the AM 3500 and the material stacker and which cuts the material to length by a thermal process. Due to the special electric welding process used here, the individual wires do not twist up during cutting, and a smooth rope start and a smooth rope end without thickening are produced.

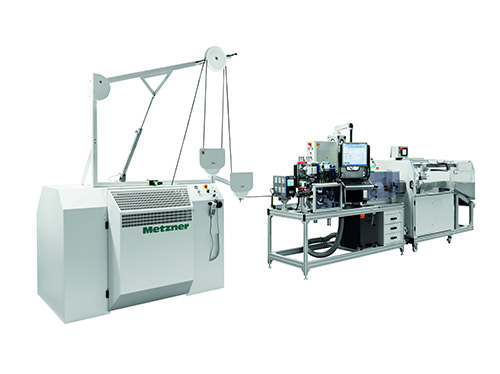

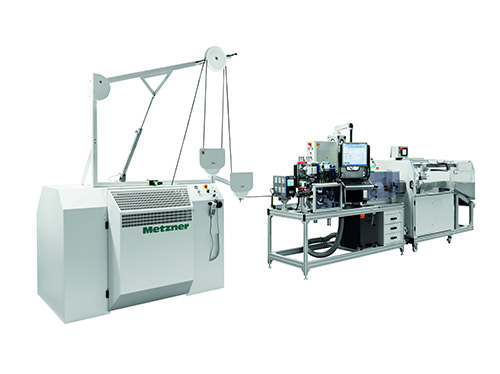

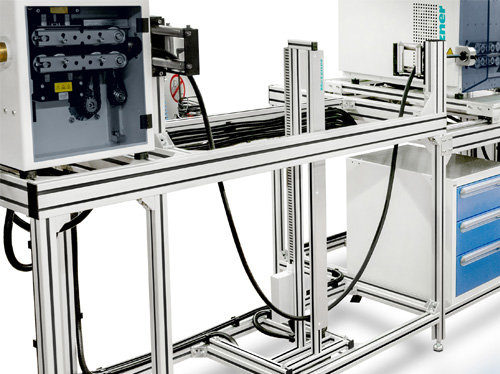

Fully automated processing of network cable wires

-

To save costs, a globally active company commissioned Metzner Maschinenbau to automate the manufacturing process of its network cable wires, including the preparation for connector assembly. The specially developed production line can unwind, label, roughen, cut to length, strip, wind, bind and automatically deposit the cable wires. The material to be processed is unwound by a motorised unwinder from the Metzner partner company Ramatech and fed to a thermal transfer printer via a straightener. The latter prints the cable with two QR codes and a serial number. This ensures that each cable can be identified throughout the entire processing and manufacturing process and assigned to the stations which have already passed through. This traceability offers great advantages – for example in the diagnosis of faults. The cable then passes through a roughening station, which lightly roughens the material surface so that the connector overmoulding adheres better later on. An AM 3550 from Metzner Maschinenbau cuts to length and strips the cable, which is then transported to the winding station and onwards by a gripper to the binding machine. The latter winds the cable according to customer specifications to form a cable ring which is bound together on two opposite sides, such that the two cable ends protrude from the ring by a defined length. This specific winding pattern is the prerequisite for further automated processing of the material with another machine.

