- Offer Profile

- Founded in 1863, Klingelnberg

is one of the leading companies in the gear industry. On the background of

many innovations in the areas of calculation, production, and measuring

technology, Klingelnberg sees itself as a leader in this sector. With the

acquisition of the core business of Höfler Maschinenbau GmbH in 2012,

Klingelnberg expanded its product portfolio with the addition of gear

manufacturing machines for cylindrical gears, thereby strengthening its

position as a single-source system supplier. The business units include four

product lines:

- Oerlikon Bevel Gear Technology

- Höfler Cylindrical Gear Technology

- Klingelnberg Precision Measuring Centers

- Klingelnberg Drive Technology/Customized Bevel Gears

BUSINESS DIVISIONS

-

EXPERTISE IN COUNTLESS INDUSTRIES

SOLUTIONS FOR MORE PRODUCTIVITY

Klingelnberg's product range comprises machines for bevel gear and cylindrical gear production, for measurement of gearing and axially symmetrical components, and for the production of high-precision gear components. OERLIKON BEVEL GEAR TECHNOLOGY

-

INTELLIGENT SOLUTIONS FOR DISCERNING USERS

The Oerlikon Bevel Gear Technology division does not just allow users to manufacture bevel gears economically and with high precision. All machines in the system have been designed to work together to enable pre-machining and finishing of even the most complex gears. Klingelnberg offers the most advanced technology and the most efficient machines for each and every step in the process chain. The production process chain for bevel gears includes tool preparation, cutting, measuring, hardening, grinding or lapping and testing, among others. The powerful KIMoS (Klingelnberg integrated Manufacturing of Spiral Bevel Gears) design software and the Closed Loop concept ensure transparency and documented quality throughout the entire process chain. Oerlikon bevel gear machines are developed with real-world applications in mind and meet the varying demands of a whole range of industries. The target markets include the automotive industry, the commercial vehicle industry, the agricultural industry, shipbuilding and aviation, as well as industrial gearbox manufacturing and plant engineering. As a leading system supplier and in combination with these high-performance tool systems, Klingelnberg meets every requirement for flexible, efficient production — for the smallest and the largest batch sizes. TOOL MANAGEMENT

-

TOP-NOTCH EXPERTISE IN A UNIQUE CLOSED-LOOP PROCESS

State-of-the-art tool adjusting and measuring devices guarantee an optimum workflow, from servicing and repairing the tool to use in the machine tool. To enable efficient, trouble-free production of drive components for our customers, Klingelnberg offers a broad portfolio in a unique closed-loop process.

B 27 OERLIKON BLADE GRINDING MACHINE

-

GRINDING MACHINE FOR STICK BLADES FROM ANY BEVEL GEAR TYPE

Maximum precision, economic production, multi-grinding methods, compact machine layout and automatic handling are the key features of the Oerlikon B 27 stick blade grinding machine, which has been designed for grinding the HSS and carbide blades that are used to cut spiral and hypoid gears in any system. The intelligent machine concept which is designed for robustness is the guarantee of maximum profile and repetition accuracy, while at the same time providing the shortest machining times.- Preparation of stick blades and cutter heads with a modern, high-precision blade grinding machine

- All standard stick blade cross sections from approx. 5 x 9 mm to 19.05 x 27.94 mm

- Clamping device for rectangular cross sections and Pentac® cross sections

- Stick blades for bevel gear and power skiving cutter heads can be manufactured

- Integrated in the unique closed-loop method

- Patented low-wear dual grinding wheel for maximum accuracy

- Cost-effective production of tools thanks to internal automation

- Process has been tried and tested around the world

BC 12 OERLIKON STICK BLADE MEASURING DEVICE

-

FOR HIGH-PRECISION MEASUREMENT OF STICK BLADES

The quality control loop between the blade grinding machine and the ground blade can be closed efficiently and simply by measuring the stick blades. With the standard basic configuration, both the position and the shape of the main and secondary blades can be recorded using a scanning procedure. The KIMoS (Klingelnberg Integrated Manufacturing of Spiral Bevel Gears) calculation program supplies the necessary contour data, which eliminates the need for manual data entry and minimizes the preparation time.- Convenient measurement and correction of stick blades

- Quick scanning of complete stick blade geometry

- Easy operation with no manual entry of corrections

- Universal quick clamping device for all blade cross sections from approx. 5 x 9 mm to 19.05 x 27.94 mm

- Accurate measuring results with Klingelnberg P machine technology in machine construction, 3D tracer head, and CNC control

- Closed loop production of stick blades for maximum gearing quality

- Consistent use of stick blade shank as reference for production, measurement, and mounting of stick blades

- Measuring device can be operated directly alongside stick blade grinding machine in production

CS 200 OERLIKON CUTTER HEAD SETTING DEVICE

-

OPTIMAL CUTTERHEAD SETTING FOR LONG SERVICE LIFE AND HIGH-QUALITY GEAR TEETH

The Oerlikon CS 200 cutter head setting and checking device makes it possible to set the individual blades quickly and easily, checks the position thereof and documents the measuring results. Through the combination of a semi-automated setting procedure, operator-guided setup actions and an automatic measuring procedure, cutter heads can be set easily, quickly and extremely accurately.- CNC machine for highly efficient, high-precision setting and checking of stick blade heads

- Innovative, precision setting/measuring system

- Allows setting of ARCON®, RSR®, SPIRAPID, SPIRON®, TRI-AC® tools

- Neutral data format interface

- Documentation of setting accuracy

- Diameter clamping for cutter head types up to 18"

- Machine design suitable for inline use

- Measuring axis drive uses linear motor direct drive technology

BEVEL GEAR CUTTING MACHINES

-

LEADING-EDGE TECHNOLOGY FOR OPTIMAL FLEXIBILITY AND MAXIMUM PRODUCTIVITY

"Simplified with Passion" – true to this motto, Klingelnberg is driven to provide simple, unconventional solutions to high-tech challenges. A team of engineers and technical experts makes it possible – always with the goal of ensuring the highest technological standards in application-matched machine designs that are also easy to use. Case in point: The Oerlikon bevel gear cutting machines are based on established design concepts that are continually undergoing further development.

C 15 OERLIKON BEVEL GEAR CUTTING MACHINE

-

HIGHLY EFFICIENT, ENVIRONMENTALLY FRIENDLY DRY-CUTTING

Among other things, the C 15 concept is based on the modern production technology of dry-cutting without the use of cooling lubricant, with an application range that is suited to smaller gearbox sizes. This machine is equipped with direct drives for the workpiece spindle and the tool spindle.

- 6-axis CNC machine for highly efficient bevel gear cutting

- Well-tried axis concept for compact high-performance carbide tool design

- Short retooling times thanks to ergonomic machine design

- Unrivaled gearing and surface quality

- Energy efficient (e2)

C 27 OERLIKON BEVEL GEAR CUTTING MACHINE

-

HIGHLY EFFICIENT, ENVIRONMENTALLY FRIENDLY DRY-CUTTING

The application range of the C 27 bevel gear cutting machine is ideal for the gearbox sizes found in passenger car and small truck applications. This machine is equipped with direct drives and is designed for cutting workpiece diameters up to 270 mm. The C 27 makes it possible to achieve cutting speeds that allow highly cost-effective dry-cutting even for a large number of cutter head starts and small numbers of teeth.- 6-axis CNC machine for highly efficient bevel gear cutting

- Well-tried axis concept for compact high-performance carbide tool design

- Short retooling times thanks to ergonomic machine design

- Unrivaled gearing and surface quality

- Energy efficient (e2)

C 30 OERLIKON BEVEL GEAR CUTTING MACHINE

-

HIGHLY EFFICIENT, ENVIRONMENTALLY FRIENDLY DRY-CUTTING Thanks to continuous

further development of the vertical concept, the Oerlikon C 30 bevel gear cutting machine sets new standards in dry processing. All of the bevel gear machines in this series are equipped with a thermostable, vibration-damping machine bed. The cutting machine utilizes an optimized axis arrangement, resulting in reduced traversing paths that significantly reduce the load on the drive components and stiffen the structure of the overall system at the same time. An integrated deburring tool also provides maximum productivity and maximum process safety using the PULSAR method. Use of the optional Power Skiving method makes it possible to achieve even greater machine flexibility and productivity.

