BINDER Fördertechnik

Videos

Loading the player ...

- Offer Profile

SOLUTIONS THAT MOVE

Burgstetten near Stuttgart is home to BINDER GmbH, an owner-managed family company run by two generations of the Binder family. Since its foundation in 1971 BINDER has been designing and implementing innovative and customer-centric solutions in material handling.

45 years of experience, modern machinery and a wide range of services – this is what makes up BINDER. Our knowledge, experience and vision allow us to meet our customers as partners and to support them during the entire project. Reliability, punctuality and high-quality implementation are the guiding principles which are at the bottom of our success as a company. Our effective company structure and motivated staff provide us with the necessary flexibility to meet our customers‘ demands.

Product Portfolio

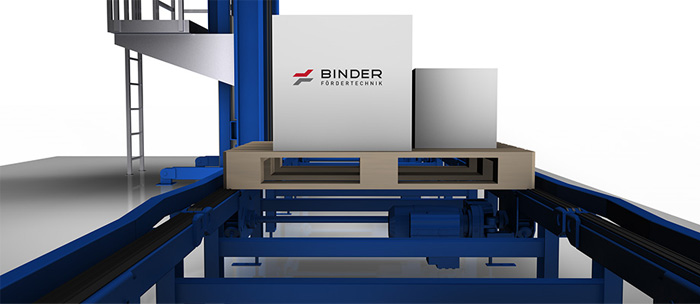

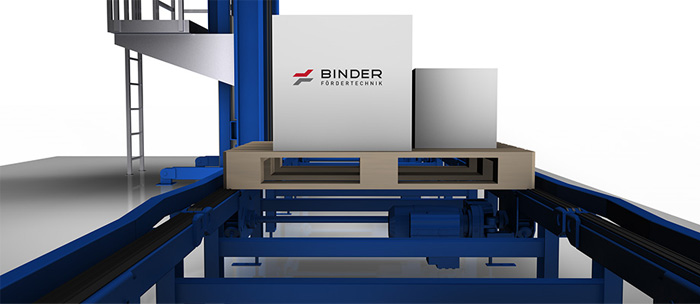

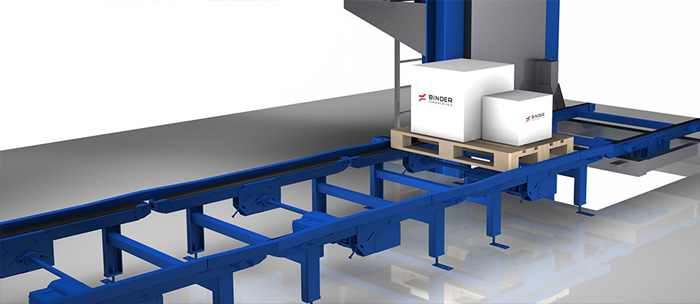

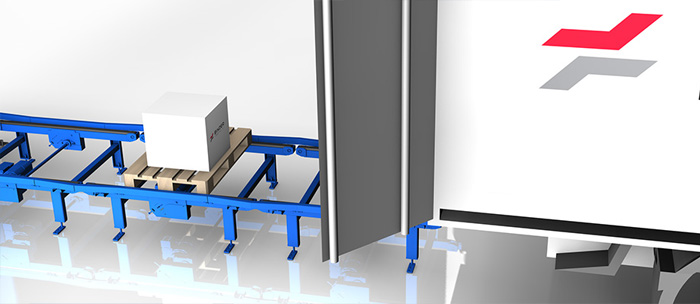

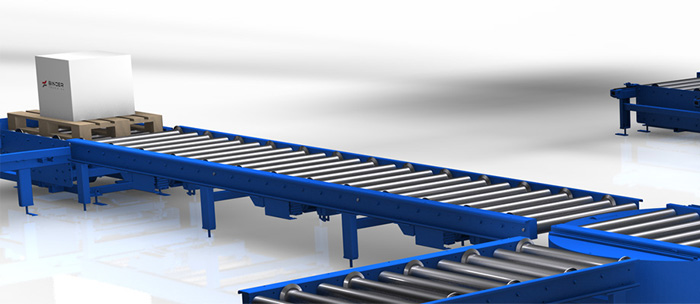

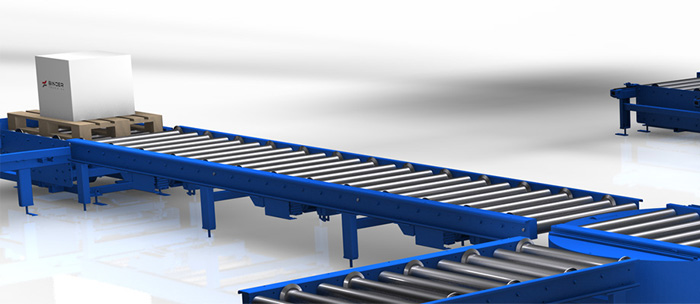

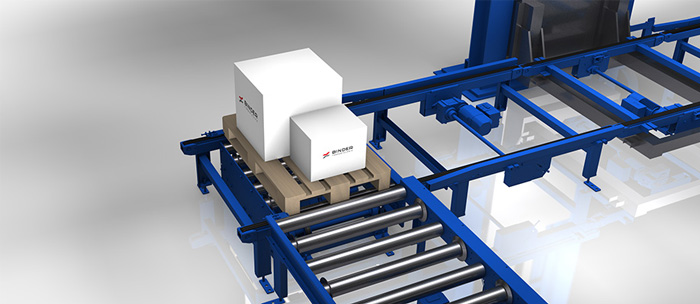

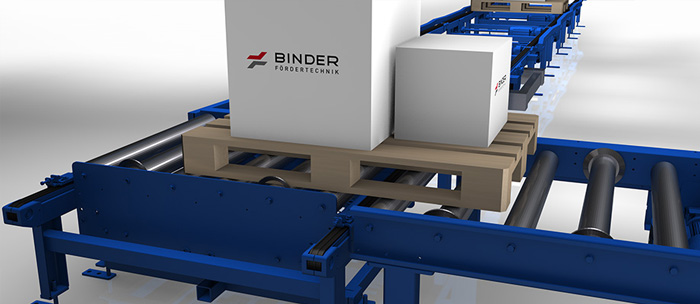

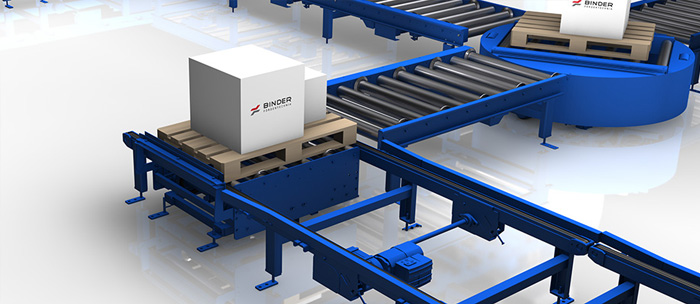

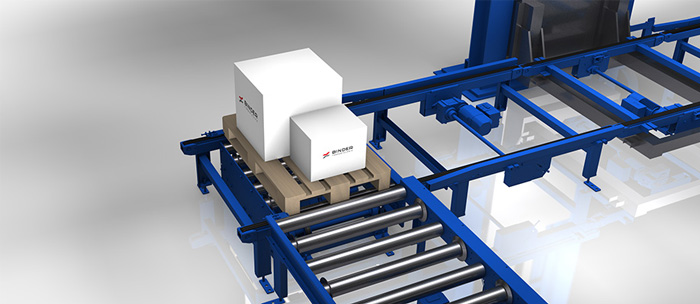

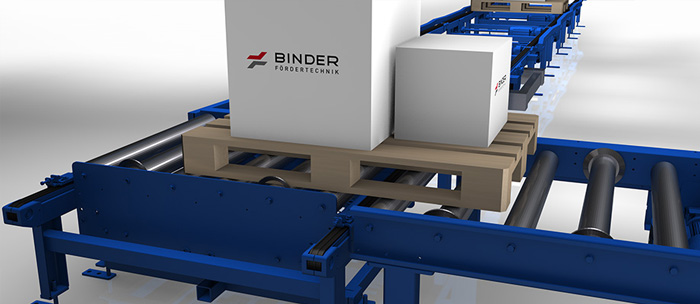

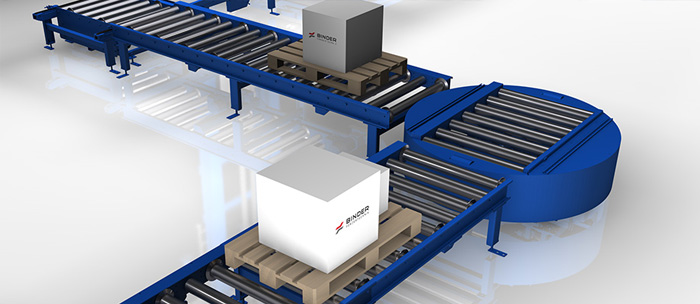

PALLET CONVEYING

OUR SPECIALTY

We are an established partner for high-end integrated solutions. We are also happy to implement small and medium-sized installations as system supplier.

