- Offer Profile

- For over 40 years Sensor Technology has researched and developed solutions for customers' torque and load measurement problems, developing its own unique technologies for the instrumentation, test and OEM markets worldwide and supported by a global network of distributors. The TorqSense rotary torque sensors and LoadSense wireless load sensors offer accurate, affordable, market leading products across the whole range of industrial applications. The HeliNav Wireless LoadMaster provides accurate measurement of underslung loads for the helicopter industry.

Rotary Torque Transducers & Wireless Load Sensors

- For over 40 years Sensor Technology has researched and developed solutions for customers' torque and load measurement problems, developing its own unique technologies for the instrumentation, test and OEM markets worldwide and supported by a global network of distributors. The TorqSense rotary torque sensors and LoadSense wireless load sensors offer accurate, affordable, market leading products across the whole range of industrial applications. The HeliNav Wireless LoadMaster provides accurate measurement of underslung loads for the helicopter industry.

Torque Transducers & Torque Sensors

-

TorqSense

We offer a range of rotary torque sensors and torque transducers to suit a variety of industrial applications, our standard range of sensors can measure torque ranges from 10mNm up to 13000Nm.

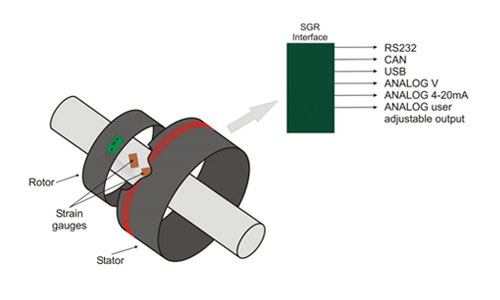

SGR510/520 Torque Transducer

- New for 2020 is the TorqSense Digital rotary strain gauge series (SGR) Transducers use non contact technology eliminating the need for noisy slip rings. The SGR510/520 series torque sensors are suitable for torque measuring, testing, feedback control of drive mechanisms and process control applications.

The SGR series transducers use modern strain gauge signal conditioning techniques to provide a high bandwidth low cost torque measuring solution with high overrange and overload capabilities.

If you require separate electronics, please see our SGR530/540 Series transducers.

Key Benefits – SGR510/520 Torque Sensors:- Transducers from 1Nm to 13000Nm

- Large fully functional overrange capability of 250% (SGR520) Minimal side and end load errors

- Low linearity deviation of ± 0.05% FSD

- Low hysteresis error of ± 0.05% FSD Zero variation in torque signal with rotation (cyclic variation)

- Non contact signal transmission, no slip rings to wear out

- High digital sample rate of 4000 samples per second

- Adjustable torque data smoothness, low pass filter (SGR520)

- Speed measurement / Power computation

- Wide power supply range 12-32 VDC

- Compatible with ethernet gateway module

- Lifetime Warranty

TorqSense SGR510 Series transducers offer:- Fixed voltage or current analog outputs (one for torque and the other for speed or power) for interfacing with analog instrumentation

- BIT Self-diagnostics for letting the manufacturer know that the transducers torque, speed ratings and calibration due date have not been exceeded

- Simple ‘Sensor status’ output pin

- Sensors to monitor shaft temperature for better compensation and accuracy

Whereas, TorqSense SGR520 Series transducers offer:- Digital outputs such as RS232, CANbus and USB for interfacing with modern instrumentation and laptops

- Digital input for configuring transducer via PC 2 x user selectable voltage or current analog outputs (one for torque and the other for speed, power or peak torque) for interfacing with analog instrumentation

- Transducer configuration software to allow user to change transducer variables

- BIT Self-diagnostics for letting users know data is trustworthy, that the transducers torque, speed ratings and calibrated due date have not been exceeded

- Simple ‘Sensor status’ output pin

- Sensors to monitor shaft temperature for better compensation and accuracy

- Ability to connect up to 10 transducers using USB

- Optional external ethernet gateway module

SGR530/540 Torque Meter with Separate Electronics

-

New for 2020 is the TorqSense Digital rotary strain gauge series (SGR) Transducers. With a separate electronics module, the transducers use non contact technology eliminating the need for noisy slip rings. The SGR530/540 series torque sensors are suitable for torque measuring, testing, feedback control of drive mechanisms and process control applications.

