HURON

Videos

Loading the player ...

- Offer Profile

- A COMPLETE RANGE OF

INNOVATING PRODUCTS

High Speed Milling Machines in 3 & 5 Axes- Fast, dynamic, powerful, accurate machines.

- Intelligent, conversational CNC systems for high-speed machining of complex

surfaces and drilling, boring and tapping operations in all metallic and

composite materials used in the mechanical engineering sectors.

Product Portfolio

Vertical Milling 5 axes

Umill Series

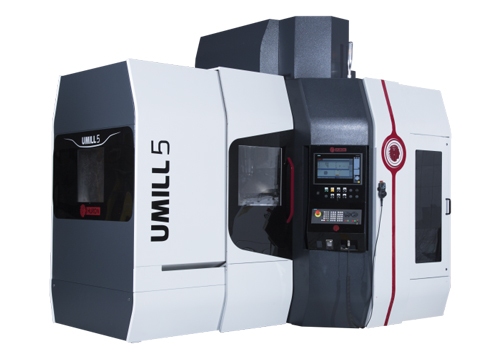

UMILL 5

-

Umill range is a 5-axis machining centres with a portal structure and a swivelling rotary table on cradle.

Its modern design and compact size are optimized to guarantee a minimal footprint without compromising either to the workpiece volume or to the fundamental caracteristic of the HURON machines : enhanced rigidity for high performance and quality machining.

This range is ideally suited for complex parts in 3 or 5 axes, from roughting to finishing, for various sectors such as high precision mechanical parts, automotive, rail, energy, machining of 3D forms, or aerospace.

Key Features

Structure- structure with fixed portal in ribbed cast iron with stiffness walls attenuate the torsional stresses

- cast iron with a high mechanical performance which maximizes structure rigidity and allows optimum harmonic stability and maximum damping during demanding cutting conditions

- modular design allowing maximum flexibility in machine configurations

- swivelling rotary table fixed on cradle

- excellent approach to the workpiece on its 5 faces thanks to the swivelling of the table

- optimized travels to offer an important distance under the spindle nose

Spindle

- powerful spindle with high torque allowing high metal removal rates

- spindle body designed to facilitate accessibility to the workpiece during the 5-axis machining

Technical Specification:

Axes- X - Y - Z axes mm 500 x 560 x 450

- Rapid feedrate m/min 40

Table - A/C axes- A axis : Swiveling - Swivelling speed -20° / +110° - 25 rpm

- C axis - Rotary - Rotary speed 360° - 45 rpm

- Table dimension mm dia. 500

- Admissible load kg 450

Spindle- Spindle speed rpm 10.000

- Taper ISO 40

- Power (S1/S6) kW 12 / 18

- Torque (S1/S6) Nm 115 / 173

- Caracteristic speed rpm 1.000

Automatic tool changer- Qty housings 30

- Max. diameter of tool mm 80

- Max. weight of tool kg 7

- Max. length of tool mm 300

Accuracy (according VDI / DQG 3441)- Positioning uncertainty (P) X / Y / Z : 0,015 mm

- Repeatability (Ps medium) X / Y / Z : 0,005 mm

Dimensions- Weight of the machine kg 11.000

- Width (doors closed + chips conveyor mm 4.200

- Depth mm 3.800

- Height mm 3.300

UMILL 6

-

Umill range is a 5-axis machining centres with a portal structure and a swivelling rotary table on cradle.

Its modern design and compact size are optimized to guarantee a minimal footprint without compromising either to the workpiece volume or to the fundamental caracteristic of the HURON machines : enhanced rigidity for high performance and quality machining.

This range is ideally suited for complex parts in 3 or 5 axes, from roughting to finishing, for various sectors such as high precision mechanical parts, automotive, rail, energy, machining of 3D forms, or aerospace.

Key Features

Structure- structure with fixed portal in ribbed cast iron with stiffness walls attenuate the torsional stresses

- cast iron with a high mechanical performance which maximizes structure rigidity and allows optimum harmonic stability and maximum damping during demanding cutting conditions

- modular design allowing maximum flexibility in machine configurations

Table- swivelling rotary table fixed on cradle

- excellent approach to the workpiece on its 5 faces thanks to the swivelling of the table

- optimized travels to offer an important distance under the spindle nose

Spindle- powerful spindle with high torque allowing high metal removal rates

- spindle body designed to facilitate accessibility to the workpiece during the 5-axis machining

Technical Specification:

Axes- X - Y - Z axes mm 700 x 740 x 550

- Rapid feedrate m/min 40

Table - A/C axes- A axis : Swiveling - Swivelling speed -20° / +110° - 20 rpm

- C axis - Rotary - Rotary speed 360° - 35 rpm

- Table dimension mm dia. 630

- Admissible load kg 600

Spindle- Spindle speed rpm 10.000

- Taper ISO 40

- Power (S1/S6) kW 12 / 18

- Torque (S1/S6) Nm 115 / 173

- Caracteristic speed rpm 1.000

Automatic tool changer- Qty housings 30

- Max. diameter of tool mm 80

- Max. weight of tool kg 7

- Max. length of tool mm 300

Accuracy (according VDI / DQG 3441)- Positioning uncertainty (P) X / Y / Z : 0,015 mm

- Repeatability (Ps medium) X / Y / Z : 0,005 mm

Dimensions- Weight of the machine kg 13.000

- Width (doors closed + chips conveyor mm 4.406

- Depth mm 4.170

- Height mm 3.540

MuTech Series

MUTECH 6

-

The MuTech is a rapid, powerful, multipurpose machine that is particularly suitable for general mechanical and precision engineering. It offers a unique solution for a wide range of milling operations requiring a

high degree of precision and a broad workpiece clamping area.

Key Features- Ribbed cast iron structure for geometric stability

- Measuring on all axes

- Wide door opening for easy access to the workpiece

- Integrated Ø 600 mm rotary table for positioning or for simultaneous five-axis machining

- Tilting head for machining on five sides

- Negative angles possible

- Excellent, high-capacity swarf removal

- Compact machine

Technical Specification:

Linear axes- X axis mm 750

- Y axis mm 650

- Z axis mm 560

- Rapid feedrate m/min X / Y / Z : 30

Head - B axis- Rotating axes B - Swivelling axis : +30° / -120°

- Rotating speed rpm 35

Table- Fixed table with integrated rotating table: Fixed table : 1.000 x 600 Rotating table : Ø 600

- Dimension of workpiece mm Ø 800 x 550

- Admission load on table kg 500

Spindle- Rotating speed rpm 15.000

- Tool taper ISO 40

- Power (S1 / S6) kW 23,6 / 23,6

- Torque (S1 / S6) Nm 84 / 110

- Characteristic speed rpm 2.680

Automatic tool changer- No. of housings 24

- Max. tool diameter mm 75 / 125

- Max. tool weight kg 7

- Max. tool length mm 300

Accuracy (as per VDI / DGQ 3441)- Uncertainty (P) X / Y / Z : 0,010 mm

- Repeatability (Ps medium) X / Y / Z : 0,005 mm

Other data- Weight kg 9.500

- Length (doors closed + conveyor) mm 4.220

- Width mm 3.000

- Height mm 2.600

KX Five Series

K3X 8 FIVE

-

The KX Five series is a combination of dynamics and precision for continuous five-axis machining of complex parts. Through the excellent standard of machining vibration damping, high-quality surface finishes and optimum precision can be achieved on a variety of materials.

Key Features- Large-sized monoblock bed and reinforced portal

- Cast iron with high mechanical properties

- Guiding system for the headstock, saddle and table providing high stability during movement

- Continuously controlled two-axis table

- permanent visibility over the workpiece

- Floor anchor points guaranteeing optimum speeds and acceleration

- Compact machine

Technical Specification:

Linear axes- X axis mm 780

- Y axis mm 700

- Z axis mm 500

- Rapid feedrate m/min X / Y / Z : 50

- Rotating axes: A - Tilting axis : +30° / - 180° C - Rotating axis : 360°

- Rotating speeds rpm A, C : 50

Table- Structure: Rotating table on a 55° plane

- Table size mm Ø 500

- Admission load on table kg 250

- Distance from spindle face to table top mm 525

Spindle- Rotating speed rpm 24.000

- Tool taper HSK 63-A

- Power (S1 / S6) kW 20 / 25

- Torque (S1 / S6) Nm 32 / 40

- Characteristic speed rpm 6.000

Automatic tool changer- No. of housings 24

- Max. tool diameter mm 90

- Max. tool weight kg 7

- Max. tool length mm 250

Accuracy (as per VDI / DGQ 3441)- Positioning (P) X / Y / Z : 0,004 mm A, C : 7,2 sec

- Repeatability (Ps medium) X / Y / Z : 0,002 mm A, C : 3,6 sec

Other data- Weight kg 10.000

- Length (doors closed + conveyor) mm 4.710

- Width mm 2.690

- Height mm 3.320

K2X 10 FIVE

-

The KX Five series is a combination of dynamics and precision for continuous five-axis machining of complex parts. Through the excellent standard of machining vibration damping, high-quality surface finishes and optimum precision can be achieved on a variety of materials.

Key Features- Large-sized monoblock bed and reinforced portal

- Cast iron with high mechanical properties

- Guiding system for the headstock, saddle and table providing high stability during movement

- Continuously controlled two-axis table

- permanent visibility over the workpiece

- Floor anchor points guaranteeing optimum speeds and acceleration

- Compact machine

Technical Specification:

Linear axes- X axis mm 900

- Y axis mm 900

- Z axis mm 500

- Rapid feedrate m/min X / Y / Z : 50

- Rotating axes: A - Tilting axis : +45° / - 180° C - Rotating axis : 360°

- Rotating speeds rpm A : 40 C : 90

Table- Structure: Rotating table on a 45° plane

- Table size mm Ø 630

- Admission load on table kg 500

- Distance from spindle face to table top mm 700

Spindle- Rotating speed rpm 24.000

- Tool taper HSK 63-A

- Power (S1 / S6) kW 20 / 25

- Torque (S1 / S6) Nm 32 / 40

- Characteristic speed rpm 6.000

Automatic tool changer- No. of housings 30

- Max. tool diameter mm 90

- Max. tool weight kg 8

- Max. tool length mm 300

Accuracy (as per VDI / DGQ 3441)- Positioning (P) X / Y / Z : 0,004 mm A, C : 7,2 sec

- Repeatability (Ps medium) X / Y / Z : 0,002 mm A, C : 3,6 sec

Other data- Weight kg 14.500

- Length (doors closed + conveyor) mm 4.910

- Width mm 3.510

- Height mm 3.470

KX Large Series

KX 50 M

-

The KX Large Series offers a wide selection of machines for continuous five-axis/five-side machining of complex parts.

