- Offer Profile

- ATS is an industry-leading automation solutions provider to many of the world’s most successful companies. ATS uses its extensive knowledge base and global capabilities in custom automation, repeat automation, automation products and value-added services, including pre-automation and after-sales services, to address the sophisticated manufacturing automation systems and service needs of multinational customers in markets such as life sciences, chemicals, consumer products. electronics, food, beverage, transportation, energy, and oil and gas.

Founded in 1978, ATS employs approximately 4,200 people at 20 manufacturing facilities and over 50 offices in North America, Europe, Southeast Asia and China.

Industries

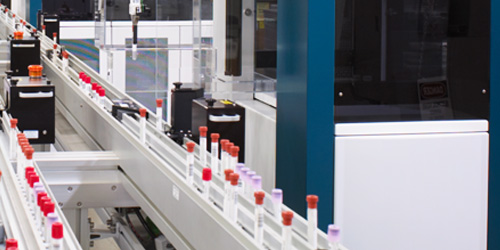

Life Sciences

ATS Life Sciences Group of Companies

- ATS Life Sciences Group of Companies refers to the ATS affiliate businesses with a focus on the life sciences industry. From API production to packaging, from research and development to commercial production and after sales and services, the ATS Life Sciences Group of Companies offer both custom and standard solutions for many manufacturing needs. ATS has a significant global install base representing over 40 years of delivering CGMP compliant solutions to many of the industry’s leading companies.

Medical Technology

- ATS Life Sciences provides state-of-the-art CGMP manufacturing solutions to the world’s leading medical technology OEMs. We have expertise and experience in the assembly of a wide variety of medical devices and diagnostics products including; bio-sensors, biofluidics, DNA microarrays, contact lenses, catheters and stents, tube sets, and syringes. Our customers count on us to solve complex assembly problems typically characterized by tight tolerances, no-touch zones, low particulate generation constraints, challenging geometries, and rigorous quality control. Our commitment is to design and build systems that suit your specific needs.

Pharmaceuticals

-

Higher equipment utilization rates. Faster time to market. More productive use of your staff and resources. 100% quality verification for every product you manufacture. Faster payback of your equipment investment. These are just some of the benefits possible when you source your manufacturing equipment with us.

Automated Manufacturing Solutions

- ATS Life Sciences provides customers with total automation solutions; from cleanroom material handling and assembly to final quality control.

End-to-End Automation Services

- ATS provides an end-to-end automation manufacturing solution with unrivaled value for our customers. Whatever stage you are at in your product’s life cycle, from product design to product iteration, from clinical trials to full commercial production, ATS Life Sciences can complement your staff with CGMP-experienced consultants, engineers, and skilled trades and service people. ATS is a single source systems integrator and enterprise solution provider, bringing cohesion, consistency and accountability to a program.

Consumer Goods and Industrial Products

-

Specialized Knowledge–Consumer Goods

We serve the global consumer market with a full range of platforms allowing ATS to provide our customers with optimized solutions. A proven selection of suitable technologies, supported by expert partners ensures the design of a superior system.

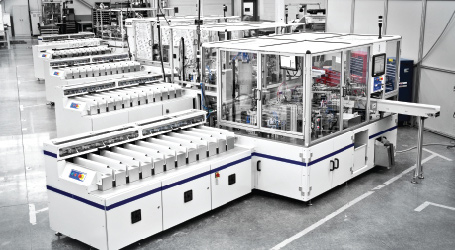

High Volume Assembly

-

Full Service High Technology Solution

ATS assembly systems for consumer products often require a range of highly technical stations to provide a quality product. With assembly rates from 0.2 – 20 seconds per part, the material handling approaches are also critical. These include :

- ATS Supertrak™ linear mover conveyance platform with pneumatic, cam driven or CNC Assembly servo driven actuation

- Electrical interconnect technologies such as soldering and welding

- Component feeding and assembly

- Screw driving

- Pressing, staking and swaging operations

- Vision inspection and alignment

- Laser processing for marking, welding and cutting

- ATS Tray Handlers are used when delicate parts require tray based material presentation while robotic flex feeders can provide a viable option when a high degree of part type flexibility is desired

The ATS Illuminate™ Manufacturing Intelligence software is used to gather, monitor and report key equipment operational data to provide true industry 4.0 capability.

Web Handling

-

Expertise at your disposal

ATS has developed a wide variety of web handling systems from simple index feed systems to complex multi-web, high accuracy continuous feed systems. This expertise is leveraged on every system to deliver a robust automated solution.

The nature of each web handling system hinges on the processing requirements of the web material. Some examples of processes that have been incorporated into our web handling systems include:

- High accuracy laser processing

- Marking

- Ablation

- Cutting

- Slitting

- Lamination

- Steering

- Slot die coating

- Dispensing

- Vision inspection

- Cutting, punching

- Closed loop process controls

- Auto-splice

- Multiple tension zones

- Part tracking

- Excising/singulation

- Indexed and continuous web feed

Let ATS demonstrate how our expertise can be applied to your unique web handling requirements

Dispensing

-

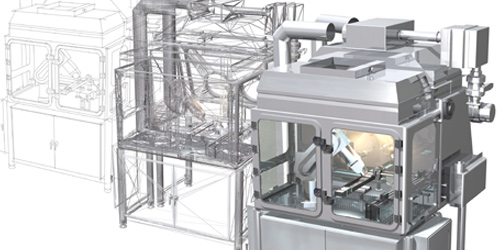

Complete Automation Solutions

Our single-source capabilities in integration, precision machine building, control software, and test and measurement systems make us one of the few companies in the world that can deliver the complete spectrum of automation solutions—from “one-off” demonstration systems to multiple-build or plant-wide manufacturing integration.

