DMG MORI

Videos

Loading the player ...

- Offer Profile

- DMG MORI brings together German and Japanese tradition, precision and technological leadership in CNC Lathes and Milling Machines.

Dynamic . Excellence – worldwide

Digitization is changing our world both quickly and radically. The switch to digitization requires fundamental further development which can only be achieved globally and jointly, in strong partnerships and on an equal footing. DMG MORI continues to develop positively – technologically, structurally and culturally. Our business is marked by Dynamic and Excellence.

Product Portfolio

Machines

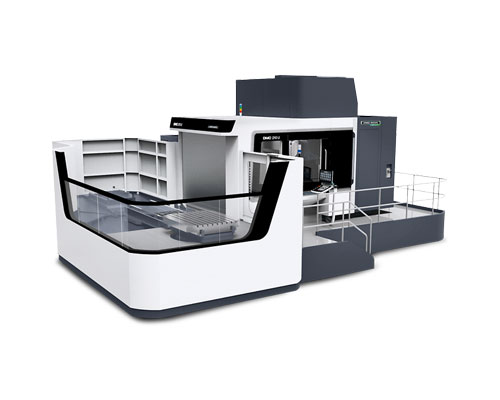

The DMG MORI group is one of the largest manufacturers of metal cutting machines and a leading global manufacturer of CNC-controlled Turning centres and Milling machines.

Products of DMG MORI include innovative high-tech CNC machines like lathes, milling machines, advanced technologies (ULTRASONIC / LASERTEC) as well as Software Solutions and Systems. Industrial services include a wide range of services in relation to the whole machine lifetime, used machines, accessories and energy solutions.GREENMODE - Energy- and emission-efficient operation at the customer's site

Up to 30 % energy savings compared to previous machine models.Turning

- Regardless of whether they are for use in the automobile industry, engineering, medical technology or other manufacturing and production applications in metalworking: lathes are needed everywhere turned parts are manufactured. DMG MORI can provide you with the most up-to-date, high-performance and innovative CNC turning machines in the design you need for your production. This is made possible by our modular system with high-tech components that can be adapted to meet your individual requirements. To ensure that your machines can be operated seamlessly, we provide you with a service package you can rely on day and night.

Benefits of our turning machines at a glance:

- High-performance, flexible, and easy-to-operate lathes

- Different sizes, shapes and features

- Individual configuration to meet your specific requirements

- Automated and digitalised production

- Around the clock service

- Spindlereplacement within 24 hours or repair

- In 96 per cent of cases, replacement parts are available immediately

Universal Turning

- These lathes are true all-rounders and the backbone of many production operations: CNC-controlled universal turning machines by DMG MORI. The highest-possible cutting performance is ensured by spindle drives of up to 12,080 Nm. A large turning diameter of up to 930 mm, optimum chip fall, and measuring systems by MAGNESCALE for extremely precise results also ensure that these turning machines stand out from the crowd:

- Counter-spindle for six-side full processing

- Y-axis for eccentric milling processing of complex workpieces

- Big-bore spindles with an outlet of up to 375 millimetres in diameter

- Processing of workpieces up to 930 mm in diameter and a turning length of up to 6,000 mm

- Flat track for optimum attenuation properties and dynamic rigidity

- MASTERspindles with a 36-month guarantee and no usage hours limit

DMG MORI makes turning machines in the following series:

- NEF

- CLX

- CTX

- NLX

- SL

CLX 350

- The new benchmark in universal turning – with direct measuring system (X or X/Y) and IoTconnector in standard

- Max. workpiece diameter 320 mm

- Max. workpiece length 530 mm

- Max. bar capacity diameter 65 mm

- Max. X-Axis 185 mm

- Max. Y-Axis 80 mm

- Max. Z-Axis 540 mm

CLX 450

- The new benchmark in universal turning – with direct measuring system (X or X/Y) and IoTconnector in standard

- Max. workpiece diameter 400 mm

- Max. workpiece length 800 mm

- Max. bar capacity diameter 80 mm

- Max. X-Axis 276 mm

- Max. Y-Axis

- Max. Z-Axis 755 mm

CLX 550

- The new benchmark in universal turning – with direct measuring system (X or X/Y) and IoTconnector in standard

- Max. workpiece diameter 700 mm

- Max. workpiece length 1,240 mm

- Max. bar capacity diameter 102 mm

- Max. X-Axis 308 mm

- Max. Y-Axis 120 mm

- Max. Z-Axis 1,240 mm

CTX 2500

- Max. workpiece diameter 430 mm

- Max. workpiece length 1,284 mm

- Max. bar capacity diameter 102 mm

- Max. X-Axis 260 mm

- Max. Y-Axis 100 mm

- Max. Z-Axis 1,345 mm

CTX alpha 500

- Max. workpiece diameter 500 mm

- Max. workpiece length 500 mm

- Max. bar capacity diameter 67 mm

- Max. X-Axis 210 mm

- Max. Y-Axis 80 mm

- Max. Z-Axis 525 mm

CTX beta 800

- Max. workpiece diameter 410 mm

- Max. workpiece length 800 mm

- Max. bar capacity diameter 104 mm

- Max. X-Axis 300 mm

- Max. Y-Axis 120 mm

- Max. Z-Axis 850 mm

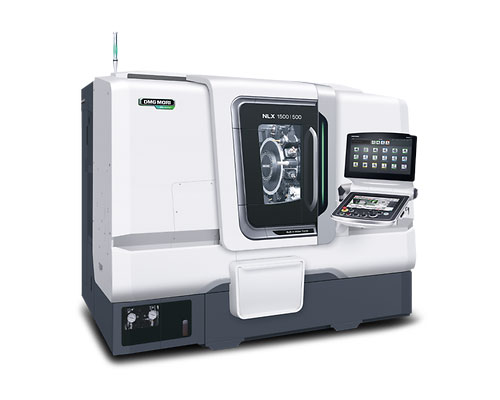

NLX 1500

- Max. workpiece diameter 386 mm

- Max. workpiece length 515 mm

- Max. bar capacity diameter 52 mm

- Max. X-Axis 260 mm

- Max. Y-Axis 100 mm

- Max. Z-Axis 590 mm

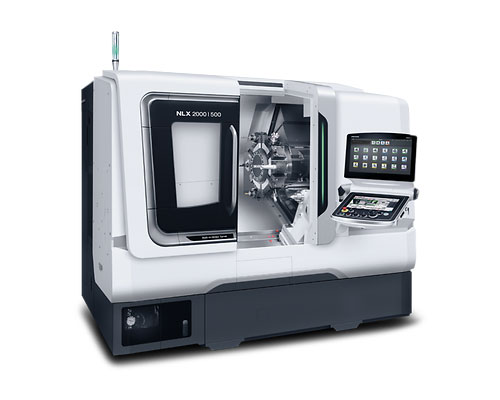

NLX 2000

- Max. workpiece diameter 366 mm

- Max. workpiece length 510 mm

- Max. bar capacity diameter 65 mm

- Max. X-Axis 260 mm

- Max. Y-Axis 100 mm

- Max. Z-Axis 590 mm

NLX 2500

- Max. workpiece diameter 366 mm

- Max. workpiece length 1,255 mm

- Max. bar capacity diameter 90 mm

- Max. X-Axis 260 mm

- Max. Y-Axis 100 mm

- Max. Z-Axis 1,345 mm

NLX 4000

- Max. workpiece diameter 600 mm

- Max. workpiece length 1,584 mm

- Max. bar capacity diameter 117 mm

- Max. X-Axis 365 mm

- Max. Y-Axis 120 mm

- Max. Z-Axis 1,685 mm

SL 403

- A machine that maximizes and stabilizes speed and high

precision.

- Max. workpiece diameter 650 mm

- Max. workpiece length 2,158 mm m

- Max. bar capacity diameter 185 mm

- Max. X-Axis 345 mm

- Max. Z-Axis 2,000 mm

SL 603

- A machine that maximizes and stabilizes speed and high precision.

