- Offer Profile

-

Your Vehicle Navigation Partner

At BlueBotics we help companies meet the challenge of vehicle automation. We provide the ANT® navigation technology and expert support they need to bring their automated guided vehicle (AGV), automated forklift or mobile robot successfully to market. We also offer professional robotic engineering services to help companies go from idea to product.

Choose BlueBotics as your expert partner and let’s bring your automated product to life.- 20 years of natural feature navigation

- 3,000+ ANT® driven vehicles in operation

- 1,000+ end-user installations

- 10+ million KM driven by ANT®

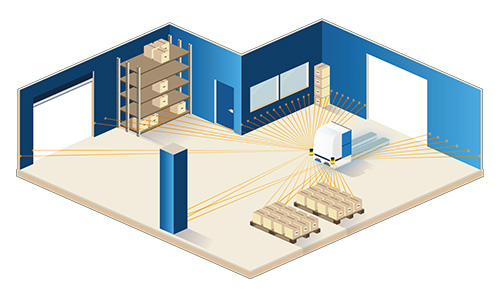

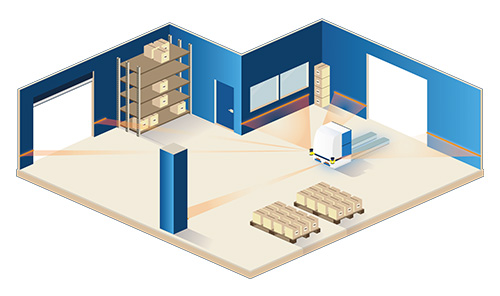

Autonomous Navigation Technology (ANT®)

-

Natural feature navigation for your automated guided vehicle (AGV), automated forklift or mobile robot.

ANT® navigation technology is an accurate, robust and flexible solution that meets the evolving needs of vehicle producers and operators. Based on 20 years of industry experience, ANT® is simple to use and cost-effective to install and modify.

- Quick to install & modify

- Accurate to ±1 cm / ±1°

- Scalable - create an ANT® fleet

ANT® lite+

Positioning & control for your vehicle-

Fully automate your vehicle

ANT® lite+ is a vehicle control and positioning system for AGVs, automated forklifts and mobile robots. this complete natural feature navigation solution calculates the vehicle’s position (localization), controls its motion, and can interface directly with the vehicle’s safety laser scanners. when combined with ANT® server software, ant® lite+ also offers mission and fleet management, including traffic control.

- Positioning & control for:

- Automated guided vehicles (AGVs)

- Automated forklifts

- Autonomous mobile robots (AMRs)

- Service robots

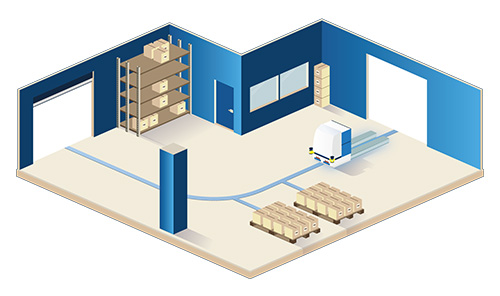

ANT® localization+

Positioning & emulation of line following for your vehicle-

Upgrade to virtual line following

ANT® localization+ is a positioning system for the upgrading of line following AGVs. It enables a vehicle to follow a virtual line using natural feature navigation, effectively replacing the antenna used to follow physical lines such as magnetic tape, inductive wire, tags etc.

Positioning for:

- Line-following AGVs

ANT® localization

Positioning for your vehicle-

Know exactly where your vehicle is

ANT® localization is a vehicle positioning system for automated guided vehicles (AGVs), automated forklifts and mobile robots. It can also be used to track manual vehicles. ANT® localization simply provides position coordinates to the main vehicle controller. Therefore, it suits vehicle makers who have their own control system.