We design, build and can easily integrate continuous or indexed motion dispensing systems for liquids or solids. By adding a single low cost, cross-servo axis, we can achieve fully programmable X-Y dispensing motion.

Ultra High-Precision Assembly System

ATS high-precision assembly systems provide an automation platform to handle your most demanding assembly requirements. Designed to work with a wide range of tooling, these standalone or integrated systems provide maximum performance and capability on a standard machine platform. These systems provide post-placement accuracy to less than 1 micron for dispensing of epoxy, flux, frit and other materials.

Personal Care Products

- Consumer products involve the assembly of both consumables and the delivery devices. ATS has capabilities in plastic part and electrical component assembly, interconnect completion, precision tooling, a variety of material handling variations. These may include winding systems, dispensing automation and various other pieces of process equipment. With its high speed Supertrak™, Omnitrak™ and CNC Assembly platforms, ATS brings unmatched capability to the flexible, high speed assembly of consumables to our customer base. ATS assembly automation with the use of robotics, vision and laser processes in the our systems provides unmatched levels of performance and quality to our customers.

Heavy Part Assembly

- The oil and gas, automotive, aerospace, solar, nuclear and other sectors involve the movement and joining of many different components which tend to be larger in scale. ATS has developed solutions which utilize the flexibility of lean solutions where possible while automating the transfer of materials which would lead to ergonomic strain if left to completely manual assembly techniques. In addition, these cells often allow customers to improve output and yield as the automation is less constrained by the weight of the parts. Assembly precision on these projects is often more critical than on lighter weight plastic component based products, a factor which needs to be included in any solution. Typical tools such as robotics, vision and laser processing play a role in providing high performance solutions. The addition of ATS Illuminate™ Manufacturing Intelligence, services offerings and test equipment where required, allows ATS to deliver leading solutions for the heavy component manufacturing space.

Electronics

- Our systems build complex electronic assemblies and are designed, built and integrated by our experienced teams. By integrating suitable technologies supported by expert partners ATS delivers high performance consumer product automation.

Computers and Peripherals

-

ATS is the world’s largest and most experienced integrator of automated high precision assembly, vision guidance, granite tables, micron level assembly accuracies, dispensing, clean room.

Advanced Automation

We specialize in designing, developing and manufacturing engineered solutions from Class 10 clean rooms, die and wafer cleaning systems to fully integrated single- or multi-station high-precision assembly, cleaning and test systems. We design and build some of the industry’s most advanced custom automation solutions.

Optical Devices

Computer peripherals assembly is often a combination of discrete part assembly, high precision micron tolerance assembly, optical alignment and various process technologies involving welding/soldering, laser processes, dispensing and high speed pick and place transfer.

Ink Jet Printers

ATS has a long history of manufacturing equipment for the assembly of hard disk drives. High precision coupled with the completion of assembly in clean room environments down to ISO 8 provide challenges in the assembly process for which ATS has developed an extensive skill set over the years.

Repeat Equipment Manufacturing

The ATS value proposition for companies looking to scale the production of machines for the electronics industry is extensive. ATS is a trusted partner to numerous companies with volume machine needs. They look to ATS to provide core manufacturing engineering and design engineering support, high volume machine build, access to the ATS global supply chain, multi-facility installation services, ongoing support and the ability to grow with programs over the product life cycle.

Industrial Electronics

-

ATS flexibly configures assembly solutions for a variety of industrial electrical products from electronic controller assemblies, to contactors and relays, to smart meters.

ATS has delivered numerous systems for completing electrical product assembly. ATS solutions are tailored to the customer’s cycle time and labour environments while reflecting system designs which help to ensure that no defective products leave the line. Having completed systems from 10 to more than 50 stations in this space, ATS has significant experience in parts feeding and assembly, soldering, marking, and material transport at cycle times between 2.5 seconds and 25 seconds per assembly. The functionality of these systems is enhanced by the addition of ATS Illuminate™ Manufacturing Intelligence software and other services which provide assurance of optimized machine productivity throughout the life of the asset.

Telecommunication Devices

-

ATS has the capability to deliver ultra high-accuracy automated manufacturing systems for the telecommunications industry. Glass handling, vision guided robotics, vision inspection, integrated test solutions, assembly through to customized packaging solutions, SuperTrak™ based assembly solutions, CNC assembly and ATS Illuminate™ Manufacturing Intelligence for data collection.

Custom Automation Solutions

Our unmatched capability in automation integration, optical path engineering, precision machine building, control software and test and measurement systems make ATS uniquely qualified to deliver a complete spectrum of automation solutions—single work cells to multiple-build or turnkey manufacturing integration.

ATS provides custom automation solutions including clean room environments, high-accuracy placement, assembly, testing, real-time data acquisition and analysis for the precision manufacture of a wide range of coaxial, wireless components and sub-assemblies.

