- Offer Profile

- The competence of Schneider

Messtechnik in contactless, optical measuring technology was already

established in the early-going. The production of optics and physical units

was decisive for the first 25 years of the company.

SIMPLY PRECISE

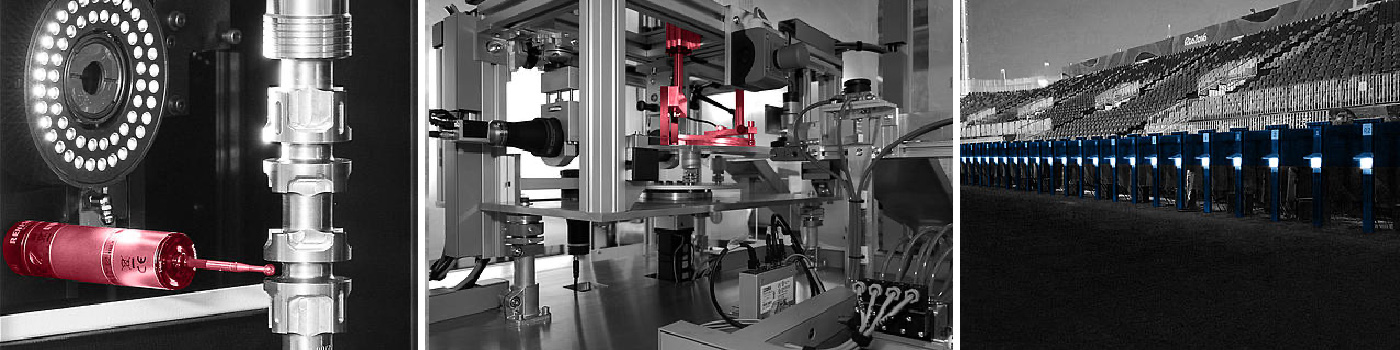

The combination of grown core competences in the optical, mechanical and tactile measuring technology enables the manufacturing of innovative products with highest precision claims.

PRODUCTS

-

As individual as your applications: Our tailored solutions

Do you have to measure exceptional sizes? Do you have to meet special customer requirements or employ your measurement technology under unusual conditions? Whatever it is: We find the right solution for you, e.g. with

- a modification of our standard measurement technologies and machines tailored to your needs

- customised development of additional machine functions or software tools

- development of customised forms tailored exactly to your needs (see example aerospace)

Let us formulate your wishes and applications together. Our specialists will be happy to advise you individually and will certainly find the right solution for you.

2D MULTISENSOR

WM1 707 G / WM1 710 G

-

Integrated image processing features, specially conceived for the measurement of large

- Blanked parts

- Milled parts

- Plastic parts

- Rubber parts

- Printed circuit boards

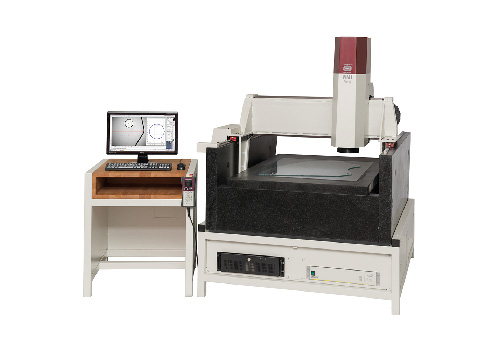

WM1 400 (300)

-

High-tech low budget, with integrated image processing or as small multisensor device for measurement of:

- Blanked parts

- Plastic parts

- Rubber parts

- Tools

- Seals

- Profiles, etc.

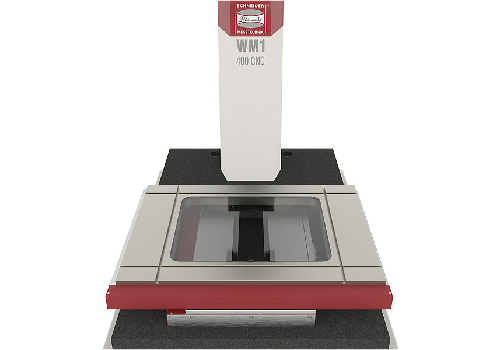

WM1 300 / WM1 400 / WM1 500

-

High-tech low budget, with integrated image processing or as small multisensor device for measurement of:

- Blanked parts

- Plastic parts

- Rubber parts

- Tools

- Seals

- Profiles, etc.

