WMS

- Offer Profile

- The range of services provided by Werkzeugmaschinenbau Sinsheim GmbH covers all upkeep work, maintenance, servicing, repairs, modernisation, deliveries of spare parts and a whole range of special tasks, including finalising machining technology and accompanying production. Services range from preventative maintenance for individual machines to assuming complete responsibility for the upkeep of the customer machinery through maintenance contracts.

Product Portfolio

Service

Service hotline

-

Our service hotline for fast technical assistance in the event of a problem is occupied 365 days a year, and in line with our “one face to the customer” policy is always the right contact for you, whether your concern is coordination of operations or spare parts orders! Our hotline team coordinates your concern and passes it on

promptly to the service staff responsible, who will then provide competent feedback.

Your benefit:

ONE contact you can rely on!!!

We have a service hotline which is always available even at weekends and on national holidays, since our customers’ machines are usually in 2 or 3-shift operation on up to 7 days a week.

The remote service is a further important step for increasing your productivity and the availability of your machines. The Siemens control units used permit the use of remote diagnosis and remote service to diagnose problems as well as direct intervention as if we were on the premises. It allows both machine problems and pure application difficulties with the programming of CNC programs to be recognised and eliminated. This use of remote diagnosis allows service operations to be planned and carried out faster and much more efficiently, and sometimes to be avoided completely.

Service & maintenance

-

We turn every product into a reference.

Tooling machines are used in a wide range of different fields – from the automotive industry through machine, mould and plant engineering, turbine and tool construction, the aviation industry through to job order production.

WMS basic maintenance service + remote service & more Regular maintenance pays off. Internal studies have shown that regular servicing and maintenance work is a sensible mid- and long-term investment. If this work is done carelessly or not at all, it usually results in significantly higher follow-on costs caused by quality problems and unplanned machine downtimes, for example. We schedule all the maintenance intervals we plan together for you. Thanks to these regular “check-ups” unpleasant incidents can be avoided to a major extent and machine availability is increased. Production takes place with usual reliability.

Downtimes and follow-on costs are minimised; your productivity increases.

A plus in reliability in your production department. We have a maintenance service to match every tooling machine. Your individual manufacturing intensity defines the demands made on our service. If the measures defined in the inspection documents should become necessary earlier than planned, you are free to commission these at any time, of course. Flexibility is our motto.

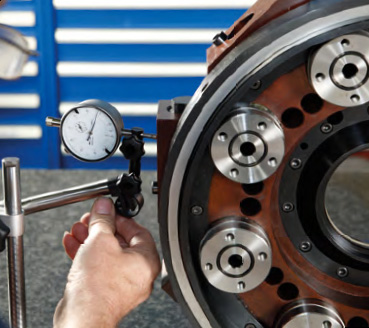

We check the following for you:- Main drive, milling head and milling spindle

- Function of the complete machine

- Head offset dimensions

- Safety equipment

- Geometry settings on the complete machine

- Chip conveyor

- Hydraulic system

- Chip scraper

- Steel covers

- Tool changer

Maintaining availability is the most important objective for ongoing production. To avoid machine failure and increase availability, we offer the possibility of establishing the machine’s current state in the context of an inspection. All the necessary reconditioning or modification measures are listed in an inspection report which also includes a plan of action with quotation. In our experience, maintenance should be carried out at least once a year to guarantee availability at all times. We will be happy to agree on cost-effective, flat-rate inspection and maintenance intervals with you.

Process optimization

-

Maximum productivity is required for metal-cutting machine tools. This productivity is limited by the capacity of the drives installed and the tools and cutting materials used as well as by the dynamic flexibility of the machine systems.

Following commissioning and production preparation, machine manufacturers and users are often confronted with the problem of not being able to implement planned machining capacities on account of instable processes. This problem often leads to long and uneconomical start-up periods for industrial series production processes, since comprehensive series of tests are necessary to determine process-reliable and efficient production conditions. Consequently, instable machining operations lead to problems with workpiece quality – requirements such as geometric accuracy and dimensional stability and particularly the required surface quality cannot be fulfilled. The vibrations which occur on the machine structure also restrict the service life of mechanical and mechatronic machine components and shorten tool lifetime. For this reason, we not only offer our customers a classic machine service, we pay particular attention to process optimisation/stability. We develop tailor-made drive and technology concepts for the machine type and the workpiece!