Applicable products:

- Smart phones

- Multiplexers

- Switching Modules

- Amplifiers

- Receivers and Transceivers

- Thin Film

- Displays

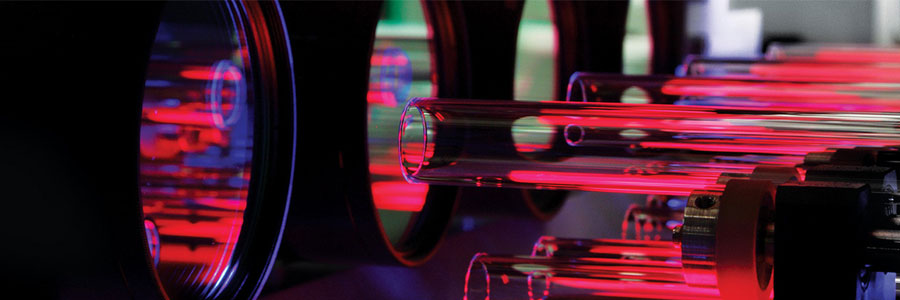

Opto-Electronic Devices

-

ATS has an extensive history in the supply of automated manufacturing solutions for the optoelectronics industry.

Complete Solution

Our capabilities include automation integration, optical path engineering, precision machine building, control software, and test and measurement systems .

Our expertise in lighting and optics (including co-linear and back lighting, UV, IR, NIR, laser interferometry and laser displacement) ensures we can meet the most demanding ultra high-accuracy inspection challenge.

Machine vision, nano-positioning, high-speed active alignment and different bonding technologies can be integrated on ATS’ assembly platforms.

ATS provides digitally controlled positive displacement, pin transfer or jet dispense technology, to achieve fluid dot sizes of 100 microns or less.

The ATS Illuminate™ Manufacturing Intelligence platform is used to report on and optimize machine production throughout the life cycle of the product.

Energy

- Specialized Knowledge

For 25 years ATS has been a leading integrator of technologies for the energy sector. We specialize in automating complex and high value processes for energy creation, storage and conversion.

Solar Automation Solutions

-

ATS has a 25 year track record in the solar industry. Our successes in the solar space include:

- Turnkey module assembly lines

- Cell manufacturing line integration

- Cell flash testing and vision inspection

- Thin film module assembly lines and line integration

- Automated J-Box attach

- Automated flash testers

ATS’s long history in solar processing and our technology expertise will provide you with your specialized solar panel assembly project needs and a competitive edge in the market.

Thin Film Module Assembly

ATS turnkey backend and process capability on thin film module assembly allow customers to minimize cost per watt and maximize line performance.

Battery Assembly and Line Integration Technology

-

ATS brings years of experience delivering exceptional results to automation solution clients.

From careful cell stacking and module assembly to the precise welding of terminals and filling of cell cavities, you can count on ATS to introduce the right level of automated manufacturing to your next battery project.

Our wealth of experience in material handling and robotics allows us to optimize assembly precision and reduce system delivery times. We also integrate our core technologies with the very best from our partners to design web handling processes for battery manufacturing.

ATS has decades of experience incorporating advanced vision systems, optics and lighting to improve the functionality of our automated systems.

We complement our technology with our Illuminate™ Manufacturing Intelligence platform to provide production line control and visibility throughout the life of the asset.

- Welding

- Formation, aging and testing

- Filling

- Web handling and processing

- Vision Systems

- Full factory MES systems

- Planning, reliability engineering and OEE improvement

Food & Beverage

- MARCO Limited (an ATS company) is a globally recognized UK technology company, founded in 1985, specializing in productivity-enhancing hardware and software solutions for manufacturing and packaging operations.

Soft Fruit Weighing and Packaging

MARCO offer innovative pack house and factory floor solutions that provide control from the arrival of the raw material to dispatch of the packed product. Increased productivity and profitability are central to the MARCO product delivery with a full return on investment typically achieved within twelve months from installation.

Food On The Go - Weighing and Packaging

- Convenience food or Food on the Go (FOTG) is one of the fastest growing industries worldwide. As consumers are living increasingly busy lifestyles, the demand for fast, fresh, and healthy food is rapidly increasing. To ensure food manufacturers keep up with this demand it is vital to have a productive and efficient manufacturing and packing process.

Recipe Formulation Applications

- MARCO Trac-IT Recipe Formulation Module (RFM) ensures your staff consistently adheres to a template of how to handle and mix recipe ingredients within the production facility. RFM controls the ingredient/lot picking and codifies all the manufacturing instructions to increase operational speed and efficiency.

Semi-Automated Systems

- The BWS (Belt Weighing System) is designed for sticky, fresh cut and difficult to handle raw materials like diced meats and shredded vegetables. Similar to the BWS, the AWS (Augar Weighing System) uses augars rather than conveyor belts to move very sticky and wet ingredients/raw materials, product such as ready meals, pasta and seafood.

Automation for the Food and Beverage Market

- For customers looking to increase the level of automation in food and beverage applications, ATS brings many years of providing hardware and software solutions to the industry. Customers in this space have similar challenges: increasing labour costs, labour availability, repetitive motion disorders, often cold and wet environments, and virus impacts on factory personnel positioning and the need to reduce energy costs. In addition, recent trends in online grocery shopping and delivery combined with the increasing capabilities of automation technologies including robotics, vision and 3D picking are boosting the needs for automation across the industry.

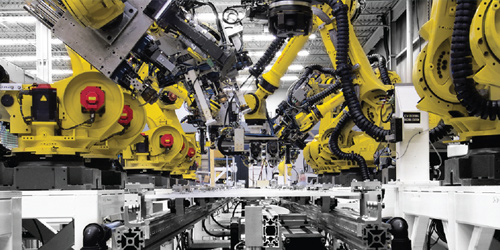

Mobility & Transportation

- Bringing thousands of unique transportation automation projects to market has helped us develop an extensive range of technology and experience. Whether you need ATS to build custom automation globally or to help you take advantage of our contract equipment manufacturing, we have the scale to reduce costs and speed time to market.