CHAIN CONVEYOR

- A roller chain bears the weight of the material for conveying. The highly wear-resistant plastic slide rail attached to the frame structure guarantees low-friction, low-noise running. The conveyor is driven by a continuous shaft with a geared motor. The individual sections of the chain are tensioned separately. Reversing operation is possible. Small chain deflectors on roller bearings allow common loading aids to be transported longitudinally or transversely without changing track. Grouping is effected by clocked operation or bunching of the material for conveying.

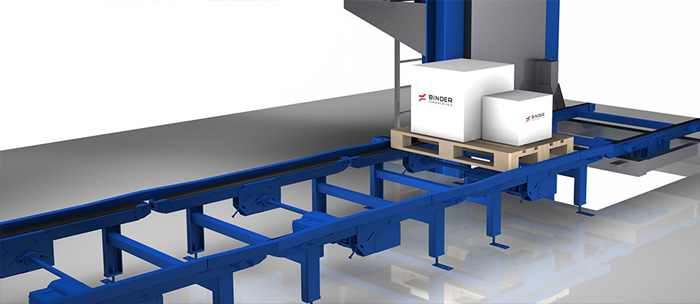

ROLLER BED

- The conveyor rollers are driven from roller to roller or tangentially, with the drive and chain tensioning usually arranged in the centre. Reversing operation is possible. The material for transport is guided by flanges welded or clamped onto the rollers. Conveying is continuous, the material for transport can be grouped by the control unit by means of increasing clocking or bunching. Special designs in accordance with individual customer requirements.

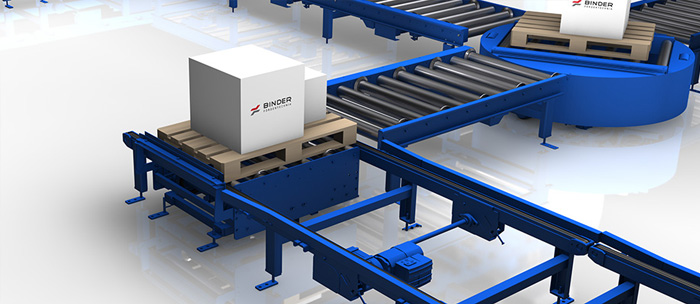

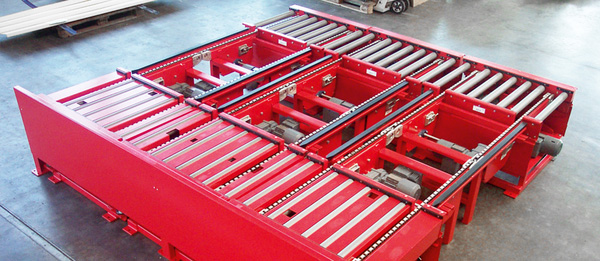

ANGULAR TRANSFER UNIT

- Lifting elements are fitted in the conveyor systems to load and retrieve products at right angles to the direction of travel and to transfer them between conveyor lines running in parallel. The lifting movement is executed electromechanically using eccentric lifting shafts. Axial rollers guide lifting precisely.

