RAMPF Gruppe

- Offer Profile

- The RAMPF Group stands for

ENGINEERING AND CHEMICAL SOLUTIONS and caters to the economic and ecological

needs of industry.

Our range of competencies includes:- Production and recycling of materials for modeling, bonding, and protection

- Technical production systems for positioning and automation, which can be utilized as a stable basis for achieving precision and dynamics

- Comprehensive range of solutions and services, particularly for innovative customer-specific requirements

Product Portfolio

RAMPF Machine Systems

-

Innovative mechanical engineering solutions

On the solid basis of machine beds made of MINERAL CASTING and NATURAL HARD STONE EPUCRET supplies its customers worldwide with innovative system solutions, “rump machines” (the main machine body), and high-end POSITIONING AND MOVING SYSTEMS:- Reliable supplies and proximity thanks to state-of-the-art production processes and plants in Germany and China

- Development partner for your machine solutions with impressive in-house CAD design and FEM calculation capacities

- Engineering and chemical/physical research shapes your future innovations

- Effective quality management to ISO 9001:2008 ensures our products and services meet your requirements

Machine Beds

EPUMENT

-

Mineral casting machine beds for highly dynamic mechanical

engineering applications and technologies

Specially selected minerals and a high-quality binding agent based on epoxy resin pave the way for machine components with impressive properties, a wide variety of design options, and tangible economic benefits

EPUSTONE

-

Machine beds made of natural hard stone for maximum precision in

complex measuring and production systems

With the EPUSTONE brand, RAMPF Machine Systems offers a comprehensive service for processing natural hard stone (granite) in shorter production runs for specialized mechanical engineering applications, prototypes, or pilot machines.

EPUDUR

-

machine beds made of ultra-high performance concrete (UHPC)

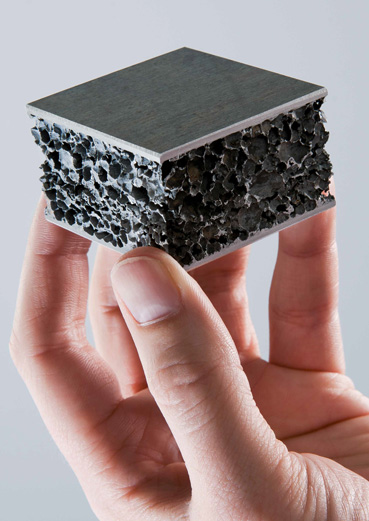

RAMPF Machine Systems supplies a broad range of materials and services for machine beds. The product range includes epoxy resin-bonded mineral casting, filled steel composite structures, natural hard stone, aluminium foam, fiber composites and ultra-high performance concrete (UHPC).

Systems

EPULIGHT

- Lightweight construction of dynamic assemblies

Increasing the productivity of machinery, equipment, and systems in mechanical engineering is hard to imagine without lightweight construction using fiber composites such as CFRP. This is particularly true for dynamic machine components such as carriages, tables, and traveling gantries.

EPULIGHT solutions are based primarily on metal foams (EPUFOAM) and fiber composites (EPUFIBER).

EPUTRONIC

- Customized mechatronic positioning and moving systems

that deliver optimum performance

RAMPF Machine Systems offers innovative complete solutions for customer-specific positioning and moving requirements based on stable beds made of natural hard stone and mineral casting – from design and layout to production, installation, and commissioning.

Services

EPUFILL

- Machine beds with a steel/composite structure and

mineral casting filling for specialized mechanical engineering applications

EPUFILL technology is our response to the ever-increasing demands placed on the static and dynamic performance of machine beds in shorter production runs, e.g. in specialized mechanical and plant engineering applications

EPUGRIND

- Precision grinding of machine beds made of cast iron,

steel, hard stone, and mineral casting

With its own temperature-controlled precision grinding center and high-performance equipment, RAMPF Machine Systems offers an integrated service portfolio for high-precision machine components made of cast iron, steel, granite, and mineral casting.

