sigma 4

- Offer Profile

- SIGMA 4 progressively

abandoned its artisan dimension while keeping the very same attention to the

detail and its passionate approach. Today SIGMA 4 is a modern and well

structured company, which is able to meet all demands in terms of front end

loaders.

Thanks to its 30-year-long co-operation with the tractor's Major Manufacturers, SIGMA 4 is market leader in Italy and among the first 6 loader manufacturers on an international level.

Product Portfolio

Front Loaders

CHROME

CHROME M

-

Our Chrome front end loader range, completely updated in design and performance, are exceptionally reliable machines due to the latest solutions adopted, and are extremely competitively priced within this market segment.

BOOM SECTION

For the Chrome series, the section of the boom is formed by an integral metal plate in the outer area and a C profile in the inner area, an ideal solution in terms of great strength and overall lightness.

Front loader with mechanical implement self-levelling system- Fitting brackets supporting loader from tractor front end to rear axle shafts

- Hydraulic system conforming to tractor specifications

CHROME F

-

Our Chrome front end loader range, completely updated in design and performance, are exceptionally reliable machines due to the latest solutions adopted, and are extremely competitively priced within this market segment.

BOOM SECTION

For the Chrome series, the section of the boom is formed by an integral metal plate in the outer area and a C profile in the inner area, an ideal solution in terms of great strength and overall lightness.

Front loader with manual implement levelling- Fitting brackets supporting loader from tractor front end to rear axle shafts

- Hydraulic system conforming to tractor specifications

IRON

IRON M

-

Our IRON front end loader range, completely updated in design and performance, are exceptionally reliable machines due to the latest solutions adopted, and are extremely competitively priced within this market segment.

HYDRAULIC PIPES

By replacing the iron pipes with flexible pipes, it has been possible to partially integrate the hydraulics on the inside of the boom, thus providing enhanced protection, better visibility and reduced dirt accumulation. A rugged sheath covering the pipes is also supplied, both for looks and safety.

BOOM SECTION

For the IRON series, the section of the boom is formed by an integral metal plate in the outer area and a C profile in the inner area, an ideal solution in terms of great strength and overall lightness.

Front loader with mechanical implement self-levelling system- Fitting brackets supporting loader from tractor front end to rear axle shafts

- Hydraulic system conforming to tractor specifications

IRON F

-

Our IRON front end loader range, completely updated in design and performance, are exceptionally reliable machines due to the latest solutions adopted, and are extremely competitively priced within this market segment.

HYDRAULIC PIPES

By replacing the iron pipes with flexible pipes, it has been possible to partially integrate the hydraulics on the inside of the boom, thus providing enhanced protection, better visibility and reduced dirt accumulation. A rugged sheath covering the pipes is also supplied, both for looks and safety.

BOOM SECTION

For the IRON series, the section of the boom is formed by an integral metal plate in the outer area and a C profile in the inner area, an ideal solution in terms of great strength and overall lightness.

Front loader with manual implement levelling- Fitting brackets supporting loader from tractor front end to rear axle shafts

- Hydraulic system conforming to tractor specifications

IRON H

-

Our IRON front end loader range, completely updated in design and performance, are exceptionally reliable machines due to the latest solutions adopted, and are extremely competitively priced within this market segment.

HYDRAULIC PIPES

By replacing the iron pipes with flexible pipes, it has been possible to partially integrate the hydraulics on the inside of the boom, thus providing enhanced protection, better visibility and reduced dirt accumulation. A rugged sheath covering the pipes is also supplied, both for looks and safety.

BOOM SECTION

For the IRON series, the section of the boom is formed by an integral metal plate in the outer area and a C profile in the inner area, an ideal solution in terms of great strength and overall lightness.

Front loader with hydraulic implement self-levelling system- Fitting brackets supporting loader from tractor front end to rear axle shafts

- Hydraulic system conforming to tractor specifications

GOLD

GOLD M

-

The new GOLD range offers multiple options for implement self-levelling and increased lifting power. It is supplied as standard with the anti-bounce GENIUS SYSTEM.

HYDRAULIC PIPES

By replacing the iron pipes with flexible pipes, it has been possible to partially integrate the hydraulics on the inside of the boom, thus providing enhanced protection, better visibility and reduced dirt accumulation. A rugged sheath covering the pipes is also supplied, both for looks and safety.