The SGR series transducers use modern strain gauge signal conditioning techniques to provide a high bandwidth low cost torque measuring solution with high overrange and overload capabilities.

If you require integral electronics, please see our SGR510/520 series transducers.Key Benefits – SGR530/540 Torque Sensors:

- Transducers from 1Nm to 13000Nm

- Large fully functional overrange capability of 250% (SGR540)

- Separate digital electronics

- Minimal side and end load errors

- Low linearity deviation of ± 0.05% FSD

- Low hysteresis error of ± 0.05% FSD

- Zero variation in torque signal with rotation (cyclic variation)

- Non contact signal transmission, no slip rings to wear out

- High digital sample rate of 4000 samples per second

- Adjustable torque data smoothness, low pass filter (SGR540)

- Speed measurement / Power computation

- Wide power supply range 12-32 VDC

- Compatible with ethernet gateway module

- Lifetime Warranty

TorqSense SGR530 Series transducers offer:

- Fixed voltage or current analog outputs (one for torque and the other for speed or power) for interfacing with analog instrumentation

- BIT Self-diagnostics for letting the manufacturer know that the transducers torque, speed ratings and calibration due date have not been exceeded

- Simple ‘Sensor status’ output pin

- Sensors to monitor shaft temperature for better compensation and accuracy

- Digital outputs such as RS232, CANbus and USB for interfacing with modern instrumentation and laptops

- Digital input for configuring transducer via PC

- 2 x user selectable voltage or current analog outputs (one for torque and the other for speed, power or peak torque) for interfacing with analog instrumentation

- Transducer configuration software to allow user to change transducer variables

- BIT Self-diagnostics for letting users know data is trustworthy, that the transducers torque, speed ratings and calibrated due date have not been exceeded

- Simple ‘Sensor status’ output pin

- Sensors to monitor shaft temperature for better compensation and accuracy

- Ability to connect up to 10 transducers using USB

- Optional external ethernet gateway module

ORT230/240 Series Optical Low Capacity Torque Sensor

- The ORT 230/240 low capacity torque sensor offers an ideal means for precise dynamic measurement of rotary and static torque less than 100Nm and for bandwidths of up to 50Khz.

The new TorqSense ORT 230/240 torque sensors replace the E200 ORT series and feature all new electronics that have produced significant performance gains in resolution, frequency response, reduced sensor current consumption and faster digital data throughput.

Key Benefits of our Low Capacity Optical Torque Sensor- Low inertia – High Speed capability because electronics are not fixed onto shaft

- Non contact/brushless measurement

- High Bandwidth

- 200% safe mechanical overload

- Excellent noise immunity

- Separate digital electronics

- Operates both statically and dynamically

- Any full scale torque can be specified within standard range: 10mNm through to 100Nm

- Lifetime warranty

– clockwise/anti-clockwise

TorqSense ORT230 Series transducers offer:- Fixed voltage or current analog outputs (one for torque and the other for speed or power) for interfacing with analog instrumentation

- BIT Self-diagnostics for letting the manufacturer know that the transducer’s torque, speed ratings and calibration due date have not been exceeded

- Simple ‘Sensor status’ output pin

- Sensors to monitor shaft temperature for better compensation and accuracy

Whereas, TorqSense ORT240 Series transducers offer:- Digital outputs, such as RS232, CANbus and USB, for interfacing with modern instrumentation and laptops

- Digital input for configuring transducer via PC

- 2 x user selectable voltage or current analog outputs (one for torque and the other for speed, power or peak torque) for interfacing with analog instrumentation

- Transducer configuration software to allow user to changes transducer variables

- BIT Self-diagnostics for letting users know data is trustworthy, that the transducer’s torque, speed ratings and calibration due date have not been exceeded

- Simple ‘Sensor status’ output pin

- Sensors to monitor shaft temperature for better compensation and accuracy

- Ability to connect up to 10 transducers using USB

SIT 105/110/120 Series Strain Gauge Torque Sensors

-

The SIT 105/110/120 strain gauge reaction transducers are designed for operation in any industrial environment.

Models are available in sizes ranging from 50Nm to 5000Nm, offering outputs from mV/V outputs, to ratiometric voltage outputs, to digital data connection via RS232 or USB.