The fixed-portal architecture and machine design ensure maximum rigidity for extremely precise machining in a variety of difficult materials.

Its large work area, capable of supporting up to 20 tonnes in weight and accomodating processable volumes up to 4.080 x 2.180 x 1.550 mm, is suited to machining large parts for general mechanical and precision engineering, 3D shapes, and the aeronautical and energy sectors.

Customer reguirements are comfortably met by the modularity of design, the choice of variants, and equipment.

Key Features- Machine with palletizing function for increased productivity

- Volumetric precision for making moulds and complex parts

- Wide clearance between the columns to exploit the work volume fully

- Spindle offering optimum performance for roughing and finishing

- Spindle suited to high chip rates

- Structural design guaranteeing long mechanical life

- High degree of precision due to direct measurement on the linear and rotary axes

Technical Specification:

Linear axes- X axis mm 2.000

- Y axis mm 1.700

- Z axis mm 900

- Rapid feedrate m/min X / Y / Z : 40

Rotating axes on head- Type of head Forked head

- Rotating axes B - Swivelling axis : +/- 105° C - Rotating axis : +/- 200°

- Rotating speed rpm B, C : 100

- Torque : motor / clamping Nm 4.000

Table- Structure Fixed table

- Table size mm 2.200 x 1.250

- Admission load on table kg 4.000

Spindle- Rotating speed rpm 20.000

- Tool taper HSK 63-A

- Power (S1 / S6) kW 60 / 75

- Torque (S1 / S6) Nm 60 / 75

- Characteristic speed rpm 9.550

Automatic tool changer- No. of housings 30

- Max. tool diameter mm 90

- Max. tool weight kg 8

- Max. tool length mm 300

Accuracy (as per VDI / DGQ 3441)- Uncertainty (P) X / Y / Z : 0,007 mm B, C : 10 sec

- Repeatability (Ps medium) X / Y / Z : 0,004 mm B, C : 5 sec

- Reversal (U medium)

Other data- Weight kg 31.000

- Length (doors closed + conveyor) mm 5.340

- Width mm 7.520

- Height mm 5.140

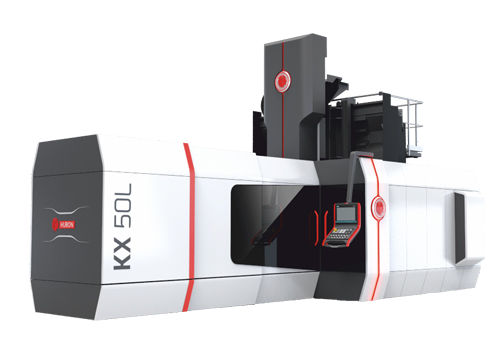

KX 50 L

-

The KX Large Series offers a wide selection of machines for continuous five-axis/five-side machining of complex parts.

The fixed-portal architecture and machine design ensure maximum rigidity for extremely precise machining in a variety of difficult materials.

Its large work area, capable of supporting up to 20 tonnes in weight and accomodating processable volumes up to 4.080 x 2.180 x 1.550 mm, is suited to machining large parts for general mechanical and precision engineering, 3D shapes, and the aeronautical and energy sectors.

Customer reguirements are comfortably met by the modularity of design, the choice of variants, and equipment.

Key Features- Machine with palletizing function for increased productivity

- Volumetric precision for making moulds and complex parts

- Wide clearance between the columns to exploit the work volume fully

- Spindle offering optimum performance for roughing and finishing

- Spindle suited to high chip rates

- Structural design guaranteeing long mechanical life

- High degree of precision due to direct measurement on the linear and rotary axes

Technical Specification:

Linear axes- X axis mm 3.000

- Y axis mm 1.700

- Z axis mm 900

- Rapid feedrate m/min X / Y / Z : 40

Rotating axes on head- Type of head: Forked head

- Rotating axes B - Swivelling axis : +/- 105° C - Rotating axis : +/- 200°

- Rotating speed rpm B, C : 100

- Torque : motor / clamping Nm 4.000

Table

- Structure: Fixed table

- Table size mm 3.300 x 1.250

- Admission load on table kg 6.000

Spindle

- Rotating speed rpm 20.000

- Tool taper HSK 63-A

- Power (S1 / S6) kW 60 / 75

- Torque (S1 / S6) Nm 60 / 75

- Characteristic speed rpm 9.550

Automatic tool changer- No. of housings 30

- Max. tool diameter mm 90

- Max. tool weight kg 8

- Max. tool length mm 300

Accuracy (as per VDI / DGQ 3441)- Uncertainty (P) X / Y / Z : 0,007 mm B, C : 10 sec

- Repeatability (Ps medium) X / Y / Z : 0,004 mm B, C : 5 sec

Other data- Weight kg 36.000

- Length (doors closed + conveyor) mm 5.340

- Width mm 10.150

- Height mm 5.140

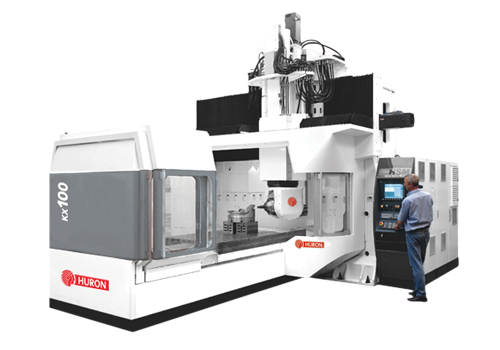

KX 100

-

The KX Large Series offers a wide selection of machines for continuous five-axis/five-side machining of complex parts.

The fixed-portal architecture and machine design ensure maximum rigidity for extremely precise machining in a variety of difficult materials.

Its large work area, capable of supporting up to 20 tonnes in weight and accomodating processable volumes up to 4.080 x 2.180 x 1.550 mm, is suited to machining large parts for general mechanical and precision engineering, 3D shapes, and the aeronautical and energy sectors.

Customer reguirements are comfortably met by the modularity of design, the choice of variants, and equipment.

Key Features- Machine with palletizing function for increased productivity

- Volumetric precision for making moulds and complex parts

- Wide clearance between the columns to exploit the work volume fully

- Spindle offering optimum performance for roughing and finishing

- Spindle suited to high chip rates

- Structural design guaranteeing long mechanical life

- High degree of precision due to direct measurement on the linear and rotary axes

Technical Specification:

Linear axes- X axis mm 2.300

- Y axis mm 2.300

- Z axis mm 1.000

- Rapid feedrate m/min X / Y / Z : 40

Rotating axes on head- Type of head: Forked head

- Rotating axes: B - Swivelling axis : +/- 105° C - Rotating axis : +/- 190°

- Rotating speed rpm B, C : 30

- Torque : motor / clamping Nm 7.000

Table- Structure: Fixed table

- Table size mm 2.500 x 1.250

- Admission load on table kg 6.000

Spindle- Rotating speed rpm 18.000

- Tool taper HSK 63-A

- Power (S1 / S6) kW 20 / 30

- Torque (S1 / S6) Nm 160 / 240

- Characteristic speed rpm 1.200

Automatic tool changer- No. of housings 40

- Max. tool diameter mm 100 / 190

- Max. tool weight kg 8

- Max. tool length mm 300

Accuracy (as per VDI / DGQ 3441)- Uncertainty (P) X / Y / Z : 0,007 mm B, C : 10 sec

- Repeatability (Ps medium) X / Y / Z : 0,004 mm B, C : 5 sec

Other data- Weight kg 35.000

- Length (doors closed + conveyor) mm 7.280

- Width mm 7.890

- Height mm 5.390

KX 200

-

The KX Large Series offers a wide selection of machines for continuous five-axis/five-side machining of complex parts.

The fixed-portal architecture and machine design ensure maximum rigidity for extremely precise machining in a variety of difficult materials.

Its large work area, capable of supporting up to 20 tonnes in weight and accomodating processable volumes up to 4.080 x 2.180 x 1.550 mm, is suited to machining large parts for general mechanical and precision engineering, 3D shapes, and the aeronautical and energy sectors.

Customer reguirements are comfortably met by the modularity of design, the choice of variants, and equipment.

Key Features- Machine with palletizing function for increased productivity

- Volumetric precision for making moulds and complex parts

- Wide clearance between the columns to exploit the work volume fully

- Spindle offering optimum performance for roughing and finishing

- Spindle suited to high chip rates

- Structural design guaranteeing long mechanical life

- High degree of precision due to direct measurement on the linear and rotary axes

Technical Specification:

Linear axes- X axis mm 3.300

- Y axis mm 2.300

- Z axis mm 1.000

- Rapid feedrate m/min X : 25 Y / Z : 40

- Type of head: Forked head

- Rotating axes: B - Swivelling axis : +/- 105° C - Rotating axis : +/- 190°

- Rotating speed rpm B, C : 30

- Torque : motor / clamping Nm 7.000

Table- Structure: Fixed table

- Table size mm 3.500 x 1.250

- Admission load on table kg 9.000

Spindle- Rotating speed rpm 18.000

- Tool taper HSK 63-A

- Power (S1 / S6) kW 20 / 30

- Torque (S1 / S6) Nm 160 / 240

- Characteristic speed rpm 1.200

Automatic tool changer- No. of housings 40

- Max. tool diameter mm 100 / 190

- Max. tool weight kg 8

- Max. tool length mm 300

Accuracy (as per VDI / DGQ 3441)- Uncertainty (P) X / Y / Z : 0,007 mm B, C : 10 sec

- Repeatability (Ps medium) X / Y / Z : 0,004 mm B, C : 5 sec

Other data- Weight kg 41.000

- Length (doors closed + conveyor) mm 7.190

- Width mm 10.690

- Height mm 5.410

KX 300

-

The KX Large Series offers a wide selection of machines for continuous five-axis/five-side machining of complex parts.

