- Offer Profile

- BURKHARDT+WEBER built the first transfer line in Europe in 1951 and introduced the world's first NC-controlled machining centre in 1959 - at the time with punched tape control. BW was one of the pioneers in digital control technology, had the first true rack magazine and is to this day a world leader in tool magazine technology – often copied, never equalled, the automatic tool extension and many, many other developments that are typically BW.

MCX – Roller-guided machining centres

-

The latest version of the successful MCX machining centres, with a well-conceived classification into 9 different types with 1,400 to 4,800 mm swing diameter and 1,500 to 20,000 kg payload. Robust sizing and performance, rapid traversing speeds of up to 65 m/min and acceleration to 5 m/s² ensure outstanding dynamics and short downtimes. A top-class machining centre that leaves nothing to be desired.

Dynamics and power for universal use.

All MCX machining centres are robustly dimensioned, featuring high-torque spindle units and preloaded precision ball-screw drives or, in the case of very large travel ranges, a high-precision rack-and-pinion drive. This guarantees high long-term accuracy, even in the case of rough machining combined with fine machining.- Roller-guided.

- 1,400 to 3,700 mm swing Diameter (option 4,800 mm).

- Work pieces to 4,100 x 3,000 x 3,200 mm.

- Payload from 1,500 to 20,000 kg.

- Rapid traversing speeds up to 60 m/min.

- Acceleration up to 5 m/s2.

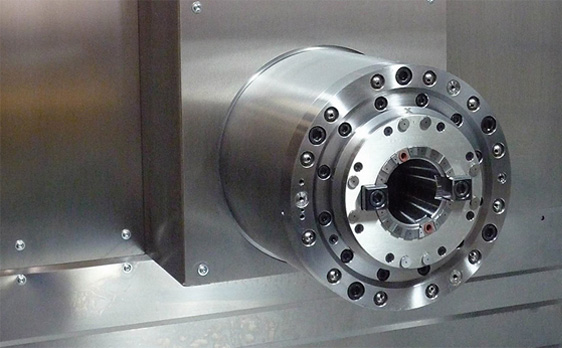

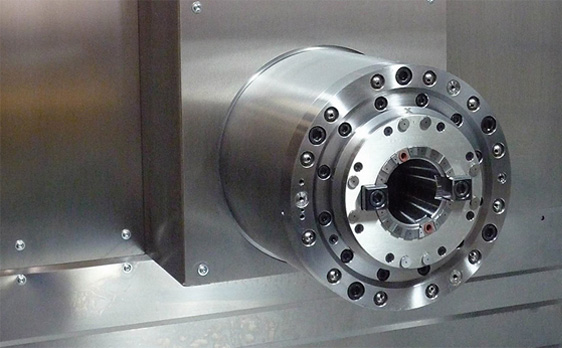

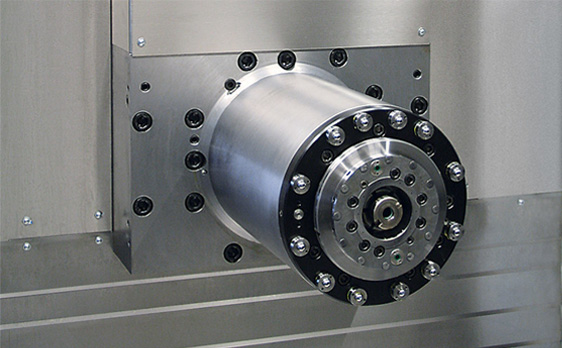

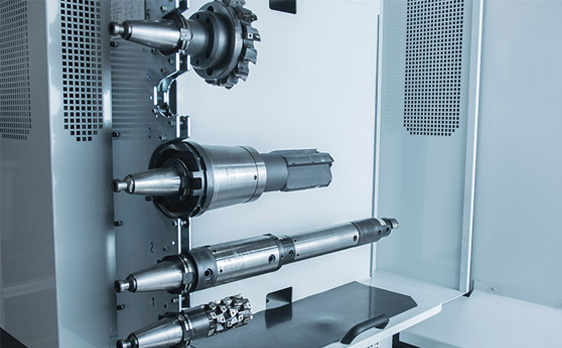

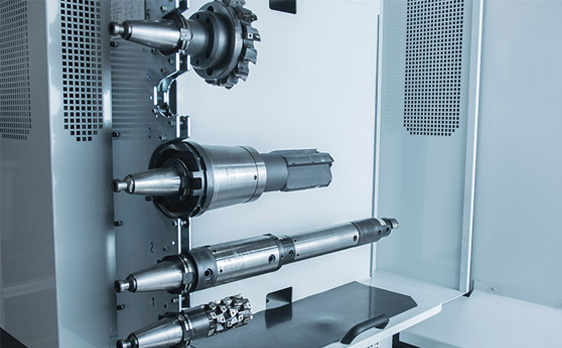

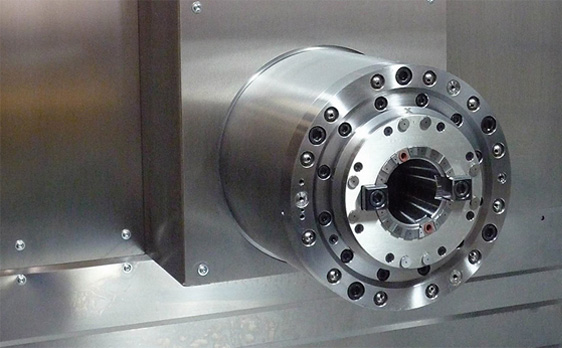

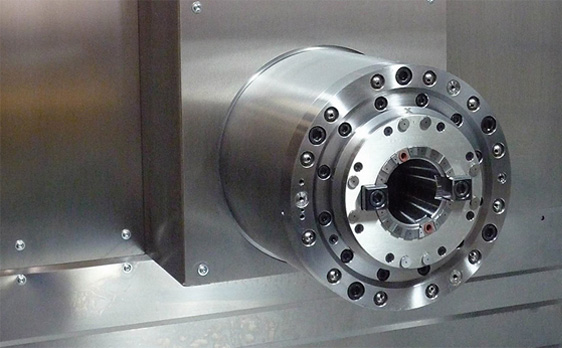

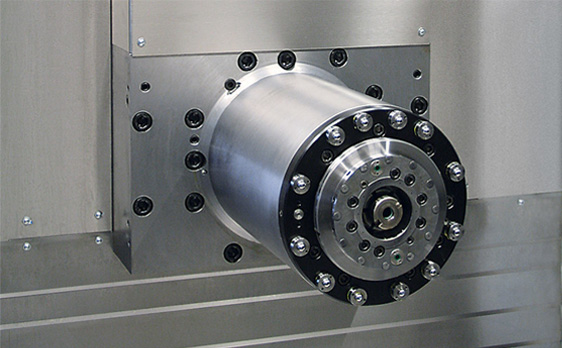

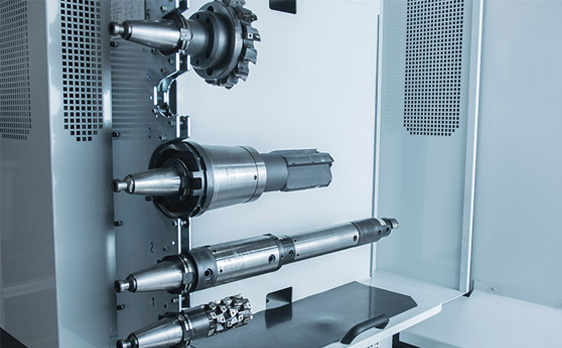

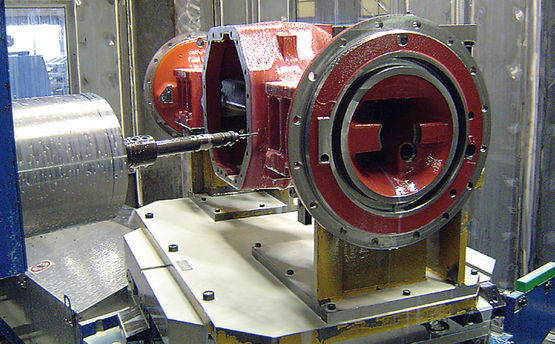

MACHINING UNIT

-

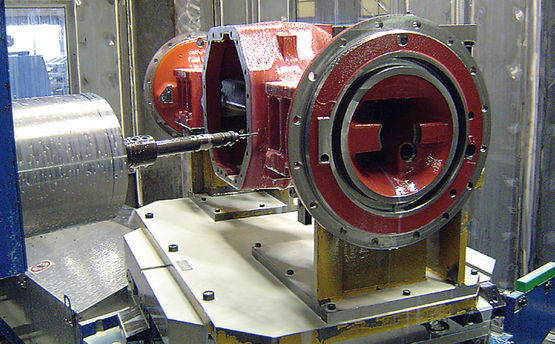

- Made by BURKHARDT+WEBER.

- Powerful and robustly dimensioned.

- Strictest quality controls.

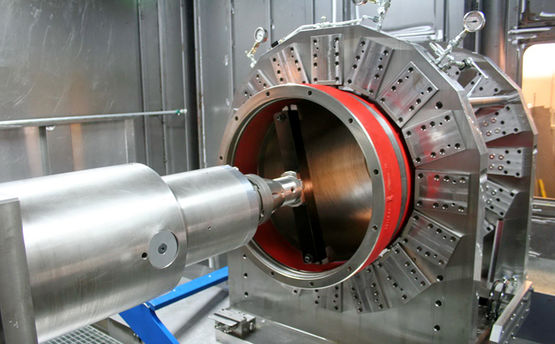

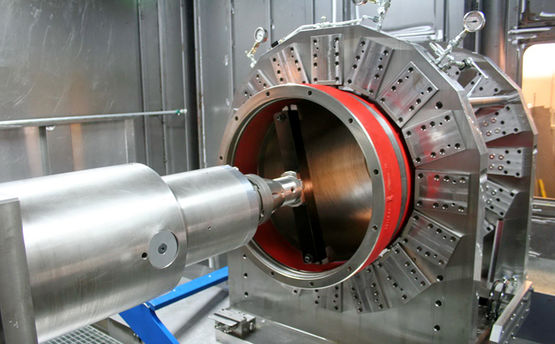

- 24-hour load spectrum on BW test stand with programmable counter-loads.

