- Offer Profile

By using innovative high-tech solutions WEWO Techmotion optimizes logistics processes. We develop reliable, intelligent and flexible transport solutions for customers in the Netherlands and far beyond. Our solutions enable them to fully automate their internal logistics.

Solutions

Always the right choice: an automated guided vehicle, electric transport or a special solution

Automated guided vehicles from WEWO Techmotion

Based on years of experience, our specialists have developed their own system for AGV vehicles: automated guided vehicles . The possibilities offered by an AGV system from WEWO Techmotion are therefore endless. Thanks to our in-house engineering, software development, production and assembly, we can also make your customer wishes a reality.

Electric transport

The industry makes extensive use of electro transport , for example to optimize the production process. But electric carts also come in very handy in catering or in warehouses. And although our electric carts come in different shapes and sizes, they have one thing in common: they are intended for the easy and fast transport of products and materials, making heavy lifting or pushing a thing of the past.

Our standard solutions

Many issues concern the efficiency of product handling and the ROI should not be lost sight of. That is why we have a wide range of innovative and sustainable standard solutions, which make the investment in optimization of internal transport feasible for both large organizations and SMEs.

Our special solutions

Other cases require tailor-made solutions. WEWO Techmotion is the supplier par excellence. With us you are guaranteed to find a unique total solution. A special solution , as we call it. And because of our flexible and innovative character, these solutions are extremely suitable for interacting with both physical installations - ranging from work tables to robot cells - and software solutions - ranging from simple PLC control to ERP/WMS packages.

Automatic Guided Vehicle (AGV)

All over the world, more and more automated guided vehicles (AGVs) are replacing manual work in warehouses and factories, among other things. WEWO Techmotion specializes in automated guided vehicles (AGVs) that are used to move materials and products in various environments. Our automated guided vehicles are therefore designed to optimize your internal logistics. As a result, our solutions fit seamlessly with the lean manufacturing principle and technology 4.0.

Customized automated guided vehicles

Firstly, all our AGVs are characterized by a modular construction, flexibility and easy-to-use properties. The WEWO Techmotion product range also consists of various basic versions, but customized automated guided vehicles are also possible. From our strong basic range, each type can be fully tailored to your specific situation. And of course all our AGVs - whichever you request from us - can be linked to existing systems and production processes.

Customized AGV for smarter and more efficient working

In the development of our automated guided vehicles, we have a clear focus on the optimization and flexibility of the process for you as our customer. At the same time, our AGVs can be used to improve your competitive position. Thanks to AGVs, work can be carried out smarter and more efficiently.

Custom-made automated guided vehicles

Our solutions range from traditional AGVs to latest-generation custom-made automated guided vehicles. Each designed to maximize the flexibility, efficiency and effectiveness of intralogistics. We naturally think about:

- AGV software

- AGV navigation

- AGV type

- The battery

AGV Types

AGV Move

The AGV Move is a series of compact AGVs, developed for a variety of applications.

- Various models available as standard

- Unique lift module

- Custom-made AGV possible

In many cases, the AGV Move is the ideal automated guided vehicle for you. The AGV is compact, intelligent, moves weights of up to 800 kilos and is equipped with 360-degree safety. The AGV Move is centrally controlled and communicates easily with other control systems.

- Unique lift module: The AGV is equipped with a powerful lift module with a capacity of 800 kilos.

- For large rolls: Transporting large rolls? View our custom AGV Move for roll and coil handling.

- Very low version: A very low variant is available: the AGV Underrider, only 150 mm high.

- In stainless steel: The AGV Move is available in stainless steel - ideal for the food and beverage industry.

- Easy to expand: Is there product expansion? Then you can easily expand your AGVs.

- Customization possible: The AGV Move can also be supplied fully custom-made.

AGV Move Underrider

The AGV Move Underrider is perfect for moving trolleys, bins, product stands, frames and carriers.

