- Offer Profile

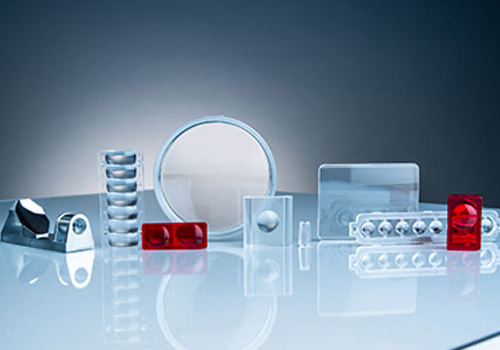

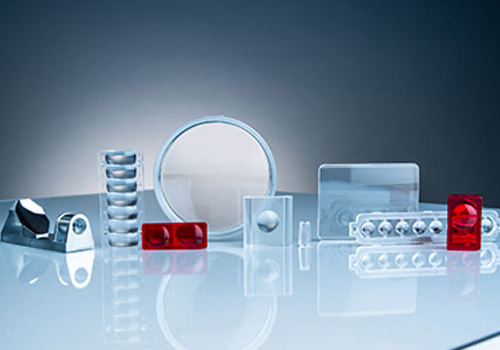

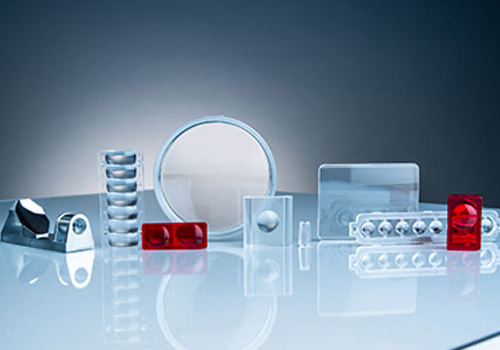

- We, B&M Optik GmbH, are a medium-sized company with our headquarters in Limburg/ Lahn in Hessen. Since our founding in 1991, we have earned ourselves a good reputation as a reliable and valued manufacturer of optical elements and components. As an owner-managed company with tradition and experience, we know how important it is to respond individually to customer requirements. For this reason, we devote particular attention to co-operation with our customers. We also offer the highest quality in all areas - from the product through individual advice to quick reaction times when it comes to solving the customer’s particular problem. We not only live up to this aspiration, we attempt to exceed it. Day after day. Always in our customers’ interest.

Excellence in optics

-

Good is not good enough as long as there is a better way.

B&M Optik GmbH is a mid-sized business headquartered in Limburg an der Lahn (Hessen). Since being incorporated, we have developed an outstanding reputation as a reliable and trusted manufacturer and partner for optical assembly elements and components. As an owner-operated business with tradition and experience, we know how important it is to respond to customer requirements individually. This is why we place a top priority on cultivating the collaboration with our customers.

We also provide the best-possible quality in everything we do - from the product to customized consulting and ending with short response times for solutions to problems. Our day-to-day objective is to repeatedly exceed these expectations, entirely to the benefit of our customers. You too should get to know our innovative products, technologies, and expertise. We will gladly support you during the development phase of your product. We believe that the sooner we can work hand-in-hand, the faster we can found a solution that meets your engineering and commercial needs.

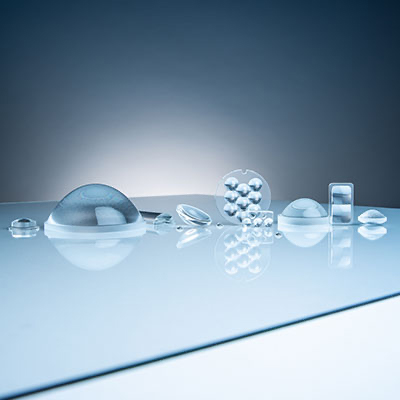

Lenses - moulded

-

Finish moulding hot glass into optical elements is an advantageous technology for technical optics. By continuing to develop precision tools, manufacturing processes, and the technology itself, we have in recent years significantly improved the quality of optical components.

Moulding tools can be manufactured cost-effectively and in 4 – 6 weeks. At B&M Optik we use glass rods or gobs as the raw material, which are partially heated to the correct temperature and then moulded in the moulding tool. The parts are then stress-relieved or tempered depending on the application of the spherical or aspherical glass lenses.

LED optics

-

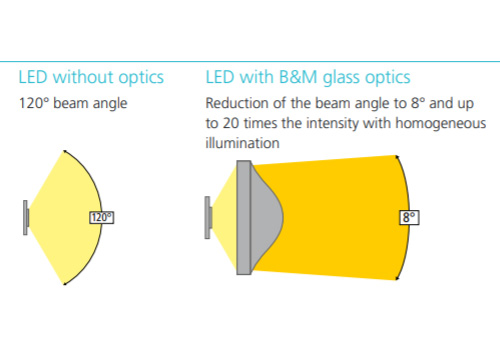

For use in LED optics, we very frequently employ finish moulded aspherical lenses with blank, precision-textured, medium-textured, or coarse-textured plane surfaces. Alternatively, and depending on customer need, moulded plano convex lenses, cylindrical lenses, biconvex lenses, freeform lenses, or a lens array can also be used as LED optics.

The optimal beam angle can be adjusted for the respective LED light application as a function of the LED beam surface and the distance between the plane surface of the optical lens and the LED.

We will gladly advise you on the choice of the LED, the technical optics, and the optical design of your application.