- Max. workpiece diameter 930 mm

- Max. workpiece length 4,000 mm

- Max. bar capacity diameter 375 mm

- Max. X-Axis 485 mm

- Max. Z-Axis 4,150 mm

Turn & Mill

Turn & Mill

- Our Turn & Mill turning machines in the CTX TC, NT and NTX series allow turning and milling capabilities in one machine. Equipped with the counter-spindles that are available, these turning/milling centre workpieces can be fully processed from all six sides. The built-in B-axis is fitted with a direct drive. This means the lathes in the CTX TC, NT and NTX series also facilitate the five-axis CNC milling of complex workpieces along with free-form surfaces.

The advantages of our turn and mill centres:

- One machine for lots of work steps with our high-performing Turn & Mill machines in the CTX TC, NT and NTX series.

- B-axis with the compactMASTER Turn & Mill spindle for five-axis simultaneous processing at up to 220 Nm

- Turning spindles in the turnMASTER series with up to 1,194 Nm torque

- 36-month warranty on all MASTER spindles with no usage hours limit

- Counter-spindle for six-side full processing

- Additional lower revolver as a second tool carrier for productive four-axis processing

Three Series for turn and mill processing:

- CTX TC

- NT

- NTX

CLX 450 TC

- Universal turning new defined

- Max. workpiece diameter 400 mm

- Max. workpiece length 1,100 mm

- Max. bar capacity diameter 65 mm

- Max. X-Axis 750 mm

- Max. Y-Axis 200 mm

- Max. Z-Axis 1,100 mm

CTX beta 800 TC

- Turn & Mill complete machining with the new ultra-compact patented turn-mill spindle compactMASTER

- Max. workpiece diameter 500 mm

- Max. workpiece length 750 mm

- Max. bar capacity diameter 102 mm

- Max. X-Axis 480 mm

- Max. Y-Axis 200 mm

- Max. Z-Axis 845 mm

CTX beta 1250 TC

- Turn & Mill complete machining with the new ultra-compact patented turn-mill spindle compact

- Max. workpiece diameter 500 mm

- Max. workpiece length 1,200 mm

- Max. bar capacity diameter 102 mm

- Max. X-Axis 490 mm

- Max. Y-Axis 250 mm

- Max. Z-Axis 1,300 mm

CTX beta 1250 TC 4A

- Turn & Mill complete machining with compactMASTER turn-mill spindle and a second tool carrier

- Max. workpiece diameter 340 mm

- Max. workpiece length 1,185 mm

- Max. bar capacity diameter 102 mm

- Max. X-Axis 490 mm

- Max. Y-Axis 200 mm

- Max. Z-Axis 1,200 mm

NTX 1000

- Covering Extensive Range of Machining Across All Fields

- Max. workpiece diameter 430 mm

- Max. workpiece length 800 mm

- Max. bar capacity diameter 65 mm

- Max. X-Axis 455 mm

- Max. Y-Axis 105 mm

- Max. Z-Axis 800 mm

NTX 2000

- Covering Extensive Range of Machining Across All Fields

- Max. workpiece diameter 660 mm

- Max. workpiece length 1,538 mm

- Max. bar capacity diameter 65 mm

- Max. X-Axis 675 mm

- Max. Y-Axis 300 mm

- Max. Z-Axis 1,562 mm

NTX 2500

- 6-sided machining with Turn & Mill Spindle compactMASTER

- Max. workpiece diameter 670 mm

- Max. workpiece length 1,530 mm

- Max. bar capacity diameter 80 mm

- Max. X-Axis 675 mm

- Max. Y-Axis 300 mm

- Max. Z-Axis 1,562 mm

NT 4200 DCG

- All-round machine for various fields

- Max. workpiece diameter 660 mm

- Max. workpiece length 1,596 mm

- Max. bar capacity diameter 65 mm

- Max. X-Axis 750 mm

- Max. Y-Axis 420 mm

- Max. Z-Axis 1,550 mm

NT 4250 DCG

- All-round machine for various fields

- Max. workpiece diameter 660 mm

- Max. workpiece length 1,542 mm

- Max. bar capacity diameter 80 mm

- Max. X-Axis 750 mm

- Max. Y-Axis 420 mm

- Max. Z-Axis 1,650 mm

NT 4300 DCG

- All-round machine for various fields

- Max. workpiece diameter 660 mm

- Max. workpiece length 1,498 mm

- Max. bar capacity diameter 90 mm

- Max. X-Axis 750 mm

- Max. Y-Axis 420 mm

- Max. Z-Axis 1,650 mm

NT 5400 DCG

- All-round machine for various fields

- Max. workpiece diameter 920 mm

- Max. workpiece length 1,921 mm

- Max. bar capacity diameter 103 mm

- Max. X-Axis 1,040 mm

- Max. Y-Axis 510 mm

- Max. Z-Axis 2,140 mm

NT 6600 DCG

- Ultimate Integrated Mill Turn Center

Capable of Handling Long and Large-diameter Workpieces- Max. workpiece diameter 1,070 mm

- Max. workpiece length 6,076 mm

- Max. bar capacity diameter 164 mm

- Max. X-Axis 1,040 mm

- Max. Y-Axis 660 mm

- Max. Z-Axis 6,150 mm

Horizontal Production Turning

Horizontal production turning with revolvers

Our revolver production turning machines have up to three revolvers with three Y-axes and a built-in B-axis. Thanks to up to three tool carriers, our horizontal lathes are perfect for the series production of both bars and feed components. In addition, the versions are available with three revolvers without a B-axis and with two revolvers. It should also be noted that the two-revolver version also uses the TWIN concept that is available for our production turning machines.

This unique workspace concept with two revolvers and the cross stroke of the counter-spindle and tailstock combination makes possible processing in two independent workspaces in parallel. On the one hand, you can process long workpieces, such as shafts, on our turning machines with the support of the tailstock on a four-axis basis. On the other hand, this enables the collision-free front machining of long parts on the main spindle and counter-spindle.

The turning machines in the NZX-S series and the CTX beta 1250 CS are designed for manufacturing crankshafts or camshafts.Our production turning machines with revolver:

- NZX-S

- CTX CS

- SPRINT revolver

- NZX

- CTX 4A

WASINO G 100 | 300

- High-quality Workpieces Generated by Super-high-precision Machining

- Max. workpiece diameter 285 mm

- Max. workpiece length 280 mm

- Max. bar capacity diameter 38 mm

- Max. X-Axis 300 mm

- Max. Z-Axis 285 mm

WASINO A 150SY | 15

- Ultra-high-precision Machining

- Max. workpiece diameter 240 mm

- Max. workpiece length 245 mm

- Max. bar capacity diameter 67 mm

- Max. X-Axis 180 mm

- Max. Y-Axis 100 mm

- Max. Z-Axis 350 mm

WASINO JJ-1

- Space-saving 2-spindle 2-turret machine with high functionality and high precision

- Max. workpiece diameter 100 mm

- Max. workpiece length 100 mm

- Max. bar capacity diameter 45 mm

- Max. X-Axis 148 mm

- Max. Z-Axis 170 mm

NZX-S 1500

- Professional machine for small diameter shaft machining

- Max. workpiece diameter 120 mm

- Max. workpiece length 1,055 mm

- Max. X-Axis 60 mm

- Max. Z-Axis 1,100 mm

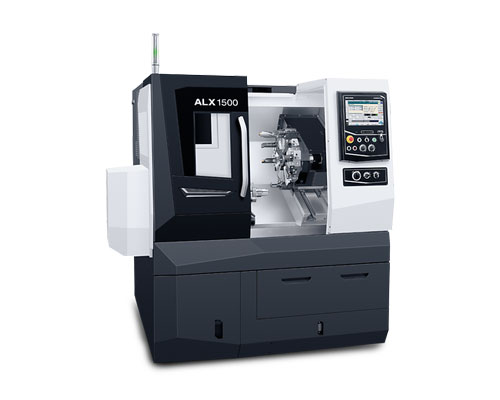

ALX 1500

- Base Machine for Automation for Every Shop Floor

- Max. workpiece diameter 440 mm

- Max. workpiece length 2,036 mm

- Max. bar capacity diameter 52 mm

- Max. X-Axis 260 mm

- Max. Y-Axis 100 mm

- Max. Z-Axis 2,075 mm

NRX 2000

- Ideal for mass-production of flange parts

- Max. workpiece diameter 180 mm

- Max. workpiece length 100 mm

- Max. X-Axis 100 mm

- Max. Z-Axis 220 mm

SPRINT 20|5

- Complete machining of workpieces measuring up to ø 20 à 600 mm in a footprint of under 2m²