- Continuous further development of the vertical concept with minimal traversing paths

- New materials with optimal attenuation properties while providing an extremely stiff structure and thermal stability

- Integrated deburring in the same clamping as for gear cutting

- New operating software with touchscreen display and clear screen layout

- Vertical spindle arrangement makes clamping device changes easy

- Optional Power Skiving of internal and external gearing by means of cylindrical monoblock tools

- Optimal energy efficient (e2) thanks to recovery and on-demand control of units

C 50 OERLIKON BEVEL GEAR CUTTING MACHINE

-

HIGHLY EFFICIENT, ENVIRONMENTALLY FRIENDLY DRY-CUTTING

The vertical design of the C 50 bevel gear cutting machine and the direct drives for the tool, workpiece and angle drive make it ideal for dry-cutting bevel gears with coated carbide cutters. The C 50 is designed exclusively for dry-cutting processes. When used in conjunction with the high-performance ARCON® and SPIRON® cutters, the bevel gear cutting machine can be used to produce all common spiral bevel gears in both continuous indexing and single indexing processes with maximum efficiency.

- 6-axis CNC machine for ultra-efficient dry-cutting of bevel gears

- Optimal chip flow thanks to vertical axis configuration

- Machining: Continuous indexing, single indexing, straight gearing

- High-performance carbide tools

- Unrivaled gearing and surface quality

- Short setup and clamping times

- Optional: Automatic deburring, KOMPASS workpiece measurement system

- Ideally suited for automatic loading

- Energy efficient (e2)

C 60 OERLIKON BEVEL GEAR CUTTING MACHINE

-

HIGHLY EFFICIENT, ENVIRONMENTALLY FRIENDLY DRY-CUTTING

The C 60 bevel gear cutting machine covers the upper application range of the C series. It is used for cutting bevel gearboxes for heavy-duty trucks and tractors, and has the same well-tried design as every C machine. In the C 60, special emphasis was placed on high static and dynamic rigidity. A look at the large, extremely stiff machine components makes this apparent. And the proof is in the gear-cutting performance and quality.

- 6-axis CNC machine for highly efficient bevel gear cutting

- Well-tried axis concept for compact design

- High-performance carbide tools

- Short retooling times thanks to ergonomic machine design

- Unrivaled gearing and surface quality

- Energy efficient (e2)

C 40 U OERLIKON U BEVEL GEAR CUTTING MACHINE

-

SIMPLE BEVEL GEAR PRODUCTION WITH SMALL TOOL VOLUMES

This series was developed based on the C series machines, primarily for manufacturing spiral-cut bevel gears using Klingelnberg's Zyklo-Palloid® method. With this system, the main focus is on simple, on-target production of spiral bevel gears with an extremely small tool volume for the application area of ring gears with a diameter up to 450 mm.

- 6-axis CNC machine for highly efficient bevel gear cutting

- Well-tried axis concept for compact design

- Universal tool system provides maximum flexibility

- Short retooling times thanks to ergonomic machine design

- Unrivaled gearing and surface quality

- Energy efficient (e2)

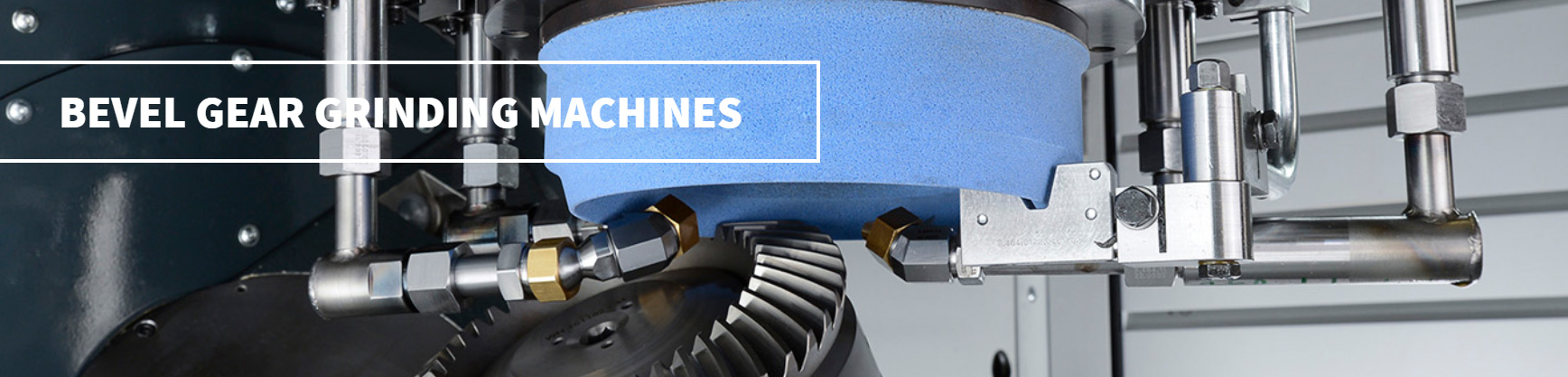

BEVEL GEAR GRINDING MACHINES

-

SUPERIOR GRINDING TECHNOLOGY FOR GREATER ECONOMIC EFFICIENCY

Oerlikon bevel gear grinding machines were developed with real-world applications in mind to meet the varying demands of a whole range of different application industries. Used throughout the world, the "Simplified with Passion" system plays an important part in ensuring that machining tasks are made simple. Moreover, the Klingelnberg system contributes to standardization and quality assurance on a global scale.

G 30 OERLIKON BEVEL GEAR GRINDING MACHINE

-

ECONOMICAL CONCEPT FOR HIGH-PRECISION FINAL MACHINING OF BEVEL GEARS

Thanks to continuous further development of the vertical concept, the G 30 bevel gear cutting machine sets new standards in grinding. The grinding machine utilizes an optimized axis arrangement resulting in reduced approach paths that ensure a significantly reduced load on the drive components and at the same time a more rigid design of the complete system. The G 30 can be optionally equipped with a side loading door. This allows easy loading in automatic mode using a machine-integrated loading shuttle or handling robot. For series production, the machine also offers a range of process monitoring functions.

- Ongoing advancement of the vertical concept to eliminate grinding sludge deposits in the working chamber

- Extremely rigid, thermally stable machine for optimal machining results, even for highly productive processes

- Side loading with machine-integrated shuttle or handling robot (optional)

- Modern operating software with touchscreen display and a clear screen layout

- Optimal energy (e2) efficiency thanks to recovery and on-demand control of units

G 60 OERLIKON BEVEL GEAR GRINDING MACHINE

-

ECONOMICAL CONCEPT FOR HIGH-PRECISION FINAL MACHINING OF BEVEL GEARS

Thanks to its outstanding grinding performance and universal design, this CNC-controlled bevel gear grinding machine from the G model series is an extremely economical concept for high-precision final machining of the curved-toothed spiral bevel gears of any gearing system as well as face-type clutches. These machines operate up to a ring gear diameter of 600 mm, and have a vertical grinding spindle.

