PROMOT

Videos

Loading the player ...

- Offer Profile

PROMOT Automation boosts your success with the automation of machine tools.

Promot Automation was founded in Roitham in Upper Austria in 1980. Since then we have specialized in the automation of machine tools, focusing on manufacturers and users with competence in metal cutting.

On the basis of a flexible module system we offer fully automatic and customized handling of workpieces, pallets, and tools. Due to our reliability, competence and long years of experience we see ourselves as our customers’ partner, promoting their success with a lasting effect.

Product Portfolio

Workpiece handling

- More than 5,000 completed projects speak for

themselves - and the number is growing every day.

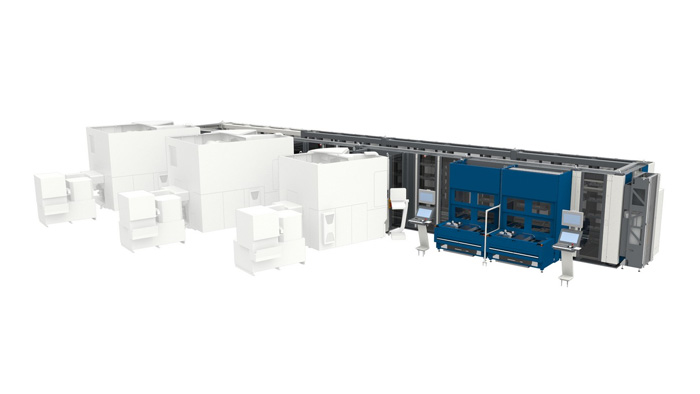

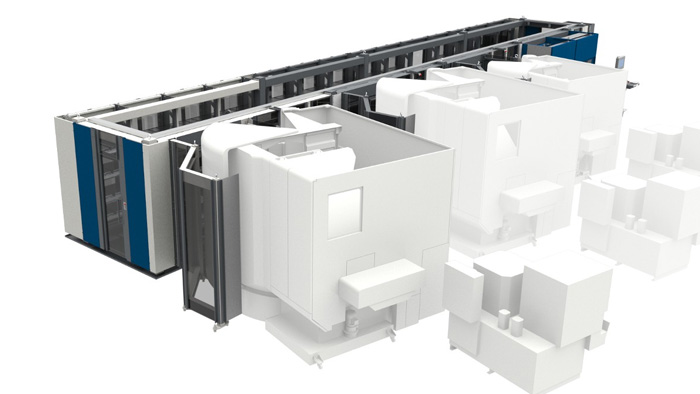

Machine Tools Automation

With more than 35 years of experience, PROMOT is one of the leading specialists for the classical automation of machine tools.

Irrespective of the general conditions, batch sizes and production technologies, the focus is on a common goal: to reduce costs for the individual workpieces. The PROMOT modular system

- We offer you the

most comprehensive and versatile modular system available for portal robots

and robot cells. Together with project-specific stations, we create your

individualized solution with a high degree of standardization.

- High availability due to proven, standardized modules

- A common modular system for gantry loaders and robot cells

- Standard modules available for workpieces weighing from 1kg to 250kg

- Uniform operation of portal and robot cell

- One modular system for gantry loaders and robot cells, offering a common modular system for both automation variants.

- Machine manufacturer independent - we always offer you the best solution, perfectly adapted to your production and logistics philosophy.

- The modules are standardized, tested and continuously optimized in each individual functional area.

- Uniform operation of the portal and robotic cells reduces training requirements and learning curves.

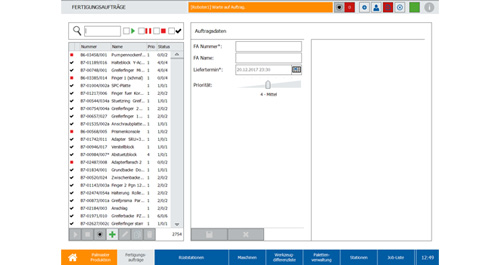

The PROMOT ProHMI 2.0

- With the ProHMI 2.0 user interface, we have created a

user-friendly visualization interface especially for automation systems.

With PROMOT ProHMI 2.0, we provide for the first time a uniform and simple operating concept for gantry loaders and robot cells, thereby reducing training requirements.- Simple position correction without a separate teaching step

