- Offer Profile

-

EOS is the world's leading technology supplier in the field of industrial 3D printing of metals and polymers. Formed in 1989, the independent company is pioneer and innovator for comprehensive solutions in additive manufacturing. Its product portfolio of EOS systems, materials, and process parameters gives customers crucial competitive advantages in terms of product quality and the long-term economic sustainability of their manufacturing processes. Furthermore customers benefit from deep technical expertise in global service, applications engineering and consultancy.

Welcome to EOS

Additive Manufacturing

-

Additive Manufacturing refers to a process by which digital 3D design data is used to build up a component in layers by depositing material. The term "3D printing" is increasingly used as a synonym for Additive Manufacturing. However, the latter is more accurate in that it describes a professional production technique which is clearly distinguished from conventional methods of material removal.

Like no other company, EOS is mastering the interaction of laser and powder material. Additionally, EOS provides all essential elements for industrial 3D printing. System, material and process parameters are intelligently harmonized to ensure a reliable high quality of parts and thus facilitating a decisive competitive edge. Furthermore customers benefit from deep technical expertise in global service, applications engineering and consultancy.

Your benefits and possibilities using additive manufacturing with EOS systems:- Functional Integration

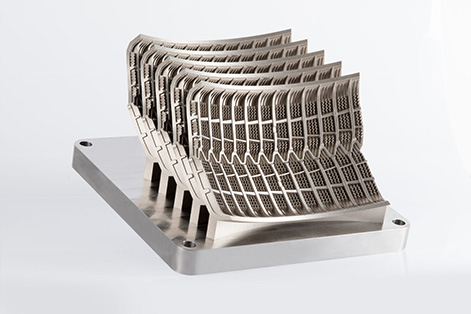

Fewer assembly components, less logistical effort and greater flexibility: Additive Manufacturing technology from EOS makes it possible to integrate functions in parts – during serial production. - Lightweight Construction

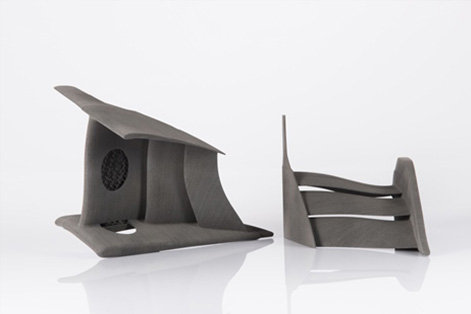

Additive Manufacturing from EOS enables the construction and manufacture of highly stable lightweight structures that cannot be produced using conventional production processes. - Complex Geometries

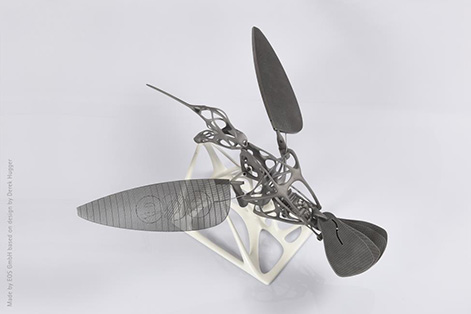

Additive Manufacturing makes design-driven production a reality. Innovative EOS technology offers designers the greatest possible freedom and enables extremely complex structures to be manufactured. - Bionic Structures

Conventional production processes are pushed to their absolute limits with bionic structures. On the other hand, Additive Manufacturing offers maximum construction freedom, which is ideal for bionic technology. - Shorten R&D Times

The fast track to the serial product – Additive Manufacturing from EOS takes users from the first design idea to the finished prototype with no detours along the way. - Reduce Manufacturing Costs

Additive Manufacturing permits cost-effective production for individual items as well as batch items. The complexity of a part has almost no bearing on manufacturing time and costs. - Customized Products

Additive Manufacturing from EOS requires no tools. It permits customized, batch-size-appropriate serial production.