The fixed-portal architecture and machine design ensure maximum rigidity for extremely precise machining in a variety of difficult materials.

Its large work area, capable of supporting up to 20 tonnes in weight and accomodating processable volumes up to 4.080 x 2.180 x 1.550 mm, is suited to machining large parts for general mechanical and precision engineering, 3D shapes, and the aeronautical and energy sectors.

Customer reguirements are comfortably met by the modularity of design, the choice of variants, and equipment.

Key Features- Machine with palletizing function for increased productivity

- Volumetric precision for making moulds and complex parts

- Wide clearance between the columns to exploit the work volume fully

- Spindle offering optimum performance for roughing and finishing

- Spindle suited to high chip rates

- Structural design guaranteeing long mechanical life

- High degree of precision due to direct measurement on the linear and rotary axes

Technical Specification:

Linear axes- X axis mm 5.000

- Y axis mm 3.100

- Z axis mm 1.500

- Rapid feedrate m/min X / Y / Z : 20

Rotating axes on head- Type of head: Forked head

- Rotating axes: B - Swivelling axis : +/- 105° C - Rotating axis : +/- 190°

- Rotating speed rpm B, C : 30

- Torque : motor / clamping Nm 7.000

Table- Structure: Fixed table

- Table size mm 5.200 x 2.000

- Admission load on table kg 13.000

Spindle- Rotating speed rpm 18.000

- Tool taper HSK 63-A

- Power (S1 / S6) kW 20 / 30

- Torque (S1 / S6) Nm 160 / 240

- Characteristic speed rpm 1.200

Automatic tool changer- No. of housings 40

- Max. tool diameter mm 100 / 190

- Max. tool weight kg 8

- Max. tool length mm 300

Accuracy (as per VDI / DGQ 3441)- Uncertainty (P) X / Y / Z : 0,007 mm B, C : 10 sec

- Repeatability (Ps medium) X / Y / Z : 0,004 mm B, C : 5 sec

Other data- Weight kg 100.000

- Length (doors closed + conveyor) mm 7.000

- Width mm 15.000

- Height mm 7.050

MX Series

MX 4

-

The MX 4 offers outstanding power, precision, rapidity and rigidity for the very high quality machining of complex parts in difficult materials in minimum time.

Key Features- Linear motors on Y and Z axes to increase speed of movement and boost acceleration and rapid tool change

- Light, rigid mobile structures to get the most out of linear motor performance

- Ballscrew on X-axis to eliminate the risks of pollution

- Floor anchoring for improved rigidity and greater dynamics

- Excellent positioning accuracy and repeatability

- Palletizable concept for increased productivity

Technical Specification:- Linear axes

- X axis mm 750

- Y axis mm 700

- Z axis mm 500

- Rapid feedrate m/min X : 60 Y / Z : 120

- Rotating axes on table

- Rotating axes: A - Tilting axis : -45° / + 180° C - Rotating axis : 360°

- Rotating speeds rpm A, C : 100

- Torque : motor / clamping Nm A : 740 - C : 430 / A, C : 2.500

Table- Structure Rotating table on a 45° plane

- Table size mm Ø 440

- Dimension of workpiece mm Ø 440 x Height 405

- Admission load on table kg 250

Spindle- Rotating speed rpm 24.000

- Tool taper HSK 63-A

- Power (S1 / S6) kW 20 / 25

- Torque (S1 / S6) Nm 32 / 40

- Characteristic speed rpm 6.000

Automatic tool changer- No. of housings 36

- Max. tool diameter mm 70 / 90

- Max. tool weight kg 5

- Max. tool length mm 250

Accuracy (as per VDI / DGQ 3441)- Positioning (P) X / Y / Z : 0,004 mm A, C : 7,2 sec

- Repeatability (Ps medium) X / Y / Z : 0,002 mm A, C : 3,6 sec

Other data- Weight kg 8.700

- Length (doors closed + conveyor) mm 4.170

- Width mm 4.300

- Height mm 3.020

MX 8

-

The MX multifunctions machining centre is a high flexibility machine enabling machining operations in 5 axes and on 5 sides, in one setup part clamping, from roughing to finishing, as well as turning operations.

Key Features

Milling (M) and Mill-Turn (MT) centres- 5 axes machining

- Hard material machining in a minimal time

- Very high accuracy in contouring and profiles

- Complete automation of the machine

Head and spindle- Head equipped with integrated torque motor

- Head on a 45° plane allowing tilting from -45° to 180°

- Powerful spindle with high torque allowing high metal removal rate

- Monitoring of the machining’s vibrations to secure all the elements of the machine, the tool as well as the workpiece

Technical Specification: MX 8 M - MX 8 MT

Linear axes- X - Y - Z axes mm 1.160 x 1.000 x 900

- Rapid feedrate m/min 40

- Head - Rotating axis A

- Type of head Universal head

- Swivelling -45 ° / +180°

- Rotating speed rpm 100

- Torque : working / clamping Nm 1.410 / 2.500 - 1.410 / 2.500

Table - Rotating axis C : Milling - Mill/Turn- Table size mm Ø 1.000 x 800 - Ø 800

- Dimension of workpiece mm Ø 1.000 x Height 1.035 - Ø 800 x Height 1.035

- Admission load on table kg 2.000

- Positioning 360°

- Rotating speeds rpm 50 - 500

- Torque : working / clamping Nm 1.210 / 10.000 - 1.580 / 10.000

Spindle- Rotating speed rpm 18.000 - 10.000

- Tool taper HSK 63-A - HSK 100-A

- Power (S1 / S6) kW 20 / 30 - 32 / 50

- Torque (S1 / S6) Nm 160 / 240 - 180 / 280

- Characteristic speed rpm 1.200 - 1.700

Automatic tool changer- No. of housings 60 - 48

- Max. tool diameter mm 95 - 125

- Max. tool weight kg 8 - 15

- Max. tool length mm 400

Accuracy (as per VDI / DGQ 3441)- Uncertainty (P) X / Y / Z : 0,007 mm A, C : 10 sec

- Repeatability (Ps medium) X / Y / Z : 0,004 mm A, C : 5 sec

Other data- Weight kg 22.000

- Length (doors closed + conveyor) mm 6.180

- Width mm 5.800

- Height mm 3.760

MX 10

-

The MX multifunctions machining centre is a high flexibility machine enabling machining operations in 5 axes and on 5 sides, in one setup part clamping, from roughing to finishing, as well as turning operations.

Key Features

Milling (M) and Mill-Turn (MT) centres- 5 axes machining

- Hard material machining in a minimal time

- Very high accuracy in contouring and profiles

- Complete automation of the machine

Head and spindle- Head equipped with integrated torque motor

- Head on a 45° plane allowing tilting from -45° to 180°

- Powerful spindle with high torque allowing high metal removal rate

- Monitoring of the machining’s vibrations to secure all the elements of the machine, the tool as well as the workpiece

Technical Specification: MX 10 M - MX 10 MT

Linear axes- X - Y - Z axes mm 1.200 x 1.200 x 1.000

- Rapid feedrate m/min 40

Head - Rotating axis A- Type of head Universal head

- Swivelling -45 ° / +180°

- Rotating speed rpm 100

- Torque : working / clamping Nm 1.750/ 2.500

Table - Rotating axis C Milling - Mill/Turn- Table size mm Ø 1.250 x 900 - Ø 1.000

- Dimension of workpiece mm Ø 1.250 x Height 1.130

- Admission load on table kg 2.500 - 2.000

- Positioning 360°

- Rotating speeds rpm 65 - 500

- Torque : working / clamping Nm 2.700 / 10.000 - 3.270 / 10.000

Spindle- Rotating speed rpm 10.000

- Tool taper HSK 100-A

- Power (S1 / S6) kW 32 / 50

- Torque (S1 / S6) Nm 180 / 280

- Characteristic speed rpm 1.700

Automatic tool changer- No. of housings 48

- Max. tool diameter mm 125

- Max. tool weight kg 15

- Max. tool length mm 400

Accuracy (as per VDI / DGQ 3441)- Uncertainty (P) X / Y / Z : 0,007 mm A, C : 10 sec

- Repeatability (Ps medium) X / Y / Z : 0,004 mm A, C : 5 sec

Other data- Weight kg 35.000

- Length (doors closed + conveyor) mm 6.335

- Width mm 7.950

- Height mm 4.380

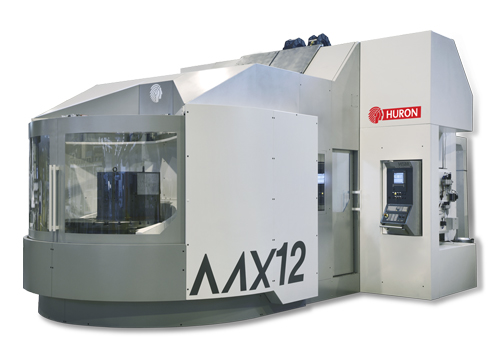

MX 12

-

The MX multifunctions machining centre is a high flexibility machine enabling machining operations in 5 axes and on 5 sides, in one setup part clamping, from roughing to finishing, as well as turning operations.