2-STAGE HORIZONTAL

- Powerful gear spindles, up to 60 kW and 1,985 Nm.

- Up to 10,000 rpm for state-of-the-art tools.

2-STAGE HORIZONTAL

- Powerful gear spindles for heavy machining, up to 80 kW, 3,600 Nm.

- Generously dimensioned bearings with large support span and speeds up to 5,000 rpm.

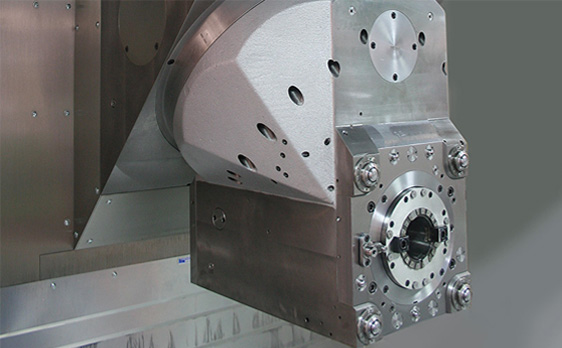

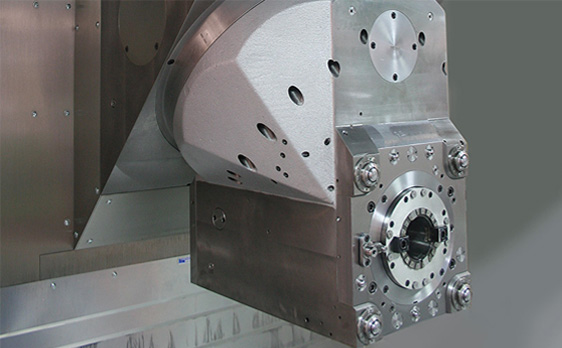

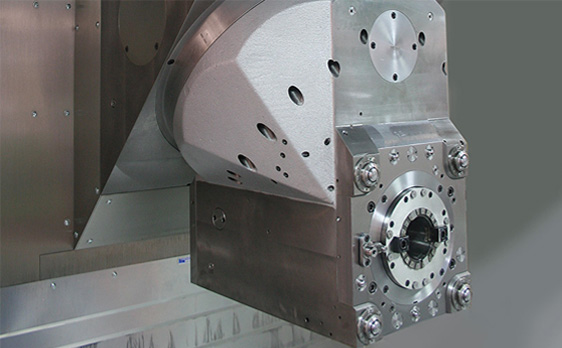

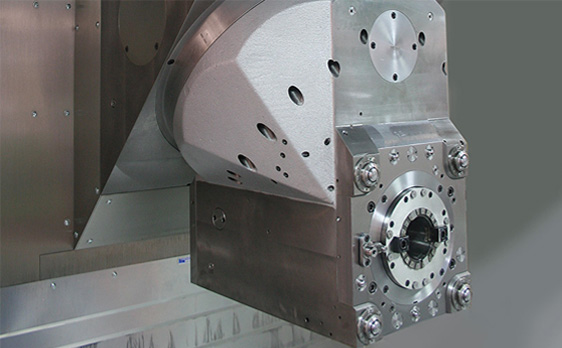

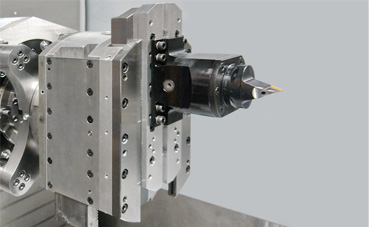

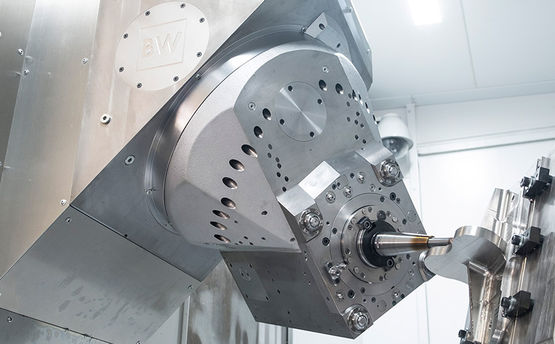

5-AXIS SWIVEL HEAD.

- NC-controlled, two gear stages.

- Up to 58 kW, 1,980 Nm, 8,000 rpm.

- 5-axis simultaneous machining.

- Generously-dimensioned bearing and high holding torque.

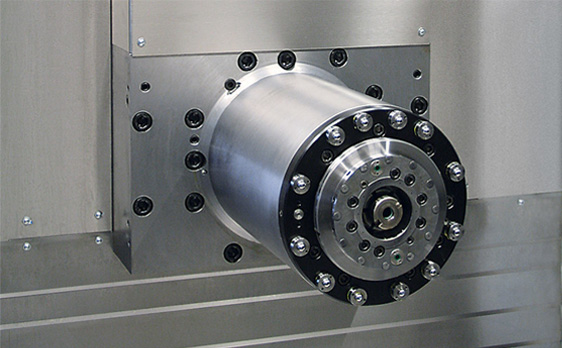

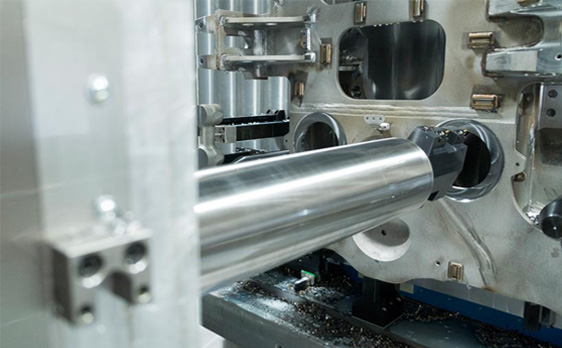

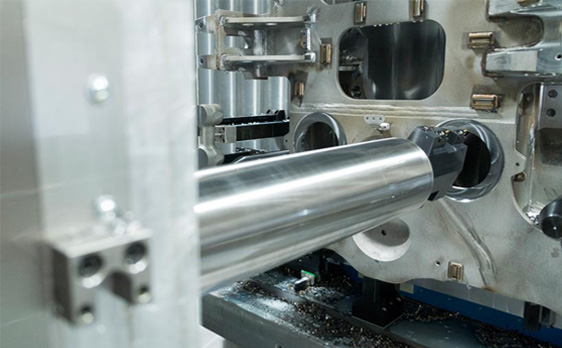

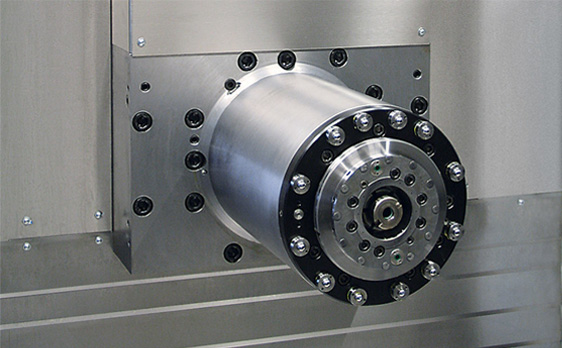

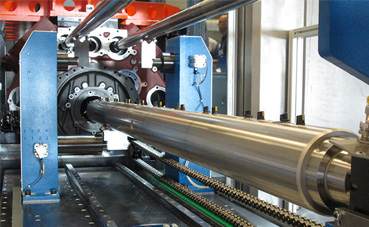

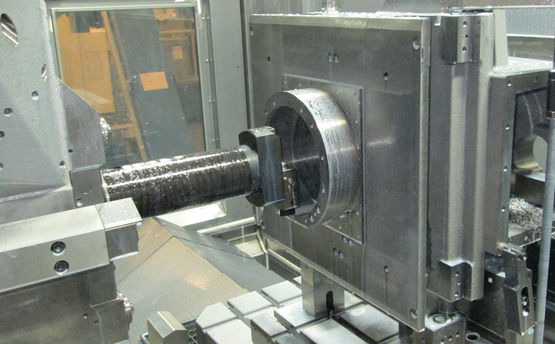

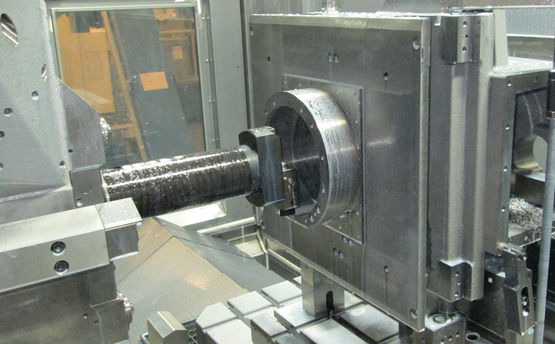

QUILL SPINDLE

- 2-speed transmission unit.

- Up to 60 kW, 2,000 Nm, 4,000 rpm.

- D 160 mm / 1,000 mm stroke.

- 2 feed motors.

- Automatic length and sag compensation in the µ range.