- Functional Integration

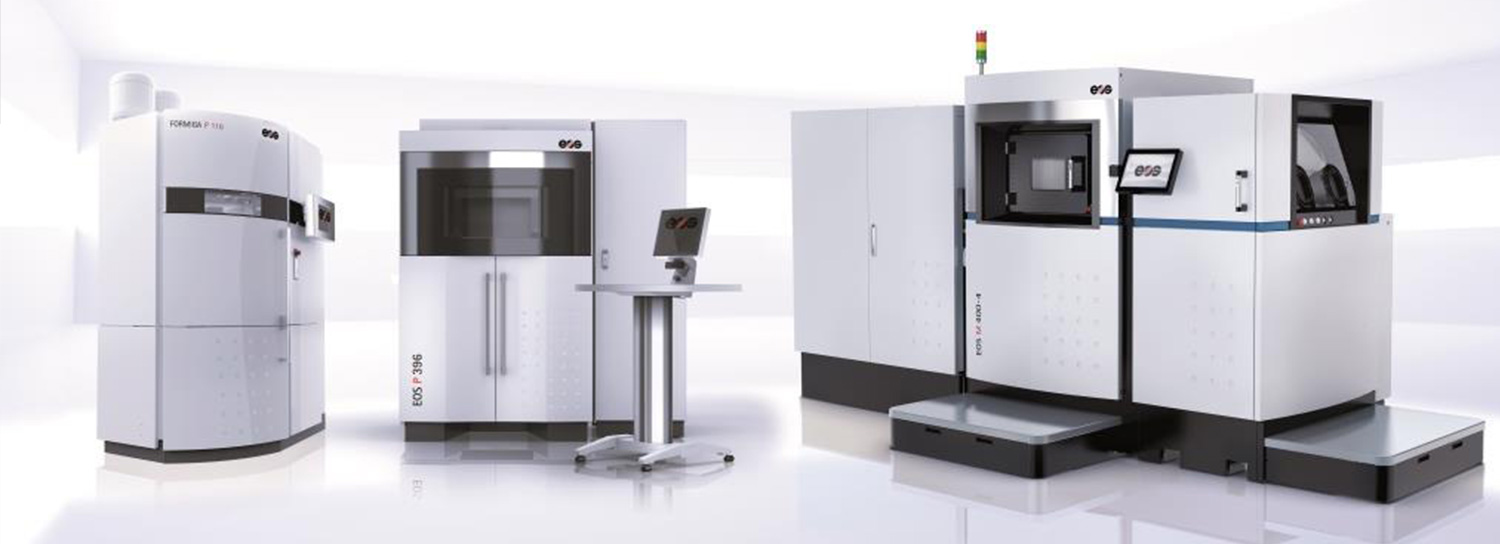

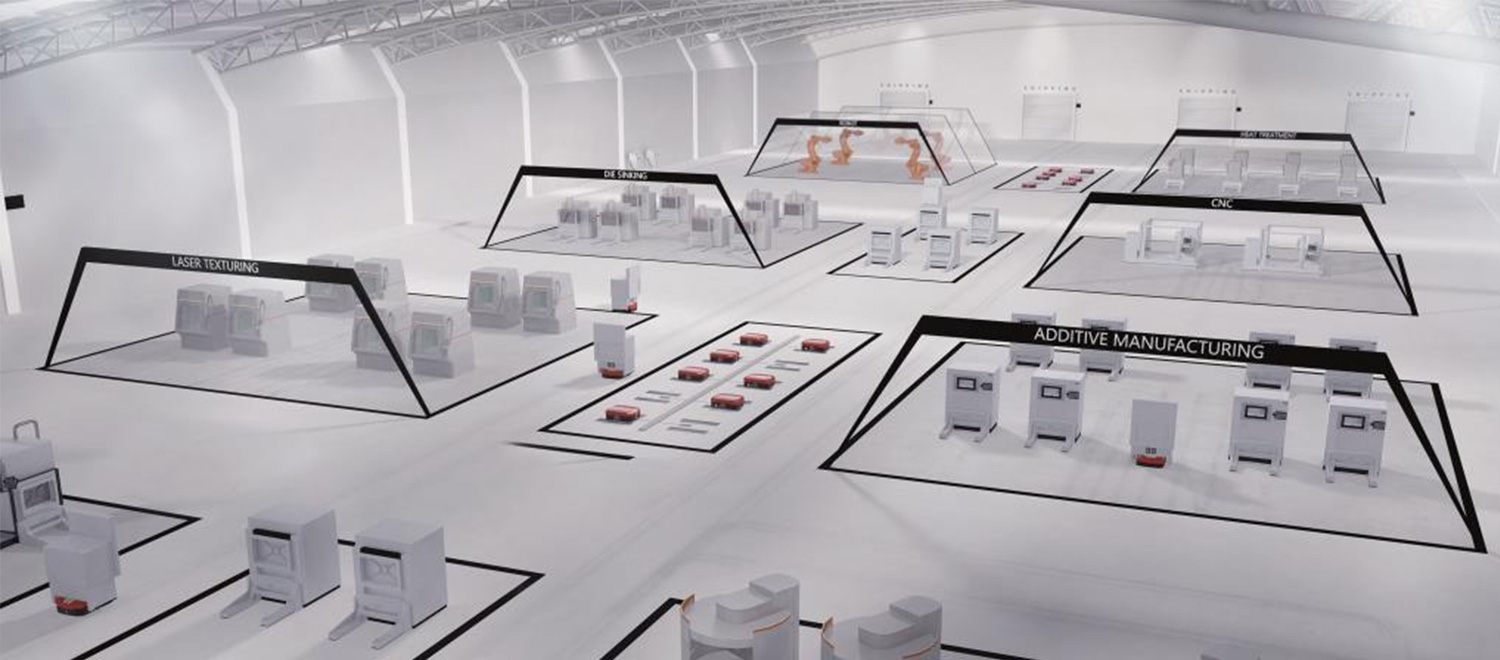

Systems & Solutions for Additive Manufacturing

- EOS offers solutions to meet complex challenges in industrial 3D Printing / Additive Manufacturing that are geared towards specific industries and customers. The EOS solution portfolio is modular in structure, its elements are perfectly harmonized and can be combined according to needs. In addition to systems for Additive Manufacturing, the EOS solution portfolio comprises a wide range of materials, software and processes as well as extensive services and supplementary products.

Systems and Equipment for Plastic Additive Manufacturing

- EOS provides Systems and Solutions for Additive Manufacturing of Polymer Series Products, Spare Parts and Prototypes. Without requiring tools, EOS systems make direct use of digital CAD data to produce polymer parts of the highest quality.

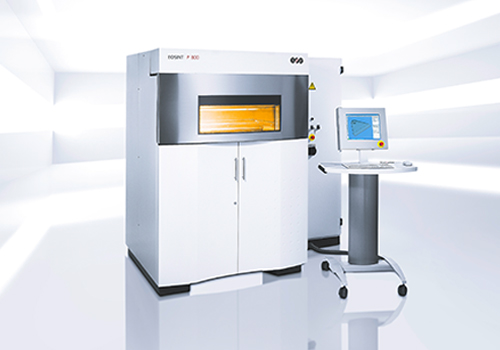

FORMIGA P 110 Velocis

-

The benchmark for industrial 3D printing of polymer parts with outstanding quality — now 20% faster.

The most successful industrial 3D printer is now up to 20% more productive thanks to new software and hardware features. Maintaining high reliability and FORMIGA quality, which set the standard in the market, the cost is more attractive than ever.

EOS P 396

-

About 38% less energy consumption and up to 32% faster

System for Additive Manufacturing of serial parts and functional prototypes from polymer materials. With total build size of 340 x 340 x 600 mm, the EOS P 396 covers the medium build volume range. This modular and highly productive system allows the tool-free manufacture of serial components, spare parts, functional prototypes and models directly from CAD data.