- Only 150 mm high

- Unique lift module

- Custom-made AGV possible

The AGV Move Underrider is a variant of our regular AGV Move. With a height of only 150 mm, this AGV can also transport product carriers with a low ground clearance.

The AGV Move Underrider also communicates easily with other operating systems. As a result, this automated guided vehicle can pick up products - such as trolleys and totes - on demand and deliver them to a delivery point or assembly line. And due to the modular nature of the AGV, the lift height and payload can easily be adjusted for you.

- Unique lift module: Supplemented with a unique lift module, the AGV is perfect for moving products.

- Safety: The AGV Move Underrider has two safety scanners for optimal safety.

- Standard version: Need a different height? Then choose our standard AGV Move of 210 mm.

- In stainless steel: The AGV Move is available in stainless steel - ideal for the food and beverage industry.

- Easy to expand: With product expansion you can easily expand your AGVs.

- Customization possible: We can fully customize the AGV Move Underrider for you.

AGV Pallet Mover

The AGV Palletmover has been developed to collect and deliver pallets automatically, quickly and efficiently.

The AGV Palletmover is an AGV system for internal pallet transport. The AGV can easily move weights of up to 1300 kilograms and navigates with ease in relatively small spaces.

The AGV Palletmover is therefore extremely suitable for various applications, including moving products from the reception to the warehouse and/or production, supplying the outbound docks and unloading the inbound docks. Picking products at the end of the production line - such as packaged boxes, pallets, containers and more - is also possible.

The regular AGV Palletmover has a lifting height of up to 1,300 mm, the Palletmover Stacker goes up to 2,500 mm. The fork construction can also be adapted as desired, for example for moving large rolls or trolleys.

- Communication: You can easily link your business software to our control software via API.

- Various models: This AGV is available in various models, such as the Stacker and the Stainless Steel.

- Pallet mover Stacker: The standard Pallet Mover goes up to 1,290 mm, the Stacker has a lifting height of up to 2,500 mm.

- Pallet mover Stainless Steel: A Stainless Steel version is also available: ideal for the food and beverage industry.

- Safety: The AGV is equipped with 360-degree safety, pinch prevention and blue spot, among other things.

- Customization possible: The AGV Palletmover can also be supplied fully custom-made.

AGV Pallet Mover Stacker

Want to move pallets automatically, quickly and efficiently? This is possible with the AGV Palletmover Stacker.

- Lifting height up to 2.5 meters

- Each pick position programmable

- Compact AGV

The powerful AGV Palletmover Stacker is the ideal AGV for double stacking, the transport of products and storage at different levels (up to 2,500 metres).

Due to its modular character, this automated guided vehicle is also easy to adapt to your situation. The lift height, the load capacity, the navigation (safety scanners or a top scanner): you choose it yourself, so that you are best served. The fork construction can also be adapted as desired, for example for moving large rolls or trolleys.

Just like the standard AGV Palletmover, the AGV Palletmover Stacker can move a relatively large amount of weight - up to 1,300 kilos.

Due to the compact design, the AGV has a relatively small turning circle. This makes the Stacker extremely suitable for narrow aisles between storage racks. Whether you want to use the AGV for moving products from receiving to warehouse and/or production, picking products at the end of the production line, stocking the outbound docks or unloading the inbound docks : it is possible.

- Communication: You can easily link your business software to our control software via API.

- Various models: The Palletmover is available in various models, including the Stainless Steel.

- Information display: Every Palletmover is equipped with an informative user display for quick management.

- Pallet mover Stainless Steel: A Stainless Steel version is also available: ideal for the food and beverage industry.

- Safety: The AGV is equipped with 360-degree safety, pinch prevention and blue spot, among other things.

- Customization possible: The AGV Palletmover can also be supplied fully custom-made.

AGV Pallet Mover Stainless Steel

This stainless steel AGV is perfect for use in the food and beverage industry, among others.

- Made in IP65

- Hygienic design

- Compact AGV

The powerful AGV Palletmover Stainless Steel is the dynamic automation solution within the food processing industry. The AGV is fully geared to the high requirements within this industry. Damp and wet floors, or high humidity? This AGV performs its tasks without any problems. Completely autonomous, completely safe.