- Max. workpiece diameter 20 mm

- Max. workpiece length 180 mm

- Max. bar capacity diameter 20 mm

- Max. X-Axis 50 mm

- Max. Y-Axis 325 mm

- Max. Z-Axis 60 mm

SPRINT 42 linear

- High speed automatic turning with linear drives for the highest precision

- Max. workpiece diameter 42 mm

- Max. workpiece length 320 mm

- Max. bar capacity diameter 42 mm

- Max. X-Axis 50 mm

- Max. Y-Axis 350 mm

- Max. Z-Axis 120 mm

SPRINT 50

- 4-axis production turning with 3 Y-axes, B-axis and 3 turrets for up to 36 driven tools for max diameter 65mm

- Max. workpiece diameter 140 mm

- Max. workpiece length 235 mm

- Max. bar capacity diameter 50 mm

- Max. X-Axis 165 mm

- Max. Y-Axis 70 mm

- Max. Z-Axis 235 mm

NZ DUE

- Two turrets with two 80 mm Y-axes and up to two B-axes. Free positioning of turrets on T1 - T4

- Max. workpiece length 1,290 mm

- Max. bar capacity diameter 72 mm

- Max. X-Axis 210 mm

- Max. Y-Axis 80 mm

- Max. Z-Axis 1,290 mm

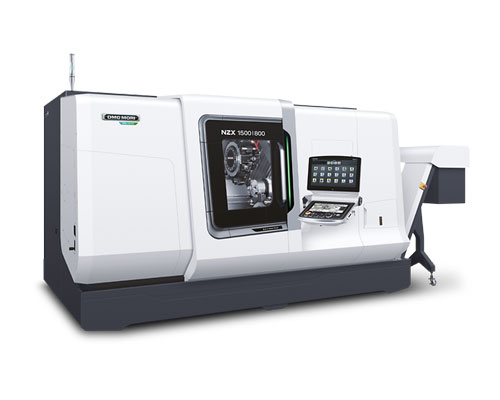

NZX 1500

- Precise Machining of High-performance Mass Production Parts

- Max. workpiece diameter 300 mm

- Max. workpiece length 810 mm

- Max. bar capacity diameter 52 mm

- Max. X-Axis 210 mm

- Max. Y-Axis 110 mm

- Max. Z-Axis 810 mm

NZX 6000

- Large-scale high-efficiency 4-axis turning center that achieves the ultimate in productivity with long and large diameter workpieces

- Max. workpiece diameter 900 mm

- Max. workpiece length 4,000 mm

- Max. X-Axis 485 mm

- Max. Y-Axis 200 mm

- Max. Z-Axis 4,150 mm

CTX beta 800 4A

- Compact high productive turning centre with TWIN-concept for 4 axes complete machining

- Max. workpiece diameter 340 mm

- Max. workpiece length 735 mm

- Max. bar capacity diameter 102 mm

- Max. X-Axis 300 mm

- Max. Y-Axis 120 mm

- Max. Z-Axis 800 mm

MULTISPRINT 36

- Top class flexibility thanks to MULTISPRINT modular system and Y-axes in every position

- Max. workpiece diameter 36 mm

- Max. workpiece length 170 mm

- Max. bar capacity diameter 36 mm

- Max. X-Axis 50 mm

- Max. Y-Axis 100 mm

- Max. Z-Axis 170 mm

Milling

- Milling machines are indispensable for industrial production. At DMG MORI, the world leading manufacturer of machine tools, not only will you find tailor-made milling machines but also an end-to-end solution designed to meet your needs along with our comprehensive range of services - and all this for the entire lifecycle of your machine. Our milling machines guarantee the highest standard of technology. So increase your productivity with machine tools from DMG MORI.

Our milling machines - the benefits for you

- Coverage of the entire range of CNC-controlled milling machines, from 3-axis to 5-axis machining

- Unique monoBLOCK / duoBLOCK design

- Machines in travelling column, portal and gantry models

- Milling heads and replacements available in vertical, A-axis, B-axis or angular formats

- The paths of x, y and z-axes up to 6,000mm for workpieces up to 120t Space-saving

- High-performance MASTER spindles with 3-year guarantee

- Compatible with working materials of all degrees of hardness

- Linear actuators with 5-year guarantee for optimal performance, the highest quality finish and the greatest long-term precision

- Optimal accessibility and visibility of the work area

DMG MORI - your milling machine partner

Our range encompasses both lathe machines and milling machines along with advanced technologies such as ULTRASONIC, LASERTEC and ADDITIVE MANUFACTURING and automated and integrated technological solutions. Among our numerous customers we work with businesses from the aerospace, automotive, die & mould and medical sectors.

We are active all over the world and offer you everything from a single source: machine tools both new and old, trainings programmes, accessories, maintenance and servicing and unique software solutions.Service benefits

- Round-the-clock hotline, 24 hours a day, 7 days a week

- Professional inspection by our highly qualified DMG MORI service technicians

- Complete servicing at regular intervals via maintenance checklist

Vertical milling machines

- Our vertical processing stations do everything possible to fulfil your requirements, no matter what kind of work pieces you wish to work on with the milling machine. This is possible thanks to our high-performance milling spindles, innovative cooling systems and tool systems in all conventional sizes as well as rapid tool changers for milling tools. High-tech controls by SIEMENS, HEIDENHAIN, MITSUBISHI and FANUC ensure that complex assignments can always be carried out with precision. With milling machines from DMG MORI, you are opting for a production solution of the very highest standard.

Series of vertical milling machines

- CMX V

- DMC V

- NVX

- NV/NVD

- i-Series

- MILLTAP

M1

- M1 – Designed for your profit!

- Max. X-Axis 550 mm

- Max. Y-Axis 550 mm

- Max. Z-Axis 510 mm

- Max. workpiece length 850 mm

- Max. workpiece width 650 mm

- Max. workpiece height 615 mm

- Max. workpiece weight 600 kg

CMX 600 V

- The solution-based CMX V - from now on with IoTconnector and direct measuring system in standard

- Max. X-Axis 600 mm

- Max. Y-Axis 560 mm

- Max. Z-Axis 510 mm

- Max. workpiece length 900 mm

- Max. workpiece width 560 mm

- Max. workpiece height 630 mm

- Max. workpiece weight 600 kg

DMV 115

- Vertical Machining Center for Workpieces up to 1,500 kg and large Y travel of 700 mm

- Max. X-Axis 1,150 mm

- Max. Y-Axis 700 mm

- Max. Z-Axis 550 mm

- Max. workpiece length 1,350 mm

- Max. workpiece width 750 mm

- Max. workpiece height 700 mm

- Max. workpiece weight 1,500 kg

DMC 650 V

- Vertical Machining Center for Workpieces up to 800 kg

- Max. X-Axis 650 mm

- Max. Y-Axis 520 mm

- Max. Z-Axis 475 mm

- Max. workpiece length 850 mm

- Max. workpiece width 570 mm

- Max. workpiece height 625 mm

- Max. workpiece weight 800 kg

NVX 5060 2nd Generation

- Best-ever high-precision vertical machining center

- Max. X-Axis 600 mm

- Max. Y-Axis 530 mm

- Max. Z-Axis 510 mm

- Max. workpiece length 900 mm

- Max. workpiece width 600 mm

- Max. workpiece height 510 mm

- Max. workpiece weight 800 kg

NV 4000 DCG

- Presenting the ideal vertical machining center

- Max. X-Axis 600 mm

- Max. Y-Axis 400 mm

- Max. Z-Axis 400 mm

- Max. workpiece length 750 mm

- Max. workpiece width 450 mm

- Max. workpiece height 400 mm

- Max. workpiece weight 350 kg

i 30 V

- Compact body full of high-performance features

- Max. X-Axis 400 mm

- Max. Y-Axis 270 mm

- Max. Z-Axis 280 mm

- Max. workpiece length 600 mm

- Max. workpiece width 300 mm

- Max. workpiece height 520 mm

- Max. workpiece weight 150 kg

DMP 35

- Vertical high speed machining center

- Max. X-Axis 350 mm

- Max. Y-Axis 420 mm

- Max. Z-Axis 380 mm

- Max. workpiece length 740 mm

- Max. workpiece width 420 mm

- Max. workpiece height 580 mm

- Max. workpiece weight 400 kg

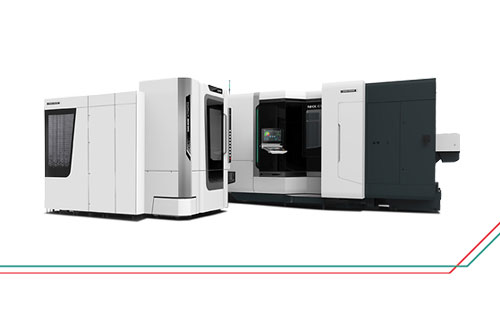

Horizontal Milling

- Do you require a milling machine for universal machining of various unit quantities? Do you use highly-automated serial production to manufacture your components? Do you need a high-speed solution with dynamic linear actuators? Or do you prefer to use a heavy-load model with a 1600Nm drive spindle? No matter what your production specialty is, with horizontal processing stations by DMG MORI, you will always find the right milling machine for your individual requirements. We are specialists in horizontal CNC-machining.