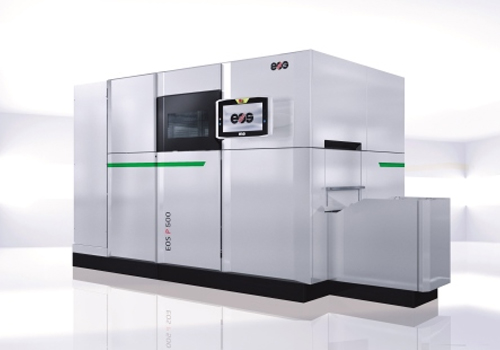

EOS P 500

-

The automation-ready manufacturing platform for laser sintering of plastic parts on an industrial scale

EOS P 500 is the automation-ready manufacturing platform for laser sintering of plastic parts on an industrial scale. It offers high quality components at the lowest cost-per-part and maximum productivity for processing polymers at operating temperatures of up to 300°C.

The innovative manufacturing platform produces components that fulfill highest requirements regarding mechanical and dimensional accuracy and reproducibility. Thanks to clever hardware interfaces and accessories, the uptime of the EOS P 500 increases by up to 75% compared to predecessor systems and competition models.

EOS P 770

-

High productive Laser Sintering System for parts of up to one meter in length

Additive manufacturing system with two lasers for the production of large parts and for industrial high-throughput manufacturing. The system has the largest building volume available on the market for parts of up to one meter in length. With 10 commercial polymer materials and 18 combinations of materials/layer thicknesses currently available for the EOS P 770, EOS is a benchmark in terms of material variety.

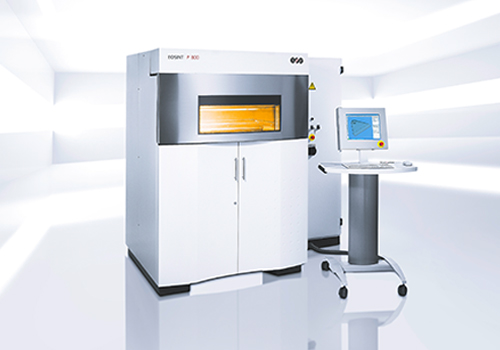

EOS P 800

-

Additive Manufacturing System for processing high performance polymers

Additive Manufacturing System for processing high performance polymers with high-temperature laser sintering for process temperatures of up to 385 °C.

EOS P 810

-

High-temperature polymer laser sintering solution for serial production of demanding composite components

EOS P 810 & HT-23: The perfect solution for demanding high-performance applications

With a building volume of 700 x 380 x 380 mm, EOS P 810 enables a fast and cost efficient production of plastic parts directly from CAD data. Parts made out of HT-23 material offer high strength at low weight and withstand high temperatures.

Systems and Solutions for Metal Additive Manufacturing

- Tool-less manufacturing of high-quality prototypes and end products of metal. EOS offers a comprehensive portfolio of systems, materials, software and services for all process steps of industrial 3D printing.

EOS M 290

-

The benchmark for the industrial 3D printing of high-quality metal parts - with enhanced quality management features.

With a building volume of 250 x 250 x 325 mm, the EOS M 290 allows a fast, flexible and cost-effective production of metal parts directly from CAD data. An intuitive user interface, the intelligent software concept with a combination of open and standardized parameter sets and the improved filter system are specially designed for the industrial production.

EOS M 300-4

-

Digital Additive Manufacturing for the Industrial Production of High-Quality Metal Parts

Designed for industrial applications, the EOS M 300 series offers a high degree of flexibility and enables DMLS quality at up to 10x higher productivity. The new exposure module offers the flexibility to choose the number of lasers, their power as well as a fixed or variable focus

