- Offer Profile

-

VENSYS ENERGY is a leading manufacturer of gearless wind turbines in the megawatt and multi-megawatt class. More than 50,600 MW installed power already has been connected to the grid worldwide.

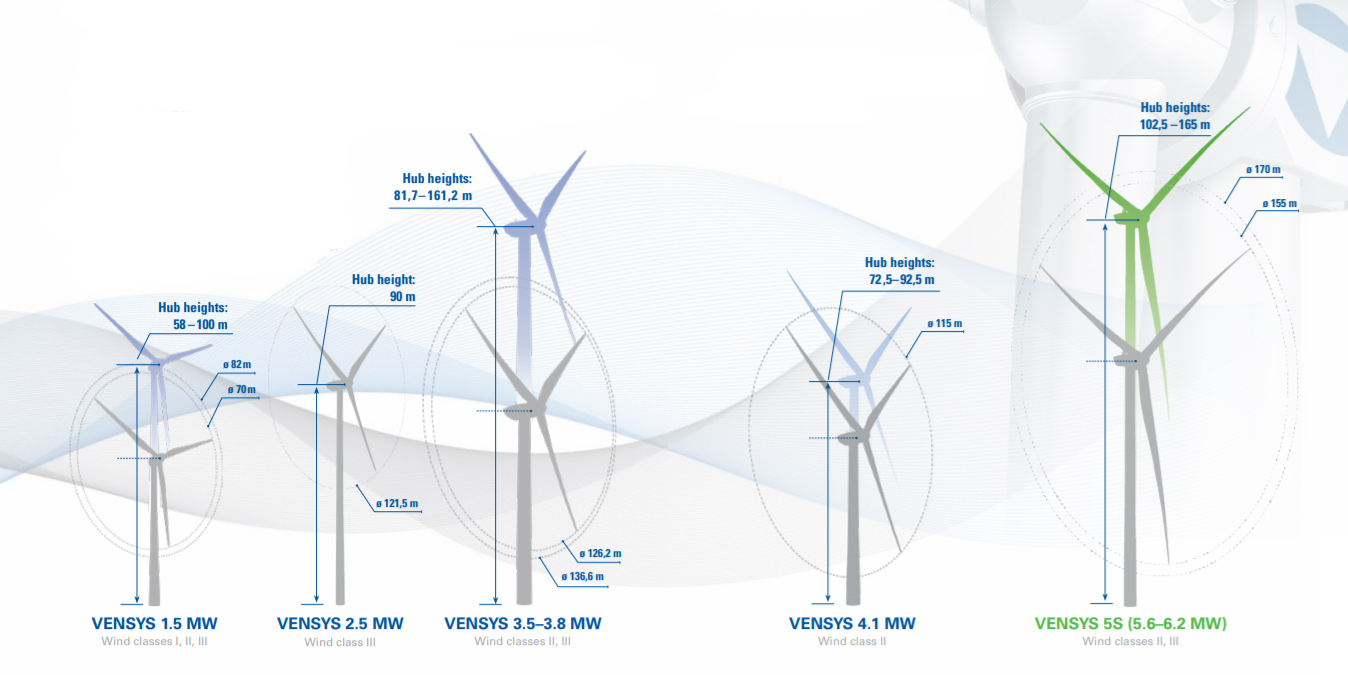

The right solution for every requirement

High yields in every locationA wide range of platforms featuring variable tower heights, rotor diameters and generators with different power outputs ensure configurations that are perfectly adapted to local requirements and provide the maximum energy yields for all wind classes even in areas where wind conditions are poor.

VENSYS also erects all kinds of tower systems and has extensive experience with up to 165-meter hybrid towers as well as single-blade assembly in a demanding construction environment. Low sound emissions are another reason why our turbines are perfect for virtually any location.

