- Offer Profile

- TRIES hydraulic elements and control systems are used all over the world in all areas of mechanical engineering.

A selection of products and their areas of use can be found on our product pages.

HYDRAULIC ELEMENTS

- TRIES hydraulic elements and control systems are used all over the world in all areas of mechanical engineering.

A selection of products and their areas of use can be found on our product pages.

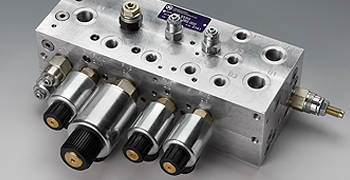

CONTROL BLOCKS

-

Hydraulic blocks from Tries form the control system of machine tools, mobile devices and vehicles. They fulfil important tasks in all areas of mechanical engineering. Tailor-made customer-specific solutions guarantee a reliable and precise function.

- Customer-specific construction or use of existing solutions

- Materials of all kinds (e.g. aluminium, cast iron, steel, stainless steel and many more)

- 100% testing

- Compact, efficient, durable

- 50 years of experience in development and manufacturing

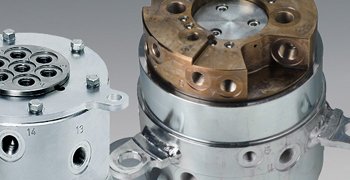

ROTARY JOINTS

-

360° rotations and more - twisted hoses are consigned to the past with rotary joints from TRIES. Developed entirely in accordance with the customer's wishes and the application, various media can be transferred between stationary and rotating machine parts without hoses.

- Customer-specific construction or use of existing solutions

- Media of all kinds (e.g. oil, gas, diesel, coolant, water and many more)

- Up to 500 bar

- High precision and low wear

- 100% testing

- Redundant seal

- Materials: Steel & cast iron

- 50 years of experience in development and manufacture

VALVES

-

TRIES hydraulic valves form the ideal basis not only for TRIES control blocks, because they guarantee a reliable and precise function. The screw-in valves are available with standardised receiving bores according to ISO 7789 as

- directional control valves

- pressure control valves

- flow control valves

- shut-off valves

We also manufacture proportional and special valves of all kinds. You are welcome to contact our employees directly in this case.

UNITS

-

From compact small units up to complete test stands, TRIES develops a suitable hydraulic unit for every application. For maximum flexibility our range also includes mobile units in addition to the stationary versions.

- Customer-specific construction

- Tank capacities between 10 and 1000 litres

- Power installation (consumption) up to 50 KW

- including hydraulic and electrical controller

SPECIAL CYLINDERS

-

Whether integrated valve technology, compact design or special functions according to your wishes - hydraulic cylinders from Tries adapt themselves perfectly to your system. We design, develop and manufacture solutions for your special application. Cylinders from TRIES offer more than the standard in cases of extreme loads, difficult installation situations or unusual framework conditions.

- Customer-specific construction, also with integrated valve technology

- Piston diameter 20 - 300 mm

- Stroke up to 5500 mm

- Space-saving

- Economical

- Powerful

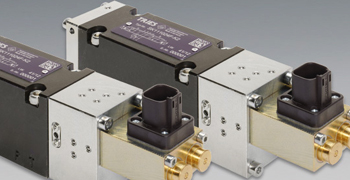

ELECTRONICS

-

TRIES electronic modules provide for the ideal connection of powerful proportional valve technology, whether compact module electronics with up to 8 connections or the powerful multi-module with 24 inputs and 36 outputs.

Multi-module (TMM):

The multi-module features outputs with which both continuous and proportional valves can be controlled. Thanks to additional inputs, analogue setpoints or digital signals can be processed. Its structure makes it ideally suited to mobile and industrial use (protection class IP 42/65/68)

Module electronics (TME):

The module electronics is a universal control electronics. Apart from use in the module series 940 it can also be used for controlling all other proportional and switching valves with 24 V / max. 2 A. The electronics is available in a compact size of 90 x 74 x 29 mm.- contains 4x prop. (I-constant) in the basic version

- additionally universally adaptable with an extension of max. 4x prop. (I-constant) or 4-20 mA current input

- features 5 pull-up inputs, which are used as the plug coding of the ID assignment.