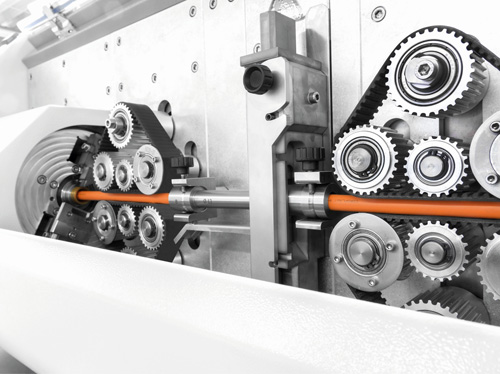

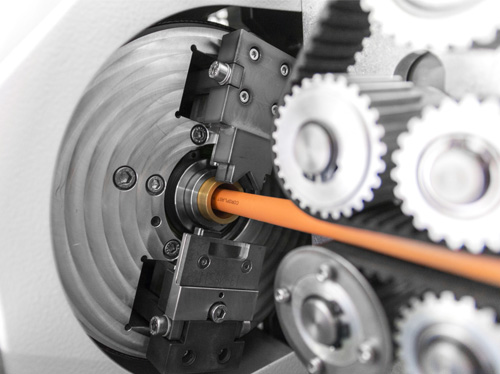

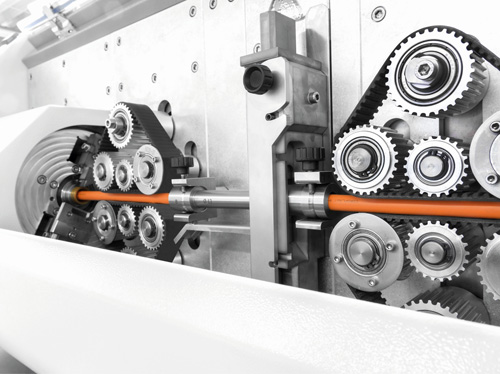

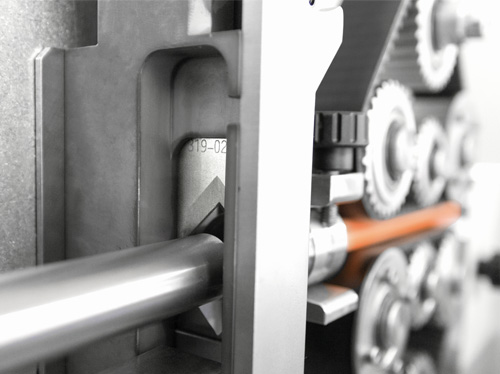

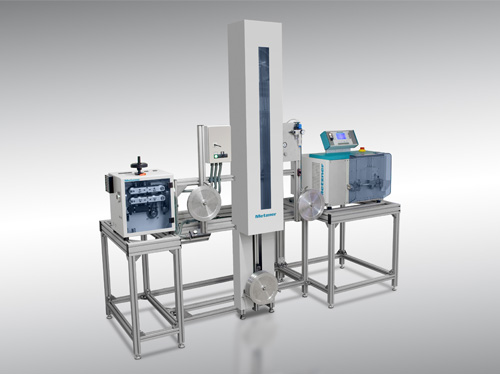

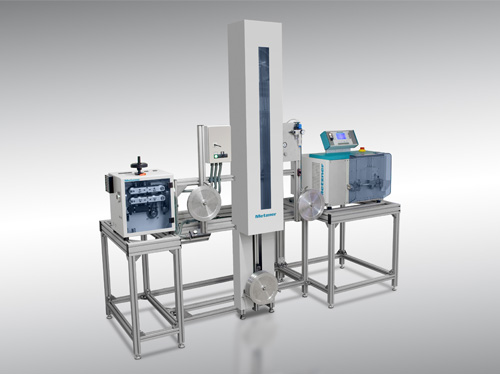

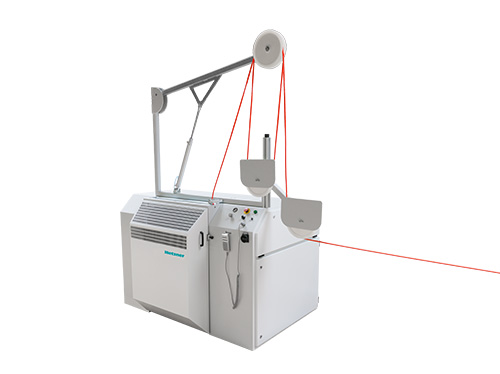

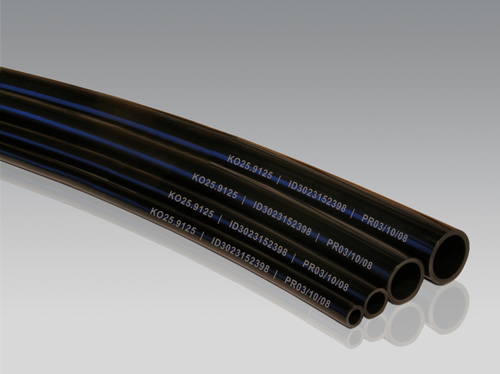

Fully automatic processing of high-frequency coaxial cables

-

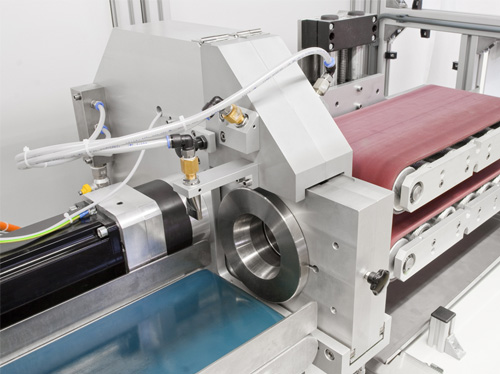

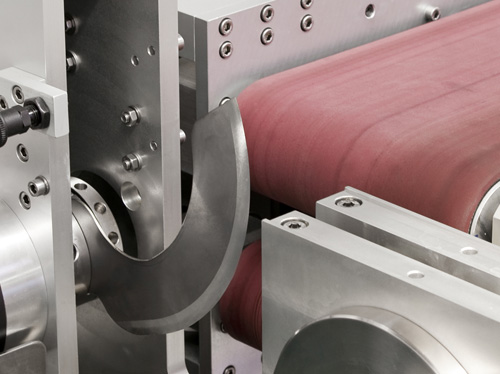

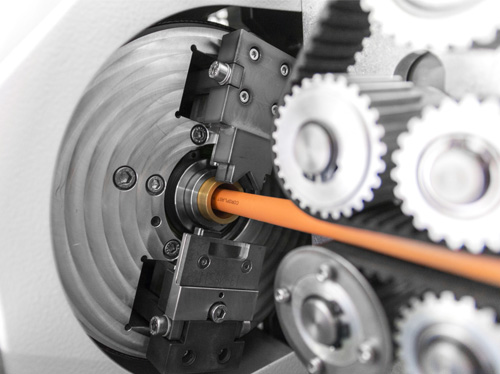

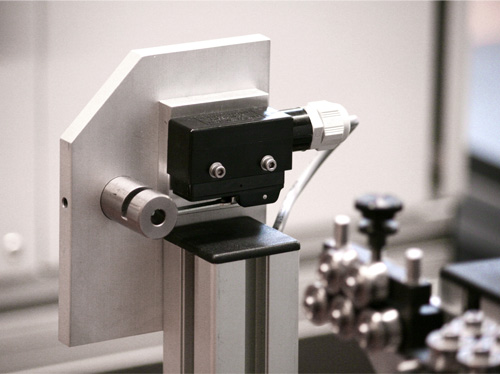

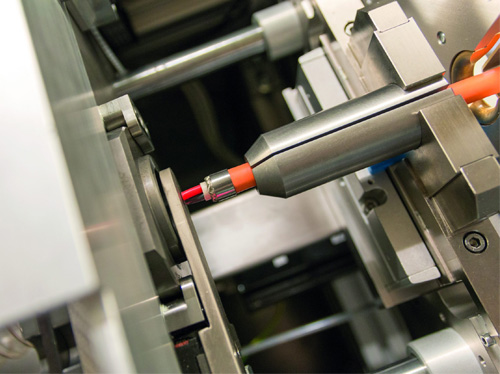

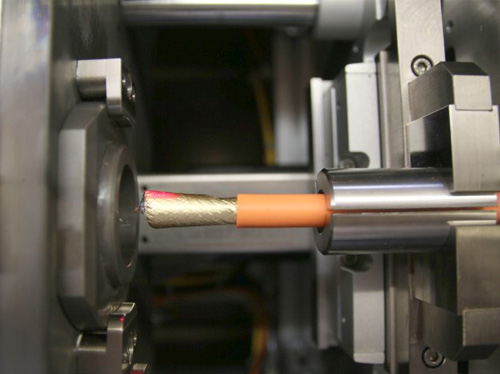

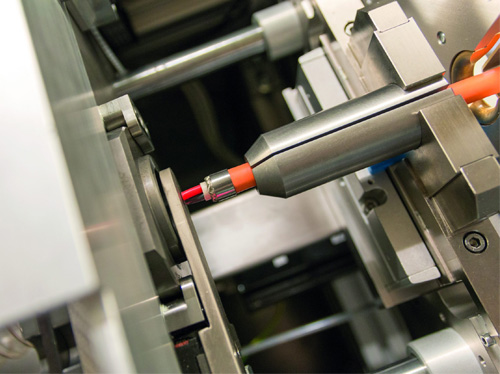

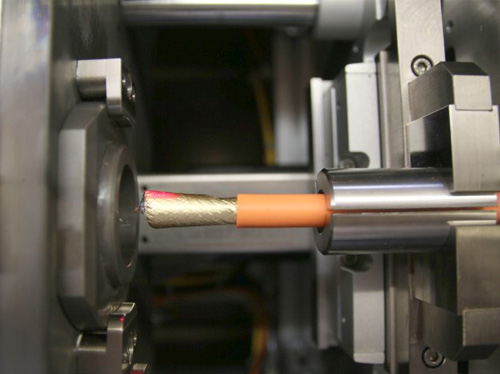

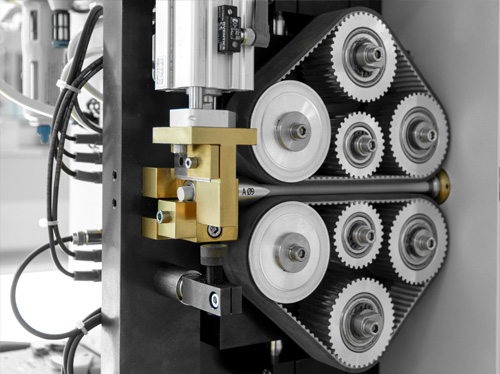

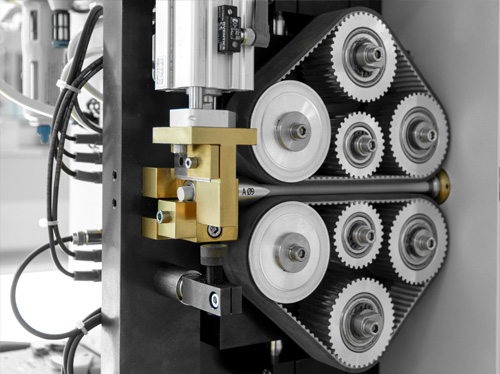

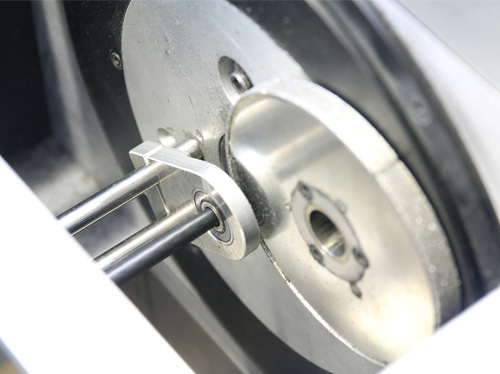

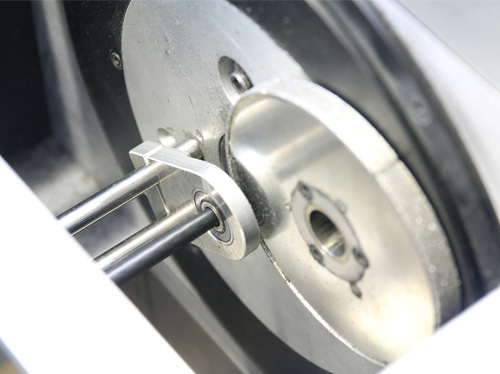

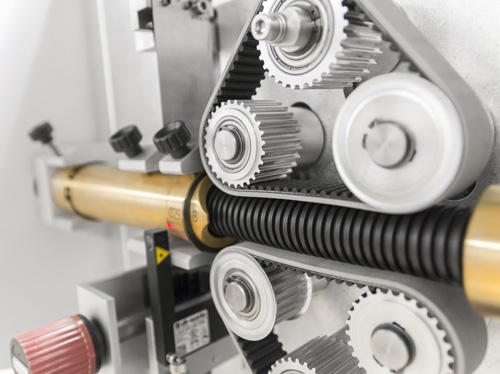

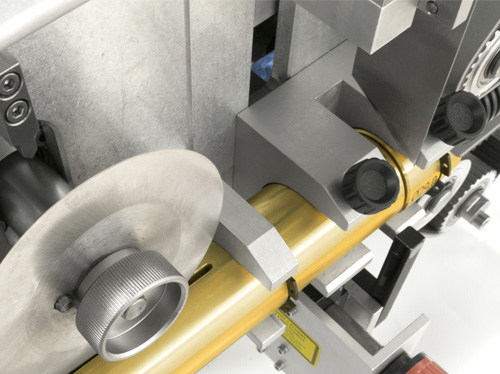

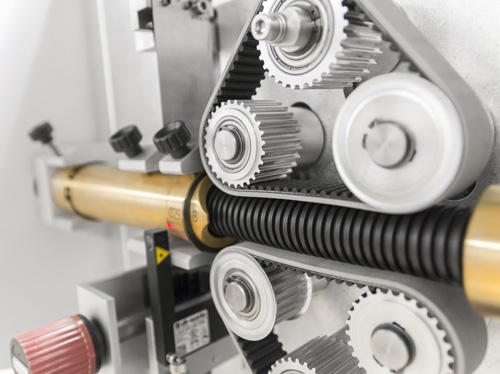

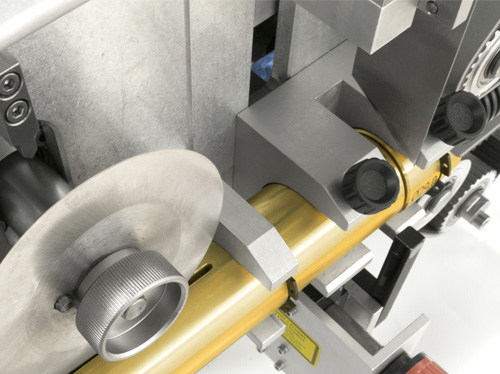

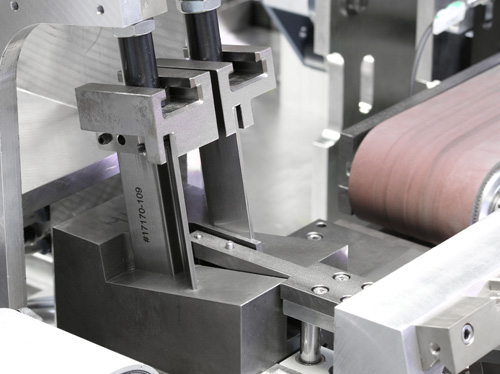

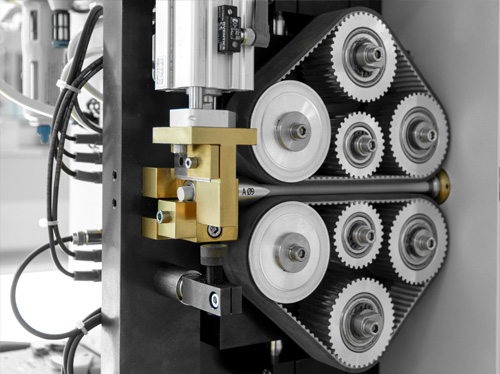

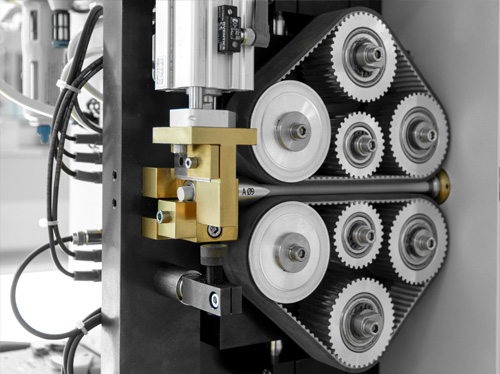

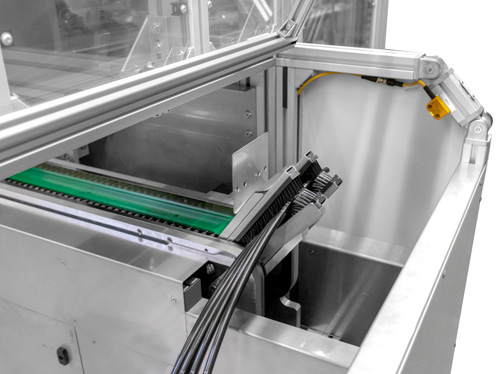

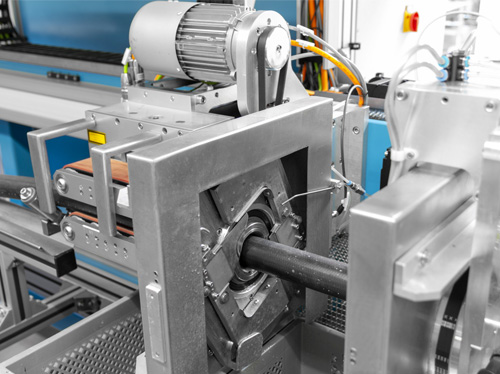

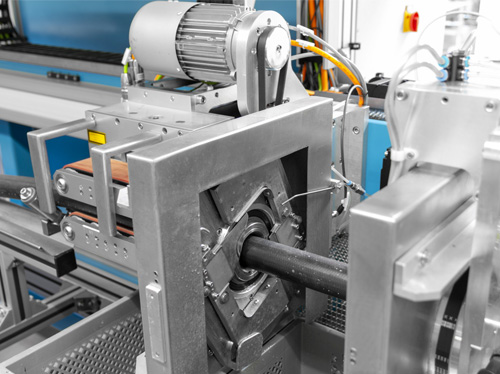

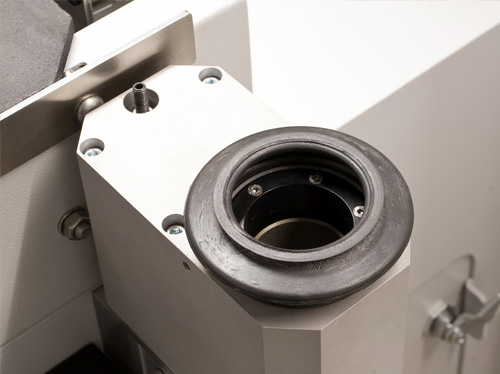

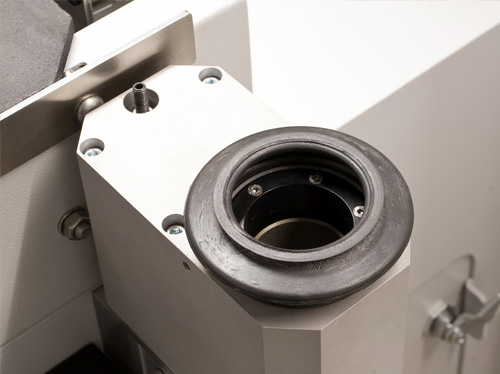

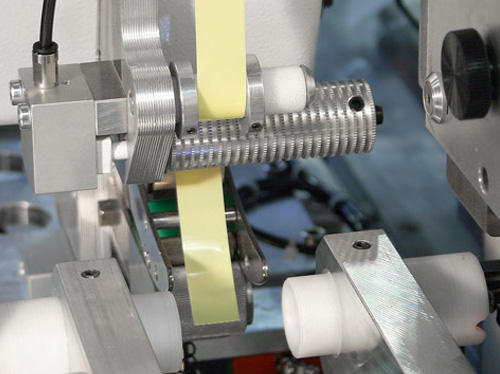

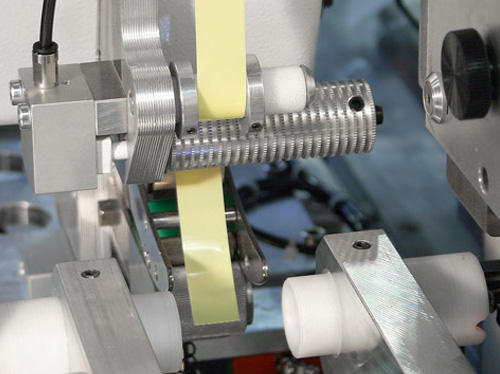

Flawless processing of high-frequency corrugated-jacket coaxial cable is not possible with a standard series machine. This is why Metzner has developed a pioneering process for the fully automatic processing of these cable wires for a leading supplier in the field of high-frequency coaxial plug connections. The fully automatic machining process starts with a material-specific straightener station for aligning the unusually stiff cable wires. This alignment is an important prerequisite for the subsequent processing steps as well as for the subsequent further processing.