Wind Turbines

-

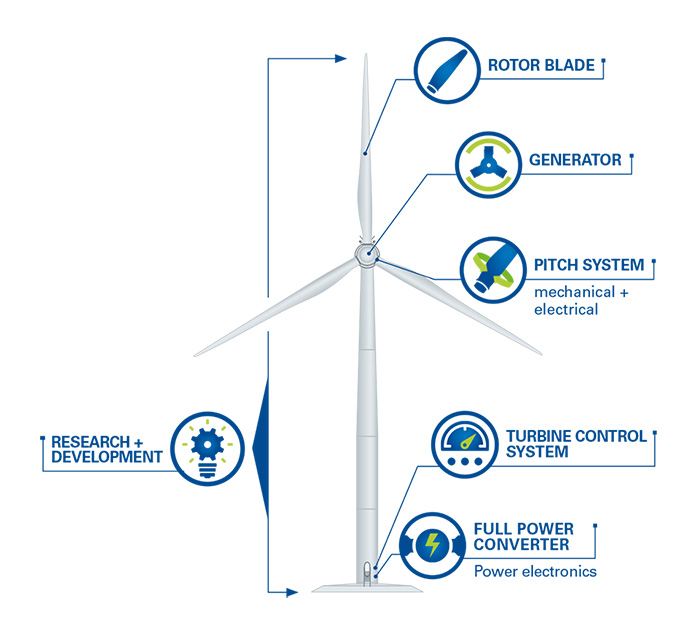

THE IDEA - Brilliantly simple

Fewer components, higher wind energy yield, reliable operation

VENSYS Energy AG with its head office in Neunkirchen/Germany develops and manufactures gearless wind turbines

We have made a name for ourselves with high-performance turbines that feature a permanently magnet-excited multi-polar generator, a low-maintenance toothed-belt drive for the blade pitch system, a simple generator cooling and the full-power converter system that allows for a wide range of grid requirements to be met.

The special turbine design relies on a minimum number of high-quality and long-lasting components. High efficiency, low maintenance as well as the compact design and the advantages of systems that are virtually free of wear ensure consistently higher yields.

We deliver the complete range: from the tower base to the tip of the rotor blade

-

All the core components of VENSYS wind turbines are designed by our experienced engineers and manufactured in different production facilities of the VENSYS Group.

While the full-power converter and the special electrical pitch system are produced at Vensys Elektrotechnik in Diepholz, the multi-polar generatoris assembled in Neunkirchen. Production of our rotor blades for different power classes is carried out by E-Blades, our subsidiary in Spain.

It is this interaction of perfectly-coordinated key components paired with our own turbine control system which guarantees reliable engine technology – made by VENSYS.

The NEW VENSYS

-

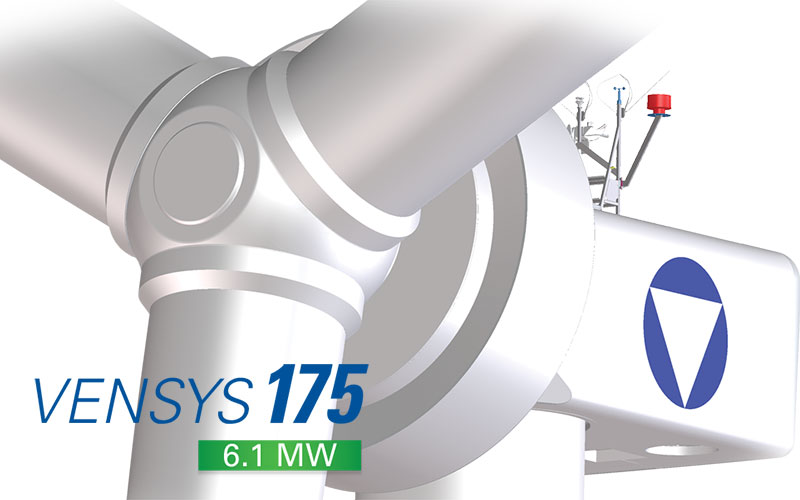

PLATFORMS: 6.1-6.2

VENSYS 175

-

Wind Turbine Operating Data:

- Rated Power: 6.1 MW

- Cut-in Wind Speed: 3 m/s

- Cut-out Wind Speed: 22 m/s

- Operating Temperature: -20 °C to 40 °C

VENSYS 155

-

Operating Data:

- Rated power: 6.2 MW

- Cut-in wind speed: 3 m/s

- Cut-out wind speed: 25 m/s

- Operating temperature: -20 °C to 40 °C

VENSYS 5S Platform

-

- The ongoing reduction of energy costs will be continued with this platform

- Transport optimisation through segmented design of components

- Thirty years of experience using permanent magnet technology

- Low-wear and low-maintenance rotor blade pitch system

- Joint development with Goldwind

VENSYS 155

- Rated power: 6,2 MW

Cut-in wind speed: 3 m/s

Cut-out wind speed: 25 m/s

Rotor diameter: 155,0 m

Swept area:18,869 m2

Rated speed: 9,1 rpm

Hub heights: 102,5 | 122,5 m (Steel tube) – 152,5 m (Hybrid tower)