- Fast fault diagnosis and error handling by the operator

- Guided switch-on and switch-back routines with graphical support

- Easy changing of production parameters or on/off selection of stations

Products from our modular system

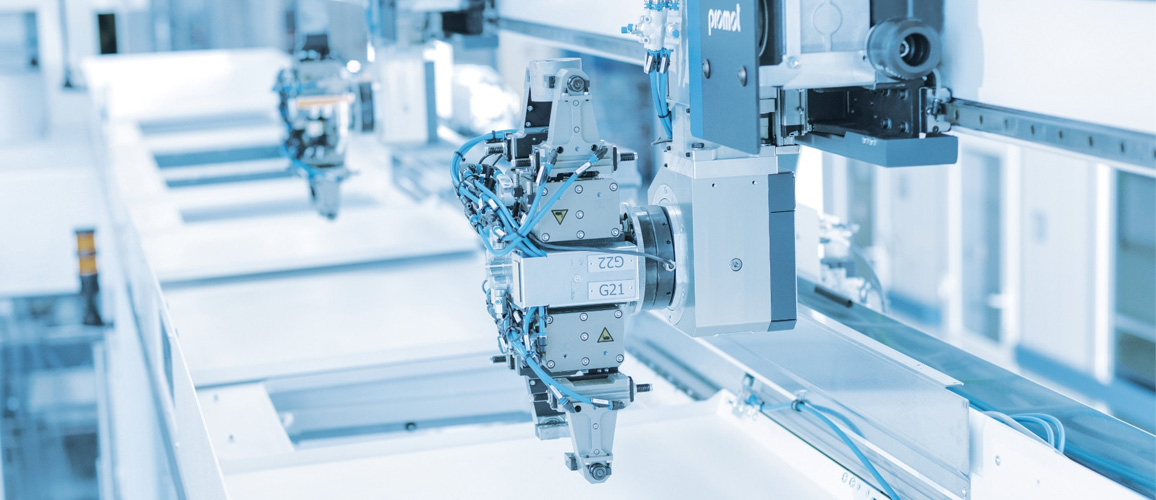

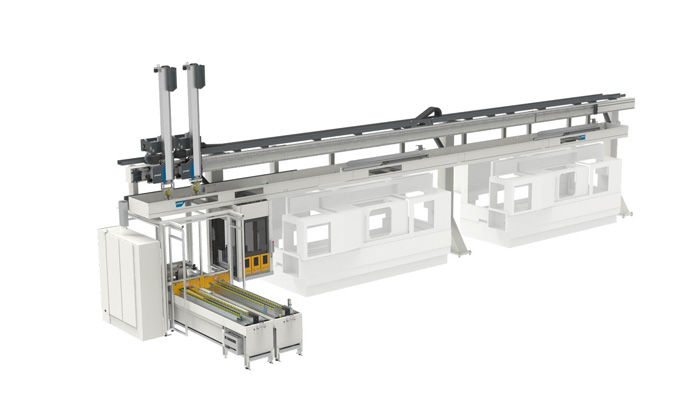

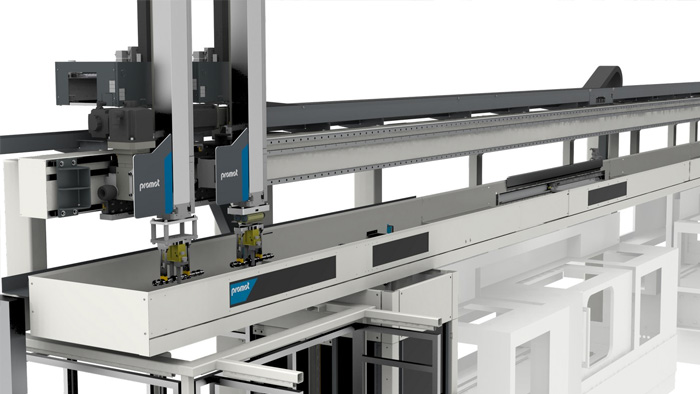

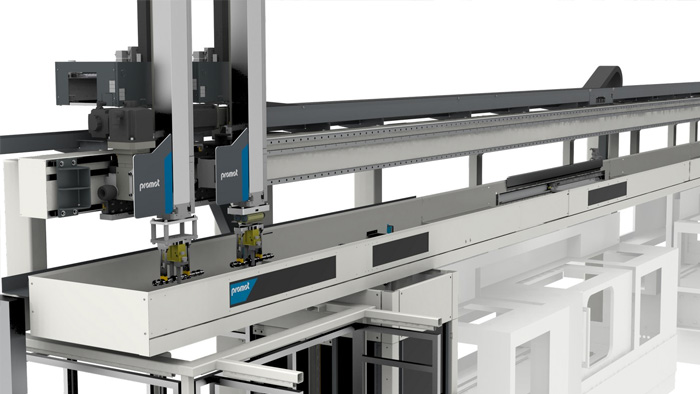

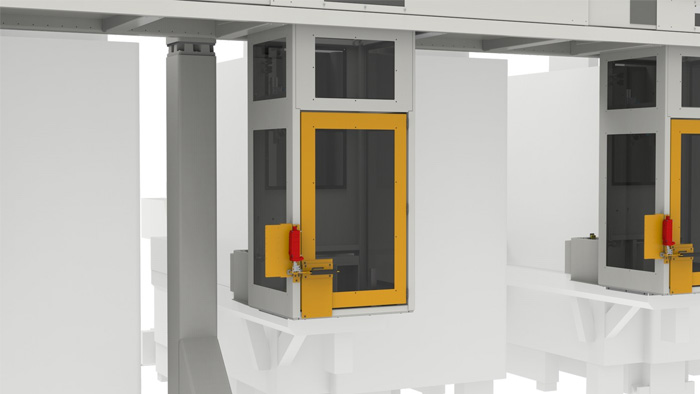

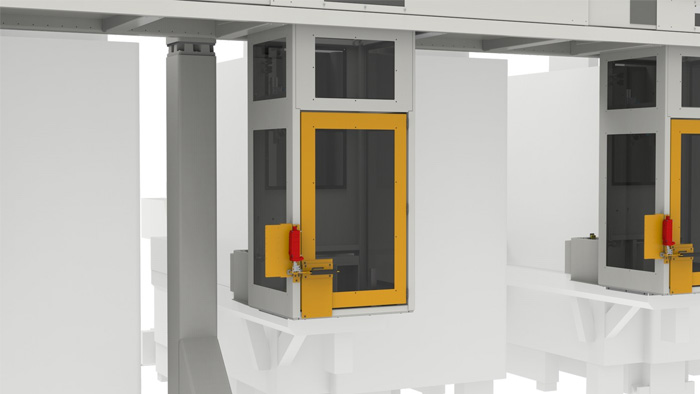

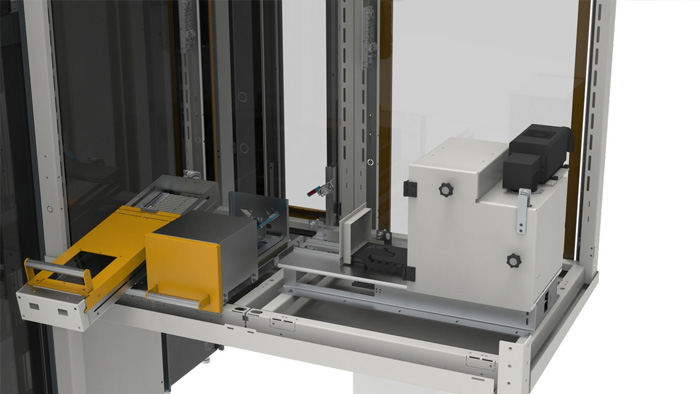

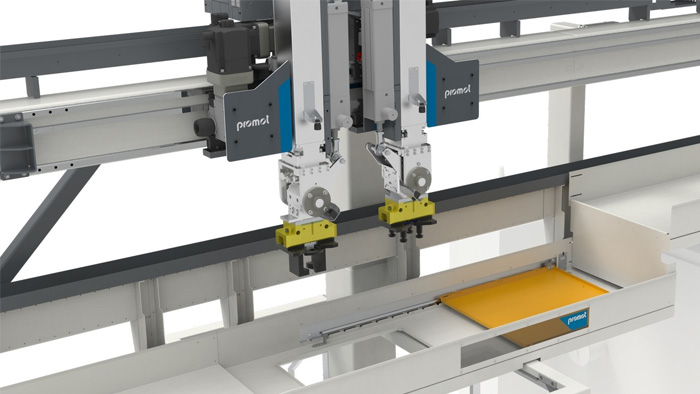

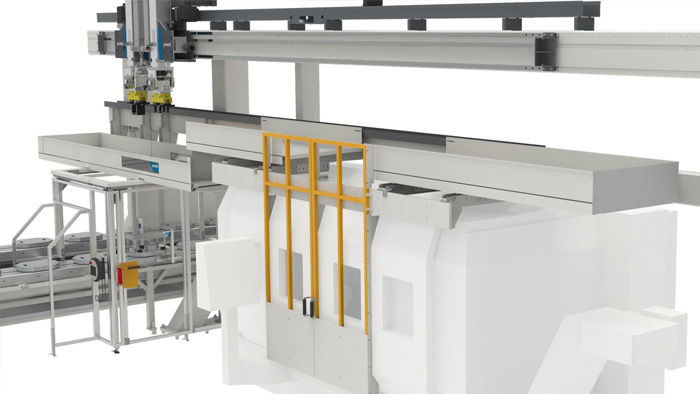

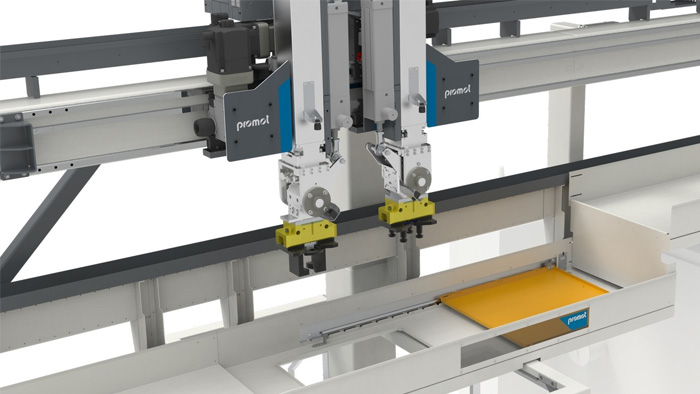

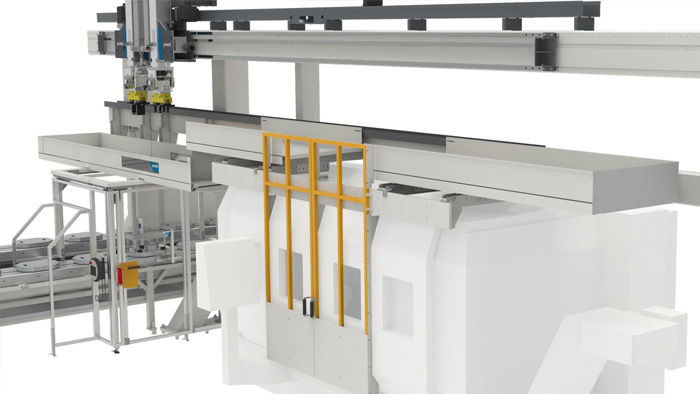

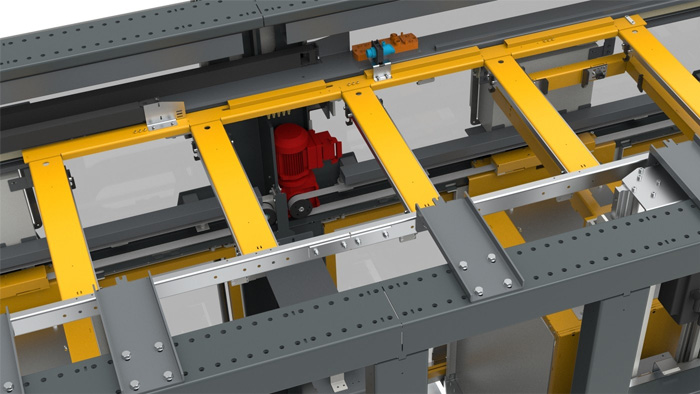

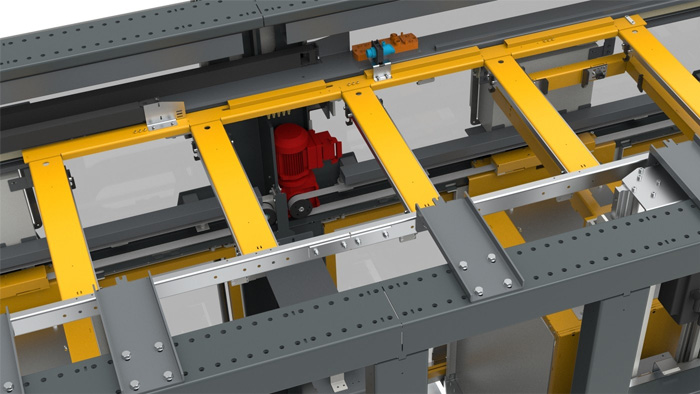

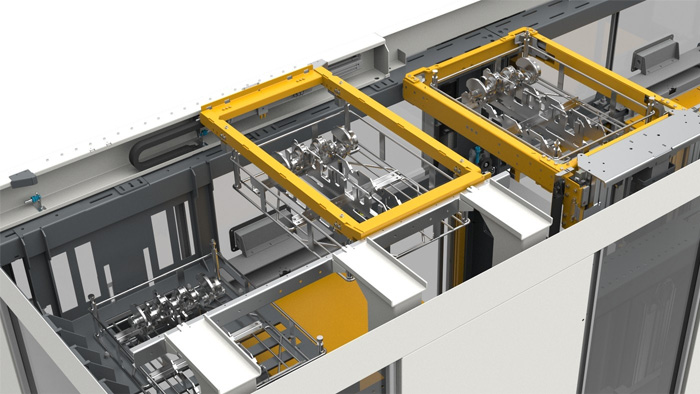

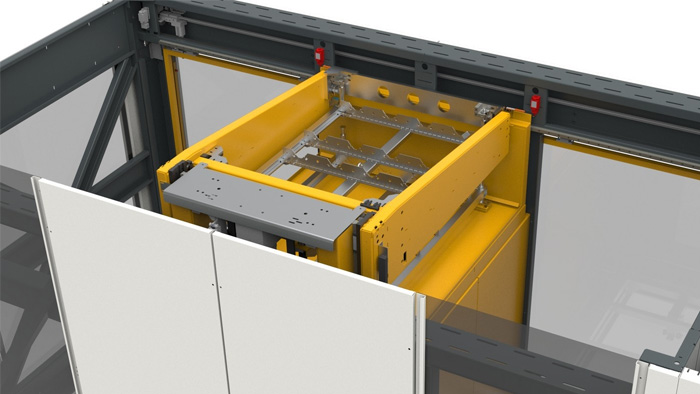

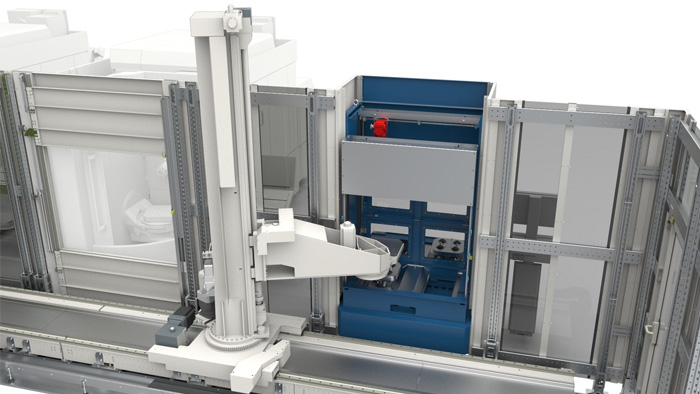

Gantry Loader LP

- The possibility to load the machines from above

ensures accessibility. This is particularly important for set-up procedures

and monitoring activities. The linear axes allow easy operation, programming

and training of the machine.

As the space above the machine is used, valuable production space can also be saved.

PROMOT Gantry Loader LP – Modular in every dimension

PROMOT gantry loaders are characterized in particular by the consistent modularization across all functional modules and weight classes. This allows us to focus on the respective system layout without having to reinvent the wheel for standard functions each time.- Standard sizes LP1 to LP4 from 1 kg to 250 kg workpiece weight

- Low maintenance due to rack and pinion drive

- Shortest workpiece change times owing to high accelerations

- Reduction of noise pollution stemming from quiet drives and damped energy chains

- Fast installation on site due to the compact, modular design

- Custom-made solution based on configured, field proud and standardized modules.

- Small footprint and excellent stability due to Finite Element Analysis (FEA).

- Highest positioning and ride-off accuracy due to the high degree of rigidity.

- Easy reusability of components during modifications due to modular design.

Typical application of a Gantry Loader LP

Loading of a bevel gear milling machine

- Loading of a bevel gear milling machine from a basket stack with our Cell Master stacking cell, an SPC drawer and a telescopic gantry arm.

Automation of two grinding machines

- Automation of two machines with in- and outfeed tac conveyors. In addition, SPC drawers and a station for radial pre-orientation of the workpieces have been integrated.

Loading of 3 lathes

- Loading of 3 lathes from basket stacks. The standard modules SPC drawer and NiO chute, as well as a project-specific DMC laser marking station create a highly productive, complete system.

Loading of a turn-mill center

- The automation of a turning and milling center. The workpieces are magazined on a WS-UNI 150 pallet conveyor. In addition, a marking station is integrated for signing the finished parts.

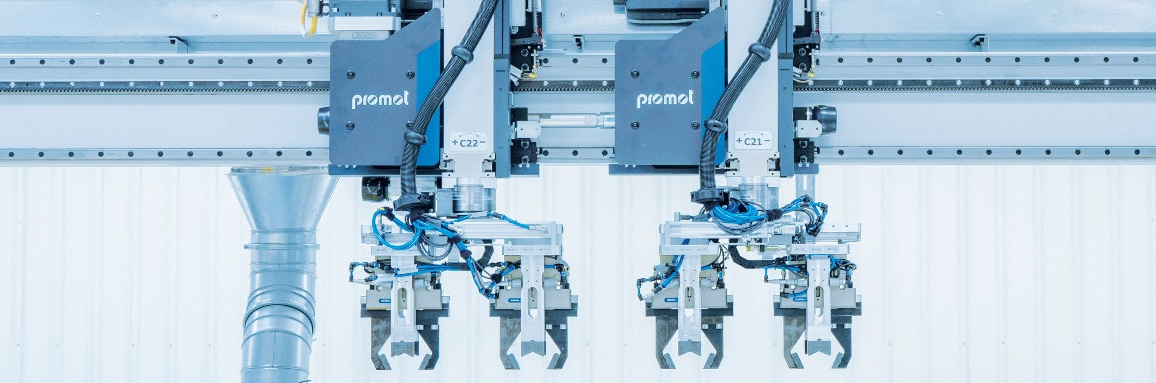

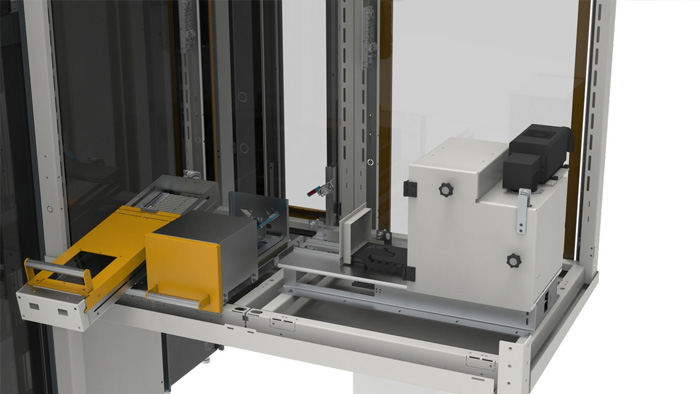

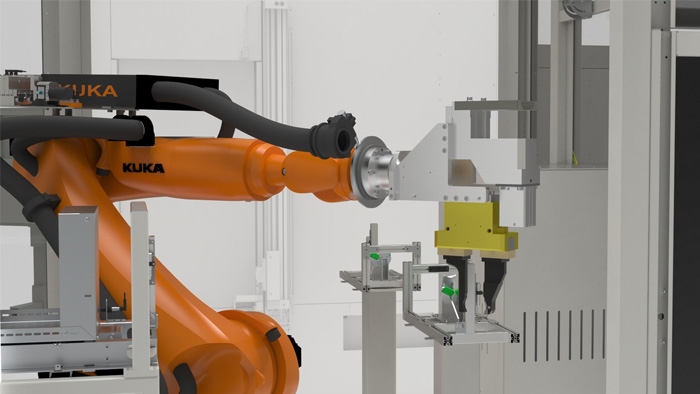

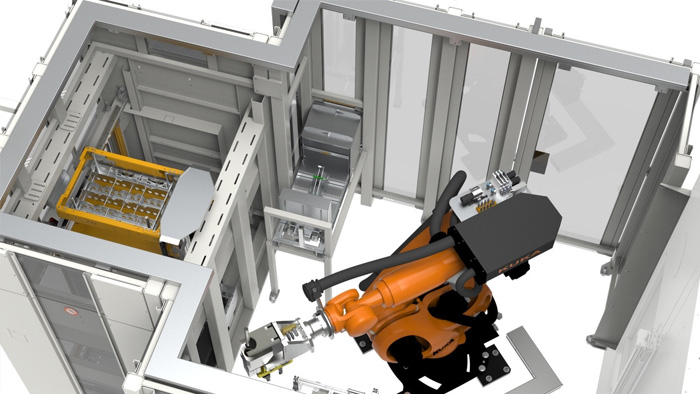

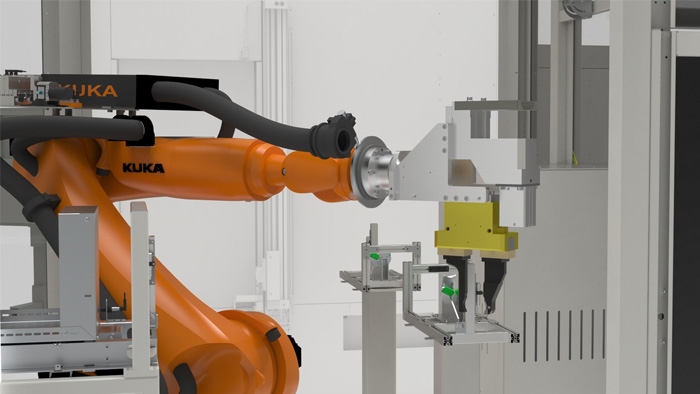

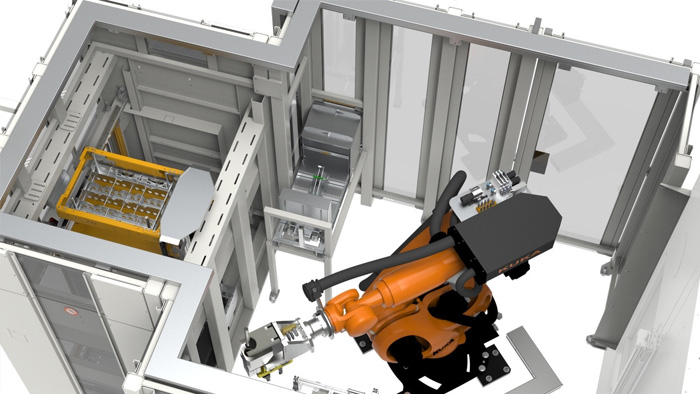

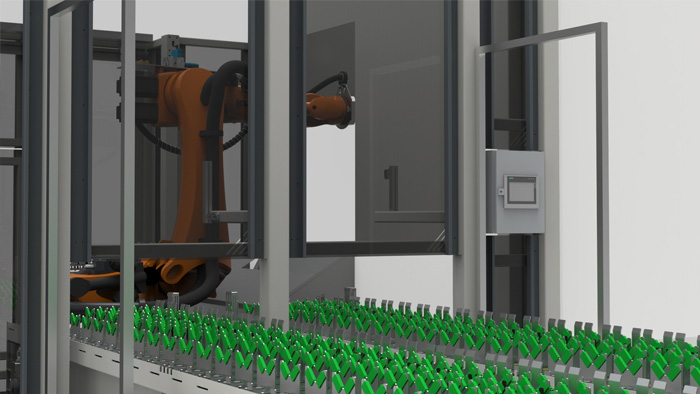

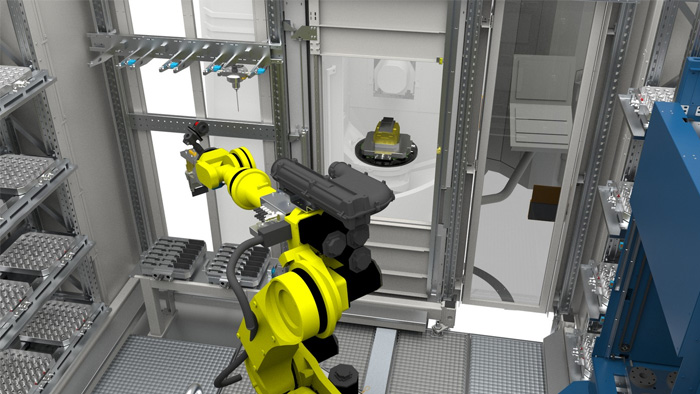

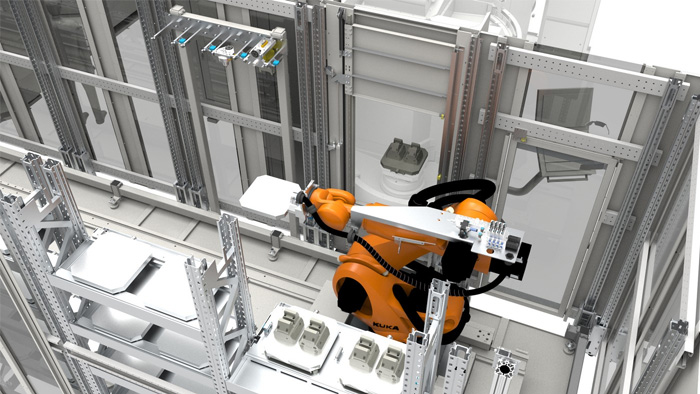

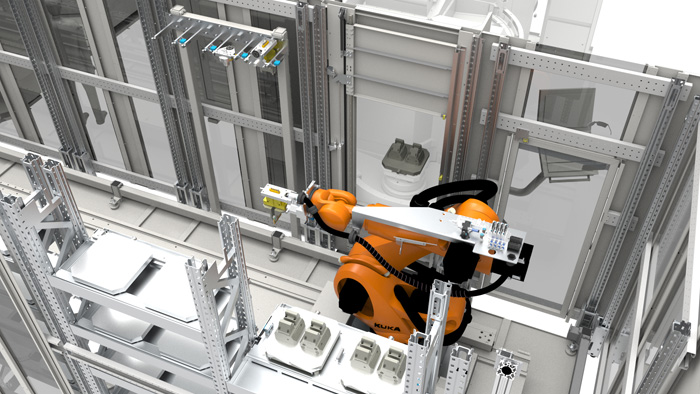

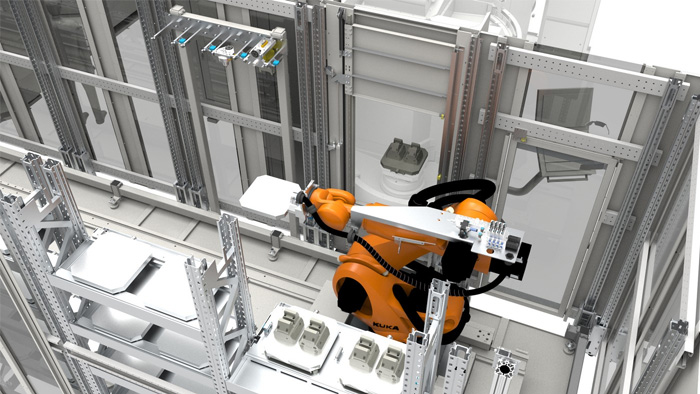

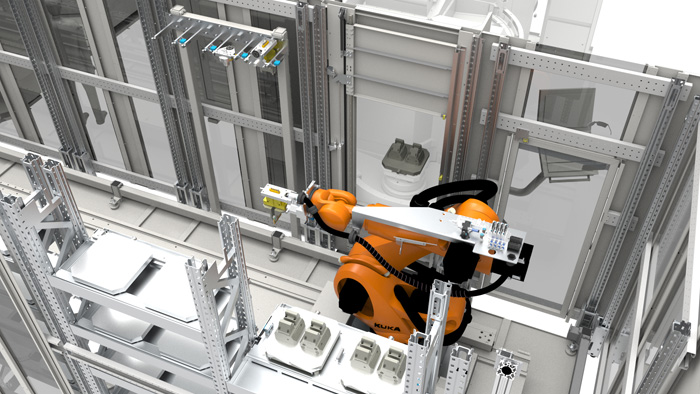

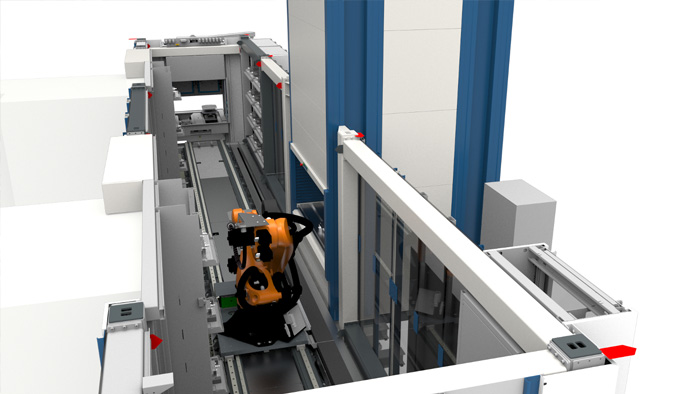

Robot Cell RZ

- Robot cells represent the flexible way to automate

machine tools.