EPUSELF

- a high-performance mineral casting for do-it-yourself

manufacture of customized components and products in the industrial and

leisure sectors

Epoxy resin-bonded mineral casting is a construction and design material with a real future. Selected minerals and a low proportion of binding agents form the basis for a high-performance casting material for a wide range of technical and artistic applications. The brand EPUSELF brings together over 35 years of experience in mineral casting technology and makes it available for do-it-yourself manufacture. Institutes, mechanical engineering companies, tradesmen, artists, and DIY enthusiasts can benefit from the easy handling and the excellent properties of their own cast parts.

Customer Service

- Customer-oriented, skilled, committed – as an end-to-end development partner and service provider, we offer innovative production solutions ranging from machine base to basic machinery

RAMPF Production Systems

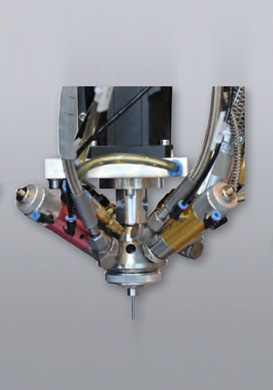

- Innovative low-pressure mixing and dispensing systems

With more than 2,500 system solutions on the market, RAMPF Production Systems is one of the leading manufacturers of low-pressure mixing and dispensing systems. As a technology driver and leader in quality, RAMPF Production Systems offers:- Powerful low-maintenance mixing systems for reliable processing of fast-sedimenting, highly abrasive, and highly viscous materials

- Dispensing systems and robots for reliable sealing, foaming, casting, and bonding of single- and multi-component materials

- High-precision dispensing systems for all kinds of materials, independent of fillers and viscosities

Mixing Systems

- Ultra-precise mixing

We offer you exceptionally powerful low-maintenance mixing systems. We also develop solutions for processing fast-sedimenting, highly abrasive, and highly viscous materials to suit your specific requirements.

MS-C 76 model series

- The MS-C 76 model series covers a dispensing output range of approx. 0.2 - 3 g/s. The mixer and mixing chamber simply need to be adjusted to the materials' reactivity.

MS-C 100 model series

- The MS-C 100 model series covers a dispensing output range of approx. 1.5 - 120 g/s. Various mixing chamber geometries are available for the many different materials.

MK107 model series

- The MK 107 model series covers a dispensing output range of approx. 2 - 20 g/s. The mixing heads in this series can be equipped with up to three component valves, one flushing valve, and one blowing valve.

MK 108/111 model series

- The MK 108/111 model series covers a dispensing output range of approx. 0.01 - 3 g/s. The mixing heads in this series can be equipped with two component valves, one flushing valve, and one blowing valve.

MS-S static mixing head

- The static mixing head is used to mix materials that are highly viscous or have a paste-like consistency. Due to the high operating pressures, a steel tube is used to stabilize the disposable plastic mixer. A shut-off system that operates without any displacement ensures a clean thread break and a smooth transition. This system can be used in a dispensing output range of approx. 0.01 - 0.5 g/s

MS-SC static mixing head

- The MS-SC static mixing head is equipped with diaphragm valves and is therefore suitable for mixing highly abrasive materials. These valves also have a suck-back effect that ensures a clean thread break. There are no moving parts in reacting material.

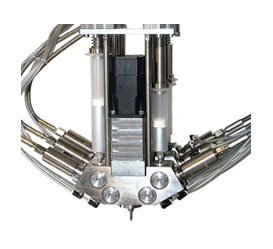

Dispensing Systems & Robots

- Foaming, casting, bonding, and sealing up to four

components

We offer you dispensing systems that will ensure your current and future development. We develop complete, tailored solutions for reliable sealing, casting, and bonding of single- and multi-component materials.

DC-RS 250 dispensing cell

- The slimline DC-RS 250 robot dispensing cell with the

KUKA KR6 R900 is small and versatile. It is used to process 2-component

materials.

- 600 mm wide with a max. part width of 350 mm

- Ideal for lean manufacturing concepts

- Compatible with all RAMPF mixing systems

- Flexible structure thanks to separate material conditioning

DC-CNC compact dispensing cell

- The MS-SC static mixing head is equipped with diaphragm

valves and is therefore suitable for mixing highly abrasive materials. These

valves also have a suck-back effect that ensures a clean thread break. There

are no moving parts in reacting material. The DC-CNC dispensing system is

the ideal solution for anyone who is looking for a compact machine structure

without wishing to compromise when it comes to control technology. Further

benefits of the compact dispensing system:

- Suitable for manual or automatic part loading

- Can be used as an integrated solution in production lines or as a stand-alone concept

- Compatible with all RAMPF mixing systems

- Comprehensive process visualization

DC-CNC 1150 dispensing cell

- Compact & flexible: The large version of the compact

dispensing cell enables reliable sealing, bonding, and casting of up to 4

components.