EV Technologies

- The most innovative area in vehicle development and production today is in electrification through Hybrid Electric Vehicle (HEV), Electric Vehicles (EV) and Plug-in Electric Vehicles (PEV).

Automotive Assembly Systems

- We have engineered over 6,500 assembly systems responsible for building the critical components that bring vehicles to life.

Engine Assembly & Test

- We have a long history of outstanding performance ranging from the assembly and test of the entire range of heavy duty diesel engines and transmissions.

Aerospace

- ATS has an extensive knowledge base and technology portfolio that can be applied to aerospace manufacturing. Whether you are an OEM, Tier 1, or Tier 2 supplier,our manufacturing know-how can help you succeed.

Powertrain Final Test

- We perform complete powertrain final tests for engines, transmissions, and axles. ATS is your solution to FTT (First time through) and lower product life cycle costs.

Nuclear

-

ATS designs, builds and services mission critical automation and test solutions for the nuclear industry. Our customers rely on us, as a trusted partner, to deliver what we promise, on time and on budget.

Producing affordable and reliable, clean electricity is realized by the nuclear industry through a commitment to finding safer, more efficient ways of operating.

ATS designs and supplies precise and reliable automated solutions proven to dramatically improve timelines, while reducing costs and worker exposure in radiation environments.

Decommissioning & Waste Material Handling

- ATS has proven experience deconstructing nuclear reactors and using automated solutions for reactor inspection, segmentation and waste packaging. ATS provides innovative solutions for the demanding challenges in decommissioning, reducing costs and radiation dose. Our nuclear customers trust in our vast remote material handling and remote operations expertise, across diverse industries, to provide them with an unparalleled mix of technology, experience and scale.

Maintenance & Inspection

- We have a lifetime of experience providing custom remote operated tooling and systems to achieve the necessary inspection and maintenance requirements for nuclear power plant operators. We are widely recognized as a key partner in achieving operational excellence with the growing use of automation in the nuclear industry.

Engineering & Field Services

- We have developed the industry’s most comprehensive automation engineering and assembly team, with over 4000 people. And with our vast global footprint, ATS is there when needed.

Nuclear Fuel

- ATS automation experience is harnessed across all stages of the nuclear fuel cycle. Whether that be modernizing fuel fabrication facilities for customers producing new fuel, or the retrieval and handling systems of used fuel and repackaging spent fuel for safe storage.

Medical Isotopes, Research & Small Modular Reactors

- Many of the world's nuclear reactors are used for research, testing, or the production of radioisotopes for medicine and industry. ATS and our subsidiary Comecer have decades of experience in medical isotopes and the systems needed by these facilities to maintain their safe operation. And as the nuclear industry evolves and new technology is developed, including new reactor types, ATS capabilities continually adapt to keep pace.

Packaging

- IWK Verpackungstechnik GmbH focuses on the efficient, precise, and attractive packaging of pharmaceutical and cosmetic products. IWK systems are used in industries that demand very high standards; while improving efficiency and meeting the growing demand for packaging solutions.

Tube Filling

- IWK is the market leader in automatic tube filling machines, and delivers reliable, high quality solutions to its customers.

Cartoning

- IWK offers a cartoning machine program with continuous and intermittent motion cartoners, primarily designed for the pharmaceutical and cosmetics industries.

Transfer Systems

- IWK offers flexible, high speed solutions for collating, sorting and handling of various products in a precise manner.

Warehousing & Distribution

-

As e-commerce and logistics companies strive to ramp up their operations, ATS can play an important role in meeting their objectives. As volumes increase, ATS can help to address the major challenges faced by the industry.

- Minimizing impact of labour availability, cost, and health and safety

- Task efficiency and accuracy – use automation to improve throughput, repeatability and consistency

- Scale up efficiency – ATS provides rapid machine build scale up capacity globally

ATS as an Engineering and Repeat Machine Build Partner

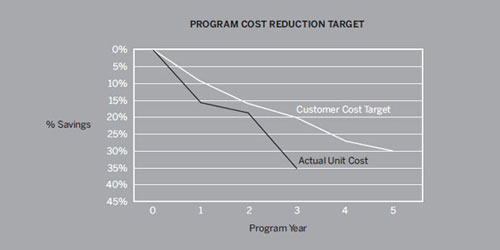

- Looking for a competitive edge, e-commerce and various growth companies have pioneered their own unique ways of solving e-commerce and logistics challenges. ATS partners with companies to augment unique ideas with ATS engineering depth and then provides build capacity to deliver the logistics solutions to dozens or hundreds of warehouses. ATS REM (repeat equipment manufacturing) offers volume build services to our customers. Key hallmarks of ATS involvement in repeat build programs include: 1. Machine build quantities as required (multiple machines per month) 2. Cost down models based upon continued volume evolution 3. Engineering and build engagement supporting customers in industrializing and controlling cost as machine generations progress to volume build.

Pick and Sort Automation

- ATS delivers automated solutions to solve pick and sort challenges using robotics, servo systems, vision and material movement (AGV/conveyors). With a network of companies providing technologies to augment ATS internal developments, optimal system performance can be achieved.

Elevate your AGV game with Illuminate™ Manufacturing Intelligence

- Acceptance of Autonomous Guided Vehicles (AGVs) has reached a tipping point even in the most change-resistant industries. Today it is not uncommon to find several generations of AGVs from different suppliers in a single manufacturing facility moving product from warehouse to production line and finished goods to distribution. More vehicle types on the plant floor means more complexity. Anticipating where AGVs are needed before they are called can reduce congestion in pathways which can cause bottlenecking and lower Overall Equipment Effectiveness (OEE). Illuminate™ Manufacturing Intelligence fills the gap between your AGV Fleet Manager and Manufacturing Execution System, predicting where AGVs need to be based on real-time production performance data and the status of every vehicle in your autonomous fleet.