BOOM SECTION

For the GOLD series, the section of the boom is formed by an integral metal plate in the outer area and a C profile in the inner area, an ideal solution in terms of great strength and overall lightness.

Front loader with mechanical implement self-levelling system- Fitting brackets supporting loader from tractor front end to rear axle shafts

- Hydraulic system conforming to tractor specifications

GOLD F

-

The new GOLD range offers multiple options for implement self-levelling and increased lifting power. It is supplied as standard with the anti-bounce GENIUS SYSTEM.

HYDRAULIC PIPES

By replacing the iron pipes with flexible pipes, it has been possible to partially integrate the hydraulics on the inside of the boom, thus providing enhanced protection, better visibility and reduced dirt accumulation. A rugged sheath covering the pipes is also supplied, both for looks and safety.

BOOM SECTION

For the GOLD series, the section of the boom is formed by an integral metal plate in the outer area and a C profile in the inner area, an ideal solution in terms of great strength and overall lightness.

Front loader with manual implement levelling- Fitting brackets supporting loader from tractor front end to rear axle shafts

- Hydraulic system conforming to tractor specifications

GOLD H

-

The new GOLD range offers multiple options for implement self-levelling and increased lifting power. It is supplied as standard with the anti-bounce GENIUS SYSTEM.

HYDRAULIC PIPES

By replacing the iron pipes with flexible pipes, it has been possible to partially integrate the hydraulics on the inside of the boom, thus providing enhanced protection, better visibility and reduced dirt accumulation. A rugged sheath covering the pipes is also supplied, both for looks and safety.

BOOM SECTION

For the GOLD series, the section of the boom is formed by an integral metal plate in the outer area and a C profile in the inner area, an ideal solution in terms of great strength and overall lightness.

Front loader with hydraulic implement self-levelling system- Fitting brackets supporting loader from tractor front end to rear axle shafts

- Hydraulic system conforming to tractor specifications

TITANIUM

TITANIUM M

-

High-duty front end loader which combines power with technologically advanced solutions, the ideal mix of lifting force and fully-accessorised equipment for the professional users. All hydraulic pipes are covered by protection plates which protect them completely. The plates can be easily removed in case of need while servicing pipes. Thanks to this equipment visibility is highly improved and dirt/residue accumulation on the pipes is prevented.

Standard features to the TITANIUM series are the anti-bounce GENIUS SYSTEM and the hydraulic multi-connector device FLASH SYSTEM.

BOOM SECTION

The boom section is mono-bloc, that is consisting of a single metal sheet duly bent and welded only in the lower area to form a solid structure which is robust and “light” at the same time, as well as nicely finished.

Front loader with mechanical implement self-levelling system- Fitting brackets supporting loader from tractor front end to rear axle shafts

- Hydraulic system conforming to tractor specifications

TITANIUM F

-

High-duty front end loader which combines power with technologically advanced solutions, the ideal mix of lifting force and fully-accessorised equipment for the professional users. All hydraulic pipes are covered by protection plates which protect them completely. The plates can be easily removed in case of need while servicing pipes. Thanks to this equipment visibility is highly improved and dirt/residue accumulation on the pipes is prevented.

Standard features to the TITANIUM series are the anti-bounce GENIUS SYSTEM and the hydraulic multi-connector device FLASH SYSTEM.

BOOM SECTION

The boom section is mono-bloc, that is consisting of a single metal sheet duly bent and welded only in the lower area to form a solid structure which is robust and “light” at the same time, as well as nicely finished.

Front loader with manual implement levelling- Fitting brackets supporting loader from tractor front end to rear axle shafts

- Hydraulic system conforming to tractor specifications

TITANIUM H

-

High-duty front end loader which combines power with technologically advanced solutions, the ideal mix of lifting force and fully-accessorised equipment for the professional users. All hydraulic pipes are covered by protection plates which protect them completely. The plates can be easily removed in case of need while servicing pipes. Thanks to this equipment visibility is highly improved and dirt/residue accumulation on the pipes is prevented.

Standard features to the TITANIUM series are the anti-bounce GENIUS SYSTEM and the hydraulic multi-connector device FLASH SYSTEM.

BOOM SECTION

The boom section is mono-bloc, that is consisting of a single metal sheet duly bent and welded only in the lower area to form a solid structure which is robust and “light” at the same time, as well as nicely finished.