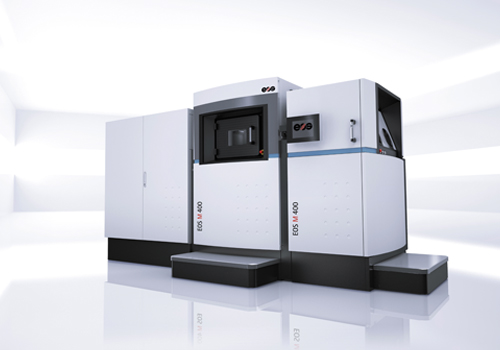

EOS M 400

-

3D Printing of Metal Parts on an Industrial Scale

The EOS M 400 is an additive manufacturing system for the industrial production of high-quality metal parts. A 1 kW laser boosts productivity due to higher build rates and increased layer thickness. With a building volume of 400 x 400 x 400 mm, EOS M 400 allows the production of large metal parts on an industrial scale – directly from CAD data and with no need for tools. The extensive monitoring features take quality management to a new level.

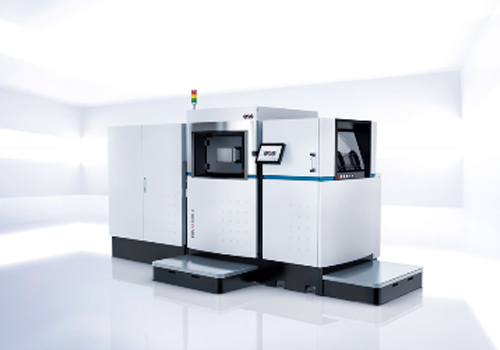

EOS M 400-4

-

The Ultra-Fast Quad-Laser System with a Large Building Volume

Designed for industrial applications, the EOS M 400-4 offers a large building volume of 400 x 400 x 400 mm combined with four lasers for up to four times higher productivity. It shatters boundaries of manufacturing as it meets the most demanding requirements of modern production environments in terms of efficiency, scalability, usability and process monitoring. The modular platform design can easily be integrated into existing production environments and flexible consolidated with future innovation.

EOS M 100

-

Ideal entry level model for industrial 3D printing

EOS M 100 is the high-end system for the fast and efficient production of complex metal parts by means of additive manufacturing. The size and modular design of the EOS M 100 make it ideal as an entry level model for Additive Manufacturing. In terms of process and component quality, it corresponds to the EOS M 290, the leading system on the market for Direct Metal Laser Sintering (DMLS).

Materials

-

EOS embodies a high level of competence in materials and provides an extensive portfolio of highly developed materials for Additive Manufacturing. EOS' materials, systems, and process parameters are perfectly matched to each other. The portfolio provides the best materials for achieving the targeted property profiles for products. Moreover, EOS is constantly refining its high-tech materials on the basis of specific customer requirements.