Like the standard AGV Palletmover, the AGV Palletmover Stainless Steel moves a relatively large amount of weight - in this case up to 1,000 kilos. The AGV Palletmover Stainless Steel is powerful and compact. The hygienic design, the high IP value and the diversity of sensors make this AGV the smart and safe mobile robot for your internal transport processes.

- Communication: You can easily link your business software to our control software via API.

- Various models: The Palletmover is available in various models, including the Stacker.

- Information display: Every Palletmover is equipped with an informative user display for quick management.

- Pallet mover Stacker: The AGV Pallet Mover goes up to 1,000 mm, the Stacker has a lifting height of up to 2,500 mm.

- Safety: The AGV is equipped with 360-degree safety, pinch prevention and blue spot, among other things.

- Customization possible: The AGV Palletmover can also be supplied fully custom-made.

AGV L Cart

Lifting and moving products: that is exactly what you can use the AGV L-cart for:

- With unique lift module

- Large battery capacity

- Different drive options

The AGV L-cart from WEWO Techmotion has a smart construction that combines a low lift platform with a large battery capacity. The AGV L-cart navigates by means of a 360-degree top scanner, extra obstacle detection and blue spot. The automated guided vehicle moves your products efficiently, quickly and completely safely.

The main advantages of the AGV L-cart are the large battery capacity, the various navigation options and a compact design. The AGV is equipped with a powerful drive, is equipped with protection brushes to prevent small parts and can drive and navigate in small environments. The AGV L-cart can also navigate by means of a top scanner. This is ideal when natural navigation at ground level is not sufficient.

- Battery capacity: This AGV can effortlessly be used continuously for one shift, without having to recharge.

- Navigation (1): The AGV L-cart navigates by means of contour scanning.

- Navigation (2): The vertical part allows the AGV to navigate both at ground level and at height.

- Various models: The AGV L-cart is available in two models: the standard L-cart and the L-cart Heavy.

- AGV L-cart Heavy: The regular L-cart moves a maximum of 600 kilos, the Heavy can handle a maximum of 2,500 kilos.

- Customization possible: The AGV L-cart can also be supplied fully custom-made.

AGV L-cart Heavy

Lifting and moving large products such as industrial carriers or frames: the AGV L-cart Heavy is perfect for this.

- Up to 2,500 kilograms

- Robust vertical drive unit

- Customization possible

The AGV L-cart Heavy is equipped with a powerful, unique lift module, so that products weighing up to 2,500 kilos can be easily lifted and transported. The AGV carries out drive orders autonomously, whereby heavy products are easily moved. This AGV is also available with navigation at different levels. In addition, the AGV is equipped with a Lithium Ion Battery Pack with an action radius of at least one shift.

Just like the regular AGV L-cart, the Heavy has two important advantages: large battery capacity and various navigation options. The AGV is equipped with a robust steering-drive unit, safety around the AGV, and a powerful lift system with a capacity of up to 2.5 tons. The AGV can also be easily linked to your own business software via our control software.

- Battery capacity: The AGV L-cart Heavy can be used continuously for one shift, without having to recharge.

- Navigation: The vertical part allows the AGV to navigate both at ground level and at height.

- Floor conditions: Is also suitable if navigation at ground level is not sufficient or if the floor is not level.

- Various models: The AGV L-cart is available in two models: the standard L-cart and the L-cart Heavy.

- AGV L-cart Heavy: The regular L-cart moves a maximum of 600 kilos, the Heavy can handle a maximum of 2,500 kilos.

- Customization possible: The AGV L-cart Heavy can also be supplied fully custom-made.

AGV Assembly Line

The AGV Assembly Line is available in two 'flavours': the regular Assembly Line and the Assembly Line Lifting.