End-to-End Services

- Providing Digital and non-Digital life cycle solutions - including installation, training and spare parts services - to multinational e-commerce and logistics companies using a range of ATS After Sales and Services unique capabilities. ATS professionally organizes and deploys support assets from around the global network to fulfill commissioning and on site assignments in dozens of sites simultaneously.

Services

After Sales and Service

- Our After Sales and Service team has the knowledge and experience to support the total life cycle of your automation system. We understand your needs and will tailor a solution that creates the greatest value. Whether to mitigate risk or improve performance, at any stage of the life cycle, we have a solution.

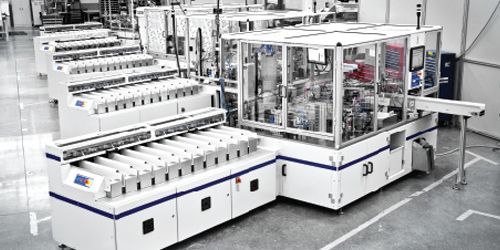

Contract Manufacturing

- Our customers’ needs don’t stop with the delivery of a single system. Many customers require a reliable and cost-effective supply of repeat solutions to their customers. In addition to custom systems, ATS Automation also provides turnkey repetitive equipment manufacturing services for complex machines. More than a traditional contract manufacturer, ATS works with you to incorporate lean methodologies, and to apply value engineering, process flow optimization, and cost containment strategies. The benefit to you? An agile partner with global reach and service who can support your product’s complete life cycle.

End-to-End Automation Services

- With broad and in-depth knowledge from across multiple industries and technical fields, ATS delivers single-source solutions to customers that lower their production costs, accelerate delivery of their products and improve quality control. We engage with our customers on both greenfield programs, such as equipping new factories, and brownfield programs, such as capacity expansions, line moves, equipment upgrades, software upgrades, efficiency improvements and factory optimization.

Capabilities

Project Management

- Our project management is modeled after the Project Management Institute’s five-phased project lifecycle. A combination of proven methods an global best practices builds quality into every phase and ensures successful implementation of your project requirements.

Linear Motion Technology

- ATS is a leading supplier of linear motion technologies.

Linear motion technology is the basis of the SuperTrak CONVEYANCE™ lineup of products including SuperTrak GEN3™ and SuperTrak MICRO™. These conveyance platforms act as the foundation of your manufacturing automation processes, allowing you to create powerful world-class automation.

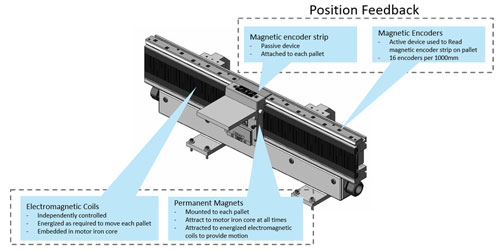

What is linear motion technology (LMT)?

A basic linear motion system integrates a power component, such as a motor; a thrust mechanism, such as an actuator; and a guidance infrastructure, such as a rail. Unlike a traditional motor which creates a rotating movement, linear motion technologies created a linear forward and backward motion.

Innovative Solutions

- “Innovation starts by intimately observing your customer.” – Jeremy Gutsche. ATS has a rich history of being a world leader designing and building customer-engineered technologies and innovative automation solutions across diverse sectors. Our success hinges on our ability to create value for our customers by solving previously unsolvable problems, reducing complexity and cost, shortening development cycles, improving production efficiencies, and simplifying change.

Turnkey Solutions

- Project management

- Core ATA Automation

- Third Party Integration

- Material Handling Integration

- Controls Integration

Inspection, Testing and Vision

- ATS has broad capabilities in test instrumentation and custom software, and vision applications enabling us to design and build precisely the right solution for each customer’s product and process. Every phase of system design and manufacturing is accomplished in-house by our team of engineers and technical specialists. They are dedicated to developing inspection, test and vision automation systems that are extremely robust. The result is an exceptionally high level of reliability and data integrity.

Case Studies

- At ATS, a $1.8B publicly traded global enterprise with a proud 40-year history, we are helping advance the future with our factory-wide automation solutions.

Within ATS Mobility | Nuclear | Specialty Automation, what we do matters – it matters to both our customers and their customers. With 800 skilled associates around the world, we design, build and service mission critical automated assembly and test solutions for mobility, nuclear and specialty automation. Our customers are leaders in their industries and rely on us to deliver what we promise, on time and on budget. Together with our wide product range, our financial strength and global footprint, we provide the best automation solutions to our customers where and when they need it.