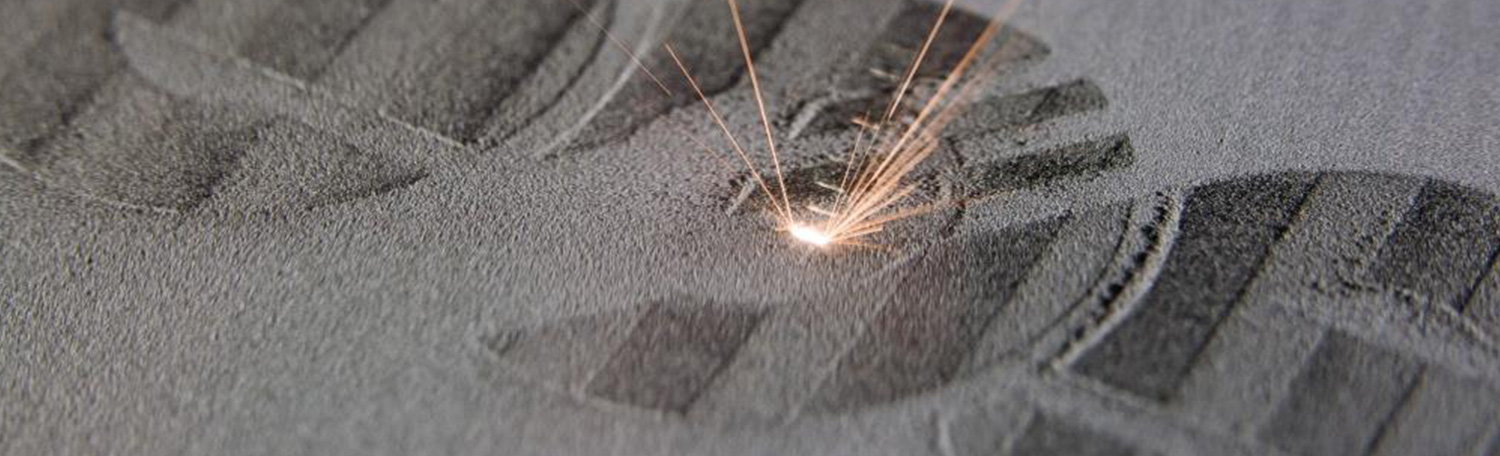

EOS metal materials for additive manufacturing

- For the production of metal components using DLMS (Direct Metal Laser Sintering), EOS offers a comprehensive selection of metal powders ranging from aluminium, maraging steel and high-grade steel through to titanium as well as nickel and cobalt chrome alloys. This allows highly individualized products to be manufactured in exceptional quality.

EOS plastic materials for additive manufacturing

-

The Additive Manufacturing of plastic products can make use of polyamides (PA), polystyrenes (PS), thermoplastic elastomers (TPE), and polyaryletherketones (PAEK). EOS provides a comprehensive range of materials for the Additive Manufacturing process. Customized products can be manufactured to the highest quality.

Industries & Markets

-

Additive manufacturing overcomes the limits imposed by conventional production techniques. It is already benefiting companies in a wide range of sectors.

Aerospace

-

Engine and turbine parts as well as cabin interior components are typical applications for industrial 3D printing / Additive Manufacturing (AM. This is where the benefits of innovative EOS technology come to the fore: functional components with complex geometries and defined aerodynamic properties can be manufactured quickly and cost-effectively. Material and weight savings lower fuel consumption and CO² emissions. Manufacturer-specific adaptations and small production runs are further arguments in favor of additive manufacturing (AM) technology. This is why leading aerospace companies have integrated EOS additive manufacturing into their production strategies.

Automotive

-

Innovative, tool-less EOS additive manufacturing provides a new approach to tackling the current challenges facing the automotive industry. It offers maximum design freedom while allowing the creation of complex yet light components with high levels of rigidity.

Additive Manufacturing enables the production of components with integrated functionality - without the need for tools, thereby cutting development and production costs. What is more, suppliers can respond to customer requirements by offering individualized serial production of parts.

Industry

-

Sustainable energy efficiency, constant cost pressures, special-purpose parts in short-run productions, unrelenting deadline pressures – industrial companies are confronted with many challenges. The production of small runs, however, can scarcely be cost effective with conventional, tool-based methods. Moreover, responding quickly to a changed part geometry just before the start of production involves a lot of work and costs. This can jeopardize delivery to schedule, for instance, at parts suppliers.

Lifestyle

- Additive Manufacturing is not subject to design restrictions and breaks down the boundaries imposed by conventional manufacturing methods. The latter tend to be geared towards high quantities: design changes cannot be implemented at short notice and individualized serial production involves considerable effort. This puts pressure on companies in areas such as jewelry and watches, footwear and web applications: they struggle with increasing raw material prices, rising demand for individualized products and a need for more flexible and decentralized serial production.

Medical

-

Every person is unique. Therefore, optimal patient care in dentistry, orthopedics and implantology requires medical products that provide a perfect fit. There is a high demand for one-off components and components produced in small production runs whose materials and manufacturing standards have to fulfil extremely stringent quality requirements. This also applies to specialized surgical instruments and medical devices. In addition, these products must be made available quickly and cost-effectively.

Tooling

-

In many industries, the production of specialist tools us one of the most expensive aspects of the production processes. It is generally expensive, time consuming and very technically demanding to use conventional processes. EOS has the solution: Based on Additive Manufacturing, EOS enables single parts or individualized serial products to be manufactured quickly, cost-effectively and flexibly – even in small batch sizes.