Wind Class: IEC IIA

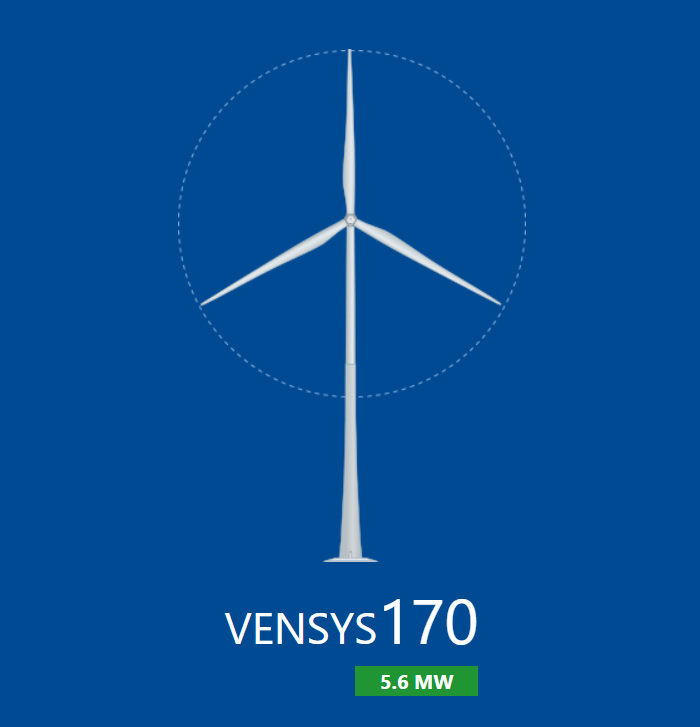

VENSYS 170

-

Rated power: 5,6 MW

Cut-in wind speed: 3 m/s

Cut-out wind speed: 22 m/s

Rotor diameter: 170,0 m

Swept area:22,698 m2

Rated speed: 8,3 rpm

Hub heights: 115 m (Steel tube) – 165 m (Hybrid tower)

Wind Class: IEC IIIA

VENSYS 4.x MW Platform

VENSYS 115

-

- Lower repair and maintenance costs through high-quality and durable components.

- Fully encapsulated generator cooling system with air-to-air heat exchangers.

- High-quality permanent magnets for a higher energy yield.

- Low-wear and low-maintenance blade pitch system with toothed belt drive.

Rated power: 4,1 MW

Cut-in wind speed: 3 m/s

Cut-out wind speed: 25 m/s

Rotor diameter: 114,95 m

Swept area: 10,378 m2

Hub height: 72,5m, 92,5m Steel tube/hybrid (concrete/steel)

Wind Class: IEC IIA

VENSYS 3.x MW Platform

-

VENSYS 3.5 MW: The logical upgrade

Based on the VENSYS 3.0 MW platform, the VENSYS 136 with an output of 3.5 MW is the logical upgrade of our proven bestseller.

The gearless alternative from VENSYS for the 3 MW class.

- We deliberately dispense with a gearbox, thus reducing repair and maintenance costs. The product´s main feature, however, is the significantly increased yield, especially in the partial-load range.

- Both the generator and the air-to-air heat exchanger cooling system are fully encapsulated, dispensing with the need for additional cooling liquids or oils – environmentally a step in the right direction.

- The use of high-quality permanent magnets instead of electrical excitation power results in higher electricity production.

VENSYS 126

- Rated power: 3,8 MW

Cut-in wind speed: 3 m/s

Cut-out wind speed: 25 m/s

Rotor diameter: 126,15 m

Swept area: 12499 m2

Rated speed: 11,5 rpm

Hub height: 86m, 96m Steel tube/hybrid (concrete/steel)

Wind Class: IEC IIA

VENSYS 136

- Rated power: 3,5 MW

Cut-in wind speed: 3 m/s

Cut-out wind speed: 22 m/s

Rotor diameter: 136,6 m

Swept area:14,655 m2

Rated speed: 10.7 rpm

Hub height: 82m, 100m, 132m Steel tube/hybrid (concrete/steel)

Wind Class: IEC IIA

VENSYS 1.5 MW Platform

-

Gearless and with permanent magnet technology instead of excitation power and gearbox losses. With an air-cooled generator and air-cooled VENSYS frequency converter for the most varied grid requirements.