- CNC machine for high-precision final machining of the curved-toothed bevel gears of any gearing system as well as face-type clutches

- Vertical grinding spindle for optimal, unobstructed downward chip flow

- Ring gear diameters to 600 mm

- Easy access to all additional components, including oil mist extraction system, grinding oil return pump and hydraulics

- Minimal setup times

- Grinding wheel profiling takes place under CNC path control with diamond dressing roll

- Ideally suited for automatic loading

- Energy efficient (e2)

G 80 OERLIKON BEVEL GEAR GRINDING MACHINE

-

ECONOMICAL CONCEPT FOR HIGH-PRECISION FINAL MACHINING OF BEVEL GEARS

Thanks to its outstanding grinding performance and universal design, this CNC-controlled bevel gear grinding machine from the G model series is an extremely economical concept for high-precision final machining of the curved-toothed bevel gears of any gearing system as well as face-type clutches. These machines operate up to a ring gear diameter of 850 mm. The G machines are equipped with a side loading door for automation purposes, making loading using handling robots easy during automatic operation.

- CNC machine for high-precision final machining of the curved-toothed bevel gears of any gearing system as well as face-type clutches

- Vertical grinding spindle for optimal, unobstructed downward chip flow

- Ring gear diameters to 850 mm

- Easy access to all additional components, including oil mist extraction system, grinding oil return pump and hydraulics

- Minimal setup times

- Grinding wheel profiling takes place under CNC path control with diamond dressing roll

- Ideally suited for automatic loading

- Energy efficient (e2)

BEVEL GEAR LAPPING MACHINES

-

HIGHLY EFFICIENT LAPPING OF SPIRAL BEVEL AND HYPOID GEAR SETS

The Oerlikon bevel gear lapping machine is designed to allow all operational tasks, loading, unloading, and lapping compound replacement to be carried out from the front of the machine. A tried-and-tested horizontal spindle concept, with a clever arrangement of the axes and the use of an innovative compound slide, ensures optimal functionality – without compromising the space requirement, accessibility, or process.

L 60 OERLIKON BEVEL GEAR LAPPING MACHINE

-

HIGHLY EFFICIENT LAPPING OF SPIRAL-BEVEL AND HYPOID GEAR SETS

The bevel gear lapping machine is designed to allow all operational tasks, loading, unloading, and lapping compound replacement to be carried out from the front of the machine. This opens up completely new ways of setting up the machine shop. In addition to the machine design itself, which primarily minimizes the active space requirements, special emphasis was placed on optimizing the passive footprint so that the individual machines can be arranged closer together, therefore reducing unproductive areas and distances for the operating personnel.

- CNC-machine for highly efficient lapping of spiral bevel gear and hypoid gear sets

- Ring gear diameters up to 500 mm (600 mm optional)

- Shaft angle 90° (79° - 101° optional)

- Mechanical-pneumatic clamping system with clamping stroke monitoring > no hydraulics

- Suitable for automatic loading

- Operator-friendly, easy-to-service lapping-compound unit

- Automatic temperature compensation (Y and Z axis)

- Highly flexible parameterization of the lapping process

- Reduced-load acceleration to lapping rotation speed

- Can also be used as a roll tester

- Energy efficient (e2)

BEVEL GEAR TESTING MACHINES

-

ADVANCED MACHINE DESIGNS WITH CUTTING-EDGE TECHNOLOGY

The Oerlikon bevel gear testing machine T 60 has an advanced machine design that features sophisticated technology and an ultra-modern CNC; is universal and user-friendly; and is designed for maximum reproducibility and test safety. The bevel gear test stands TS 30 make it possible to check bevel gear sets of different sizes for wear and fatigue strength.

TS 30 OERLIKON BEVEL GEAR TEST STAND

-

EASY CHECKING OF BEVEL GEAR SETS FOR WEAR AND FATIGUE STRENGTH

The TS 30 bevel gear test stands are used to check bevel gear sets of different sizes for wear and fatigue strength. Electric drives initiate the rotary motion at the drive side (motor) and the brake torque at the output side (generator). This concept makes it possible to operate the test stand in an extremely energy-efficient way.

T 60 OERLIKON BEVEL GEAR TESTING MACHINE

-

HIGHLY FLEXIBLE TESTING OF HARD, FINISHED, AND GREEN SPIRAL-BEVEL AND HYPOID GEAR SETS

The T 60 bevel gear testing machine is a CNC testing machine with three linear axes for fully automatic hard and soft testing of spiral-bevel and hypoid gear sets with a 90° shaft angle. It offers a wide range of objective and subjective testing options, with speeds of up to 3,250 rpm and maximum brake torque of 95 Nm.

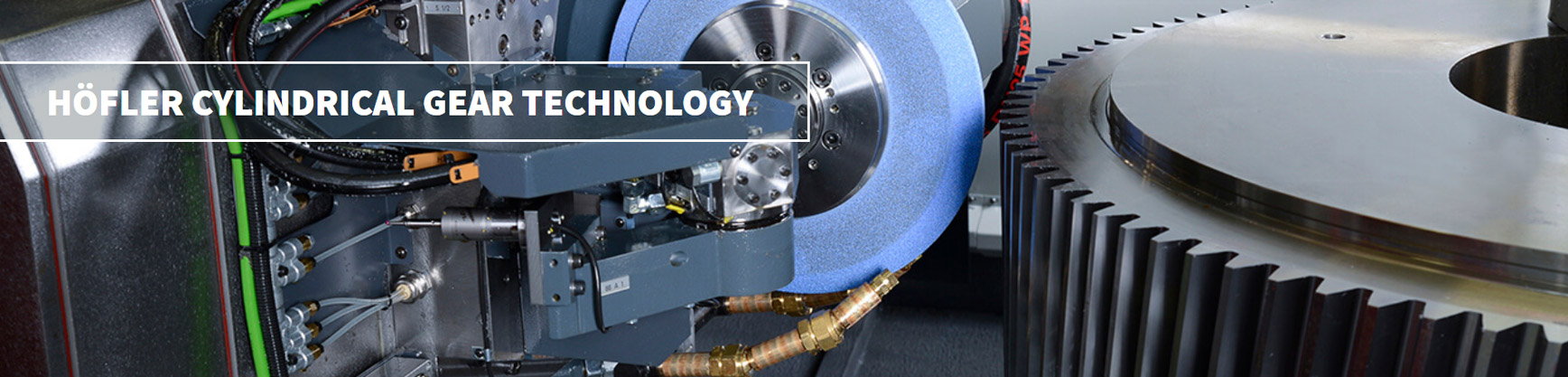

HÖFLER CYLINDRICAL GEAR TECHNOLOGY

-

CYLINDRICAL GEAR MACHINING FOR FLEXIBLE REQUIREMENTS

The Höfler Cylindrical Gear Technology division does more than just allow users to manufacture cylindrical gears economically and with high precision. All machines have been perfectly designed to work together as a system family, enabling pre-machining and finishing of even the most complex gears. And high research and development standards, a global service network and an in-house application engineering service ensure a leadership position – now and in the years to come – thanks to our decadeslong expertise and high innovation capacity. Klingelnberg offers the most advanced technology and the most efficient machines for each and every step in the cylindrical gear process chain: process design, cutting, measuring, deburring, grinding and quality control. A key factor in the successful completion of each work step is the Klingelnberg machine operating software, providing optimal process control and extreme ease-of-operation to guarantee maximum efficiency in the daily production routine. Höfler cylindrical gear machines are developed with real-world applications in mind and satisfy a whole host of industry requirements. Customers include contract gear manufacturers and gearbox manufacturers in the aviation, automotive, mining, construction, industrial gearbox and wind power industries, among others. CYLINDRICAL GEAR CUTTING MACHINES

-

A TECHNOLOGICAL ADVANTAGE THROUGH POWER AND RELIABILITY

The Höfler cylindrical gear cutting machines of the HF range have become firmly established in the market due to their stable and solid construction. The machine series is completely suitable for environmentally friendly dry cutting and can be provided with wet cutter equipment if desired. All cutting machines in the HF range have ideal damping properties between the moving housings or slides and the machine bed.