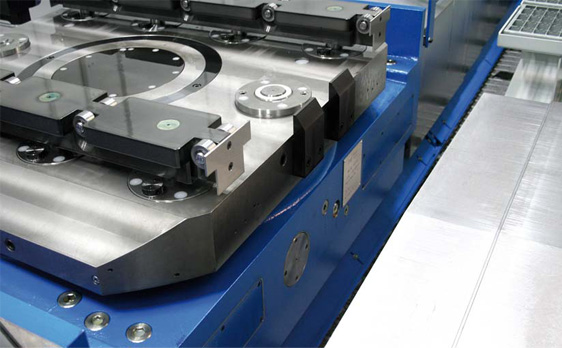

MACHINE TABLES AND PALLETS

-

- Made by BURKHARDT+WEBER.

- Pallet loads from 1,500 kg to 20,000 kg.

- Particularly high tilting and tangential moments due to low table design and generously dimensioned axial roller bearings and holding brakes for optimum machining performance and excellent geometric results.

- For pallet loads over 12,000 kg, all tables have hydrostatic axial and radial bearings.

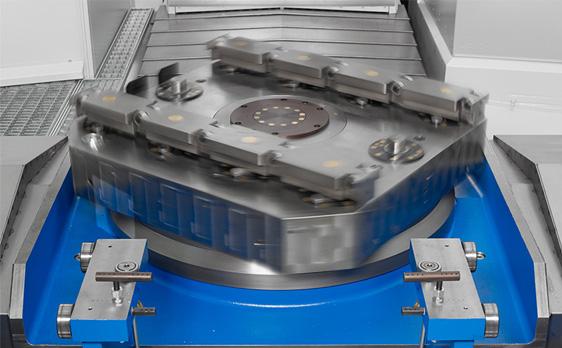

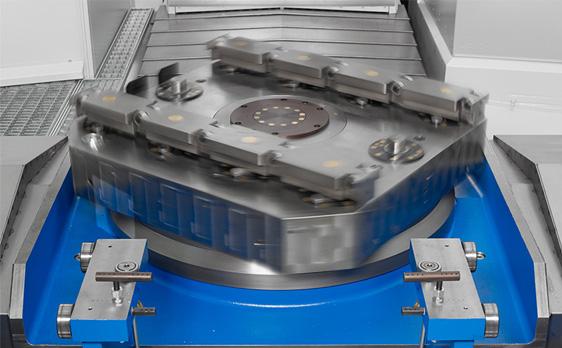

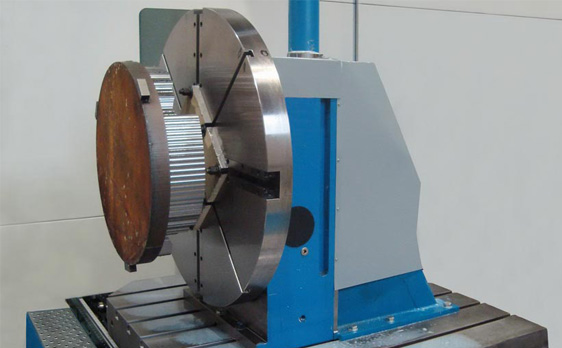

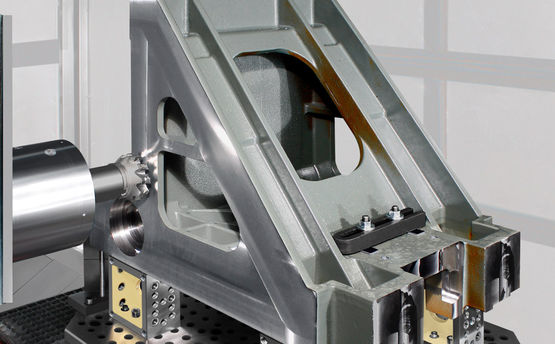

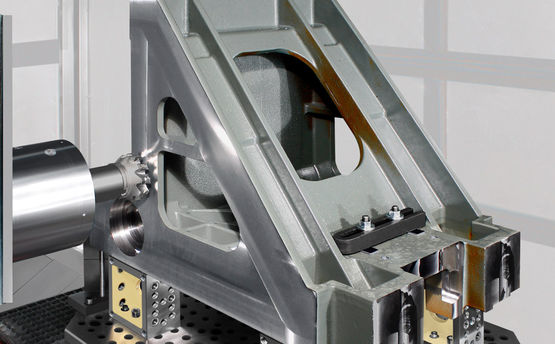

ROTARY/TILTING TABLE

- Simultaneous 5-axis machining with horizontal spindle or in combination with pivoting spindle.

- Generously dimensioned NC tilting table. Machine table integrated in a heavily ribbed, non-flexing swing bridge.

- High dynamic and positioning accuracies.

- All spatial positions are reproducible. Optimum chip clearance.

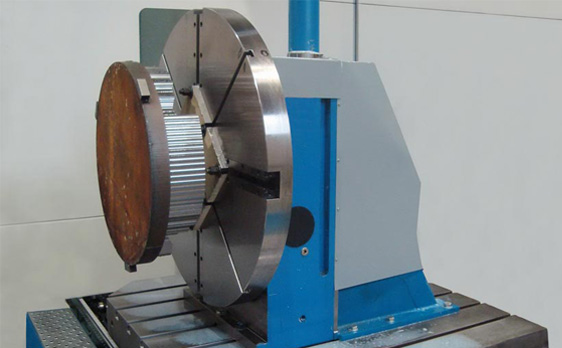

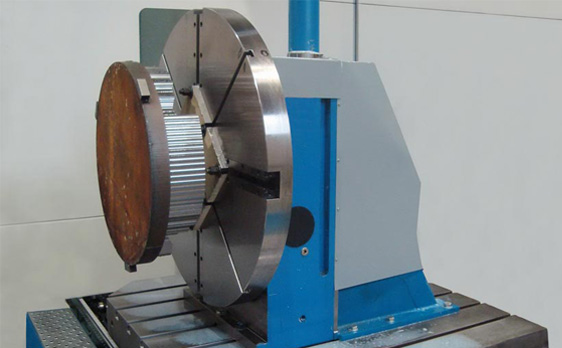

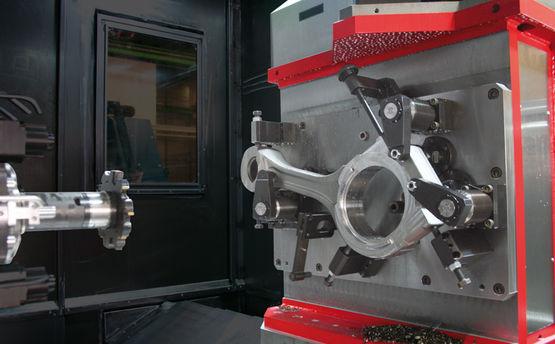

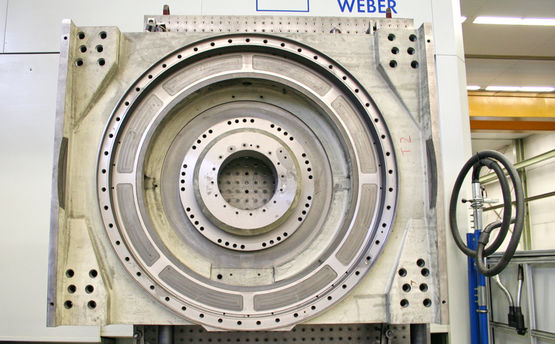

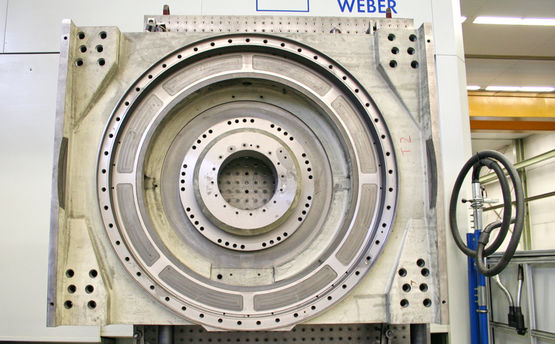

FACE PLATES

- Face plates fitted vertically on the machine table.

- Optimum chip clearance and easy access when using short tools

- With a 5th NC-controlled axis

- Face plate diameter up to 2,000 mm

- Automatic switching from the pallet changer tooling station to the working area.

- Reliable and virtually wear-free thanks to cable-guided connection (no couplings).

- Face plate surfaces are freely configurable, because they are made in-house.