With a low-maintenance blade pitch system made by VENSYS using a toothed belt drive featuring its own pitch control system.

With over 11,200 turbines installed, the VENSYS 1.5 MW platform is the world's most frequently installed gearless 1.5 MW turbine of our time.

70, 77, 82 and 87 meters: Offering a choice between four different rotor diameters, it is suitable for the most varied wind zones. Further information can be obtained from the technical data sheet.

The best-seller in its classProduct advantages:

- Dispensing with a gearbox means less repair work and lower maintenance costs while at the same time enjoying a higher yield, especially when working in the partial-load range.

- High-quality permanent magnets save excitation power, resulting in higher energy yields.

- The air-cooling system on both the generator and the VENSYS frequency converter further reduces the number of components and eliminates the need for cooling agents and maintenance work.

- The blade pitch system with a toothed belt drive works without lubrication and keeps wear and maintenance to a minimum.

A gearless VENSYS wind turbine in the 1.5 MW class requires fewer components, reduces wear and carries a higher yield. It complies with all grid requirements and qualifies for the “Systems Service Bonus”

VENSYS 70

-

Rated power: 1.5 MW

Cut-in wind speed: 3 m/s

Cut-out wind speed: 25 m/s

Rotor diameter: 70.3 m

Swept area: 3882 m2

Rated Speed: 19 rpm

Gearbox: no gears

Power control: pitch

Brakes: single-blade adjustment, triple redundant

Grid Connection: frequency converter

Yaw System: geared electric motors

Tower: 65m, 85m steel tube

VENSYS 82

- Rated power: 1.5 MW

Cut-in wind speed 3 m/s

Cut-out wind speed: 22 m/s

Rotor diameter: 82.3 m

Swept area: 5320 m2

Rated Speed: 17,3 rpm

Gearbox: no gears

Power control: pitch

Brakes: single-blade adjustment, triple redundant

Grid Connection: frequency converter

Yaw System: geared electric motors

Control system: microprocessor controlled

Tower: 58m, 70m, 75m, 85m, 100m steel tube

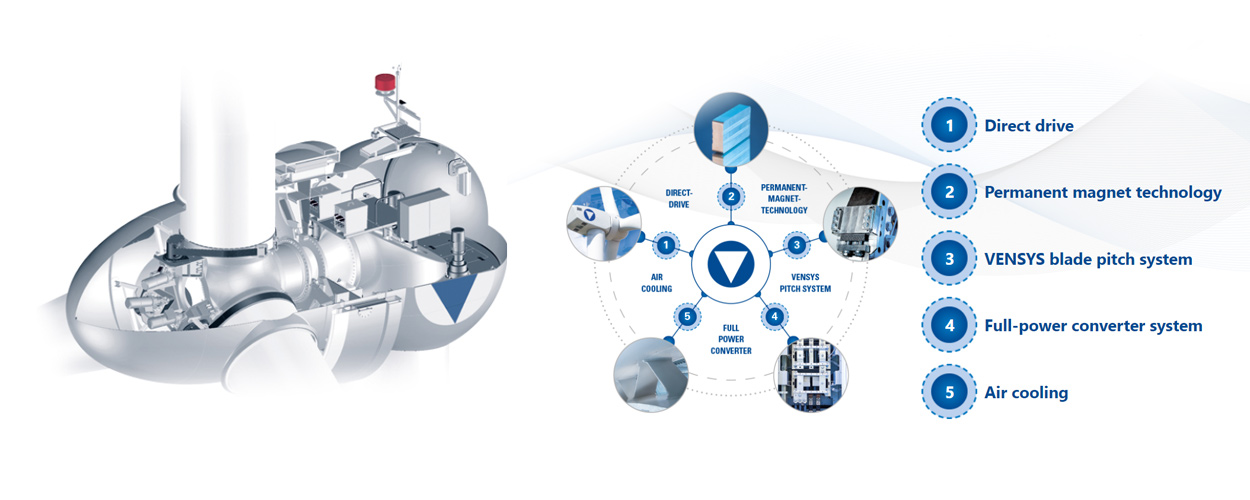

Technology

Five distinctive features

- Generator

- Permanent Magnet Technology

- Full-power converter

- Blade Pitch System

- Generator Cooling

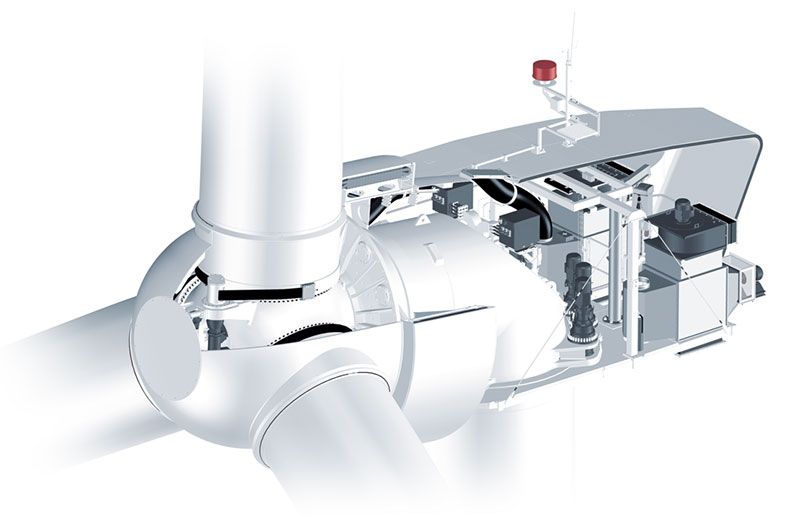

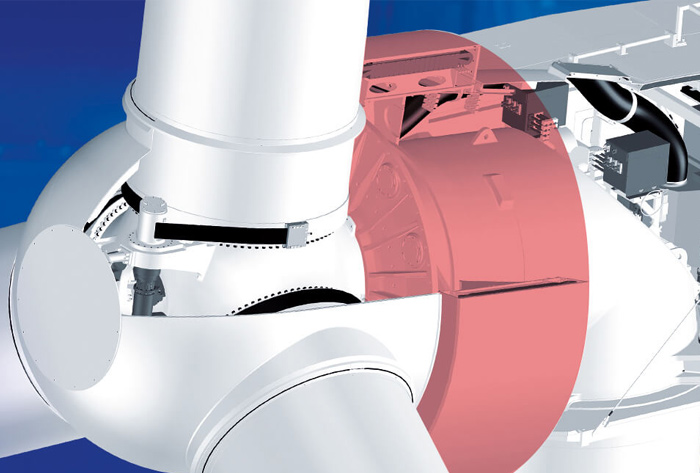

THE GENERATOR

-

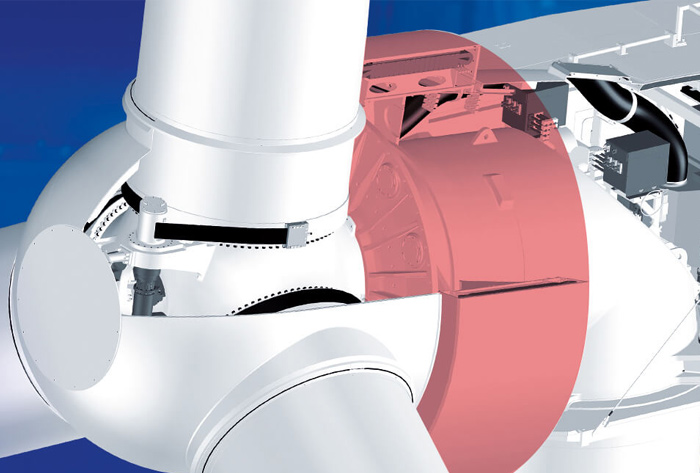

The direct-drive system – all the advantages of gearless machines

Wind turbines designed by VENSYS operate without high-maintenance gearboxes that are prone to wear. They save on elaborate technology and require fewer environmentally hazardous lubricants and consumables than conventional transmission systems. Safe and efficient operation thus go hand in hand.