- Flexible in scalability and product type

- Determine the working height yourself

- Compact AGV

The big advantage of the regular AGV Assembly Line compared to conventional vehicles is flexibility. Applying the AGV Assembly Line in a line assembly creates flexibility in terms of scalability and product type. It becomes easier to assemble different types of products on the same line and also to lengthen or shorten the assembly line.

In addition to the regular AGV Assembly Line, you can also opt for the AGV Assembly Line Lifting. The AGV Assembly Line Lifting is additionally equipped with an integrated lifting module. This allows you to determine at what height you want to work for each assembly station. This makes the AGV very ergonomically sound. When the automated guided vehicle arrives at the station, it automatically assumes the desired height. You can also adjust the height via remote control. Good to know: The AGV can be custom-made to meet the criteria of your assembly line.

- Very flexible: The big advantage over conventional vehicles is the flexibility.

- Omnidirectional: In addition to the standard drive, an omnidirectional drive is also possible.

- Expansion: If there is product expansion, you can easily expand your AGVs.

- Routing: The routing can be adjusted, which makes it easier to move an assembly line.

- Ergonomic: The AGV Assembly Line Lifting is very ergonomically sound.

- Dynamic and completely safe: Available with 360 degree safety and additional components, such as safety bumpers.

AGV Custom Made

Out-of-the-box solutions: that is where WEWO Techmotion can help you. The result? A tailor-made AGV.

- Fully customised

- From engineering to implementation

- Unique solutions

Out-of-the-box solutions: that's what we can help you with. This almost automatically means that you can also contact us for a custom-made AGV. An AGV Custom is always fully in line with your internal logistics issue. Our own design department will work with all your specific wishes. This is how your custom-made automated guided vehicle is created in our collaboration.

We do more than realize your custom-made AGV. We are also there for you when it comes to the planning, implementation, service and maintenance of your AGV. It is not for nothing that we have been a partner for organizations in various industries for many years. From automotive to production, from food to paper & printing: we are now known as the supplier of custom-made AGVs.

- Unique issue: Ideal when you have a specific issue about your internal logistics.

- All under one roof: With us you will find in-house engineering, software development, production and assembly.

- Omnidirectional: In addition to the standard drive, an omnidirectional drive is also possible.

- Security: We can tailor your AGV exactly to your requirements - from navigation to safety.

- Total solution: WEWO Techmotion is happy to realize your total solution for internal logistics.

- Standard possible: Prefer no customization? Then choose a standard AGV, such as a Palletmover or Move.

AGV Applications

WEWO Techmotion offers a wide variety of standard AGV solutions on the one hand and is an expert in customized automated guided vehicles on the other. Whether you opt for standard or custom work: many applications are possible.

In all those branches, there are a lot of possibilities in the field of automated guided vehicles at WEWO Techmotion. This is due to our in-house engineering, software development, production and assembly. This enables us to make special customer wishes come true. We are also able to tailor your AGV exactly to the requirements of your project and the specific application.

- Bulk & Roll Handling: Raw materials, semi-finished products… Whatever kind of bulk goods you want to transport, WEWO Techmotion's automated guided vehicles make bulk handling smooth, safe and fast. WEWO Techmotion has developed unique solutions for roll handling especially for organizations in the packaging industry and in paper & printing.

- Assembly automation: One of our applications is assembly automation : assembling products in a line by means of automated guided vehicles.

- Machine cell loading: Loading and unloading machines - in other words: machine cell loading - can be a difficult and time-consuming task. The automated guided vehicles from WEWO Techmotion help you with this.

Pallet Handling

ABB's AGV transports pallets with crates from one department to another. The automated process detects pallets using sensors and sends the AGV to this location to pick it up. In other words: the AGV receives orders through sensors, after which the Fleet Management Software ensures that these orders are handled automatically. In concrete terms, this means that dirty pallets are taken fully automatically from the production area to the washing area for cleaning.