SYSTEM SUPPLIER

-

The many proprietary products developed and designed by Tries represent the perfect basis for us to serve our customers as a recognised system supplier. Whether complete hydraulic systems or complex hydraulic control systems including piping and attached parts, we deliver just in time and precisely tailored to your needs. The advantages of this are obvious:

- Reduction in the number of suppliers

- Central contact

- Relief of your own production

- Concentration on your own core competencies

JOYSTICK

-

Joysticks from TRIES support you in your daily work when it comes to the sensitive control of devices weighing several tonnes or the pinpoint-accurate manoeuvring of mobile machines. The proportional control functions of directional control valves are implemented via hydraulic or electrical joysticks (manual control encoders). Tries offers tailor-made solutions for both areas on request.

Hydraulic joysticks:

- Operation of up to four double-action cylinders

- Stepless multi-axis movements

- No software or electronics necessary

- Piston symbols can be individualised

- Integrated pressure protection up to 350 bar

Electrical joysticks:- Perfect connection to the Tries proportional valve solutions

- Freely configurable to the customer's needs

- Ergonomical grip shape

- Space-saving construction

- ecentral hydraulic system outside the driver's cab

SPECIAL MACHINES

- A strong new line of business grew in part out ofnew ideas of our own and partly out of challenges beyond every standard presented by our customers: we are your partner for successful solutions in special machine construction.

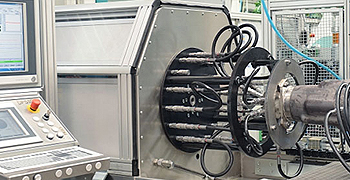

UNIVERSAL TEST STANDS

- The universal test stand is for the testing of the hydraulic products. The respective quantity and pressure settings for the respective inputs can be input via the multi-function display. These are then set fully automatically after confirmation.

The oil temperature is kept at a pre-determined level by a control loop.

A heating and cooling circuit is used for this. At the same time, the oil purity is constantly checked and a warning is output if necessary. Measuring inputs for additional sensors such as pressure sensors or measuring turbines are installed in the test chamber.

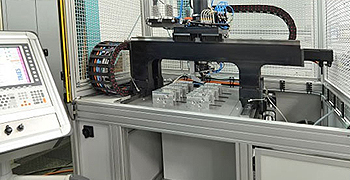

PART-SPECIFIC TEST STANDS

- This type of test stand is specialised for larger series of a product. Depending on needs, the test stand can be semi-automated or fully autonomous. The measurement results are recorded and archived with LabView.

The recorded characteristic curves can be compared with envelopes. The fully-autonomous test stand can make the settings on the product in such a way that the pre-defined characteristic values are achieved. If necessary, the test stand can accomplish further processes, such as screwing in blanking plugs and/or the subsequent washing of the products.

SPECIAL HYDRAULIC UNITS

- Special units are developed by us for the specific customer. These can be manufactured with or without a controller, depending on wishes.

Thanks to our experience in the field of hydraulics we can adapt the unit optimally to the requirements and the area of use.

ASSEMBLY / AUTOMATION

- Virtually no limits are imposed in the field of machine automation. In order to optimise the results of your work-facilitating machines, we offer you a wide range of automation variants.

From the laser engraving machine that automatically inscribes the type plates to the grinding machine equipped with an automatic supply - we have the right automation solution for yo

SQUEEZER-EX

- The TRIES Squeezer-EX motion expander and ball press revolutionises the setting of ball expanders. Very simple operation and intuitive handling makes the reliable closure of auxiliary bores child's play.

The saving of time, relief of employees and increases in quality are only the major advantages of this machine. The Squeezer-EX motion has controlled axes that press in the expanders or balls via a DIN-CNC program.