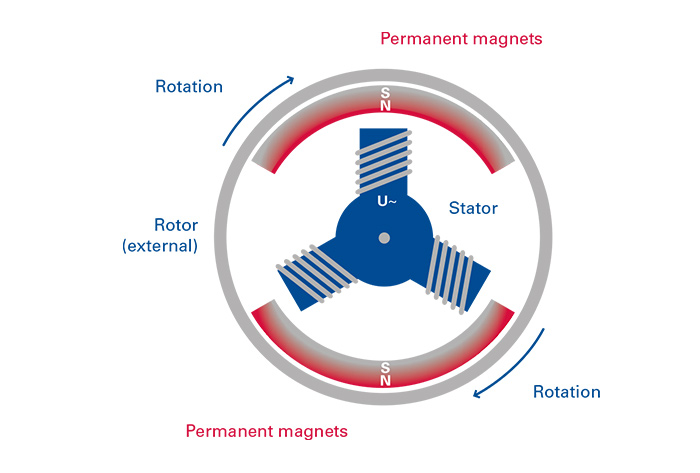

VENSYS combines the advantages of gearless technology with the generator concept of a synchronous machine with permanent magnet excitation. The rotor speed is transferred directly to the multi-polar generator – completely without any excitation losses. The gearless technology design concept used by VENSYS thus leads to high wind yields and high returns.

High performance paired with a low tower head mass

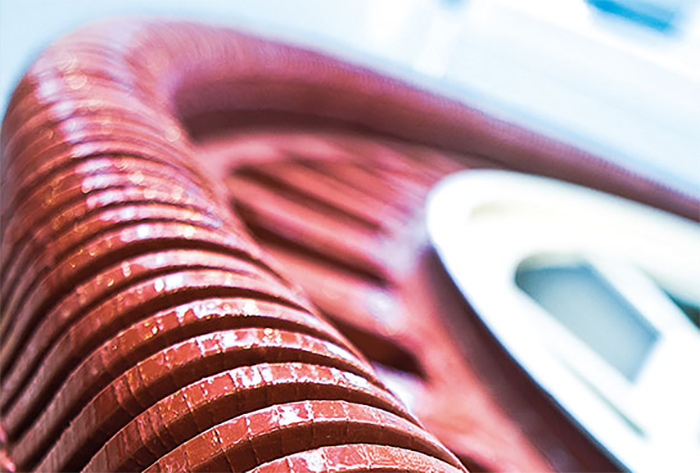

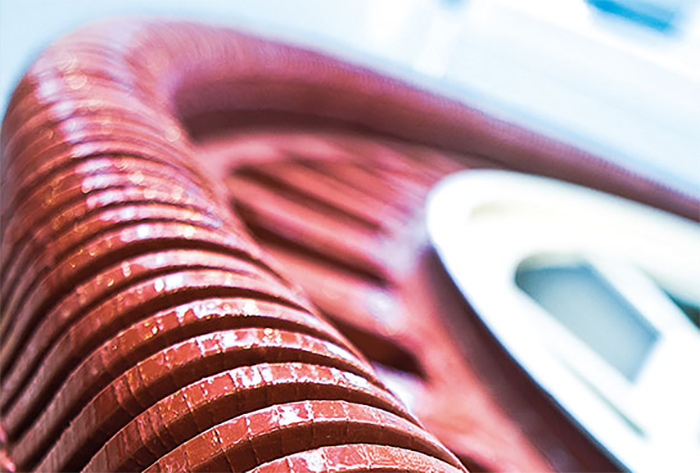

VENSYS wind turbines are equipped with a directly driven, permanently magnet-excited synchronous generator. The high-quality permanent magnets are fitted to the outer cover of the rotor, reducing heat losses in the generator and providing for simple and efficient cooling.

The shape of the external rotor supports a compact design, making the best possible use of the tower head volume. A maximum generator diameter can be achieved on a reduced surface – yet another aspect why VENSYS is synonymous with enhanced efficiency.

Permanent Magnet Technology

-

High efficiency = higher yield

VENSYS utilizes permanent magnet technology known from electric drives in navigation and electric vehicles with a tailor-made turbine design concept for wind energy purposes.

The robust VENSYS generators bring together three decades´ worth of know-how in independent research work on permanent magnet technology. The generators of the 2.5/3.0 platform are performance-optimized enhancements with an even larger diameter and greater length yet lower speed.

No excitation losses = even higher yield

Unlike electrical excitation, permanent magnet technology does not have the disadvantage of excitation losses. The savings in excitation power are thus fully available as additional energy yield in VENSYS wind turbines.

This leads to improved efficiency, in particular in the low or partial-load range. In addition, there is no need to transfer the excitation power by means of slip rings, which saves on complex turbine components and reduces production and operation costs.