As the heart of the processing method, Metzner uses a newly developed stripping head that combines a rotary cut with a powerful clamping and simultaneous rotation of the material. This enables a high-precision, multi-stage radial cut through the various layers of material. Microscopic quality inspection confirms that the processing is flawless with no scratches, pressure or abrasion marks. In addition to the high machining quality, the machinery also offers special precision: both the overall length and the machining position are maintained with an accuracy of 0.2 mm. The machine can process cable wires with diameters up to 28 mm. The processing steps include long slitting, sawing, circumferential cutting, stripping, brushing and depositing. An integrated ink jet printer labels the cable wires with information or markings which are necessary for further processing.

Fully automatic cutting of steel cable wiress

-

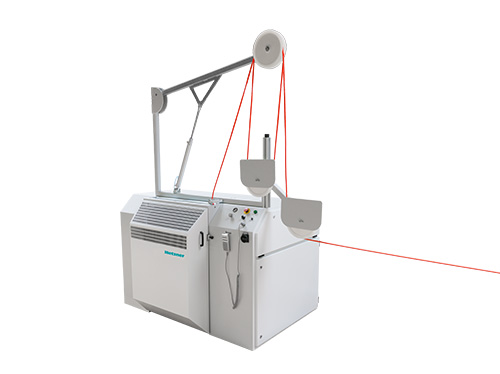

Standard machines for cable processing can neither perform a precise cut nor prevent the wires from "popping up". Because of this, Metzner has developed a fully automatic processing machine with outstanding cutting quality and great length accuracy for steel cable wires of up to 20 mm diameter. The steel cable wires are fed by a motorised feeding device in combination with a contact-free loop control. Then, program-controlled and positionally accurate marking tapes are applied to the steel cable – with a cycle time of less than two seconds. In addition, a wax printer marks all the fastening and processing points that will be required for subsequent processing. This labelling method is carried out in a continuous process. The cut is then made using a special cutting process. Precise length accuracy is achieved by a special laser measuring system. A material stacker with a storage area of up to 12 metres ensures that the steel cable wires are deposited in an orderly manner. All cut steel rope can be stored and sorted according to length to allow it to be removed at a later point.

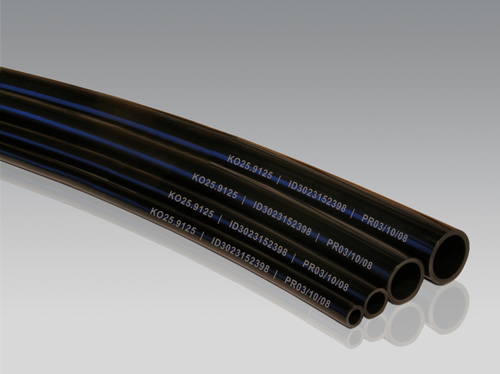

Corrugated Tube Processing

SLIT & UNSLIT CORRUGATED TUBES

- Corrugated tubes are employed as protect cables and cable harnesses. When cutting to length, it is vital that the cut is made exactly on the top of the corrugation, as otherwise, sharp cut edges would result, which would damage the cable being pulled in.

Metzner corrugated tube cutting machines offer absolute precision to cut the tube at the top of the corrugation. Slit and unslit corrugated tubes are cut exactly and reliably at the top of the corrugation.

FEATURES- For corrugated tubes from 4.5 mm to 40 mm extenal diameter

- Processing of slit and unslit corrugated tubes

- Precise cut on the top of the corugation

- Quick-change system for all bushes

METZNER SM 4000

-

Precision machines for slotted corrugated tubes

Corrugated tubes are used to protect cable wires and cable harnesses. When cutting this corrugated tube sheathing to length, it is important to cut precisely and reliably on the crest of the shaft, to avoid forming sharp cutting edges which damage the in-drawn cable wires.

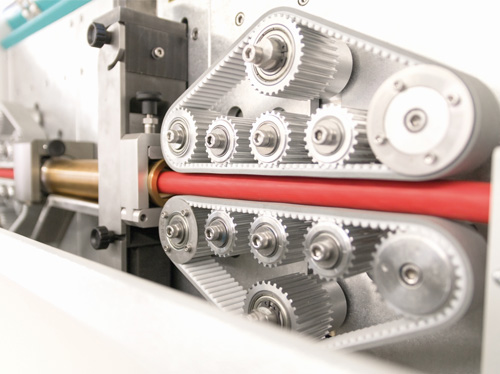

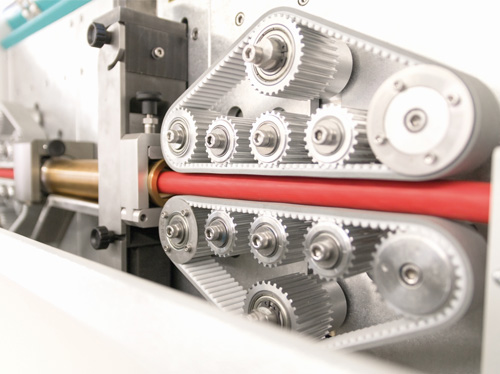

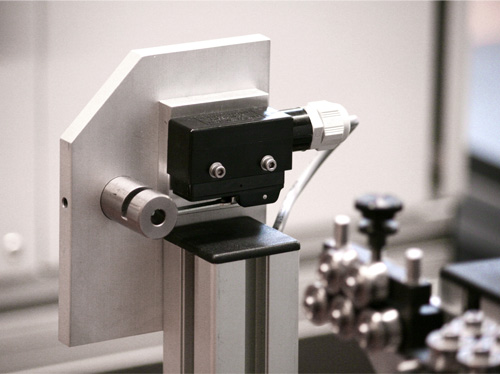

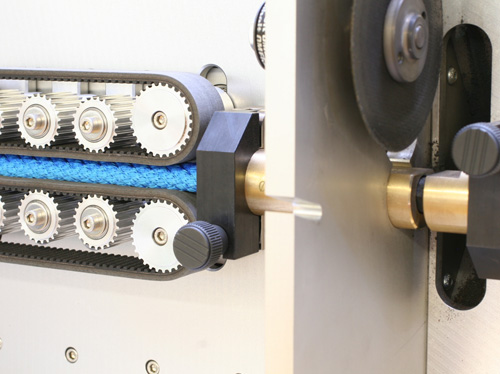

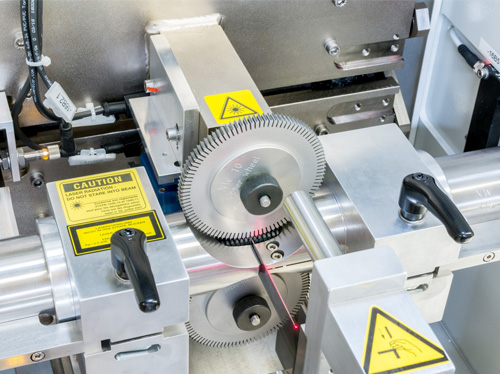

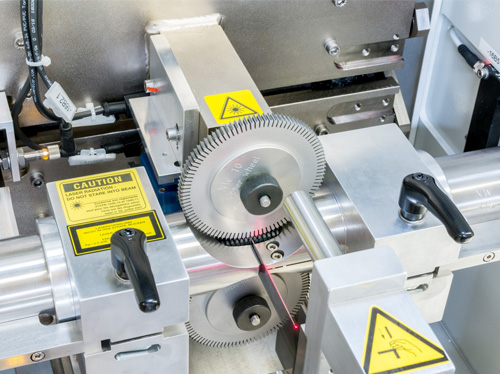

Metzner revolutionised the cutting to length of slotted corrugated tubes with the SM 4000 corrugated tube cutting machine. It is the only machine in the world that can guarantee a precision cut on the crest of the shaft due to its unique and patented feed and cutting technology. A laser sensor monitors the production and activates the cut precisely and repetitively with up to 8000 cuts per hour.

The SM 4000 with its patented "toothed wheel laser system" is the only machine in the world that guarantees twist-proof feed- and cutting technology for slotted corrugated tubes

METZNER CT 4000

-

Precision machines for unslotted corrugated tubes

Unslotted corrugated tubes are used to protect cable wires and cable harnesses. When cutting this corrugated tube sheathing to length, it is important to cut precisely and reliably on the crest of the wave, to avoid forming sharp cutting edges which damage the in-drawn cable wires.

Metzner corrugated tube cutting machines of the CT 4000 series process corrugated tubes with great reliability and precision. Thanks to our many years of experience in processing corrugated tubes, we know the challenges that some corrugated tubes present and are well prepared for them. Our wide range of standard equipment ensures the best possible processing of your corrugated tubes.

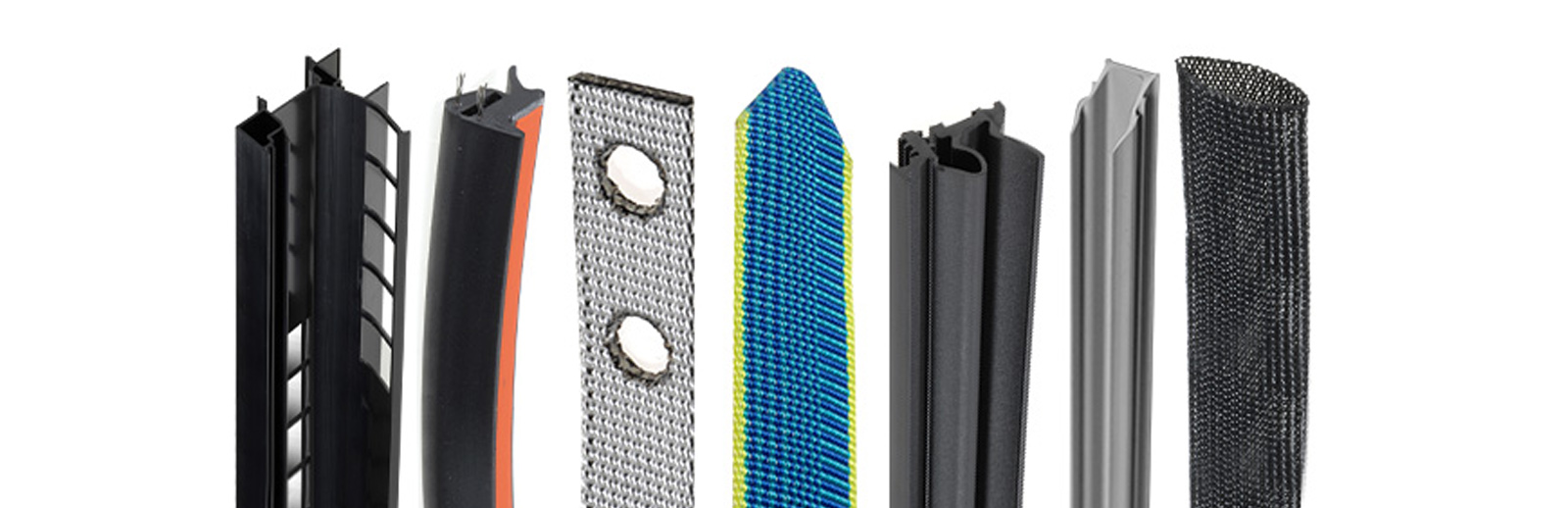

Rubber- & Plastics Processing

AUTOMATIONS

- In industrial machining processes, it is often necessary to integrate several machining processes into one automatic sequence. This is the world of our complex machinery. You can use them to cut, drill, mill, saw or punch and realise different angles or contours. If required, automatic changeover between different tools is also possible.

INDIVIDUAL SOLUTIONS- for automatic continuous punching

- for automatic drilling units

- for workstations

AUTOMATIC DRILLING UNITS

-

for precise profile drilling

Profiles and sealing systems often require ventilation holes or mounting holes. Drilling equipment from Metzner carries out these tasks. We provide the following solutions adapted to your specific requirements:

- In-line as an eccentric drilling station for regular drilling at equal distances

- In-line as travelling drilling station for drilling at the same or variable distance

- In-line as "drilling beam", which carries out all drillings for an entire sealing profile with variable distances in one operation

- Off-line for drilling in combination with final trimming

AUTOMATIC CONTINUOUS PUNCHING

-

With automatic continuous punching machines, machine and tool merge into a high-performance system with high output and remarkable flexibility. Whether sealing profiles for the automotive industry, applications for furniture, or thermal insulation for buildings or household appliances – complex trimming is often required here. Thanks to the Metzner automatic throughfeed punching machines, processing operations such as contour cutting, drilling and milling can be integrated into a throughfeed system. All these machines store all machining parameters and machine settings in a machining recipe. When starting production, an integrated barcode scanner activates all presettings on the basis of the working papers and simultaneously reports the correct tool and material on the machine display. The barcode also contains the required quantities and lengths. Thanks to well thought-out quick-change systems, tools and materials are generally changed within no more than 30 seconds, minimizing downtimes. Thanks to an integrated tool coding system, the machine automatically checks whether the right tool is available when changing tools.