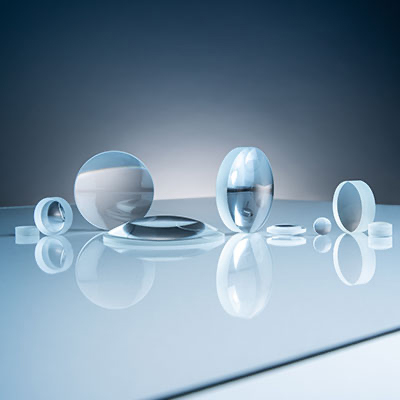

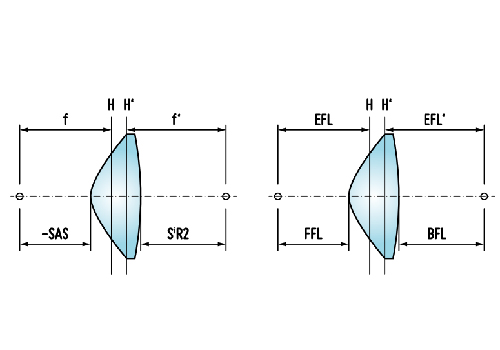

Lenses - polished

-

Our manufacturing and final inspection of the optical components is based on DIN ISO 10110 to ensure uniform, controllable quality of the spherical lenses.

Using CNC manufacturing processes, we will manufacture your plano convex lenses, biconvex lenses, plano concave lenses, biconcave lenses, achromatic lenses (doublets), quartz lenses, cylindrical lenses, menisci, and spheres.

We can also offer all our optical components with AR coating and also as a subassembly.

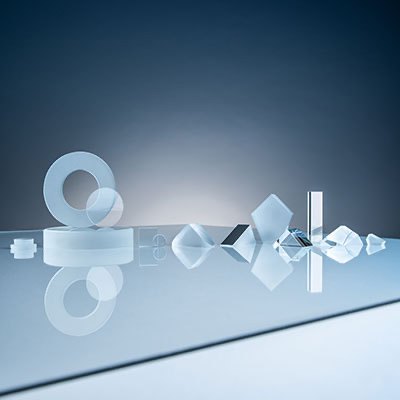

Prisms / plano optics

-

Prisms are plane and precise optical elements that are precision-shaped by grinding and polishing and have optical effects. They are used for optical beam guidance and deflection.

The angles, orientation, and the number of surfaces determine the type and function. Optical prisms need to meet a wide range of requirements. In optical systems, our prisms ensure that light is deflected exactly to your technical specifications.

Let us know what your specifications are so that we can give you a customized quote. The advantage of prisms is that these optical systems can be realized with a minimum of space requirements.