Key Features

Milling (M) and Mill-Turn (MT) centres- 5 axes machining

- Hard material machining in a minimal time

- Very high accuracy in contouring and profiles

- Complete automation of the machine

Head and spindle- Head equipped with integrated torque motor

- Head on a 45° plane allowing tilting from -45° to 180°

- Powerful spindle with high torque allowing high metal removal rate

- Monitoring of the machining’s vibrations to secure all the elements of the machine, the tool as well as the workpiece

Technical Specification: MX 12 M - MX 12 MT

Linear axes- X - Y - Z axes mm 1.200 x 1.600 x 1.000

- Rapid feedrate m/min 40

Head - Rotating axis A- Type of head Universal head

- Swivelling -45 ° / +180°

- Rotating speed rpm 100

- Torque : working / clamping Nm 1.750 / 2.500

Table - Rotating axis C Milling - Mill/Turn- Table size mm Ø 1.600 x 1.250 - Ø 1.400

- Dimension of workpiece mm Ø 1.600 x Height 1.130

- Admission load on table kg 4.000

- Positioning 360°

- Rotating speeds rpm 50 - 250

- Torque : working / clamping Nm 4.590 / 12.000 - 5.670 / 12.000

Spindle- Rotating speed rpm 10.000

- Tool taper HSK 100-A

- Power (S1 / S6) kW 32 / 50

- Torque (S1 / S6) Nm 180 / 280

- Characteristic speed rpm 1.700

Automatic tool changer- No. of housings 48

- Max. tool diameter mm 125

- Max. tool weight kg 15

- Max. tool length mm 400

Accuracy (as per VDI / DGQ 3441)- Uncertainty (P) X / Y / Z : 0,007 mm A, C : 10 sec

- Repeatability (Ps medium) X / Y / Z : 0,004 mm A, C : 5 sec

Other data- Weight kg 35.000

- Length (doors closed + conveyor) mm 6.405

- Width mm 8.360

- Height mm 4.800

MX 16

-

The MX multifunctions machining centre is a high flexibility machine enabling machining operations in 5 axes and on 5 sides, in one setup part clamping, from roughing to finishing.

Key Features

Milling (M)- 5 axes machining

- Hard material machining in a minimal time

- Very high accuracy in contouring and profiles

- Complete automation of the machine

Head and spindle- Head equipped with integrated torque motor

- Head on a 45° plane allowing tilting from -45° to 180°

- Powerful spindle with high torque allowing high metal removal rate

- Monitoring of the machining’s vibrations to secure all the elements of the machine, the tool as well as the workpiece

Technical Specification:

Linear axes- X - Y - Z axes mm 2.300 x 2.300 x 1.250

- Rapid feedrate m/min 40

Head - Rotating axis A- Type of head: Universal head

- Swivelling -45 ° / +180°

- Rotating speed rpm 100

- Torque : working / clamping Nm 1.410 / 2.500

Table - Rotating axis C Milling- Table size mm Ø 1.750

- Dimension of workpiece mm Ø 2.000 x Height 1.300

- Distance between columns mm 2.000

- Admission load on table kg 10.000

- Positioning 360°

- Rotating speeds rpm 9

- Torque : working / clamping Nm 12.000 / 35.000

Spindle- Rotating speed rpm 10.000

- Tool taper HSK 100-A

- Power (S1 / S6) kW 32 / 50

- Torque (S1 / S6) Nm 180 / 280

- Characteristic speed rpm 1.700

Automatic tool changer- No. of housings 40

- Max. tool diameter mm 120

- Max. tool weight kg 10

- Max. tool length mm 300

Accuracy (as per VDI / DGQ 3441)- Uncertainty (P) X / Y / Z : 0,007 mm A, C : 10 sec

- Repeatability (Ps medium) X / Y / Z : 0,004 mm A, C : 5 sec

Other data- Weight kg 45.000

- Length (doors closed + conveyor) mm 8.000

- Width mm 9.000

- Height mm 6.570

MX 20

-

The MX multifunctions machining centre is a high flexibility machine enabling machining operations in 5 axes and on 5 sides, in one setup part clamping, from roughing to finishing.

Key Features

Milling (M)- 5 axes machining

- Hard material machining in a minimal time

- Very high accuracy in contouring and profiles

- Complete automation of the machine

Head and spindle- Head equipped with integrated torque motor

- Head on a 45° plane allowing tilting from -45° to 180°

- Powerful spindle with high torque allowing high metal removal rate

- Monitoring of the machining’s vibrations to secure all the elements of the machine, the tool as well as the workpiece

Technical Specification:

Linear axes- X - Y - Z axes mm 3.000 x 3.100 x 1.500

- Rapid feedrate m/min 40

Head - Rotating axis A- Type of head Universal head

- Swivelling -45 ° / +180°

- Rotating speed rpm 100

- Torque : working / clamping Nm 1.410 / 2.500

Table - Rotating axis C Milling- Table size mm Ø 2.200

- Dimension of workpiece mm Ø 2.500 x Height 1.650

- Distance between columns mm 2.500

- Admission load on table kg 12.000

- Positioning 360°

- Rotating speeds rpm 7

- Torque : working / clamping Nm 18.000 / 38.000

Spindle- Rotating speed rpm 10.000

- Tool taper HSK 100-A

- Power (S1 / S6) kW 32 / 50

- Torque (S1 / S6) Nm 180 / 280

- Characteristic speed rpm 1.700

Automatic tool changer- No. of housings 40

- Max. tool diameter mm 120

- Max. tool weight kg 10

- Max. tool length mm 300

Accuracy (as per VDI / DGQ 3441)- Uncertainty (P) X / Y / Z : 0,007 mm A, C : 10 sec

- Repeatability (Ps medium) X / Y / Z : 0,004 mm A, C : 5 sec

Other data- Weight kg 90.000

- Length (doors closed + conveyor) mm 8.500

- Width mm 10.350

- Height mm 6.570

KXG Series

KXG 45-14

-

The KXG series comprises gantry milling centres that are particularly effective in machining large, complex parts.

Key Features- Design suited to continuous 5-axis machining of very large parts

- Machining with very high feed speeds

- High rigidity enabling very high metal removal rates

- Design and structure

- Gantry structure with reinforced, U-type moving crossrail

- Polymer concrete walls, each incorporating a linear motor assembly and a double guiding system

- Optimization of the moving axes by finite element structural calculation

- Dedicated foundation for improved dynamics

- Ergonomics and environment

- Retractable roof for easy access to the work area and workpiece

- Tool magazine outside of the work area

- Tilting, inclined operator panel

- Energy efficiency for the production of large-sized parts

Technical Specification:

Linear axes- X axis mm 4.500

- Y axis mm 1.400

- Z axis mm 800

- Rapid feedrate m/min X / Y : 60 Z : 45

Rotating axes on head- Type of head: Forked head

- Rotating axes: B - Swivelling axis : +/- 105° C - Rotating axis : +/- 190°

- Rotating speed rpm B, C : 100

- Torque : motor / clamping Nm 4.000

Table- Structure: Fixed table

- Table size mm 4.700 x 1.390

- Admission load on table kg 18.000

Spindle- Rotating speed rpm 20.000

- Tool taper HSK 63-A

- Power (S1 / S6) kW 60 / 75

- Torque (S1 / S6) Nm 60 / 75

- Characteristic speed rpm 9.550

Automatic tool changer- No. of housings 40

- Max. tool diameter mm 100 / 190

- Max. tool weight kg 8

- Max. tool length mm 300

Accuracy (as per VDI / DGQ 3441)- Positioning (P) X : 0,025 mm Y / Z : 0,010 mm B, C : 10 sec

- Repeatability (Ps medium) X / Y / Z : 0,005 mm B, C : 5 sec

Other data- Weight kg 60.000

- Length (doors closed + conveyor) mm 7.550

- Width mm 9.700

- Height mm 4.980

KXG 45-23

-

The KXG series comprises gantry milling centres that are particularly effective in machining large, complex parts.

Key Features- Design suited to continuous 5-axis machining of very large parts

- Machining with very high feed speeds

- High rigidity enabling very high metal removal rates

- Design and structure

- Gantry structure with reinforced, U-type moving crossrail

- Polymer concrete walls, each incorporating a linear motor assembly and a double guiding system

- Optimization of the moving axes by finite element structural calculation

- Dedicated foundation for improved dynamics

- Ergonomics and environment

- Retractable roof for easy access to the work area and workpiece

- Tool magazine outside of the work area

- Tilting, inclined operator panel

- Energy efficiency for the production of large-sized parts

Technical Specification:

Linear axes- X axis mm 4.500

- Y axis mm 2.300

- Z axis mm 800

- Rapid feedrate m/min X / Y : 60 Z : 45

Rotating axes on head- Type of head: Forked head

- Rotating axes: B - Swivelling axis : +/- 105° C - Rotating axis : +/- 190°

- Rotating speed rpm B, C : 100

- Torque : motor / clamping Nm 4.000

Table- Structure: Fixed table

- Table size mm 4.700 x 2.480

- Admission load on table kg 25.000

Spindle- Rotating speed rpm 20.000

- Tool taper HSK 63-A

- Power (S1 / S6) kW 60 / 75

- Torque (S1 / S6) Nm 60 / 75

- Characteristic speed rpm 9.550

Automatic tool changer- No. of housings 40

- Max. tool diameter mm 100 / 190

- Max. tool weight kg 8

- Max. tool length mm 300

Accuracy (as per VDI / DGQ 3441)- Positioning (P) X : 0,025 mm Y / Z : 0,010 mm B, C : 10 sec

- Repeatability (Ps medium) X / Y / Z : 0,005 mm B, C : 5 sec

Other data- Weight kg 75.500

- Length (doors closed + conveyor) mm 8.940

- Width mm 10.000

- Height mm 4.980

KXG 60-23

-

The KXG series comprises gantry milling centres that are particularly effective in machining large, complex parts.