With a further automation level, material and tool changes are even fully automatic: The machine reads the barcode and the operating personnel press the start button. The rest is done fully automatically and without personnel. If required, fully automatic continuous punching presses are equipped with intelligent length measuring systems and quality monitoring functions that achieve excellent accuracies of approx. 0.1 % (but min. 0.5 mm), depending on the material. Parts that do not meet the specifications are automatically detected and sorted out separately.

UNIVERSAL CUTTING MACHINES

- The idea: : Equip robust and reliable basic models with the right cutting technology (punch cut, shear cut, tube cut) and choose between the three equipment lines "Red Green Blue".

The Metzner universal cutting machines are designed for the automatic cutting to length and cutting of a wide range of materials. For flexible profiles, tubes, plastic pipes, cords, seals, foils, labels, cable wires, strands, wires, etc., the universal cutting machines provide precise results with outstanding cutting quality and high working speed. The KL-BV has a rather special position among the universal cutting machines: it is specially designed for precise cutting to length of elastic and pressure-sensitive tubes.

METZNER UNIVERSALSCHNEIDEMASCHINEN- Excellent cutting quality

- Simple and logical operation

- Outstanding cutting and pull-off force

- Robust, durable construction

METZNER KL-BV

-

Outstanding value for money

The tubing specialist with unique precision and working speed for very thin, tension-elastic and pressure-sensitive materials. KL-BV is available in the equipment line Green and as KL-BV Gasket.ESPECIALLY MATERIAL-FRIENDLY

The Metzner KL-BV cutting machine stands out for its precision, compact design, and the wide range of processing options such as silicone tubes, flexible profiles and gaskets.

METZNER ST-OB

-

COMPACT, PRECISE AND EFFICIENT

The »All-rounder« with particularly gentle and fine adjustment of the pressure between the transport belts. Ideal for soft and elastic material. The ST-OB is available in Red or Green versions.

METZNER VARIOCUT

-

Outstanding Pulling and Cutting Force

The powerful "universal cutting machine" with superior pulling and cutting strength. The contact pressure between the conveyor belts is pneumatically controlled and opens and closes automatically when the cover is opened and closed. Ideal for solid and dimensionally stable materials.

Metzner also offers the Variocut in three “Red – Green – Blue" equipment lines. Each equipment variant is based on the same basic model with the same high-quality mechanical components. The individual models differ in speed, control and the interfaces for peripherals.

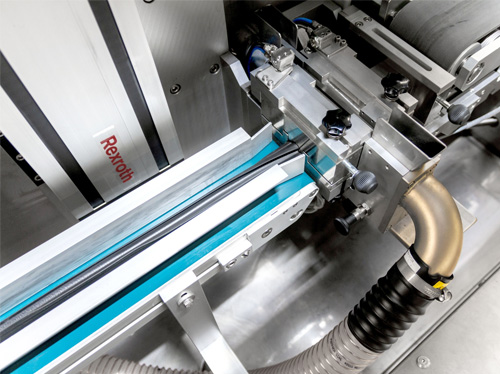

CIRCULAR KNIFE CUTTING MACHINES

- Our CCM machines are adapted to the special material requirements of metal-reinforced sealing profiles and tubing as well as foam rubber seals. The electrically driven circular blade ensures the proper conditions for cutting through rubber and metal and, in combination with other parameters such as optimum material guidance, blade speed, direction of blade rotation, blade feed and moistening, results in superior cutting quality.

METZNER CIRCULAR KNIFE CUTTING MACHINES- For processing steel-reinforced profiles and seals

- Exact cut to mark

- Second cutting tool as option

- Quickly exchangeable material guides without using tools

- Precise length measurement with measuring wheel or end-sensing

- Large selection of circular knives

METZNER CCM 6

-

Traveling circular knife

The travelling circular knife machine CCM 6 cuts rigid profiles and tubes accurately to length. The CCM 6 achieves very long processing times of several seconds for excellent "final trim quality" thanks to a standard servo linear drive for the tool carrier, and at the same time extremely short cycle times of less than one second for machining short parts at high line speeds. Added to this is the servo linear drive for circular knife feed with different feed speeds for different material sections, e.g. a gentle material penetration or knife exit with low feed to reduce burr formation.

High speed ranges

As far as the knife speed is concerned, we offer you outstanding possibilities of alternatively 2,000 – 6,000 rpm or 4,000 – 12,000 rpm. This means that there are no limits to the use of various types of circular knives, including clamping and grinding in continuous operation. Our product videos will give you an insight into the machining process.

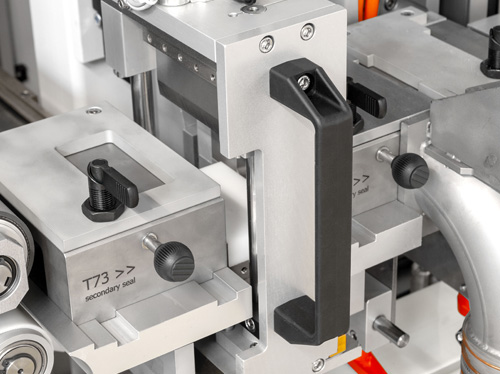

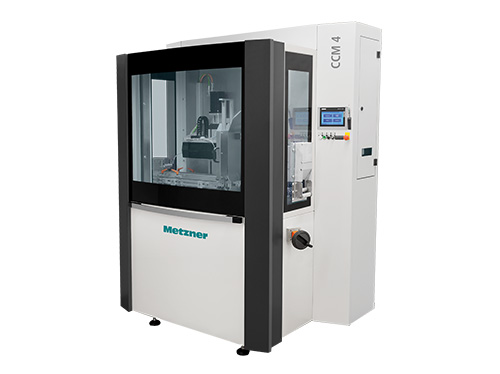

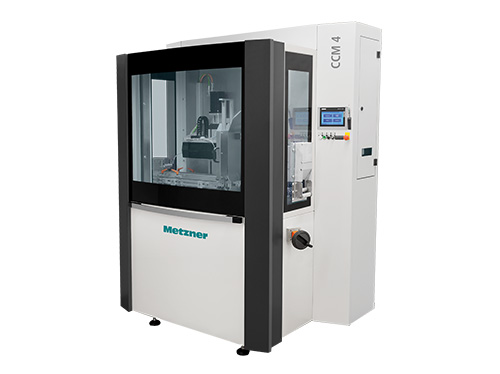

METZNER CCM 4 / CCM 4 GASKET

-

Versatile Showpiece

The special feature of the Metzner CCM 4: the circular cutting machine handles both wet and dry cutting. Depending on the type of cut, the CCM 4 is equipped with a water-cooling lubrication system or micro-knife moistening and preparation for suction. The standard model comes with an integrated discharge conveyor (800 mm length); application range both in-line and off-line.

METZNER CCM 2

-

Economical and compact

The Metzner CCM 2 circular cutting machine processes steel-reinforced profiles and sponge rubber materials with dry cutting (optionally with micro-knife moistening to cool the circular knife). The standard model comes with an integrated discharge conveyor (1300 mm length); range of application both in-line and off-line.

MODULAR CUTTING MACHINES

- Many machining and cutting tasks are as varied as the materials themselves. With the MBS system, more than 130 standard components can be combined with each other, resulting in more than 10,000 possibilities to find the optimum solution for your requirements. A machine that is customised to the task in hand will always offer you more benefits.

By using standard parts, MBS machines are created with virtually no development effort and within a very short time. As a result, modular cutting machines are not only optimally adapted to the machining tasks, but also extremely economical.

METZNER MBS-SERIES- Eight different cutting technologies

- Tool cut for contours

- Adaptation to material-specific requirements

- Special equipment as eccentric cutting machine

METZNER MBS 400

-

Standard and customised at the same time

The modular system of the MBS series is available in three sizes. The MBS 400 is the “largest" of the three models and processes materials such as tubes and profiles of up to 390 mm wide. Depending on the material size, further machine elements such as type and number of cutting tools, length and width of the belt feed, control, feed, running direction, coating material of the conveyor belts and base frames are selected.

METZNER ST 25

-

More performance. More speed. Therefore eccentric.

Where pneumatic tools of the MBS series reach their performance limits, the eccentric cutting machine opens up new possibilities in cutting performance. Instead of a pneumatic cutting tool, the Metzner ST 25 uses an electrically driven eccentric mechanism that carries a punching blade. This enables us to increase the performance of the die-cut into completely new dimensions, of up to 800 cuts per minute. An agreeable side-effect: With the electric drive for the cutting tool, the ST 25 works very quietly – which is why customers with low-noise working environments also like to opt for this model.

METZNER MBS 200

-

Standard and customised at the same time

The modular system of the MBS series is available in three sizes. The MBS 200 is the "medium-sized" of the three models and processes materials such as tubes and profiles up to 190 mm wide. Depending on the material size, further machine elements such as type and number of cutting tools, length and width of the belt feed, control, feed, running direction, coating material of the conveyor belts and base frames are selected.

METZNER MBS 100

-

Standard and customised at the same time

The modular system of the MBS series is available in three sizes. The MBS 100 is the "smallest" of the three models and processes materials such as tubes and profiles of up to 90 mm wide. Depending on the material size, further machine elements such as type and number of cutting tools, length and width of the belt feed, control, feed, running direction, coating material of the conveyor belts and base frames are selected.

MANDREL CUTTING MACHINES

- Flat gaskets are mainly employed in apparatus engineering or pipeline construction as a sealing element between two flanges. Depending on the application (fluids, temperatures, pressures, chemical stress), a range of materials are available such as elastomers, carbon fibre, mineral fibre and metal. There are special machines to produce these gaskets, which cut sealing rings from injection-moulded or extruded tubes with different diameters. For this purpose, Metzner has developed mandrel cutting machines, which are characterised by their unique processing method and high cutting quality and feature a high output rate. For differing capacity requirements we offer different solutions, which can be operated without extensive specialist knowledge due to their easy handling.

METZNER SR-SERIES- for the production of sealing rings with highest precision

- for the simultaneous processing of up to seven tubes

- for a comfortable control with PLC control

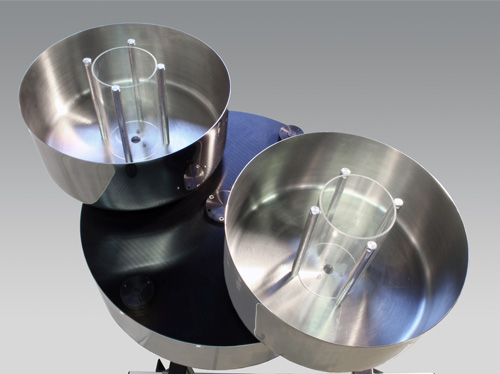

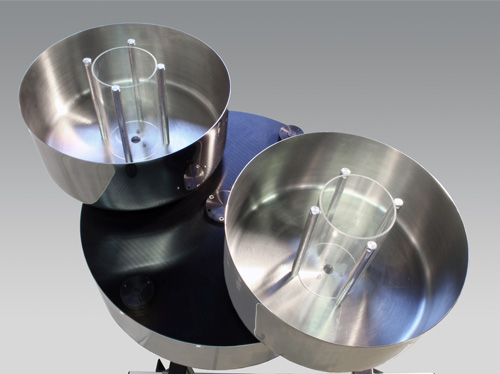

METZNER SR-SERIES

-

Metzner has developed the mandrel cutting machines of the SR series for cutting off sealing rings from injection-moulded or extruded tubes with different diameters. These machines are characterised by their unique processing method and high cutting quality. First, pre-extended "rubber tubes" are clamped onto mandrels. Due to the special design of the mandrels, the mandrel can be set up and removed quickly and without special previous knowledge. The mandrels are then automatically clamped in the machine between rotating spindles and production is started. A knife carriage travels along the tubes and cuts the flat sealing rings to the desired length with either push-fit or circular knives, depending on the requirements. This cutting method is particularly impressive with its high cutting quality in combination with a high output.