Series of Horizontal Milling Machines

- NHX

- NH

- i-Series

- DMC H linear

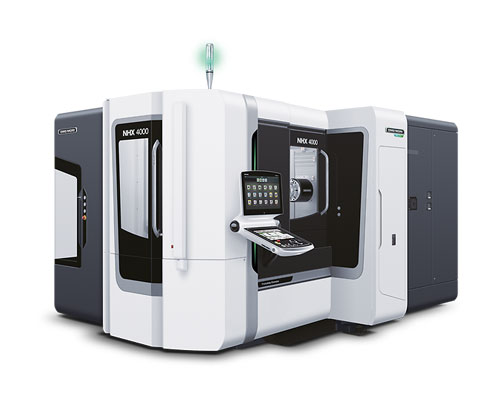

NHX 4000

- Horizontal machining center with highest stability, precision and dynamics

- Max. X-Axis 560 mm

- Max. Y-Axis 560 mm

- Max. Z-Axis 660 mm

- Max. workpiece diameter 630 mm

- Max. workpiece height 900 mm

- Max. workpiece weight 400 kg

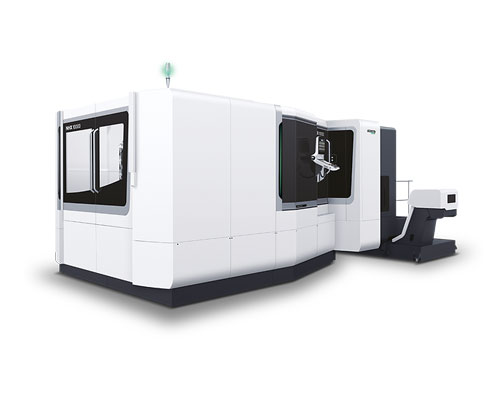

NHX 10000

- Expert on machining of large and difficult-to-cut workpieces

- Max. X-Axis 1,700 mm

- Max. Y-Axis 1,400 mm

- Max. Z-Axis 1,510 mm

- Max. workpiece diameter 2,000 mm

- Max. workpiece height 1,600 mm

- Max. workpiece weight 3,000 kg

NH 4000 DCG

- Presenting the ideal machining center

- Max. X-Axis 560 mm

- Max. Y-Axis 560 mm

- Max. Z-Axis 630 mm

- Max. workpiece diameter 630 mm

- Max. workpiece height 900 mm

- Max. workpiece weight 400 kg

i 50

- Optimum for mass production machining of cylinder heads and cylinder blocks

- Max. X-Axis 500 mm

- Max. Y-Axis 550 mm

- Max. Z-Axis 500 mm

- Max. workpiece diameter 620 mm

- Max. workpiece height 700 mm Max. workpiece weight 400 kg

DMC 60 H linear

- The DMC H linear- line offers a wide area of operations

- Max. X-Axis 630 mm

- Max. Y-Axis 800 mm

- Max. Z-Axis 850 mm

- Max. workpiece diameter 800 mm

- Max. workpiece height 1,030 mm

- Max. workpiece weight 600 kg

DMU 65 H monoBLOCK

- Evolution in universal machining. Flexible, productive and process-safe.

- Max. X-Axis 650 mm

- Max. Y-Axis 950 mm

- Max. Z-Axis 700 mm

- Max. workpiece diameter 840 mm

- Max. workpiece height 770 mm

- Max. workpiece weight 600 kg

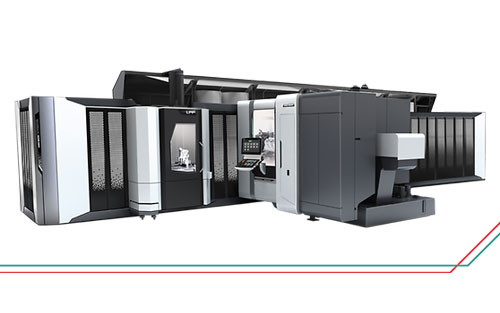

5-Axis Milling

- As world market leader in 5-axis milling machines, we offer you the whole range of universal milling machines. Volumetric precision to within 15µm, work pieces weighing up to 120t or machining paths up to 6 metres - with our 5-axis milling machines, anything is possible. Our universal machining stations with automated features, such as the palette changer or the workpiece management system bring together maximum versatility, high-performance cutting dynamic precision and optimal accessibility. From automated 5-side machining up to challenging 5-axis simultaneous milling - with 5-axis milling machines from DMG MORI you are in the safest of hands.

Series of 5-Axis Milling Machines

- CMX U

- DMU

- NMV

- DMU monoBLOCK

- DMC monoBLOCK

- DMU eVO

- HSC linear

- DMF

- DMU duoBLOCK

- DMC duoBLOCK

- DMU Portal

- DMC Portal

- DMU Gantry

CMX 50 U

- The solution for 5-sided machining - from now on with direct measuring system and IoTconnector in standard

- Max. X-Axis 500 mm

- Max. Y-Axis 450 mm

- Max. Z-Axis 400 mm

- Max. workpiece diameter 630 mm

- Max. workpiece height 550 mm

- Max. workpiece weight 200 kg

DMU 50

- Universal Milling Machine

- Max. X-Axis 500 mm

- Max. Y-Axis 450 mm

- Max. Z-Axis 400 mm

- Max. workpiece diameter 630 mm

- Max. workpiece height 500 mm

- Max. workpiece weight 300 kg

NMV 3000 DCG

- High-precision, 5-axis control vertical machining center that uses DDM on rotary axes

- Max. X-Axis 500 mm

- Max. Y-Axis 350 mm

- Max. Z-Axis 510 mm

- Max. workpiece diameter 350 mm

- Max. workpiece height 300 mm

- Max. workpiece weight 100 kg

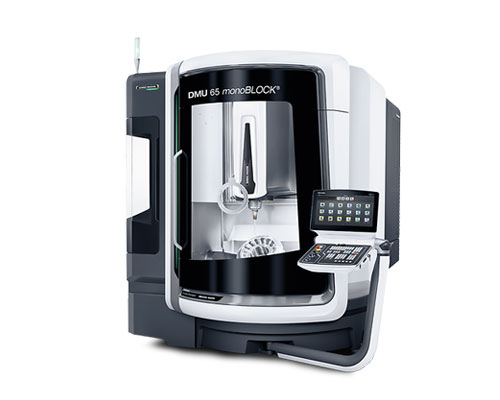

DMU 65 monoBLOCK

- The monoBLOCK series has a machine concept for every sector

- Max. X-Axis 735 mm

- Max. Y-Axis 650 mm

- Max. Z-Axis 560 mm

- Max. workpiece diameter 840 mm

- Max. workpiece height 500 mm

- Max. workpiece weight 1,000 kg

DMU 40 eVo linear

- Universal Machining Center

- Max. X-Axis 400 mm

- Max. Y-Axis 400 mm

- Max. Z-Axis 375 mm

- Max. workpiece diameter 450 mm

- Max. workpiece height 460 mm

- Max. workpiece weight 250 kg

HSC 20 linear

- Compact, precise, process reliable with >2 g acceleration and spindle speeds up to 60,000 1/min