Pallet detection, autonomous dropping and safety

Pallet detection and the autonomous dropping of pallets are also possible. Pallet detection means that the AGV anticipates the position of the pallet and adjusts its route accordingly. The autonomous dropping of pallets means that the AGV determines the drop position of the pallet based on vision. The subject of safety is also of great importance for all our automated guided vehicles for pallet handling. In order to guarantee the highest level of safety, safety scanners are used on our AGVs, among other things.

Product Handling

Whether it concerns a few pallets with products or full containers, our automated guided vehicles arrange the logistics automation of your product handling down to the last detail. For example, your products are brought from the end station to your warehouse, or from the end station to the outbound transport. We have developed an AGV for this organization that communicates with both injection molding machines and the automatic warehouse system. The AGV is used for the fully automatic supply of empty crates from the warehouse. The crates are then filled with injection molded parts, after which the AGV collects the filled crates from the machines to return them to the automatic warehouse.

From clean rooms in the pharmaceutical industry to industrial environments: our automated guided vehicles can handle it. Your AGV is tailored to the unique situation in your building, such as seams in a floor or a transition of concrete slabs. WEWO Techmotion's automatic guided vehicles can be fully customized and are therefore suitable for product handling in various industries. From production to automotive , from pharmaceuticals to paper & printing .

Cart Handling

Many carts and trolleys have a relatively low ground clearance. Our compact AGVs are able to drive under it, no matter how little space there is. Furthermore, the turning circle and the routing are determined by the size of the cart or trolley. The big advantage of WEWO Techmotion's AGVs? Many carts and trolleys have a relatively low ground clearance. This is the space between the bottom of the cart or trolley and the ground. You may recognize this. Our compact AGVs are able to drive under it, no matter how little space there is. Also good to know: the turning circle and the routing are always determined by the size of the cart or trolley. Important: the combination of your AGV and the product remains compact for optimal navigation.

The advantages of WEWO Techmotion

In addition to the advantages of our AGVs, WEWO Techmotion as an organization also has a number of advantages for you. We like to think along with you throughout the entire process, resulting in an optimal logistics flow for your carts and trolleys. To give an example: we can also provide your work area with centering rails, also known as guide rails. This is a mechanical interface on the ground where your employees can put the carts and trolleys. From this interface, the transport is arranged automatically and no manual actions are involved.

With all our automated guided vehicles for cart handling, the subject of safety is of great importance. To guarantee the safety of your people, machines, carts and trolleys, safety scanners are used on our AGVs, among other things. In addition, we naturally think about matters such as edge protection (in connection with the risk of crushing), safety bumpers as additional protection, blue spots, lighting and acoustic signals.

Roll & Bulk Handling

Our automated guided vehicles transport products in bulk efficiently, resulting in lower costs and higher capacity. And when it comes to roll handling, there are many options. Picking and dropping a roll, for example, or retrieving rolls from a machine, transporting them to your warehouse and preparing them for transport. Raw materials, semi-finished products… Whatever kind of bulk goods you want to transport, with the automated guided vehicles from WEWO Techmotion this will run smoothly, safely and quickly. Our AGVs naturally also interact with any filling and mixing stations or other machines and your warehouse. And of course our AGV solutions can handle large weight classes. In our range you will find AGVs of different levels and weight classes (standard up to no less than 3.5 tons).

At WEWO Techmotion you will find robust, but very compact AGVs that can move heavy weights. The size of the product to be moved determines the route that the automated guided vehicle follows, in order to keep the routing as compact as possible. The greatest strength of WEWO Techmotion therefore lies in the supply of compact standard solutions for optimum handling of bulk goods.

Assembly Automation

Assembly automation is one of our solutions for the automotive industry. Assembly automation is also an ideal choice for the production industry. With our AGVs you ensure maximum efficiency, productivity and flexibility in your assembly.

At WEWO Techmotion you will find AGVs of various levels and weight classes (standard up to no less than 2.5 tons). In short: with us you will always find the right AGV for assembly automation. This way you ensure maximum efficiency, productivity and flexibility for your assembly. Our reference Audi also found the right solution at WEWO Techmotion. Audi likes to make its production fit for the future and is always striving for more flexibility and efficiency. Thanks to our in-house engineering , software development, production and assembly, we were able to make all special customer wishes come true for Audi.