2D OPTICAL

V-CAD 300

-

Quick and precise measurement simple and intuitive

Highlights of the V-CAD 300

- Automatic recognition of control geometries without pre-selection

- No alignment of workpieces in the image field

- 4-step motor zoom for precise measurement of even the smallest features

- Measurements every second

V-CAD 80

-

The V-CAD 80 is a portable, optical video measuring device for the measurement of objects up to 76 x 63 mm.

Highlights of the V-CAD Series

- 2D digitization und BestFit included in the basis scope of supply

- Object detection in a matter of seconds as no axis movement is necessary

- Mobile installation in the production process possible

V-CAD 60

-

Quick and precise measurement simple and intuitive

Highlights of the V-CAD 60

- Automatic recognition of control geometries without pre-selection

- No alignment of workpieces in the image field

- 4-step motor zoom for precise measurement of even the smallest features

- Measurements every second

2D OPTICAL SHAFT

WMM 100 / WMM 200

-

WMM 100 and 200 Measuring made easy!

Highlights of the WMM 100 and 200

- Simple and quick measurement in seconds

- Intuitive user interface

- Reproducible measurement

- Calibration to ISO 10370-7

WMM 65

-

The WMM 65 optical measuring device can be modularly configured to meet the requirements of internal quality assurance processes.

The highlights

- Simple management of measurement programs

- Integration into the company network

- Interfacing to your CAQ interface

- Measurement directly on the production line

- Plug & Play installation thanks to works calibration

- Intuitive operation measurement within seconds

WMB 350

-

The perfect introduction to shaft measurement technology

Standard configuration of the WMM 350

- 5 megapixel CMOS b/w camera

- Telecentric lens for precise measurement

- Multi-touch panel PC with Windows operating system

- LAN and WLAN network interface

- Telecentric LED transmitted light illumination

- Green LED light and filter for reduction of interferences

- Works calibration certificate

- SAPHIR measurement and analysis software with SAPHIR shaft

3D MULTISENSOR CUBIC

PMS 400 / PMS 500

-

The stable portal construction of the measurement machine has not only been designed for measurement rooms but specifically to be used directly in the production hall. Completing measurements in close proximity to production thus significantly reduces non-productive times and saves money. In addition to a high-resolution CCD camera, the tactile or scanning probe and/or the optional measurement laser ensures it is suitable for universal use in many industrial sectors. A rotating/pivoting head offers additional options for three-dimensional measurements using the probe system provided.

PMS 600 / PMS 700

-

The stable portal construction of the measurement machine has not only been designed for measurement rooms but specifically to be used directly in the production hall. Completing measurements in close proximity to production thus significantly reduces non-productive times and saves money. In addition to a high-resolution CCD camera, the tactile or scanning probe and/or the optional measurement laser ensures it is suitable for universal use in many industrial sectors. A rotating/pivoting head offers additional options for three-dimensional measurements using the probe system provided.

PMS 500 LL / PMS 900 LL / PMS 1200 LL

-

The development team in Bad Kreuznach, Germany, has achieved a milestone for measurement technology by developing the PMS LL Series. It has the smallest dimensions, while offering maximum precision via all of the sensors using an above-average measurement volume. The PMS LL uniquely combines maximum precision with speed and flexibility. The individual configuration options meet every possible requirement. High resolution CCD matrix camera with 1.4 megapixels, telecentric precision lens with fixed focal length, LED transmitted light and LED sector incident light, rotating/pivoting head PH10 with tactile 6-way probe TP200 or scanning probe SP25, conoscopic measurement laser, fully integrated CNC rotation axis and individual software options ensure that the configuration of your measurement tasks is affordable and effective.