Thanks to the use of state-of-the-art servo technology, the SR machines are even more versatile: Insertion and feed movements are freely programmable – for optimised processing of materials with different material properties. The SR series ranges from two- to seven-strand machines. Metzner therefore offers the most economical solution for different capacity requirements.

Precise and high-performance

Metzner mandrel cutting machines of the SR series are ideally suited for the precision cutting of gaskets from injection-moulded or extruded tubes. They are characterised by the possibility of processing up to seven tubes simultaneously. Our product videos will give you an insight into the machining process.os.

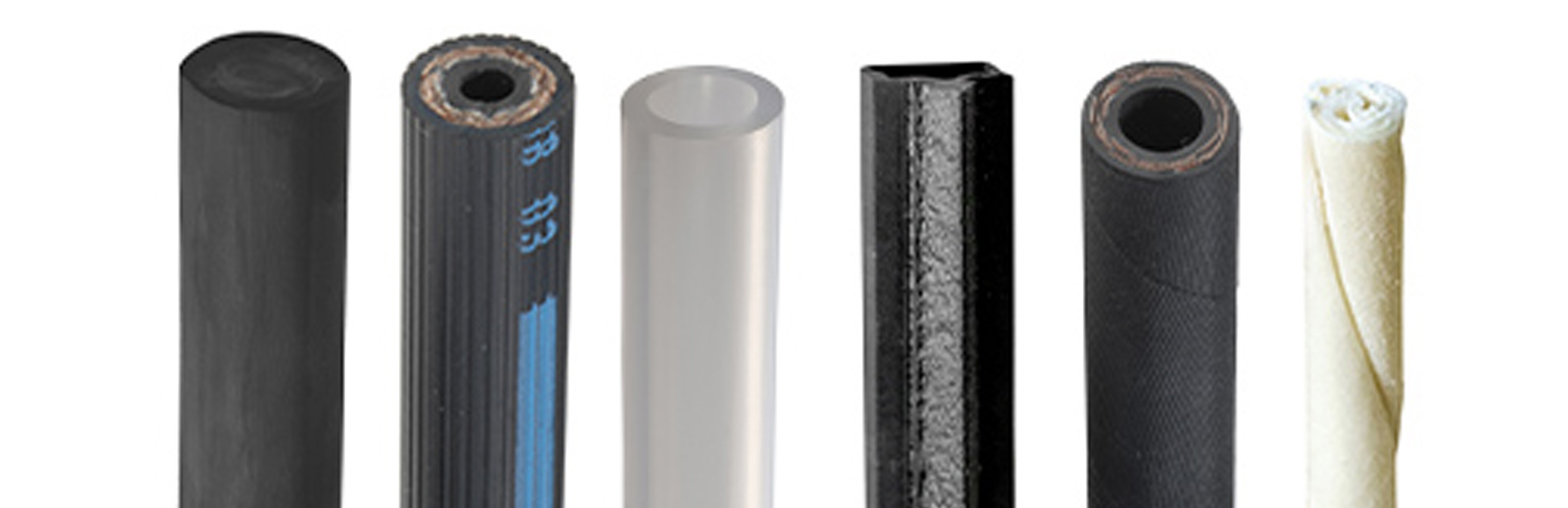

FLY-KNIFE CUTTING MACHINES

- Tubes are flexible elongated hollow bodies with mostly round cross sections, in contrast to inflexible tubes. A tube can be used as a conduit for conveying solid, liquid and gaseous substances, can serve as their container, or can be given desired properties by a medium inside. Tubes are also used as protective sheathing, for insulation, or for thermal insulation. Depending on the intended use, tubes are made of different materials, such as rubber, synthetic rubber or plastic. They can also be reinforced with a fabric insert, for example pneumatic tubes. Metzner has been developing and designing production machinery for tube machining for nearly three decades. Fly-knife cutting machines are used as soon as tubes have to be cut in very large quantities. They achieve up to 4000 cuts per minute with one knife and, if required, an even higher cutting performance with multiple knives.

METZNER DYNAMAT-SERIES- for outstanding cutting performance of up to 4000 cuts per minute

- for "stop-and-go" cut or continuous cut

- for precise length measurement with measuring wheel or overtravel measurement

- for long knife life

METZNER DYNAMAT SERIES

-

impresses with high-speed cutting with precision

Metzner has been developing and designing production machinery for tube machining for nearly three decades. Thanks to these many years of experience, today we can offer solutions that are adapted to the variety of different tube diameters and material properties. Wherever tubes have to be cut in very large quantities, impact knife machines are used. The Metzner Dynamat series achieves up to 4000 cuts per minute with one knife and, if required, an even higher cutting performance with multiple knives. Customers have the choice between "stop & go" cut or continuous cut. There are different machine sizes for materials of up to 120 mm diameter, which are prepared as standard for a wide range of peripheral equipment and knife moistening. The Dynamat machines process elastic materials reliably and with repetitive accuracy – from silicone tubes for the medical sector to fabric-reinforced tubes and profiles. It makes no difference whether the material comes from an extruder or is unwound from a coil.

CUSTOMER SPECIFIC PROJECTS

- Whether complex processing lines for silicone hoses or sophisticated solutions for cutting to length and sorting vulcanised hoses and partially vulcanised blanks - Metzner plans, develops and manufactures machines and systems according to customer requirements for all applications that go beyond the functions of standard machines. Thus, based on many years of experience as a machine manufacturer and our inventive spirit, application-oriented machines are created which are also used under high demands. The Metzner development team has already developed individual systems for the most diverse applications. Read about our customer-specific solutions and discover starting points for your task!

INDIVIDUAL SOLUTIONS- for vulcanised hoses and partially vulcanised blanks

- for silicone hoses

PROGRAM-CONTROLLED, FULLY AUTOMATIC CUTTING TO LENGTH AND LABELLING/MARKING OF PA CABLE WIRES WITH DIFFERENT DIAMTERS/LENGTHS

-

With a customer-specific special machine, Metzner provides a fully automatic solution for safe and material-friendly feeding of elastic silicone tubes and for cutting to length, winding, labelling and depositing. All tubes are cut to a total length of 2000 mm. A special laser knife procedure allows the machine to guarantee high length accuracy – even at high feed rates. For further processing in production, the cut tubes are each wound onto a reel. This process takes place directly in the machine. For identification and quality control, all silicone tubes are then provided with a barcode label containing all relevant production information. This label is automatically scanned and stored in the IT system after application to the coil of tubes. This permits continuous production monitoring and allocation. Metzner gripper systems then remove the wound and labelled reel and place it on a conveyor belt, which automatically transports the tubes for further processing.

Reliable process automation

This special Metzner development automatically carries out all processing steps, from the safe and material-friendly feeding of the elastic tubes and cutting to length, right through to winding, labelling and depositing. Our product video will give you an insight into the machining process.

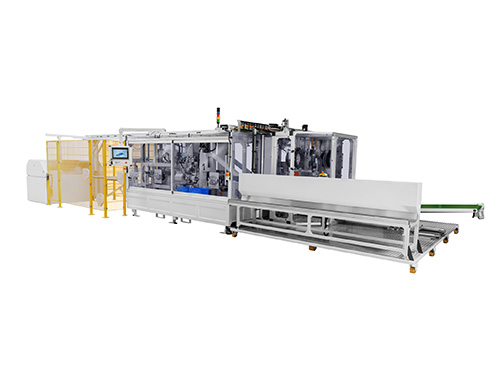

MULTI-STAGE FULLY AUTOMATIC PROCESSING OF PA AND TPE TUBING

-

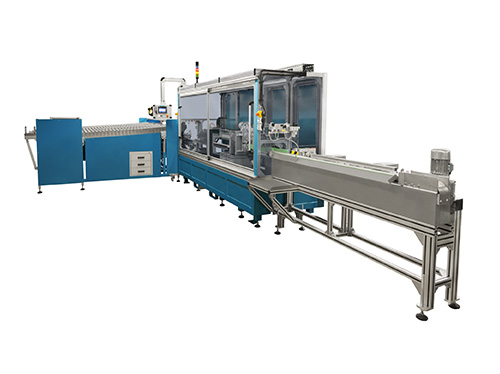

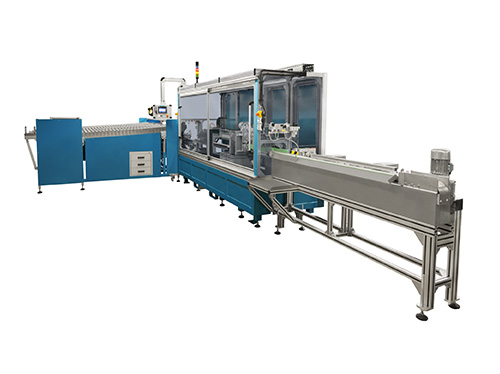

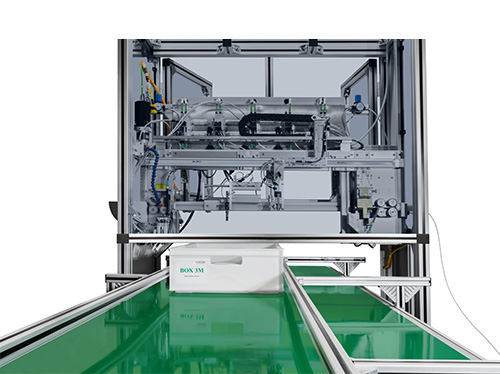

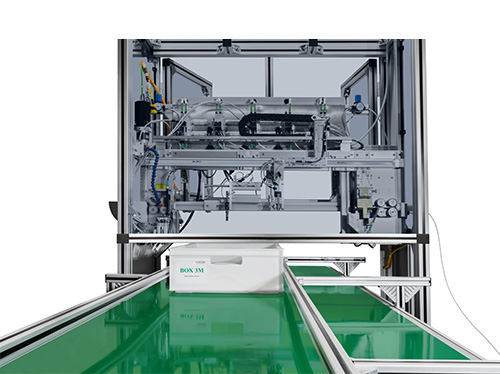

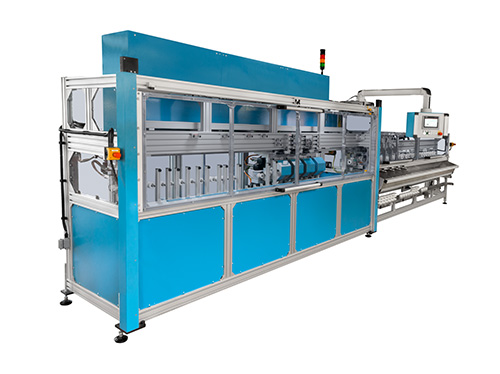

A global manufacturer of commercial vehicles and buses launched a new truck model in which a wide variety of PA lines for brake fluid and coolant are used. As the existing production facilities for processing and machining the PA lines for the existing truck and bus models were already reaching their capacity limits, a new production facility was needed. Metzner Maschinenbau GmbH provided the solution with fully automatic machinery, which offers the customer a multitude of advantages. The line was dimensioned in such a way that it still has sufficient capacity reserves for an increase in production if sales of the new truck model increase.

One of the challenges for the Metzner development team was to achieve the required output quantity for all PA brake tubes installed in the new truck model in different lengths, diameters and quantities with only one production line. In addition, the machinery should always produce complete tube sets which can be clearly assigned to the subsequent assembly stations. The Metzner development team mastered this difficulty by, among other things, a combination of seven unwinders, two production lanes and a suitable storage system, as well as the elaborate allocation of the two processing lanes. This required, among other things, a network connection of the production line to a central database for material requirements. The Metzner production line is now fully integrated into the customer's MES system with automatic order transfer and feedback function.

AUTOMATED PROCESSING OF VULCANISED TUBES AND PARTIALLY VULCANISED SEMI-FINISHED PARTS

-

A company that develops and produces demanding products and solutions for the automotive industry, includes in its product range vulcanised and partially vulcanised tubes of different diameters. These products serve as connections between vehicle tanks and tank supports and have to be precisely cut to length and sorted during manufacture. Metzner Maschinenbau GmbH developed an innovative solution for this automotive sub-supplier in the form of a special cutting line that carried out several working stages and - thanks to a new cutting process – saves costs. In addition, the company profits from shorter cycle times, so that now larger quantities can be manufactured.

For feeding the over 3 metre long vulcanised and partially vulcanised tubes, which consist of multi-layer elastomers with or without fabric reinforcement and an internal foil, to the cut-to length station, there is a circular plate transport belt with 28 compartments that can be quickly filled by an operator.