A jointed-arm robot offers high flexibility due its greater range of movement, yet the systems are just as easy to operate as a gantry robot due to the cell control and our ProHMI 2.0 visualization software.

PROMOT Robot Cell RZ – Modularity taken further

PROMOT robot cells are based on the same modular system as our gantry robots.

They also benefit from the well-proven modules, such as gripper assemblies and magazines

All of our robot cells are equipped with a cell control system, which enables us to implement robot-independent, open interfaces and standardized control concepts.- Standardized control concept

- Independent of robot brand

- Common modular system for gantry loaders and robot cells

- Identical HMI like our gantry loaders

- Common modular system for gantry loaders and robot cells – unique on the market.

- Standardized control concept independent of robot brand.

- Consistent operating concept thanks to ProHMI 2.0 operating interface - 100% identical to our gantry loaders.

- Modular design allows the robots and additional stations to be reused at modifications.

Typical applications of a Robot Cell RZ

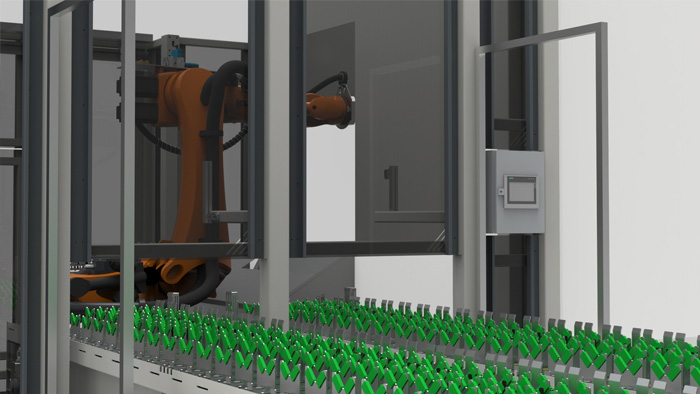

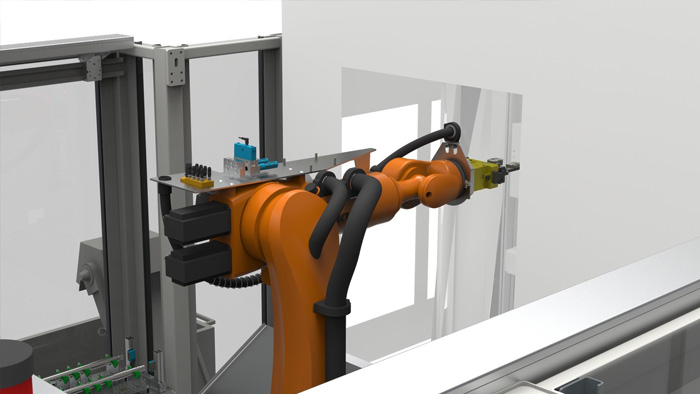

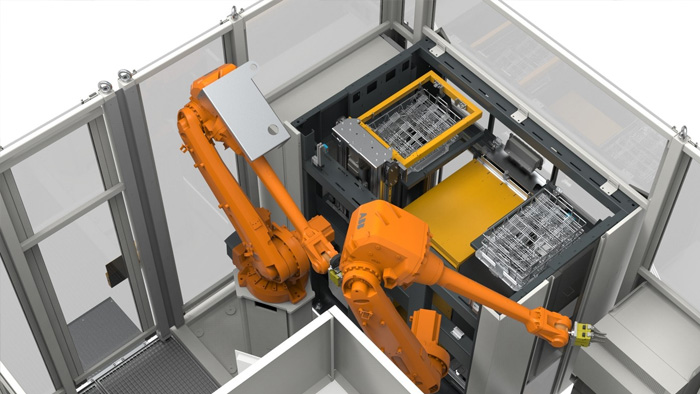

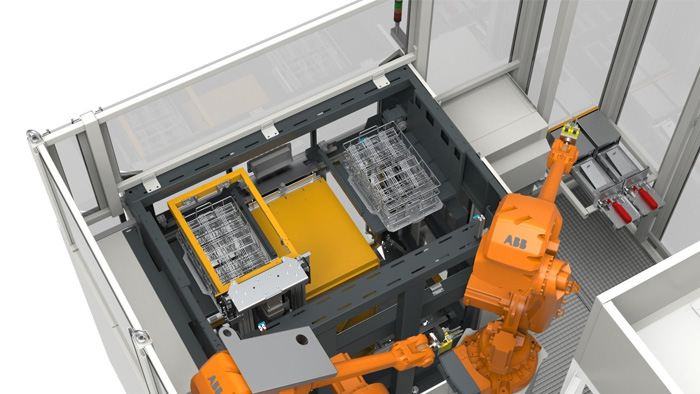

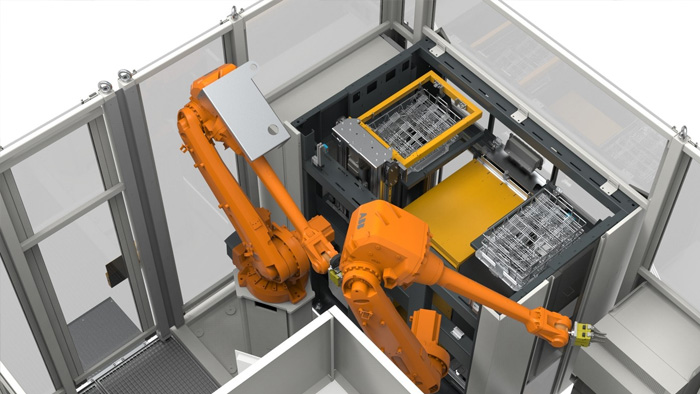

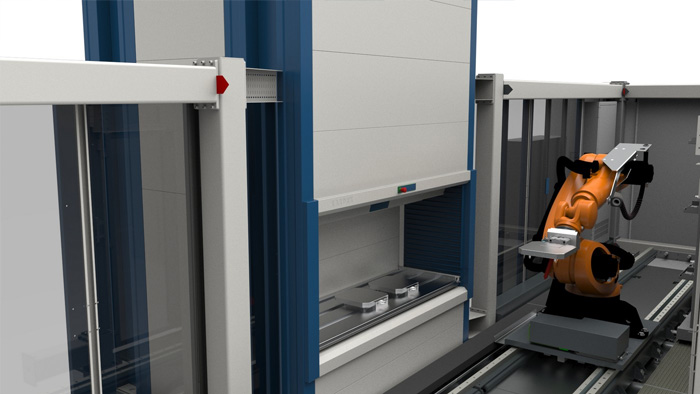

Loading of a gear toothing machine

- Loading of a bevel gear toothing machine with a KUKA 6-axis robot and Cell Master CM-S stacking cell, as well as the integration of a DMC reading station and an SPC drawer.

Automation of an ECM deburring machine

- Automation of an ECM deburring machine and the associated cleaning and preservation basins by means of robots. The workpieces are fed and discharged via the customer's hall interlinking system.

Loading of a gear grinding machine

- Automation of a gear grinding machine with a KUKA robot, storage of raw and finished parts with WS-PL conveyors from our modular system

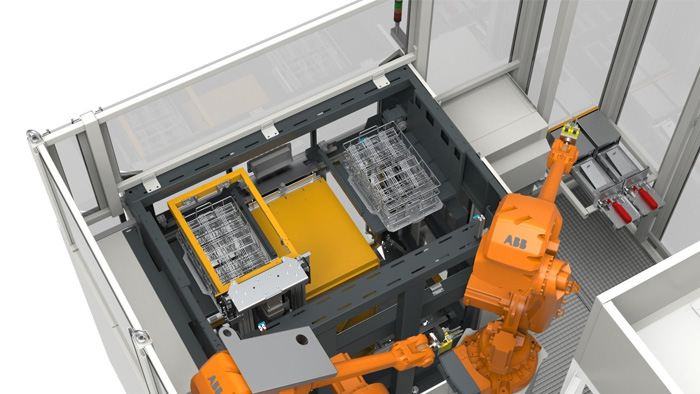

Robot cell with Cellmaster

- Loading connecting rods into a grinding machinebased on two robots and a Cellmaster CM stacking cell.