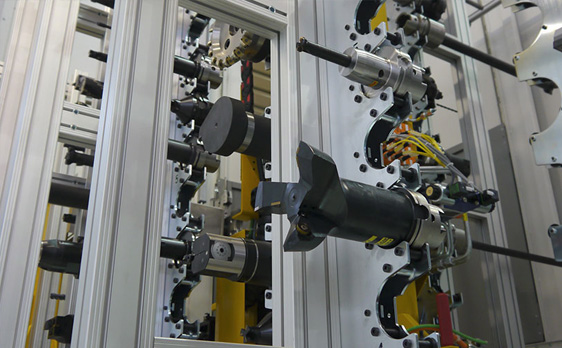

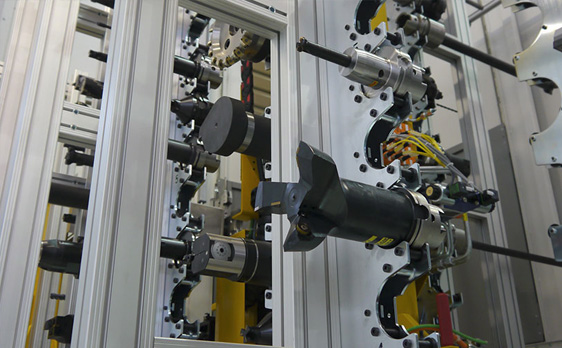

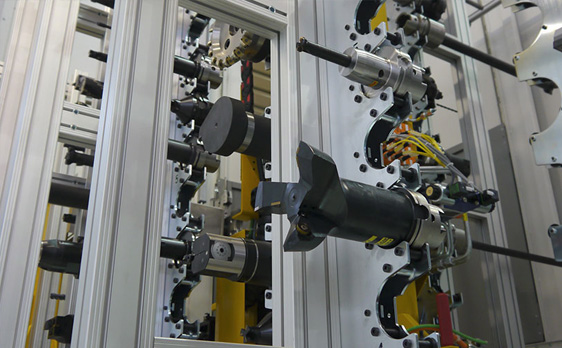

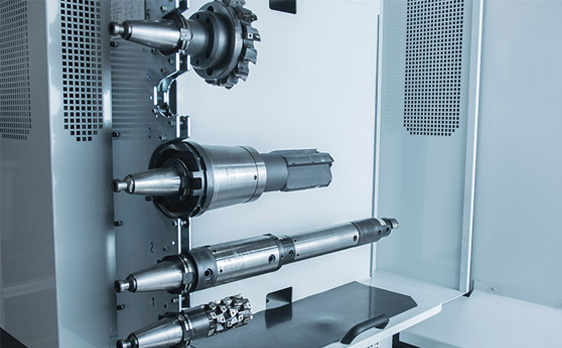

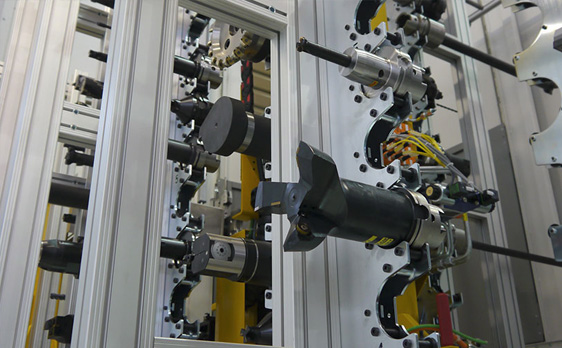

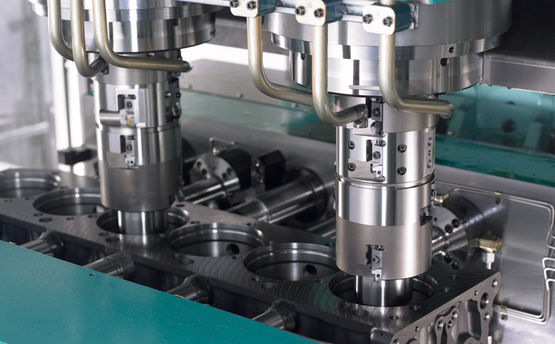

TOOL MAGAZINE

-

The modular, highly flexible tool magazines are peerless and market-leading worldwide.

- Made by BURKHARDT+WEBER.

- Maximum capacity of 608 tools.

- 5 highly dynamic NC axes.

- Traversing speeds up to 200 m/min.

- Changeable weight up to 60 kg, tilting moment up to 150 Nm.

- Tool lengths up to 1200 mm.

- Boring bar diameters up to 900 mm.

- Automatic determination of the tool tilting moment and weight.

- Application-oriented pre-storage and comprehensive tool management for maximum convenience.

- Every magazine can be fully customised at the time of ordering and easily retrofitted or expanded, if required, even years later.

- Loading and unloading at a loading station with 2 x 8 locations operating in parallel with machining.

- Clever tool management and 21" smart control panel (optional).

- Tool data transfer via chip, print code or online.

Versions:- 128 locations in basic version for series production.

- 352 locations for machining workpiece families.

- 608 locations for maximum flexibility.

We develop customer-specific solutions for special applications, such as automatic insertion equipment for very long series boring bar lengths up to 3,000 mm or 8 additional magazines for fast changeover of special tools weighing up to 500 kg each.

MCC- The ultra-compact series

-

HIGHLY PRODUCTIVE MACHINING CENTRES.

As a stand-alone machine in 630 pallet format or as part of an interlinked production system.

The MCC series consequently expands the lower end of the BW range. The new compact machine combines all BW key features: power, accuracy, outstanding stiffness and availability.

Whether a horizontal unit with power gear spindle or A-axis for the 5-axis performance. Large bearings and a wide distance between the guide elements offer an outstanding stiffness. With its high torque values the machine is a real workhorse. The result: powerful cutting capacity for the machining of steel, cast iron and titanium.

Equipped with the BW characteristic rack-type tool magazine and with cutting-edge information and communication technology the machines can be interlinked – but they are also ready for digital networking in self-organised production processes.

BW machining centres are normally highly individual. With the MCC, however, we have developed a standard production machine, which offers the specific features required for its typical use. The proven design of the large machining centres has been adopted which makes the MCC a 100% BURKHARDT+WEBER machine.Technical data MCC-series:

- Working range up to X | Y | Z mm 1,100 | 900 | 1,100 (1,300)

- swing diameter Ø x H mm 1,100 x 1,300

- Pallet size mm 630 x 630 (630 x 800)

- Rapid traverse X | Y | Z m/min 60 | 60 | 60

SWIVEL SPINDLE- Spindle power, 100 % duty cycle kW 30 HP 40

- Max. torque, 100 % duty cycle Nm 300

- Standard speed range rpm 20 – 6,000 (10,000)

- Swivel range degr +45 / -110

MOTOR SPINDLE- Spindle power, 100 % duty cycle kW 30

- Max. torque, 100 % duty cycle Nm 300

- Standard speed range rpm 20 – 6,000 (10,000)

GEAR SPINDLE- Spindle power, 100 % duty cycle kW 41

- Max. torque, 100 % duty cycle Nm 1,300

- Standard speed range rpm 20 – 6,000 (10,000)

- Number of tool positions 64 – 128 (256) 64 – 128 (256) Max. tool weight kg 30 (40)

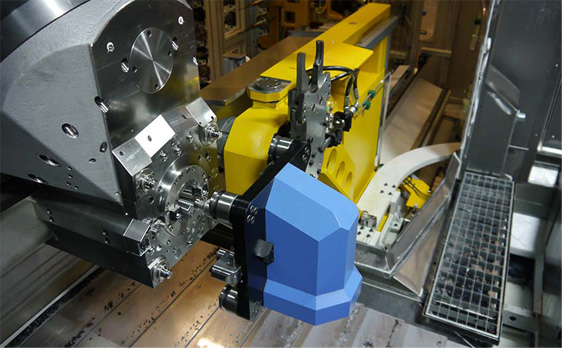

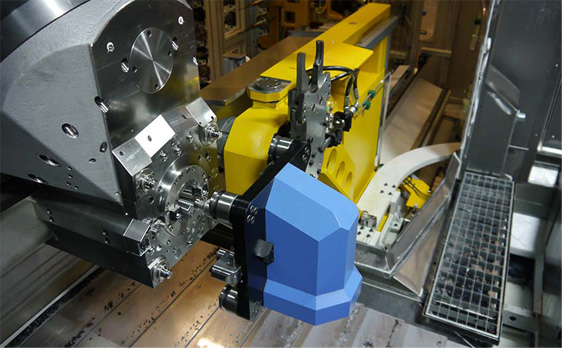

MCT – Milling/turning machining centres

-

MILLING, TURNING AND DRILLING – MCT SERIES MULTITASKING MACHINING CENTRES.

The six MCT machining centres are designed specifically for multitasking applications. Milling, drilling, turning – all on one machining centre with high power density thanks to NC-controlled tilting spindle, rugged turning tool holder and fast-turning torque table. Integrated horizontal and vertical turning replaces use of multiple additional lathes.

Maximum efficiency through flexibility.

BW's own rotary tables with powerful torque motors for turning and generously dimensioned holding brakes for milling and drilling permit demanding steel and cast-iron machining operations with maximum cutting performance. All BW options of other series are also available for the MCT series. The MCT machining centres can also be operated together with other BW machining centres in one system, because the same pallets are used.

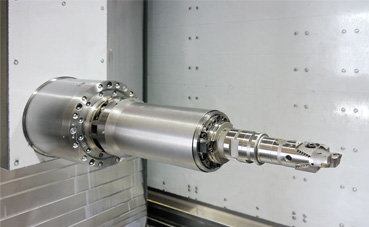

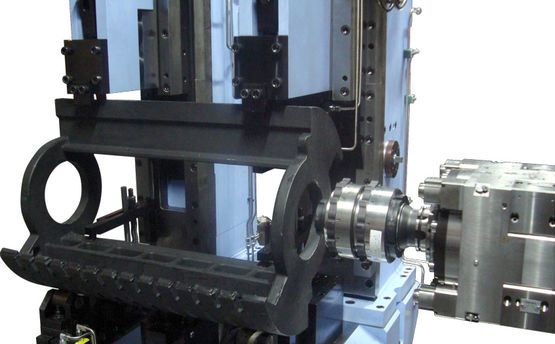

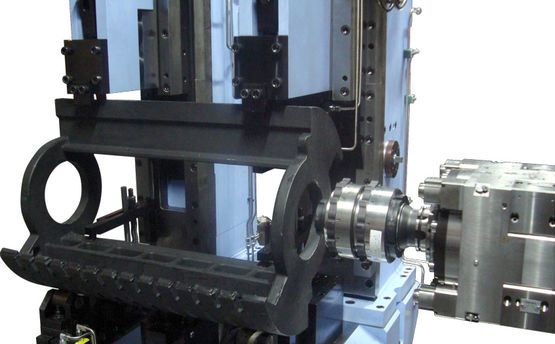

MACHINING UNIT

-

- Made by BURKHARDT+WEBER.

- Powerful and generously-supported horizontal/vertical head.

- To accommodate the optional turning tool holder, the swivel head is equipped as standard with a sturdy four-point clamping system.