HF 1000 HÖFLER CYLINDRICAL GEAR CUTTING MACHINE

-

VERSATILE MACHINE DESIGN FOR HIGH QUALITY STANDARDS

Designed for workpiece diameters of up to 1,000 mm, the HF 1000 cylindrical gear hobbing machine combines leading technology with the perfect design: a machine table with torque motor drive, a heavy-duty gray cast iron machine bed, and integrated workpiece inspection are just some of its features. Through the use of HSS or indexable insert cutters and high-performance gashers in wet or dry cutting processes, this versatile cutting machine sets new standards in productivity and quality ideal for suppliers of durable, heavy-duty industrial gearboxes.

- Reliable machine table with torque motor drive

- Transmission precision with Capto® tool interface

- Optional internal cutting heads

- High stability through double V cassette guides

- Heavy-duty gray cast iron machine bed

- Energy efficiency (e2)

HF 1250 HÖFLER CYLINDRICAL GEAR CUTTING MACHINE

-

VERSATILE MACHINE DESIGN FOR HIGH QUALITY STANDARDS

Designed for workpiece diameters of up to 1,250 mm, the HF 1250 cylindrical gear hobbing machine combines leading technology with the perfect design: a machine table with torque motor drive, a heavy-duty gray cast iron machine bed, and integrated workpiece inspection are just some of its features. Through the use of HSS or indexable insert cutters and high-performance gashers in wet or dry cutting processes, this versatile cutting machine sets new standards in productivity and quality ideal for suppliers of durable, heavy-duty industrial gearboxes.

- Reliable machine table with torque motor drive

- Transmission precision with Capto® tool interface

- Optional internal cutting heads

- High stability through double V cassette guides

- Heavy-duty gray cast iron machine bed

- Energy efficiency (e2)

HF 1600 HÖFLER CYLINDRICAL GEAR CUTTING MACHINE

-

VERSATILE MACHINE DESIGN FOR HIGH QUALITY STANDARDS

Designed for workpiece diameters of up to 1,600 mm, the HF 1600 cylindrical gear hobbing machine combines leading technology with the perfect design: a machine table with torque motor drive, a heavy-duty gray cast iron machine bed, and integrated workpiece inspection are just some of its features. Through the use of HSS or indexable insert cutters and high-performance gashers in wet or dry cutting processes, this versatile cutting machine sets new standards in productivity and quality ideal for suppliers of durable, heavy-duty industrial gearboxes.

- Reliable machine table with torque motor drive

- Transmission precision with Capto® tool interface

- Optional internal cutting heads

- High stability through double V cassette guides

- Heavy-duty gray cast iron machine bed

- Energy efficiency (e2)

HF 2000 HÖFLER CYLINDRICAL GEAR CUTTING MACHINE

-

VERSATILE MACHINE DESIGN FOR HIGH QUALITY STANDARDS

Designed for workpiece diameters of up to 2,000 mm, the HF 2000 cylindrical gear hobbing machine combines leading technology with the perfect design: a machine table with torque motor drive, a heavy-duty gray cast iron machine bed, and integrated workpiece inspection are just some of its features. Through the use of HSS or indexable insert cutters and high-performance gashers in wet or dry cutting processes, this versatile cutting machine sets new standards in productivity and quality ideal for suppliers of durable, heavy-duty industrial gearboxes.

- Reliable machine table with torque motor drive

- Transmission precision with Capto® tool interface

- Optional internal cutting heads

- High stability through double V cassette guides

- Heavy-duty gray cast iron machine bed

- Energy efficiency (e2)

HF 2500 HÖFLER CYLINDRICAL GEAR CUTTING MACHINE

-

SOLID, STURDY DESIGN PLUS MAXIMUM PRECISION

Designed for workpiece diameters of up to 2,500 mm, the HF 2500 cylindrical gear hobbing machine is known for its solid, sturdy design and high precision. Modern high-performance tools can make use of their full machining potential due to having appropriately powerful machines. With its high degree of functionality, the HF model series is not only capable of meeting this requirement, but also the requirements of the future.

- Reliable machine table with torque motor drive

- Transmission precision with Capto® tool interface

- Optional internal cutting heads

- High stability through double V cassette guides

- Heavy-duty gray cast iron machine bed

- Energy efficiency (e2)

HF 3000 HÖFLER CYLINDRICAL GEAR CUTTING MACHINE

-

SOLID, STURDY DESIGN PLUS MAXIMUM PRECISION

Designed for workpiece diameters of up to 3,000 mm, the HF 3000 cylindrical gear hobbing machine is known for its solid, sturdy design and high precision. Modern high-performance tools can make use of their full machining potential due to having appropriately powerful machines. With its high degree of functionality, the HF model series is not only capable of meeting this requirement, but also the requirements of the future.

- Reliable machine table with torque motor drive

- Transmission precision with Capto® tool interface

- Optional internal cutting heads

- High stability through double V cassette guides

- Heavy-duty gray cast iron machine bed

- Energy efficiency (e2)

HF 4000 HÖFLER CYLINDRICAL GEAR CUTTING MACHINE

-

SOLID, STURDY DESIGN PLUS MAXIMUM PRECISION

Designed for workpiece diameters of up to 4,000 mm, the HF 4000 cylindrical gear hobbing machine is known for its solid, sturdy design and high precision. Modern high-performance tools can make use of their full machining potential due to having appropriately powerful machines. With its high degree of functionality, the HF model series is not only capable of meeting this requirement, but also the requirements of the future.

- Reliable machine table with torque motor drive

- Transmission precision with Capto® tool interface

- Optional internal cutting heads

- High stability through double V cassette guides

- Heavy-duty gray cast iron machine bed

- Energy efficiency (e2)

HF 6000 HÖFLER CYLINDRICAL GEAR CUTTING MACHINE

-

SOLID, STURDY DESIGN PLUS MAXIMUM PRECISION

Designed for workpiece diameters of up to 6,000 mm, the HF 6000 cylindrical gear hobbing machine is known for its solid, sturdy design and high precision. Modern high-performance tools can make use of their full machining potential due to having appropriately powerful machines. With its high degree of functionality, the HF model series is not only capable of meeting this requirement, but also the requirements of the future.

- Reliable machine table with torque motor drive

- Transmission precision with Capto® tool interface

- Optional internal cutting heads

- High stability through double V cassette guides

- Heavy-duty gray cast iron machine bed

- Energy efficiency (e2)

HF 8000 HÖFLER CYLINDRICAL GEAR CUTTING MACHINE

-

SOLID, STURDY DESIGN PLUS MAXIMUM PRECISION

Designed for workpiece diameters of up to 8,000 mm, the HF 8000 cylindrical gear hobbing machine is known for its solid, sturdy design and high precision. Modern high-performance tools can make use of their full machining potential due to having appropriately powerful machines. With its high degree of functionality, the HF model series is not only capable of meeting this requirement, but also the requirements of the future.