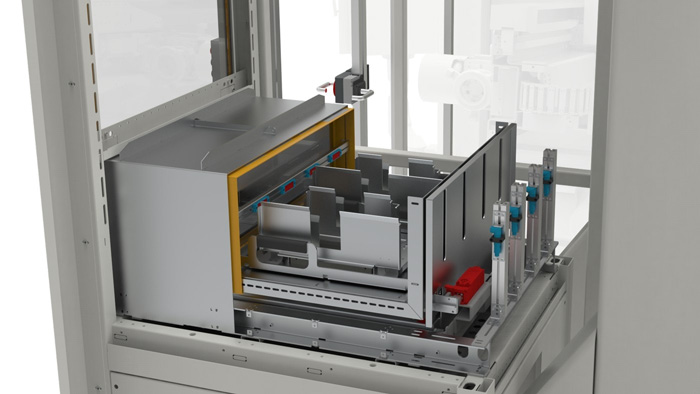

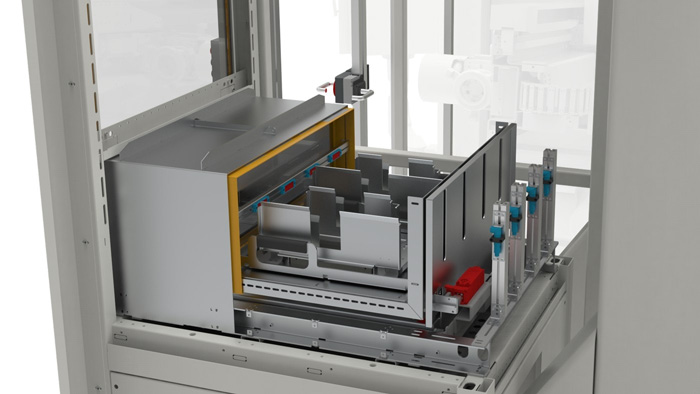

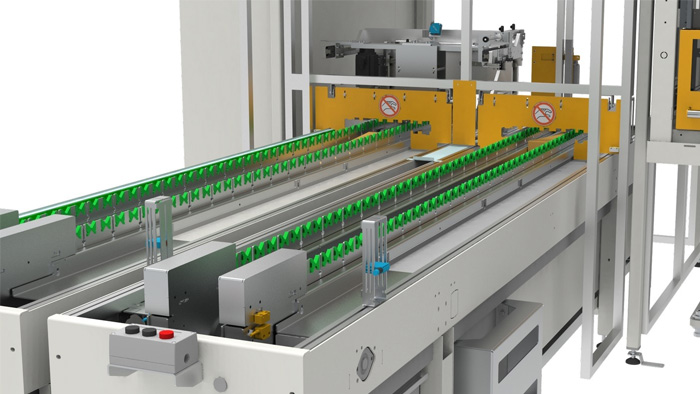

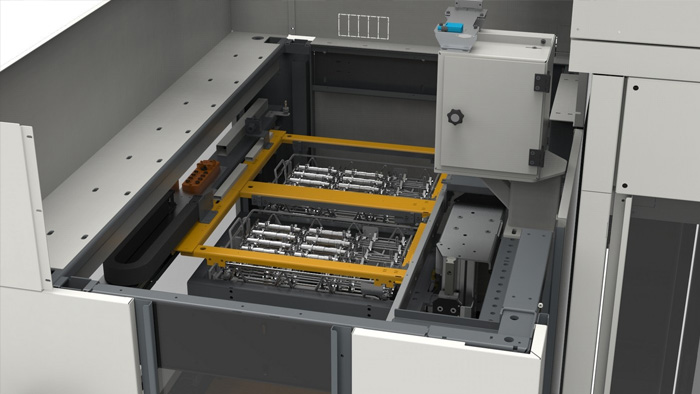

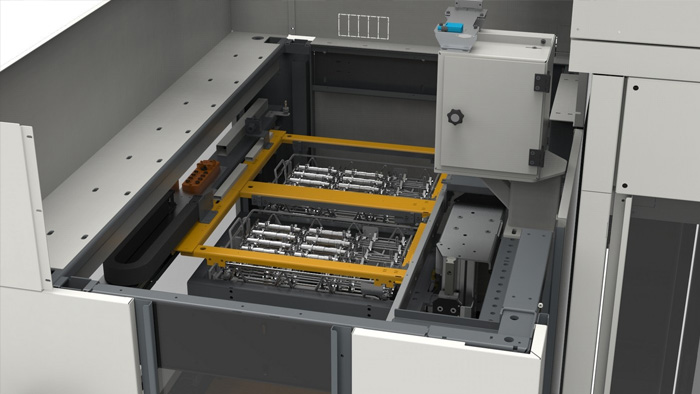

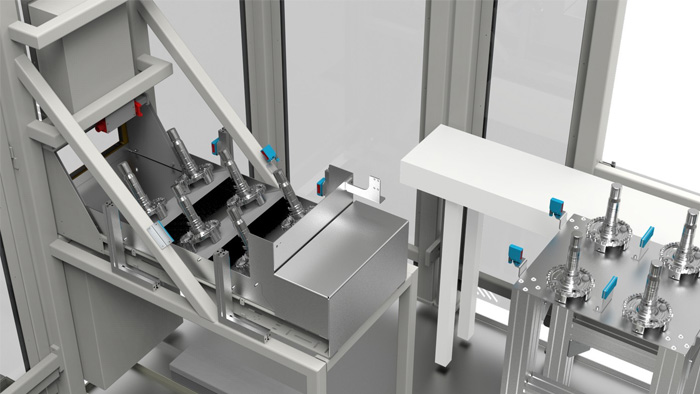

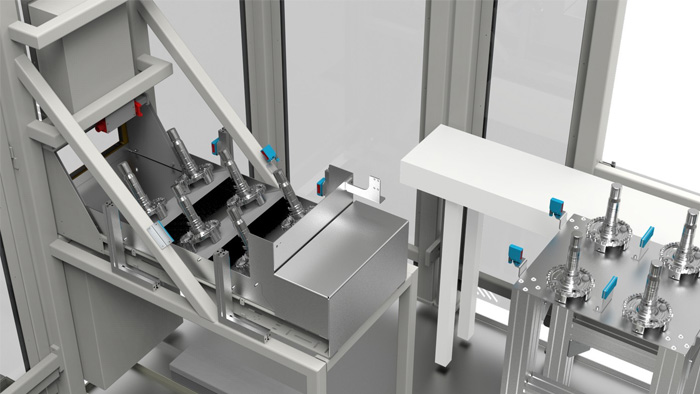

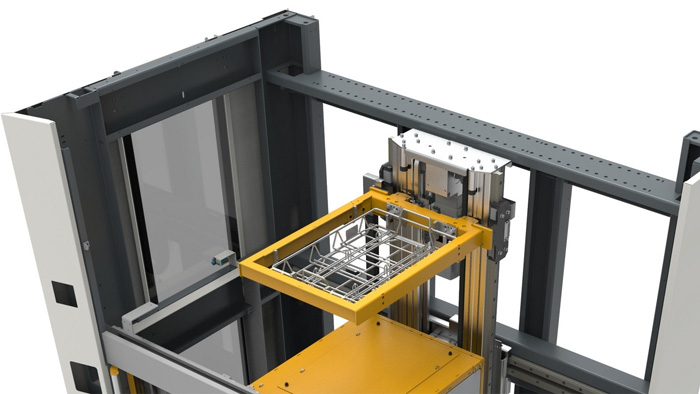

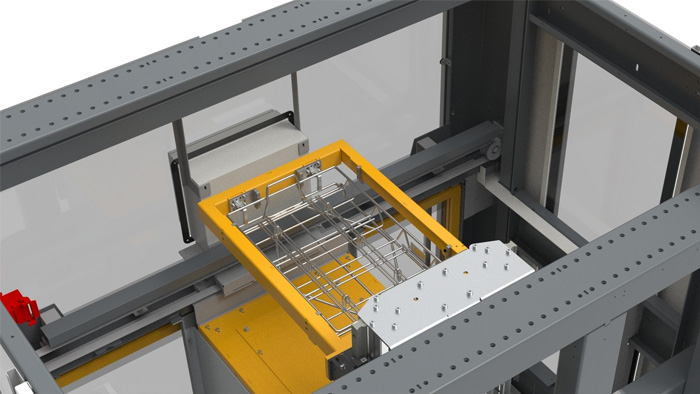

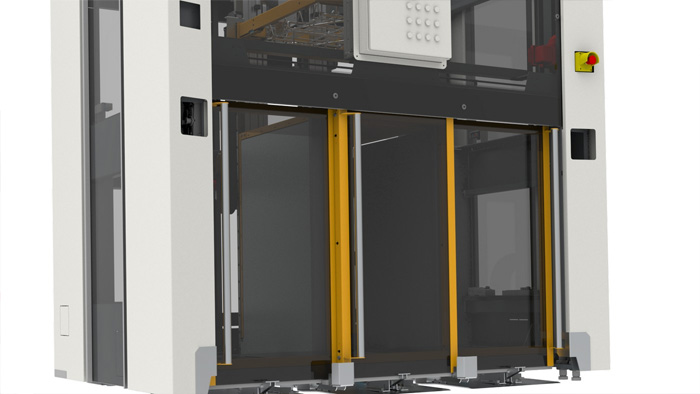

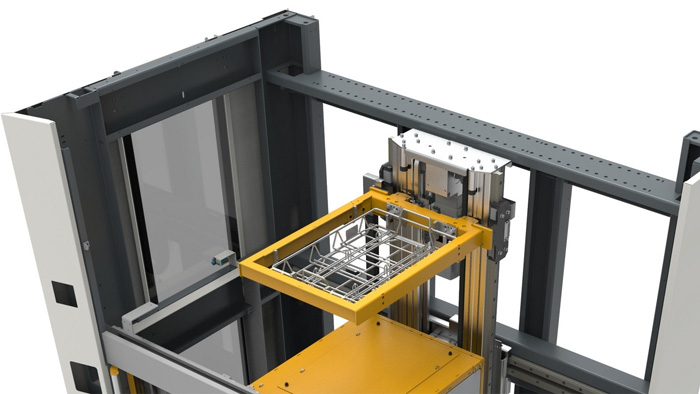

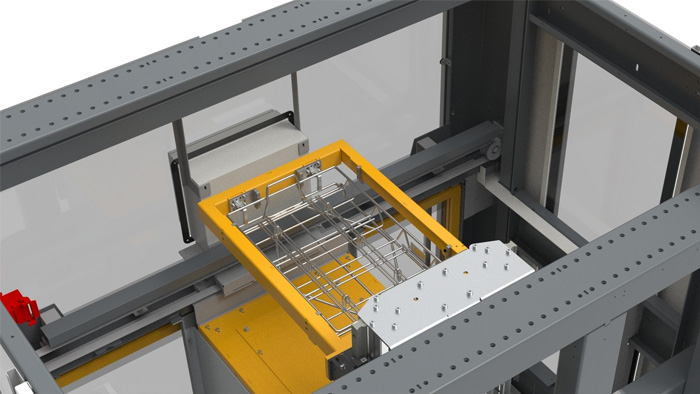

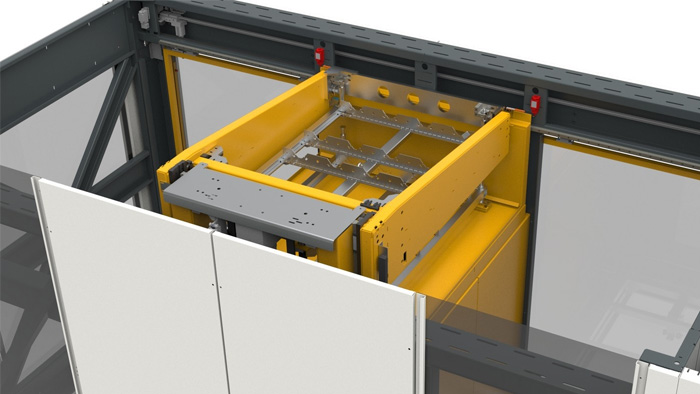

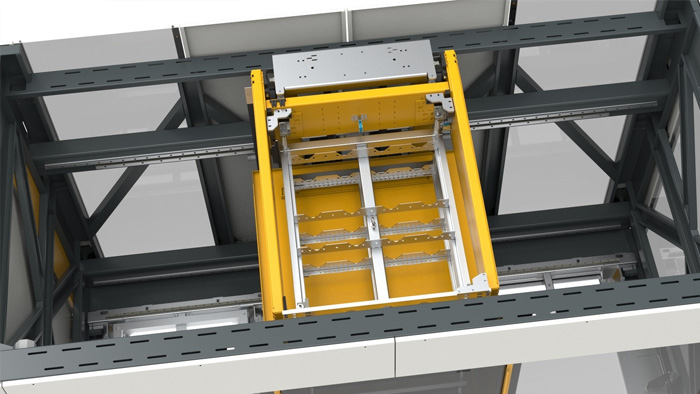

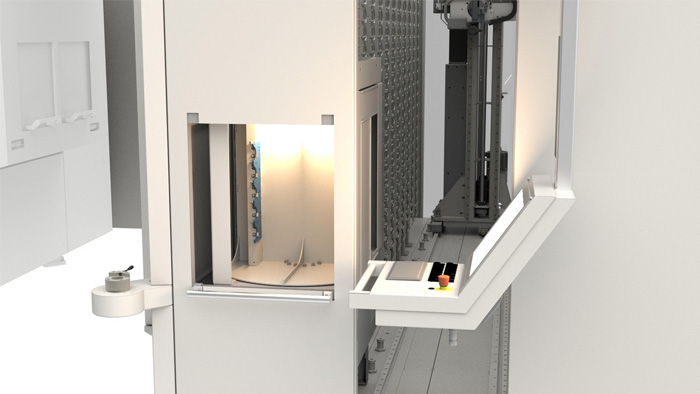

Stacking cell Cellmaster CM

- The Stacking cell Cellmaster CM-S is available as a

standard module in the modular system in various standard sizes

The basic module is equipped with 3 chambers which are directly accessible through sliding doors. This allows you to react quickly to production changes without having to wait for the entire stack to be restacked each time. Remove semi-finished stacks, load a new stock stack and done! Each finished part chamber is sealed off by a slide guard, so the stacks can be changed without interrupting the production process.

PROMOT Cellmaster CM – Modularly adaptable to your project

No task is quite like another. As a modular system, the PROMOT Cellmaster CM can be adapted to meet any requirements. In addition to expansion modules for additional cells, various basket provisioning options are also available. Using a decoupling module makes it possible, for example, to change baskets during operation without creating any waiting time for the loading system. The modularity is not limited to the mechanics - the Cellmaster CM will adapt to your existing logistics systems with standardized software processes.

The following standardized software sequences are possible:- Standard sequence

- Standard sequence with basket on the sliding guard for filling and emptying operations

- Gap collection in the topmost basket

- Single basket sequence

- Single stack sequence

- High degree of autonomy due to the stacking of workpieces.

- Mechanical design and software modularly adaptable to your individual logistics and production processes.

- Quick reaction time to changing production requirements due to direct access to all stacking positions.

- Dimensions: 400 x 600 mm; 600 x 800 mm; 800 x 1,200 mm

Typical applications of a Cellmaster CM

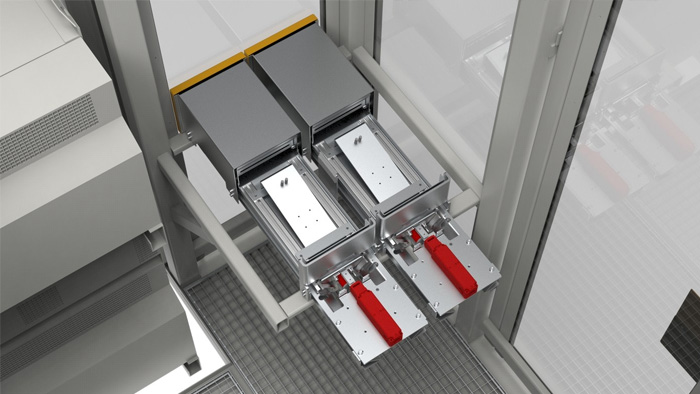

Standard configuration Cellmaster CM-S

- The fully automatic Cellmaster is a standardized magazine that contains three stacks of baskets or pallets. This enables uninterrupted production. The Cellmaster makes the individual baskets available for handling in such a way that the workpieces can be unloaded.

6-fold stacking cell for 2 part types

- Project-specific solution with 2 x 3 chambers for the simultaneous provisioning of 2 part types, including a provision shuttle for basket and stack change when machining.

Decoupling module for material flow chains

- The Cellmaster can also be configured for use as a decoupling module in material flow chains and ensures targeted decoupling of the production steps.

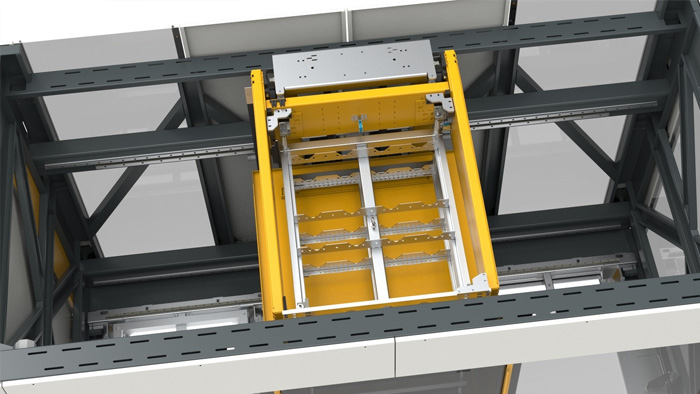

Stacking cell CM-S-400 for pallets 1200 x 800 mm

- For pallets with a size of 1200 x 800 mm, our stacking cell CM-S-400 is available as standard module. The load capacity of the gripper fork is designed for pallet weights up to a maximum of 400kg.

Material Flow Solutions

- We offer our customers the optimal automation solution

for every application. The most economical interlinking solution is

selected, taking lean production criteria into account. This offer is

rounded out by our competent consultation.

All this takes place under exact consideration of the manufacturing conditions and the desired degree of flexibility, as well as the logistical conditions. PROMOT Material Flow Solutions – Flexible and modular

- Our standard modules form the basis for your individual

material flow solution.

Whether simple cell solutions, rigid portal linking or a highly-flexible production network, all our solutions are configured using the same standardized and proven modules from our modular system.

This not only simplifies spare parts inventory, but also reduces operator and maintenance training to a minimum