- Assembled by highly experienced employees.

- Strictest quality controls.

- 24-hour load spectrum on BW test stand with programmable counter-loads.

- NC-controlled as HVP positioning head or as a fully-fledged 5-axis HVC swivel head.

- Each with 8,000 rpm an up to 56 kW / 2,000 Nm thanks to two gear stages.

- Swivel time 2 s at full speed.

- Turning tools are automatically loaded from the tool magazine into a special turning tool holder.

- Turning tool holder with quadruple hydraulic clamping on the spindle unit.

- The vertical precision spindle bearing arrangement bears no stress whatsoever during turning. All forces are absorbed by the 4 hydraulic clamping sleeves, which also feature large support spacing for reliable absorption of all lateral forces.

MACHINE TABLE AND PALLETS

-

- Fast-turning, high-performance milling/turning tables.

- Made by BURKHARDT+WEBER.

- Speeds up to 650 rpm.

- Loads of up to 7,000 kg, 4,000kg in turning mode.

- Automatic balancing cycle with unbalance monitoring during turning operation.

- Display of the position and weight of balancing aids.

- Reliable disconnection in milling mode by means of a generously dimensioned brake disc, no rotating of the position when hydraulic brake pressure is applied.

- High-performance, all-round cooling of the torque motor from 4 sides to prevent heat growth in one direction.

- Special pallet surfaces are possible, because they are produced in-house.

- Optional hydraulic couplings. Turning is performed contact-free and consequently virtually wear-free. Multiple pressure levels possible.

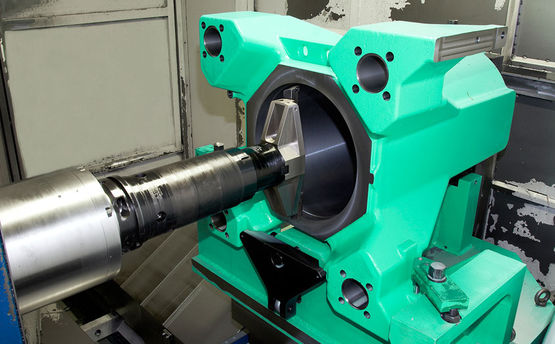

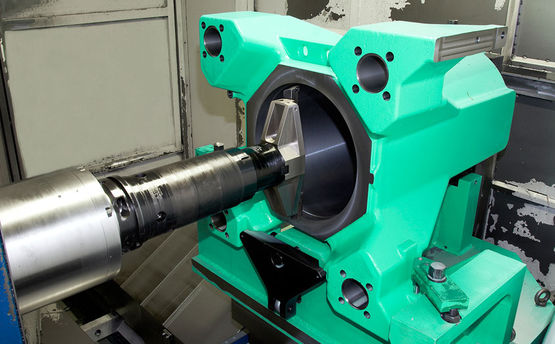

- Quality and functional acceptance testing on specially designed table testing station at BW.

TOOL MAGAZINE

-

The modular, highly flexible tool magazines are peerless and market-leading worldwide.

- Made by BURKHARDT+WEBER.

- Maximum capacity of 608 tools.

- 5 highly dynamic NC axes.

- Traversing speeds up to 200 m/min.

- Changeable weight up to 60 kg, tilting moment up to 150 Nm.

- Tool lengths up to 1200 mm.

- Boring bar diameters up to 900 mm.

- Automatic determination of the tool tilting moment and weight.

- Application-oriented pre-storage and comprehensive tool management for maximum convenience.

- Every magazine can be fully customised at the time of ordering and easily retrofitted or expanded, if required, even years later.

- Loading and unloading at a loading station with 2 x 8 locations operating in parallel with machining.

- Clever tool management and 21" smart control panel (optional).

- Tool data transfer via chip, print code or online.

Versions:- 128 locations in basic version for series production.

- 352 locations for machining workpiece families.

- 608 locations for maximum flexibility.

MCR – Slide-guided machining centres

-

MCR – THE ULTRA-HEAVY SERIES.

THE MCR SERIES OF SLIDE-GUIDED MACHINING CENTRES.

The perfect solution for all applications calling for heavy-duty cutting with optimum damping characteristics, coupled with high-precision fine machining. BW offers nine different types with 1,400 to 3,500 mm (option 4,800 mm) workpiece swing diameter and 1,500 to 20,000 kg payload.

Pure power for difficult machining tasks.

MCR machining centres are very robustly dimensioned and feature high-performance spindle units. In addition to the cast-iron gantry column, extra-wide laser-hardened sliding guides guarantee optimum damping characteristics during machining of difficult materials as well as very high long-term precision due to extremely low surface pressures.

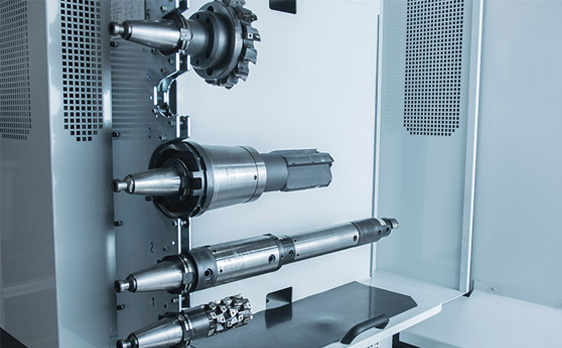

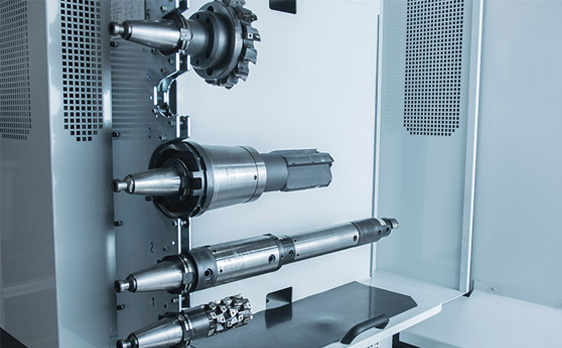

MACHINING UNIT

-

- Made by BURKHARDT+WEBER.

- Powerful and robustly dimensioned.

- Strictest quality controls.

- 24-hour load spectrum on BW test stand with programmable counter-loads.

2-STAGE HORIZONTAL

- Powerful gear spindles, up to 60 kW and 1,985 Nm.

- Up to 10,000 rpm for state-of-the-art tools.

2-STAGE HORIZONTAL

- Powerful gear spindles for heavy machining, up to 80 kW, 3,600 Nm.

- Generously dimensioned bearings with large support span and speeds up to 5,000 rpm.

5-AXIS SWIVEL HEAD.

- NC-controlled, two gear stages.

- Up to 58 kW, 1,980 Nm, 8,000 rpm.

- 5-axis simultaneous machining.

- Generously-dimensioned bearing and high holding torque.

MACHINE TABLES AND PALLETS

-

- Made by BURKHARDT+WEBER.

- Pallet loads from 1,500 kg to 20,000 kg.

- Particularly high tilting and tangential moments due to low table design and generously dimensioned axial roller bearings and holding brakes for optimum machining performance and excellent geometric results.

- For pallet loads over 12,000 kg, all tables have hydrostatic axial and radial bearings.

FACE PLATES.- Face plates fitted vertically on the machine table.

- Optimum chip clearance and easy access when using short tools

- With a 5th NC-controlled axis

- Face plate diameter up to 2,000 mm

- Automatic switching from the pallet changer tooling station to the working area.

- Reliable and virtually wear-free thanks to cable-guided connection (no couplings).

- Face plate surfaces are freely configurable, because they are made in-house.

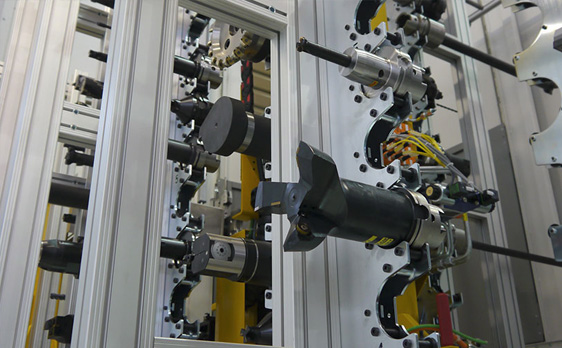

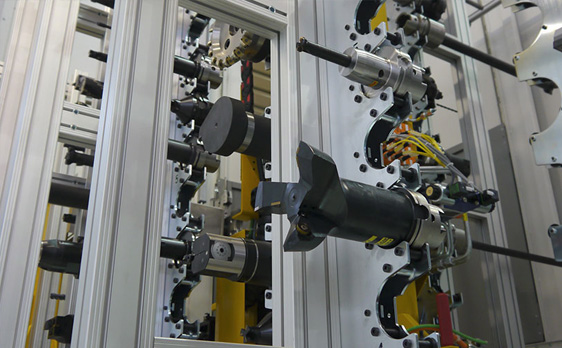

TOOL MAGAZINE

-

The modular, highly flexible tool magazines are peerless and market-leading worldwide.

- Made by BURKHARDT+WEBER.

- Maximum capacity of 608 tools.

- 5 highly dynamic NC axes.

- Traversing speeds up to 200 m/min.

- Changeable weight up to 60 kg, tilting moment up to 150 Nm.

- Tool lengths up to 1200 mm.

- Boring bar diameters up to 900 mm.

- Automatic determination of the tool tilting moment and weight.

- Application-oriented pre-storage and comprehensive tool management for maximum convenience.

- Every magazine can be fully customised at the time of ordering and easily retrofitted or expanded, if required, even years later.

- Loading and unloading at a loading station with 2 x 8 locations operating in parallel with machining.

- Clever tool management and 21" smart control panel (optional).

- Tool data transfer via chip, print code or online.