- Max. X-Axis 200 mm

- Max. Y-Axis 220 mm

- Max. Z-Axis 280 mm

- Max. workpiece diameter 200 mm

- Max. workpiece height 200 mm

- Max. workpiece weight 100 kg

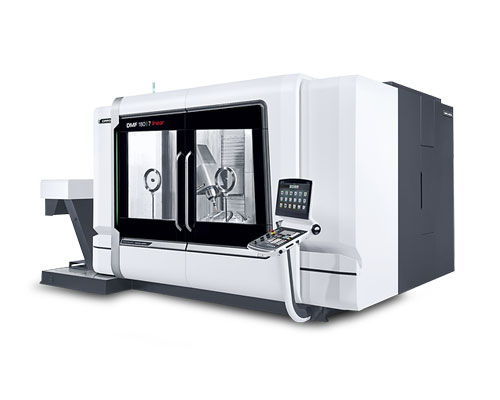

DMF 180 linear

- Travelling column machine with B-axis for highest flexibility and productivity

- Max. X-Axis 1,800 mm

- Max. Y-Axis 700 mm

- Max. Z-Axis 700 mm

- Max. workpiece length 2,100 mm

- Max. workpiece width 700 mm

- Max. workpiece diameter 750 mm

- Max. workpiece height 715 mm

- Max. workpiece weight 1,500 kg

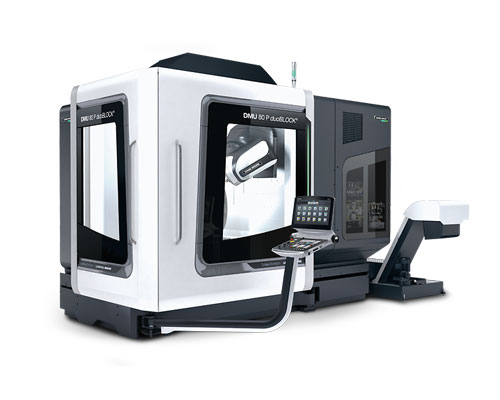

DMU 80 P duoBLOCK

- With the new duoBLOCK series, every component becomes a masterpiece.

- Max. X-Axis 800 mm

- Max. Y-Axis 1,050 mm

- Max. Z-Axis 850 mm

- Max. workpiece diameter 950 mm

- Max. workpiece height 1,450 mm

- Max. workpiece weight 1,800 kg

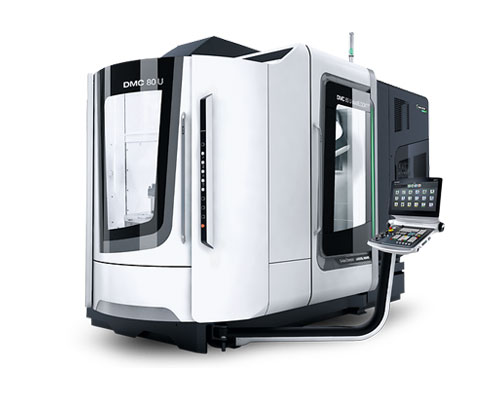

DMC 80 U duoBLOCK

- With the new duoBLOCK series, every component becomes a masterpiece.

- Max. X-Axis 800 mm

- Max. Y-Axis 1,050 mm

- Max. Z-Axis 850 mm

- Max. workpiece diameter 900 mm

- Max. workpiece height 1,450 mm

- Max. workpiece weight 1,400 kg

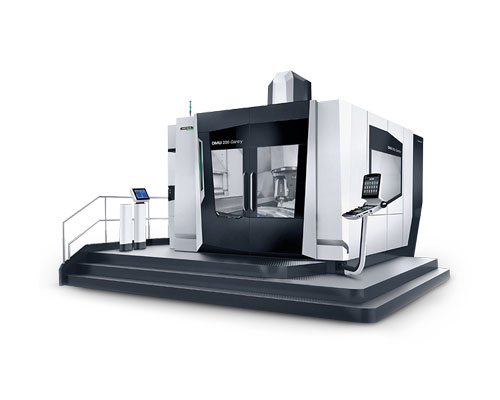

DMU 200 Gantry

- Dynamic Gantry design machine for the machining of large workpieces

- Max. X-Axis 4,000 mm

- Max. Y-Axis 2,000 mm

- Max. Z-Axis 1,200 mm

- Max. workpiece length 4,300 mm

- Max. workpiece width 2,000 mm

- Max. workpiece height 1,250 mm

- Max. workpiece weight 20,000 kg

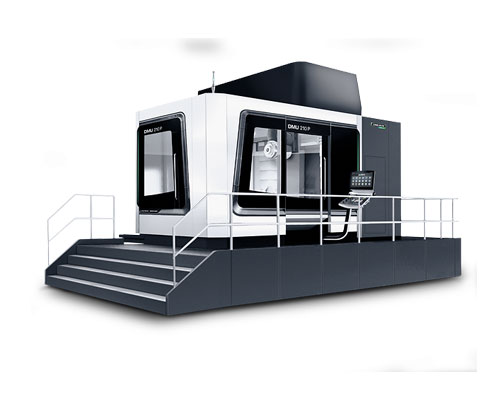

DMU 210 P

- The portal series from DECKEL MAHO – more than 1,000 machines installed.

- Max. X-Axis 2,100 mm

- Max. Y-Axis 2,100 mm

- Max. Z-Axis 1,250 mm

- Max. workpiece diameter 2,500 mm

- Max. workpiece height 1,460 mm

- Max. workpiece weight 8,000 kg

DMC 210 U

- The portal series from DECKEL MAHO – more than 1,000 machines installed.

- Max. X-Axis 2,100 mm

- Max. Y-Axis 2,100 mm

- Max. Z-Axis 1,250 mm

- Max. workpiece diameter 2,500 mm

- Max. workpiece height 1,460 mm

- Max. workpiece weight 6,000 kg

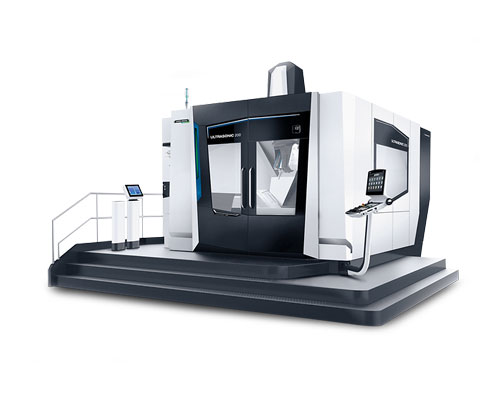

Ultrasonic

ULTRASONIC 20 linear

- Compact, precise, process reliable with <2 g acceleration and spindle speeds up to 60.000 1/min

- Max. X-Axis 200 mm

- Max. Y-Axis 220 mm

- Max. Z-Axis 280 mm

- Max. workpiece diameter 200 mm

- Max. workpiece height 200 mm

- Max. workpiece weight 100 kg

ULTRASONIC 50

- Your perfect entry into 5-axis ULTRASONIC machining

- Max. X-Axis 650 mm

- Max. Y-Axis 520 mm

- Max. Z-Axis 475 mm

- Max. workpiece diameter 630 mm

- Max. workpiece height 350 mm

- Max. workpiece weight 300 kg

ULTRASONIC 65

- ULTRASONIC machining centre in reliable monoBLOCK design

- Max. X-Axis 735 mm

- Max. Y-Axis 650 mm

- Max. Z-Axis 560 mm

- Max. workpiece diameter 840 mm

- Max. workpiece height 500 mm

- Max. workpiece weight 1,000 kg

ULTRASONIC 40 eVo linear

- Universal ULTRASONIC Machining Centre

- Max. X-Axis 400 mm

- Max. Y-Axis 400 mm

- Max. Z-Axis 375 mm

- Max. workpiece diameter 480 mm

- Max. workpiece height 460 mm

- Max. workpiece weight 250 kg

ULTRASONIC 60 eVo linear

- Universal ULTRASONIC Machining Centre

- Max. X-Axis 600 mm

- Max. Y-Axis 500 mm

- Max. Z-Axis 500 mm

- Max. workpiece diameter 630 mm

- Max. workpiece height 500 mm

- Max. workpiece weight 400 kg

ULTRASONIC 200 Gantry

- 5-axis ULTRASONIC machining in XXL

- Max. X-Axis 4,000 mm

- Max. Y-Axis 2,000 mm

- Max. Z-Axis 1,200 mm

- Max. workpiece length 4,300 mm

- Max. workpiece width 2,000 mm

- Max. workpiece height 1,250 mm

- Max. workpiece weight 20,000 kg

LASERTEC

LASERTEC 45 Shape

- High precision 3D laser ablation and texturing in a new dimension

- Max. X-Axis 700 mm

- Max. Y-Axis 420 mm

- Max. Z-Axis 485 mm

LASERTEC 50 Shape Femto

- Generation of high-end surfaces in high-performance materials up to Ra <0.1 µm with femtosecond laser