FULLY AUTOMATIC PROCESSING OF SILICONE TUBES

-

A globally active automotive supplier, which manufactures or processes brake and oil tubing, among other things, wanted to streamline its production in this area, but at the same time increase the number of units and product quality. To achieve these goals, the company replaced several manual workstations, where previously processing steps such as cutting to length, phasing, blowing out and printing of the material were carried out, with a customer-specific production line from Metzner Maschinenbau.

The machinery consists of the following components: two unwinders for tube reels, one unwinder for tube bundles, feeding device, two contact-free loop controls with additional material storage, reel straightening station, tool changer with cutting module for cutting to length, stripping, chamfering the cutting edges and blowing out the PA tubes, printer and stacker. There is a suitable tool set for each tube diameter, consisting among other things of sockets, guides and gripper jaws, which must be installed in the machine before production.

Processing Medical Articles

CUSTOMER SPECIFIC PROJECTS

- Whether complex processing lines for catheter tubing or sophisticated solutions for the production of serological pipettes - for all applications that go beyond the functions of series machines, Metzner plans, develops and manufactures machines and systems according to customer requirements. Thus, on the basis of many years of experience as a machine builder and our inventive spirit, application-oriented machines are created which are also used under high demands. The Metzner development team has already developed individual systems for the most diverse applications. Read about our customer-specific solutions and discover starting points for your task!

FEATURES- für Endotracheal tubes

- for serological pipettes

- for catheter hoses

AUTOMATED PROCESSING OF CATHETER TUBES

-

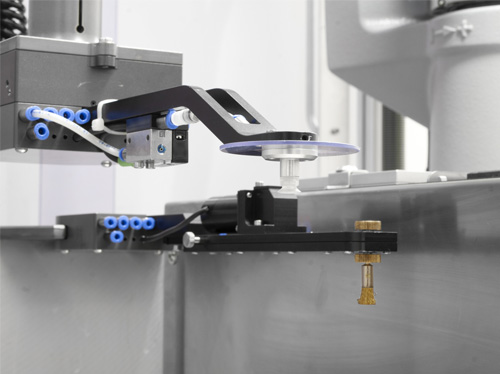

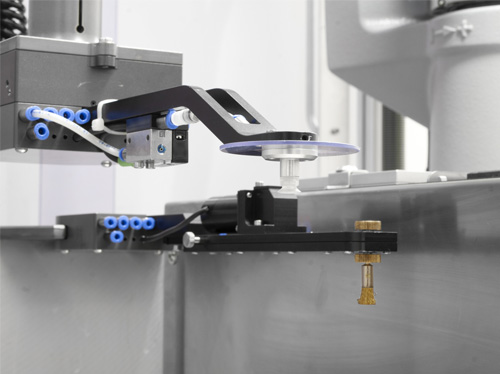

An internationally active medical technology company that produces and sells catheter tubes, among other things, has optimized its manufacturing process with the help of a production line from Metzner Maschinenbau. With Metzner's know-how, it was possible to replace a costly manual process with an automatic machine, saving costs. At the same time, the length accuracy and the cutting quality were significantly improved. The company supplied a fully automatic system that precisely cuts the catheter tubing to length, removes the mandrel present from the extrusion without leaving any residue and without longitudinal expansion, and then deposits the tubing in a collecting container at the end.

Processing with exact length accuracy and mandrel removal

The Metzner special development cuts catheter tubes to an exact length and removes the mandrel inside safely and precisely. The finished material is deposited in a collection container. You can get an insight into the machining process in our product video.

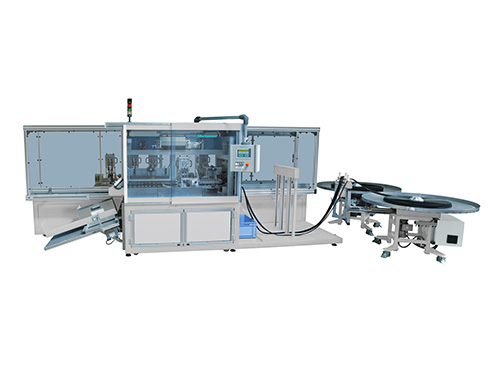

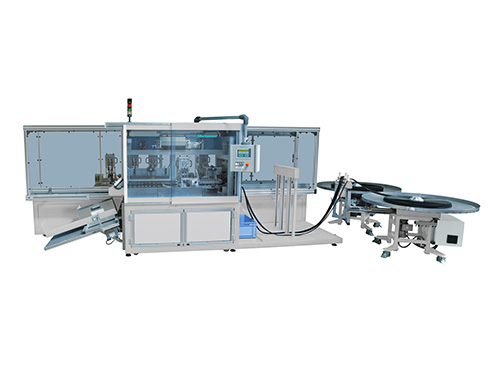

FULLY AUTOMATED PRODUCTION OF SEROLOGICAL PIPETTES

-

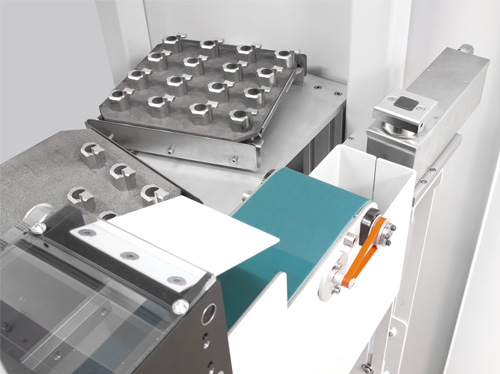

global medical device company, which produces and sells, among other things, serological pipettes made of polystyrene, needed a replacement for one of its existing production lines. The company approached Metzner Maschinenbau GmbH with its requirements for the new production line and then received machinery individually tailored to its wishes. This now offers numerous advantages over the previous solution and convinces with a large product variety and short set-up times. It was particularly important to the customer that the material coming from the upstream extrusion line, which is characterised by great hardness, is treated extremely carefully due to its brittle nature. This is because as soon as the polystyrene shows even the smallest of cracks, the produced part is already scrap.

The extruded material is first scored with the aid of several rotary cutting heads, then broken and finally deposited in collecting containers. The cycle time for four parts is only 1.5 seconds. For the production of short lengths (up to 120 mm), the cycle time is extended to approximately three seconds.

Fully automated processing line

The special Metzner development is a fully automatic machinery consisting of a contact-free loop control, an automatic cutting machine and a crushing station with storage system. It can produce polystyrene pipettes with diameters from 4 to 25 mm and lengths from 100 to 700 mm. Our product video will give you an insight into the machining process.

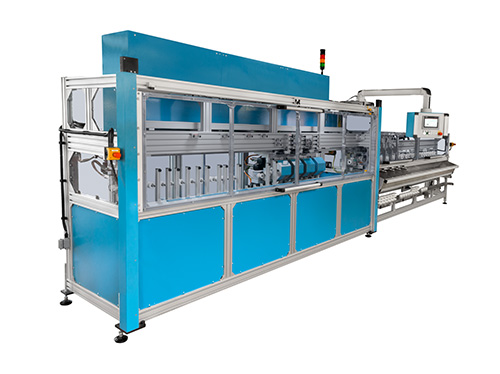

FULLY AUTOMATED PRODUCTION OF ENDOTRACHEAL TUBES

-

Medtronic, as one of the world's leading manufacturers of medical technology, is committed to supporting global healthcare by developing innovative treatments. The lives of patients during surgery depend on the endotracheal tubes the company manufactures, because these products ensure reliable ventilation. Consequently, the highest demands on uncompromising quality during manufacture and fault-free operation are essential. Metzner Maschinenbau GmbH has sustainably reduced the production costs of the end products and created additional production capacities with a fully automatic production system for endotracheal tubes.

Precise and safe machining

The Metzner special development department produces endotracheal tubes with high precision and cleanliness. This is ensured, among other things, by processes such as automatic loading, alignment and positioning of the tubes, processing by seven consecutive work stations and automatic quality control by sensors. Our product video will give you an insight into the machining process.

Robotic Automation

CUSTOMER PROJECTS FOR COATING PROCESSES

CUSTOMER PROJECTS FOR COATING PROCESSES

-

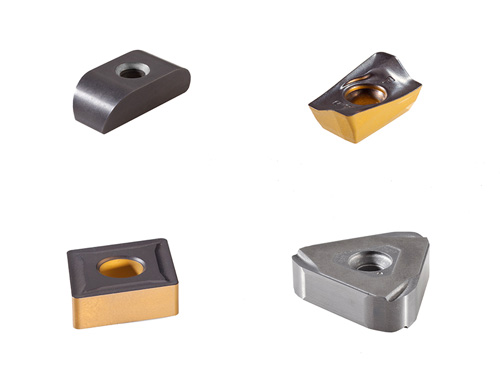

Metzner provides a number of proven automation solutions for the automatic loading and unloading of coating carriers for CVD and PVD coatings. The abbreviations PVD (Physical Vapour Deposition) and CVD (Chemical Vapour Deposition) stand for different coating processes.

When loading the PVD spears, we differentiate between "single-loading" and "back-to-back loading". In addition to part loading, spacers are loaded onto the spears in addition to the parts. In single-loading, a spacer is located behind each individual insert, whereas in back-to-back-loading, two inserts are placed "back to back" and only then is a spacer loaded.

To implement "back-to-back-loading", a turning station is integrated into the machinery. This station is used to turn the corresponding insert by 180 degrees, loading it directly onto the respective spear.

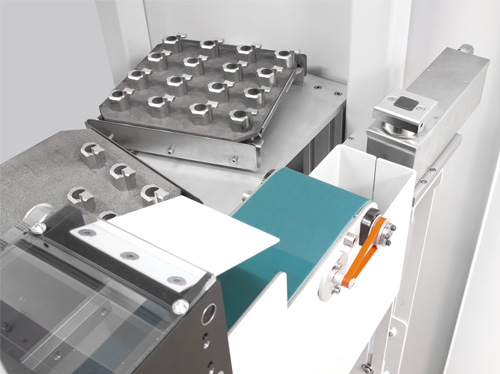

CUSTOMER PROJECTS FOR PRESS UNLOADING

- With its standard machines, Metzner offers a wide range of options for the fast, material-friendly and economical removal of pressed blanks from powder presses of up to 30 cycles/min. The spectrum includes process automation for removing pressed blanks from a powder press and their storage, as well as automation solutions for the handling of indexable inserts and small ceramic parts with medium to large batch sizes and for the handling of pressed parts made of hard metals with an outstanding storage system. We offer individual extensions wherever standard solutions do not ideally meet your requirements.

METZNER RPA SERIES- Defined interfaces to the presses of various manufacturers

- Use of any desired sintering plates

- Integrated quality assurance (deburring, weighing, measuring, etc.)

- Highest variety of parts due to different gripping systems

- User-friendly software for free definition of deposit samples on the sintering plate

METZNER RPA 60-LT

-

The "Metzner RPA 60-LT" is a powerful robot press automation with an outstanding storage system for the highest demands in the handling of pressed parts made of hard metal and metal powder.

With a storage capacity of up to 60 sintering plates, the "Metzner RPA 60-LT" offers outstanding possibilities for the production of sintered parts of all types. All sintering plates are fed to the machine via four transport trolleys with 15 plates each.

The intelligent handling system of the "RPA 60-LT" ensures uninterrupted loading of the pressed parts: While the first sintering plate is filled by a linear robot with multifunctional gripper, the handling system provides a second empty plate. As soon as the first plate is filled, the loading of the second one starts. Meanwhile, the handling system returns the loaded sintering plate to the transport carriage. The automation thus works according to the Kanban principle, which ensures that the press can be operated continuously even during the workpiece carrier change.

METZNER RPA 10-SL

-

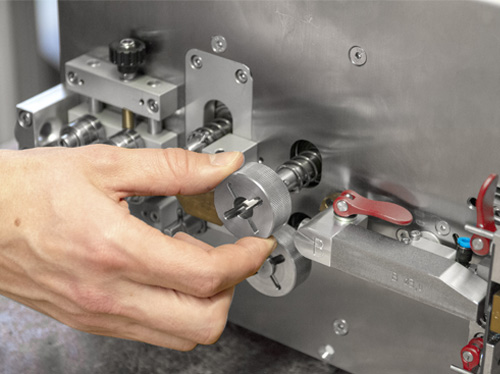

The "Metzner RPA 10-SL" is a powerful and flexible press automation system for handling indexable inserts and small ceramic parts for medium to large batch sizes.