Front loader with hydraulic implement self-levelling system- Fitting brackets supporting loader from tractor front end to rear axle shafts

- Hydraulic system conforming to tractor specificationse

PLATINUM

PLATINUM M

-

The new frontier of the SIGMA 4 front end loaders, the latest achievement combining top performances, advanced technology and greatest power, together with fully-accessorised equipment for daily professional use.

This loader series has merged a harmonious and agreeable design to the force necessary to perform the heaviest duties of the agricultural work.

The Platinum loaders are supplied as standard with the anti-bounce GENIUS SYSTEM and with the hydraulic multi-connector device FLASH SYSTEM.

The accessories fitted on the loader boom such as the GENIUS SYSTEM and the electro-valves for the 3rd and 4th hydraulic functions are also protected thanks to their placement on the cross bar, which safeguards them from possible damages and wearing agents.

BOOM SECTION

The boom section is mono-bloc, that is consisting of a single metal sheet duly bent and welded only in the lower area to form a solid structure which is robust and “light” at the same time, as well as nicely finished.

FULLY INTEGRATED HOSES AND CABLES

he new design with internal routing of hydraulic hoses and cables assures full protection to these components as well as enhanced visibility for the operator. The accumulation of dirt and residue on the pipes is prevented , but at the same time full accessibility is guaranteed to facilitate maintenance.

Front loader with mechanical implement self-levelling system- Fitting brackets supporting loader from tractor front end to rear axle shafts

- Hydraulic system conforming to tractor specifications

PLATINUM F

-

The new frontier of the SIGMA 4 front end loaders, the latest achievement combining top performances, advanced technology and greatest power, together with fully-accessorised equipment for daily professional use.

This loader series has merged a harmonious and agreeable design to the force necessary to perform the heaviest duties of the agricultural work.

The Platinum loaders are supplied as standard with the anti-bounce GENIUS SYSTEM and with the hydraulic multi-connector device FLASH SYSTEM.

The accessories fitted on the loader boom such as the GENIUS SYSTEM and the electro-valves for the 3rd and 4th hydraulic functions are also protected thanks to their placement on the cross bar, which safeguards them from possible damages and wearing agents.

BOOM SECTION

The boom section is mono-bloc, that is consisting of a single metal sheet duly bent and welded only in the lower area to form a solid structure which is robust and “light” at the same time, as well as nicely finished.

FULLY INTEGRATED HOSES AND CABLES

he new design with internal routing of hydraulic hoses and cables assures full protection to these components as well as enhanced visibility for the operator. The accumulation of dirt and residue on the pipes is prevented , but at the same time full accessibility is guaranteed to facilitate maintenance.

Front loader with manual implement levelling- Fitting brackets supporting loader from tractor front end to rear axle shafts

- Hydraulic system conforming to tractor specifications

PLATINUM H

-

The new frontier of the SIGMA 4 front end loaders, the latest achievement combining top performances, advanced technology and greatest power, together with fully-accessorised equipment for daily professional use.

This loader series has merged a harmonious and agreeable design to the force necessary to perform the heaviest duties of the agricultural work.

The Platinum loaders are supplied as standard with the anti-bounce GENIUS SYSTEM and with the hydraulic multi-connector device FLASH SYSTEM.

The accessories fitted on the loader boom such as the GENIUS SYSTEM and the electro-valves for the 3rd and 4th hydraulic functions are also protected thanks to their placement on the cross bar, which safeguards them from possible damages and wearing agents.

BOOM SECTION

The boom section is mono-bloc, that is consisting of a single metal sheet duly bent and welded only in the lower area to form a solid structure which is robust and “light” at the same time, as well as nicely finished.

FULLY INTEGRATED HOSES AND CABLES

he new design with internal routing of hydraulic hoses and cables assures full protection to these components as well as enhanced visibility for the operator. The accumulation of dirt and residue on the pipes is prevented , but at the same time full accessibility is guaranteed to facilitate maintenance.

Front loader with hydraulic implement self-levelling system- Fitting brackets supporting loader from tractor front end to rear axle shafts

- Hydraulic system conforming to tractor specifications

COMPACT TRACTOR

PC 830 - 910

-

Our PC 830-PC 910 front end loader range, completely updated in design and performance, are exceptionally reliable machines due to the latest solutions adopted, and are extremely competitively priced within this market segment.

BOOM SECTION

For the PC 830-PC 910 series, the section of the boom is formed by an integral metal plate in the outer area and a C profile in the inner area, an ideal solution in terms of great strength and overall lightness.