- Basic structure with integrated control cabinet for 2- to 4-component material conditioning

- Full cladding

- Control system

- High-speed portal robot

- High flexibility

- High-precision dispensing

- Maximum productivity

DR-CNC dispensing robot

- The DR-CNC dispensing robot is the ideal solution for

complex requirements. Further benefits of the dispensing robot:

- Highly variable X-Y axis strokes

- For manual or automatic part loading

- Can be used as an integrated solution in production lines or as a stand-alone concept

- Compatible with all RAMPF mixing systems

- One or two mixing units possible

- Comprehensive process visualization

C-DS dispensing system

- The C-DS dispensing system is highly versatile and can be

used as a manually operated unit, an automated partial solution, or a fully

automated robot system. Further benefits of the dispensing system:

- Compact

- Cost-efficient 2-component processing technology

- Can be combined with all popular automation systems

- Compatible with all RAMPF mixing systems

- Comprehensive process visualization option

DC-VAC vacuum dispensing system

- The DC-VAC vacuum dispensing system benefits from vacuum

material conditioning as standard and is equipped with a dynamic mixing

system. Further benefits of the vacuum dispensing system:

- Dispensing output range 0.2 – 30 g/s (depending on the mixing system)

- Dispensing via gear or piston pumps

- Optimum material conditioning thanks to recirculation via the mixing system

- Vacuum chamber for standard workpiece carriers up to 320 x 320 mm

- Comprehensive process monitoring options

- Process overviews are presented in graphic form in conjunction with optional OP010/012

- Integrated formulation management

Dispensing Systems

- High-precision dispensing of single- and

multi-component materials

We offer exceptionally powerful low-maintenance systems for high-precision dispensing of materials as varied as polyurethane, epoxy, and silicone, independent of fillers and viscosities.

M-KDS minimal quantity piston dispensing system

- Optimum mixing and high-precision dispensing of minimal

quantities

- Dynamic mixing optimizes the mixing of minimal volumes

- Comprehensive process visualization options

- Compact design

- Flexible material supply

- Freely programmable piston dispensing system for maximum precision

C-DSE compact dispensing system

- Compact and flexible: The cost-efficient way to move into

automatic processing of 2-component casting materials. Your benefits:

- Compact design: Material tanks, control system, and mixing system installed on mobile painted steel tub

- High flexibility: Processing of 2-component casting materials and adhesives

- Reliable process: High-quality material conditioning using special agitators and recirculation via a mixing tube

K-DP piston dispensing pump

- Precise dispensing with a wide range of fillers and

viscosities Your benefits:

- Variable dispensing quantities and times

- Different chamber volumes

- Low maintenance

- Intelligent drive

- Process monitoring

30 VAC vacuum barrel press

- Material changeovers made easy – ideal for conveying

medium- to high-viscosity materials. Your benefits:

- Bubble-free bonding and sealing

- Optimal material utilization

- Reliable operation

- Significantly higher process reliability

Customer Service

- The RAMPF Production Systems Team provides fast and

skilled support for you throughout the entire product life cycle of your

machine.

You can reach us daily Monday to Friday between 7 a.m. and 5 p.m. Spare Parts

- Should you require spare parts, you can request them

directly using the spare parts form. Our team will make you a tailored offer

in a timely manner.

Contact our spare parts service team should you require any assistance.

Technical Support

- Our technical support hotline can help you if you are

experiencing difficulty with your dispensing system.

Use our support form to help us respond to your problem more quickly. Our service team is also available for any other questions you may have.

Services

- In with cooperation with our project planning team, we will happily process your inquiries about alterations to existing systems. Should you require any other services, e.g. repairs, maintenance contracts or training, you can let us know using the services form, or by contacting us directly.