Positioning for:

- Automated guided vehicles (AGVs)

- Automated forklifts

- Autonomous mobile robots (AMRs)

- Service robots

- Manual vehicles (e.g. forklift trucks)

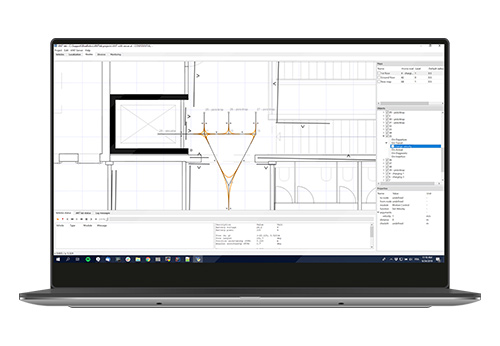

ANT® lab

Vehicle & mission configuration software-

Configure, install, deploy

ANT® lab is our proven vehicle and mission configuration software. Use it to configure and install your customers' AGVs. Then, in the future, use ANT® lab to update their installations, modifying routes and actions as required.

- Configure & calibrate vehicles

- Map sites

- Create routes & actions (e.g. move forks)

- Configure devices (e.g. chargers, elevators etc.)

- Define traffic rules (to be managed by ANT® server)

- Simple monitoring for testing & validation

- Supplied with every ANT® product

- Free, regular updates

ANT® server

Mission & fleet management software-

Put your AGVs to work

ANT® server is our advanced mission and fleet management software. Use it to manage and optimize your on-site operation (including AGV traffic control).

- Simulate vehicles and missions

- Schedule missions

- Automatically control AGV traffic

- Monitor your fleet in real-time

- Manage the charging of vehicles

- Interface with existing equipment (software/elevators etc.)

WHY CHOOSE NATURAL FEATURE NAVIGATION?

- There are numerous types of AGV navigation technology available today. The table below explains the relative strengths and weaknesses of each.

LINE FOLLOWING

-

These AGVs are equipped with a specific sensor to follow a physical line on the ground (e.g. magnetic tape, inductive wire).

PROS:- Reliable

- Accurate

- Not affected by changes in environmen

- Time-consuming/expensive to install

- Time-consuming/expensive to modify

- Fleet management difficult

TAGS

-

These vehicles are equipped with a specific sensor (e.g. a camera or code reader), which follows a route defined by tags.

PROS:- Reliable

- Accurate

- Not affected by changes in environmen

- Time-consuming/expensive to install

- Time-consuming/expensive to modify

- Fleet management difficult

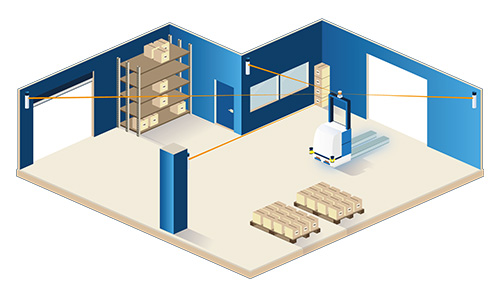

LASER TRIANGULATION

-

The position of the vehicle is triangulated using laser beams that are reflected back from reflectors. The paths followed are virtual.

PROS:- Reliable

- Accurate

- Modification simple (unless more reflectors needed)

- Efficient fleet management

- Installation of reflectors time-consuming/expensive

mini™ lite

VISION GUIDANCE-

Uses cameras to recognize features in the environment, with which the

PROS:- Quick & simple to install

- No infrastructure changes

- Accuracy affected by changes in lighting conditions

- Accuracy affected by changes in environment

NATURAL FEATURE NAVIGATION

-

hese AGVs are equipped with a specific sensor to follow a physical line on the ground (e.g. magnetic tape, inductive wire).

PROS:- Quick & simple to install/modify

- Minimal infrastructure changes (possibly reflective stickers)

- Sensitive to changes in environment (affecting accuracy/robustness)

- Additional laser scanners (high on vehicle) add cost

- Software tools (configuration/fleet management) often basic

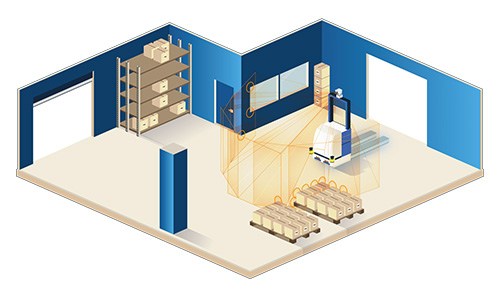

NATURAL FEATURE WITH ANT®

-

Uses features measured with a laser scanner to identify  and thereafter match  structures in the environment. The paths followed are virtual

PROS:- Quick & simple to install/modify

- Minimal infrastructure changes (possibly reflective stickers)

- Accurate & robust to environmental change

- Advanced fleet management (incl. multi-brand)

Success Stories

AGV Scandinavia, 2016

-

Objective

Automation of a standard forklift.