- Reliable machine table with torque motor drive

- Transmission precision with Capto® tool interface

- Optional internal cutting heads

- High stability through double V cassette guides

- Heavy-duty gray cast iron machine bed

- Energy efficiency (e2)

CYLINDRICAL GEAR GRINDING MACHINES

-

CUTTING-EDGE TECHNOLOGY FOR MAXIMUM PERFORMANCE

Klingelnberg is regarded as the leading specialist for high-precision cylindrical gear grinding machines, a position it maintains through significant investments in research and development. Extreme reliability and high efficiency are hallmarks of the Höfler cylindrical gear grinding machines in the HELIX/PROMAT, RAPID, VIPER 500 and SPEED VIPER ranges.

SPEED VIPER 300 HÖFLER CYLINDRICAL GEAR GRINDING MACHINE

-

THE NEW FORCE IN HIGH-PRODUCTIVITY GENERATING GRINDING

The Höfler cylindrical gear grinding machine Speed Viper – which focuses on high-productivity generating grinding in large-series manufacturing – draws on the successful concept of the Viper 500 series. It is available in four different configurations based on individual requirements. The Speed Viper 300 is designed for maximum workpiece diameters of 300 mm. In addition to toothed gears, it can also grind extra-long shafts. This is possible thanks to a distance between centers over table of up to 1,100 mm.

- Highly productive generating grinding thanks to intelligent machine software and a robust machine base

- Large component range up to 300 mm workpiece diameter and up to 1,100 mm workpiece length

- Long tool life thanks to large tool diameters of 320 mm and a tool length of 200 mm

- Minimal auxiliary times

- Short set-up times thanks to automatic tool clamping system

- Flexible automation concept

- Innovative operating concept

- Optimal energy efficiency (e2)

SPEED VIPER 180 HÖFLER CYLINDRICAL GEAR GRINDING MACHINE

-

THE NEW FORCE IN HIGH-PRODUCTIVITY GENERATING GRINDING

The Höfler cylindrical gear grinding machine Speed Viper – which focuses on high-productivity generating grinding in large-series manufacturing – draws on the successful concept of the Viper 500 series. It is available in four different configurations based on individual requirements. The Speed Viper 180 is designed for maximum workpiece diameters of 180 mm. In addition to toothed gears, it can also grind extra-long shafts. This is possible thanks to a distance between centers over table of up to 1,100 mm.

- Highly productive generating grinding thanks to intelligent machine designs and a robust machine base

- Large component range to 180 mm workpiece diameter and 1,100 mm workpiece length

- Long service life thanks to large tool diameters of 320 mm and a tool length of 200 mm

- Minimal auxiliary times

- Short set-up times thanks to automatic tool clamping system

- Flexible automation concept

- Innovative operating concept

- Optimal energy efficiency (e2)

SPEED VIPER2 180 HÖFLER CYLINDRICAL GEAR GRINDING MACHINE

-

THE NEW FORCE IN HIGH-PRODUCTIVITY GENERATING GRINDING

The Höfler cylindrical gear grinding machine Speed Viper – which focuses on high-productivity generating grinding in large-series manufacturing – draws on the successful concept of the Viper 500 series. It is available in four different configurations based on individual requirements. The Speed Viper2 180 is designed for maximum workpiece diameters of 180 mm. In addition to toothed gears, it can also grind extra-long shafts. This is possible thanks to a distance between centers over table of up to 895 mm. The Speed Viper² dual-spindle concept achieves minimal auxiliary times, fulfilling the productivity requirements of the automotive industry.

- Highly productive generating grinding thanks to intelligent machine software and a robust machine base

- Large component range up to 180 mm workpiece diameter and up to 895 mm workpiece length

- Long tool life thanks to large tool diameters of 320 mm and a tool length of 200 mm

- Minimal auxiliary times

- Short set-up times thanks to automatic tool clamping system

- Flexible automation concept

- Innovative operating concept

- Optimal energy efficiency (e2)

SPEED VIPER2 80 HÖFLER CYLINDRICAL GEAR GRINDING MACHINE

-

THE NEW FORCE IN HIGH-PRODUCTIVITY GENERATING GRINDING

The Höfler cylindrical gear grinding machine Speed Viper – which focuses on high-productivity generating grinding in large-series manufacturing – draws on the successful concept of the Viper 500 series. It is available in four different configurations based on individual requirements. The Speed Viper2 80 is designed for maximum workpiece diameters of 80 mm. In addition to gears, it can also grind extra-long shafts. This is possible thanks to a distance between centers over table of up to 895 mm. The Speed Viper² dual-spindle concept achieves minimal auxiliary times, fulfilling the productivity requirements of the automotive industry.

- Highly productive generating grinding thanks to intelligent machine software and a robust machine base

- Large component range up to 80 mm workpiece diameter and up to 895 mm workpiece length

- Long tool life thanks to large tool diameters of 320 mm and a tool length of 200 mm

- Minimal auxiliary times

- Short set-up times thanks to automatic tool clamping system

- Flexible automation concept

- Innovative operating concept

- Optimal energy efficiency (e2)

HELIX 400 HÖFLER CYLINDRICAL GEAR GRINDING MACHINE

-

COMPACT, FLEXIBLE MACHINE WITH WELL-ENGINEERING MECHANICAL SYSTEM

The HELIX 400 cylindrical gear grinding machine is a compact, flexible profile grinding machine for workpiece diameters of up to 400 mm. Its well-engineered mechanical system makes it a reliable partner for precision manufacturing. The innovative control and software functions are also ideal for manufacturing special profile and tooth trace modifications for special series.

- Maximum flexibility is provided by the K/KK/SK variants (optionally available)

- Maximum efficiency by means of reliable automation (optionally available)

- Uncompromising accuracy thanks to an integrated testing system

- Reliable, directly driven machine table

- Solid single-bed design

- Ergonomically compact and easily accessible

- Energy efficiency (e2)

VIPER 500 HÖFLER CYLINDRICAL GEAR GRINDING MACHINE

-

CONVERTIBLE MACHINE FOR INDIVIDUAL REQUIREMENTS

The VIPER 500 cylindrical gear grinding machine is designed for component diameters of up to 500 mm and is optimally suited for small to medium-sized batches. To suit individual requirements, the machine is available in three different configurations: profile grinding, small grinding wheels for custom jobs and multiple-wheel technology (K) and generation grinding (W) . The special machine axis arrangement is a contributing factor to the machine's tried-and-tested precision, consistent quality and tremendous flexibility. The highly dynamic axes allow optimized 5-axis machining of wide variety of modifications in the shortest possible grinding time.

- Convertible machine for generating, profile, and internal grinding (VIPER 500 W)

- Retooling from generation grinding to profile grinding in less than 5 minutes (VIPER 500 W)

- Retooling to internal grinding in less than 15 minutes

- Highly dynamic axes at 5 m/sec2 acceleration and 20 m/min rapid traverse

- Low-maintenance machine concept due to separation of working chamber from drive technology

- No pump station needed for grinding oil

- Optimal energy efficiency (e2) thanks to recovery and on-demand powering of units

RAPID 650 HÖFLER CYLINDRICAL GEAR GRINDING MACHINE

-

REDUCED GRINDING TIMES FOR MORE PRODUCTION EFFICIENCY

Cylindrical gear manufacturers all around the world appreciate the advantages and productivity of the RAPID 650 for workpiece diameters of up to 650 mm. With standard features that include a cast polymer machine bed, a torque motor-driven machine table, an integrated inspection system, a sturdy grinding spindle, and a dressing system for frequent profile modifications, it is the perfect solution for cylindrical gear manufacturers. Technologies such as high-speed grinding [HsG] and best-fit grinding [BfG] also reduce grinding times by up to 30 % ensuring a clear leading edge in production efficiency for the entire manufacturing process.