Versions:- 128 locations in basic version for series production.

- 352 locations for machining workpiece families.

- 608 locations for maximum flexibility.

We develop customer-specific solutions for special applications, such as automatic insertion equipment for very long series boring bar lengths up to 3,000 mm or 8 additional magazines for fast changeover of special tools weighing up to 500 kg each.

MCµ – Ultra-precise machining centres

-

ULTRA-PRECISE MACHINING CENTRES – UNCOMPROMISING IN EVERY DETAIL.

Machines in the MCµ series are designed for ultimate precision and long-term accuracy. Close to µ accuracy and – as always at BW – not just on the day of commissioning, but over many years of use. The MCµ series is no standard machine trimmed for accuracy. The MCµ is based much more on a fundamentally new concept. Because the final µ is the result of many specific individual measures, such as careful design, best materials, strict production methods and very experienced employees. MCµ: Accuracy by design, not compensation.

The result is the most precise machine series we've ever built.

When accurate is not accurate enough.

The MCµ provides tightest geometric tolerances (positioning, flatness, radial eccentricity, concentricity, angularity, repositioning) for the most demanding applications. The basis for long-term accuracy is maximum stability from the ground up. High guide bars, FEM-optimised structures cast from mineral casting material, a thermally inert system and active tempering are examples of the many measures taken. BW's very high degree of vertical integration in all core components is decisive for the successful implementation of such accurate machines.

Quality philosophy

The µ on the finished component depends on many factors: positioning accuracy, machine geometry, tool concentricity, fixture warpage, material characteristics, process sequence, temperature differential and measuring method. Consequently, every component of an MCµ is subject to the tightest tolerances and undergoes special quality assurance measures, just like the finished machine. Finally, comprehensive measurements are taken of every single MCµ.

Employee expertise

The key to successful production of an MCµ lies in the extremely high qualification level of our employees. We have been building high-precision machining centres successfully for almost 60 years now. Our philosophy, calling for continuous optimisation of every component and process, is practised every day in our committed team of perfectionists.

Cost-effectiveness

Cost pressure is leading to fewer and fewer clamping operations, which in turn leads to more complex components. This is significantly increasing the demands on machining, while rapidly reducing the joining component. The MCµ targets mounting rather than adjustment.

Customization

BURKHARDT+WEBER builds highly customised machining centres. The same applies unreservedly to the MCµ series. We have broad expertise in the production of high-precision components, not least due to the high degree of vertical integration with our own precision components, and from many customer projects.

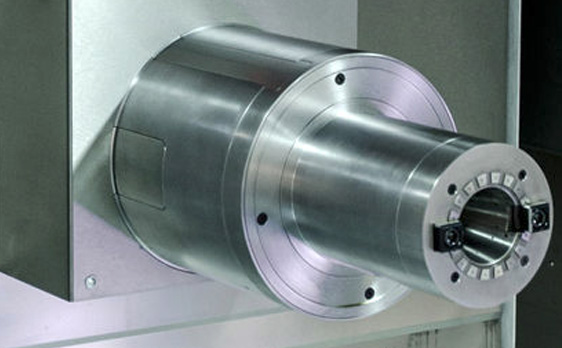

MACHINING UNIT

-

- Made by BURKHARDT+WEBER.

- Gearless and directly driven.

- Assembled by highly experienced employees.

- Strictest quality controls.

- 24-hour load spectrum on BW test stand with programmable counter-loads.

- Highest surface qualities demand the best possible concentricity and total absence of vibration. Consequently, BW only installs gearless spindle units in the MCµ, whose drive system operates decoupled from all vibration.

- With 610 Nm, 32 kW (S1) and speeds up to 6,000 rpm, cost-effective precision machining of all materials is guaranteed.

- The slim but nevertheless expansive spindle design allows loading of the spindle in house with short tools optimised for concentricity.

- The complete spindle cooling system with linear expansion compensation ensures stable length ratios in the process.

MACHINE TABLES AND PALLETS

-

- Made by BURKHARDT+WEBER.

- Best axial eccentricity and maximum swing-in accuracy.

- Highly elaborate production of table housing and head plate.

- Precision bearings and worm gears of utmost quality.

- Extremely careful assembly with frequent coordination of dimensions.

- Guarantees virtually no axial eccentricity and tightest swing-in accuracies.

- Naturally, all table units of the MCµ series are designed in-house at BW.

- Production by our experienced specialists in-house.

- Comprehensively designed run-in tests and measurements are additional safeguards for high BW quality.

TOOL MAGAZINE

-

The modular, highly flexible tool magazines are peerless and market-leading worldwide.

- Made by BURKHARDT+WEBER.

- Maximum capacity of 608 tools.

- 5 highly dynamic NC axes.

- Traversing speeds up to 200 m/min.

- Changeable weight up to 60 kg, tilting moment up to 150 Nm.

- Tool lengths up to 1200 mm.

- Boring bar diameters up to 600 mm.

- Automatic determination of the tool tilting moment and weight.

- Application-oriented pre-storage and comprehensive tool management for maximum convenience.

- Every magazine can be fully customised at the time of ordering and easily retrofitted or expanded, if required, even years later.

- Loading and unloading at a loading station with 2 x 8 locations operating in parallel with machining.

- Clever tool management and 21" smart control panel (optional).

- Tool data transfer via chip, print code or online.

Versions:- 128 locations in basic version for series production.

- 352 locations for machining workpiece families.

- 608 locations for maximum flexibility.

Special-purpose machines

-

MAXIMUM PROCESS RELEVANCE THANKS TO CUSTOMIZED DESIGNS.

With special-purpose machines and interlinked overall systems, we orient ourselves fully to your requirements for high output with optimum and consistent quality and good ergonomics. These customer-specific machines with long service lives are created from a modular system and are therefore tried-and-tested.

For production of your special components, the machine design must often originate from the required process. BW specialists have already implemented many for our customers. Gear spindles in combination with high-frequency spindles, changeable NC-controlled gear cutting heads, NC-controlled jigs and fixtures, reversible clamping devices with centre distances of 5,000 mm, use of extremely long and heavy tools - the experienced BW design engineers make it possible for you. Machine Centres Operations

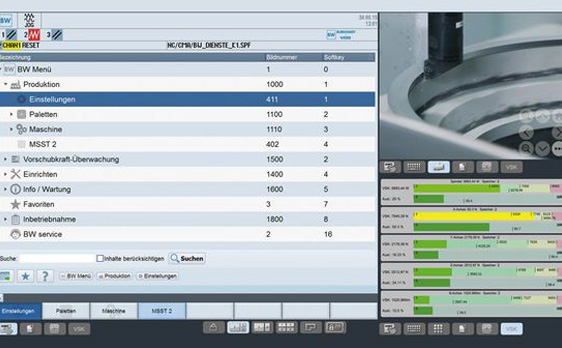

OPERATION

-

SMART PANEL: HIGH QUALITY 24“- FULL HD MULTI-TOUCH PANEL.

The machining centres are equipped with a high-quality 24" multi-touch panel that leaves nothing to be desired. Innovative design, intuitive operation and straightforward user interface make the new panel another highlight of the BURKHARDT+WEBER machines. The pioneering panel allows the operator to quickly locate the desired functions, process parameters and supporting information.- Smart panel: 24“ full HD multi-touch panel.

- Three independent display areas.

- Process data monitoring.

- Camera image.

- PDF-Viewer.

- Virtual keyboard.

- Easy-care, high-quality glass surface.

- High-quality aluminium housing.

- Machine control panel.

- Short-stroke keys with very good tactile feedback.

- Separate correction switch.

- Spindle speed.

- Feed rate.

- Rapid traversing speed.

- Keypad for customer-specific additional functions.

- Pivoted, height-adjustable mounting.

CONVENIENT OPERATING AREAS

-

The user interface of the BURKHARDT+WEBER machining centres features innovative, machine-specific operating areas. These impress with their modern design and functionality. Enhanced user-friendliness was the focus of this new development. And this succeeded in impressive fashion through use of modern control elements and additional convenience functions. The intuitively operated areas making it easier for the operator to enter data, plan jobs and control the machine.

- Intuitive and quick operation.

- New and innovative display elements.

- Operator control of machine functions.

- Linked auxiliary functions.

- Straightforward navigation.

- Process monitoring.

- Favourites list.

- Search function.

- Tool management operating area.

- Easier tool data entry.

- Graphic support.

- Automatic determination of the tool type.

- Data auto-completion.

- Straightforward and dynamic.

- Plausibility check.

Machine Centres Automation

- Flexible and unattended production

THIRD AND FOURTH PALLET CHANGING STATION

-

- Very economical in the case of multiple clamping locations or a third shift.

- Every station can be set up autonomously.

ROTARY PALLET STORE

-

- Made by BURKHARDT+WEBER.

- Rapid changeover with up to six pallets in the system.

- Motor-driven, rotating, generously dimensioned set-up station.

INTEGRATION IN HIGH RACK SYSTEMS

-

- Simple integration in modern high rack systems.

ROBOT LOADING

-

- Automated workpiece handling.

- Intelligent, self-centring, hydraulic clamping devices.

PALLET CHANGER, STANDARD

-

- Dual pallet changer; set up during machine operation.

- Load-dependent, servo-driven movements for rapid pallet changing.

LINEAR LINKING SYSTEMS

-

- Made by BURKHARDT+WEBER.

- Unmanned operation of multiple machining centres in rail-guided linked system.

Special Solutions

- SPECIAL SOLUTIONS FOR EVEN GREATER PROCESS RELEVANCE.

BW offers you many special solutions and facilities from our own production to coordinate your machining centre even more closely with your production processes. This reduces machining costs and increases quality. Your ideas lead to our designs, making your special-purpose machining centre even more cost-effective.