Front loader with mechanical implement self-levelling system

Fitting brackets supporting loader from tractor front end to rear axle shafts

Hydraulic system conforming to tractor specifications

Standard equipment- Two double acting cylinders for lifting

- Two double acting cylinders for the operation of the implement

- Quick-release of loader from tractor

- Implement quick release

- Hydraulic quick-fit couplings

- Adjustable support legs

Blade

BULLDOZER BLADE

-

The deep experience and the high manufacturing technology developed by Sigma 4 are combined in this line of front dozer blades for crawler tractors. Inspired by an industrial blade design, rugged construction and full reliability, the dozer blade can perform heavy duty jobs at the farm. Clearing land or snow, piling silage, levelling ground, grading…all operations quickly and easily performed.

The sturdy frame is built around the tractor to assure ideal repartition of loads for a high working capacity and a minimum stress on the tractor. The reversible double edged blade is made of highly resistant steel for long durability at work. The efficiency and the rapidity of the frame coupling/decoupling operations are assured by the smart Velotak quick-fit system.

The Sigma 4 dozer blades are clearing the way to higher productivity.

PC 4000 COMBI

-

High performances, innovative technology and great versatility. These are the main features of the PC 4000, a front end loader for crawler tractors easily changeable into a dozer blade. The sturdy frame is built around the tractor to assure ideal repartition of loads, for a high working capacity and a minimum stress on the tractor. The unit is supplied in a full package including a dozer blade as well as a bucket and the hydraulic system to suit tractor hydraulic output. For enhanced versatility in the works at the farm, a full set of implements is available upon request.

The efficiency and the rapidity of the frame coupling/decoupling operations are assured by the smart Velotak quick-fit system.

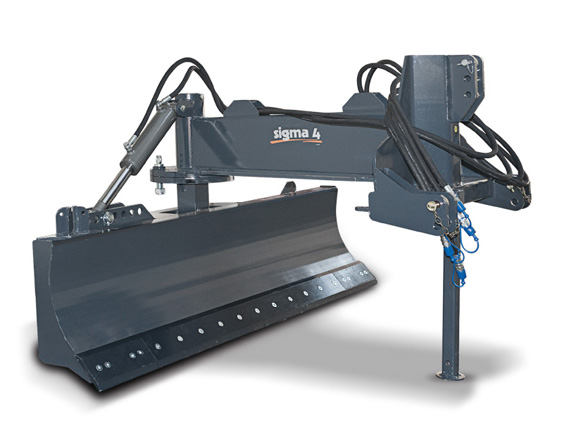

REAR BLADE RGB

-

REAR GRADER BLADE WITH MECHANICAL ANGLING

Rear-mounted equipment ideal for levelling, finish grading, backfilling and other types of maintenance operations at the farm. It is mounted on the tractor 3-point linkage and connected to the main hydraulic circuit and, as such, not requiring any extra installations.

Gauge wheels

They enable great uniformity and accuracy during levelling and finish grading operations. Height can be mechanically adjusted.

Tilt ram

Designed to hydraulically control the blade tilt (27°) and allowing for a working depth of more than 30 cm.

Side ram

Allowing for blade offset up to 60 cm on either side.

Blade angle

Mechanically adjustable and allowing a maximum rotation up to 180°.

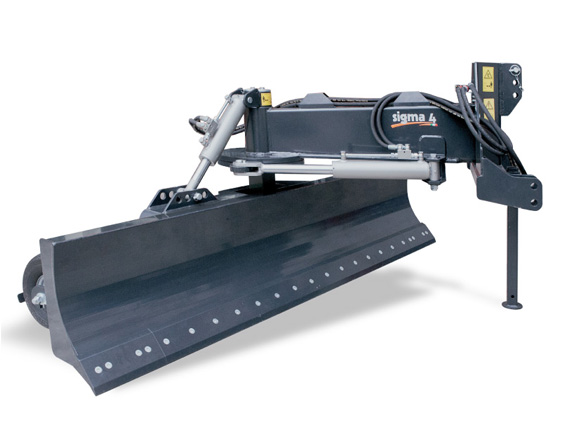

REAR BLADE RGB HD

-

REAR GRADER BLADE WITH HYDRAULIC ANGLING

High-duty equipment fitted to the 3-point linkage and requiring a tractor equipped with 3 double-acting spool valves. The blade angle is easily and comfortably regulated from the operator's seat. It is particularly suitable to all kind of grading operations on the farm and it is also suitable for snow cleaning. It guarantees the satisfaction of every user, even the most demanding ones.