Products

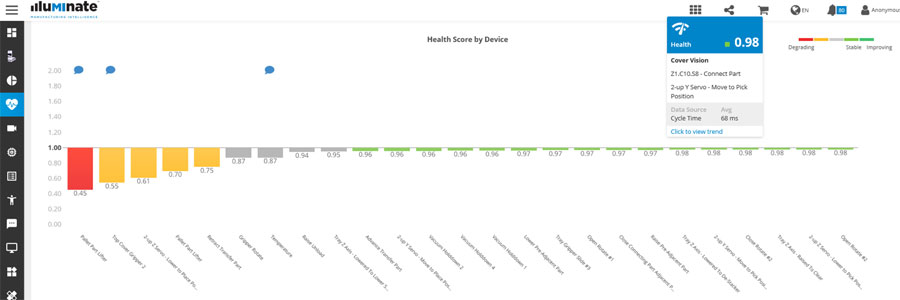

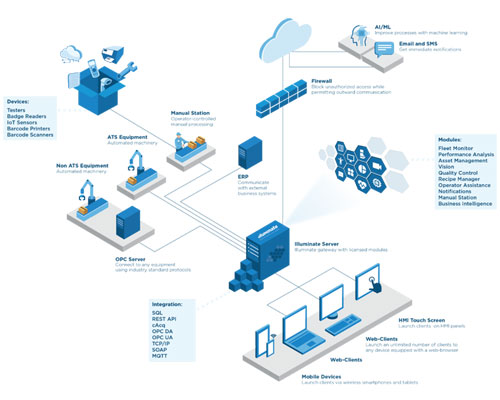

Illuminate™ Manufacturing Intelligence

- To remain competitive, manufacturers need more than production performance analytics, they need a complete Industry 4.0 Smart Manufacturing System that can adapt to their operating culture, reduce complexity and optimize production without requiring expensive capital equipment investments.

Illuminate™ Manufacturing Intelligence is an extensible architecture used by global leading manufacturers to enhance production visibility and improve operational performance.

Industry 4.0 Smart Manufacturing System developed by machine builders for machine operators

- Single pane of glass – Monitor operations anytime and anywhere from our turnkey, integrated, and secure single-point platform

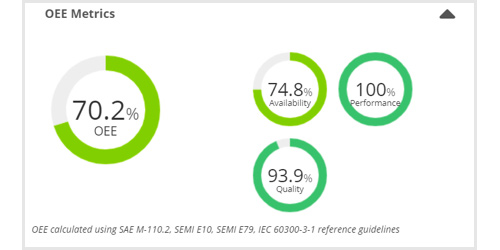

OEE in real-time – Capture real-time OEE intelligence across lines, machines, and locations for top down, bottom up continuous improvement

Visual KPIs – At-a-glance insight with dynamic charts & graphs of key data and metrics

Predictive maintenance – Improve equipment efficiency, yield, and lifespan through AI-driven predictive maintenance

Faster response times – Real-time notifications and alerts enable quicker corrective action

Unified communication – Keep operational team informed and engaged across shifts and locations

Part traceability – Track all components and their associated processes for each of your products through assembly and record it for process analysis, record keeping and compliance

Improve Your Manufacturing Operations

- Illuminate™ Manufacturing Intelligence uses real-time machine performance data to maximize throughput, Increase uptime, decrease cost and improve quality.

Maximize Throughput- Capture real-time OEE intelligence across lines, machines and locations for performance diagnostics and troubleshooting

- Identify production trends for top down, bottom up continuous improvement

- Monitor operations anytime and anywhere from our turnkey, integrated, and secure single-point IIoT platform for effective factory floor management

- Achieve continuous manufacturing improvements and production line sustainability with data-to-decision, in minutes, capability

Increase Uptime- Reduce hours of machine down time, remedy issues, and increase uptime with predictive maintenance and planning

- Mitigate down time risk by tracking individual cycle counts on: wear parts, consumables, long lead items, or repairables

- Increase uptime with integrated just-in-time ordering of spares and parts kits

- Proactively optimize spares provisioning and inventory as part of your maintenance management

- Be prepared with color-coded early warning reminders and alerts to keep you current in all your maintenance activities

- Capture maintenance log reports of repair events to support: future failure analysis, equipment performance improvements, and continuous enhancement of the work management system

Decrease Cost- Improve equipment efficiency, yield, and lifespan through predictive maintenance Respond to issues quickly and unlock hidden performance Decrease cost through automated parts management and integrated statistical process control provisioning Keep the operational team informed and engaged to drive greater operational efficiency through real-time notifications

Improve Quality- Sustain product quality through synchronous and asynchronous processing

- Gain visual insight with live stream video for production root cause analysis, and troubleshooting issues – reducing hours of machine down time

- Increase control and communication with integrated visual KPIs

- Facilitate visual machine learning on parts and product quality control inspection – decreasing hours of operator visual monitoring, performance fatigue, and quality faults

SuperTrak CONVEYANCE™

- A manufacturer’s choice in conveyance is essential as it impacts the overall functionality of your automation process.

Maximize throughput. Minimize footprint.

SuperTrak CONVEYANCE™ platforms act as the foundation for world-leading automation processes offering higher availability, increased throughput, and improved quality.

A linear motion based technology, SuperTrak CONVEYANCE™ fundamentally changes the way you build and design automation. Individually controlled shuttles allow you to increase your throughput without an increased footprint, resulting in smaller footprint, less complex, and more adaptable systems.

This is critical for achieving and maintaining the ROI for automation.

Modular automation to scale your business.

The platform’s modularity allows you the flexibility needed to effectively scale your operations and adapt to changing market demands.

Smart conveyance improves OEE.

SuperTrak GEN™ and SuperTrak MICRO™ are smart enabled technologies that get machines to production faster and more effectively than traditional methods by saving significant engineering and integration time.- Simulate: Simulation enables faster machine and process conceptualization

- Design: Remove Tooling Complexity from Stations and Implement it in the Trak

- Build: Modular assembly and integrated function with simple control make integration and assembly easy

- Perform: Maximize OEE with minimal spare parts, maintenance, and downtime

SuperTrak GEN3

- The SuperTrak GEN3™ conveyance platform enables the development of world-leading automation for the most demanding applications. Proven linear motion technology delivers performance and modularity, allowing you to confidently scale your manufacturing operations.