Challenges

- Integration of ANT® lite+ into a standard manual forklift

- Integration of the AGV solution into an existing and running production site

So why ANT?

- ANT® lite+ provides a full navigation solution with standard interfaces at a competitive price. Together with the ANT® server, it provides a complete solution for the installation of an AGV system.

- After the integration into the standard forklift, the installation at the customer site was then extremely easy and allowed AGV Scandinavia to profile itself as a key player in the Scandinavian region.

Stöcklin  Eagle-ANT, 2014

-

Objective

Design and commercialize a simple and extremely competitive autonomous guided vehicle.

Challenges

- Integrate the new ANT lite+ into a simple vehicle

- Implement point-to-point functionality

- Make available a complete traffic management

So why ANT?

- Stöcklin has been convinced by the characteristics of ANT lite+, which combines the power of ANT with a simple package resulting in a competitive setup.

- All ANT products take advantage of the ANT lab installation tools, which allow for extremely simple and fast installation.

- Stöcklin has then designed a vehicle with the same philosophy: Simple to operate and extremely competitive on the market.

Kokeisl  KPR Forklift, 2011

-

Objective

Transportation of pallets from palletizer to stock conveyor.

Challenges

- Narrow corridors and station entrances

- One vehicle to cover 2800 sqm

So why ANT?

- The AGV equipped with ANT® was purchased after a three days demo. Installation as part of one day and two days operation demonstrated the performance of the system.

- Installing reflectors, inductive lines or magnets on the 70 x 40 m surface area to be covered by a single vehicle was not cost efficient. ANT® requiring no additional infrastructure allowed the realization of the project within a tight budget.

Engineering services

-

Developing a successful AGV or mobile robot requires specialist expertise

Deciding to become one of your market's innovation leaders, or even disrupt a market, by creating an automated guided vehicle (AGV) or autonomous mobile robot (AMR) is one thing. Developing that product is quite another.

At BlueBotics we understand your challenge, because we've been helping companies to bring mobile robots and AGVs efficiently to market for over two decades.

Our experienced robotics engineers cover every skillset required, from mechatronics and system design to autonomous navigation.