Gauge wheels

They enable great uniformity and accuracy during levelling and finish grading operations. Height can be mechanically adjusted.

Tilt ram

Designed to hydraulically control the blade tilt (27°) and allowing for a working depth of more than 30 cm.

Side ram

Allowing for blade offset up to 60 cm on either side.

Angling ram

Designed to control the blade angling and allowing a maximum rotation of 40°, it enhances the operator's comfort as the regulation is operated from the tractor's seat.

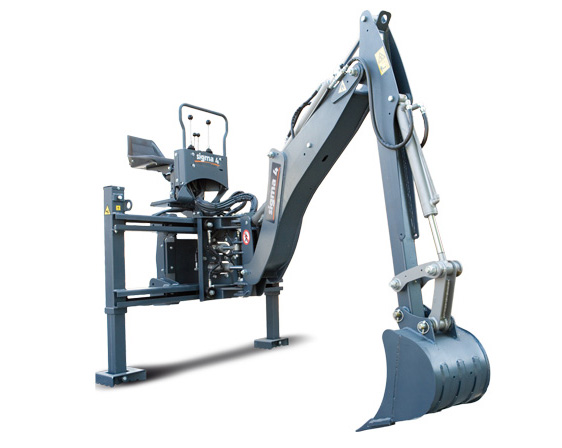

Backhoes

BACKHOES FIXED FRAME

-

BACKHOES WITH FIXED FRAME - SERIES U

The Sigma 4 backhoes are three-point-hitched through an adjustable coupling system. They are easily hitched and perfectly locked to the back of the tractor allowing for great stability as well as comfortable and safe operations. Hitching and unhitching procedures are easy and rapid even for non-professional users. While working, the stress is distributed on the two stabilizer legs, safeguarding the tractor. The hydraulic cylinders – fed by a pump which in turn is driven by the tractor P.T.O. – control the movement of arms and bucket. The rams are connected to the hydraulic distributor and operated by means of levers placed on the control console in front of the seat. The Sigma 4 backhoes are for customers looking for an excellent product at the best market price.

The backhoe series “U”, without a shifting frame, is particularly suitable for customers who are regularly working on in open fields or gardens. It is extremely stable thanks to the wide open position reached by the stabilizer legs.

Easily accessible and adjustable seat. Its ergonomic design and its position to allow for excellent visibility make the work safer and comfortable!

The two Sigma 4 backhoe series have the same components and hydraulic parts – the only difference is the shifting frame on the series “C” and the fixed frame in the series “U”.

BACKHOES SHIFTING FRAME

-

BACKHOES WITH SHIFTING FRAME SERIES C

The Sigma 4 backhoes are three-point-hitched through an adjustable coupling system. They are easily hitched and perfectly locked to the back of the tractor allowing for great stability as well as comfortable and safe operations. Hitching and unhitching procedures are easy and rapid even for non-professional users. While working, the stress is distributed on the two stabilizer legs, safeguarding the tractor. The hydraulic cylinders – fed by a pump which in turn is driven by the tractor P.T.O. – control the movement of arms and bucket. The rams are connected to the hydraulic distributor and operated by means of levers placed on the control console in front of the seat. The Sigma 4 backhoes are for customers looking for an excellent product at the best market price

The backhoe series “C” is the best selling model. Its frame can be hydraulically shifted with no need of getting off the seat. Side-shift is a very crucial feature for operators working in row cultivations, such as orchards and vineyards, and more in general in narrow areas where stabilizer legs may not be easily fitted.

Easily accessible and adjustable seat. Its ergonomic design and its position to allow for excellent visibility make the work safer and comfortable!

Independent stabilizer legs with remote-controlled locking valves. Our backhoes feature side-shift extension to optimize the equipment performance as well as the operator\'s safety in any working condition.

The two Sigma 4 backhoe series have the same components and hydraulic parts – the only difference is the shifting frame on the series “C” and the fixed frame in the series “U”.

Implements

EARTH BUCKET - BT

-

All of our buckets are tapered, and thus easy to fill as material does not need to be pressed while loading. The bucket's tapered design and absence of angles remarkably reduce the product adherence to the side plates of the implement, which can be filled and emptied completely and rapidly. On our implements, designed for professional users, the primary goal is to avoid any unintentional loss of the load during transportation.