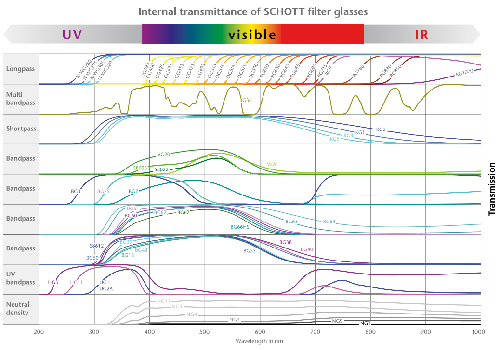

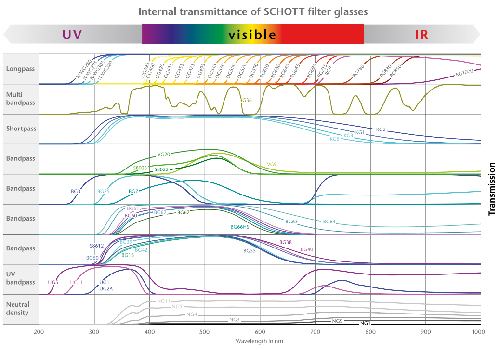

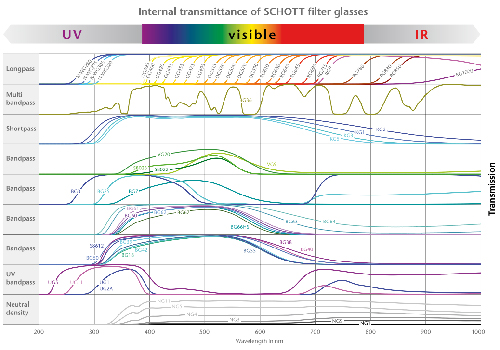

Filters

-

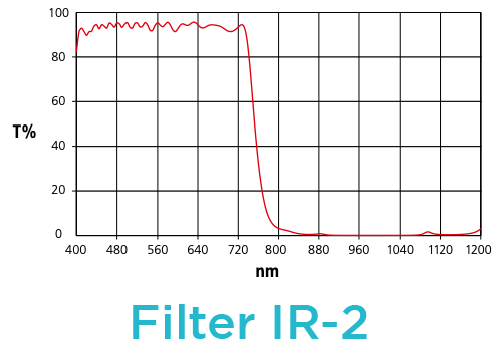

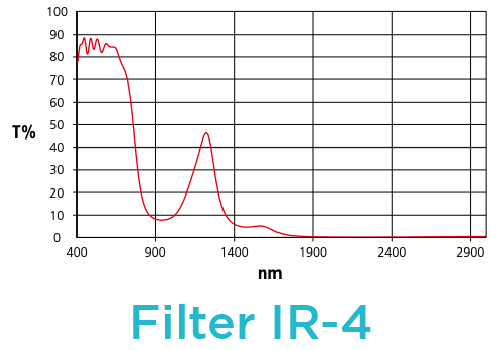

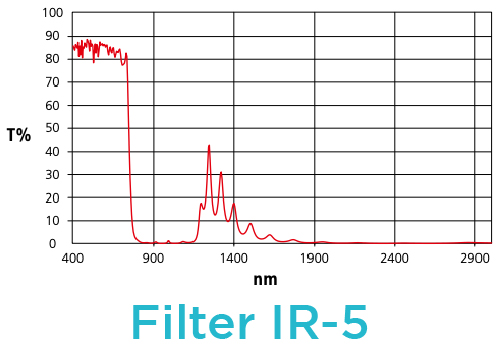

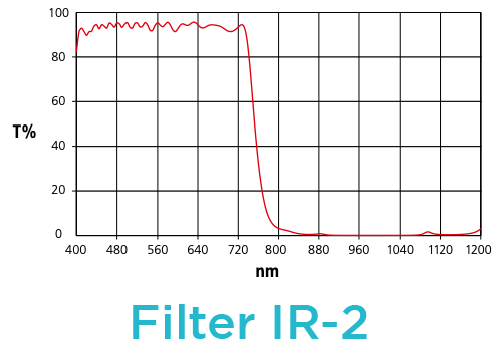

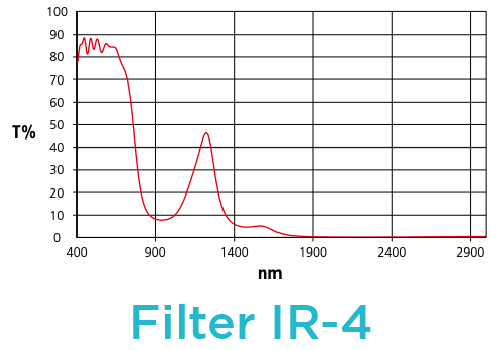

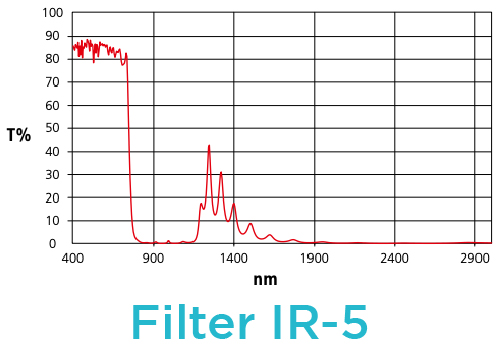

Various optical filters are used to selectively absorb user-defined wave lengths of the light. In addition to custom solutions, our offer includes many specialty products, glass color filters (various shapes and types), thermal absorption filters, plastic color filters, thermal reflection filters (IR-2 / IR-4 / IR-5), interference filters, bandpass filters, shortpass filters, longpass filters, UV filters, and customer-specific filters of all types on request and to your specifications.

Plastic lenses

-

Injection molding methods are used to manufacture plastic lenses and optical elements.

These methods are used to cost-effectively manufacture directly usable molded parts in large quantities. The specified plastic type is placed into an injection molding unit of an injection molding machine, and is then injected into an injection molding tool under high temperatures. The tooling used for this purpose are high-precision molds.

The tool cavity determines the shape and surface texture of the finished, injection molded optical element. The surface of the optics provides essentially unlimited design freedom.

Coatings

-

Our factory in Pirna has various coating capabilities on four different systems. These are reflective and anti-reflective coatings in the respectively desired wave length range.

Our offer includes anti-reflective coatings, highly-reflective mirror coatings, metallic splitter coatings, dielectric coatings, beam splitter and filter coatings.

Any glass type, and even plastic (depending on application), can be used as substrates. The coating design must of course take into account the material properties.

Sub-Assembly Services

-

On request, we also provide subassembly services for opto-mechanical components. From lens assemblies, oculars, magnifiers, mounting holders, mountings, housings, to other subassemblies with the corresponding optical components from B&M Optik, we will supply the assembled, typically cemented and inspected subassemblies according to your requirements and specifications.

We will manufacture the individual parts exactly to your requirements, and will realize the desired optical function by integrating your components to specifications; alternatively, we will use the mechanical components inspected and supplied by you for the sub-assembly.

We will gladly support any of your assembly needs. Do not hesitate to contact us so that we may jointly look toward the optical future.

Lenses moulded

Lenses moulded, LED optics - Products

Aspherical lenses

-

Aspherical surfaces perform the task of minimising the aperture error invariably found in any lens. In comparison with a spherical lens with a comparable diameter and focal length, aspherical lenses have a lower aperture error. Under certain conditions it is possible to improve image defects such as coma, distortion and astigmatism. Since grinding, as for spherical surfaces, is not possible on conventional machines, the aspherical lenses are moulded. We recommend limiting the use of moulded lenses to condenser optics and simple lighting systems. The lenses must be designed such that demoulding is possible: lenses can be supplied in an angular design with offset rim and in an array form version, for example