An option of a bench mount housing is available for torque wrench test and calibration.

The SIT 105/110/120 torque transducers use modern wire foil strain gauge technology with the latest high performance stainless steel shafts

SIT 105 transducers offer:- Calibrated 1mV/V output

SIT 110 transducers offer:- Scaled ratiometric voltage output, 2.5V zero, 4.5V CW FSD 0.5V ACW FSD

SIT 120 transducers offer:- Ratiometric voltage output as above

- RS232 output for connection to PC

An extension module for the SIT 120 series transducers also offers:- USB digital output

- User scalable voltage or current outputs, ±1V to ±10V, 4-20mA bipolar and unipolar

Ethernet Module (ENET-01)

-

The Ethernet Interface Module connects our range of Torque Transducers to a Local Area Network. By utilising existing structured cabling and infrastructure, our transducers become instantly accessible to any device on the network. Transducers can be accessed from any location within the premises where the structured cabling is present, or where it has been extended by wireless networking technologies. Furthermore, if the network is internet connected, or gateways and VPN’s are present, the transducers range can be extended without limit, enabling access and monitoring from literally anywhere.

Historically our transducers have used technologies which only allow a single device to be connected and consume data at a time. By networking our transducers, they become accessible by multiple devices simultaneously.

By implementing standard Internet Protocols, any network/internet connected device can access the transducer. Capable devices range from smart phones, tablets, PCs and laptops to Arduino/Raspberry Pi development systems. Communication is primarily via low overhead UDP packet transmissions, but is complemented by an embedded web server and database server. Torqview, our Advanced Torque Monitoring Software, has been updated to provide network support on Windows.

ETD Transducer Display Interface

-

The Transducer Display ETD is a readout suitable for all RWT transducers. Although it is primarily used to display torque and peak torque, it can also display speed and power, provide access to the analog outputs from the transducer and connect the transducer to a PC for use with TorqView and the Transducer Control Program.

Key Benefits:- Displays torque, peak torque, speed* or power* in the units specified within the transducer

- Automatically detects and displays the model, range, serial no. and calibration due date of the transducer

- Provides auto reset of peak torque values

- Provides power to the transducer in place of the standard power supply unit

- Provides access to analog torque outputs and pulse speed* output

- Provides USB output if used with RWT420/440 series with USB option fitted

- Displays warnings and high temperature if appropriate

- * Provided RWT transducer has speed option fitted and enabled

Technical Data:Display LCD 20 x 4 STN BLUE Display update rate 4Hz Overall size 220w x 290d x 100h (Aluminium enclosure Weight 1.76 kg Operating temperature range -10°C -50°C Power supply 90-250v AC, 50-60Hz, 10W, IEC connector Channel 1 analog output As specified by transducer Channel 2 analog output As specified by transducer Pulse RPM Out TTL compatible Serial output USB Type B Connection to transducer Cable ACC-04

TorqView Torque Monitoring Software

-

TorqView is an easy to use advanced torque monitoring software application available to operate in conjunction with the SGR520/540, ORT240, SIT120 Series Transducers to provide a flexible display, real time plotting and data recording facility.

TorqView 5 has been written using National Instruments LabVIEW, and is a self running executable file, so LabVIEW is not required to run this software.

Benefits:- Simple installation using serial port or USB

- Ease of operation (user friendly, a variety of user interface settings such as scales, units, etc.)

- 3 types of display: dials, digital bars and chart graph

- Wide choice of displayed units (SI, FPS, and MKS)

- Displays torque, RPM, power and temperature

- Data recording facility, real time plotting

- Output text files compatible with Matlab, Excel

- Suitable for TorqSense® SGR520/540, ORT230/240 and SIT120 series transducers. Also suitable for using with obsolete equipment including the RWT420/440/460, RWT320/340/360 series, E302 Display Interfaces, E200 ORT Series Transducers using E202 Transducer Display Interfaces, E100 SBT and E100 SIT Series Transducers using E102 Transducer Display Interfaces

- LabVIEW VIs available for users to design own process control applications

- DLLs available for users to write own custom software

- User configurable settings

Bluetooth Module for Torque Sensors

-

The optional Bluetooth interface box bring wireless flexibility to your TorqSense® transducers. The box simply plugs into the 15 way ‘D’ digital lead connector. It allows the transducer to be powered through the interface as well as providing a USB output.