- Max. X-Axis 500 mm

- Max. Y-Axis 500 mm

- Max. Z-Axis 700 mm

LASERTEC 50 PowerDrill

- Highly dynamic 5-axis laser precision machine with linear drives

- Max. X-Axis 500 mm

- Max. Y-Axis 500 mm

- Max. Z-Axis 700 mm

LASERTEC 20 PrecisionTool

- Diamond tool machining with up to 3 mm / min and up to 56% lower costs per part compared to eroding

- Max. X-Axis 200 mm

- Max. Y-Axis 400 mm

- Max. Z-Axis 280 mm

LASERTEC 50 PrecisionTool

- Take advantage of the unique quality and machining advantages for tools up to à 355 mm!

- Max. X-Axis 500 mm

- Max. Y-Axis 500 mm

- Max. Z-Axis 700 mm

Additive Manufacturing

- As a global full-liner with over 20 years of experience in the ADDITIVE MANUFACTURING of metal parts, DMG MORI represents innovative manufacturing technologies and a worldwide service. The portfolio includes four complete process chains for additive processes using powder nozzle or powder bed technologies. For this integral offer DMG MORI combines its LASERTEC SLM models and the LASERTEC DED series with the machining centres from its broadly diversified machine portfolio.

Complementary we provide a DMQP Powder Cycle within a wide powder portfolio including the related machining parameter set and validation for LASERTEC SLM machines. The DMQP Powder Cycle allows an easy and fast powder ordering and reordering via our Online Shop as well as powder returning and recycling.

DMG MORI has performed successfully on the market since 2013 with the combination of laser deposition welding and metal-cutting machining on the machines of the LASERTEC DED hybrid series. While the LASERTEC 65 DED is geared solely towards laser deposition welding as a complement to existing machining centres on the shop floor, the LASERTEC SLM series expands the portfolio to include the powder bed method using selective laser melting. Thanks to the combination of additive manufacturing technologies with conventional CNC machines DMG MORI has realised four individual needs-based process chains. The integral software solution for CAM programming and machine control CELOS rounds off the process chains with the LASERTEC SLM series.

LASERTEC 65 DED

- Uncompromising 5-axis buildup of additive parts by powder nozzle

- Max. X-Axis 735 mm

- Max. Y-Axis 650 mm

- Max. Z-Axis 560 mm

- Laser power standard 2,500 W

- Max. workpiece weight 600 kg

LASERTEC 65 DED hybrid

- Hybrid Complete Machining: Additive Manufacturing and Milling in one Machine

- Max. X-Axis 735 mm

- Max. Y-Axis 650 mm

- Max. Z-Axis 560 mm

- Laser power standard 3,000 W

- Max. workpiece weight 600 kg

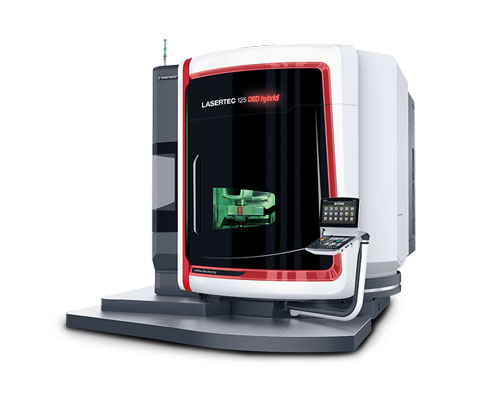

LASERTEC 125 DED hybrid

- Directed energy deposition combined with 5-axis milling, for building and repairing of high-value metal parts

- Max. X-Axis 1,335 mm

- Max. Y-Axis 1,250 mm

- Max. Z-Axis 900 mm

- Laser power standard 3,000 W

- Max. workpiece weight 2,000 kg

LASERTEC 12 SLM

- dditive Manufacturing by selective laser melting (SLM)

- Max. X-Axis 125 mm

- Max. Y-Axis 125 mm

- Max. Z-Axis 200 mm

- Min. Layer thickness 20 µm

- Min. Focus diameter 35 µm

- Laser power standard 200 W

- Max. workpiece weight 50 kg

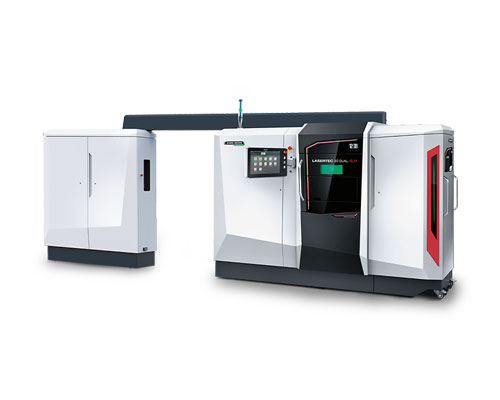

LASERTEC 30 DUAL SLM

- Additive Manufacturing by selective laser melting (SLM)

- Max. X-Axis 300 mm

- Max. Y-Axis 300 mm

- Max. Z-Axis 300 mm

- Min. Layer thickness 20 µm

- Min. Focus diameter 50 µm

- Laser power standard 600 W

- Max. workpiece weight 200 kg

Grinding

Vertical Grinding

Vertical Mate Series

- CNC Vertical Multi-Process Grinding Machine

We have successfully created highly cost-effective machine, Vertical Mate Series, by achieving simple design and reasonable price. It focused on basic performance, nevertheless its multi-processing capability and high accuracy of grinding ID, OD and face remains the same.

Highlights- TAIYO KOKI's best-selling model

- General-purpose machine with simple & optimized structure

- Grinding ID, OD and face by one-time chucking

Technical Data- Swing diameter 1,250 mm

- Max. grinding diameter 1,200 mm

- Max. workpiece height 600 mm

- Max. grinding length 500 mm

- Max. spindle speed work spindle 500 rpm

- Max. spindle speed grinding spindle 18,000 rpm

Control & Software- FANUC 32i MODEL B

CVG Series

- CNC Vertical Multi-Process Grinding Machine

Compilation model which realizes further productivity improvement, by standardizing APC (Auto. Pallet Change) system in addition to the advantages of vertical grinding machine such as high accuracy, process aggregation and workability improvement. Reducing non-grinding time and dramatically improving production capacity are enabled by employing APC as standard. Also, wheelhead with continuous indexing function and Direct Drive motor on work spindle (option) allows continuous grinding of taper and aribtrary profile grinding such as curvic coupling and cam shapes, etc.

Highlights- Productivity improvement with Auto. Pallet Change system

- Process innovation enabled by multi-grinding capability

- Work spindle DD motor spec for arbitrary profile grinding

Technical Data- Swing diameter 1,350 mm

- Max. grinding diameter 1,300 mm

- Max. workpiece height 700 mm

- Max. grinding length 600 mm

- Max. spindle speed work spindle 350 rpm

- Max. spindle speed grinding spindle 9,000 rpm

IGV Series

- CNC Vertical Internal / External Grinding Machine

This is a compact model specialized in high-accuracy, high-efficiency grinding of small/middle mass-produced parts, and provides optimal options to meet various market needs. Lineup of this series includes single spindle type for internal or external grinding, and also multi-process type with 2 spindles on a turret. Automation systems are also available as options such as robot, loader, stocker, etc. in pursuit of productivity in a compact installation space.

Highlights- Compact model suitable for mass-produced parts, and flexible for various market needs with extensive options.