The "Metzner RPA 10-SL" has an integrated magazine system for up to ten sintering inserts. Empty sintering inserts are automatically removed from the magazine, loaded and then returned as required. In this way, the powder press automation works independently over a longer period of time without loading and unloading processes leading to a press stop. Additional tasks such as weighing or deburring the pressed parts are also performed fully automatically.

With its integrated 4-axis SCARA robot, the machine achieves very high system speeds of up to 30 stroke/min. This makes the "RPA 10" ideally suited for connection to electric presses with high cycle performance.

METZNER RPA 3-SC

-

Powder press and indexable insert automation

Metzner powder press and indexable insert automations of the "RPA 3-SC series" automatically remove pressed blanks from a powder press and deposit them quickly and gently in a definable sample.

In the "RPA 3-SC1", the transfer of the individual sintering plates and the loading of the blanks is carried out by a SCARA 4-axis robot. The empty sintering plates are placed manually into a sintering plate magazine, removed with a sintering plate gripper if necessary, and fed to the loading position. The robot then moves to a gripper station, deposits the sintering plate gripper, picks up a part gripper, and starts loading the sintering plate. This process is fully automated and takes place very quickly at up to 30 cycles/min.

In the "RPA 3-SC2", sintering plates are placed manually on a double conveyor belt. One sintering plate at a time is automatically transported to the loading position via the conveyor belt. The robot immediately starts to load the blanks. Loaded sintering plates are ejected from the loading position and manually removed from the conveyor belt. This process significantly reduces the time needed for changing the plates in comparison to the "RPA 3-SC1".

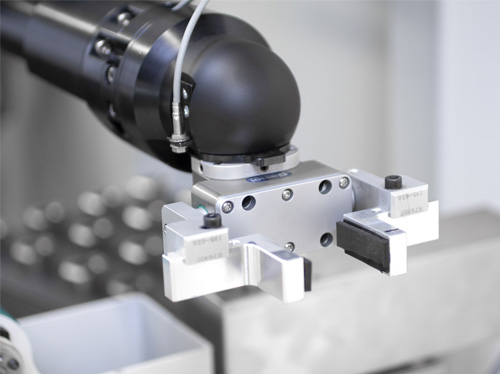

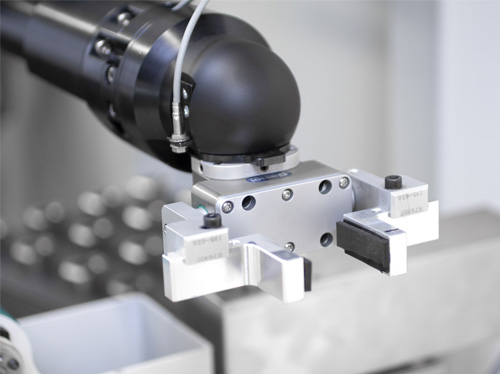

Customer Projects for Automatic Unload and Transfer

AUTOMATION SYSTEM FOR THE RELOADING OF SMALL PARTS

-

The automatic reloading of blanks is an important process in the production of inserts and other precision parts.

Automation is used to transfer parts from different workpiece carriers such as sintered inserts, flat or pin pallets, and coating carriers. A SCARA four-axis robot is used to transfer the parts. To achieve a high reloading performance, the robot is equipped with a multiple gripper, which can handle several parts at the same time. Vision systems are used for robot guidance to ensure precise picking up and placing of the parts.

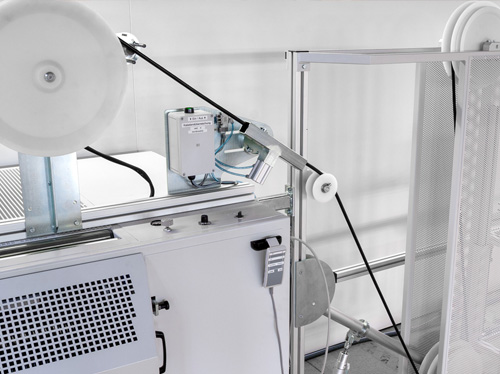

Peripheral Equipment

CUSTOMER PROJECTS FOR PRESS UNLOADING

- For optimal results when processing cables, secure transport to the machine is an important pre-requisite. Metzner offer many solutions for unrolling and feeding. Whether the materials come from a drum or a spool or weigh ten, a hundred or a thousand hundredweights. The product spectrum goes from passive or motorised unwinders, material feeder units, loop controls and linear accumulators right up to caterpillar haul-off units.

METZNER DEREEL AND FEED UNITS- For motorised dereeling

- For passive unwinding of braided and plain cables with less tension-sensitivity

- For passive unwinding of corrugated tubes and wound cable bundles

- To control feeding speed and act as reserve quantity

- For unwinding from an undriven device

- For contact-free speed control

- For careful transport of extruded rubber profiles

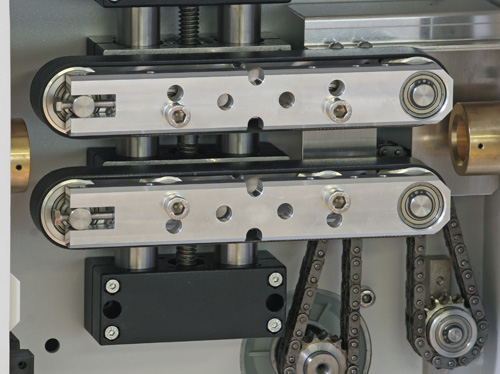

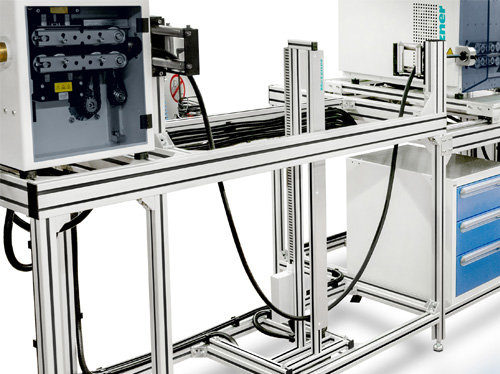

METZNER CATERPILLAR HAUL-OFFS

-

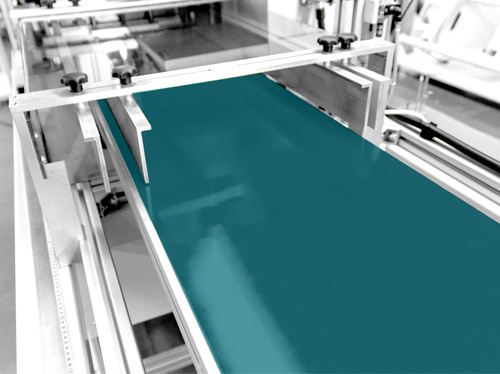

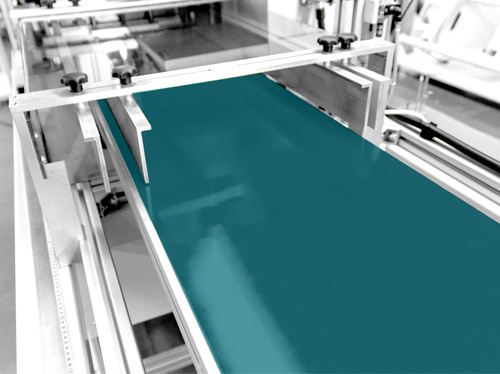

for the gentle transport of extruded rubber profiles to the processing system

Metzner caterpillar haul-offs gently transport rubber profiles, which are pulled out of a cooling bath after extrusion and further processed, to the processing system. To guarantee material feed without deformation, tension or pressure points, Metzner uses long conveyor belts that run completely synchronously. This characteristic is maintained even at speeds of up to 40 m/min.

All caterpillar haul-offs are connected to the extrusion line via an interface. This ensures that the transport speed of the caterpillar haul-offs runs parallel to the extrusion line. Simultaneously, the caterpillar haul-off sends a signal to the cutting machine when production stops or restarts. The advantage: processing is almost completely automatic.

METZNER LINEAR ACCUMULATOR

-

Buffer between feeder/cable unwinder and the downstream processing system

Linear storages serve as a "buffer" between the feeder or cable unwinder and the downstream processing system and control the feeding speed.

Linear storages represent an excellent solution for all cable processing where high acceleration and processing speeds occur or extremely tensile sensitive cable wires are processed. In the event of increased material requirements, the cable processing machines pull the material from the linear storage, which has a cable reserve of up to seven metres. At the same time, the linear storage signals an increased material requirement to the material dispenser or the feeding device, so that they increase the dispenser speed. If cable processing stops or slows down, the linear storage also passes this information on to the upstream peripheral devices.

METZNER PF SERIES

-

for feeding materials unwound from a device without drive

Material feeders from Metzner are applied wherever materials are unwound from a device without drive. This includes, for instance, cable and profile reels, spools, loose rings or processing directly from a box or cable shelf.

Metzner feeding devices ensure tension-free material feed to your processing machine. Integrated sensors regulate the optimum unwinding speed in connection with a contact-free loop control or dancer arm, with a speed of up to 180 m/min. Depending on the model, the feeders can transport materials up to 100 mm wide and 30 mm high.

DHS SERIES

-

for contactless speed control

A failure-free cable feed to the processing machine is the fundamental prerequisite for achieving high length accuracy at a high processing speed. In combination with a feed-in device or an unwinding plate, Metzner loop controls provide contactless speed control. Contact-free loop controls regulate the speed of a motorized coil unwinder or material feeder in off-line operation and the working speed of the processing machine in in-line operation. The position of the material passing through is permanently detected by intelligent sensors. This information is used to determine the optimum speed and is passed on to the feed-in devices or machine.

Adapted to the processed cable, Metzner offers loop controls with contactless control for very thin or tension-sensitive cable wires or alternatively with a weighted roller for fixed cable wires. All Metzner processing machines are equipped with interfaces for the integration of contact-free loop controls as standard.

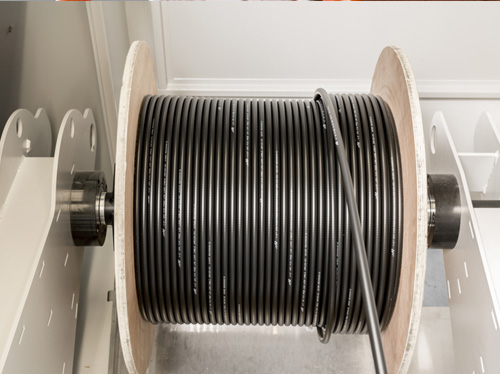

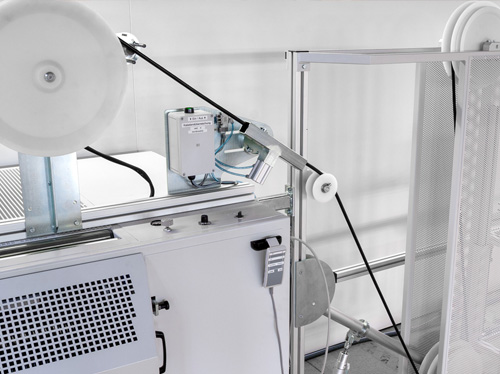

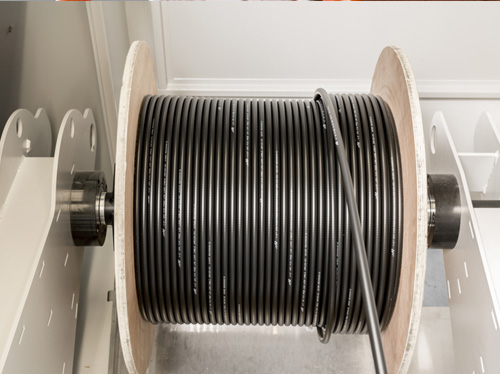

METZNER DRS SERIES

-

Feed-in of coiled goods such as cable wires or tubes with low tensile sensitivity

Metzner DRS units are suitable for feeding winding materials such as cable wires or tubes with low tensile sensitivity to downstream processing machines. In connection with a feeding device, your cable wires are fed to the processing machine without any tension.

The passive material dereelers of the DRS 1 series with double-bearing-mounted roller axle are suitable for dereeling spools, cable reels, strands and tubes up to 20 kg. Clamping of the materials is carried out in a few simple steps.

Metzner DRS 2.850 – the practical solution for dereeling wound materials such as cable rings, coils and corrugated tube coils. The outer diameter of the coil is freely adjustable via adjustable brackets, as is the coil width.

