- Offer Profile

-

Since 1937, Daifuku has focused on material handling – the movement of finished goods and work in progress. Our world-class systems lead the industry by combining conveying, storage, sorting, picking and controls. Our products serve customers in a range of industries and countries.

We have refined our expertise not only as a manufacturer but also as a system integrator, so that we can provide precise solutions to the challenges faced by customers across a variety of industries. We provide total support ranging from consulting to after-sales service, and offer 24-hour support, remote monitoring of equipment operation and preventive maintenance services.

Automation that Inspires

-

Learn more about Daifuku's innovative material handling systems and products, including AS/RSs, AGVs, conveyors, picking, and sorting systems.

Intralogistics

- Learn more about Daifuku's innovative material handling systems and products, including AS/RSs, AGVs, conveyors, picking, and sorting systems.

Automated Storage and Retrieval Systems (AS/RS)

-

High-density pallet storage, high-speed operation, and versatility make Daifuku’s unit load AS/RS the best-selling automated storage and retrieval system in the world. With its flexible design up to 40 m, the Daifuku unit load automated warehouse is customizable to fit your specific installation environment and operating conditions.

Features:

- Fast and depandable

- Advanced Control System

- Improved Operational Efficiency

Vehicle Systems (AGV)

-

From storage in and out of AS/RS, supply to picking stations, transport between production processes, to sorting before shipments,Daifuku Vehicle Systems are ideal for transporting and sorting needs.

Daifuku's Automated Guided Vehicle (AGV) systems offer flexible movement of materials without human intervention for a variety of industries and for various production phases such as followings;

- Raw material supply to production lines according to schedule

- Work-in-progress collection from production lines to buffer area

- Work-in-progress supply to subsequent processes

- Mobile working bench of car assembly lines

- Finished product storage into warehouse

- Finished product loading to delivery trucks

Conveyer and Sorters

-

The Digital Assorting System (DAS) is a manual sorting system that applies pick-to-light systems to sorting operations. An operator places goods on shelves or at an assortment location, following the instructions on a digital display. The system is suitable for sorting batch-picked products by destination and for transit operation in which incoming products are sorted and shipped immediately. It is often used for perishable items.

Picking Systems

-

From fully automated picking by robots to efficient manual picking using indicators, we offer picking, palletizing, and depalletizing solutions that are best suited to the logistics characteristics of each customer.

Pick-to-Light SystemThe digital picking system is a piece-picking system in which products are picked according to the instructions on the digital display attached to the shelf. The system can be built for a wide range of applications, from low-mix high-volume to high-mix low-volume. Since the scope of the worker's responsibility is clear, and the instructions and quantity of products are displayed, work efficiency can be improved and picking errors can be greatly reduced compared to the paper list method.

The digital display can be mounted on a variety of racks, making it easy to build a digital picking system to suit the type of cargo and application. The system is also used in combination with automated warehouses for storage and picking systems. We have a wealth of experience in order picking of food and daily necessities in wholesale, e-commerce and retail industries.

Rack Systems

- Mobile Pallet Racking

Daifuku's heavy-duty aisle-opening pallet racking, Mobile Rack, is suitable for pallet storage simplifying location control and expediting forklift input/output operation. With its smooth dolly movement, user-friendly interface, and several safety devices, Daifuku's Mobile Rack has a great reputation in the material handling industry.

FeaturesThe mobile pallet racking system consists of two fixed racks at either end of the system, with racks on dollies in-between. Compared to conventional fixed racks that require aisle space every two rows, the mobile rack needs only 1 aisle space per system since dollies slide to open an aisle where needed. This system reduces the storage rack footprint by 50%.

- Convenient operation mode

- User-friendly interface

- Safety system for user protection

IT Systems

- WMS, Scada and other software product for efficient material handling system operation.

Cleanroom

-

Daifuku provides cleanroom AMHSs (automated material handling systems) that automate semiconductor and flat panel production to users across the globe. Thanks to the incredible technical prowess that puts Daifuku at the forefront of the industry, AMHSs produce minimal amounts of dirt, keep vibration levels low, and ensure top-notch reliability to facilitate operations at cutting-edge semiconductor and flat panel plants. In recent years, unique technologies like nitrogen purging and air flotation have allowed manufacturers to miniaturize their semiconductors and give their flat panels even sharper image quality, enhancing the production of the world’s most advanced digital products.