The design is drafted according to the following aspects:- Quality

- Cycle time

- Lifetime

- Tool costs

- TCO

Design of production lines in the “PULL” process

The road to energy efficiency

Unnecessarily high energy costs directly reduce company profits. Knowledge about the inefficient use of energy can remain concealed for a long time, however. Grown structures for energy supplies often limp way behind rapidly changing production processes. This means they are not optimised for the actual application and this has a negative impact on energy efficiency in particular. It is only once the relevant energy consumers have been identified that concentrated efforts can be made to cut energy consumption. The following procedure should be used for energy-related optimisation:

1. Avoidance of unnecessary energy consumption. Unnecessary consumption neither results in additional production or service nor in an increase in comfort and convenience. avoidance of unnecessary idling times for machines checking on process parameters and safety reserves

2. Reduction of specific energy consumption- The specific energy consumption can be reduced by technical measures.

- drying using mechanical rather than thermal energy

- use of low-energy motors of the class EFF1 for secondary units

- intermittent operation (switch-on only when required) for coolant pumps, chip conveyors etc.

- use of energy recovery systems with axle and spindle drives

- frequency control for adapted power consumptions for conveyor belts etc.

3. Improvement of efficiency and capacity rates Under normal conditions, the capacity rate is often significantly lower than the nominal efficiency of the production lines. This is due to low line capacity utilisation and a poor maintenance condition. The following factors are important:- high capacity utilisation for production lines

- good control units

- reduction of distribution losses

- careful servicing and maintenance

The energy display via “DVS Energy Monitor” can be used to determine the following consumption values easily: The energy monitor can be installed on the Sinumerik 840D control unit

Training

-

The best provision for the future: optimum further qualifications and training.

Programming, hands-on machine training, service or maintenance.

We offer you expert, tailor-made further qualification for your individual requirements so that you can exploit the potential of your tooling machine to 100%.

Machine training

Practical exercises directly at the machine

Learn how to handle our machines safely and get yourself fit for day-to-day practice. We offer different courses to match our whole range of products.- Operator courses

- Technology courses

- Maintenance courses

- Repair courses

- Automation components

We offer the following tailor-made training courses for you:

Commissioning and instruction courses

You are given detailed and competent instruction in the handling of your machines and are made familiar with all the necessary maintenance procedures. Training takes place either in the plant or on your premises. The choice is yours.

Software training

Join this course for know-how related to the programming of your machine. From beginners to advanced users, tailor-made to the current knowledge level of individual operators.

Operator training

Machine training from A to Z: from machine maintenance through operation to set-up. You will find out everything you need to know about correct machine handling here.

Service training:

On request, your technicians can be given comprehensive training. This training can also be held on your premises.

Programming training

Expert instructors share their know-how! Comprehensive training on our or on your own tooling machines. The wide range of courses for all technologies is suitable both for beginners and advanced users.

And keep yourself up-to-date – WMS Update Training will teach you both about new developments and lots of tips and tricks for day-to-day applications.

Machine-independent training

Personal support promotes learning success!

We offer machine-independent training courses on the subjects of production planning and control, engineering design, materials and production process optimisation.

Retrofit

Retrofit

-

The high-precision tooling machines of railway technology companies, such as the VDM 90 from Maschinenfabrik Diedesheim here, are vital for the production of extremely demanding workpieces ( brake discs for the ICE). Tooling machines which have been modernised using our top retrofitting know-how so that they can now meet the production requirements of cutting-edge technology on a hightech level. This was achieved by means of comprehensive fault analysis and maintenance management based on our customer’s high quality standard.

The comprehensive modernisation concept was prepared in

very close cooperation between the customer and our engineering department. The machine now has a modern KSS system, process monitoring, a modern Sinumerik 840D CNC control unit, automatic adjustment of the clamping force for workpiece clamping and an optimised tool drive. We took the environment into consideration as well. The protective housing has been completely revised with a view to KSS-tightness. It goes without saying of course that the customer receives a 24-month guarantee. Spare parts deliveries are guaranteed for 10 years and with a 24-hour service. After the warranty period has expired, the tooling machines are serviced on the basis of a plant contract. This is only possible because we rely on top quality standards for our retrofit measures.