Key Features- Design suited to continuous 5-axis machining of very large parts

- Machining with very high feed speeds

- High rigidity enabling very high metal removal rates

- Design and structure

- Gantry structure with reinforced, U-type moving crossrail

- Polymer concrete walls, each incorporating a linear motor assembly and a double guiding system

- Optimization of the moving axes by finite element structural calculation

- Dedicated foundation for improved dynamics

- Ergonomics and environment

- Retractable roof for easy access to the work area and workpiece

- Tool magazine outside of the work area

- Tilting, inclined operator panel

- Energy efficiency for the production of large-sized parts

Technical Specification:

Linear axes- X axis mm 6.000

- Y axis mm 2.300

- Z axis mm 800

- Rapid feedrate m/min X / Y : 60 Z : 45

Rotating axes on head- Type of head: Forked head

- Rotating axes: B - Swivelling axis : +/- 105° C - Rotating axis : +/- 190°

- Rotating speed rpm B, C : 100

- Torque : motor / clamping Nm 4.000

Table- Structure: Fixed table

- Table size mm 6.200 x 2.480

- Admission load on table kg 30.000

Spindle- Rotating speed rpm 20.000

- Tool taper HSK 63-A

- Power (S1 / S6) kW 60 / 75

- Torque (S1 / S6) Nm 60 / 75

- Characteristic speed rpm 9.550

Automatic tool changer- No. of housings 40

- Max. tool diameter mm 100 / 190

- Max. tool weight kg 8

- Max. tool length mm 300

Accuracy (as per VDI / DGQ 3441)- Positioning (P) X : 0,035 mm Y / Z : 0,010 mm B, C : 10 sec

- Repeatability (Ps medium) X : 0,006 mm Y / Z : 0,005 mm B, C : 5 sec

Other data- Weight kg 90.000

- Length (doors closed + conveyor) mm 9.100

- Width mm 11.700

- Height mm 4.980

KXG 90-23

-

The KXG series comprises gantry milling centres that are particularly effective in machining large, complex parts.

Key Features- Design suited to continuous 5-axis machining of very large parts

- Machining with very high feed speeds

- High rigidity enabling very high metal removal rates

- Design and structure

- Gantry structure with reinforced, U-type moving crossrail

- Polymer concrete walls, each incorporating a linear motor assembly and a double guiding system

- Optimization of the moving axes by finite element structural calculation

- Dedicated foundation for improved dynamics

- Ergonomics and environment

- Retractable roof for easy access to the work area and workpiece

- Tool magazine outside of the work area

- Tilting, inclined operator panel

- Energy efficiency for the production of large-sized parts

Technical Specification:

Linear axes- X axis mm 9.000

- Y axis mm 2.300

- Z axis mm 800

- Rapid feedrate m/min X / Y : 60 Z : 45

Rotating axes on head- Type of head: Forked head

- Rotating axes: B - Swivelling axis : +/- 105° C - Rotating axis : +/- 190°

- Rotating speed rpm B, C : 100

- Torque : motor / clamping Nm 4.000

Table- Structure: Fixed table

- Table size mm 9.000 x 2.480

- Admission load on table kg 52.000

Spindle- Rotating speed rpm 20.000

- Tool taper HSK 63-A

- Power (S1 / S6) kW 60 / 75

- Torque (S1 / S6) Nm 60 / 75

- Characteristic speed rpm 9.550

Automatic tool changer- No. of housings 40

- Max. tool diameter mm 100 / 190

- Max. tool weight kg 8

- Max. tool length mm 300

Accuracy (as per VDI / DGQ 3441)- Positioning (P) X : 0,035 mm Y / Z : 0,010 mm B, C : 10 sec

- Repeatability (Ps medium) X : 0,006 mm Y / Z : 0,005 mm B, C : 5 sec

Other data- Weight kg 130.000

- Length (doors closed + conveyor) mm 10.210

- Width mm 13.650

- Height mm 4.980

Vertical Milling 3 axes

VX Series

VX 6

-

The VX Series, specially designed to meet customers' precision and reliability criteria, is extremely user-friendly and guarantees excellent profitability.

Proven rapid return on investment.

Compact - Ergonomic - Powerful - Accurate !

The VX is an ideal investment for the manufacture of tooling and for small to medium-scale production.

Key Features- C-frame structure in quality ribbed cast iron

- Broad-based architecture with reinforced column to withstand cutting forces and absorb the effects of machining vibrations

- Excellent dynamic performance for rapid changes of direction and acceleration

- Calibrated, pre-stressed ballscrews with direct motor coupling

Technical Specification:

Linear axes- X axis mm 600

- Y axis mm 400

- Z axis mm 460

- Rapid feedrate m/min X / Y / Z : 24

Table- Table dimension mm 800 x 500

- Admissible load kg 400

- T-slots mm 4 x 18 x 100

Spindle- Rotating speed rpm 10.000

- Taper ISO 40

- Power (S1 / S6) kW 10,5 / 14,5

- Torque (S1 / S6) Nm 50 / 69

- Characteristic speed rpm 2.000

Automatic tool changer- Number of housings 24

- Max. tool diameter mm 80

- Max. tool weight kg 7

- Max. tool length mm 250

Accuracy (according to VDI / DGQ 3441)- Positioning (P) mm X / Y / Z : 0,015

- Repeatability (PS medium) mm X / Y / Z : 0,003

Other datas- Weight of the machine kg 5.200

- Width (Doors opened + conveyor) mm 3.960

- Depth mm 2.470

- Height mm 2.900

VX 8

-

The VX Series, specially designed to meet customers' precision and reliability criteria, is extremely user-friendly and guarantees excellent profitability.

Proven rapid return on investment.

Compact - Ergonomic - Powerful - Accurate !

The VX is an ideal investment for the manufacture of tooling and for small to medium-scale production.

Key Features- C-frame structure in quality ribbed cast iron

- Broad-based architecture with reinforced column to withstand cutting forces and absorb the effects of machining vibrations

- Excellent dynamic performance for rapid changes of direction and acceleration

- Calibrated, pre-stressed ballscrews with direct motor coupling

Technical Specification:

Linear axes- X axis mm 820

- Y axis mm 510

- Z axis mm 510

- Rapid feedrate m/min X / Y / Z : 24

Table- Table dimension mm 1.000 x 530

- Admissible load kg 500

- T-slots mm 4 x 18 x 100

Spindle- Rotating speed rpm 10.000

- Taper ISO 40

- Power (S1 / S6) kW 10,5 / 14,5

- Torque (S1 / S6) Nm 50 / 69

- Characteristic speed rpm 2.000

Automatic tool changer- Number of housings 24

- Max. tool diameter mm 80

- Max. tool weight kg 7

- Max. tool length mm 250

Accuracy (according to VDI / DGQ 3441)- Positioning (P) mm X / Y / Z : 0,015

- Repeatability (PS medium) mm X / Y / Z : 0,003

Other datas- Weight of the machine kg 5.300

- Width (Doors opened + conveyor) mm 3.960

- Depth mm 2.310

- Height mm 2.900

VX 10

-

The VX Series, specially designed to meet customers' precision and reliability criteria, is extremely user-friendly and guarantees excellent profitability.

Proven rapid return on investment.

Compact - Ergonomic - Powerful - Accurate !

The VX is an ideal investment for the manufacture of tooling and for small to medium-scale production.

Key Features- C-frame structure in quality ribbed cast iron

- Broad-based architecture with reinforced column to withstand cutting forces and absorb the effects of machining vibrations

- Excellent dynamic performance for rapid changes of direction and acceleration

- Calibrated, pre-stressed ballscrews with direct motor coupling

Technical Specification:

Linear axes- X axis mm 1.020

- Y axis mm 510

- Z axis mm 510

- Rapid feedrate m/min X / Y / Z : 24

Table- Table dimension mm 1.200 x 530

- Admissible load kg 800

- T-slots mm 4 x 18 x 100

Spindle- Rotating speed rpm 10.000

- Taper ISO 40

- Power (S1 / S6) kW 10,5 / 14,5

- Torque (S1 / S6) Nm 50 / 69

- Characteristic speed rpm 2.000

Automatic tool changer- Number of housings 24

- Max. tool diameter mm 80

- Max. tool weight kg 7

- Max. tool length mm 250

Accuracy (according to VDI / DGQ 3441)- Positioning (P) mm X / Y / Z : 0,015

- Repeatability (PS medium) mm X / Y / Z : 0,003

Other datas- Weight of the machine kg 6.700

- Width (Doors opened + conveyor) mm 4.440

- Depth mm 2.600

- Height mm 2.900

VX 12

-

The VX Series, specially designed to meet customers' precision and reliability criteria, is extremely user-friendly and guarantees excellent profitability.

Proven rapid return on investment.

Compact - Ergonomic - Powerful - Accurate !

The VX is an ideal investment for the manufacture of tooling and for small to medium-scale production.

Key Features- C-frame structure in quality ribbed cast iron

- Broad-based architecture with reinforced column to withstand cutting forces and absorb the effects of machining vibrations

- Excellent dynamic performance for rapid changes of direction and acceleration

- Calibrated, pre-stressed ballscrews with direct motor coupling

Technical Specification:

Linear axes- X axis mm 1.220

- Y axis mm 600

- Z axis mm 610

- Rapid feedrate m/min X / Y / Z : 24

Table- Table dimension mm 1.400 x 630

- Admissible load kg 1.200

- T-slots mm 5 x 18 x 125

Spindle- Rotating speed rpm 10.000

- Taper ISO 40

- Power (S1 / S6) kW 10,5 / 14,5

- Torque (S1 / S6) Nm 50 / 69

- Characteristic speed rpm 2.000

Automatic tool changer- Number of housings 24

- Max. tool diameter mm 80

- Max. tool weight kg 7

- Max. tool length mm 250

Accuracy (according to VDI / DGQ 3441)- Positioning (P) mm X / Y / Z : 0,015

- Repeatability (PS medium) mm X / Y / Z : 0,003

Other datas- Weight of the machine kg 7.700

- Width (doors closed + conveyor) mm 4.595

- Depth mm 2.520

- Height mm 3.150

VX 15

-

The VX Series, specially designed to meet customers' precision and reliability criteria, is extremely user-friendly and guarantees excellent profitability.

Proven rapid return on investment.

Compact - Ergonomic - Powerful - Accurate !

The VX is an ideal investment for the manufacture of tooling and for small to medium-scale production.