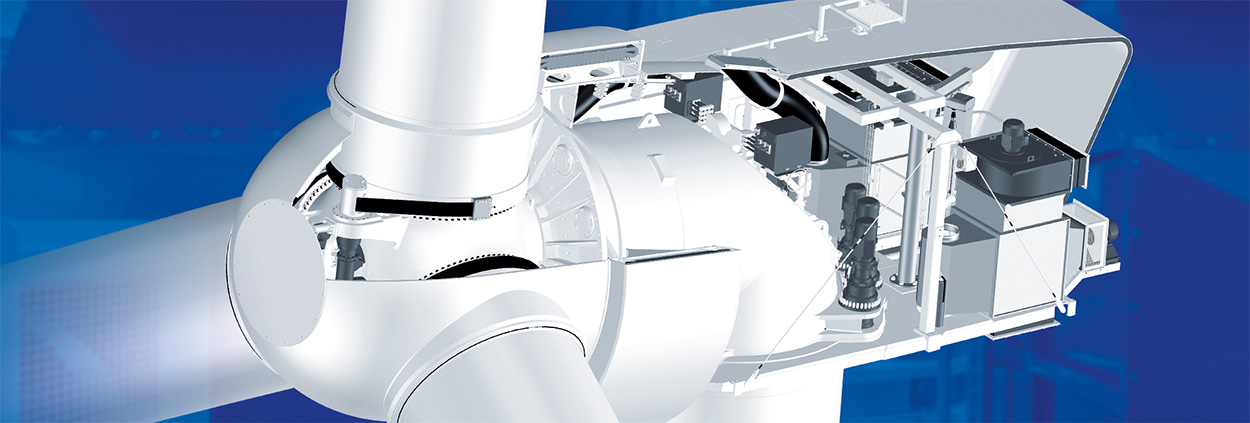

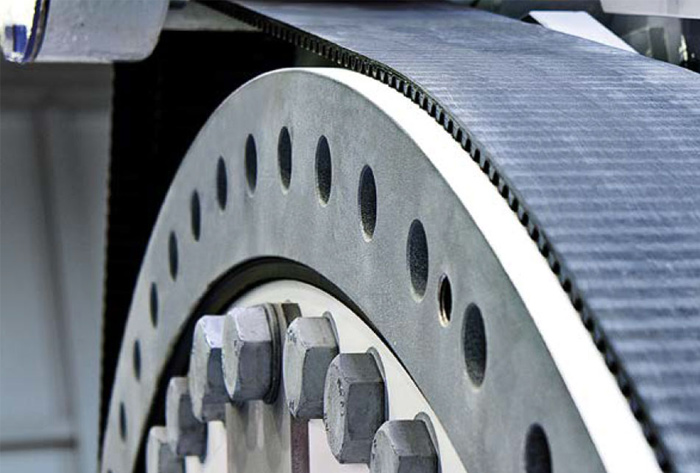

Blade Pitch

-

Low-wear and low-maintenance toothed-belt drive

A special feature of VENSYS wind turbines is the lubrication-free toothed belt for transmitting the force between the pitch drive and the rotor blade. Our extremely durable drive system thus prevents wear as a result of corrosion or pitting which can be found in conventional rotor blade adjustment systems using gearing and drive pinions.

The pitch system requires virtually no maintenance. Due to integrated special fibers, the toothed belt is also impervious to shock load and can easily be exchanged if the need arises. The variable-speed rotor blade drive ensures very good incident flow even in the partial-load range.

More safety and long-term cost advantages

Our patented toothed-belt drive for the blade pitch system has stood the test of time in the most diverse locations: impervious to moisture, dirt and temperature changes as well as constant exposure in areas with strong and turbulent winds.

In addition, triple redundancy further enhances safety. The drive of each rotor blade comes with an energy storage device (capacitor), making sure that in the event of power failure the rotor blades can safely be driven into braking position. The long-life capacitors deliver the required power even in low temperatures.

Grid Connection

-

Connection with power plant properties

Feeding in short-circuit current, quick separation from the grid or bridging short-term voltage drops and sudden voltage rises in the grid: all these are power plant properties that distinguish VENSYS converter systems, making them suitable for universal grid connections.

The total power produced is directed via the VENSYS converter, which allows for the generator to be decoupled effectively from the grid. Power network disturbances and voltage fluctuations thus do not affect the control behavior of VENSYS wind turbines. The converter can even support weak grids.