RAMPF Eco Solutions

- The

future in focus with solutions from RAMPF Eco Solutions

Based in Pirmasens and developing innovative recycling solutions.

We specializes in:- Semi-rigid to rigid integral foams based on recycled polyols

- Rigid and flexible foams based on recycled polyols

- Casting resins with fillers and recycled polyols

- Customized recycling plants based on thermal glycolysis

- Contract manufacturing of molded components

Polyurethane Systems

- Polyurethane systems have a real future

RAMPF Eco Solutions has gained specialized know-how in the formulation of polyurethane systems based on its own polyols. Polyurethane systems based on alternative waste and raw materials are just as versatile as polyurethanes based on new polyols.

Your Benefits- Less expensive than primary polyol

- Retains the former product characteristics with the new cross-linking

- Top-quality polyol mix

- Lower disposal costs

- Highly efficient resource saving

- Recycling raw materials protects the environment

Integral foams

- Semi-rigid

integral foams: RAMPF Eco Solutions produces semi-rigid integral

foams based on recycled polyols (Recypol®). Formulations can contain

anything from 25-30% Recypol. Typical applications include shoe soles

and foam insulation for beer kegs.

Rigid integral foams: In the area of rigid integral foams, RAMPF Eco Solutions offers formulations containing up to 15% recycled polyol (Recypol®). Possible applications for these products include window frame enclosures.

Rigid foams

- Rigid foams formulated by RAMPF Eco Solutions can contain up to 20% Recypol. These foams are used for applications such as insulation.

Flexible foams

- Flexible foam formulations from RAMPF Eco Solutions are used in items such as mattresses and car seats. They contain 20-30% Recypol.

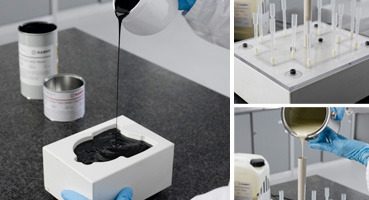

Casting resins

- Casting resin systems from RAMPF Eco Solutions can contain fillers and 18% Recypol.

Base Polyols

- Sustainable and cost-efficient recycled raw materials

For over 20 years, research teams at RAMPF Eco Solutions have been carrying out research into and developing alternative polyols. Customized polyols are produced by recycling polyurethane and PET at one of Europe's largest thermal glycolysis plants. The base polyols obtained by recycling are reintegrated into the customer's production cycle by RAMPF Eco Solutions or another polyurethane systems house. This delivers both environmental and economic benefits. And by using polyols based on renewable raw materials (biopolyols), RAMPF Eco Solutions' customers no longer need to rely on dwindling petrochemical raw materials.

Your benefits- Less expensive than primary polyol

- Retains the former product characteristics with the new cross-linking

- Top-quality polyol mix

- Lower disposal costs

- Highly efficient resource saving

- Recycling raw materials protects the environment

- No reliance on dwindling petrochemical raw materials

Recypole®

- Recypol® is the name given to alternative polyols created by recycling polyurethane.

Petole®

- Petol® is the name for polyols created by recycling PET.

Biopolyols

- Biopolyurethanes are polyurethanes made from renewable raw materials. They can replace traditional fossil-based plastics in numerous applications, thereby saving on resources and improving the sustainability of industrial applications. Starting materials for these high-grade plastics include vegetable oils, corn, wood (lignin), and greases. Targeted modification and functionalization enable biopolyols to be used in all kinds of technical applications. In some cases, the properties of the natural products give the polyols enhanced product characteristics.

Plant Engineering

- Customer-specific plants for manufacturing polyols

(PUR, PET)

Having a recycling plant on site makes it possible to produce polyols that can be fed straight back into the production process. In addition to cutting transport and disposal costs, this makes the production of PUR-based products more environmentally friendly. RAMPF Eco Solutions offers its customers the complete design of a recycling plant tailored to their specific needs, including the necessary chemical expertise and induction of the relevant personnel.