BACKGROUND MAGAZINE

- If the large machine magazines no longer suffice, there is a solution for this as well: a background magazine built from modules of the machine magazine with up to 3,000 tools and convenient magazine management.

SPECIAL HEADS

- Special heads for special tasks: fixed or adjustable angular heads, milling heads, sawing heads, gear cutting heads and multi-spindle drilling heads. Sleeves for automatic extension of large tools and associated feeding and changing equipment.

AUTOMATIC BORING BAR FEEDING

- One or more boring bars with lengths exceeding 1,200 mm are not fed from the magazine, but by means of automatic feeding from an external station. Naturally, NC-controlled and from in-house production

AUTOMATIC TOOL EXTENSION

- The original from its inventor. It can extend each tool weighing up to 40 kg automatically by 350 mm. Perfect concentricity, because no expensive intermediate adapters are required for boring bars or extensions. The integrated vibration absorber is effective against milling vibration.

QUILL UNITS

- BW offers quill spindle developed and produced in-house with extension lengths up to 1,000 mm and automatic sag compensation. We make the spindle quills insensitive to thermal expansion due to the machining environment through automatic length compensation by means of Invar inserts.

FACING HEADS

- NC-controlled facing heads featuring slide-guided facing slides and controlled counterweight for imbalance reduction. BW's own face-turning unit with control shaft in the centre of the tool adapter is NC-controlled and permits µ-accurate adjustments of the turning tool on the facing slide through the high transmission ratio in the facing head.

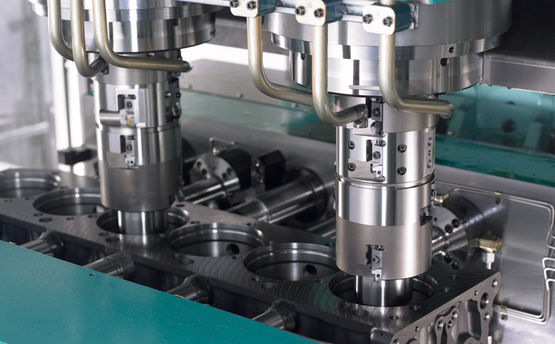

DRILLING HEAD CHANGER

- Fully integrated drilling head changer for storing two NC-controlled special heads with automatic tool change for up to 30 tools.

NC-CONTROLLED, FITTED FACE PLATES

- Vertically installed on the machine table, optimum chip clearance and easy access. Freely configurable surface. Face plate diameter up to 2,000 mm.

APPLICATIONS

-

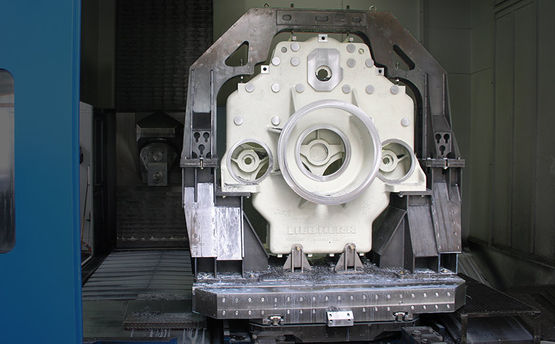

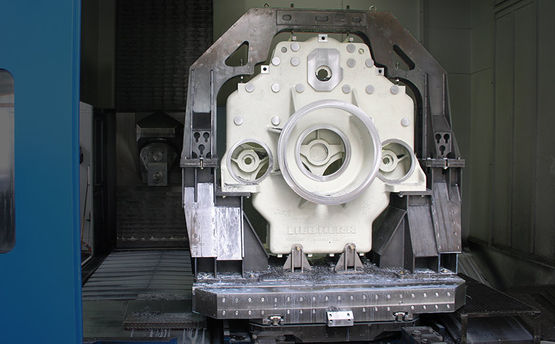

OPTIMUM SOLUTIONS FOR YOUR TASKS.

WHATEVER YOU WANT TO MACHINE, WE OFFER THE SOLUTION.

Our machines are geared to your task. Not the other way around.

If you produce ready-made goods, then ready-made machines will also suffice. In contrast, we design your machine together with you to meet your current and future requirements. In this way we ensure cost-effectiveness today and flexibility tomorrow. The priority is always the optimum process solution. Reduction in the number of clamping operations, 5-side machining, integration of necessary technologies – all with the goal of quickly providing you with workpieces ready for installation from the BW machine. Milled, drilled, turned, deep-hole drilled, deburred and measured. In perfect quality.

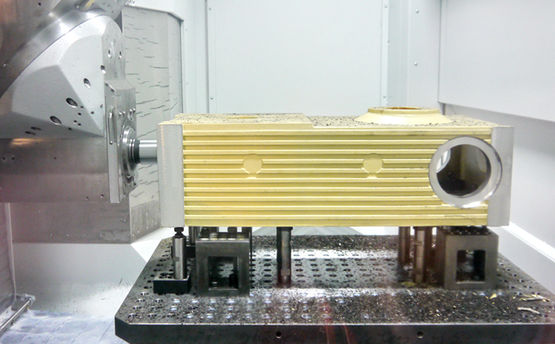

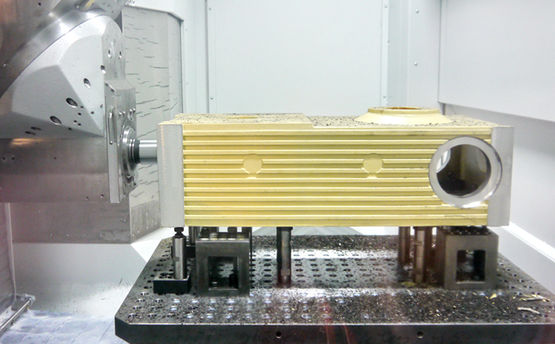

MACHINE BUILDING

- Milling, turning, drilling, deep-hole drilling, 5-axis machining, measuring, single pieces, small batches, tight tolerances and high surface qualities, steel, castings, non-ferrous metals and the need for installation-ready components – these are the daily demands on modern machine building. As a machine tool builder, BW puts these demands into practice itself every day in its production and offers you a wide range of premium-quality machining centres, all of which can be tailored to the needs of your components. So that your production is precise and quick, yet flexible.

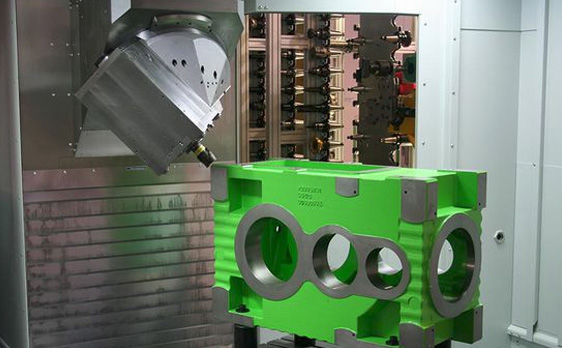

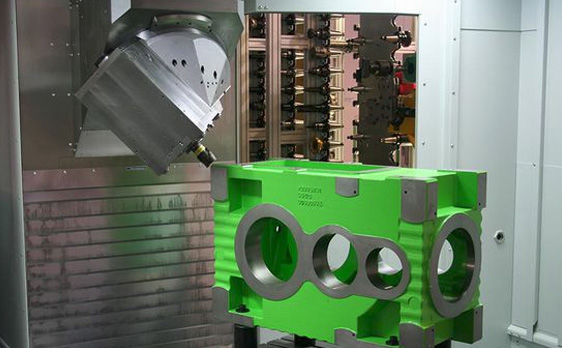

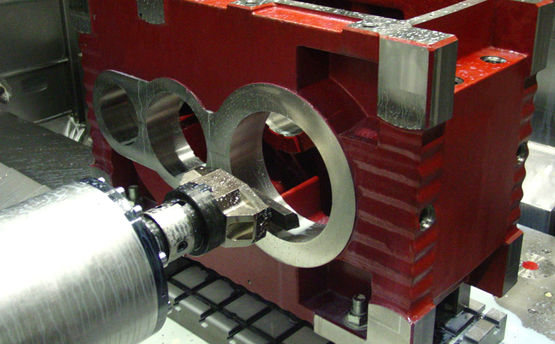

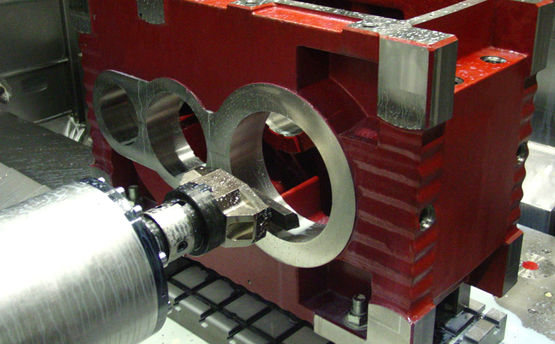

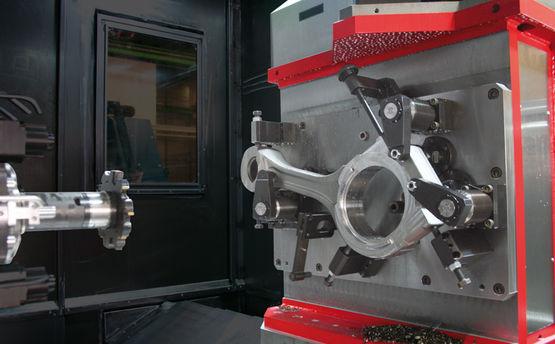

DRIVE TECHNOLOGY

- Cast or welded gearbox casings, tight centre distances and concentricities, as well as tightly toleranced angular positions – BW feels at home here. Rigid table drives with high repositioning accuracy allow the drilling of deep holes from two sides. Large table bearing diameters guarantee the necessary tilting rigidity, even when milling in high spindle positions. Automatic tool extension is used in deep casings. This can extend each standard tool up to 40 kg automatically by 350 mm allowing deep-set holes to be drilled or face seats to be milled.