Our android app enables you to view the current torque, speed and temperature from the transducer, as well as peak values. It also allows you to set filters and view the current configuration of the sensor.

As the interface has USB output it lets you connect to your PC at the same time, allowing you to run a full version of our TorqView software. For example to record at full speed while using your android device as a monitor.

Using a mobile device with Bluetooth and our software means you can quickly look at the transducer data without having to set up a computer and cables giving you fast access to the information when you need it.

Torque Transducer Signal Breakout Unit

-

The SBU-01 Transducer Signal Breakout unit can be use with any Sensor Technology Torque transducer. The unit provides easy access to all the transducer functions including Analog outputs, RS232, USB and the optional CANbus. Users can also zero the transducer with the SBU-01, and it provides indication of transducer operational status.

Benefits- No need to wire in your own switches/cables

- Connects to transducer via ACC-03 and/or ACC-04 cables

- Keeps all functions in the same place

- Useful for testing & diagnostics

Features- Analog outputs for both Torque & Speed, or user defined outputs

- Ability to zero torque

- Ability to enable peak hold

- Shows sensor status

- RPM TTL out

- RS232 output to computer (SGR52x, SGR54x, RWT42x, RWT44x, ORT24x series only)

- USB output to computer (SGR52x, SGR54x, RWT42x, RWT44x, ORT24x series only)

Load Cells

LoadSense

We are manufacturers of LoadSense Wireless Load Cells and transducers ranging from 1 to 25 tonnes.

Wireless Load Sensor

-

The wireless Load Sensor is a strain gauge based stainless steel tension type sensor. It has the capability of wirelessly transmitting its data to one of our compatible readouts and displays or recording its data locally. Its inbuilt 32MBit memory can hold up to 280 hours of data which can then be downloaded to a PC via its USB cable. The Load Sensor transmits using the worldwide licence free frequency of 2.4GHz on two built in antennas.

The Load Sensor is used with our HandHeld Receiver which can read several devices at the same time, (see data sheet WLS3626R for more details), and/or our stand alone Receiver Interface which is used to output the data via RS232/RS422, (see data sheet WLS3627R for more details)

Key Benefits:- Available in ranges from 1-50 Tonnes

- Wireless, so easy to install and remove between installations

- Transmits data up to a distance of 100m

- Transmits data at up to 10 times a second

- Internal Memory for up to 280 hours of data

- 11V to 28V external supply chargeable

- Connect to PC via USB

- PC software for customer settings

- Flexible automatic shutdown to conserve battery

- Dual ruggedised internal antennas

Handheld Receiver

- The wireless LoadSense HandHeld Receiver Display is used in conjunction with the wireless Load Sensor. It provides the user with an easy way to receive and view data from the Load Sensor.

Up to 9 Load Sensors can be selected from the HandHeld Receiver and individually displayed. These Load Sensors can be named by plugging the Load Sensor into a PC via USB and using the Load Sensor software.

They can then be easily distinguished on the display, which will show the current name of the Load Sensor being read.

The display shows the name of the current Load Sensor, the load, battery status of readout and Load Sensor and signal strength. By using the menu tree on the readout the user can select which Load Sensor to read, what units to be displayed, tare the data, display peak value and many more functions.

A 9 way D connector is provided to output data via RS232 / RS422 and a USB mini B to charge the battery and output data to a PC.

Key Benefits:- Reads multiple Load Sensors

- Receives data up to a distance of 100m

- Receives data at 10 times a second

- Connect to PC via USB for user setup

- Output data via RS232 / RS422 / USB

- Ruggedized rubber case with back stand

- Long life rechargeable battery powered

Load Sensor Cabin Display

-

The LoadSense Cabin Display is a small, lightweight, cabin / window mounted unit which is used in conjunction with our LoadSense Wireless Load Sensors to display the reading from the load sensor. Our range of Load Sensors up to 25 tonnes are shown in datasheet WLS3625R.

Using the 2.4GHz licence free band to receive the Load Sensor signal, it can display the load value in several views which are user selectable. It also allows the user to tare off any equipment weight to display just the load value of the cargo.