True to the principle: your production leftovers – your raw materials source RAMPF Polymer Solutions

- Customized casting resin systems for

sealing, bonding, casting, and coating

RAMPF Giessharze is a dependable development partner for reliable sealing, casting, bonding, and coating solutions. As a technology driver and leader in quality, RAMPF Polymer Solutions offers:- Liquid to thixotropic sealing systems based on polyurethane and silicone

- Electro casting resins made of polyurethane and epoxy for reliable protection of sensitive components

- C.A.S.E solutions made of polyurethane with versatile properties for bonding, coating, and protecting

Foam Gaskets

- Excellent sealing systems for any application

For more than 30 years, RAMPF Polymer Solutions has been developing and manufacturing innovative sealing systems based on polyurethane and silicone. RAMPF Polymer Solutions's branded systems combine top quality with exceptionally easy handling. Key features include low water absorption, good adhesion, high long-term temperature resistance, and a cost-efficient manufacturing process. Leading institutes and prestigious customers confirm the quality of the sealing systems.

Liquid Foam Gaskets

- Liquid sealing systems require a distinct groove and a

level application surface. They are applied directly to the part using

2-component low-pressure mixing and dispensing equipment and expand in situ.

Your benefits- Self-leveling

- Tolerances < 3 mm possible

- Gasket with cross-section < 1 mm possible

- Sealing of all industrial components

- Application in grooves and molds

- Ventilation grills

- Electronic boxes

- Brake lights

- Packaging

- etc.

Thixotropic Foam Gaskets

- Highly thixotropic sealing systems, which can be applied

with or without a groove. They are ideal for three-dimensional surfaces,

including steeply sloping areas.

Your benefits- Reliable sealing, especially with complex three-dimensional contours

- Overhead application with no run-off/dripping

- 1:1 height/width ratio possible

- No excessive penetration in open-pored materials (textiles)

- Three-dimensional components and open grooves

- Control cabinets

- Ventilation grills

- Fabric protector

- Roller coating

- Lights

- Door assembly support modules

- Electronic boxes

- Air conditioning plant

Molded foams

- Molded foams are elastic polyurethane foams which

are used in various applications and industries such as furniture,

automotive and construction industry.

Your benefits- Short reaction and demolding times

- Water-repellent

- High mechanical strengths

- Individual adjustable haptics

- Parts with particular haptic requirements

- Application in molds

- Arm rest automotive industry

- Sealing elements

Rigid foams

- Rigid foams are systems with a very low density

that, despite their low weight, are subject to particular static

requirements

Your benefits- Short reaction and demolding times

- High mechanical strengths

- Outstanding vibration, sound and thermal insulation

- Whenever high strength paired and low weight are needed

- Insulating foams

- Construction industry

- etc.

Compact Gaskets

- Unfoamed gaskets are produced using polymerization

without any change in volume. They can have anything from a liquid to a

paste-like consistency and can be processed on both 2-component low-pressure

equipment and high-pressure equipment.

Your benefits- Customizable hardness range up to Shore D

- Very high mechanical strength

- High elasticity

- Very good vibration and sound insulation

- For sealing, strengthening or structuring, or as a functional surface

- High-performance gasket for extreme requirements

- For cost-efficient coating and bonding of construction components

- Automotive sector

- White goods

- Electronics industry

- Leisure/construction material industry

Electro Casting Resins

- High-performance electro casting resins

Electro casting resins from RAMPF Giessharze ensure greater safety, control, cost-efficiency, and convenience. For more than 30 years, RAMPF Giessharze has been developing and manufacturing innovative reactive resins based on polyurethane, epoxy, and silicone. The company offers a wide range of products and customized solutions for insulating, protecting, and embedding sensitive components.

High-performance products

- High-performance products based on polyurethane, polyurethane foam, epoxy, and silicone adapted to suit your requirements

- Innovative, tailor-made product developments

- Production facilities in Germany, the United States, and China

- Broad spectrum of properties optimized in line with your requirements

- High quality and strict quality checks ensure excellent reproducibility at all stages of production

- Certified to ISO/TS 16949

- Our products are in accordance with EU Directive 2002/95/EG, short "RoHS"

RAMPF – a partner you can rely on- Specialists in made-to-measure products: We adapt products quickly and reliably to meet your needs

- Our expert staff use their wide-ranging experience to create future-proof solutions for all kinds of applications and numerous markets

- Our application technology team provides in-depth advice and produces sample parts that enable you to test the quality of our products for yourself

- You can rely on our contract manufacturing team to produce top-quality results and deliver your product series without any delays whatsoever

- If you so wish, material and plant technology can be provided from a single source

- We attach great importance to customer proximity and have a global presence to cater to your needs

- We have been serving well-known customers for more than 30 years.