Semiconductor

-

Daifuku's array of semiconductor solutions includes dependable storage and transport systems for keeping production lines continually running; nitrogen purge storage systems, which accommodate the increase in semiconductor miniaturization needs; and resources for maximizing utilization rates at production facilities.

Flat Panel Display

- Daifuku’s high-performance LCD (liquid crystal display) glass substrate transport and storage systems ensure an ultra-clean environment. With a wide range of cassette sizes, these systems can handle from Gen 4 all the way up to Gen 10 glass substrates. Daifuku is also involved in the development of similar systems for OLED panels, which are increasingly used in smartphones and other devices.

Automotive

- At the Daifuku Group, we have close to a century-long proven track record in automobile production line systems. We supply automated systems for the entire manufacturing process—from pressing, welding, painting, assembly, parts storage and supply, through to engine testing. Motorization is expanding on a global scale, including a worldwide increase in eco-friendly cars and locally-oriented models. At the Daifuku Group, we support this expansion with our cutting-edge logistics technologies and automobile production solutions.

Chainless conveyer system

- Chainless Conveyor System - Flexible Drive System

The Flexible Drive System transports loaded carriers and trolleys by providing driving force through friction. The force is generated when the driving wheel powered by the motor presses against the sides of the trolleys or load bars.

As the word “flexible” suggests, the system is characterized by how it can be used in many different line configurations.

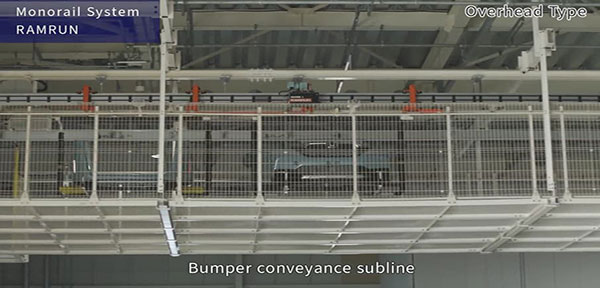

Monorail system

- Monorail System - Ramrun

Ramrun is a conveyance system where the carriers themselves are equipped with motors and wheels, allowing each to move on its own.

It is characterized by its ability to travel at variable speeds and stop at precise positions. Also, it does not require chains or lubricant due to its urethane wheels. Lifting and transferring equipment can be added to the carriers to cater to specific applications and conditions.

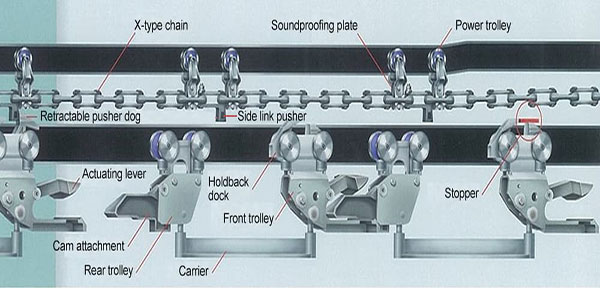

Chain conveyer systems

- Chain Conveyor System - Power and Free Conveyor

The Power and Free Conveyor is a chain conveyor system that transports loads along a set path and is able to stop at predetermined positions. It is a highly flexible system that can convey loads at speeds suited for various processes, including painting, assembly, branching, storage, and final assembly. The basic structure consists of (1) a power line that drives the X-type forged chain, and (2) a free line that supports the trolleys and carriers, which moves via stationary pushers mounted on the X-type chain.

- Enables efficient use of floor space by utilizing vertical space.

- Freely configurable layout in both horizontal and vertical directions.

- Capable of automated loading and unloading of transported objects.

- Enables loads to proceed to storage from anywhere on the conveyor line.

- Capable of automatic branching and merging to move the carriers in a fixed direction.

- Prevents damage and collision between transported objects.

- Allows for easy alteration or expansion of lines.

- Enables centralized and distributed control via computer.

Transfer and lifting equipment

-

Transfer and Lifting Equipment

We provide a wide variety of transfer and lifting equipment to match your conveyor system, with options based on conveyor type and items to be conveyed.