Technical Data- Swing diameter 380 mm

- Max. grinding diameter 300 mm

- Max. workpiece height 300 mm

- Max. grinding length 150 mm

- Max. spindle speed work spindle 2,000 rpm

- Max. spindle speed grinding spindle 75,000 rpm

Control & Software- FANUC Series 32i MODEL B

- FANUC Series 0i-TF Plus

PGV Series

- High-production CNC Vertical Grinding Machine

Next-generation model of vertical grinding machine which employed ACC (Automatic Chuck Change) system pursuing productivity to the max. Work loading/unloading station and grinding station are equipped as standard, which allows work change and set-up without stopping grinding operation. It significantly reduces non-grinding time and dramatically improves production ratio.

Highlights- Productivity improvement with Auto. Chuck Change system

- Suitable for mass production of small parts

- Reducing more cycle time by gang-tooling spec

Technical Data- Swing diameter 250 mm

- Max. grinding diameter 200 mm

- Max. workpiece height 200 mm

- Max. grinding length 200 mm

- Max. spindle speed work spindle 1,500 rpm

- Max. spindle speed grinding spindle 45,000 rpm

Control & Software- FANUC 32i MODEL B

NVGH Series

- CNC Vertical Multi-Process Grinding Machine

NVGH series is the highest spec model among Taiyo Koki’s vertical grinding machines adopting high-rigidity structure for the main parts such as bed, table, grinding spindle and work spindle.

It fulfills a wide range of customer needs by customization and automation, and contributes to various industries with its high-accuracy grinding performance.

Highlights- Powerful grinding with high accuracy by high-rigidity grinding spindle

- Hard turning function (option) for cycle time reduction

- Work spindle C-axis spec (option) for non-round grinding

Technical Data- Swing diameter 2,250 mm

- Max. grinding diameter 2,200 mm

- Max. workpiece height 700 mm

- Max. grinding length 600 mm

- Max. spindle speed work spindle 800 rpm

- Max. spindle speed grinding spindle 20,000 rpm

Conventional Machines // Education

- With the manual machines FP 4 M Special Edition and the NEF 360 LZ you are optimally prepared for a wide range of manufacturing requirements, for example in your maintenance and repair workshop. Even employees without programming skills are quickly trained and achieve the best results. In addition, these machines are ideal for basic training.

Education 4.0 – interactive, digital and future-proof: Use our exclusive complete packages with the universal lathe CTX alpha 500 and the 5-axis bestseller DMU 50! You can connect all machines in a digital learning environment. Data can be visualized and interactive training in the classroom becomes real.

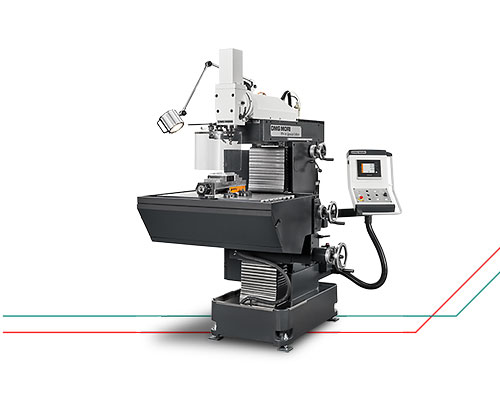

FP 4 M Special Edition

- The Conventional Milling Machine for Training and Manufacturin

Highlights- Tried-and-tested concept with over 10,000 installations

- Maximum precision and stability

- Customised to meet specific training requirements

- Small footprint – integrated switch cabinet means minimum space requirement

- Ergonomic handwheel positioning for maximum operating comfort

Technical Specifications- Workspace (X/Y/Z) 500 / 400 / 400 mm

- Rigid fixed table clamping 800 x 480 mm

- Spindle drive 25 – 3,000 rpm infinitely variable with data input at counter

- Regulated AC drive 6 – 7 kW

- Vertical head swivel-mounted head +/- 90° (180°)

- Linear axes feed range 6-500 mm/min Rapid traverse 1,500 mm/min

- Space requirement approx. 2,235 x 1,875 mm

- Machine weight approx. 1,600 kg with table and milling head

Control- Heidenhain digital display ND7013

A classic is back! DMG MORI’s state-of-the-art design coupled with timeless and top all-round performance makes the FP 4 M Special Edition the ideal milling machine for manufacturing and training.

NEF 360 LZ

- Ideal for training and conventional manufacturing

Highlights- Powerful center lathe in toolmaker accuracy in accordance with DIN 8605

- Equipment that is universally deployable in any workshop

- Infinitely variable speed and feed entry via the DMG MORI position display Intuitive operation

- Main spindle bearing with belt pull relief for highest precision

- Comprehensive range of safety equipment

- High-quality apron with drop worm Made in Germany

Technical Data

Workspace- Swing over bed 360 mm

- Swing over cross slide 195 mm

- Distance between centers DIN 806 800 mm

- Turning length 800 mm

- Width of bed 260 mm

Work spindle- Spindle head DIN 55027 (standard) Size 5

Tool slide- Tool system Size „B“

Tailstock with hand-wheel- Stroke of quill 110 mm

- Diameter of quill 50 mm

- Taper DIN 228 MK 3

Drive- Speed range Up to 4000 rpm

DMG MORI POSITION DISPLAY- 17" operating panel with color screen

New at DMG MORI: The center lathe NEF 360 LZ! Due to the comfortable equipment and highest precision it is perfect for training purposes and universally deployable in any workshop.

Education Projects

- Turnkey solutions – for educational institutions and training workshops. Future-oriented CNC Training at top industry standards is an essential factor for the economic development of a country. Therefore the DMG MORI Academy supports educational institutions with innovative concepts, products and services: from the machine tool through software solutions, to teaching aids. With our know-how from equipping more than 1,000 schools in Germany, you allow your scholars and students to enjoy training according to German standards.

- Training concepts according to German standards by a worldwide leading manufacturer of cutting machine tools

- Comprehensive training of teachers with intensive “train-the-trainer” modules

- Holistic consultation as well as competent planning and implementation of your training centre

- Training documentation and basic curricular adapted to your requirements – proven 1,000-fold in practice in Germany

- Industry 4.0 education packages for future-oriented training

Industry 4.0 education packages: CTX alpha 500 und DMU 50 2nd generation

Benefit from our exclusive complete packages at an attractive special price for training workshops in industrial companies, educational institutions and schools! Including: Universal lathe CTX alpha 500 and / or 5-axis milling machine DMU 50 2nd generation with extensive equipment, CELOS for Industry 4.0 applications, training courses, programming and training software, DMG MORI TrainingBox with teaching mater

Automation

DMG MORI Automation ex-works

Workpiece and pallet handling

Besides optimized standard solutions the automation portfolio of DMG MORI includes customised, fully-integrated solutions. Almost all DMG MORI machines can be equipped with standard automation or with a customised automation solution.

Automation Portfolio- Flexible solutions for workpiece and pallet handling

- Easy adaption to your workpiece

- Optimally adjusted and already tested in the plants

- Standardised, function orientated modules

- Integrated user interface

- Turnkey solutions

Workpiece handling - Gantry Loader

GX / GX T

- Flexible gantry loader for increased productivity

Highlights GX 3 / GX 5 / GX 6 / GX 7 / GX 15 / GX 5 T / GX 10 T / GX 15 T- Handling of workpieces up to ø 200 mm, a length of 150 mm and a weight up to 10 kg

- Compact, space saving with built-in loader

- Combinable with various kinds of automatic peripheral equipment (washing, measuring, marking etc.) and grippers available by flexible design

- Easy programming and setup due to integration into the machine control

- Loader status monitoring available via DMG MORI Messenger

- Easily expandable for two or more machines

- Optional up to 100 kg handling weight available

SR

- Flexible gantry loader for WASINO-machines

Highlights- Handling of workpieces up to ø 50 mm, a length of 40 mm and a weight up to 1 kg

- Compact, space saving with a fully included automation

- Combinable with various kinds of automatic peripheral equipment (washing, measuring marking etc.) and grippers available by flexible design

- Easy programming and setup due to integration into the machine NC control

- Loader status monitoring available via DMG MORI Messenger

Workpiece Handling - Robot

Robo2Go 2nd Generation

- Flexible, modular robot automation

Highlights- Dialog-driven programming

- Creation of the process using predefined program blocks via drag & drop

- No robot programming knowledge required

- Operation integrated into the machine control via CELOS APP

- No need to adapt your NC programs

- Collision-proof: robot with integrated shutdown function (MPC)

- Simple retraction and system setup via home function

- Full accessibility to the machine is maintained

WH

- Highlights WH Series

- Flexible solution for turning and milling machines

- Comprises several variants WH Cell (side-by-side solution in a encapsuled cell)

- WH Top (top loading robot)

- WH Front (front loading robot)

- WH Flex (flexible handling solution for loading of several machines with workpieces, pallets and tools)

- Handling of workpieces up to a length of 300 mm, a width of 300 mm, a height of 220 mm and a weight up to 25 kg for WH Cell

- Robots, grippers, workpiece logistics, housing and further options make your automation perfectly aligned to your machine and process chain

- Virtual commissioning by the digital twin reduces commissioning time on site by 60 %

IMTR

- Flexible modular robot-system

Highlights- Loading and unloading by robot

- Compact robot system with maximum use of space

- Different storage types

MATRIS

- Flexible robot modular system for increased productivity

Highlights- Handling of workpieces up to ø 150 mm, a length of 120 mm and a weight up to 20 kg

- Combinable with various kinds of standardized automatic peripheral equipment (i. e. washing, measuring marking etc.)