SuperTrak GEN3™ conveyance platform is the automation foundation of the world’s top manufacturers

Now in its 3rd generation, the SuperTrak CONVEYANCE™ platform supports payloads of up to 10 kg with spacing as low as 155 mm. Developed in the most demanding automation applications; it is the leading platform for speed, precision, and quality.

The SuperTrak CONVEYANCE™ Platform- Fast: 4G accelaration means parts are spending more time processing, not moving

- Precise: Control each individual shuttle with the ability to process on all parts of SuperTrak

- Scalable: Whether you´re in development, scaling, or high volume production, you define the size of SuperTrak

- Agnostic: SuperTrak easily integrates into your existing PLC and Controls Systems

Platform overview

Linear Motor- Highly reliable – no wear components

- Encoder strips provide real time positional feedback

- V-Rail for vertical positioning

Shuttle- Easily removed during integration, maintenance or operation; No need for disassembly

- Cantilevered for processing top and bottom

Electromagnetic coils- Independently controlled to drive shuttle velocity, acceleration, and direction

- Permanent magnet provide consistent attraction to iron metal core

Data Sheet- Motor Length: 1000 mm

- Product Fixture Width: 155-500 mm

- Maximum Speed: 4m/s

- Acceleration: 1 g with 10 kg payload

4 g with 1 kg payload - Payload: 10+kg per shuttle

- Communication: Ethernet/IP, PROFINET, discrete I/O**

- Process on Curve: Yes, full control

- Carrier Options: Standard mover configuration with 2 or 3 magnet array options

* Higher payloads possible. Contact ATS with application details.

** Other protocols are possible. Contact ATS if other protocols are desired.

SuperTrak MICRO

- The SuperTrak MICRO™ conveyance platform reinvents the way your automation is designed making it smaller and more efficient. Using proven linear motion technology, the adaptive conveyance platform offers a unique combination of speed, precision, and flexibility to allow your business to solve issues associated with small-batch or single piece part flows.

The SuperTrak MICRO™ conveyance platform reinvents the way you design your automation

With payloads of up to 1.5 kg and part spacing as low as 50 mm, SuperTrak MICRO is an ideal platform for small part assembly and processing.

The SuperTrak CONVEYANCE Platform- Fast: Sort and divert shuttles at full speed

- Precise: Part spacing as low as 50mm

- Scalable: Design options are almost endless

- Agnostic: SuperTrak MICRO easily integrates into your existing PLC and Control Systems

- Trusted: Built on more than 2 decades of development and deployments

Platform overview- Sort and divert: With part spacing as little as 50mm, process flexibility has a new meaning.

- 50mm spacing: With part spacing as little as 50mm, process flexibility has a new meaning.

- On the shuttle: Maintenance has never been easier. Remove individual shuttles without the requirement of disassembly or tools.

Data Sheet- Motor Length: 660 mm

- Product Fixture Width: 50-150 mm

- Maximum Speed: 3m/s

- Acceleration: 1.5 g with 1.5 kg payload 5 g with 0.25 kg payload

- Payload: 1.5kg for a 50mm shuttle and 3kg for a 100mm shuttle

- Communication: Ethernet/IP, PROFINET, discrete I/O**

- Process on Curve: Yes, full control

- Carrier Options: Standard mover configuration with 50 or 100 mm magnet array options

* SuperTrak ™ MICRO will not be available for sale in the United States until after September 2018.

** Higher payloads possible. Contact ATS with application details.

*** Other protocols are possible. Contact ATS if other protocols are desired.

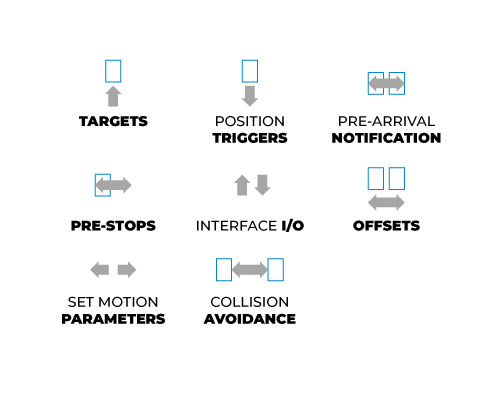

TrakMaster™ Software

- Acting as the foundation of your automation processes, smart technologies such as SuperTrak GEN3™, enable high-performance with less risk. TrakMaster™ software is the user interface that provides access to SuperTrak’s powerful features such as:

- Process Simulation

- Integrated Functionality

- Performance Optimization

- Diagnostic Insight

TrakMaster™ software enables smart conveyance and world-leading automation.

Unlike other conveyance platforms, TrakMaster™ was designed and built with the intent to reduce engineering and integration hours offering manufacturers a faster path to production with less risk.

TrakMaster™ software is a complete solution that offers:- Enhanced Simulations

- High-Performance Configurations

- Detailed Diagnostic Tools

The easy to use software empowers a PLC interface to control SuperTrak’s high-performance capability with less engineering and therefore less risk.

SIMULATION

TrakMaster™ enables better designs.

Simulation is the connection between conceptualization and design. TrakMaster’s™ simulations provide ways to optimize processes, evaluate performance requirements, and minimize expected energy consumption.

The simulation software in TrakMaster™ features:- Intuitive graphical interface

- Performance optimization tools

- Power and thermal modeling

CONFIGURATION

TrakMaster™ enables high performance.

Access and configure the SuperTrak CONVEYANCE™ platform’s integrated functionality to remove risk and engineering time by utilizing tested and proven capability.

DIAGNOSTICS

TrakMaster™ enables better machine interaction.