Our buckets are strengthened on the inside through a central limb and can be fitted with a wearing blade on the lower edge thanks to predisposed holes. These are also used to fit bucket teeth, available on demand.

CEREAL BUCKET - BC

- Developed for voluminous loads and particularly adapted to the transportation of cereals and other similar low-density products. On the upper lip against the back plate a containment edge is fitted: the latter, combined with a greater depth on the bucket design, greatly enhance the loading capacity..

4-in-1 BUCKET - B41

- Versatile bucket that can be used for a number of different operations generally requiring several implements, such as loading, snow clearing, ground grading, etc. Its use requires the fitting of a supplementary hydraulic line on the loader.

MULTIPURPOSE BUCKET - BM

- This bucket facilitates silage extraction thanks to the design of its teeth, which press the product, grab it and push it on the inside. The bucket frame is completely enclosed to avoid maize silage or other similar products which tend to crumble being dispersed. Its use requires the fitting of a supplementary hydraulic line on the loader.

MULTIGRAB BUCKET - BK

- Designed to load different types of products, such as compost, forage and straw. The bucket design with closed bottom enables an easy and accurate loading of the material, as well as a comfortable penetration into compact products such as silage. Its use requires the fitting of a supplementary hydraulic line on the loader.

ROUND BALE FORK - BRO

- Simple and robust attachment to load round bales. On demand it can be fitted with an extension that allows the transport of two bales simultaneously and with a third supplementary spike for better stability of the load.

ROUND BALE FORK WITH EXTRA LIFT - BRO/TE

- Fork for the load of round bales that offers enhanced stocking options thanks to its frame which is fitted with an extra-lift function. This requires the fitting of a supplementary hydraulic line on the loader.

GRAB FOR ROUND BALES - BRM

- Designed to load round bales into mixers and to transport other similar material such as branches and sugar canes. Its use requires the fitting of a supplementary hydraulic line on the loader.

GRAB FOR WRAPPED BALES - FMR

-

Developed for transport and loading of wrapped bales with diameter from 90 up to 160 cm.

The grab arms exert a uniform pressure on the bale without damaging its wrapping film. Its use requires the fitting of a supplementary hydraulic line on the loader.

FORK FOR WRAPPED BALES - FMP

- Robust and versatile implement enabling the loading of wrapped bales with no damage to the wrapping film. The same fork, when steel tubes are removed, can be used to transport hay or straw bales. Its use requires the fitting of a supplementary hydraulic line on the loader.

PALLET FORK - FP

- Thanks to its solid and compact structure, the loads suffer minimum oscillation and thus risk of load loss is greatly reduced. The forks are laterally adjustable so that weight can be evenly distributed.

PALLET FORK WITH SIDE SHIFT CASE GRAB - FPT-S

- Implement that offers enhanced stocking options thanks to its frame which is fitted with a side-shift function, as well as providing safer transport through the case grab. The use of this fork requires the fitting of 2 supplementary hydraulic lines on the loader.

MANURE GRAB - FLE-T

- Multipurpose attachment that reduces to the minimum the load dispersion thanks to the tiny distance between its lower teeth. The fine quality tines, fitted with special reinforcement bushes, are mounted on a solid frame that does not suffer any distortion under the load weight. Its use requires the fitting of a supplementary hydraulic line on the loader.

SILAGE CUTTER GRAB - FSC

-

Reliable, it requires very low maintenance thanks to its hardened cutting blades, our FSC leaves a clean cut on the silage.

The tines are top-quality and highly resistant, the frame is strengthened to face the hardest kind of works without torsions or component damages during operation. Its use requires the fitting of a supplementary hydraulic line on the loader.

MECHANICAL TILTING BLADE - LAI

- Solid and very adaptable blade, with mechanical angling of 30°, it is ideal for trail cleaning and for overall grading operations on the farm. It is also suitable for snow cleaning. Its use requires the fitting of a 4th floating position on the loader valve chest. The floating position adjust the implement as to follow the ground configuration.

BEET BUCKET - BB

ROUND BALE FORK - BRO-NZ

LARGE SQUARE BALE FORK - BB2

ROUND BALE FORK WITH SIDE SHIFT - BRO/T

REAR MOUNTED ROUND BALE FORK - BRO/PO

PALLET FORK WITH SIDE SHIFT - FPT

MANURE GRAB - FLET-NZ

MANURE FORK - FLE

STONE BUCKET - FSA

LOG GRAB - FT

COUNTER WEIGHT BOX