The system can operate from its rechargeable battery and does not need to be hard wired, enabling the equipment to be easily transferred between installations. The display can be operated and charged from a 28V supply

Key Benefits:- Reflective, sunlight readable LCD display

- Optional analog output for cirscale meters

- External antenna

- Units displayed: Tonne, Kg , lbs

- RAM® 1" ball mount. Base options on request

- Multiple display views. Digital, Analog Bar

- Tare function to zero out weight of equipment

Wireless Load Sensor

- The wireless receiver is used in conjunction with the wireless Load Sensor. It provides the user with an easy way to receive and output data from the Load Sensor. Enclosed in a hardwearing aluminium box, the receiver can be installed into environments where it may be subjected to harsh conditions.

The receiver is easy to install as it only requires DC power to be supplied to the unit. An SMA connector allows the use of an external antenna. It outputs a string of data from the Load Sensor which includes: Serial number, full scale, Load, Temperature, RSSI and battery voltage.

The data is constantly outputted from the receiver straight from “power on” as long as the Load Sensor is in range. The output can be provided as either RS232, RS422, USB or Analog. This provides the functionality of being able to send the data over a longer distance if the receiver was to be in a remote location.

The interface is suitable for applications where no user interaction is needed and data is fed into a data logger or remote display. An internal memory with real time clock is available for stand alone applications which may be interrogated from a PC.

Key Benefits:- Small Footprint (133mm x 67mm x 43.5mm)

- Receives data up to a distance of 100M

- Receives data at 10 times a second

- Minimal startup time

- Very simple installation

- Operates on 2.4GHz licence free band

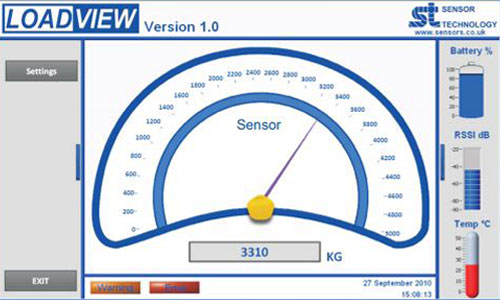

Handheld Receiver

- LoadView is an easy to use load monitoring software available to operate in conjunction with the WLS-RI Receiver Interface or WLS-HR Handheld Receiver to provide a flexible display, real time plotting and data recording facility.

LoadView has been written using National Instruments LabVIEW, and as it is a self running executable file, LabVIEW is not required to run this software.

Key Benefits:- Simple installation using serial port or USB

- Ease of operation (user friendly, a variety of user interface settings such as scales, units, etc.)

- Displays load, signal strength, battery and temperature.

- Output a text file compatible with Matlab, Excel

- LabVIEW VIs available for users to design their own Interfaces

- DLLs available for users to write their own custom software process control applications

- Data recording facility

- User configurable settings

- Multiple screen views

HeliNav Load Master

-

Our helicopter load measurement equipment is designed for underslung load

monitoring, HeliNav LoadMaster is an intelligent wireless load sensor with

inclinometer and accelerometer capabilities. Our load sensors are available

in sizes from 1 to 10 tonnes with the ability to transmit data wirelessly up

to a distance of 100m.

The HeliNav LoadMaster load cell is compatible with our range of load monitoring displays and interfaces including the Handheld Receiver, Cockpit Display or Receiver Interface.

Wireless Load Sensors

-

The wireless HeliNav LoadMaster Load Sensor is a strain gauge based

stainless steel tension type sensor. It has the capability of wirelessly

transmitting its data to one of our compatible readouts and displays or

recording its data internally. Its inbuilt 32MBit memory can hold up to 280

hours of data which can then be downloaded to a PC via its USB cable. The

Load Sensor works in the worldwide harmonized band of 2.4 GHz using two

built-in antennas so does not require a licence to operate and uses advanced

technologies to enable data to be sent and received error free, these

include, forward error correcting and data whitening. HeliNav LoadMaster is

also compatible with our Handheld

Receiver which can read several devices at the same time and our stand

alone Receiver

Interface which can be used to output the data via RS232/RS422. The Load

Sensor display is able to display a simple load value in multiple

formats which are user selectable.