By using innovative navigation techniques , the automated guided vehicles of WEWO Techmotion maneuver independently through space. In addition, two different navigation methods are possible for assembly automation.

- Line navigation, for simple assembly processes.

- Natural navigation, for more dynamic assembly processes.

With line navigation - also known as line-following guidance - an optical scanner is mounted on your AGV. The scanner determines the location of the line in the image and uses it to position the vehicle. Natural navigation uses structures and contours in the environment as a reference for localization. This makes things like inductive wires, magnets or reflectors superfluous.

Machine Cell Loading

WEWO Techmotion can build your AGV for loading and unloading machines in such a way that your product is taken safely, centered and fixed to the next robot cell. Our AGVs can also handle a wide variety of products and weight classes.

The specialists at WEWO Techmotion can build your AGV in such a way that your product is taken safely, centered and fixed to the next robot cell. In addition, our advantages are the wide variety of products that our vehicles can handle and the number of weight classes that they can handle. And of course the Fleet Management software in our AGVs communicates with all your machines and the parent software, such as an MES or ERP package.

ASCO is a world class supplier of the design and manufacture of high lift structures, complex mechanical assemblies and key functional components. Here we supplied an AGV that facilitates transfers between different robot cells.

AGV Software

No AGV is complete without advanced AGV software - including yours. WEWO Techmotion's automated guided vehicles are controlled by advanced AGV software for navigation, steering, transport management and traffic control, among other things.

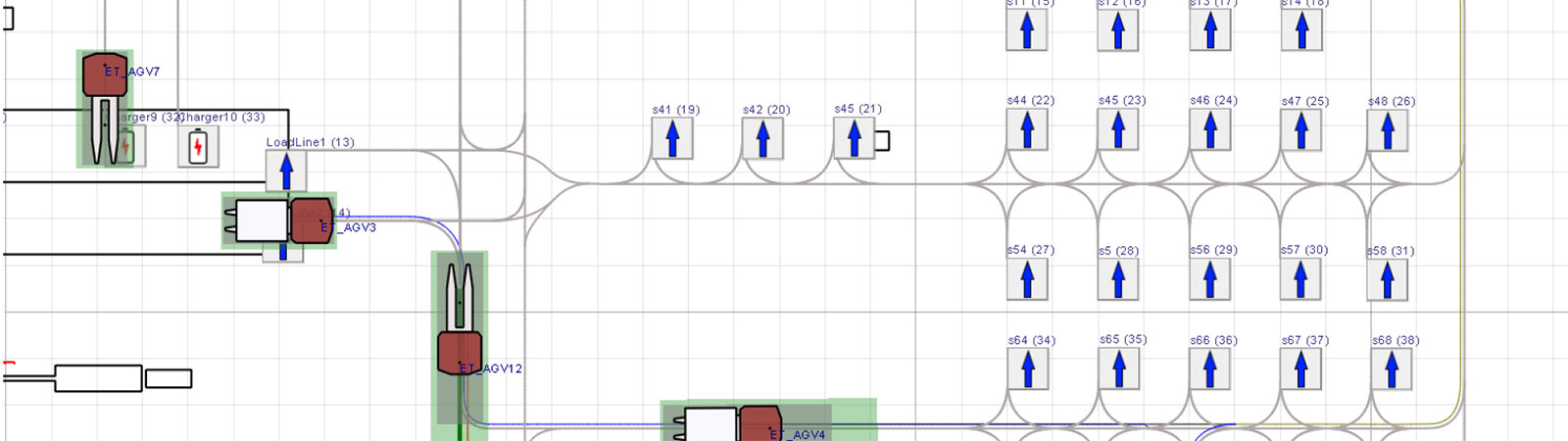

Fleet Management software for your AGV

With our Fleet Management software, your AGV is controlled and managed. The Fleet Management software contains all the tools needed to manage a warehouse, production environment or other environment, in combination with your fleet of AGVs. And of course the software can be linked to various other packages that you may use, such as MES or ERP.