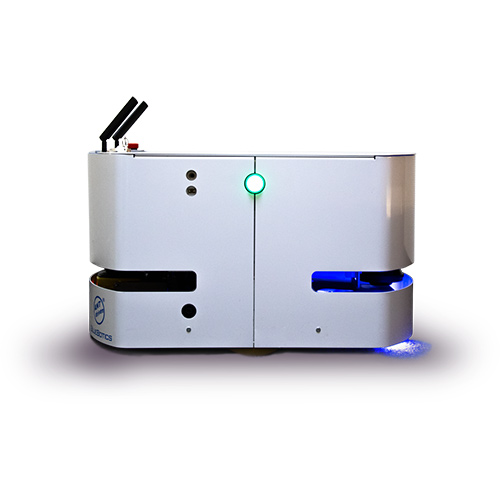

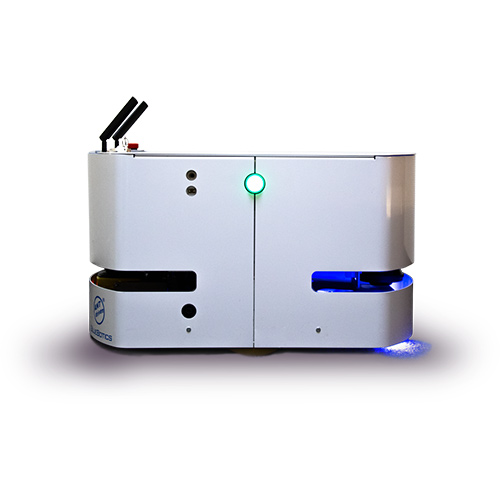

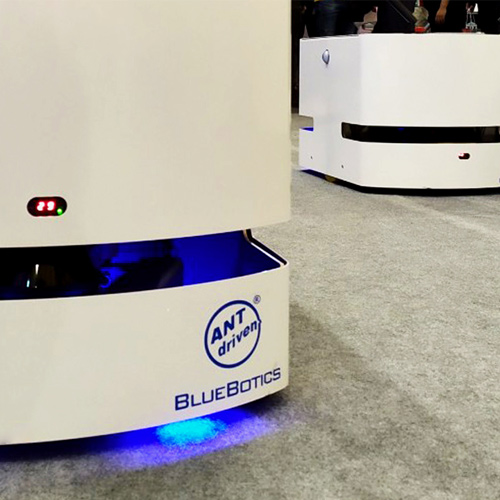

mini™ lite

The mobile robot platform for diverse applications-

The BlueBotics mini™ lite is a flexible, industry-proven autonomous mobile robot (AMR) platform. Driven by our Autonomous Navigation Technology (ANT®) and therefore immediately fleet-ready, it is the perfect base on which to develop a vehicle that meets your organization’s specific needs.

Ideal for:

- Light material handling (boxes/racks/trays)

- Integration of small industrial robots/cobots

- Custom applications

Features:

- ANT® navigation technology

- Lift module option

- Conveyor module option

- Custom module development

- Obstacle avoidance option

- Fleet management

mini™

The mobile robot platform for cleanroom applications-

The BlueBotics mini™ is a compact, low particle emission autonomous mobile robot (AMR) platform. Driven by our Autonomous Navigation Technology (ANT®) this fleet-ready performer is the perfect base on which to develop a vehicle that meets your cleanroom’s specific needs.

Ideal for:

- Cleanrooms

- Laboratories

- Light material handling (boxes/racks/trays)

- Integration of small industrial robots/cobots

- Custom applications

Features:

- Low particle emission

- Highly compact

- Articulated chassis

- ANT® navigation technology

- Lift module option

- Conveyor module option

- Custom module development

- Obstacle avoidance option

- Fleet management

mini™ UVC

Disinfect with light-

- SAFE: Safe, autonomous disinfection of public buildings

- SCALABLE: Disinfect more quickly or cover larger sites

- ROBUST: Disinfects as programmed, every time

- COST- EFFECTIVE: Reduce staff absences or healthcare associated infections

Disinfect with light

The mini™ UVC safely and autonomously disinfects any type of indoor public space, from hospitals to hotel rooms, airports and more.

Flexible enough to suit virtually any site, the mini™ UVC mobile robot can be operated 100% autonomously, semi-autonomously, or manually by a person wearing personal protective equipment.

Success stories

SITA Â Kate, 2017

-

Objective

Design and produce three prototypes of autonomous checkin’ kiosk.

Challenges

- Design three new vehicles from scratch

- Integrate existing components from standard checkin’ kiosks

- Less than four months from specification to delivery

Solution

BlueBotics firstly worked with SITA to clearly define the use case, then teamed up with designers to define the aesthetics and ergonomics before developing and producing the 3 Kate prototypes in an extremely short time.

Cleanfix  RA 660 Navi, 2014

-

Objective

Create an autonomous professional cleaning machine for airports, hospitals, hotels, and shopping centers.

Challenges

- Design a compact navigation system

- Develop a coverage solution ready for real-world

- Integrate the control of the whole cleaning machine

Solution

BlueBotics redesigned the navigation system, developed a coverage algorithm, and automated the cleaning components together with Cleanfix to obtain a fully integrated solution.

Oppent  EVOcart™, 2014

-

Objective

Design a new hospital vehicle with a complete software suite to easily integrate into the hospital’s infrastructure.

Challenges

- Design an industrial vehicle from scratch

- Develop a complete traffic management solution

- Provide flow management and infrastructure control

Solution

BlueBotics supported Oppent in the design of the vehicle, developed a complete traffic management solution and teamed up with a strategic partner for flow and infrastructure control.

Geneva Airport, 2013

-

Objective

Provide innovative and user-friendly services for the passengers at the Geneva airport.

Challenges

- Develop a robot guide for the airport

- Develop a suitable user interface

- Integrate in the airport environment

Solution

BlueBotics worked with Geneva Airport’s IT department, with their marketing department, as well as with external designers and interaction designers to develop and produce the complete solution.