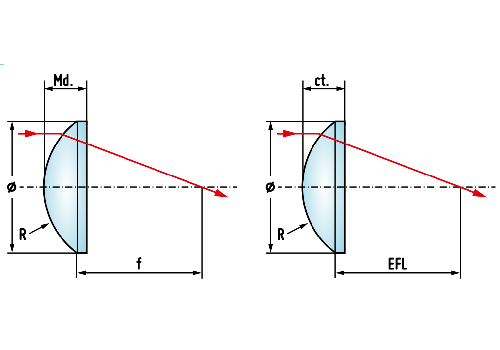

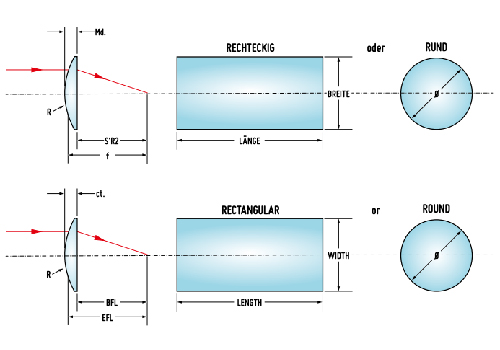

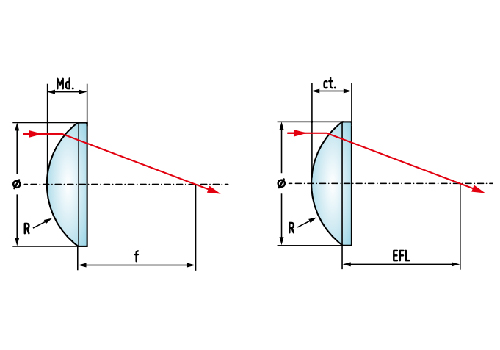

Plano convex lenses

-

Radius side and edge moulded Flat side ground and polished

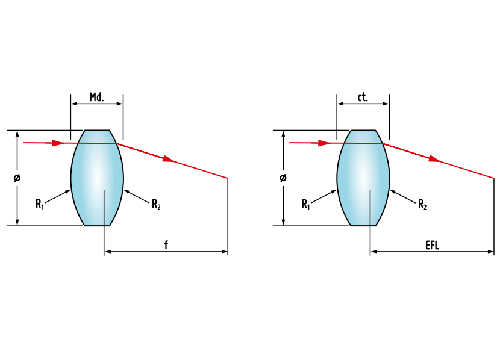

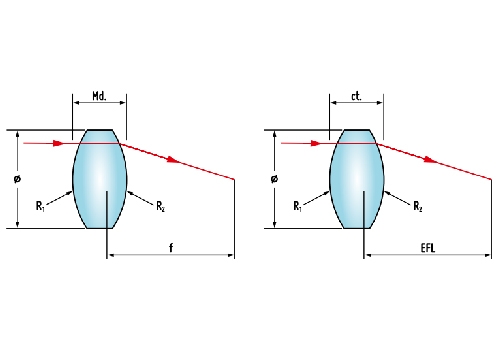

Biconvex lenses

-

Both sides finish-moulded

Cylindrical lenses

-

Finish moulded Flat side ground and polished

Freeform lenses

-

Freeform lenses are in this case lenses molded from glass, having complex, rotationally asymmetric surfaces. These are manufactured by fabricating a new molding tool to your specifications. The employed materials include LIBA2000, F4GT, SIMAX, K10P, and also Tritan. Please place an RFQ for your requested freeform lens by submitting a drawing and specifications.

We will quote the required tooling with a corresponding leadtime of approx. 7–8 weeks and the first tool-based samples, including a first article inspection report according to your requirements.

Arrays

-

Arrays are typically symmetrically arranged compound lenses that are molded from glass, having a spherical, aspherical, or cylindrical surface. These are manufactured by fabricating a new molding tool to your specifications. Materials such as LIBA2000, F4GT, SIMAX and K10P are typically used

Please place an RFQ for your lens array by submitting a drawing and specifications. We will gladly also assist you with the optical design and engineering design for your application. We will quote the required tooling with a corresponding leadtime of approx. 7–8 weeks and the first tool-based samples, including a first article inspection report according to your requirements.

Doublets

-

Doublets are compound lenses molded from glass, having a spherical or aspherical surface. These are manufactured by fabricating a new molding tool to your specifications. Materials such as LIBA2000, F4GT, SIMAX and K10P and Tritan are typically used.

Please place an RFQ for your requested doublet by submitting a drawing and specifications. We will quote the required tooling with a corresponding leadtime of approx. 5-6 weeks and the first tool-based samples, including a first article inspection report according to your requirements.

LED optics case

-

We offer you selections of optics in 3 variants, always ready to hand in neat cases.

Samples

-

In addition to our LED optics and optics sample cases, we also carry a very wide product line of sample parts that ranges from molded glass lenses to high-quality ground and polished technical optics. Our constant enhancements and updates give you access to more than 2,000 different types of our optical components.

Take advantage of our short lead times for samples and tap into the inventory we carry in our warehouse. We will gladly provide information about the specifications of the individual types and will prepare an attractive quote for you. All optics can of course be mass-produced again in the desired quantities.

LED Optics

Glass LED optics - Special lenses for LED

-

Our advantages for you

- Any change to the beam angle only with an optic (8°–60°)

- Homogeneous illumination with no colour effects

- Avoidance of dice formation through special surface textures · Standard aspherical lenses for all LEDs available on the market

- Longevity of the optics even with negative external influences

- No heat generation problems with high-power LEDs

- Attractive, high-quality glass materials

- Easy to adapt for customerspecific applications

- Low tooling costs for moulded glass lenses to customer specifications

LED optics case

-

We offer you selections of optics in 3 variants, always ready to hand in neat cases.