Navigation software for your AGV

Do you opt for the natural navigation navigation method for your AGV ? Then your vehicle will be equipped with the corresponding software. This navigation software ensures that all settings are easy and efficient to install and maintain. It does not matter whether it concerns a single AGV or several automated guided vehicles.

Mapping software for your AGV

Our mapping software is a fully integrated solution that allows you to configure your vehicles and map your environment. You also create routes with this and this information is translated to the parent system: the fleet manager.

Fleet Management Software

WEWO Techmotion's Fleet Management software has a server-client architecture and is able to control different AGVs in the same environment. For this purpose, the software contains various functionalities, such as:

- Managing and performing tasks.

- Communication with the navigation software.

- A user interface for monitoring and controlling the AGV(s).

- Alarm management.

- Collecting data in a database.

- Link with your MES, ERP or PLC system.

- Priority management.

- Traffic management of your fleet of AGVs.

- Prevent deadlocks.

The Fleet Management software also manages battery status. Your advantage? Your AGVs are charged at scheduled times or when there are no orders. The software also influences the route and planning. For an optimal route for the AGV from the current location to the target location, the software takes into account the other traffic on the route. Very handy.

The traffic control is based on both the routing and the real-time monitoring of safety fields around the vehicle. What this means in concrete terms: the software can slow down or stop AGVs when they are close to each other. The AGVs then 'choose' a different route to reach their target location. This prevents a jam or collision. This prevents deadlocks and ensures optimal AGV routing. The software can be linked to various other packages that you may use, such as MES or ERP. This way you never have to adapt your business processes to the automated guided vehicle - it is the other way around.

Navigation Software

With natural navigation, your AGV uses structures and contours in the environment to locate. This navigation method has a great advantage, as it does not require any new infrastructure. So no inductive wires, magnets, tags or QR codes need to be placed. With natural navigation you can also opt for structures and contours of the environment, possibly in combination with simple reflectors. The use of these types of reflectors ensures optimal positioning of the automated guided vehicle. Positioning accuracy is ± one centimeter and ± one degree.

When your automated guided vehicle is equipped with natural navigation, the associated software is also installed on this vehicle. WEWO Techmotion's navigation software ensures that all settings can be installed and maintained easily and efficiently. It does not matter whether it concerns a single AGV or several automated guided vehicles.

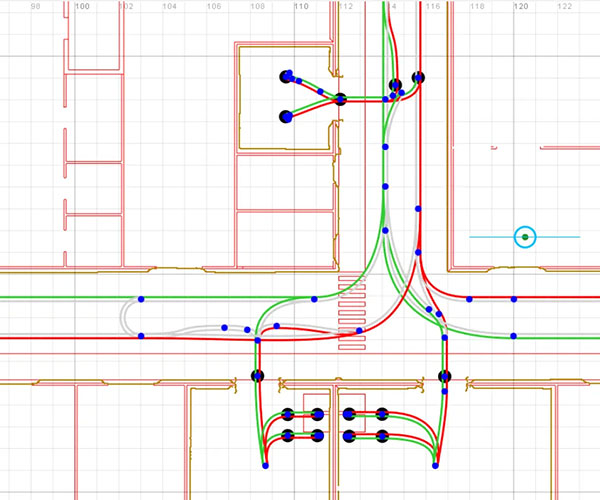

Mapping Software

Every automated guided vehicle from WEWO Techmotion that is equipped with natural navigation is supplied including mapping software. With this software:

- The scope is mapped.

- A selection is made of reliable contours for stable navigation.

- The routes and functionalities are created

- The complete information is translated to the Fleet Management software.

The operation of our mapping software is very simple. First of all, your automated guided vehicle reads in the environment. The AGV drives around by means of a remote control, so that the mapping software can register the environment, but also possible reflector positions. The measured environmental data is then transformed into the environmental map.