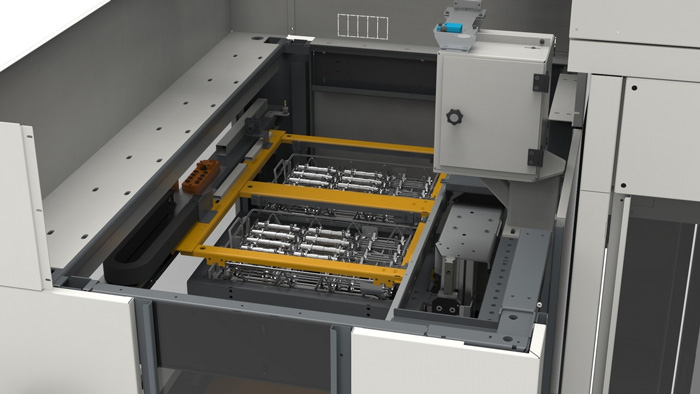

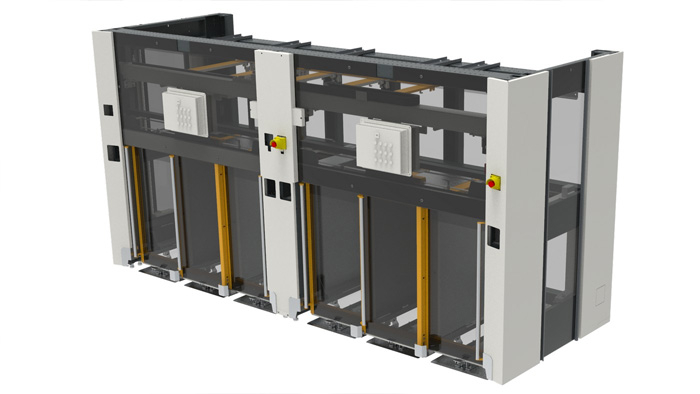

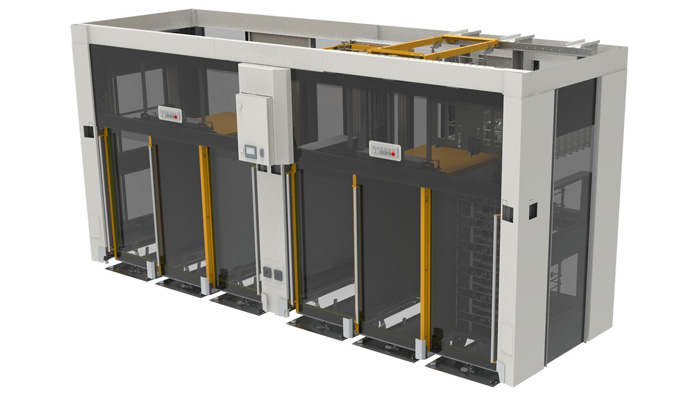

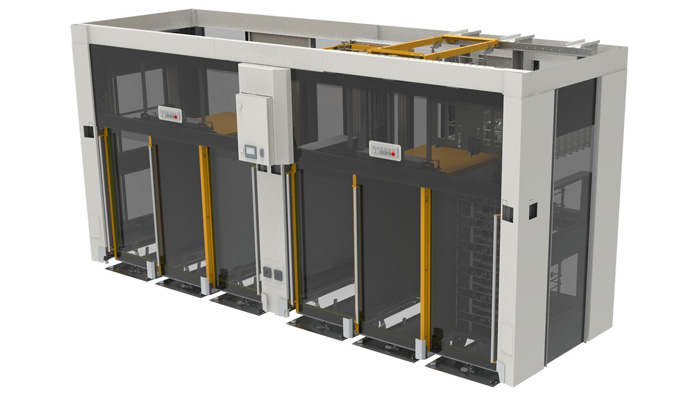

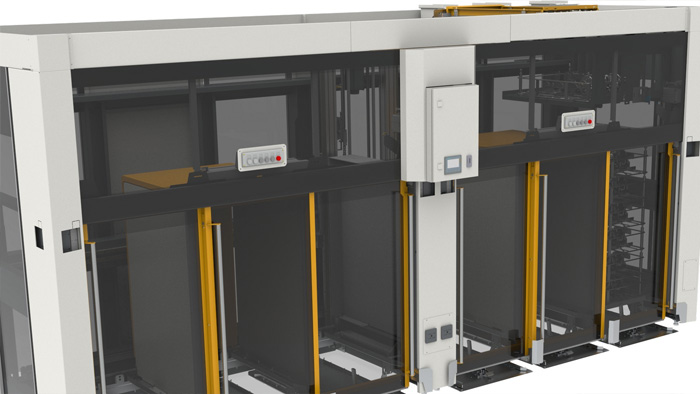

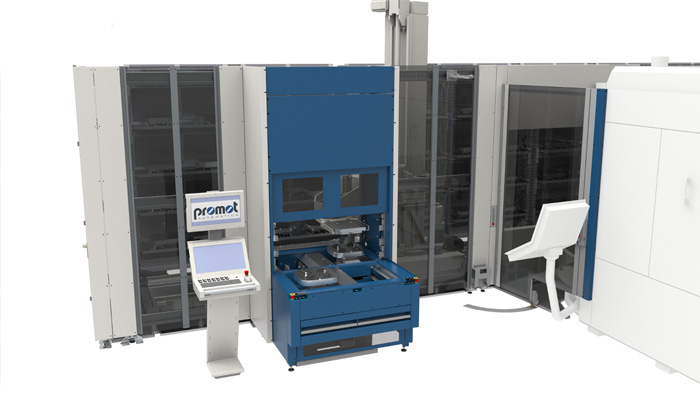

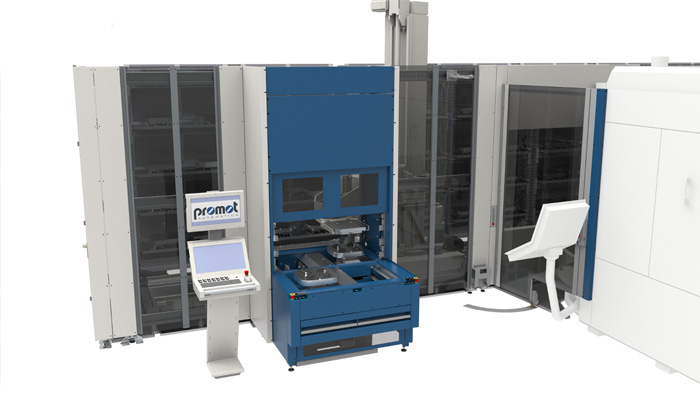

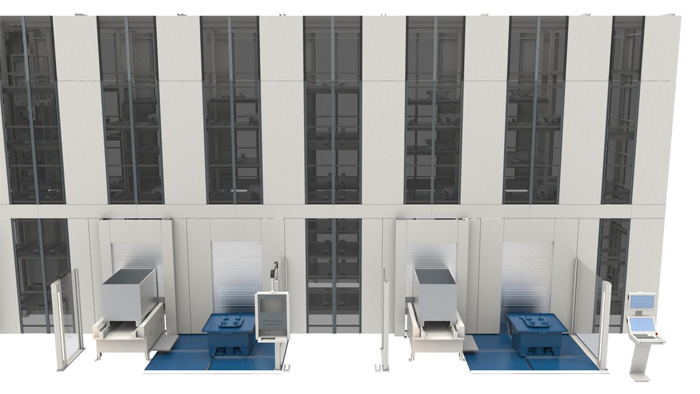

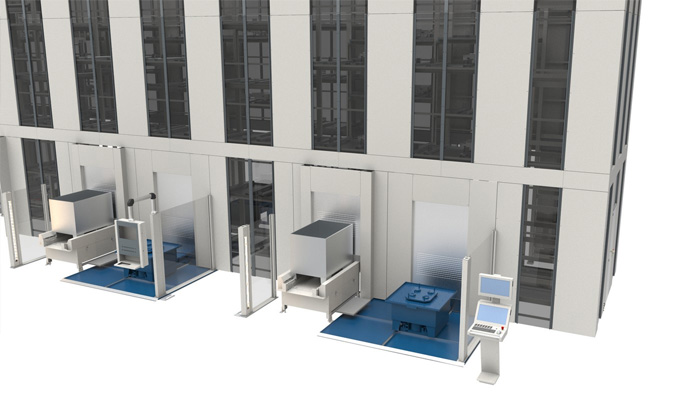

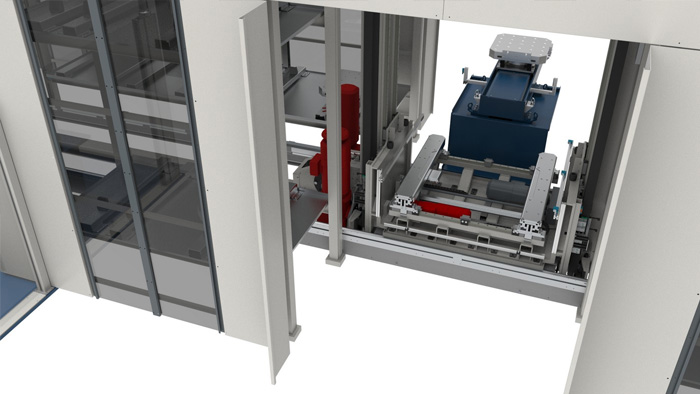

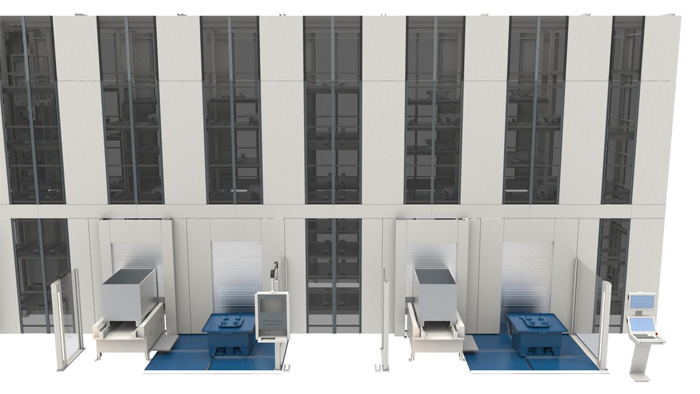

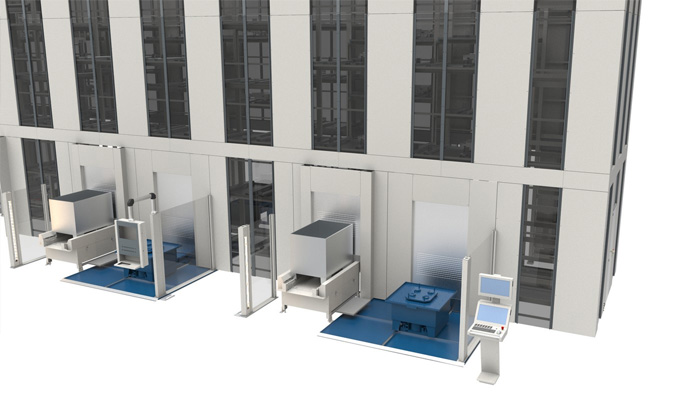

Pallet automation - Palmaster

- The automation system for small batch sizes

Automation of CNC machining centers

The economic automation of CNC machining centers for small and medium batch sizes is an exciting and demanding task. With the Palmaster product range we offer you the right solution for your pallet automation needs. This applies both to single machines and to flexible, large-scale production systems.

The complete Palmaster product range has a modular, expandable design and uses the same proven components for all areas.

With our standardized, modular construction kit, we create the optimum system configuration, tailor-made to your requirements.- Designed for single machines and for flexible manufacturing systems with several machines

- Different production strategies can be applied

- Different pallet sizes and weights are possible, even within one system

- All Palmaster configurations are also suitable for machining centers without a pallet changer

- Optimized for 5-axis machining of small batch sizes up to batch size of 1

- Adapted to your space conditions, we optimize the number of pallet spaces to maximize capacity - this in turn helps create a higher degree of autonomy and increases productivity

- The modular software Prosys is optimally adapted to meet your needs

and requirements

- Tailor-made solution

We realize the optimal solution for you using the modules from the Promot modular system. - Consulting

Consulting and design development are carried out in the Promot Workshop for optimized manufacturing processes - Independent design

Our solutions are machine manufacturer independent, with individualized, customer-specific interfaces. - Software & Hardware

Software and Hardware from a single source helps reduce the number of interfaces and the overall complexity of the system. - Productivity

Significantly higher productivity can be achieved through unmanned production and the decoupling of man and machine. - Safe investment

Our modular design makes your investment safe, because your system can be adapted or expanded in future to meet your changing production requirements.

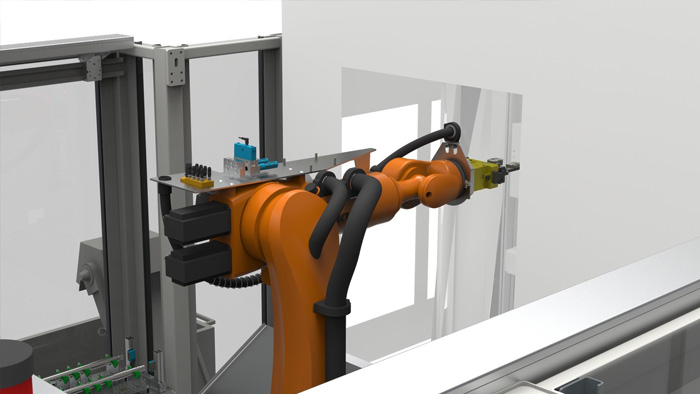

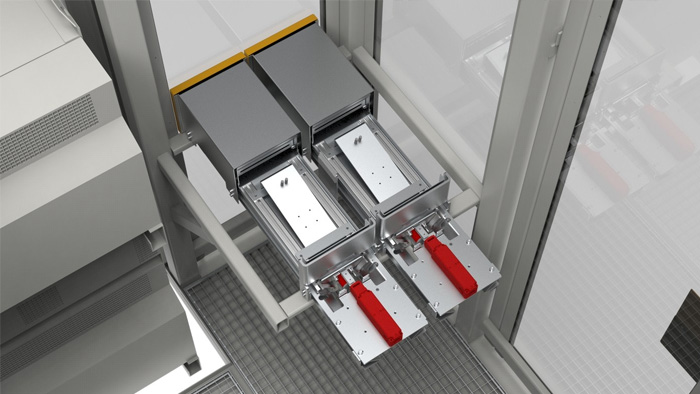

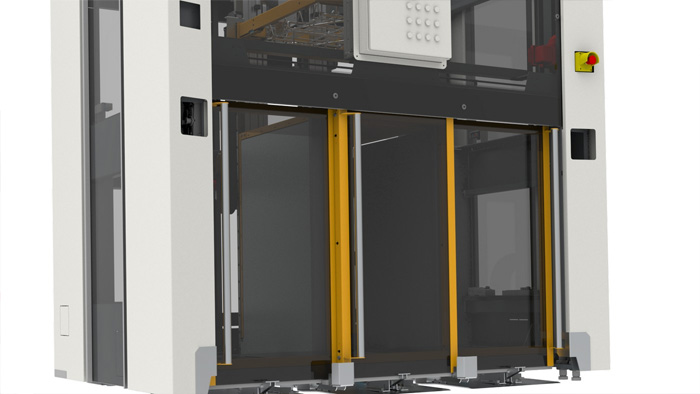

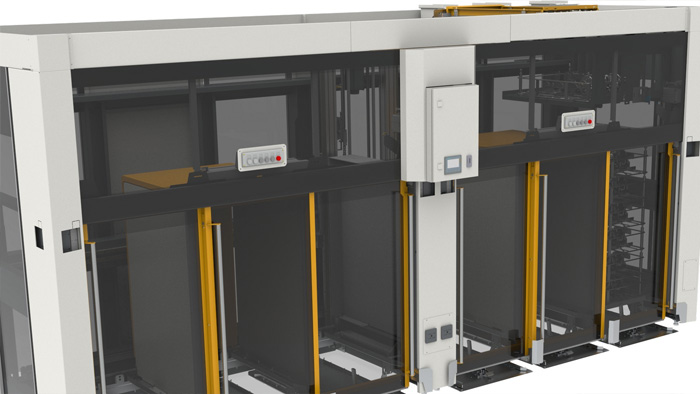

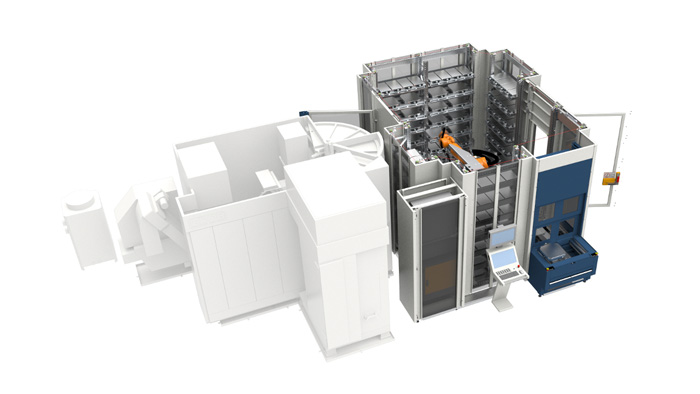

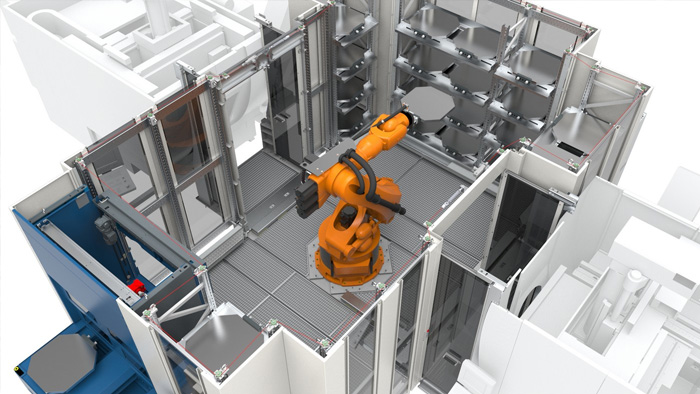

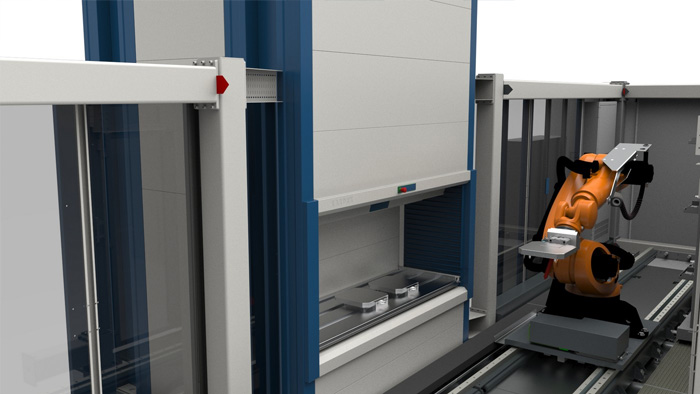

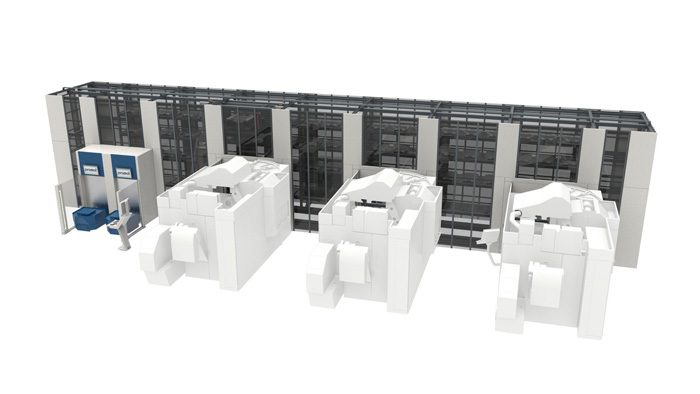

Palmaster RZ with a flexible robot

- The automation solution with a flexible robot

The Palmaster RZ is the perfect entry into automated parts production. Irrespective of the machine type and brand, the optimal system configuration is created to meet all of your production requirements.- Pallet weights up to 400 kg

- Different pallet sizes in one system - flexible storage possible

- Suitable for machines with or without pallet changer

- Double setup station for easy set-up from OP10 to OP20

- Maximized number of pallets with our modular system, depending on pallet size

- Prosys production control software for optimum order control

- Optimal size

Space-saving, but with a very high buffer capacity for unmanned operation over several shifts - Economic

Low investment costs and higher productivity than with conventional production, thereby achieving rapid amortization. - Autonomous production

Autonomous, unmanned operation over several shifts reduces the number of machine operators necessary. - Set-up mode

Manual (running-in) operation is possible at any time thanks to flexible bulkheading. - Independent

Machine manufacturer independent - with individual, customer-specific interface solutions - User friendly

Easy, intuitive operation with the Promot software ProSys, which can be adapted to your requirements.