Lenses ground and polished

Lenses (ground and polished) - Products

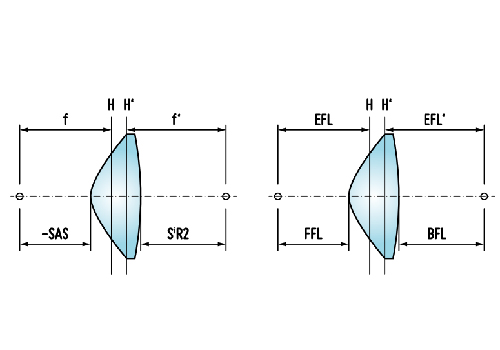

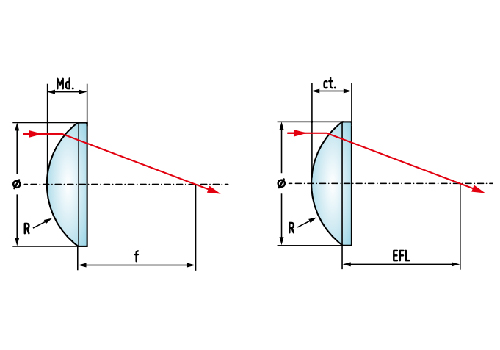

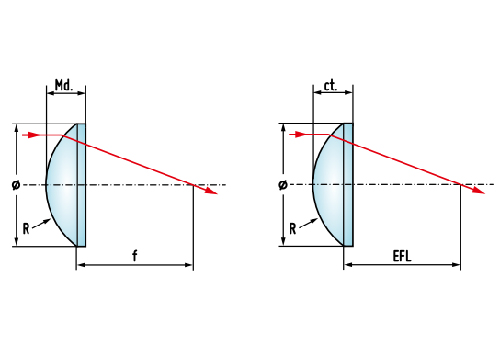

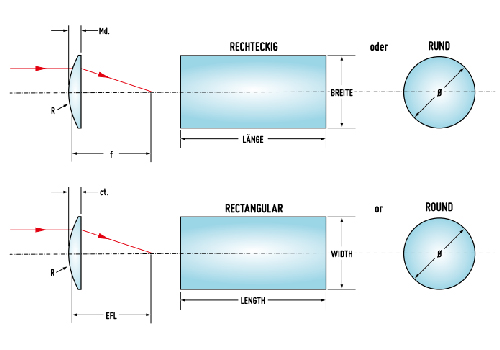

Plano convex lenses

-

Both sides ground and polished

Biconvex lenses

-

Both sides ground and polished

Plano concave lenses

-

Both sides ground and polished

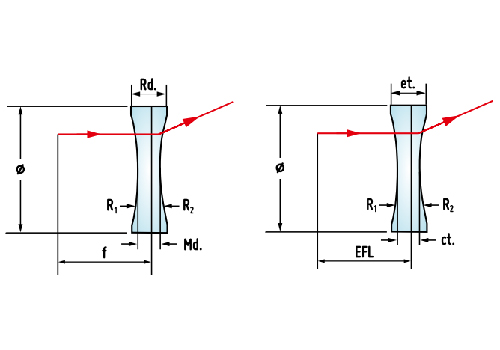

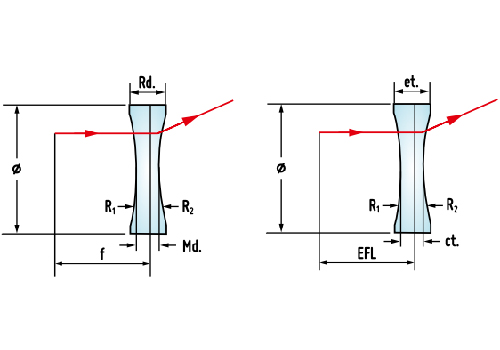

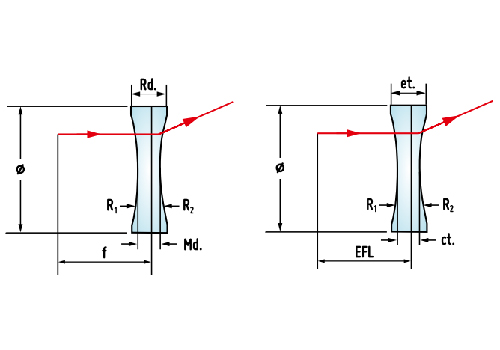

Biconcave lenses

-

Both sides ground and polished

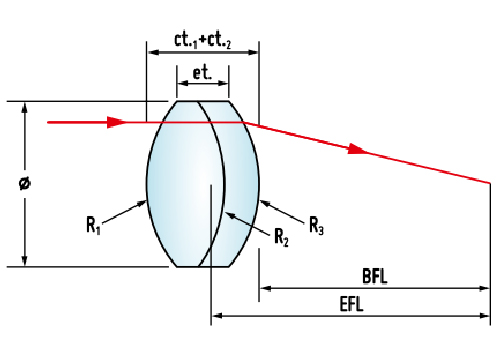

Achromatic lenses (doublets)

-

Both sides ground and polished

Triplets

-

Triplets are ground and polished high-quality triple lenses, having spherical surfaces. Triplets are manufactured on CNC machinery from various technical glasses.

Please place an RFQ for your requested triplet by submitting a drawing and specifications. We will quote your requirements with a corresponding leadtime for manufacturing and for first samples (if needed), incl. a first article inspection report according to your requirements.

Menisci

-

A meniscus lens is defined as a combination of a convex radius with a concave radius. Menisci are ground and polished lenses, having a spherical surface. Menisci are manufactured on CNC machinery from various technical glasses.

Please place an RFQ for your requested meniscus lens by submitting a drawing and specifications.

We will quote your requirements with a corresponding leadtime for manufacturing and first samples (if needed), incl. a first article inspection report according to your requirements.

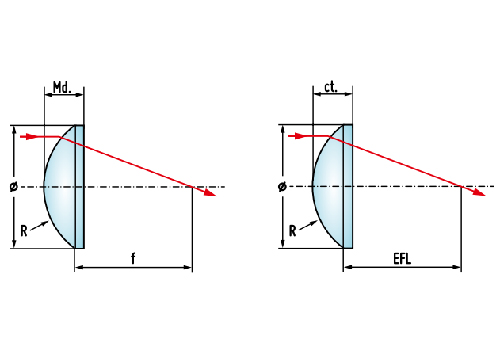

Quartz plane convex lenses

- Both sides ground and polished

Quartz biconvex lenses

-

Both sides ground and polished

Cylindrical lenses

-

Both sides ground and polished

Spheres

-

Spheres are ground and polished ultra-precision optics. Spheres are available in all technical glasses, quartz, silicon, and CaF2.

Please place an RFQ for your requested sphere by submitting a drawing and specifications. We will quote your requirements with a corresponding leadtime for manufacturing and first samples (if needed), incl. a first article inspection report according to your requirements.

Prisms / plano optics

Prisms / plano optics - Products

Safety glass for laser welding systems (quartz, value-added features)

-

A window which is used during laser welding in order to protect the laser is considered to be a wear part.

An attractive price-quality ratio and rapid delivery times are therefore of particular interest.

- Ground and polished on both sides

- Bevelled on both sides 0.1 – 0.3 mm x 45°

Standard dimensions e.g. Ø 50.8 mm or Ø 55.0 mm, any round or square shape is possible.