- Highly flexible direct-drive 5-axis grinding head and swivel angle adjustment during the grinding process

- Stable, damping-optimized single-bed base made of cast polymer

- Precise machine table control via torque motor drive

- Optional internal gear grinding arms

- Controlled grinding result through integrated measurement and automatic corrections during the grinding process

- Energy efficiency (e2)

RAPID 800 HÖFLER CYLINDRICAL GEAR GRINDING MACHINE

-

REDUCED GRINDING TIMES FOR MORE PRODUCTION EFFICIENCY

Cylindrical gear manufacturers all around the world appreciate the advantages and productivity of the RAPID 800 for workpiece diameters of up to 800 mm. With standard features that include a cast polymer machine bed, a torque motor-driven machine table, an integrated inspection system, a sturdy grinding spindle, and a dressing system for frequent profile modifications, it is the perfect solution for cylindrical gear manufacturers. Technologies such as high-speed grinding [HsG] and best-fit grinding [BfG] also reduce grinding times by up to 30 % ensuring a clear leading edge in production efficiency for the entire manufacturing process.

- Highly flexible direct-drive 5-axis grinding head and swivel angle adjustment during the grinding process

- Stable, damping-optimized single-bed base made of cast polymer

- Precise machine table control via torque motor drive

- Optional internal gear grinding arms

- Controlled grinding result through integrated measurement and automatic corrections during the grinding process

- Energy efficiency (e2)

RAPID 1000 HÖFLER CYLINDRICAL GEAR GRINDING MACHINE

-

REDUCED GRINDING TIMES FOR MORE PRODUCTION EFFICIENCY

Cylindrical gear manufacturers all around the world appreciate the advantages and productivity of the RAPID 1000 for workpiece diameters of up to 1,000 mm. With standard features that include a cast polymer machine bed, a torque motor-driven machine table, an integrated inspection system, a sturdy grinding spindle, and a dressing system for frequent profile modifications, it is the perfect solution for cylindrical gear manufacturers. Technologies such as high-speed grinding [HsG] and best-fit grinding [BfG] also reduce grinding times by up to 30 % ensuring a clear leading edge in production efficiency for the entire manufacturing process.

- Highly flexible direct-drive 5-axis grinding head and swivel angle adjustment during the grinding process

- Stable, damping-optimized single-bed base made of cast polymer

- Precise machine table control via torque motor drive

- Optional internal gear grinding arms

- Controlled grinding result thanks to integrated measurements and automatic corrections during the grinding process

- Energy efficiency (e2)

RAPID 1250 HÖFLER CYLINDRICAL GEAR GRINDING MACHINE

-

REDUCED GRINDING TIMES FOR MORE PRODUCTION EFFICIENCY

Cylindrical gear manufacturers all around the world appreciate the advantages and productivity of the RAPID 1250 for workpiece diameters of up to 1,250 mm. With standard features that include a cast polymer machine bed, a torque motor-driven machine table, an integrated inspection system, a sturdy grinding spindle, and a dressing system for frequent profile modifications, it is the perfect solution for cylindrical gear manufacturers. Technologies such as high-speed grinding [HsG] and best-fit grinding [BfG] also reduce grinding times by up to 30 % ensuring a clear leading edge in production efficiency for the entire manufacturing process.

- Highly flexible direct-drive 5-axis grinding head and swivel angle adjustment during the grinding process

- Stable, damping-optimized single-bed base made of cast polymer

- Precise machine table control via torque motor drive

- Optional internal gear grinding arms

- Controlled grinding result thanks to integrated measurements and automatic corrections during the grinding process

- Energy efficiency (e2)

RAPID 1600 HÖFLER CYLINDRICAL GEAR GRINDING MACHINE

-

REDUCED GRINDING TIMES FOR MORE PRODUCTION EFFICIENCY

Cylindrical gear manufacturers all around the world appreciate the advantages and productivity of the RAPID 1600 for workpiece diameters of up to 1,600 mm. With standard features that include a cast polymer machine bed, a torque motor-driven machine table, an integrated inspection system, a sturdy grinding spindle, and a dressing system for frequent profile modifications, it is the perfect solution for cylindrical gear manufacturers. Technologies such as high-speed grinding [HsG] and best-fit grinding [BfG] also reduce grinding times by up to 30 % ensuring a clear leading edge in production efficiency for the entire manufacturing process.

- Highly flexible direct-drive 5-axis grinding head and swivel angle adjustment during the grinding process

- Stable, damping-optimized single-bed base made of cast polymer

- Precise machine table control via torque motor drive

- Optional internal gear grinding arms

- Controlled grinding result thanks to integrated measurements and automatic corrections during the grinding process

- Energy efficiency (e2)

RAPID 2000 HÖFLER CYLINDRICAL GEAR GRINDING MACHINE

-

REDUCED GRINDING TIMES FOR MORE PRODUCTION EFFICIENCY

Cylindrical gear manufacturers all around the world appreciate the advantages and productivity of the RAPID 2000 for workpiece diameters of up to 2,000 mm. With standard features that include a cast polymer machine bed, a torque motor-driven machine table, an integrated inspection system, a sturdy grinding spindle, and a dressing system for frequent profile modifications, it is the perfect solution for cylindrical gear manufacturers. Technologies such as high-speed grinding [HsG] and best-fit grinding [BfG] also reduce grinding times by up to 30 % ensuring a clear leading edge in production efficiency for the entire manufacturing process.

- Highly flexible direct-drive 5-axis grinding head and swivel angle adjustment during the grinding process

- Stable, damping-optimized single-bed base made of cast polymer

- Precise machine table control via torque motor drive

- Optional internal gear grinding arms

- Controlled grinding result thanks to integrated measurements and automatic corrections during the grinding process

- Energy efficiency (e2)

RAPID 2500 HÖFLER CYLINDRICAL GEAR GRINDING MACHINE

-

GIANT WITH ABSOLUTE PRECISION, SPEED, AND FLEXIBILITY

The RAPID 2500 cylindrical gear grinding machine is the specialist for large, heavy workpieces up to 2,500 mm in diameter and weighing up to 25 tons. These giants combine maximum dimensions with absolute precision, speed, and flexibility: Topologically correct results with reduced grinding times and an optional internal grinding device form the basis for economical, reliable cylindrical gear production on this scale. In combination with the cutting machines, RAPID machines in the cylindrical gear technology division provide an ideal system for the cylindrical gear production process.

- Highly flexible direct-drive 5-axis grinding head and swivel angle adjustment during the grinding process

- Stable, damping-optimized single-bed base made of cast polymer

- Precise machine table control via torque motor drive

- Optional internal gear grinding arms

- Controlled grinding result thanks to integrated measurements and automatic corrections during the grinding process

- Energy efficiency (e2)

RAPID 3000 HÖFLER CYLINDRICAL GEAR GRINDING MACHINE

-

GIANT WITH ABSOLUTE PRECISION, SPEED, AND FLEXIBILITY

The RAPID 3000 cylindrical gear grinding machine is the specialist for large, heavy workpieces up to 3,000 mm in diameter and weighing up to 30 tons. These giants combine maximum dimensions with absolute precision, speed, and flexibility: Topologically correct results with reduced grinding times and an optional internal grinding device form the basis for economical, reliable cylindrical gear production on this scale. In combination with the cutting machines, RAPID machines in the cylindrical gear technology division provide an ideal system for the cylindrical gear production process.