Retrofit: YOUR money is in YOUR production

-

In line with the motto “YOUR money is in YOUR production”, more and more customers are deciding to modernise their stable, production-proven machine fleet. This is where WMS Sinsheim, the service and retrofit specialist, comes into the picture. Over the past 20 years on the market, a wide range of tooling machines from lots of different manufacturers has been reconditioned in terms of mechanical and electrical components.

When it leaves our assembly hall, a WMS retrofit machine is a stable machine basis with the latest control and drive components up to the same most stringent of high standards that can be expected of a new production machine. This means reconditioning is always an investment in the future. Here are your advantages and investment saving:- No new foundations required

- No new tooling systems

- No new clamping concept

- Reduced training expenditure

- 1:1 adoption of your machining programs

- No additional expansion of your spare parts store 30-50% lower costs compared with buying a new machine

Engineering

Laservermessung

-

Geometrie – Höchste Ansprüche an Präzision!

Aufgrund der gewachsenen Leistungsanforderungen an Ihre Werkzeugmaschine, empfiehlt es sich eine jährliche Überprüfung und Nachjustierung durchzuführen.

Wir, die WMS bieten Ihnen dafür den kompletten Service aus einer Hand.

Zum Einsatz kommen modernste und hochpräzise Messmittel.- BlueSYSTEM (Wyler AG)

- Kreisformtester (Renishaw)

- Laserinterferometer ( Renishaw)

- Elektronischer Fluchtlinienprüfer (Hubitron)

- DigiMax-PMV-3D (Fräskopfkompensation) (PETEC)

Selbstverständlich erhalten Sie im Anschluss ein ausführliches Protokoll mit allen

relevanten Daten zu Ihrer Werkzeugmaschine.

WMS Service 4.0

-

Entstehende Schäden frühzeitig erkennen, Folgekosten vermeiden und die Effizienz Ihrer Werkzeugmaschine erhöhen!

Dieses Ziel können Sie durch das ganzheitliche Servicesystem WMS Service 4.0 gemeinsam mit ifm als maintenance lifecycle system erreichen.

Mit der intelligenten Zustandsüberwachung in Ihren Werkzeugmaschinen können- Verschleißerscheinungen der Baugruppen

- Energieverbrauch

- Öl- und Luftverbrauch

überwacht und zeitnah optimiert werden.

Unser Serviceangebot sorgt für eine 24/7 Servicebereitschaft vor Ort und einer Generalüberholung Ihrer Baugruppen mit Neuwertgarantie.

Diese ganzheitliche Vorgehensweise führt zur Optimierung

Ihrer OEE und TCO Kennzahlen.

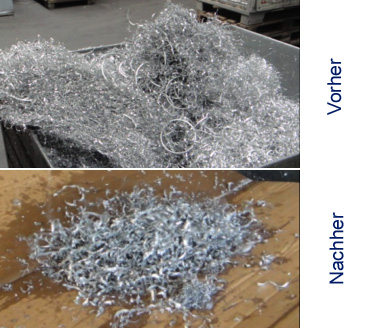

Jet-Stream

-

Mit Hochdruck zum Erfolg!

Spanbruchoptimierung mithilfe von KSS-Hochdruck!

Mit mehr als 40 bar Wasserdruck werden lange Wickelspäne gebrochen und die Stillstandszeit Ihrer Maschine reduziert. Ergebnis ist die wesentlich höhere Produktivität Ihrer Anlage durch dieses Verfahren.Gerne optimierten wir auch Ihre Maschine mit dieser zuverlässigen und hoch effizienten Technologie.