We are also happy to offer this protective glass with coatings:

For example:

Both sides R < 0.3% for 1064 nm and T >= 97/ for 450 – 650 nm, i = 0° – 14°

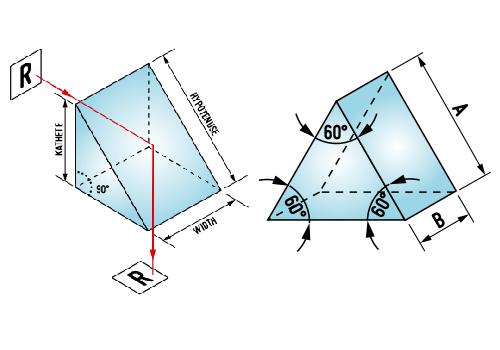

Prisms 90° / 60°

-

Made from all types of optical glass, coated on request. Surface quality up to 5/3 x 0.063; flatness up to lambda/10 (always depending on the material and dimensions)

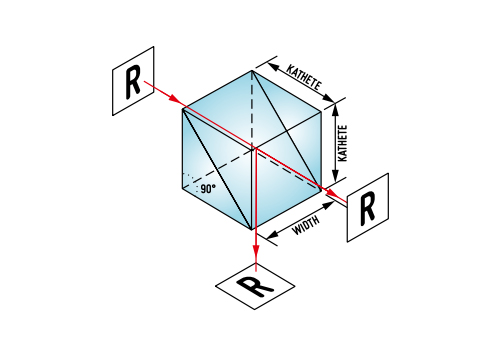

Beam splitter cubes

-

Made from all types of optical glass, coated on request. Surface quality up to 5/3 x 0.063; flatness up to lambda/10 (always depending on the material and dimensions)

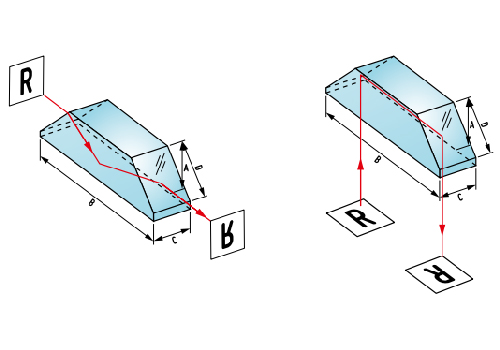

Rhomboid prisms

-

Made from all types of optical glass, coated on request. Surface quality up to 5/3 x 0.063; flatness up to lambda/10 (always depending on the material and dimensions)

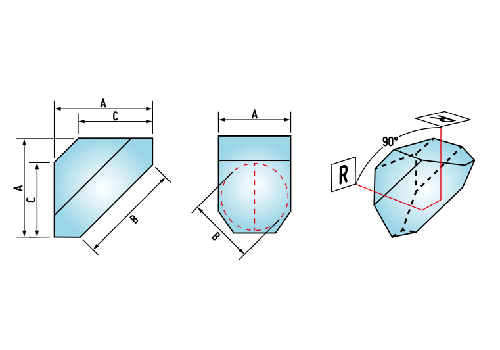

Roof prisms

-

Made from all types of optical glass, coated on request. Surface quality up to 5/3 x 0.063; flatness up to lambda/10 (always depending on the material and dimensions)

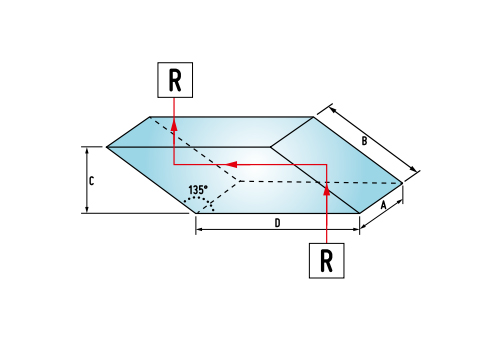

Dove prisms

-

Made from all types of optical glass, coated on request. Surface quality up to 5/3 x 0.063; flatness up to lambda/10 (always depending on the material and dimensions)

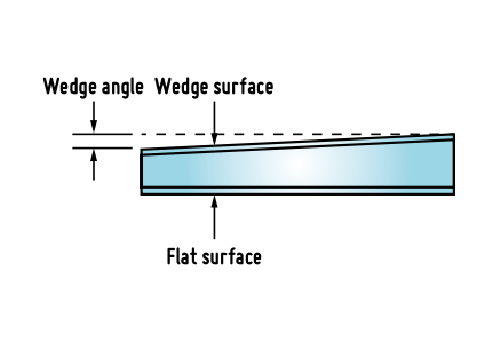

Optical wedges

-

Made from all types of optical glass, coated on request. Surface quality up to 5/3 x 0.063; flatness up to lambda/10 (always depending on the material and dimensions)

Plano mirrors / Concave mirrors / Splitter mirrors

-

Front surface mirrors with an aluminium reflection layer are used in imaging systems to prevent double images. The reflection height and centroid wavelengths can be determined using a dielectric protective coating.

Coating is temperatureresistant up to 250 °C. Standard substrate: all types of optical glass

Windows (all materials, all shapes)

-

Made from all types of optical glass, coated on request. Surface quality up to 5/3 x 0.063; flatness up to lambda/10 (always depending on the material and dimensions)

Special prisms

-

Made from all types of optical glass, coated on request. Surface quality up to 5/3 x 0.063; flatness up to lambda/10 (always depending on the material and dimensions)

Filters

Filters - Products

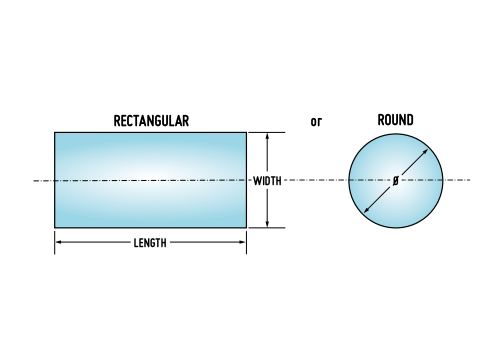

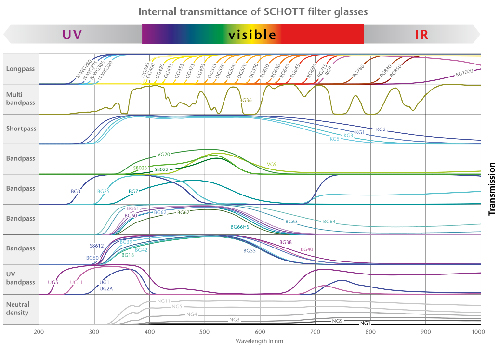

Glass color filters (all shapes and types)

-

Schott glass filters in round and square forms. Tempered or coated on request.