- Drop lifter

- Table lifter

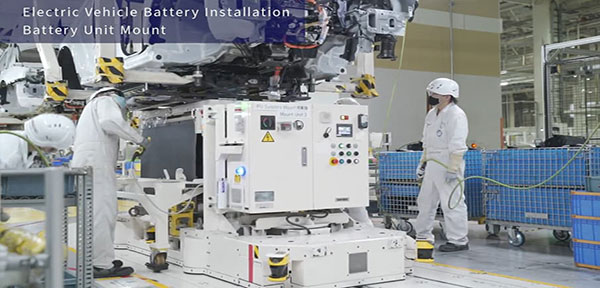

EV battery mountig equipment

- The battery unit mount can automatically align the battery unit to the mounting position. It achieves this by moving in synchronization with the overhead conveyor system that is loaded with the car body.

Temporary parts storage and sortation system

-

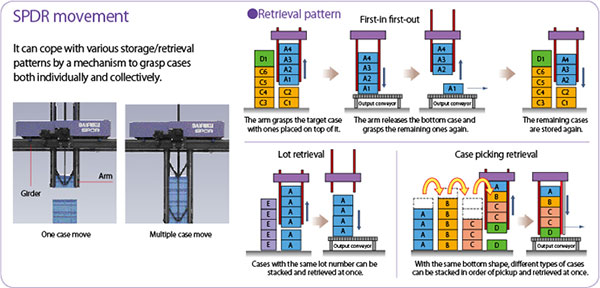

World-First Temporary Storage and Sortation System “SPDR”

In 1957, Daifuku supplied Japan’s first chain conveyor for car body transport to an automobile plant. Since then, we have achieved many results in almost all processes of automobile production. In addition to innovative conveyor systems, we have provided various solutions for improving productivity of parts handling in and parts supply to the line side of main assembly lines. However, traditional systems for the reception and storage of parts from suppliers and timely retrieval according to production schedules often required manual labor. To improve said process, we developed and launched the SPDR (pronounced spider), a temporary storage and sortation system for parts, in December 2014.

Engine testing system

Paint system

Airport

-

Daifuku Airport Technologies is a trusted partner of airports and airlines globally, providing end-to-end solutions. We provide Baggage Handling Systems, Operations & Maintenance, Passenger Screening Lanes, and Airport Operation Systems.

Our leading-edge solutions continue to revolutionize airport operations worldwide, enhancing the productivity, intelligence, accuracy, and passenger service levels of our partners.

Baggage Handling System

- Daifuku is a leading global provider of end-to-end baggage handling solutions, offering an unparalleled network of expertise and support from project conception to system maintenance. More than 500 airports around the world depend on our leading-edge technology to engineer, manufacture, install, and service baggage handling systems. Daifuku enhances the productivity, accuracy, and passenger service levels of our partners while creating a seamless airport journey for their passengers.

Sortation Systems

- We are a leading global provider of efficient, high-speed solutions for the transportation and sortation of passenger bags from check-in counters to baggage make-up areas.

Early Baggage Storage

- Our early bag storage (EBS) system is primarily used to store and release bags that have been delivered to the airport early, enhancing operations at the make-up stage.

Conveyors and Carousels

- Daifuku’s baggage transport and sorting solutions include versatile belt conveyors capable of handling baggage of virtually any shape and size. As one of the few providers that make all three types of baggage carousels, we provide flexible alternatives to accommodate the various demands of your baggage handling system.

Self-Service Technologies

- Our flexible self-service technologies are designed to enhance the passenger check-in experience, allowing airline staff to focus on customer service and support.

Security Screening

- We have designed our explosive detection systems (EDS) solutions to ensure the efficient sortation of passenger baggage across all airport environments while maintaining absolute compliance for airport security in any country.

Control Systems

- We provide efficient, high-speed solutions for the transportation and sortation of passenger bags. Our baggage handling system (BHS) management suite has two versions, Airflow and WebbView. Both products include modules necessary to manage both simple and complex BHS solutions in full compliance with IATA 753.

Simulation, Emulation and SCADA

- Daifuku understands that baggage handling systems are mission-critical within the airport terminal environment. We ensure that the software solutions are reliable, efficient, and scalable for future growth. Our entire suite of solutions features integrated redundancy architecture, providing unparalleled system resilience for day-to-day operations.