Key Features- C-frame structure in quality ribbed cast iron

- Broad-based architecture with reinforced column to withstand cutting forces and absorb the effects of machining vibrations

- Excellent dynamic performance for rapid changes of direction and acceleration

- Calibrated, pre-stressed ballscrews with direct motor coupling

Technical Specification:

Linear axes- X axis mm 1.510

- Y axis mm 810

- Z axis mm 810

- Rapid feedrate m/min X / Y / Z : 20

Table- Table dimension mm 1.700 X 810

- Admissible load kg 2.000

- T-slots mm 5 x 18 x 125

Spindle- Rotating speed rpm 10.000

- Taper ISO 40

- Power (S1 / S6) kW 10,5 / 14,5

- Torque (S1 / S6) Nm 50 / 69

- Characteristic speed rpm 2.000

Automatic tool changer- Number of housings 40

- Max. tool diameter mm 76

- Max. tool weight kg 7

- Max. tool length mm 250

Accuracy (according to VDI / DGQ 3441)- Positioning (P) mm X / Y / Z : 0,015

- Repeatability (PS medium) mm X / Y / Z : 0,008

Other datas- Weight of the machine kg 14.200

- Width (Doors opened + conveyor) mm 6.600

- Depth mm 4.540

- Height mm 4.000

VX 18

-

The VX Series, specially designed to meet customers' precision and reliability criteria, is extremely user-friendly and guarantees excellent profitability.

Proven rapid return on investment.

Compact - Ergonomic - Powerful - Accurate !

The VX is an ideal investment for the manufacture of tooling and for small to medium-scale production.

Key Features- C-frame structure in quality ribbed cast iron

- Broad-based architecture with reinforced column to withstand cutting forces and absorb the effects of machining vibrations

- Excellent dynamic performance for rapid changes of direction and acceleration

- Calibrated, pre-stressed ballscrews with direct motor coupling

Technical Specification:

Linear axes- X axis mm 1.810

- Y axis mm 810

- Z axis mm 810

- Rapid feedrate m/min X / Y / Z : 20

Table- Table dimension mm 2.000 X 810

- Admissible load kg 2.500

- T-slots mm 5 x 18 x 125

Spindle- Rotating speed rpm 10.000

- Taper ISO 40

- Power (S1 / S6) kW 10,5 / 14,5

- Torque (S1 / S6) Nm 50 / 69

- Characteristic speed rpm 2.000

Automatic tool changer- Number of housings 40

- Max. tool diameter mm 76

- Max. tool weight kg 7

- Max. tool length mm 250

Accuracy (according to VDI / DGQ 3441)- Positioning (P) mm X / Y / Z : 0,015

- Repeatability (PS medium) mm X / Y / Z : 0,008

Other datas- Weight of the machine kg 16.500

- Width (Doors opened + conveyor) mm 6.680

- Depth mm 4.560

- Height mm 4.000

Kmill Series

KMILL 8

-

KX, a timeless name given to the first portal-structured machine and one that still features in the HRUON product range. It incarnates the most efficien concept for machining complex parts along three axes, from roughing to finishing.

This series of machines combines dynamic action and precision for top quality surface finishes, espacially for 3D shapes for moulds, forgings and tooling.

Key Features- Ribbed cast iron structure offering high mechanical performance for greater rigidity

- Excellent absorption of the vibrations generated by the tough cutting conditions

- Floor anchoring to maintain geometric stability and precision over time

Technical Specification:

Linear axes- X axis mm 700

- Y axis mm 600

- Z axis mm 500

- Feedrates m/min X / Y / Z : 40

Table- Table size mm 800 x 600

- Admissible load kg 500

- T-slots mm 5 x 18 x 100

- Distance from floor to top talbe mm 848

- Distance min/max spindle face / top table mm 100 - 600

- Distance under portal mm 485

Spindle- Rotating speed rpm 15.000

- Tool taper ISO 40

- Power (S1 / S6) kW 26,4 / 26,4

- Torque (S1 / S6) Nm 84 - 110

- Characteristic speed rpm 3.000

Tool magazine- Number of housings 30

- Max. diameter of tool mm 90

- Max. weight of tool kg 7

- Max. length of tool mm 300

Accuracy (according to VDI / DGQ 3441)- Positioning uncertainty (P) mm X / Y / Z : 0,010

- Repeatability (PS medium) mm X / Y / Z : 0,005

Other datas- Weight of the machine kg 7.000

- Width (with doors closed and chips conveyor mm 4.100

- Length mm 2.050

- Height mm 3.060

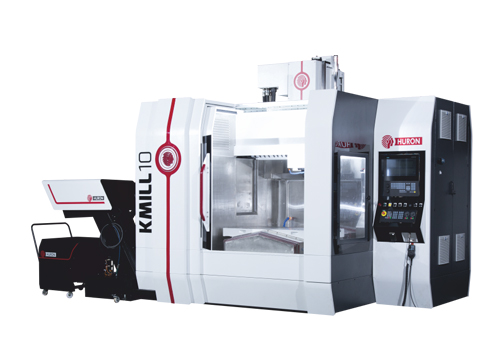

KMILL 10

-

KX, a timeless name given to the first portal-structured machine and one that still features in the HRUON product range. It incarnates the most efficien concept for machining complex parts along three axes, from roughing to finishing.

This series of machines combines dynamic action and precision for top quality surface finishes, espacially for 3D shapes for moulds, forgings and tooling.

Key Features- Ribbed cast iron structure offering high mechanical performance for greater rigidity

- Excellent absorption of the vibrations generated by the tough cutting conditions

- Floor anchoring to maintain geometric stability and precision over time

Technical Specification:

Linear axes- X axis mm 1.000

- Y axis mm 700

- Z axis mm 600

- Feedrates m/min X / Y : 30 Z : 18

Table- Table sizemm 1.250 x 700

- Admissible load kg 1.500

- T-slots mm 6 x 18 x 100

- Distance from floor to top talbe mm 930

- Distance min/max spindle face / top table mm 140 - 740

- Distance under portal mm 670

Spindle- Rotating speed rpm 15.000

- Tool taper ISO 40

- Power (S1 / S6) kW 26,4 / 26,4

- Torque (S1 / S6) Nm 84 - 110

- Characteristic speed rpm 3.000

Tool magazine- Number of housings 30

- Max. diameter of tool mm 90

- Max. weight of tool kg 7

- Max. length of tool mm 300

Accuracy (according to VDI / DGQ 3441)- Positioning uncertainty (P) mm X / Y : 0,015 Z : 0,007

- Repeatability (PS medium) mm X / Y : 0,007 Z : 0,005

Other datas- Weight of the machine kg 10.500

- Width (with doors closed and chips conveyor) mm 4.590

- Length mm 2.840

- Height mm 3.060

KX / K2X Series

K2X 8

-

KX, a timeless name given to the first portal-structured machine and one that still features in the HRUON product range. It incarnates the most efficien concept for machining complex parts along three axes, from roughing to finishing.

This series of machines combines dynamic action and precision for top quality surface finishes, espacially for 3D shapes for moulds, forgings and tooling.

Key Features- Ribbed cast iron structure offering high mechanical performance for greater rigidity

- Excellent absorption of the vibrations generated by the tough cutting conditions

- Floor anchoring to maintain geometric stability and precision over time

Technical Specification:

Linear axes- X axis mm 700

- Y axis mm 600

- Z axis mm 450

- Rapid feedrate m/min X / Y / Z : 40

Table- Dimension mm 800 x 600

- Admissible load kg 500

- Nuts mm 5 x 18 x 100

- Distance under portal mm 450

- Distance spindle nose/top table 100 / 550

Spindle- Rotating speed rpm 24.000

- Taper HSK 63-A

- Power (S1 / S6) kW 20 / 25

- Torque (S1 / S6) Nm 32 / 40

- Characteristic speed rpm 6.000

Automatic tool changer- Qty of housings 24

- Max. tool diameter mm 90

- Max. tool weight kg 7

- Max. tool length mm 300

Accuracy (according VDI / DGQ 3441)- Positioning (P) mm X / Y / Z : 0,004

- Repeatability (PS medium) mm X / Y / Z : 0,002

Other data- Weight of the machine kg 7.000

- Length (Doors opened + Conveyor mm 4.380

- Width mm 2.050

- Height mm 3.060

K2X 10

-

KX, a timeless name given to the first portal-structured machine and one that still features in the HRUON product range. It incarnates the most efficien concept for machining complex parts along three axes, from roughing to finishing.

This series of machines combines dynamic action and precision for top quality surface finishes, espacially for 3D shapes for moulds, forgings and tooling.

Key Features- Ribbed cast iron structure offering high mechanical performance for greater rigidity

- Excellent absorption of the vibrations generated by the tough cutting conditions

- Floor anchoring to maintain geometric stability and precision over time

Technical Specification:

Linear axes- X axis mm 1.000

- Y axis mm 800

- Z axis mm 500

- Rapid feedrate m/min X / Y / Z : 60

Table- Dimension mm 1.150 x 800

- Admissible load kg 1.000

- Nuts mm 8 x 18 x 100

- Distance under portal mm 525

- Distance spindle nose/top table 115 / 615

Spindle- Rotating speed rpm 18.000

- Taper HSK 63-A

- Power (S1 / S6) kW 25 / 35

- Torque (S1 / S6) Nm 86 / 120

- Characteristic speed rpm 2.800

Automatic tool changer- Qty of housings 24

- Max. tool diameter mm 90

- Max. tool weight kg 7

- Max. tool length mm 300

Accuracy (according VDI / DGQ 3441)- Positioning (P) mm X / Y / Z : 0,004

- Repeatability (PS medium) mm X / Y / Z : 0,002

Other data- Weight of the machine kg 12.500

- Length (Doors opened + Conveyor mm 4.690

- Width mm 3.100

- Height mm 3.400

K2X 20

-

KX, a timeless name given to the first portal-structured machine and one that still features in the HRUON product range. It incarnates the most efficien concept for machining complex parts along three axes, from roughing to finishing.