Typical applications of a Palmaster RZ

Robotic cell with 1 machine

- The ideal entry-level solution for the automation of a machine tool. A second machine can be added at a later date.

Robotic cell with 2 machines

- The classic robotic cell for automated pallet handling where two different machine sizes can be combined.

Robotic cell with Set-Up Master feature

- The automated set-up of small parts with the Set-Up Master can be permanently integrated in the robot cell in combination with classical pallet automation.

Robotic cell for greater pallet weights

- Using a heavy-duty robot, pallets weighing up to 400 kg can be moved through the system.

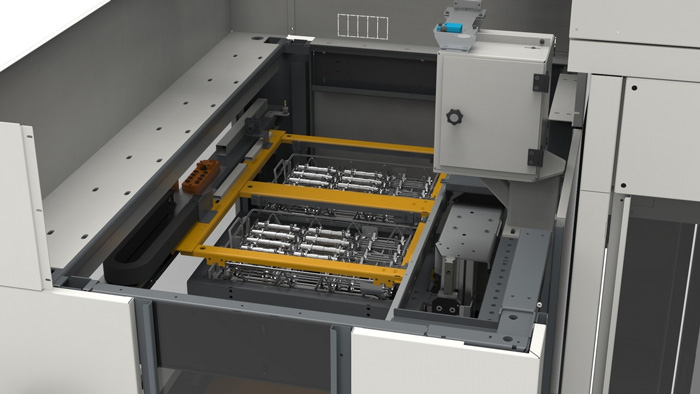

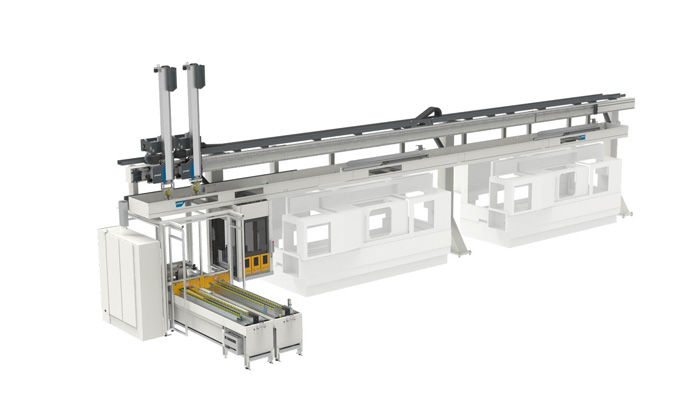

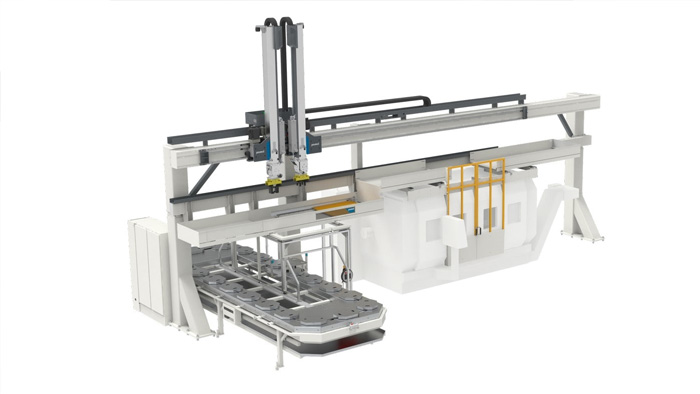

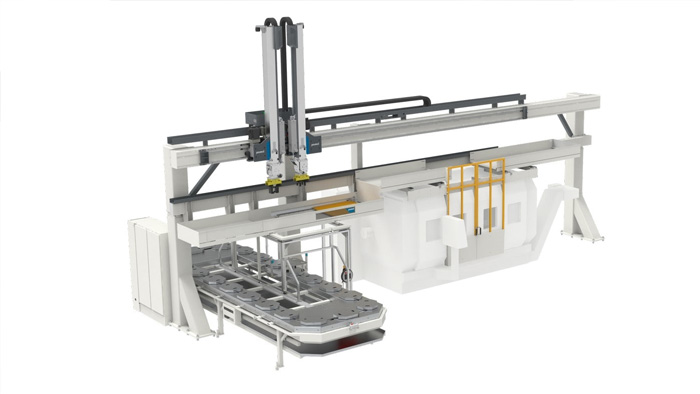

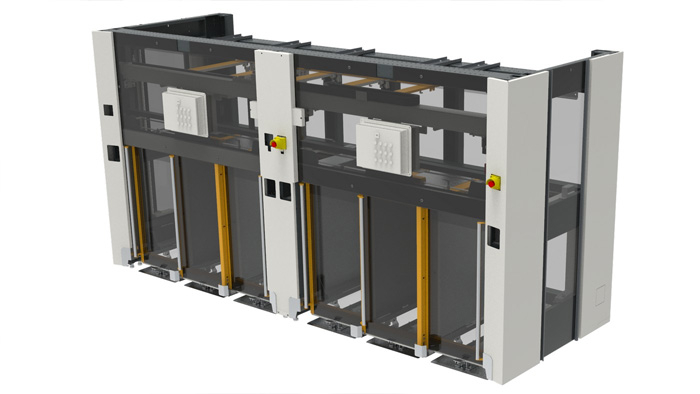

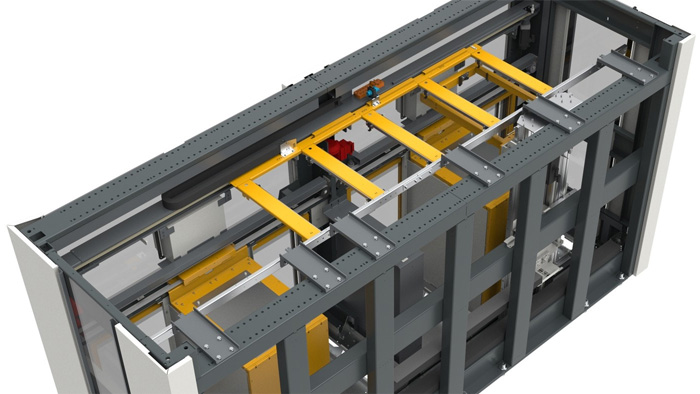

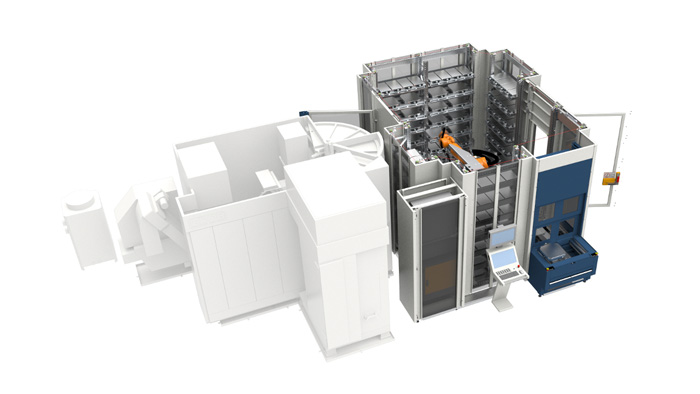

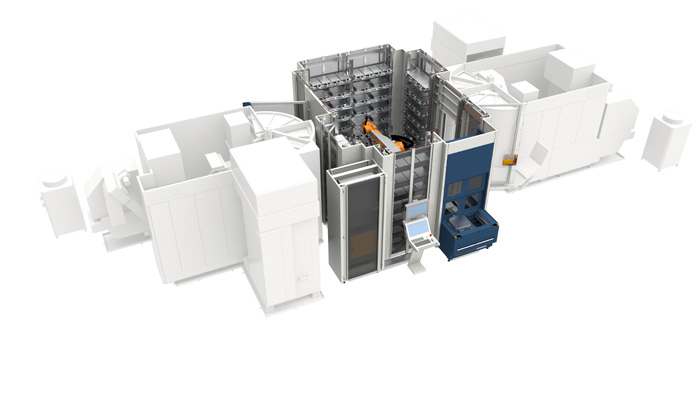

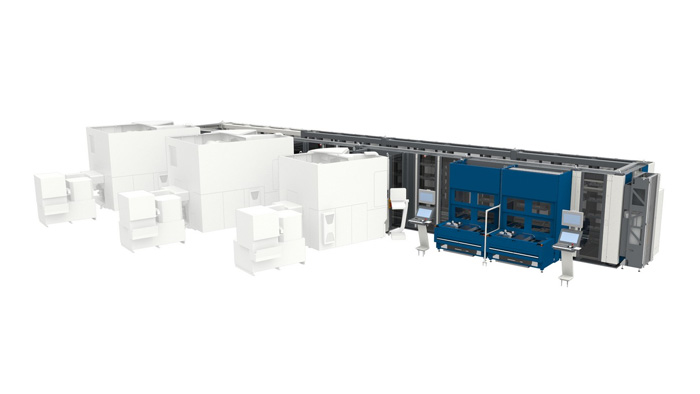

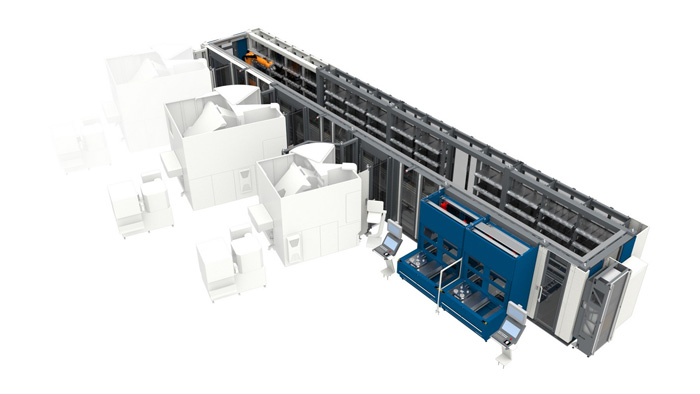

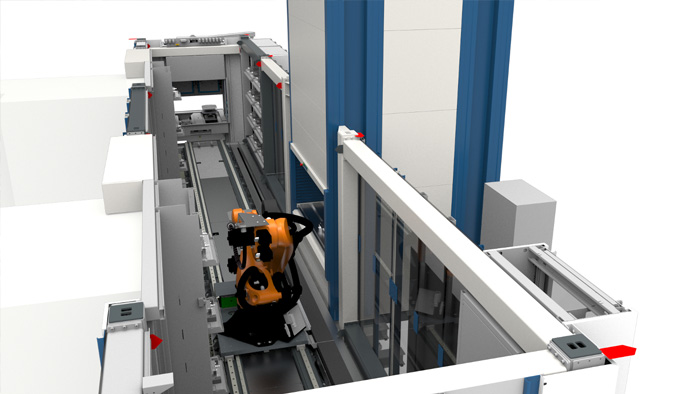

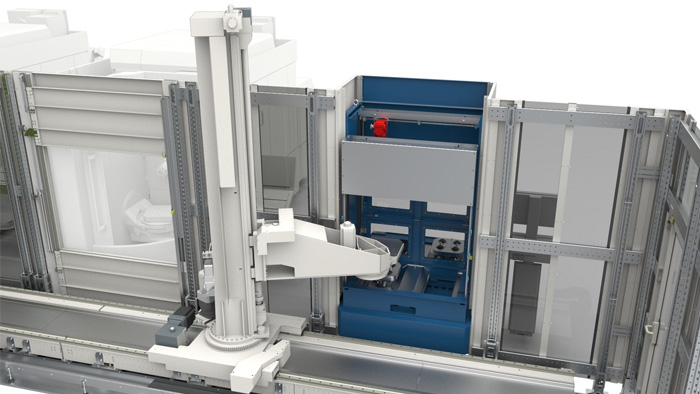

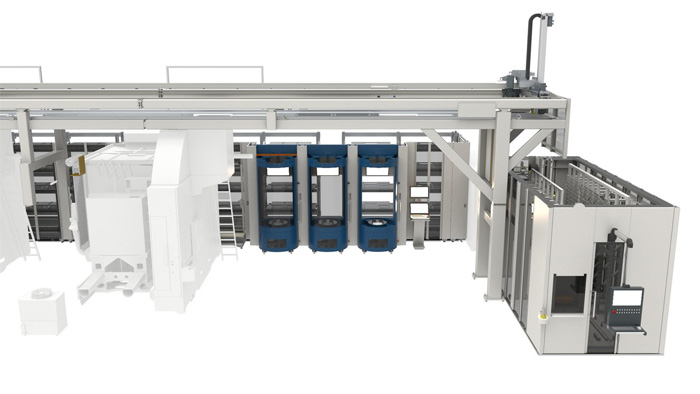

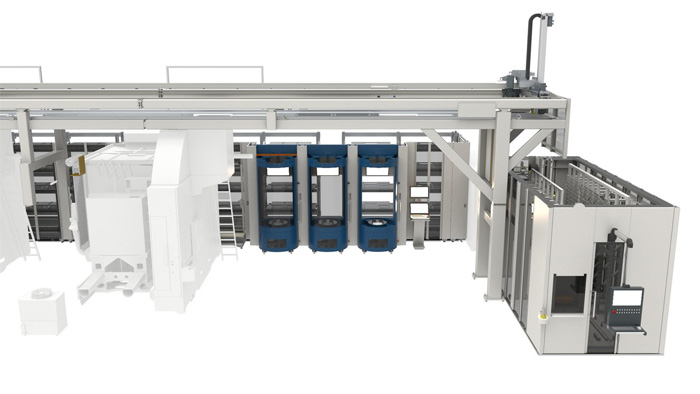

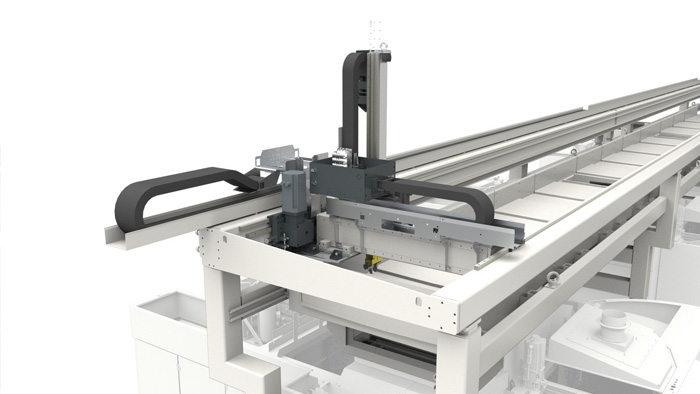

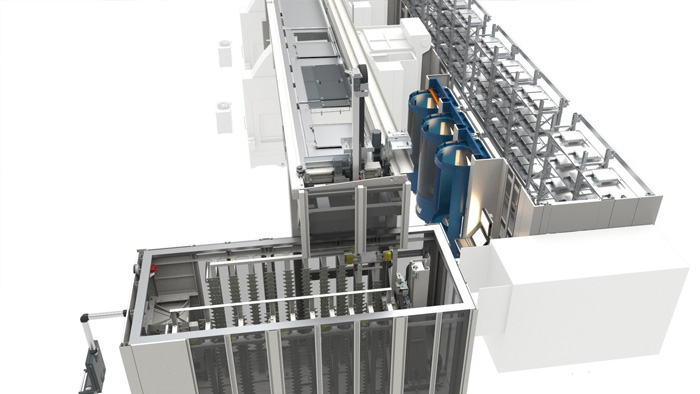

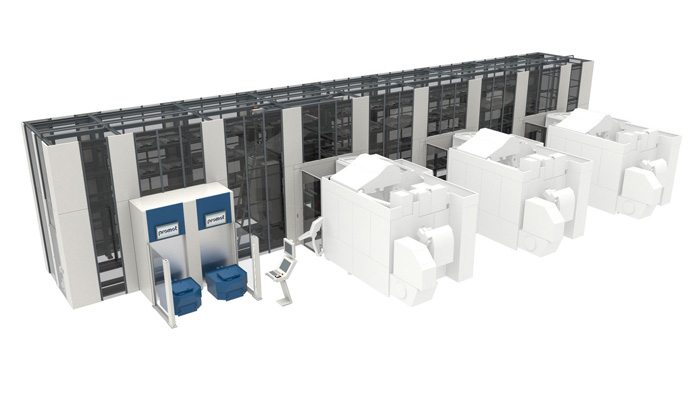

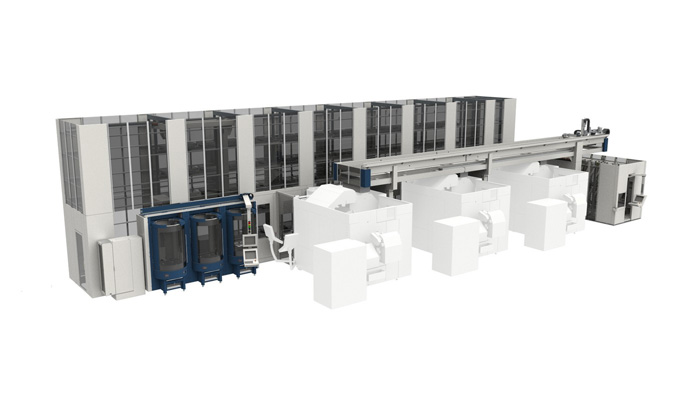

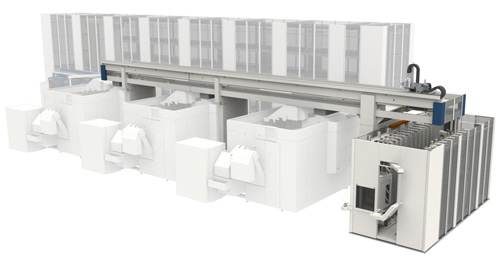

Palmaster RL with linear robots

- The linear automation solution with robots

The Palmaster RL combines the flexibility of a robot with linear axis. This creates space for a higher pallet capacity and enables the integration of several machine tools.

With the function extension Setup Master, robots can simultaneously perform the automated setup of small parts in addition to classic pallet automation, thus increasing the productivity of the overall system.- Pallet weights up to 400 kg

- Pallet size up to 630 x 630 mm, circle of rotation up to 800 mm

- Different pallet sizes in one system - flexible storage possible

- Suitable for machines with or without pallet changer

- Double setup station for easy set-up from OP10 to OP20

- Prosys production control software for optimum order control

- Centralized setup

Several machines can be supplied and controlled from a central set-up station. This reduces unnecessary walking distances and simplifies material logistics. - Safe investment

Due to the linear arrangement, your system can be expanded in future and used for additional machines - even with different machine sizes. - Unmanned production

High storage capacity owing to the linear arrangement of the shelves, allowing unmanned operation over several shifts even with short processing times - Flexible

Use of different pallet sizes in one and the same system by flexible storage rack. - Agility

Realization of complicated machine loadings by using a 6-axis robot. - Toolmaster

The system can be expanded at any time with the centralized Tool Master tool store.

Typical applications of a Palmaster RL

Differing machine sizes

- With the Promot pallet docking system, a wide variety of pallet formats can be handled in one system. This makes it possible to supply machines of different sizes with the same Palmaster.

Differing pallet sizes & set-up stations

- Different set-up stations from our modular system can be combined with each other. This increases the flexibility of the overall system with regard to pallet size and transport weight.

Linear system with Set-Up Master

- Through the automated set-up of small parts with the Set-Up Master, the potential of the robot can be fully exploited in combination with classic pallet automation.

Linear system with Lift Store

- The extended version of the RL can be fitted with the automatic pallet Lift Store for an even higher pallet capacity.

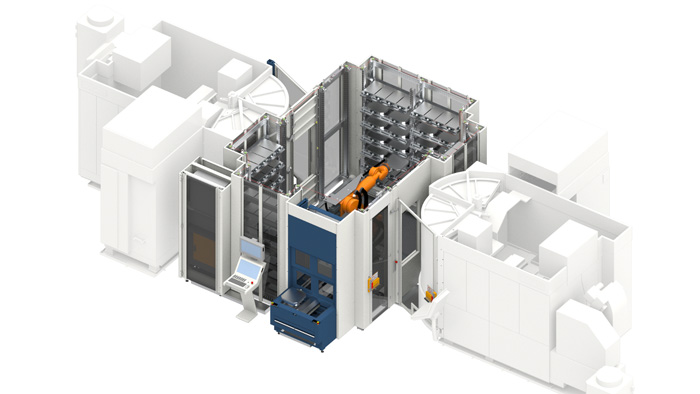

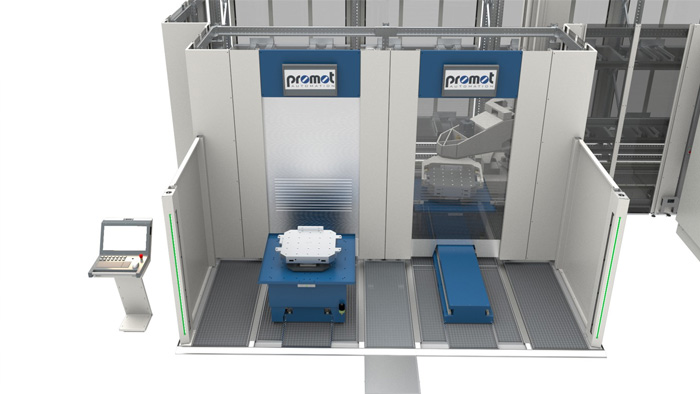

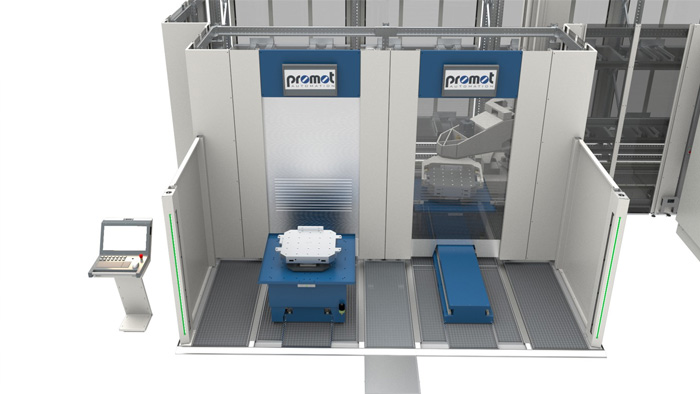

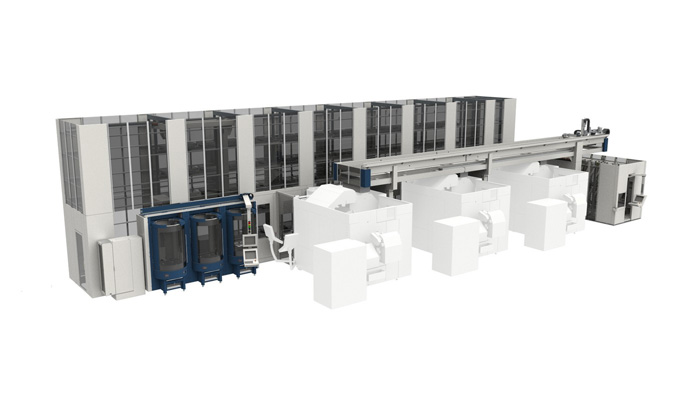

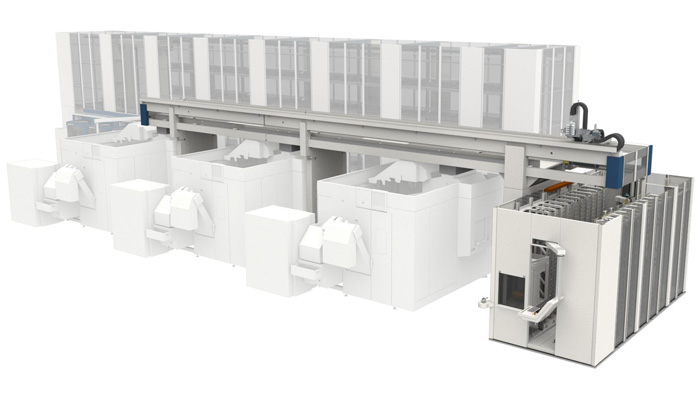

Palmaster SL

- The automation solution for pallets up to 1,500 kg