Silicones

- RAKU-SIL® Silicones:

Protecting, Bonding and Casting

RAMPF Giessharze's RAKU-SIL® silicones offer you the optimum solution for sealing, protecting, bonding, and casting components. The company develops customized systems in response to your specific requirements profile. Process reliability is ensured during manufacturing, which normally takes place on low-pressure mixing and dispensing equipment.

Comprehensive, high-performance product portfolio- 1-component, 2-component, or 3-component products

- Room temperature curing, heat and moisture curing, UV curing, or physical hardening

- Large product selection:

- Soft, gel-like, or self-healing

- Ductile elastomers or hard silicone resins

- Silicone foam elastomers

- Liquid resins or stiff pastes

- Numerous approvals: UL, FDA, drinking water etc.

- Wide range of properties, e.g. electrically insulating and conductive silicones

- Variable reaction times ranging from 1 second to 24 hours

- Excellent resistance to low and high temperatures

- Constant Properties throughout the entire temperature range

- Impressive resistance to chemicals

Applications- Casting of sensors

- Casting of electronic control modules

- Casting of circuit boards

- Casting of wind energy switches

- Mold casting of brake cylinders

- Bonding of oven parts

- Foam sealing of electronic boxes

- Sealing of ABS brake housings

- Sealing of drinking water pumps

- Coating of rollers

C.A.S.E. - Coatings, Adhesives, Sealants, Elastomers

- High-grade

plastic systems

C.A.S.E. is comprised of the product areas construction/coatings, adhesives, sealants and elastomers.

For years our RAKU-PUR® and RAKU-POX® Systems have been successfully used in different fields of application. Those range from the manufacturing of insulating panels, bonding windows, protection of wooden beams, and production of filter systems, to molds for the concrete industry. Adhesives for reliable bonding

- Quality sticks – whether you want to bond wood, plastic, metals or other materials, adhesive systems from RAMPF Polymer Solutions create a secure and reliable bond. Processing can either be done by hand or mechanically using 2-component dosing equipment.

RAKU-PUR®edge casting systems

- Edge casting systems from RAMPF Polymer Solutions are robust and provide reliable protection for components that are subject to high stresses. The versatile RAKU-PUR® materials for protecting wooden edges are suitable for all kinds of applications.

RAKU-PUR®casting materials

- The RAMPF Polymer Solutions product portfolio for the grinding and polishing media industry satisfies the highest physical and chemical demands. The materials ensure good wetting and fixing of grinding and polishing media.

RAKU-PUR® and RAKU-POX®filter systems

- RAKU-PUR® and RAKU-POX® casting and bonding systems haven been successfully used for years in filter manufacturing. They contribute to fulfill the increasing requirements for filter systems in the market. Short cycle times allow for an optimal production process. Our casting materials can be uses for bonding of filter end plate, seam sealing and the production of filter end plates.

Tooling Solutions

- Innovative modeling and mold engineering solutions

RAMPF Tooling Solutions develops and produces first-class materials and semi-finished goods for modeling and mold engineering. As a technology driver and leader in quality, RAMPF Tooling Solutions offers:- A very large selection of board and liquid materials

- Made-to-measure products and services for Close Contour models such as pastes, large-volume/1:1 castings, and prototyping systems

- Expert advice/service and fast technical support for projects

Boards for Modeling and Tooling

- We find solutions for your applications

As the market leader in board materials, we have developed the world's largest production operations for styling, modeling, and working board materials.

You, too, can benefit from our high-performance products:- High-performance standard range that we can adapt quickly to meet technical requirements on the market

- "Complete package" available, consisting of board material, adapted adhesive and appropriate repair paste

Modeling & Styling Boards

- RAKU-TOOL® board materials

combine high quality with outstanding mechanical properties. Our styling

board (SB) material has a fine surface structure. It lends itself to

both manual and mechanical processing. Our modeling boards (MB) have

an even finer surface structure and excellent dimensional

stability.