Generator Cooling

-

Air cooling: simple, clean, easy to maintain

The generator is one of the core elements in the nacelle of any wind turbine. Generating electricity always entails heat losses, causing the copper windings to heat up. To prevent damage to the generator, the heat must be dissipated.

To do so, VENSYS relies on a simple yet efficient air cooling method. The generators of the 1.5 MW platform are cooled using a passive, maintenance-free air circulation system without any moving parts. The ambient air is directed through special cooling channels on the generator housing

Service

- Service: Our main focus is on your system – around the

clock

Making sure VENSYS wind turbines perform at their best over decades is what the VENSYS Service team is motivated by. We can control your wind turbine 24 hours a day using remote data monitoring. Around the clock, year in, year out. As a client you can log into your wind park or receive e-mail notifications from us to keep you informed at all times about the current status and the kilowatt hours produced.

Services are coordinated globally by office-based VENSYS employees via our cooperation partners on site. The office also provides competent client support for all technical questions. We offer a full maintenance agreement which includes all repair and service work - on a long-term basis. Additionally, we guarantee you high turbine availability. References

-

26.803 turbines featuring VENSYS technology

Wind farm Panama

-

- Turbine type: GW 109 | 2.5 MW

- Number of turbines: 86 turbines

- Total power installed: 215 MW

Wind farm Johnston USA

-

- Turbine type: VENSYS 120 | 3.0 MW

- Number of turbines: 7 turbines

- Total power installed: 21 MW

Wind farm Brasilien Südamerika

-

- Turbine type: VENSYS 70 + 77 | 1.5 MW

- Number of turbines: 63 turbines

- Total power installed: 79.5 MW

Wind farm Shady Oaks North America

-

- Turbine type: GW 82 + 100 | 1.5 MW / 2.5 MW

- Number of turbines: 71 turbines

- Total power installed: 109.5 MW

Wind farm Pakistan

-

- Turbine type: GW 77 | 1.5 MW

- Number of turbines: 33 turbines

- Total power installed: 49.5 MW

Wind farm Gullen Range Australia

-

- Turbine type: GW 82 + 100 | 1.5 MW / 2.5 MW

- Number of turbines: 73 turbines

- Total power installed: 165.5 MW

Wind farm Geneseo USA

-

- Turbine type: VENSYS 77 | 1.5 MW

- Number of turbines: 2 turbines

- Total power installed: 3 MW

Wind farm Chaiyaphum Thailand

-

- Turbine type: GW 121 | 2.5 MW

- Number of turbines: 32 turbines

- Total power installed: 80 MW

Wind farm Ethiopia

-

- Turbine type: GW 77 | 1.5 MW

- Number of turbines: 34 turbines

- Total power installed: 51 MW

Wind farm Zafarana Egypt

-

- Turbine type: VENSYS 70 | 1.5 MW

- Number of turbines: 2 turbines

- Total power installed: 3 MW

Wind farm Alexigros Zypern

-

- Turbine type: VENSYS 82 | 1.5 MW

- Number of turbines: 21 turbines

- Total power installed: 31.5 MW

Wind farm Kartowice Polen

-

- Turbine type: VENSYS 77 | 1.5 MW

- Number of turbines: 1 turbine

- Total power installed: 1.5 MW

Wind farm Nant Bach UK

-

- Turbine type: VENSYS 82 | 1.5 MW

- Number of turbines: 1 turbine

- Total power installed: 1.5 MW

Wind farm Kings Lynn UK

-

- Turbine type: VENSYS 77 | 1.5 MW

- Number of turbines: 1 turbine

- Total power installed: 1.5 MW

Wind farm Quarrendon UK

-

- Turbine type: VENSYS 87 | 1.5 MW

- Number of turbines: 1 turbine

- Total power installed: 1.5 MW

Reliable and virtually free of maintenance

Wherever reliability, operating safety and low maintenance requirements are needed, VENSYS wind turbines show what they are capable of. Not only do we deliberately dispense with a gearbox, our turbines also make do with a minimum number of high-quality components.

Unique turbine design

VENSYS has optimized wind turbines to the smallest detail. The simple setup of the system combines high durability and operating safety, which aims at high energy yields while minimizing losses. All of this is guaranteed by the five distinctive features of VENSYS technology: direct drive, permanent magnet technology, full-power converter system, the VENSYS blade pitch system and air cooling.