METZNER DRC SERIES

-

Feed-in of coiled goods such as corrugated tubes or tubes with low tensile sensitivity

Metzner DRC dereelers are suitable for feed-in of winding materials such as corrugated tubes or tubes with low tensile sensitivity. In connection with a feed-in device or a conveyor belt, the coiled materials are fed to the processing machine.

The "DRC 1" series offers feed-in solutions for different diameter sizes. Corrugated tube coils, tube and cable rings can be unwound without any problems up to an outer diameter of 1000 mm. The pull-off force is adjusted with a mechanical brake so that the dereeler cannot run after it. The centre of the unwinding device is optimally adapted to the respective core diameter of the material rings by means of adjustable brackets and supports trouble-free dereeling.

METZNER DR SERIES

-

Motorised and powerful high-performance unwinders

Motorised cable unwinders ensure that cable is fed safely into the cable processing machine. They are the ideal complement to your wire processing machines for automatic wire feed-in at high processing speeds while working gently with the lowest possible tractive force. Electrically driven cable unwinders contribute significantly to the constant length accuracy of your wire processing machine. Missing or imprecisely working cable unwinders are often the cause of temporary cable stretching during the material feed-in. As a rule, the material contracts again after processing, with the result that the correct processing dimensions change after a short rest period and no longer correspond to the desired result.

PRINTING & MARKING

- Profiles and tubes are often labeled or marked to identify and determine installation positions. Due to the different requirements, we offer different printing systems from leading manufacturers for almost all Metzner machines.

METZNER PRINTING SYSTEMS:- For ink-jet printing

- For thermal transfer printing

- For laser printing

- For Brady Wraptor

- For hot stamping

- For marker printing

METZNER INK JET PRINTING

-

Economic solutions for labelling tubes and profiles

The ink-jet printers Metzner Ink Jet 01 LP and 02 SP are the uncompromising and at the same time innovative result of our long-standing experience in contactless material marking. With their very high printing speeds, these ink jet printers can be used in all modern high performance production lines. Both text input and configuration are conveniently and easily carried out via the PC user interface of the Metzner converting machine or as a stand-alone unit via the modern touchscreen display.

The Ink Jet 01 LP is designed for processing non-pigmented or lightly pigmented inks, while the Ink Jet 02 SP is designed for processing heavily pigmented inks – white in particular, but also other colours. Ink and solvent are stored in practical reusable containers that can even be refilled during operation. The permanent ink viscosity measurement with the automatic solvent dosing system guarantees a reliable and environmentally friendly operation.

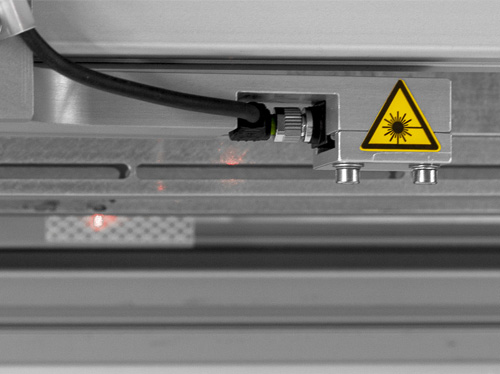

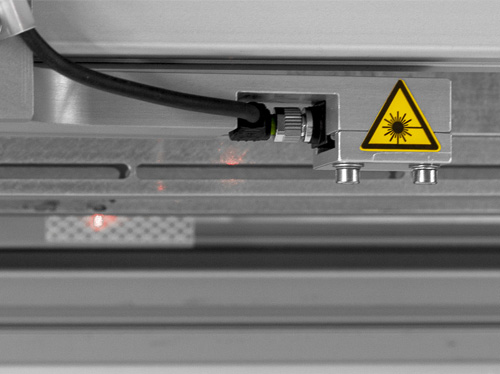

METZNER LASERPRINTING

-

Metzner Laser Printing – Guaranteed first-class print quality

To identify and determine installation positions, profiles and tubes must often be labeled or marked. Due to the different requirements, Metzner currently offers various printing systems from leading manufacturers that can be used in combination with Metzner machines.

With marking lasers, freely programmable texts, logos and label are also transferred with no loss of time. The print quality is outstanding, but the purchase price is higher than for ink jet printers or thermal transfer printers.

METZNER MARKING

-

Motorised and powerful high-performance unwinders

Marking and bundling stations are always used when materials have to be marked, fixed or bundled. Based on customer requirements, Metzner integrates marking and bundling stations directly into a production line so that the processing machine is optimally coordinated with the marking station.

In the automotive industry, tubes with coloured marking tapes are often used to define assembly fixed points. Marking tapes enable the fitter to quickly identify the points at which, for example, PA tubes are connected to the chassis.

In addition to position markings, bundling and fixing units are also used if the material would open due to a cut. In this case, the tube is wrapped at a predefined position and then cut in the middle of this fixing. This ensures that all material properties are retained as desired and can be further processed without any problems.

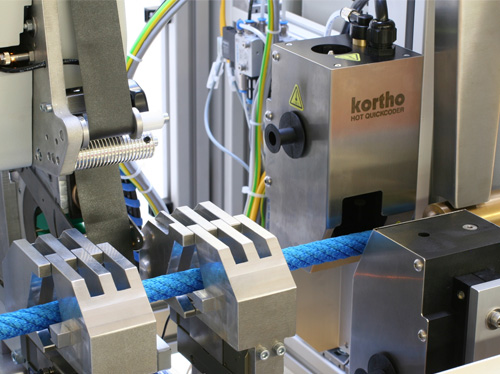

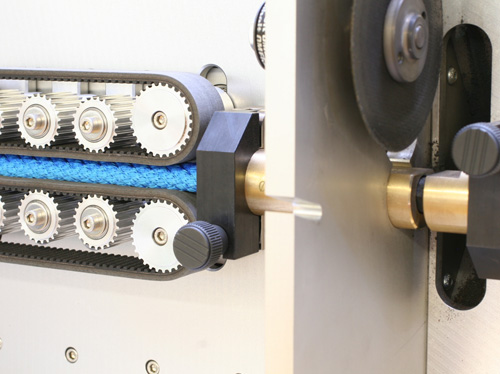

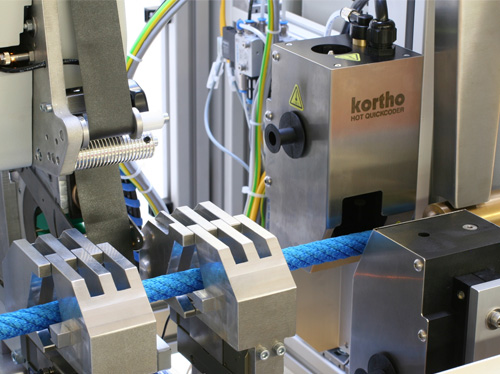

METZNER HOT STAMPING

-

For premium print quality via embossing stamp and stamping foil

Hot stamping units are used wherever materials are to be labeled with the same characters in high quality. In this process, pre-heated embossed characters on a precision printing plate are pressed onto the surface of the material by a coloured stamping foil. The shape of the embossed characters, coordinated with the material to be marked, optimally supports the marking process.

Hot stamping is ideal for materials such as cable wires, strands, shrink tubes, tubing, flat materials and other thermoplastic materials. The devices allow the exact setting of the parameters embossing temperature, embossing time and contact pressure. This ensures the highest quality – and reproducible markings. Hot stamping units are usually integrated into a processing line. The marking process is therefore carried out parallel to the machining process with no loss of cycle time.

THROWOFF & WINDING

- After the material processing, precise positioning, sorting or winding are vital steps to ensure the quality of the whole working process. For this, Metzner offers well-thought out and practically proven solutions. Our material placers lay and sort the finished parts in a tray to present the optimal exit situation for the subsequent further processing. Winder units, too, which wind the materials in time with the processing machine, ensure totally tension free wind-up, thus giving a good solution for intermediate storage or onwards transport.

METZNER MATERIAL PLACERS AND WINDING UNITS:- For orderly material placing in a tray

- For careful placing of delicate materials

- Winder units with synchronised control to give tension-free winding

- Winder units without synchronised control for materials that are not affected by tension

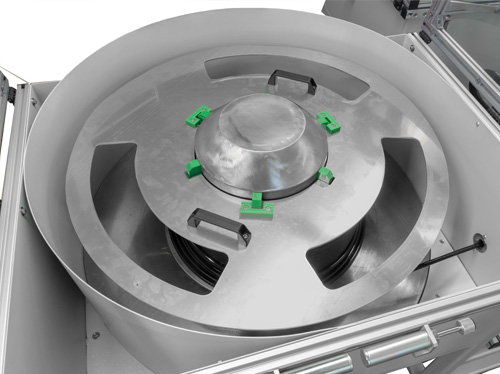

METZNER SRW 350

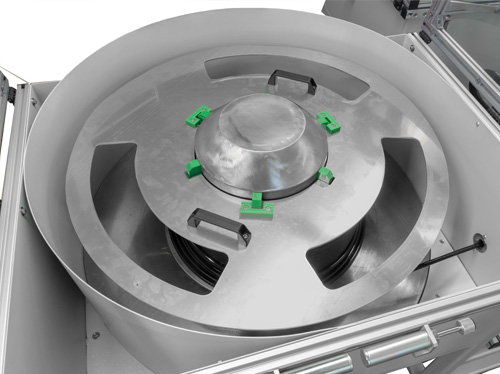

-

Tube ring winder for winding tubes of up to 350 mm diameter

Tubes must be frequently rewound and preassembled into a ring. This task is performed quickly, safely and efficiently by the Metzner SRW 350 tube ring winder: after the start of the tube is placed in the winding mandrels, the start button is pressed. The protection cover then closes and the rotary plate starts to wind the tube into the desired size.

A potentiometer controls the winding speed between zero and 200 revolutions per minute. The size of the wound tube rings is adjustable; the inner diameter of the cable ranges from 150 mm to 350 mm, the outer diameter from 200 mm to 450 mm. With the four standard lockable castors, the SRW 350 is mobile and can be easily rolled to different locations.

METZNER CPC-SERIES

-

Cable pot winder without synchronous control

Cable pot winders without synchronous control are a less expensive alternative to devices equipped with synchronous control and are preferably used for cable wires without tensile sensitivity.

When cable processing starts, a signal from the processing machine starts the rotation of the winding device and stops it after the cable has been finished. A further signal regulates the filling of the next cable into the second winding device while the first cable is being removed from the first winding device.

The cable ring winder Metzner CPC 200 is suitable for cable wires with an outer diameter of up to 12.5 mm. The pot outer diameter is available in multiple versions from 160 mm to 600 mm; the core diameter is adjustable in the range from 140 mm to 260 mm.

METZNER CRC SERIES

-

Automatic cable ring winders with controlled function sequence

Long cable wires frequently have to be wound up into a ring after assembly. The Metzner CRC series cable ring winders have been developed to do this. Metzner CRC 350 – The cable ring winder with synchronous control, for cable rings of up to 350 mm outer diameter. The cable wires are automatically fed into the winding mandrels through a guide tube, and the winding process starts and stops program-controlled. After completion, the mandrels are lowered automatically, the protection cover opens, and the finished cable ring can be removed.

METZNER CROSS CONVEYOR

-

For depositing sensitive profiles and tubes

Sensitive profiles and tubes (e.g. with flocking or textile lamination) must be transported and deposited with great care. Metzner cross conveyors units are an ideal solution for this.

After processing, the profiles and tubes are transported out of the machine on a conveyor belt and transferred to the cross conveyor. With one or more grippers, the materials are lifted onto a cross conveyor belt and transported for visual inspection and removal.

METZNER MA SERIES

-

Active stackers for cable wires, profiles, tubes and other materials

Metzner's active material stackers place your machined parts straight and orderly in a trough. This ensures that you achieve a high-quality starting situation for subsequent processing. We distinguish between cable stackers and stackers for profiles, tubing and other materials.

In the material stackers MA 2000, MA 4000 and MA 6000, the standard and controlled intermediate storage compartment supports optimum sorting functions in the automatic processing of complex production lists or large quantities. These stackers are equipped with a conveyor belt that transports cable wires and tubes straight and in the working cycle of the processing machine, an indispensable advantage when processing thin cable wires and tubes or long cable lengths. The cable processing machines offer the necessary interfaces for the controlled operation of the cable stacker for material lengths of up to 6 m. Thanks to the open design on the outlet side, the material stackers also offer the possibility of stacking cable lengths that are "overlong".