Modeling boards are used for original, cubing, and presentation models and for design and form studies.

Working Boards

- RAKU-TOOL® working board materials combine high

quality with excellent mechanical properties.

Working board material is used for metal forming, hammer forms, casting facilities, molds, checking fixtures, and lay-up tools.

Close Contour Products

- Every job is different

And so are our solutions with RAKU-TOOL®.

Close Contour products: Close Contour Pastes, Close Contour Blocks and Close Contour Castings are high-performance products and are the result of our painstaking development work and practical experience.

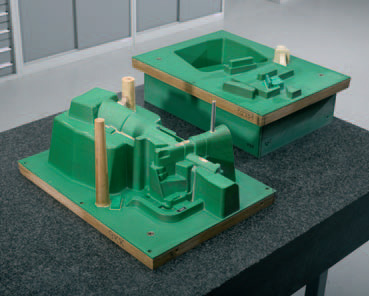

Close Contour Casting/Close Contour Blocks

- RAKU-TOOL® 3C Close Contour Casting uses

special casting technique to produce Close Contour models. 3C is

transformed into 3D and your idea takes shape. We adapt the product

properties precisely to match your requirements, thus ensuring your 3C

casting is of the highest quality. Close Contour Casting delivers a

three-dimensional casting that is cast close to the final contour.

Close Contour Blocks are supplied as custom-made, rectangular, unmachined board.

Close Contour Pastes

- RAKU-TOOL® Close Contour Pastes enable cost-effective modeling and mold engineering. Our materials can be processed easily and exhibit excellent dimensional stability. Areas of application include automotive engineering, shipbuilding, wind energy, and aviation.

Liquid Systems

- Gelcoats and laminating, casting, and multi-purpose

resins

Our systems for your applications

RAKU-TOOL® liquid materials offer you a wide range of innovative and efficient gelcoats and laminating, casting, and multi-purpose resins for various manufacturing processes, construction methods, and applications. Laminating Systems

- RAKU-TOOL® laminating resins enable the production of lightweight, rigid (depending on the type of fiber) high-strength molds and components with or without gelcoat. Among other things, RAKU-TOOL® laminating pastes are used for fast manufacture of negative molds, as the necessary thickness of shell coating can be applied in a single process.

Prototyping Systems

- RAKU-TOOL® rapid prototyping systems are used for the fast manufacture of functional prototype parts and small batches in various sectors such as the automotive, aviation, electronics, and leisure industries. They simulate the appearance and properties of thermoplastics such as HDPE, PP, ABS, and PE.

Gelcoat Resins

- RAKU-TOOL® gelcoats can be used to achieve various surface properties. Rigid to flexible, chemically resistant, polishable, etc. The backing can be adapted to operational requirements and the mold – from lightweight (laminate structures) to heavy (tamping), post-curing possible.

Casting Resins

- RAKU-TOOL® casting resins can be used for full and face casting. They are suitable for quick and easy manufacture of models, molds, and tools.

Infusion Systems

- RAKU-TOOL® infusion systems are used to impregnate dry fibers under pressure and in a vacuum. This enables impregnation of larger fibers in a single process and production of homogeneous components and molds void-free.

Ancillaries

- RAKU-TOOL®ancillaries consist of mold sealers, release agents, and fillers. These are used to seal porous surfaces, help with demolding, and act as fillers for a whole range of applications

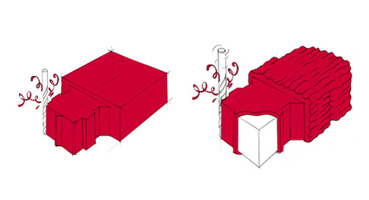

Build-up Methods

Milling

- Find out more about milling. We offers you benefits,

processing and products for the following areas:

- Board materials

- Close Contour Casting

- Close Contour Pastes

Lay-Up

- Find out more about the lay-up method. The RAKU-TOOL

Scout offers detailed information on benefits, processing, and products:

- Gelcoats/coupling layer

- Backing – full casting

- Backing – tamping

- Laminating fibers

- Laminating pastes

Casting

- Find out more about the casting method. The RAKU-TOOL

Scout shows you the benefits, processing procedures, and products for the

following areas:

- Full casting

- Face casting