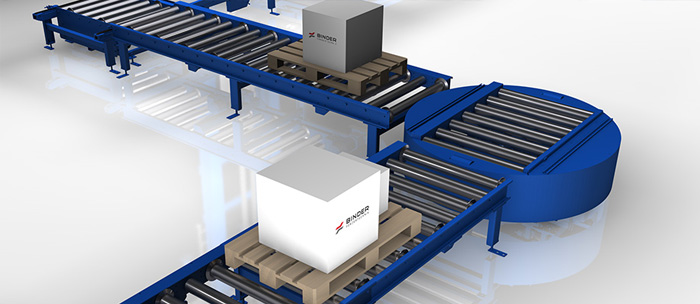

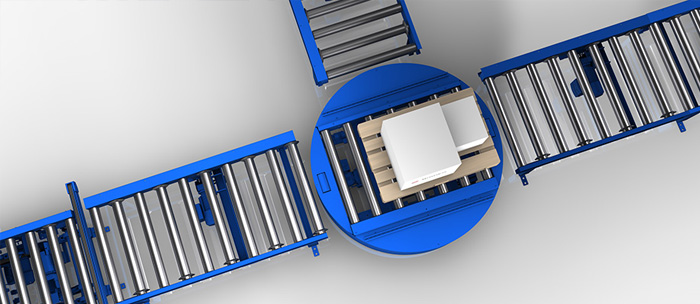

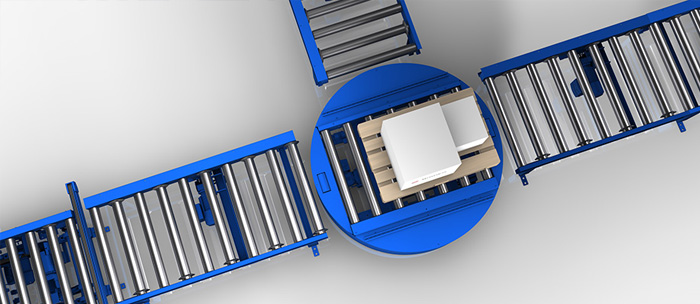

TURNTABLE & TILTING TABLE

- The turntables and tilting tables with chain conveyors or roller beds mounted on top can swivel up to 360°; they are fitted in conveyor systems at intersections and to effect a change in direction. Both horizontal and vertical movements can be integrated to suit customer requirements. The turning element is a high-quality single-row ball bearing slewing ring with external gear.

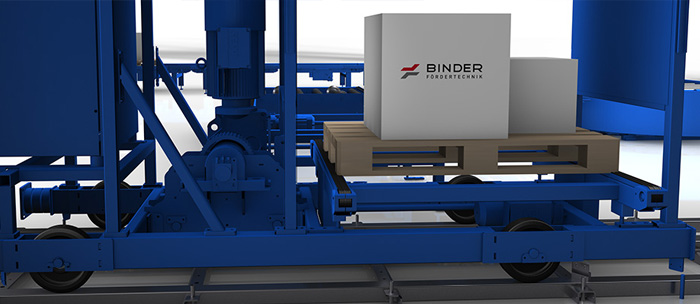

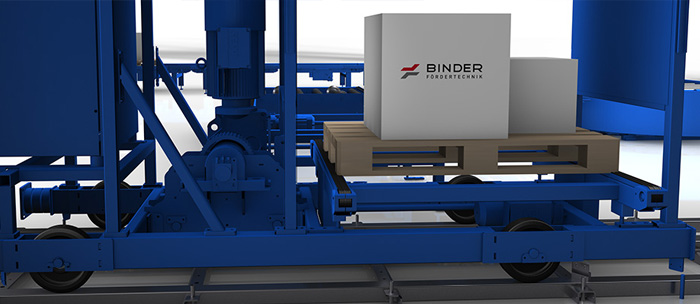

TRANSFER CAR

- Transfer cars are used for supplying and emptying spurs, for picking stations and pallet stations and for connecting conveying sections arranged offset from one another. The basic design consists of a welded frame with an integrated chassis. Travelling movement is achieved essentially by means of direct-driven wheels or toothed belts. When driven by toothed belts, the motor can be arranged either stationary or travelling on the car. Directional stability is ensured by adjustable guide rollers on the sides. The Vulkollan wheels have very smooth-running and shock-absorbing characteristics. It is possible to mount a variety of components on top for transferring and forwarding the material for transport, such as chain conveyors, roller beds or telescopic tables.

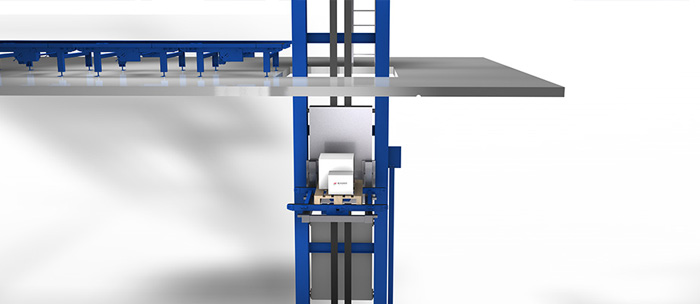

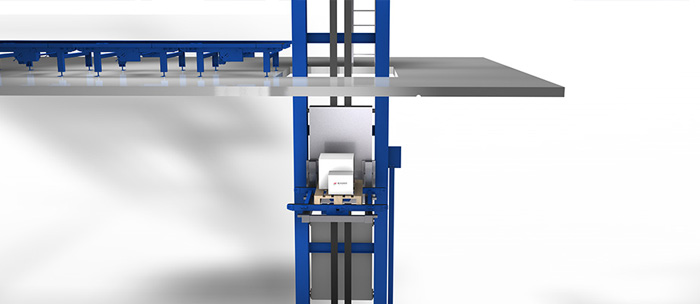

VERTICAL CONVEYOR

- VERTICAL CONVEYOR

Vertical conveyors are used to connect conveyor systems on different levels. The lifting drive is provided by an electric motor, with flat belts, toothed belts, cables or chains being used as carrier media. Depending on requirements, 2-column or 4-column designs with the drive above or below can be used. The type of conveyor mounted on the lifting carriage can be realized to suit the individual application – in the form of a telescopic fork, chain conveyor, roller bed, turntable or angular transfer unit.