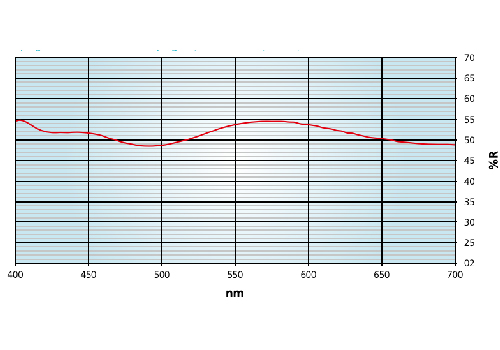

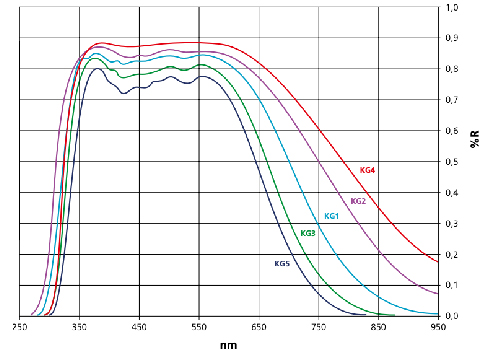

Thermal absorption filters (transmission linear)

-

Linear transmission at a thickness of 3.0 mm

Plastic color filters (acrylic)

-

Thicknesses:

0.5 mm / 0.8 mm / 1.0 mm / 1.5 mm / 2.0 mm / 2.5 mm / 3.0 mm / 4.0mm

Thickness tolerances ± 0.2 mm

- Various types of filter such as IR filters and diffusion filters

- Any dimensions you want up to max. 1500 mm x 100 mm

- With AR or hard finish coating as required

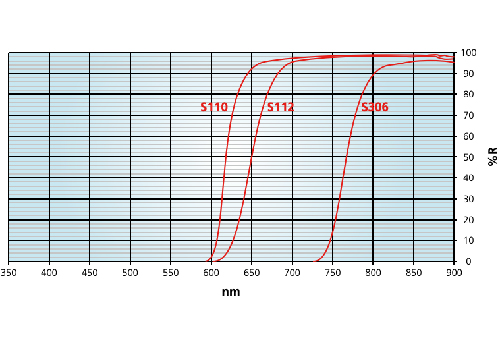

Thermal reflection filters

-

Properties and technical specifications

Heat reflection filters are permeable to light radiation. Through reflection of IR radiation, the proportion of heat in light is reduced.

- Coating temperatureresistant up to 400 °C

- Dimensions upon request

Interference filters

-

Our factory in Pirna has various coating capabilities on four different systems. We offer various filter coatings. Any glass type, and even plastic (depending on application), can be used as substrates. The coating design for the respective filter must of course take into account the material properties

Please place an RFQ for your requested filter function by submitting a drawing and specifications. We will gladly quote your requirements with a corresponding leadtime and first samples according to your requirements.

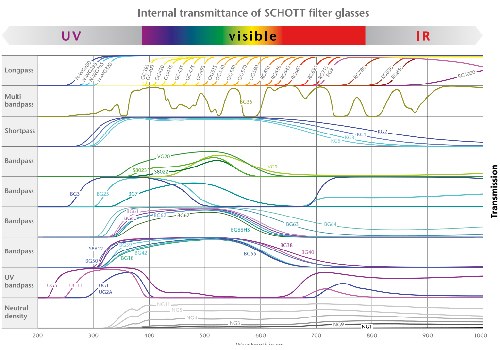

Bandpass filters

-

Schott glass filters in round and square forms. Tempered or coated on request.

Shortpass filters

-

Schott glass filters in round and square forms. Tempered or coated on request.

Longpass filters

-

Schott glass filters in round and square forms. Tempered or coated on request

UV filters

-

Schott glass filters in round and square forms. Tempered or coated on request

Plastic lenses

Plastic lenses - Products

Aspherical lenses

-

Made from Plexiglas 7N (nd 1.491) or other materials

Bi-aspherical lenses

-

Made from Plexiglas 7N (nd 1.491) or other materials

Plano convex lenses

-

Made from Plexiglas 7N (nd 1.491) or other materials

Bi-convex lenses

-

Made from Plexiglas 7N (nd 1.491) or other materials

Plano concave lenses

-

Made from Plexiglas 7N (nd 1.491) or other materials

Cylindrical lenses

-

Made from Plexiglas 7N (nd 1.491) or other materials

Doublets

-

Made from Plexiglas 7N (nd 1.491) or other materials

Arrays

-

Plastic lens Arrays

Arrays are typically symmetrically arranged compound lenses that are injection moulded from plastics, having a spherical or aspherical surface. These are manufactured by fabricating a new injection molding tool to your specifications. Materials such as plexiglass (PMMA) or other suitable technical plastics are typically used.

Please place an RFQ for your lens array by submitting a drawing and specifications. We will quote the required tooling with a corresponding leadtime of approx. 8-10 weeks and the first tool-based samples, including a first article inspection report according to your requirements.

Freeform lenses

-

Plastic freeform lenses

Freeform lenses are lenses injection moulded from plastics, having complex, rotationally asymmetric surfaces. These are manufactured by fabricating a new injection molding tool to your specifications. The employed materials include plexiglass (PMMA), polycarbonate (PC), Zeonex and other technical plastics. Please place an RFQ for your requested freeform lens by submitting a drawing and specifications.

We will quote the required tooling with a corresponding leadtime of approx. 8–10 weeks and the first tool-based samples, including a first article inspection report according to your requirements.