This series of machines combines dynamic action and precision for top quality surface finishes, espacially for 3D shapes for moulds, forgings and tooling.

Key Features- Ribbed cast iron structure offering high mechanical performance for greater rigidity

- Excellent absorption of the vibrations generated by the tough cutting conditions

- Floor anchoring to maintain geometric stability and precision over time

Technical Specification:

Linear axes- X axis mm 1.200

- Y axis mm 1.000

- Z axis mm 500

- Rapid feedrate m/min X : 50 Y / Z : 60

Table- Dimension mm 1.400 x 1.000

- Admissible load kg 2.000

- Nuts mm 7 x 18 x 125

- Distance under portal mm 653

- Distance spindle nose/top table 250 / 750

Spindle- Rotating speed rpm 18.000

- Taper HSK 63-A

- Power (S1 / S6) kW 25 / 35

- Torque (S1 / S6) Nm 86 / 120

- Characteristic speed rpm 2.800

Automatic tool changer- Qty of housings 24

- Max. tool diameter mm 90

- Max. tool weight kg 7

- Max. tool length mm 300

Accuracy (according VDI / DGQ 3441)- Positioning (P) mm X / Y / Z : 0,005

- Repeatability (PS medium) mm X / Y / Z : 0,003

Other data- Weight of the machine kg 14.400

- Length (Doors opened + Conveyor mm 4.690

- Width mm 4.510

- Height mm 3.560

KX 30

-

KX, a timeless name given to the first portal-structured machine and one that still features in the HRUON product range. It incarnates the most efficien concept for machining complex parts along three axes, from roughing to finishing.

This series of machines combines dynamic action and precision for top quality surface finishes, espacially for 3D shapes for moulds, forgings and tooling.

Key Features- Ribbed cast iron structure offering high mechanical performance for greater rigidity

- Excellent absorption of the vibrations generated by the tough cutting conditions

- Floor anchoring to maintain geometric stability and precision over time

Technical Specification:

Linear axes- X axis mm 1.800

- Y axis mm 1.000

- Z axis mm 700

- Rapid feedrate m/min X / Y : 30 Z : 18

Table- Dimension mm 2.000 x 1.000

- Admissible load kg 4.000

- Nuts mm 10 x 18 x 100

- Distance under portal mm 770

- Distance spindle nose/top table 225 / 925

Spindle- Rotating speed rpm 18.000

- Taper HSK 63-A

- Power (S1 / S6) kW 25 / 35

- Torque (S1 / S6) Nm 86 / 120

- Characteristic speed rpm 2.800

Automatic tool changer- Qty of housings 24

- Max. tool diameter mm 90

- Max. tool weight kg 7

- Max. tool length mm 300

Accuracy (according VDI / DGQ 3441)- Positioning (P) mm X : 0,009 Y / Z : 0,007

- Repeatability (PS medium) mm X / Y / Z : 0,005

Other data- Weight of the machine kg 17.000

- Length (Doors opened + Conveyor mm 4.340

- Width mm 6.310

- Height mm 3.425

NX Series

NX 40

-

The NX series of flexible, modular three-axis portal milling centres fulfils the most exacting demands in the field of general mechanical and precision engineering.

Its portal structure, wide distance between uprights and optimized cutting conditions provide an ideal environment for intense, quality machining of large, heavy and complex parts.

Key Features- Robust construction and floor anchoring to guarantee precision and geometric stability

- High chip removal capacity on roughing with the friction guiding system on the vertical axis

- Large table area and wide distance between uprights to process the full volume of the workpiece

- Outstanding accessibility to the table and workpiece thanks to the tunnel-type shroud

- Efficient swarf removal

- Tilting operator panel

- Simpler maintenance

Technical Specification:

Linear axes- X axis mm 2.200

- Y axis mm 1.500

- Z axis mm 800

- Rapid feedrate m/min X / Y : 20 Z : 15

Table- Table dimension mm 2.200 x 1.250

- Admissible load kg 6.000

- Slots mm 9 x 18 x 125

- Distance top table / floor mm 790

- Distance spindle nose / top table mm 200 / 1.000

- Distance between the columns mm 1.600

Spindle- Rotating speed rpm 6.000

- Taper ISO 50

- Power (S1 / S6) kW 21,5 / 32,3

- Torque (S1 / S6) Nm 117 / 170

- Nenndrehzahl rpm 1.500

Tools changer- Nb of housings 24

- Max. tool diameter mm 127 / 254

- Max. tool weight kg 15

- Max. length of tool mm 350

Accuracy (according to VDI / DGQ 3441)- Positioning (P) mm X / Y / Z : 0,020

- Repeatabilità (PS medium) mm X / Y / Z : 0,008

Other informations- Weight of the machine kg 22.000

- Width (Doors opened + chips conveyor) mm 5.200

- Length mm 7.400

- Height mm 4.420

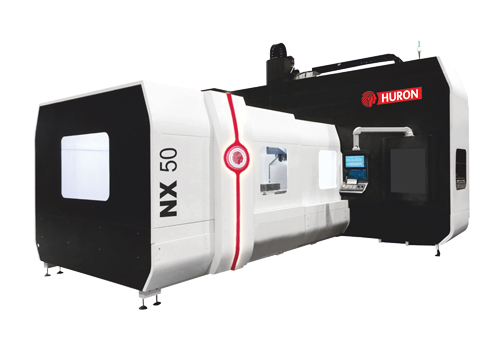

NX 50

-

The NX series of flexible, modular three-axis portal milling centres fulfils the most exacting demands in the field of general mechanical and precision engineering.

Its portal structure, wide distance between uprights and optimized cutting conditions provide an ideal environment for intense, quality machining of large, heavy and complex parts.

Key Features- Robust construction and floor anchoring to guarantee precision and geometric stability

- High chip removal capacity on roughing with the friction guiding system on the vertical axis

- Large table area and wide distance between uprights to process the full volume of the workpiece

- Outstanding accessibility to the table and workpiece thanks to the tunnel-type shroud

- Efficient swarf removal

- Tilting operator panel

- Simpler maintenance

Technical Specification:

Linear axes- X axis mm 3.200

- Y axis mm 1.500

- Z axis mm 800

- Rapid feedrate m/min X / Z : 15 Y : 20

Table- Table dimension mm 3.000 x 1.250

- Admissible load kg 8.000

- Slots mm 9 x 18 x 125

- Distance top table / floor mm 790

- Distance spindle nose / top table mm 200 / 1.000

- Distance between the columns mm 1.600

Spindle- Rotating speed rpm 6.000

- Taper ISO 50

- Power (S1 / S6) kW 21,5 / 32,3

- Torque (S1 / S6) Nm 117 / 170

- Nenndrehzahl rpm 1.500

Tools changer- Nb of housings 24

- Max. tool diameter mm 127 / 254

- Max. tool weight kg 15

- Max. length of tool mm 350

Accuracy (according to VDI / DGQ 3441)- Positioning (P) mm X / Y / Z : 0,020

- Repeatabilità (PS medium) mm X / Y / Z : 0,008

Other informations- Weight of the machine kg 25.000

- Width (Doors opened + chips conveyor) mm 5.400

- Length mm 9.550

- Height mm 4.420

NX 60

-

The NX series of flexible, modular three-axis portal milling centres fulfils the most exacting demands in the field of general mechanical and precision engineering.

Its portal structure, wide distance between uprights and optimized cutting conditions provide an ideal environment for intense, quality machining of large, heavy and complex parts.

Key Features- Robust construction and floor anchoring to guarantee precision and geometric stability

- High chip removal capacity on roughing with the friction guiding system on the vertical axis

- Large table area and wide distance between uprights to process the full volume of the workpiece

- Outstanding accessibility to the table and workpiece thanks to the tunnel-type shroud

- Efficient swarf removal

- Tilting operator panel

- Simpler maintenance

Technical Specification:

Linear axes- X axis mm 3.200

- Y axis mm 2.200

- Z axis mm 800

- Rapid feedrate m/min X / Y / Z : 15

Table- Table dimension mm 3.000 x 2.000

- Admissible load kg 10.000

- Slots mm 12 x 22 x 160

- Distance top table / floor mm 920

- Distance spindle nose / top table mm 200 / 1.000

- Distance between the columns mm 2.500

Spindle- Rotating speed rpm 6.000

- Taper ISO 50

- Power (S1 / S6) kW 21,5 / 32,3

- Torque (S1 / S6) Nm 117 / 170

- Nenndrehzahl rpm 1.500

Tools changer- Nb of housings 24

- Max. tool diameter mm 127 / 254

- Max. tool weight kg 15

- Max. length of tool mm 350

Accuracy (according to VDI / DGQ 3441)- Positioning (P) mm X / Y / Z : 0,020

- Repeatabilità (PS medium) mm X / Y / Z : 0,008

Other informations- Weight of the machine kg 30.000

- Width (Doors opened + chips conveyor) mm 6.160

- Length mm 9.550

- Height mm 4.420

NX 70

-

The NX series of flexible, modular three-axis portal milling centres fulfils the most exacting demands in the field of general mechanical and precision engineering.

Its portal structure, wide distance between uprights and optimized cutting conditions provide an ideal environment for intense, quality machining of large, heavy and complex parts.