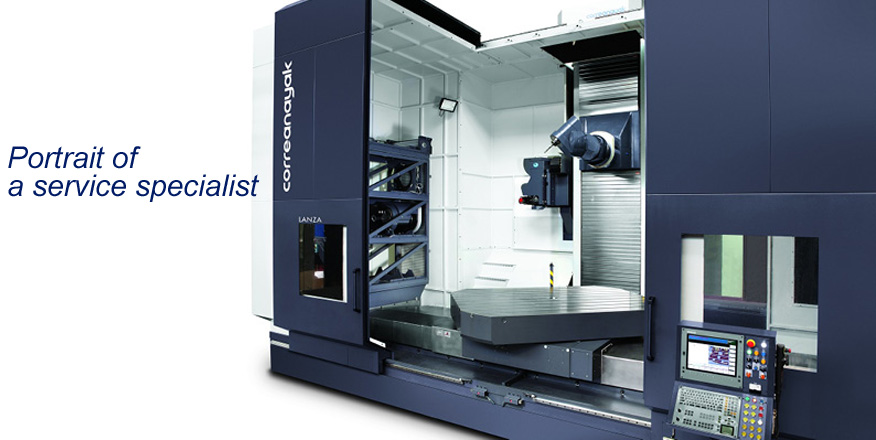

Correanayak

Vertrieb

-

Das Unternehmen Nicolás Correa

NICOLAS CORREA widmet sich seit seiner Gründung im Jahr 1947 der Herstellung von Fräsmaschinen. Bei seiner kontinuierlichen Weiterentwicklung setzt das Unternehmen auf modernste Technologien und kann so innovative und zuverlässige Fräslösungen anbieten. NICOLAS CORREA ist seit 1989 an der Madrider Börse. Damit ist das zu den führenden Herstellern von mittel und groß dimensionierten Fräslösungen gehörende Unternehmen der einzige spanische Werkzeugmaschinenhersteller, der an der Wertpapierbörse vertreten ist.

Derzeit verfügt die Gruppe mit Hauptsitz in Burgos über vier Produktionsstätten für Fräsmaschinen: zwei in Burgos, eine in Itziar-Deba (Spanien) und eine in Kunming (China). Außerdem hat die Gruppe drei Tochtergesellschaften in Burgos, die Zubehör liefern: Hypatia (ATC und Fräsköpfe); GNC Electronica (elektrische Baugruppen); und GNC Calderería (strukturelle Stahlkomponenten und Verkleidungssysteme). Die hoch qualifizierten und motivierten Mitarbeiterteams dieser Unternehmen fertigen eine große Zahl alternativer Fräs- und Bohrlösungen, die den Bedürfnissen der anspruchsvollsten Kunden genügen.

Durch das Zusammenspiel des technischen Know-hows der beiden Hauptproduktionsstätten in Burgos und Itziar ist es möglich, Spitzentechnologie für Fräsköpfe und -maschinen zu entwickeln und zuverlässige und innovative Fräslösungen mit langer Lebensdauer zu bieten. Das internationale Verkaufsnetzwerk umfasst eine große Anzahl von Partnern auf der ganzen Welt. Dadurch stehen überall flexible und fähige Kontaktpersonen zur Verfügung, die in der Lage sind, die Anforderungen unserer Kunden zu befriedigen. Genau an dieser Stelle tritt die WMS als zuverlässiger Vertriebs- und Servicepartner auf.

Um den Kunden in allen Bereichen einen optimalen Service zu bieten, steht Ihnen unser technischer Kundendienst zur Verfügung, dessen Elektrotechniker und Maschinenbauer bei Wartungs- und Reparaturbedarf schnell und effizient intervenieren. Dienstleistungen

-

Service für Werkzeugmaschinen in Übergröße! Kein Problem!

Für die präzise Bearbeitung großer Bauteile aus den verschiedensten Werkstoffen sind leistungsfähige „Groß - Werkzeugmaschinen“ von correanayak gefragt. Ziel ist es, in so wenig wie möglichen Aufspannungen ein Teil komplett zu bearbeiten. Hohe Genauigkeit und Flexibilität sind ebenso gefordert wie Zuverlässigkeit und hohe Verfügbarkeit, wenn es um die Bearbeitung von großen, oft tonnenschweren Werkstücken geht.

Vor allem aber steigt die Bedeutung der Flexibilität, um die großen und schweren Werkstücke möglichst in einer Aufspannung fertig bearbeiten zu können, statt sie wie bisher üblich in separaten Arbeitsgängen von „Schruppen” zum „Schlichten” transportieren und fertigen zu müssen. Aufgrund dieser Tatsache ist es umso wichtiger, einen verlässlichen Servicepartner zu haben, der schnell und effektiv reagieren kann und Ihre Großmaschine wieder schnell in die Produktion zurückführt.

Deshalb auch im Bereich "groß, größer am Größten" können sie sich immer auf unseren „WMS FULL- Service” verlassen.

Wir bieten Ihnen ein umfassendes Servicekonzept vom Teleservice über Inspektion, Wartung, Baugruppenüberholung bis hin zur Generalüberholung Ihrer Werkzeugmaschine.

Setzten Sie sich mit uns in Verbindung. Wir freuen uns auf Ihren Anruf!