- Grippers available by flexible design

- Enable to start mass production quickly by patternization of robot program and teaching

- Easy maintenance and operations due to modular setup and MAPPS connected

- Loading of oversized tooling in case of vertical machining center

Pallet Handling - Round Storage System

PH

- Pallet handling system by DMG MORI

PH Cell- Best ergonomics and accessibility to the working area due to side loading

- Modular automation concept with up to 40 storage locations

- Handling of different pallet sizes in one system - 320 x 320; 400 x 400 and 500 x 500 mm

- Up to 300 kg transfer weight (workpiece incl. pallet)

- Subsequent expandability of the second shelf module

- Separate set-up station for ergonomic and parallel rusting of the pallets

- Attractively priced automation in DMG MORI VERTICO design

AWC

- Large capacity automatic workpiece changer with smallest foot print

Highlights- Handling of workpieces up to ø 350 mm, a length of 300 mm and a weight up to 80 kg

- Easy programming and setup due to integration into the machine control Space saving, compact solution by multi layer storage (1,595 Ã 2,340 mm)

- Accessibility of all operational areas (work setting, control, machining area and tool magazine) from front side of machine

- Easy operation using machine controller of machine center to handle automation

RPS

- Machine integrated automation for smallest foot prints

Highlights RPS 3 / RPS 4 / RPS 5 / RPS 6 / RPS 7 / RPS 9 / RPS 12- Handling of workpieces up to ø 3,400 mm, a length of 1,650 m and a weight up to 10,000 kg

- Reduction of auxiliary process time through loading and unloading during machining

- Manless shifts for recurring workpieces through ring buffer with max. 12 pallets in the system

Pallet Handling - Linear Storage System

CPP

- Entry option for a flexible pallet handling solution

Highlights- Handling of workpieces up to ø 2,000 mm, a length of 1,600 mm and a weight up to 3,000 kg

- 1 layer pallet pool solution in multiple possible setups for automated, unmanned operation fit to the customers facility:

- straight line arrangement (S) or right-angle arrangement (R)

- Up to 29 pallets and 2 work setup stations / up to 4 machining center (on request)

- Easy operation using machine controller of machine center with Pallet Manager

- Combination with various kinds of options

PH‑AGV

- Pallet automation with maximum of flexibility

Highlights- Flexible automation concept

- Free access to the machine

- Simple extension with additional machines

- Maximum safety due to laser scanners

- Transportation of machine and material pallets

LPP

- Superior and advanced high-productivity system

Highlights- Handling of workpieces up to ø 3,400 mm, a length of 2,000 mm and a weight up to 10,000 kg

- Most flexible, multi-layer pallet pool system with up to 8 machines, 99 pallets and 5 setup stations (10 machines and 199 pallets possible on request)

- Handling of up to 3 different sizes of pallets possible in one system (2 sizes machine pallets, 1 size material pallet)

- 2 different levels (Standard, Advanced) of cell controller available

- Monitoring and management tools for all relevant areas (scheduling, parts, workhold, tooling etc.)

- Integration in customer network / workflow possible

- Option for tool management

Digitization

Integrated Digitazion

- From the CELOS Machine and CELOS Manufacturing to the Digital Factory

DMG MORI is a trailblazer in the field of digitalisation for machine tool engineering. Under the keyword Integrated Digitization, DMG MORI provides software products and solutions for planning, preparation and production, as well as monitoring, maintenance and servicing. Always from the CELOS Machine to CELOS Manufacturing to the Digital Factory.

Digital Manufacturing Package

Highlights

1. DMG MORI Connectivity: Free as standard in all new DMG MORI machines

2. CELOS Update: PLC-independent from any previous CELOS version

3. DMG MORI MESSENGER: With individually configurable dashboard

4. my DMG MORI – Customer Portal: For consistent service optimization

5. NETservice: For direct remote communication with the DMG MORI service

CELOS Machine & Manufacturing

- Integrated digitization of the DMG MORI machines & the shop floor

CELOS was developed by DMG MORI in 2013 and supports DMG MORI customers in integrated digitization. Center of the "CELOS Machine" is the APP-based user interface, which enables access to all production-relevant information via the control system. Under the keyword "CELOS Manufacturing", a total of 27 CELOS APPs allows optimal preparation as well as fast and consistent processing of production orders.

CELOS is available for DMG MORI machines with controls from Siemens, Heidenhain and MAPPs. The supplementary CELOS PC-Version also enables consistently digitized processes from work preparation to the DMG MORI machine with CELOS.

CELOS UPDATE

With the latest CELOS version, customers for the first time have the option of integrating all existing systems directly into CELOS at the machine (Application Connector). With the new job import function of the Job Manager, orders can be transferred completely automatically from the existing MES or ERP directly into CELOS.

CELOS Update

Highlights- Update possible from any existing CELOS version since 2013

- PLC independent & without data loss

- New APPs since 2019: Application Connector, job import function in the Job Manager, TULIP Player, optimized Messenger, my DMG MORI, Power Probe for Renishaw probes (optional APP)

TULIP – Easy way to paperless production

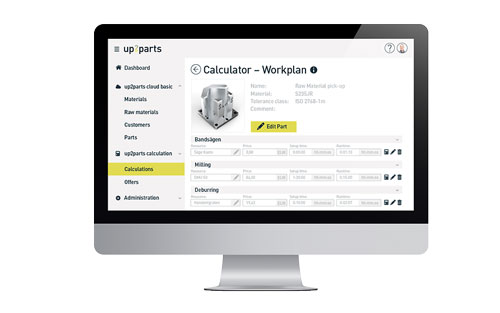

- Simplify Manufacturing with up2parts

Create calculations & quotations in seconds, increase efficiency and reduce costs:

Increase the competitiveness of your manufacturing business with up2parts- up2parts calculation - Calculate up to 80% faster and create a quotation with just two clicks.

- up2parts cloud basic - Digitally map your manufacturing business with unlimited storage space

Simplify Manufacturing with up2parts

- Create calculations "ations in seconds, increase efficiency and reduce costs:

Increase the competitiveness of your manufacturing business with up2parts- up2parts calculation - Calculate up to 80% faster and create a quotation with just two clicks.

- up2parts cloud basic - Digitally map your manufacturing business with unlimited storage space

Digital Manufacturing Package

- DMG MORI offers existing customers the Digital Manufacturing Package for simple and fast entry into digitisation with five coordinated products.

DMG MORI Connectivity-

DMG MORI Connectivity

Networking of DMG MORI machines & selected third-party products -

CELOS UPDATE

PLC-independent update to the latest CELOS version -

DMG MORI MESSENGER

Current status of networked machines at a glance -

my DMG MORI – Customer Portal

End-to-end service optimisation for DMG MORI machines -

DMG MORI NETservice

Direct remote communication with DMG MORI Service

-

DMG MORI Connectivity

DMG MORI STORE powered by ADAMOS

- Central and convenient access to the world of data-based services and digital business models from DMG MORI.

- Single sign-on concept: uniform login to DMG MORI STORE, my DMG MORI customer portal and selectable partner applications

- Central administration: simple management of data, applications, licenses and users