Coatings

Coatings / reflection surfaces - Products

AR coatings

-

Anti-reflection coatings reduce the reflection of glass surfaces. Increased light transmission and a reduction in imaging errors in the desired wavelength range. All types of mineral glass can be used as substrates, provided that the material properties are taken into account in the design of the coating, of course

Metallic mirror surfaces

-

Anti-reflection coatings reduce the reflection of glass surfaces. Increased light transmission and a reduction in imaging errors in the desired wavelength range. All types of mineral glass can be used as substrates, provided that the material properties are taken into account in the design of the coating, of course

Metallic splitter mirror surfaces

-

Anti-reflection coatings reduce the reflection of glass surfaces. Increased light transmission and a reduction in imaging errors in the desired wavelength range. All types of mineral glass can be used as substrates, provided that the material properties are taken into account in the design of the coating, of course

Dielectric prisms

-

Anti-reflection coatings reduce the reflection of glass surfaces. Increased light transmission and a reduction in imaging errors in the desired wavelength range. All types of mineral glass can be used as substrates, provided that the material properties are taken into account in the design of the coating, of course

Industrial Sectors

Interior LED Lighting

-

The rapid advances for LED lighting places an increasing number of wide-ranging demands on the optical components. This is precisely why we are today - and have been for 30 years - a trusted supplier for a number of globally leading lighting manufacturers for spotlights and downlights. This is the case because we are in lock-step with the times, technology, and design.

Our customers know us as a responsive, reliable, and innovative partner. You can confidently place the development and manufacturing of your prototypes, low-volume, and high-volume orders in our expert hands.

B&M Optik products are found in a significant number of technical lighting applications.

Sensors, sensor technology

-

Everywhere in our daily lives, we are surrounded by sensors, smoke alarms, automatic doors, the technology in our smartphones and cars, and in countless other places. Sensors are the “eyes” of a factory or a device - and we improve the performance of these systems as optics engineers.

Nowadays, a sophisticated industrial plant is no longer conceivable without sensors. Likewise, a successful sensor technology manufacturer is unimaginable for us without collaborating with B&M Optik.

Sensors and sensor technology are an indispensable key technology for today’s times, and the expectations placed on this technology are extremely high, even in the coming years.

Together with its customers, B&M Optik repeatedly confronts precisely these expectations, while backing the high standards with tireless support, continuous research & development, and tightly-controlled quality management.

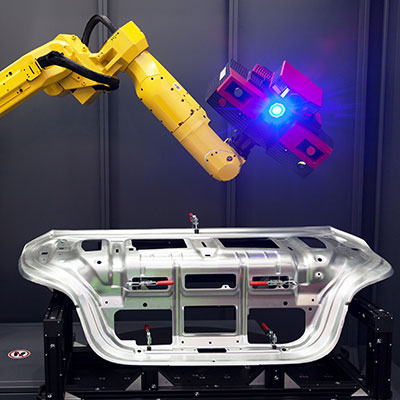

Optical metrology, metrology equipment

- In contrast to tactile metrology, optical metrology contactless scans the object under test using light. Optical metrology methods are used for quality control and also to detect e.g. shapes for 3D printing. Optical 3D metrology is used to verify compliance with geometrical dimensions of components, and it can now in many cases replace previously employed tactile measurements that rely on mechanical gauges or coordinate measurement machinery. Optical metrology includes measurement methods, measurement systems, and measurement methods that rely on light to determine physical variables or to directly determine properties of light.

Medical devices, analytics

-

Our specialty is to support our customers for lighting applications related to dental and medical device engineering, from research to development, and also for manufacturing your treatment and research devices.

Our lenses for LEDs permit shadow-free illumination of the treatment location.

Optical lenses permit and improve a wide range of medical methods, for example with the help of lasers.

Our components are also used for cosmetic laser treatment. A particular related challenge is that the equipment – such as endoscopes and otoscopes, as well as surgical instruments – must be sterilized.

Automation, control technology

-

Automation is the autonomous operation of machinery that reduces or makes human communication or control redundant, provided everything works as intended. Ford Motor Company was the first to use automation in the late forties. Since then, automation technology has become the engine of today’s modern society.

Processes can be seamlessly controlled and observed from afar. The related components are mechanical, electrical, electronic, and optical elements from control technology, drive technology, sensor technology, and from communications technology.

Laser technology, laser protection

-

Laser optics are used in a wide range of laser devices and laser applications, such as beam guidance or material processing.

B&M laser optics feature specific substrates, coatings, or a combination of these, giving them high quality at specific laser wave lengths or across entire wave length ranges. A known challenge is that a number of laser optics have high damage thresholds, either for pulsed or CW lasers.

This means that when laser optics are used in combination with an insufficient laser damage threshold, the optical component of the laser can be damaged. And here again, our customers benefit from B&M Optik’s decades of experience. Do not hesitate to contact us, and let us celebrate our common success stories for your next project.

Image processing

-

Image processing systems are based on digital sensors in industrial cameras that are equipped with special-purpose imaging optics. A combination of hardware and software processes, analyzes, and measures various decision-making attributes for.

Today, image processing systems are available for many industrial sectors and applications and can offer solutions for a wide range of inspection tasks. Choosing the right image processing technology for a specific applications in all cases requires expert knowledge - as does the choice of the installed optical components.

As an optics expert, B&M Optik has been developing, manufacturing, and distributing optical components of all types for 30 years.

Aircraft lighting, airport technology

-

In the aerospace field, our products are at work both in the air and on the ground.

Together with our customers, we use B&M optics to illuminate passenger cabins with particularly light-transmissible optics, both with homogeneous white light and also in tunable mode with a color spectrum, depending on the daytime/nighttime conditions or to match the current aircraft position as it progresses through the global time zones.

During aircraft takeoff or landing, we are again at work with the matching B&M optics to show the pilot the right path to, and on, the runway.

Anyone who has ever flown has come into contact with optics from B&M, for example when operating the reading light.