- Highly flexible direct-drive 5-axis grinding head and swivel angle adjustment during the grinding process

- Stable, damping-optimized single-bed base made of cast polymer

- Precise machine table control via torque motor drive

- Optional internal gear grinding arms

- Controlled grinding result thanks to integrated measurements and automatic corrections during the grinding process

- Energy efficiency (e2)

RAPID 4000 HÖFLER CYLINDRICAL GEAR GRINDING MACHINE

-

GIANT WITH ABSOLUTE PRECISION, SPEED, AND FLEXIBILITY

The RAPID 4000 cylindrical gear grinding machine is the specialist for large, heavy workpieces up to 4,000 mm in diameter and weighing up to 40 tons. These giants combine maximum dimensions with absolute precision, speed, and flexibility: Topologically correct results with reduced grinding times and an optional internal grinding device form the basis for economical, reliable cylindrical gear production on this scale. In combination with the cutting machines, RAPID machines in the cylindrical gear technology division provide an ideal system for the cylindrical gear production process.

- Highly flexible direct-drive 5-axis grinding head and swivel angle adjustment during the grinding process

- Stable, damping-optimized single-bed base made of cast polymer

- Precise machine table control via torque motor drive

- Optional internal gear grinding arms

- Controlled grinding result thanks to integrated measurements and automatic corrections during the grinding process

- Energy efficiency (e2)

RAPID 6000 HÖFLER CYLINDRICAL GEAR GRINDING MACHINE

-

GIANT WITH ABSOLUTE PRECISION, SPEED, AND FLEXIBILITY

The RAPID 6000 cylindrical gear grinding machine is the specialist for large, heavy workpieces up to 6,000 mm in diameter and weighing up to 50 tons. These giants combine maximum dimensions with absolute precision, speed, and flexibility: Topologically correct results with reduced grinding times and an optional internal grinding device form the basis for an economical, reliable cylindrical gear production on this scale. In combination with the cutting machines, RAPID machines in the cylindrical gear technology division provide an ideal system for the cylindrical gear production process.

- Highly flexible direct-drive 5-axis grinding head and swivel angle adjustment during the grinding process

- Stable, damping-optimized single-bed base made of cast polymer

- Precise machine table control via torque motor drive

- Optional internal gear grinding arms

- Controlled grinding result thanks to integrated measurements and automatic corrections during the grinding process

- Energy efficiency (e2)

RAPID 8000 HÖFLER CYLINDRICAL GEAR GRINDING MACHINE

-

GIANT WITH ABSOLUTE PRECISION, SPEED, AND FLEXIBILITY

The RAPID 8000 cylindrical gear grinding machine is the specialist for large, heavy workpieces up to 8,000 mm in diameter and weighing up to 100 tons. These giants combine maximum dimensions with absolute precision, speed, and flexibility: Topologically correct results with reduced grinding times and an optional internal grinding device form the basis for an economical, reliable cylindrical gear production on this scale. In combination with the cutting machines, RAPID machines in the cylindrical gear technology division provide an ideal system for the cylindrical gear production process.

- Highly flexible direct-drive 5-axis grinding head and swivel angle adjustment during the grinding process

- Stable, damping-optimized single-bed base made of cast polymer

- Precise machine table control via torque motor drive

- Optional internal gear grinding arms

- Controlled grinding result thanks to integrated measurements and automatic corrections during the grinding process

- Energy efficiency (e2)

COMPLETE MACHINING CENTER

-

TURNING, CUTTING, BORING, SLOTTING AND GEARING ON A SINGLE MACHINE

Gear manufacturing today is not just limited to gear cutting machines. These days, machining centers are equally capable of manufacturing gears. With the TM 65, Klingelnberg is taking a fresh approach to complete machining of toothed gears using a method that relies on Klingelnberg’s Closed Loop system. Bevel gears designed with KIMoS (Klingelnberg Integrated Manufacturing of Spiral Bevel Gears) are manufactured true to design on the basis of a virtual twin, making technological knowhow for the automotive industry available for small-batch production.

TM 65 HÖFLER COMPLETE MACHINING CENTER

-

CUSTOMIZED SOLUTIONS FOR EVERY PRODUCTION REQUIREMENT

With the HÖFLER complete machining center TM 65, Klingelnberg has designed a machine that can produce gear bodies and gearing systems of any complexity up to 65 mm in diameter, in a complete machining process starting with rod material – whether bevel gears, cylindrical gears or internal gearing with an involute or non-involute tooth profile. The presence of a main spindle and subspindle allows complete machining of even complex components on a single machine.

- Complete machining of gears from rod material up to 65 mm

- Klingelnberg gear technology for bevel and cylindrical gearing

- Turning, cutting, boring, slotting and gearing on a single machine

- Maximum spindle speed of 30,000 rpm

- Subspindle freely pivots by 90°

- Integrated tool changer with up to 90 tool slots

- Easy system accessibility and compact design

- Wear-free, highly dynamic linear drives

PRECISION MEASURING CENTERS

-

SUSTAINABLE QUALITY MANAGEMENT OF DRIVE ELEMENTS

Stringent accuracy requirements for gear measurements and increasingly complex drive components demand the best measuring technology available and a machine and software concept optimized for these applications. That's why leading manufacturers put their trust in Klingelnberg precision measuring centers, which represent the most widely used standard in the industry, while also serving as the reference for metrology institutes. Klingelnberg precision measuring centers (P-series) today are ideally suited to handle most measurement tasks in a wide range of sectors: Users in the automotive and commercial-vehicle industries, the aerospace and aeronautical engineering industries rely on this technology, which replaces up to four conventional measuring devices. This allows the following measurement tasks to be fully automated in a single setting: gear measurement, general coordinate measurement, form and position measurement, and roughness measurement.

All Klingelnberg Precision Measuring Centers are equipped with heavy-duty, stable beds and guide bodies made of cast iron. At the same time, all bearings and guides are backlash-free at the measuring axes. These form the basis for the measuring centers' high basic mechanical accuracy. The integrated 3D tracer head enables both discrete-point probing and scanning, continuous measured value logging.

P 16 KLINGELNBERG PRECISION MEASURING CENTER

-

CUTTING-EDGE TECHNOLOGY FOR MAXIMUM SAFETY AND PRECISION

The fully automatic CNC-controlled P 16 precision measuring center is designed as a compact unit for the workpiece diameter range up to 160 mm. The machine is used to inspect cylindrical gears, pinion type cutters, worms and worm wheels, hobs, bevel gears, general dimension, shape, and positional deviations of axially symmetrical workpieces, cam and camshaft measurement and rotor measurement.

- Suitable for use on the production floor thanks to temperature compensation reliable measuring results even in the + 15°C to + 35°C range

- Fast and accurate measurement acquisition, combined with a high-precision workpiece turntable

- A wide range of measurement tasks in a single clamping, suitable for coordinate, shape, gear tooth and roughness measurements

- Versatile scanning 3D tracer head with digital measurement acquisition in all coordinate directions

- High basic accuracy with low tolerances

- Simple graphical programming environment and simple software operating concept

- Tremendous time savings due to quick availability of measuring results

P 16 G KLINGELNBERG PRECISION MEASURING CENTER

-

MAXIMUM SAFETY AND PRECISION FOR PROCESS CONTROL

Whether turning blanks, ground workpieces, circular blades, spacers for circular blades, or ball bearings – the new P 16 G precision measuring center is purpose-designed – not to measure gear teeth, but rather specifically for use in manufacturing round components. The P 16 G is the only machine in the P series to be equipped with software for dimension, form, and position measurement as standard. The software records diameter and cylindrical form/conicity, measures axial runout, evenness, and angularity, and delivers a wealth of information for quality management as required. Hence with this precision measuring center, there’s no need for gages.