CARRIER PLATE CONVEYING

- SPECIFICALLY FOR METAL CARRIER PLATES

CARRIER PLATE CONVEYING

- Chain conveyors and roller conveyors with plastic coatings ensure gentle and low-noise transport of metal carrier plates of various sizes with total weights of up to 300 kg.

MODULAR BELT CONVEYING

- CAN BE USED FOR DIFFERENT LOADING AIDS

MODULAR BELT CONVEYING

- Modular belt conveyors are used for the continuous transport of pallets and load carriers of various sizes.

DOLLY CONVEYING

- FLEXIBLE & SAFE CONVEYING

DOLLY CONVEYING

- Chain conveyors or belt conveyors safely transport rolling containers of various sizes. Combined transport of rolling containers and pallets is also possible.

SPECIAL SOLUTIONS

- INDIVIDUAL & CHALLENGING

SPECIAL SOLUTIONS

- In addition to individual solutions we offer special solutions, both integrated into complete systems and as separate elements for new and existing installations.

Services

- CONVEYING IS A PROCESS:

AND WE ARE THE ONE-STOP PROVIDER TO SUPPORT IT

We are experts in providing special conveying solutions: covering everything from project planning, in-house design and on-site manufacture to assembly and commissioning at the location of use. Our portfolio also includes upgrading and updating existing machinery and providing operator training after successful commissioning. A staff of more than 50 skilled and competent professionals with innovative ability guarantees our quality and delivery reliability. PROJECT PLANNING

- YOUR REQUIREMENTS ARE OUR CHALLENGE

Different product requirements, local conditions and differences in production processes require made-to-measure conveying solutions. At BINDER, experienced professionals design for example storage and retrieval systems for pallet high-bay racking, picking and dispatch areas and car body transfer at the welding stage and for fi nal assembly. For this, various types of loading equipment, such as pallets, rolling containers or carrier plates are used. Our solutions make use both of tried and tested components of unit load handling technology such as chain conveyors, roller conveyors and modular belt conveyors, including any subassemblies required, and of customised designs. MANUFACTURING

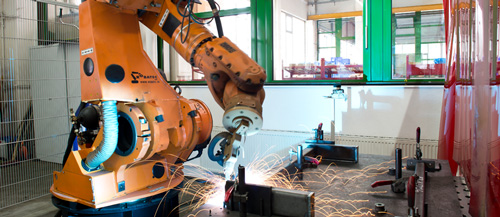

- QUALITY MANUFACTURING MADE BY BINDER:

WE WORK FOR YOUR SUCCESS

Our highly qualified and motivated staff and our modern machinery allow us to manufacture virtually all the components needed in virtually any depth of production. Our services also include contract manufacturing – based on your drawings –, manufacturing of single pieces and the manufacture of special-purpose machines, both for conveying and other equipment.

MACHINING- CNC milling machines

- CNC automatic lathes

- Conventional lathes

- CNC drilling machine

- CNC saws

WELDING- Welding robot

- Several welding machines for MIG, MAG und TIG welding

- Laser cutting plant

- Stroke scissors

- Mechanical press brakes

PAINTING- Wet painting box

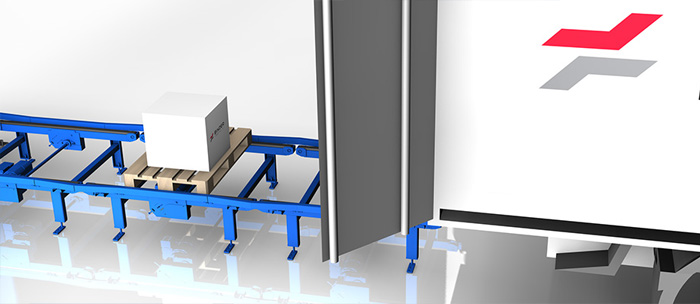

ASSEMBLY

- ASSEMBLY & SERVICE:

OUR SERVICES DO NOT STOP AT THE FACTORY GATES

Only ideally matched individual components will be shipped to the customer. But we all know that the whole is more than the sum of its parts, and therefore our conveyor systems are fine-tuned on site. Our customers expect flawless installation and commissioning at their production sites, after all. After going live we offer competent maintenance and a fast spare parts service to ensure trouble-free operation. With our aftersales service we will be your partner for the complete life cycle of your equipment.