Airport Operation Systems (AOS)

- Daifuku's dynamic suite of integrated digital systems offers a range of operational and informational benefits for our global partners. By giving operators access and control over complex flight, passenger, and retail data, we provide the tools required to enhance both operational efficiency and profitability.

Operations and Maintenance

- Our team of maintenance, engineering, and trade specialists optimizes the performance of critical airport systems. Services and solutions are baggage handling system maintenance, facility maintenance, ground support equipment, and passenger boarding bridges.

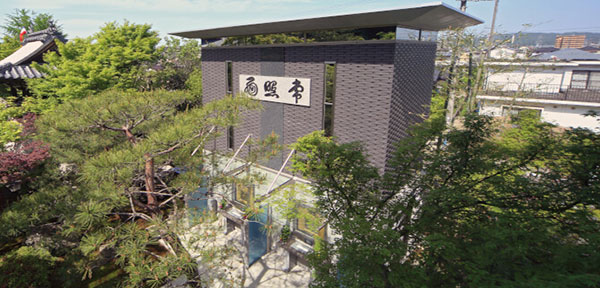

Columbarium

-

In urban area where land space is limited, the needs for having nearby columbaria instead of having tombs in far-distant cemetery gardens is increasing. Daifuku's automated columbarium uses vertical space efficiently to provide adequate rooms for urns as well as rooms for prayers within a limited land space of urban area.

Indoor prayer rooms always provide comfortable praying environment to visitors and allow them to pay their respects to the deceased regardless of the weather outside. Besides, the indoor barrier-free worship area provides smooth access to elderly people and visitors with wheelchairs comparing to outdoor grave.

Stacker cranes, the core of automated columbarium system, are backed up with Daifuku's technology and know-how accumulated though 80+ years experience in the material handling industry.

Indoor model system

-

- Storage capacity: 4,000 ~ 10,000 boxes

- Floor space: 150m² (*1)

- # of stacker cranes: 2/aisle x 2 aisles = 4 units

Outdoor model system

-

- Storage capacity: 508 boxes

- Floor space: 17m² (*1)

- Building size (m): 6.5W x 2.6D x 7H

- # of booth: 2

- # of stacker cranes: 1

Wireless Power Supply Solutions

-

Since the development of the world's first monorail-type, non-contact power supply system in 1993, Daifuku's wireless power systems have been employed in a wide range of industrial fields including the automotive, semiconductor, flat panel display (FPD), medical products, food, and food container industries. Clean, safe, and maintenance-free, we have sold over 8,000 units.

The D-PAD wireless charging system is a battery charging system that can be equipped to various mobile manipulators and AGVs.

Noncontact Power SupplyThe noncontact power supply system (HID) can supply power to systems without the need for trolleys or moveable cables.

Since it does not generate dust, the system is regularly used to power transportation and storage systems in cleanroom environments such as semiconductor and flat panel display production lines. Car Wash Machines

- Daifuku's lineup of car wash machines makes the most of the techniques and quality that the company has accumulated over the years as a manufacturer of material handling systems. From tunnel-type car washes for passenger vehicles to drive-throughs, gate-type car washes, and large-scale car washes for trucks, buses, and semi-trailers, Daifuku offers a wide variety of car wash machines and products to service stations, car dealerships, maintenance shops, transportation companies, and coin-operated car washes.

Tunnel-type

-

The Magic Thru, which incorporates conveyer system technologies, is the industry's only roller conveyer-based tunnel-type car wash. By achieving industry-leading vehicle processing rates, the machine washes quickly and thoroughly, even during seasons with high demand.

Drive-through

Daifuku’s smart-looking Twinfect Riscia is a one-way drive through car wash machine that offers improved drying power and processing capacity by separating the washer and dryer. In addition, the Treus/Cordia, a 1.5-way drive-through car wash machine, is also available.

Gate-type

-

The lineup includes the Grossa, which features inclined and split side brushes for improved cleaning quality; and the Zechs, a compact system that boasts the industry's smallest footprint. Each model can be equipped with a variety of options to suit different purposes and applications, which can help boost non-oil profits for service stations and operational efficiency for car dealers and auto-repair shops.

Large-scale

-

The Camion Custom is a vehicle wash machine designed specially for large vehicles. Installing the system reduces driver workload and work hours, thereby improving the working environment. In recent years, the system has been increasingly adopted in distribution centers and truck terminals.