- Suitable for use in production thanks to temperature compensation – reliable results even in the +15°C to +35°C range

- Machine design with optimal axis arrangement for axially symmetrical test specimens

- Production floor application through the use of temperature neutral scale rulers and a homogeneous machine design

- High geometrical long-term stability thanks to optimally sized components for machine base and guide bodies

- Smooth, wear- and maintenancefree

- AC direct drives in all measuring axes

- Use of the high-precision 3D tracer head

- Powerful, intuitive software

- Efficient data management through output of measuring results via a data connection or printout and interface to a statistical control loop

P 26 KLINGELNBERG PRECISION MEASURING CENTER

-

CUTTING-EDGE TECHNOLOGY FOR MAXIMUM SAFETY AND PRECISION

The fully automatic CNC-controlled P 26 precision measuring center is designed as a compact unit for the workpiece diameter range up to 260 mm. The machine is used to inspect cylindrical gears, pinion type cutters and shaving cutters, worms and worm wheels, hobs, bevel gears, general dimension, shape, and positional deviations of axially symmetrical workpieces, cam and camshaft measurement and rotor measurement.

- Suitable for use on the production floor thanks to temperature compensation reliable measuring results even in the + 15°C to + 35°C range

- Fast and accurate measurement acquisition, combined with a high-precision workpiece turntable

- A wide range of measurement tasks in a single clamping, suitable for coordinate, shape, gear tooth and roughness measurements

- Versatile scanning 3D tracer head with digital measurement acquisition in all coordinate directions

- High basic accuracy with low tolerances

- Simple graphical programming environment and simple software operating concept

- Tremendous time savings due to quick availability of measuring results

P 40 KLINGELNBERG PRECISION MEASURING CENTER

-

CUTTING-EDGE TECHNOLOGY FOR MAXIMUM SAFETY AND PRECISION

The fully automatic CNC-controlled P 40 precision measuring center is designed as a compact unit for the workpiece diameter range up to 400 mm. The machine is used to inspect cylindrical gears, pinion type cutters and shaving cutters, worms and worm wheels, hobs, bevel gears, general dimension, shape, and positional deviations of axially symmetrical workpieces, cam and camshaft measurement and rotor measurement.

- Suitable for use on the production floor thanks to temperature compensation –reliable measuring results even in the + 15°C to + 35°C range

- Fast and accurate measurement acquisition, combined with a high-precision workpiece turntable

- A wide range of measurement tasks in a single clamping, suitable for coordinate, shape, gear tooth and roughness measurements

- Versatile scanning 3D tracer head with digital measurement acquisition in all coordinate directions

- High basic accuracy with low tolerances

- Simple graphical programming environment and simple software operating concept

- Tremendous time savings due to quick availability of measuring results

P 65 KLINGELNBERG PRECISION MEASURING CENTER

-

CUTTING-EDGE TECHNOLOGY FOR MAXIMUM SAFETY AND PRECISION

The fully automatic CNC-controlled P 65 precision measuring center is designed as a compact unit for the workpiece diameter range up to 650 mm. The machine is used to inspect cylindrical gears, pinion type cutters and shaving cutters, worms and worm wheels, hobs, bevel gears, general dimension, shape, and positional deviations of axially symmetrical workpieces, cam and camshaft measurement and rotor measurement.

- Suitable for use on the production floor thanks to temperature compensation reliable measuring results even in the + 15°C to + 35°C range

- Fast and accurate measurement acquisition, combined with a high-precision workpiece turntable

- A wide range of measurement tasks in a single clamping, suitable for coordinate, shape, gear tooth and roughness measurements

- Versatile scanning 3D tracer head with digital measurement acquisition in all coordinate directions

- High basic accuracy with low tolerances

- Simple graphical programming environment and simple software operating concept

- Tremendous time savings due to quick availability of measuring results

P 100 KLINGELNBERG PRECISION MEASURING CENTER

-

CUTING-EDGE TECHNOLOGY FOR MAXIMUM SAFETY AND PRECISION

The fully automatic CNC-controlled P 100 / P 100 L precision measuring centers are designed as compact units for the workpiece diameter range up to 1000 mm and 1250 mm respectively. The machines are used to inspect cylindrical gears, pinion type cutters and shaving cutters, worms and worm wheels hobs, bevel gears, general dimension, shape, and positional deviations of axially symmetrical workpieces., cam and camshaft measurement and rotor measurement.

- Suitable for use on the production floor thanks to temperature compensation reliable measuring results even in the + 15°C to + 35°C range

- Fast and accurate measurement acquisition, combined with a high-precision workpiece turntable

- A wide range of measurement tasks in a single clamping, suitable for coordinate, shape, gear tooth and roughness measurements

- Versatile scanning 3D tracer head with digital measurement acquisition in all coordinate directions

- High basic accuracy with low tolerances

- Simple graphical programming environment and simple software operating concept

- Tremendous time savings due to quick availability of measuring results

P 150 KLINGELNBERG PRECISION MEASURING CENTER

-

CUTTING-EDGE TECHNOLOGY FOR MAXIMUM SAFETY AND PRECISION

The fully automatic CNC-controlled P 150 precision measuring center is designed for the workpiece diameter range up to 1800 mm. The machine is used to inspect a wide range of cylindrical gear designs, as well as large bevel gearings and worm gears.

- Fast and accurate measurement acquisition, combined with a high-precision workpiece turntable

- A wide range of measurement tasks in a single clamping, suitable for coordinate, shape, gear tooth and roughness measurements

- Versatile scanning 3D tracer head with digital measurement acquisition in all coordinate directions

- High basic accuracy with low tolerances

- Simple graphical programming environment and simple software operating concept

- Tremendous time savings due to quick availability of measuring results

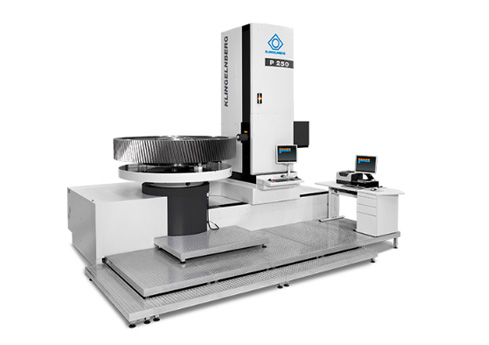

P 250 KLINGELNBERG PRECISION MEASURING CENTER

-

CUTTING-EDGE TECHNOLOGY FOR MAXIMUM SAFETY AND PRECISION

The fully automatic CNC-controlled P 250 precision measuring center is designed for the workpiece diameter range up to 2800 mm. The machine is used to inspect a broad range of cylindrical gear designs, as well as large bevel gearings and worm gears.

- Fast and accurate measurement acquisition, combined with a high-precision workpiece turntable

- A wide range of measurement tasks in a single clamping, suitable for coordinate, shape, gear tooth and roughness measurements

- Versatile scanning 3D tracer head with digital measurement acquisition in all coordinate directions

- High basic accuracy with low tolerances

- Simple graphical programming environment and simple software operating concept

- Tremendous time savings due to quick availability of measuring results

P 350 KLINGELNBERG PRECISION MEASURING CENTER

-

CUTTING-EDGE TECHNOLOGY FOR MAXIMUM SAFETY AND PRECISION

The fully automatic CNC-controlled P 350 precision measuring center is designed for the workpiece diameter range up to 3800 mm. The machine is used to inspect a wide range of cylindrical gear designs, as well as large bevel gearings and worm gears.

- Fast and accurate measurement acquisition, combined with a high-precision workpiece turntable

- A wide range of measurement tasks in a single clamping, suitable for coordinate, shape, gear tooth and roughness measurements

- Versatile scanning 3D tracer head with digital measurement acquisition in all coordinate directions

- High basic accuracy with low tolerances

- Simple graphical programming environment and simple software operating concept

- Tremendous time savings due to quick availability of measuring results