Key Features- Robust construction and floor anchoring to guarantee precision and geometric stability

- High chip removal capacity on roughing with the friction guiding system on the vertical axis

- Large table area and wide distance between uprights to process the full volume of the workpiece

- Outstanding accessibility to the table and workpiece thanks to the tunnel-type shroud

- Efficient swarf removal

- Tilting operator panel

- Simpler maintenance

Technical Specification:

Linear axes- X axis mm 4.200

- Y axis mm 2.200

- Z axis mm 700

- Rapid feedrate m/min X / Y / Z : 15

Table- Table dimension mm 3.500 x 2.000

- Admissible load kg 10.000

- Slots mm 12 x 22 x 160

- Distance top table / floor mm 920

- Distance spindle nose / top table mm 200 / 1.000

- Distance between the columns mm 2.500

Spindle- Rotating speed rpm 6.000

- Taper ISO 50

- Power (S1 / S6) kW 21,5 / 32,3

- Torque (S1 / S6) Nm 117 / 170

- Nenndrehzahl rpm 1.500

Tools changer- Nb of housings 24

- Max. tool diameter mm 127 / 254

- Max. tool weight kg 15

- Max. length of tool mm 350

Accuracy (according to VDI / DGQ 3441)- Positioning (P) mm X / Y / Z : 0,020

- Repeatabilità (PS medium) mm X / Y / Z : 0,008

Other informations- Weight of the machine kg 37.000

- Width (Doors opened + chips conveyor) mm 6.160

- Length mm 10.650

- Height mm 4.790

EX Series

EXP 20

-

As a pioneer of high-speed machining, the EX has boosted its users’ productivity levels enormously. Today, the modularity in terms of the configurations and applications of this timeless series meets the widest variety of customer requirements, from the machining of prototypes to small and medium-scale parts production.

Key Features- Cast iron structure for high stability and rigidity

- Head type « P » (Continuous servi axis for 5 axes machining)

- Spindle mounted on moving column to cover a wide work area

- Versatility and ease of use

- Accessibility to the workpiece through the wide-opening doors

- Panel mounted on tilting arm

- High-performance spindl available

- Variety of fixed or rotary tables available

Technical Specification:

Linear axes- X axis mm 1.600

- Y axis mm 800

- Z axis mm 800

- Rapid feedrate m/min X / Y / Z : 30

Rotating axes on head- Type of head Head type "P"

- Rotating axes B - Swivelling axis : +/- 110°

- Rotating speed rpm 17,5

- Torque : motor / clamping Nm 6.000

Table- Structure Fixed table

- Table size mm 2.000 x 750

- Thickness of table mm 120

- Admission load on table kg 3.500

- Distance from floor to table 1.000 / 920

Spindle- Rotating speed rpm 12.000

- Tool taper HSK 63-A

- Power (S1 / S6) kW 26 / 26

- Torque (S1 / S6) Nm 84 / 110

- Characteristic speed rpm 3.000

Automatic tool changer- No. of housings 36

- Max. tool diameter mm 100

- Max. tool weight kg 10

- Max. tool length mm 300

Accuracy (as per VDI / DGQ 3441)- Positioning (P) X / Y / Z : 0,010 mm B : 6 sec

- Repeatability (Ps medium) X / Y / Z : 0,006 mm B : 8 sec

Other data- Weight kg 18.000

- Length (doors closed + conveyor) mm 6.445

- Width mm 5.460

- Height mm 3.600

EXP 30

-

As a pioneer of high-speed machining, the EX has boosted its users’ productivity levels enormously. Today, the modularity in terms of the configurations and applications of this timeless series meets the widest variety of customer requirements, from the machining of prototypes to small and medium-scale parts production.

Key Features- Cast iron structure for high stability and rigidity

- Head type « P » (Continuous servi axis for 5 axes machining)

- Spindle mounted on moving column to cover a wide work area

- Versatility and ease of use

- Accessibility to the workpiece through the wide-opening doors

- Panel mounted on tilting arm

- High-performance spindl available

- Variety of fixed or rotary tables available

Technical Specification:- Linear axes

- X axis mm 2.400

- Y axis mm 800

- Z axis mm 800

- Rapid feedrate m/min X / Y / Z : 30

Rotating axes on head- Type of head Head type "P"

- Rotating axes B - Swivelling axis : +/- 110°

- Rotating speed rpm 17,5

- Torque : motor / clamping Nm 6.000

Table- Structure Fixed table

- Table size mm 2.800 x 750

- Thickness of table mm 120

- Admission load on table kg 4.500

- Distance from floor to table 1.000 / 920

Spindle- Rotating speed rpm 12.000

- Tool taper HSK 63-A

- Power (S1 / S6) kW 26 / 26

- Torque (S1 / S6) Nm 84 / 110

- Characteristic speed rpm 3.000

Automatic tool changer- No. of housings 36

- Max. tool diameter mm 100

- Max. tool weight kg 10

- Max. tool length mm 300

Accuracy (as per VDI / DGQ 3441)- Positioning (P) X / Y / Z : 0,010 mm B : 6 sec

- Repeatability (Ps medium) X / Y / Z : 0,006 mm B : 8 sec

Other data- Weight kg 18.000

- Length (doors closed + conveyor) mm 6.445

- Width mm 5.460

- Height mm 3.600

Horizontal machining

HSX Series

HSX 540

-

A revolutionary concept of High Dynamic High Precision HSX Series suitable for a wide range of applications right from heavy duty cutting to high speed machining typically designed to increase positional accuracy at actual working feed acceleration and decelerations with optimized dynamic characteristics, while reducing metal cutting or ideal machining time so that it can delivers quick response to commands.

Key Features- High table load carrying capacity with wider working area

- Efficien chip removal and coolant system

- 180° indexing hydraulic type auto pallet changer

- High torque 10.000 rpm electro-spindle

- 40-tool 180° indexing arm type Auto Tool Changer

- Operator-friendly panel

Technical Specification:

Linear axes- X axis mm 630

- Y axis mm 600

- Z axis mm 600

- Rapid feedrate m/min X / Y / Z : 50

Pallet device- Qty pallets mm 2

- Pallet size mm 400 x 500

- Workpiece size (Ø x height) mm 650 x 750

- Max. load on each pallet kg 400

- Rotating speeds rpm 80

- Distance from pallet surface to spindle centre mm 80 - 680

- Distance from pallet centre to spindle nose mm 100 - 700

Spindle- Rotating speed rpm 12,000

- Tool taper ISO 40

- Power (S1 / S6) kW 26

- Torque (S1 / S6) Nm 125

Automatic tool changer- No. of housings 40

- Max. tool diameter mm 76 / 127

- Max. tool weight kg 7

- Max. tool length mm 300

Accuracy (as per VDI / DGQ 3441)- Uncertainty (P) X / Y / Z : 0,010 mm

- Repeatability (Ps medium) X / Y / Z : 0,005 mm

Other data

Weight kg 12,000

Length (doors closed + conveyor) mm 4,235

Width mm 2,775

Height mm 2,650

HSX 650

-

A revolutionary concept of High Dynamic High Precision HSX Series suitable for a wide range of applications right from heavy duty cutting to high speed machining typically designed to increase positional accuracy at actual working feed acceleration and decelerations with optimized dynamic characteristics, while reducing metal cutting or ideal machining time so that it can delivers quick response to commands.

Key Features- High table load carrying capacity with wider working area

- Efficien chip removal and coolant system

- 180° indexing hydraulic type auto pallet changer

- High torque 10.000 rpm electro-spindle

- 40-tool 180° indexing arm type Auto Tool Changer

- Operator-friendly panel

Technical Specification:

Linear axes- X axis mm 780

- Y axis mm 730

- Z axis mm 750

- Rapid feedrate m/min X / Y / Z : 50

Pallet device- Qty pallets mm 2

- Pallet size mm 500 x 630

- Workpiece size (Ø x height) mm 800 x 950

- Max. load on each pallet kg 700

- Rotating speeds rpm 60

- Distance from pallet surface to spindle centre mm 80 - 810

- Distance from pallet centre to spindle nose mm 100 - 850

Spindle- Rotating speed rpm 10,000

- Tool taper ISO 50

- Power (S1 / S6) kW 41

- Torque (S1 / S6) Nm 170

Automatic tool changer- No. of housings 40

- Max. tool diameter mm 125 / 230

- Max. tool weight kg 15

- Max. tool length mm 350

Accuracy (as per VDI / DGQ 3441)- Uncertainty (P) X / Y / Z : 0,010 mm

- Repeatability (Ps medium) X / Y / Z : 0,005 mm

Other data- Weight kg 19,000

- Length (doors closed + conveyor) mm 3,255

- Width mm 5,212

- Height mm 3,500

HSX 860

-

A revolutionary concept of High Dynamic High Precision HSX Series suitable for a wide range of applications right from heavy duty cutting to high speed machining typically designed to increase positional accuracy at actual working feed acceleration and decelerations with optimized dynamic characteristics, while reducing metal cutting or ideal machining time so that it can delivers quick response to commands.

Key Features- High table load carrying capacity with wider working area

- Efficien chip removal and coolant system

- 180° indexing hydraulic type auto pallet changer

- High torque 10.000 rpm electro-spindle

- 40-tool 180° indexing arm type Auto Tool Changer

- Operator-friendly panel

Technical Specification:

Linear axes- X axis mm 1,000

- Y axis mm 900

- Z axis mm 900

- Rapid feedrate m/min X / Y / Z : 50

Pallet device- Qty pallets mm 2

- Pallet size mm 630 x 800

- Workpiece size (Ø x height) mm 1.000 x 1.100

- Max. load on each pallet kg 1,100

- Rotating speeds rpm 50

- Distance from pallet surface to spindle centre mm 80 - 980

- Distance from pallet centre to spindle nose mm 100 - 1.000

Spindle- Rotating speed rpm 10,000

- Tool taper ISO 50

- Power (S1 / S6) kW 41

- Torque (S1 / S6) Nm 170

Automatic tool changer- No. of housings 40

- Max. tool diameter mm 125 / 230

- Max. tool weight kg 15

- Max. tool length mm 350

Accuracy (as per VDI / DGQ 3441)- Uncertainty (P) X / Y / Z : 0,015 mm

- Repeatability (Ps medium) X / Y / Z : 0,007 mm

Other data- Weight kg 22,000

- Length (doors closed + conveyor) mm 6,500

- Width mm 3,300

- Height mm 3,375

Horizontal Turning

DX Series

DX 200

-

The DX 200 two-axis turning centre is ideal for the production of parts in a single setup.

Particularly flexible and equipped with a turret with tools for drilling, boring and turning operations, the DX 200 turning centre helps to produce with significant time savings.

The rigidity and high degrees of positioning accuracy and repeatability make this a cost-effective choice investment that offers excellent value for money.