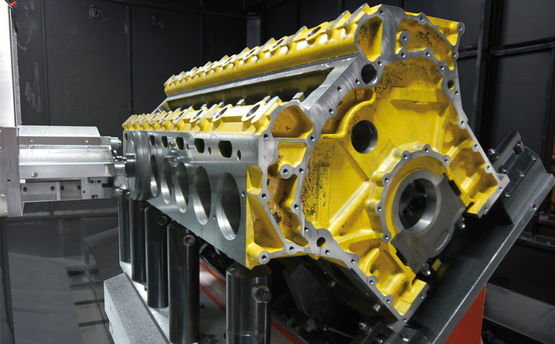

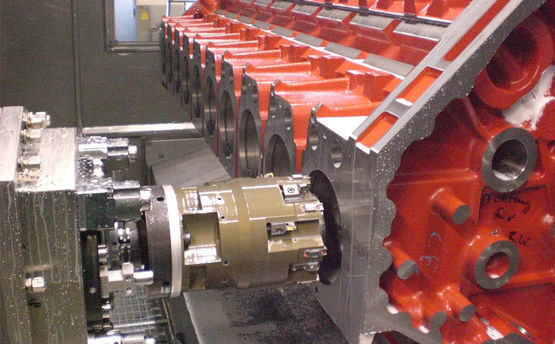

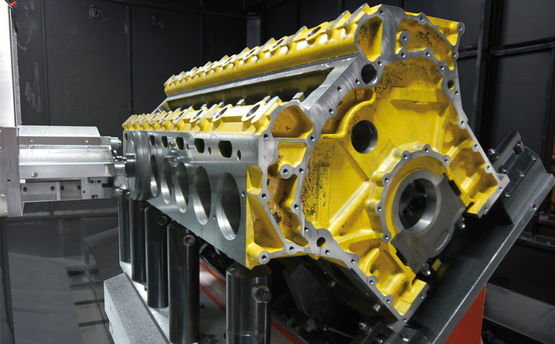

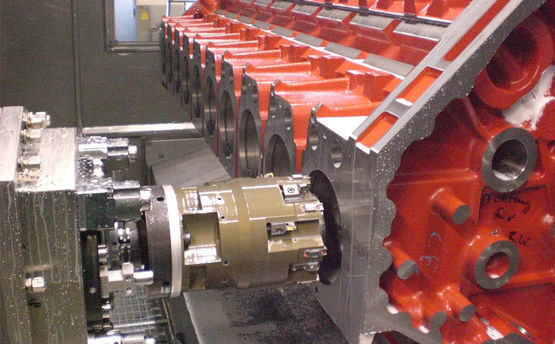

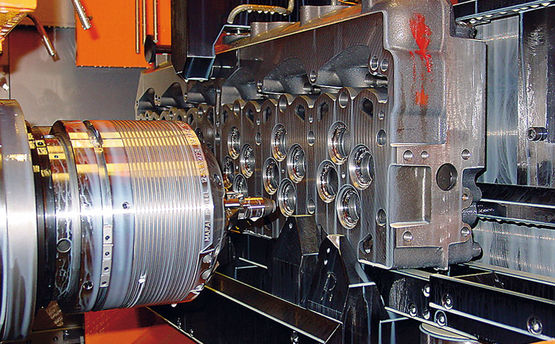

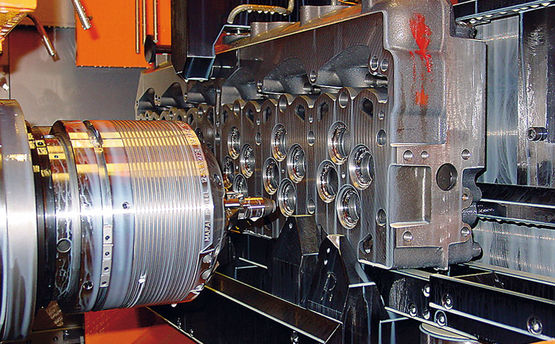

ENGINES AND SYSTEMS

- Powerful diesel engines in series or V-blocks, V12 to V24 engines with block lengths up to 5,000 mm, partial or complete machining including the crankshaft and camshaft bores. BURKHARDT+WEBER can present many references for its machining centres in this field. Large working areas, BW's own machine tables with high tilting and torsional rigidity, coordinated special equipment such as transverse feeds, automatic boring bar and boring head changers, part-specific contact tools and series boring bars. In addition, the complete range of BW fixture technology is available on request. Our expertise for your success.

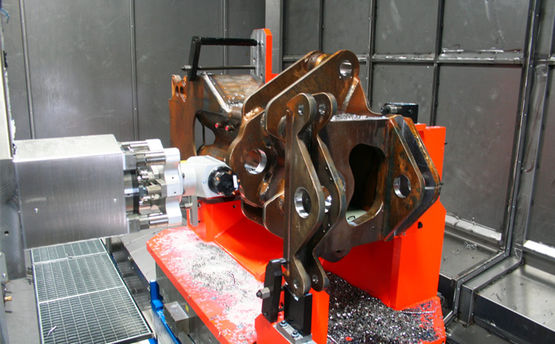

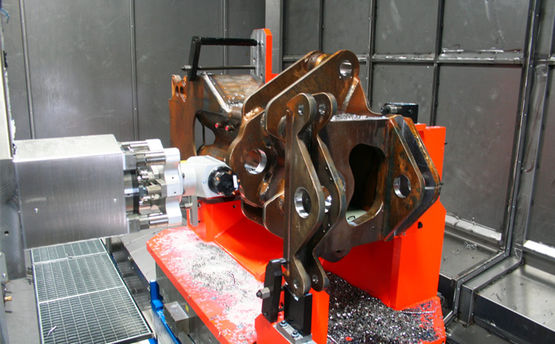

COMMERCIAL VEHICLES

- Whether it be trucks, tractors, earthmoving equipment or mining vehicles, whether it be diesel engines, gearboxes, chassis or axles, in quantities of a few hundred up to 100,000 per year, BURKHARDT+WEBER offers you a comprehensive solution. Linked and fully automated machining centres, also in combination with special-purpose machines for machining larger quantities of engine parts, manual or hydraulic fixtures, tools, automatic loading systems, measuring equipment – everything from a single source and in perfect accord. The high long-term precision of BW machines guarantees you a stable process for many years.

POWER GENERATION

- High-alloy steam turbine blades, large generator housings, wind power planetary gears and hubs made from cast iron – all these components are expansive, difficult to machine and demand outstanding expertise. Horizontal spindles with 4-speed automatic gearboxes up to 80 kW and 3,600 Nm enable efficient machining, even with difficult materials and high cutting volumes. Alternatively, high-performance quill spindle with 160 mm diameter and up to 1,000 mm extension. Parts weighting of up to 20 tons can be loaded on the pallet changer parallel to machining, thereby significantly reducing setup times.

ROLLING MILLS AND MINING

- Framework, large welded constructions, booms, compact gearboxes, segment parts – up to 20 tons in weight are manufactured efficiently on customised BURKHARDT+WEBER machining centres. X-axes with up to 8,000 mm of travel, Y-axes up to 3,000 mm, quill spindle with 160 mm diameter and stroke of 1,000 mm, special magazines with special tools and individual weights of 300 kg, boring head changing equipment and the powerful BW tool magazine guarantee precise machining of your components.

MACHINE TOOLS

- Numerous references attest to our expertise in machine tool manufacturing. Together with our strategically high degree of vertical integration, this makes us a premium professional partner. Whether slide units with tightest flatness and angular tolerances, spindle housing with tight concentricity and minimal radial run-outs or components with close to µ precision – BW has a range of machining centres with increased precision up to our MCµ machining centres that are 100% thermally stabilised. All BW machining centres are manufactured to meet your specific requirements in air-conditioned production halls.

AEROSPACE

- Vertically installed on the machine table, optimum chip clearance and easy access. Freely configurable surface. Face plate diameter up to 2,000 mm.

HYDRAULICS AND COMPRESSORS

- Deep-set compressor bores, interrupted cuts for screw compressors, tough and hardest materials such as Superduplex and laser-welded Inconel®, deep boreholes with unfavourable length-to-diameter ratios. BURKHARDT+WEBER answers these extreme challenges with a sturdy basic design, on request with highly damping, extra-wide sliding guides and generally with high-mass, cast-iron machine stands, powerful, high-torque gear spindles and tools weighing up to 75 kg with lengths up to 1,200 mm and automatic changeover as well as automatic facing equipment for contour-controlled internal and external turning.

PLASTICS AND WOOD

- BURKHARDT+WEBER has many years of experience in machining components for plastic injection moulding machines such as base frames, cylinders, clamping plates, connecting rod drives and others up to 20 tons in weight. BW is at home with the exacting requirements for stay hole gauges and clamping plate flatness, deep boreholes and high cutting volumes. The generously dimensioned machining centres offer highest positioning accuracies and best angular positions, even in the case of large dimensions. High-performance pre-machining followed by fine machining is the speciality of BW.

PRINTING, PAPER AND PACKAGING

- Whether it be side walls with the tightest of gauges and maximum flatness or expansive machine frames with multi-sided machining – the BW machining centre is specially designed for your process. If extreme precision is required, then every BW machining centre is also available in a high-precision version. Our experts hand-scrape the final microns, drives are cooled, and active component tempering is installed. Water/water coolers reduce the release of hot air to the immediate machine environment as required. Production at the highest technical level. The µ is generated, not only compensated.