The Palmaster SL is particularly suited to higher pallet weights. The swing arm loader is available in several sizes capable of handling from 400 - 1,500 kg as well as the storage rack.- Pallet weight up to 1,500 kg

- Pallet size up to 1,000 x 1,000 mm, circle of rotation up to 1,250 mm

- Suitable for machines with or without pallet changer

- Optimum storage capacity due to different rack heights with our modular storing system

- Different setup stations possible - with revolving door or as height-adjustable, Vario-setup station

- Prosys production control software for optimized job control

- Heavy payload

The Palmaster SL can handle significantly higher weights (1,500 kg) and larger pallets (1,000 x 1,000 mm) than the Palmaster RL. - Toolmaster

The system can be extended at any time with the Toolmaster centralized tool storage system. - Package heights

Various package heights can be realized in the storage system. This maximizes the overall storage capacity of the system. - User friendly

Easy, intuitive operation with the PROMOT software, Prosys, which can be adapted to your requirements. - Safe investment

The linear arrangement allows our system to be expanded in future and used for additional machines. - Unmanned production

High storage capacity owing to the linear arrangement of the shelves, allowing unmanned operation over several shifts even with short processing times.

Typical applications of a Palmaster SL

SL 400 with dual set-up station

- The Palmaster SL 400 is particularly space-saving for lower pallet weights, especially in combination with the convenient dual set-up station.

The Palmaster SL 1500 with Vario-setup station

- The Vario-setup station is particularly ergonomically designed. It is rotatable, height-adjustable, and accessible from 270°, thus making it the perfect solution for set-ups on high fixture towers or complex fixtures.

Palmaster SL with the Toolmaster

- The Toolmaster ensures optimum tool storage on the machines. We can adapt the size of the tool magazine exactly to your needs with our modular system.

Expandable linear system

- The possibility for expansion makes the linear system a particularly safe investment. This applies not only to the Palmaster SL but also to the RL and the FFS.

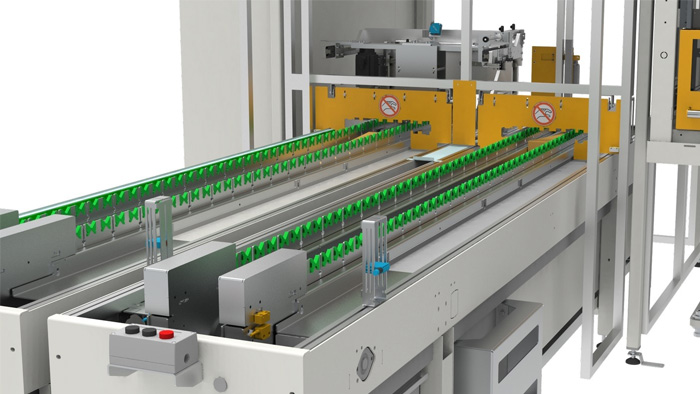

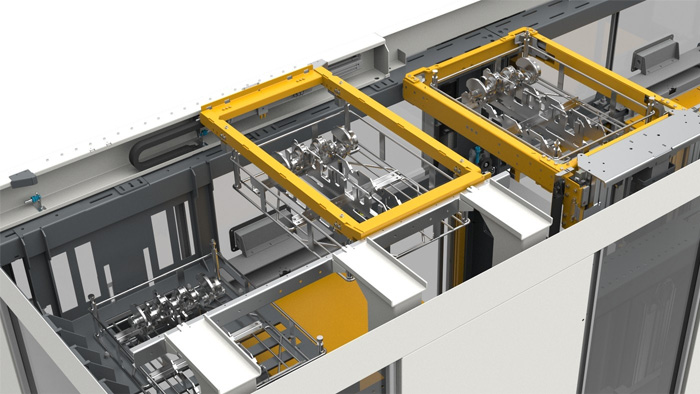

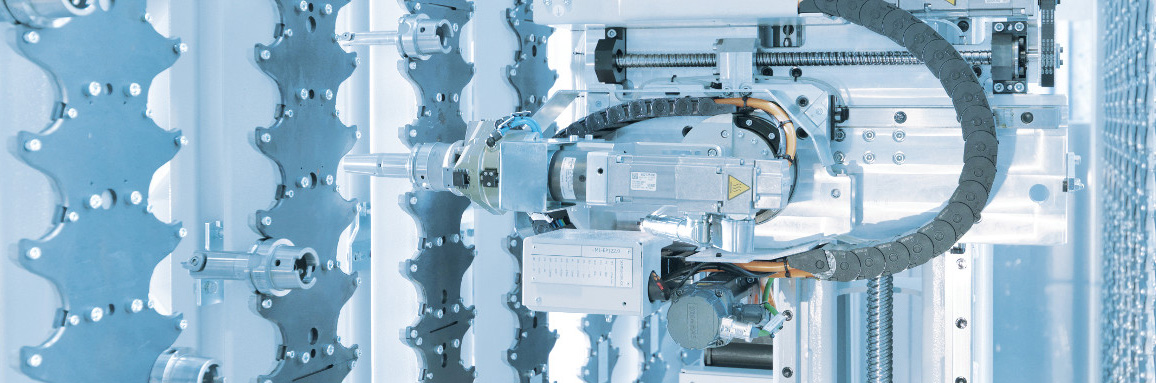

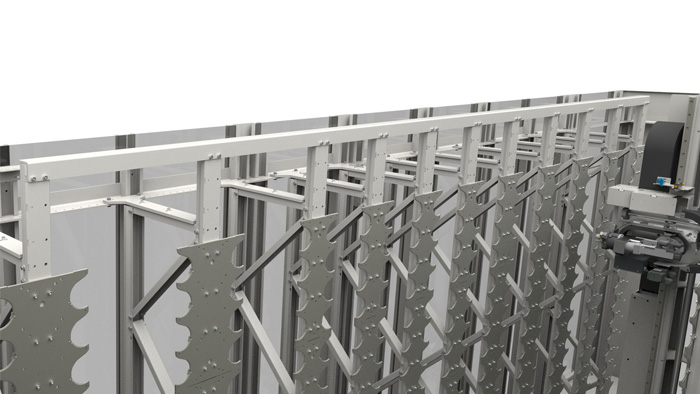

Toolmaster TM the centralized tool store

-

A centralized tool magazine for the automation of several machines

Toolmaster - tool handling for unmanned production

For unmanned production on several machines with small batch sizes, a large number of tools is required. The Toolmaster provides the machines with the right tools at any time.

- Storage capacity variable according to requirements (1,000 - 2,500 tools)

- Designed for different toolholder types (e.g. HSK63 or HSK100)

- Storage of different tool sizes in the centralized magazine

- Tool difference list of all missing tools for the tool pre-setter

- Subsequent integration of additional machines

- Reduction of the number of operators necessary by storing any number of twin tools

- Error-free data transmission using RFID technology

Benefits of using a Toolmaster TM

- Unmanned operation

Fully automated tool changes reduce operational staff to a minimum - Fewer tools

Intelligent software control allows multiple tools to be used in different machines, reducing the total number of tools necessary. - Optimum logistics

The centralized tool storage replaces multiple tool stores. A centralized operating station for several machines simplifies internal processes. - Software

The Palmaster and Toolmaster use a single software application with a common data base. This simplifies operation, reduces interfaces and increases the reliability of the overall system. - Tool management

Versatile options for connection to tool management systems and/or tool setting devices - Exchange during processing time

Tool changes in the tool magazine are executed in parallel machining times of the machining center, so that the machining processing is unaffected.