Diagnostic Tools provide valuable insight for fault handling and recovery, system status, and highlights station metrics (cycle time, shuttle transfer, etc.) for optimization and improved OEE.

TrakMaster™ diagnostics include:- Fault description and troubleshooting guide

- Power and thermal monitoring

- Oscilloscope for signal tracking

CONTROL INTERFACE

TrakMaster™ enables high performance with simple control.

PLC function blocks provide an intuitive interface to control shuttle motion, access data, and set parameters. This removes significant time from programming and integration and allows you to get up and running quickly.

TrakMaster™ software provides access to SuperTrak CONVEYANCE’S™ control interface:- Intuitive function blocks

- Release and forget shuttle routing

- Set motion parameters

- Fault handling

SMART COACH™

- Our experts create content – your operators and technicians access it, on demand, when ever they need it and wherever they are.

- Convenient

- Mobile

- On demand

- Globally accessible

- Customizable

ATS Vision Products

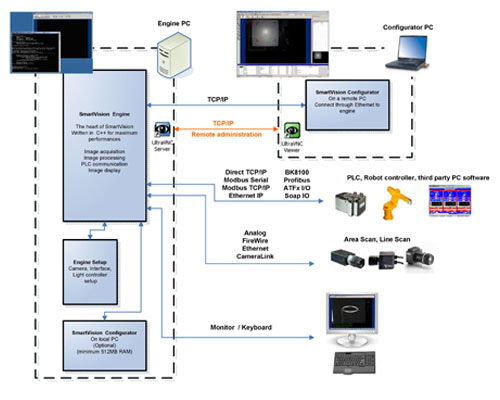

- ATS SmartVision Software represents a significant breakthrough in cost-effectiveness, connectivity, and customization in vision systems. The ATS Cortex system is an all-in-one vision device that reduces integration time with standardized hardware and software.

ATS SmartVision™

- Combining Ease of Use with High Performance

ATS SmartVision software is a highly scalable PC-based vision system that combines a high-performance, platform independent vision engine with an easy-to-use standard interface.

Using programmable software logic, ATS SmartVision software can control virtually any industry-standard third-party camera and lighting system to perform high-precision part and defect identification, measurement, sorting, and robotic guidance. Over 3,000 ATS SmartVision software licenses are in use around the world.

Scalable Across Application Types and Levels of Complexity

The ATS SmartVision engine can control multiple cameras in a single application to perform numerous independent sequences comprised of ordered lists of steps. Each step contains one ATS SmartVision software tool. Sequences can be single-stepped for debugging.

Results can range from a simple pass/fail condition to the more involved precise position of objects for complex applications. These results can then be used by other steps in the application. Programmable flow control provides for simple branching within sequences.

Powerful Toolkit

A complete set of modern vision tools is provided, including edge finding, blob analysis, measurement, OCR, barcode reading, scripting and image processing tools. Tools are dragged and dropped into an inspection sequence and are easily configured using simple dialog boxes. In addition, ATS SmartVision software has the capability of integrating third party vision tools for specific applications. Several third party tools are available and more are added as required.

Rapid Application Development

ATS SmartVision software provides a rapid application development platform for machine vision applications. Many applications can be developed with no traditional programming required.

For highly complex applications, a scripting tool is provided to allow programming logic to be created without the need for a compiler or any other external development environment. For the most sophisticated users, ATS SmartVision software can be embedded into a traditional software to create custom interfaces. ATS SmartVision software also leverages leading open source software.

Strong Communications Infrastructure

ATS SmartVision software takes advantage of advanced communications protocols making integration faster and easier for standardization across your organization.

Remote Configuration and Troubleshooting

A TCP/IP link can be used to create and modify inspection sequences. As a result, the support and troubleshooting of vision applications can be deployed remotely from anywhere around the world.

Benefits- Extensive and powerful vision toolkit

- Rapid application development

- Highly scalable range of applications

- Remote configuration over TCP/IP

- Strong integrated communications

- Competitively priced

- Proven in a wide range of industrial environments

- Hardware independent

- Easy to learn

- Standard or custom GUI interfaces

- Flexible local and remote image viewing

- Multiple Language Support (English, French, German, Simplified Chinese)

ATS Cortex™ System

- An Integrated Hardware/Software Vision System

The ATS Cortex system is an all-in-one vision device running ATS SmartVision software. The system is designed to reduce your integration time by providing an integrated vision solution that comes complete with standardized hardware and software. The system interfaces with a Programmable Logic Controller (PLC) through the use of a wide variety of field bus interfaces.

The ATS Cortex system is equipped with discrete I/O connectors that are used to trigger the attached cameras and lights. The I/O Ports are programmable and can be used to trigger any combination of camera devices.

The USB connectors are standard USB 2.0 plug and play connectors. These connectors are used for the integrated backup device and other peripherals such as a keyboard and mouse.

Currently two models are available: ATS Cortex 812 system and ATS Cortex 204 system. The ATS Cortex 812 system supports up to eight cameras and twelve lights while the ATS Cortex 204 system supports up to two cameras and four lights.

ATS Cortex Vision Enclosure

The ATS Cortex system is a family of vision enclosures.

The ATS Cortex System is designed for use with Opteon Ethernet cameras. It provides camera power over the Ethernet cable known as Power Over Ethernet (PoE). The ATS Cortex is powered by 100-240VAC with a maximum current draw of 8A. The light outputs are provided with pins for +5V, +12V and +24V lighting. Cameras can be triggered using hardware I/O lines or in software over Ethernet.

The ATS Cortex system uses ATS SmartVision software as its integrated vision development platform.