Typical applications of a Toolmaster

Tool Master for HSK tools

- In the central tool magazine, different tool diameters can be stored due to the flexible allocation of the tool combs, pictured here with HSK63 holders.

Toolmaster with small area gantry

- The PROMOT small area gantry allows the tool to be moved in all three axes. This makes it possible to solve difficult tool changes in the magazine of the machine tool.

Setup station with RFID data transmission

- Up to five tools can be stored or removed simultaneously in the Toolmaster setup station. The data is conveniently transferred by RFID, and data changes can be made at the operating terminal at any time. The Prosys software automatically generates lists for tool life times, unused tools and much more.

Tool Master with extended magazine capacity

- The Toolmaster magazine is available in different capacities. Thus, the most diverse production approaches can be realized.

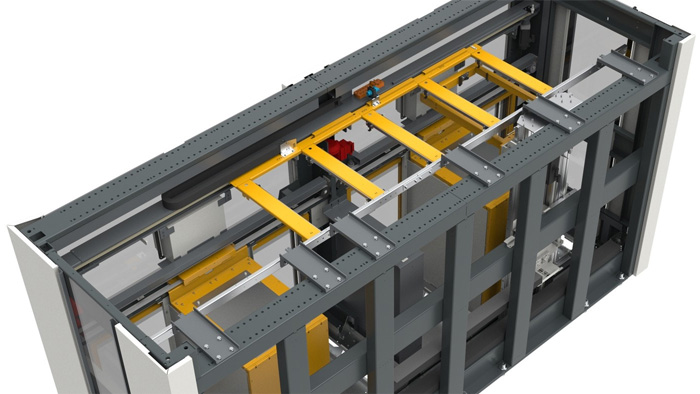

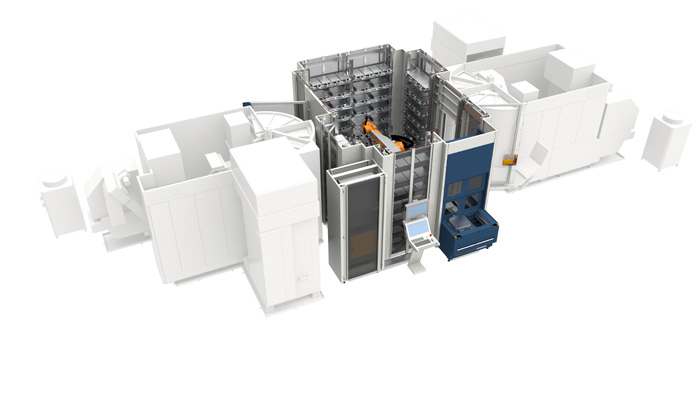

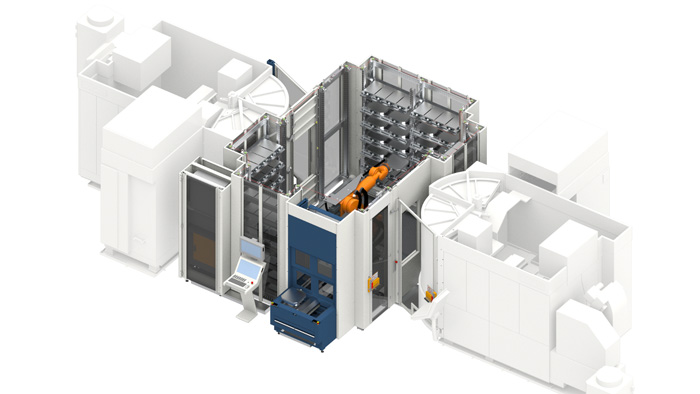

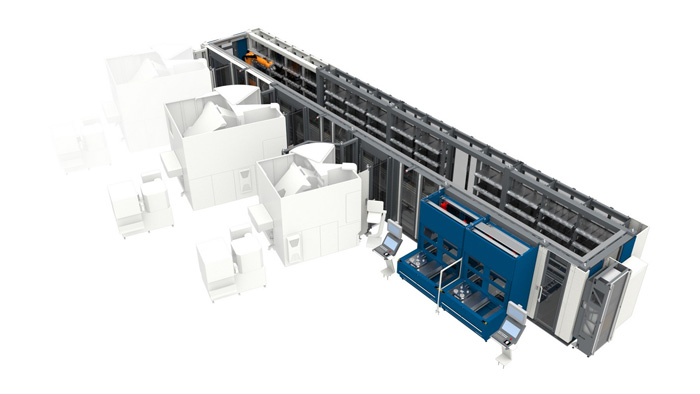

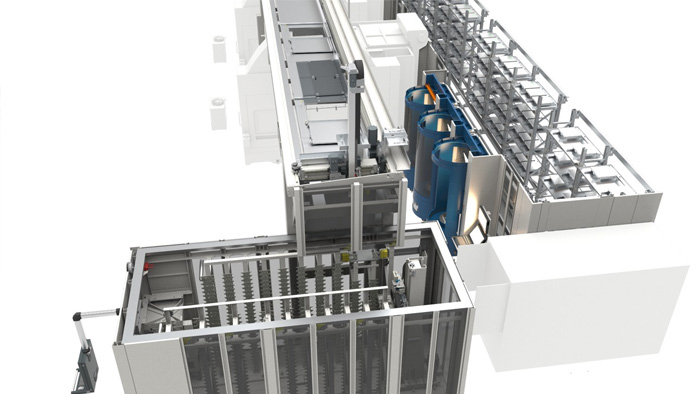

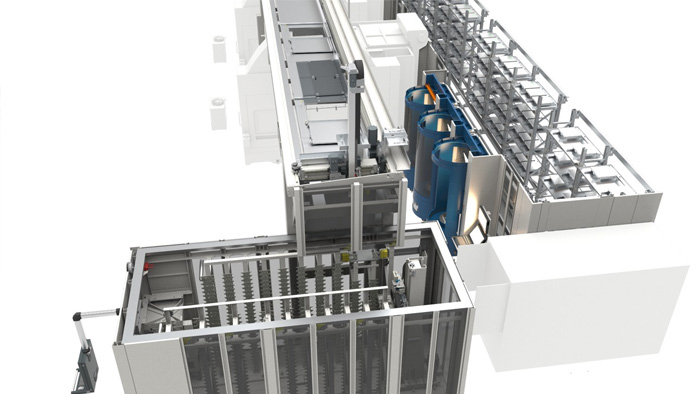

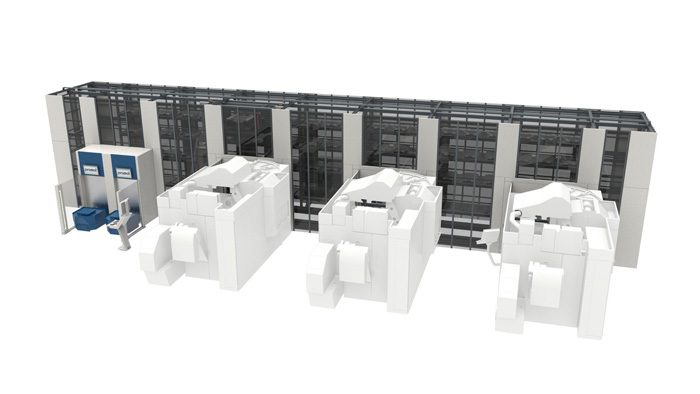

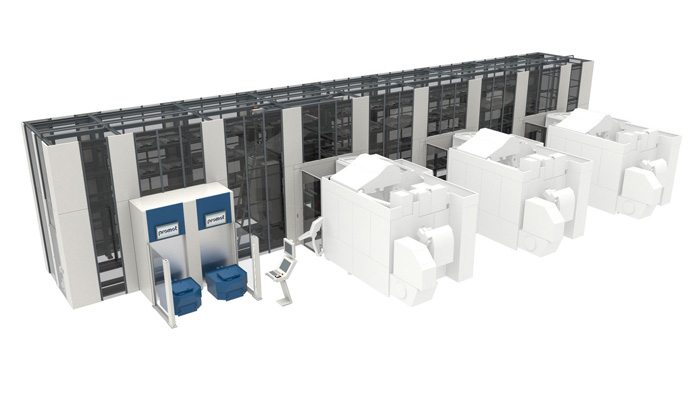

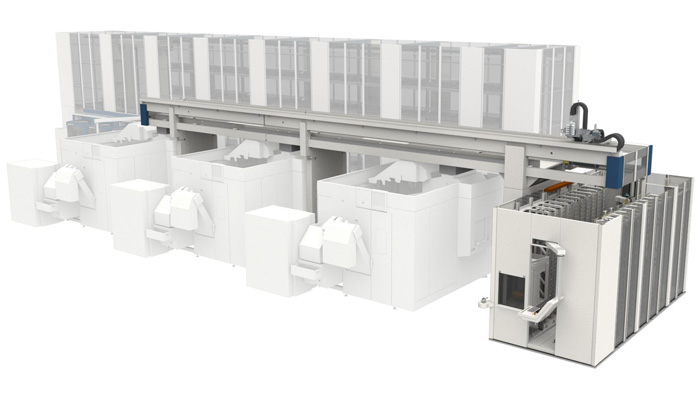

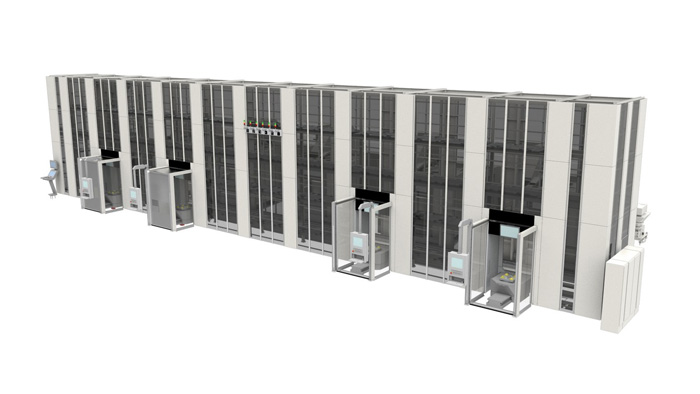

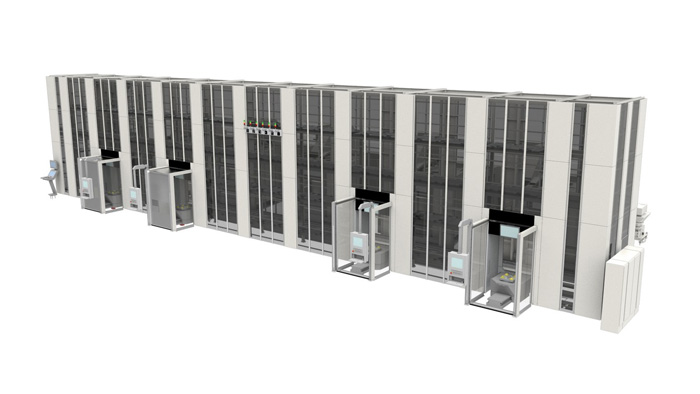

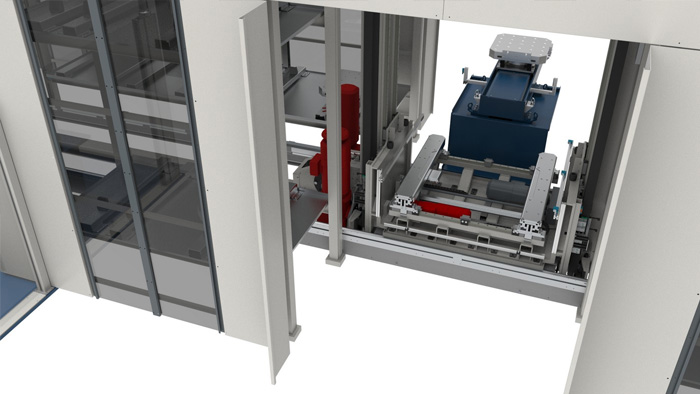

Palmaster FFS - Flexible Production System

- The flexible production system with a high-bay

warehouse for more machines

The Palmaster FFS creates the largest possible storage capacity by making optimum use of room height. The pallets and fixtures are stored in a fully automatic high-bay warehouse. Pallets are handled by a stacker crane for transport weights of up to 2,500 kg. Due to their modular design, both the high-bay warehouse and the stacker crane can be optimally adapted to the spatial conditions.- Pallet weights up to 2,500 kg

- Pallet size up to 1,000 x 1,000 mm, circle of rotation up to 1,600 x 1,250 mm

- High-bay warehouse for maximal storage capacity, making full use of the available hall height

- Different setup stations possible - with a revolving door or as a height-adjustable, variable-setup station

- Mixed storage of material and machine pallets possible

- Prosys production control software for optimized job control

- Toolmaster

The system can be extended at any time with the Toolmaster centralized tool storage system. - Productivity

Owing to its highly dynamic drive motion, the storage and retrieval machine increases throughput, leading to higher productivity - Capacity

The high-bay warehouse maximizes storage capacity and with your autonomy, especially for heavy pallets with a large circle of rotation - User friendly

Easy, intuitive operation with the Promot software ProSys, which can be adapted to your requirements. - Safe Investment

Low investment costs and higher productivity than with conventional production, thereby achieving rapid amortization - Unmanned production

Maximal storage capacity on account of the high-bay warehouse. The storage and retrieval machine ensures fast changeover times, which in turn increases autonomy and productivity.

Typical applications of a Palmaster FFS

FFS with a variable-setup station

- The variable-setup station is height-adjustable and rotatable, thus ensuring the ergonomics of all set-up activities. The double set-up station makes re-clamping easy.

FFS with Toolmaster

- The Toolmaster provides the machines with the right tools at any time. The setup stations can be arranged flexibly

Flexible layout

- Due to its modular construction, we can tailor the layout to your individual production processes. The setup stations and machines can be paced variably

FFS with material storage

- The flexibility of the Pallet Master FFS also enables the storage of material pallets. To accomplish this Promot has created not only special Input/Output stations but also the perfect software solution to manage it all.

Palmaster Workshop / Palmaster Prosys / Toolmaster TM

Palmaster Workshop – permanently sink costs per part

- Together we can find the optimal automation solution

Our common, declared goal is to reduce cost per part. Therefore, we work closely with our customers, examining the entire process chain down to the last detail in order to find the optimal solution.- Automation alone is only one part of the solution, so the entire process chain has to be taken into consideration

- We support our customers with methodical and well-structured workshops, both in the project planning and in the execution phase

- Your employees involved in the workshop are actively involved in the process

- The experience of more than 35 years in the automation of machine tools

and successful problem-solving from numerous projects in our own

production flow into the workshop

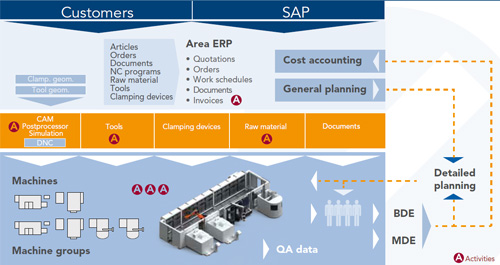

Palmaster Prosys - production control software

- The Prosys production control software for optimized

manufacturing

With our modular software, Prosys, numerous production strategies can be realized. Beside many others the following key features are available:- Production / order planning

- Part administration

- Process management

- Pallet and pallet type management

- Fixture and fixture-type management

- Tool difference list including calculation of remaining life time

- NC program management

- Interface to ERP software

- Machine data acquisition

- Automatic display of setup documents and images

- Automatic versioning of NC programs

- SMS / E-Mail messenger system

- Ability to set various operator permission levels

Toolmaster TM – the centralized tool store

- Toolmaster - tool handling for unmanned production

For unmanned production on several machines with small batch sizes, a large number of tools is required. The Toolmaster provides the machines with the right tools at any time.- Storage capacity variable according to requirements (1,000 - 2,500 tools)

- Designed for different toolholder types (e.g. HSK63 or HSK100)

- Storage of different tool sizes in the centralized magazine

- Tool difference list of all missing tools for the tool pre-setter

- Subsequent integration of additional machines

- Reduction of the number of operators necessary by storing any number of twin tools

- Error-free data transmission using RFID technology