Key Benefits:

Load Sensor Handheld Receiver

-

The wireless HeliNav LoadMaster Handheld Receiver is used in conjunction with the HeliNav LoadMaster wireless Load Sensor. It provides the user with an easy way to receive and view data from the Load Sensor.

Up to 9 HeliNav LoadMaster Load Sensors can be selected from the Handheld Receiver and individually displayed. These Load Sensors can be individually named by plugging the Load Sensor into a PC via USB and using the Load Sensor software. They can then be easily distinguished on the display, which will show the name of the Load Sensor currently being read.

The display shows the name of the current Load Sensor, the load, battery status of readout and Load Sensor and signal strength. By using the menu tree on the readout the user can select which Load Sensor to read, what units to be displayed, tare the data, display peak value and many more functions.

A 9 way D connector is provided to output data via RS232/RS422 and a USB mini B to charge the battery and output data to a PC.

Key Benefits:- Reads multiple Load Sensors

- Receives data up to a distance of 100m

- Receives data at 10 times a second

- Connect to PC via USB for user setup

- Output data via RS232 / RS422 / USB

- Ruggedized rubber case with back stand

- Long life battery powered

Load Sensor Cockpit Display

-

The HeliNav LoadMaster Cockpit Display is a small, lightweight, cockpit / window mounted unit which is used in conjunction with our

HeliNav LoadMaster Load Sensors to show the current load on the screen. Our range of Load Sensors up to 10 tons are shown in datasheet HLM3599R.

Using the 2.4GHz licence free band to receive the Load Sensor signal, it can display the load value in several views which are user selectable. It also allows the user to tare off any equipment weight to display just the load value of the cargo.

The system can operate from its rechargeable battery and does not need to be hard wired, enabling the equipment to be easily transferred between aircraft. The display can be operated and charged from a 28V supply.

Key Benefits:- Reflective, sunlight readable LCD display

- Optional analog output for cirscale meters

- RAM® 1" ball mount. Base options on request

- Multiple display views. Digital, Analog Bar

- Tare function to zero out weight of equipment

- Units displayed: Tonne, Ton, Kg, lbs

- External antenna

Load Sensor Receiver Interface

-

The wireless HeliNav LoadMaster Receiver Interface is used in conjunction with the

wireless Load Sensor. It provides the user with an easy way to receive and output data from the Load Sensor. Enclosed in a hardwearing aluminium box the receiver is suitable to be installed into environments where it may be subjected to harsh conditions.

The receiver is easy to install as it only requires DC power to be supplied to the unit. An SMA connector allows the use of an external antenna.

The receiver outputs a string of data from the Load Sensor which includes: Serial number, full scale, Load, Temperature, RSSI and battery voltage. The data is constantly outputted from the receiver straight from "power on" as long as the Load Sensor is in range. The output can be provided as either RS232, RS422, USB or Analog. The interface is suitable for applications where no user interaction is needed and data is fed into a third party data logger or remote display.

Key Benefits:- Small Footprint (133mm x 67mm x 43.5mm)

- Receives data up to a distance of 100m

- Receives data at 10 times a second

- Analog or digital data outputs

- Minimal startup time

- Very simple installation

- Operates on 2.4GHz licence free band

Wireless Strain Gauge

-

The Wireless Strain Gauge transmitter (WSG) series is capable of turning any manufacturers strain gauge based sensors into wireless systems which can be read using our standard range of displays, readouts and software.

The unit is capable of working with 350 ohm strain gauges and above. Calibration data can be set by the user for the corresponding sensor, using our simple interface software.

When used with our displays and readouts, it creates a versatile and easy to install system which can be moved between installations if required.

The WSG-STM transmitter box has an internal rechargeable battery or can be powered from 11-32V and also provides the USB connection for the PC. The WSG-STD DIN mounted box can be powered from a standard DIN rail supply 11-32V.Wireless Strain Gauge – Key Benefits:

- Compatible with any strain gauge based sensor from any manufacturer.

- Works with 350 ohm gauges or above

- Rechargeable battery powered for up to 50 hours (WSG-STM)

- Wireless using 2.4GHz technology

- Designed to work with our standard range of displays and readouts

- Wall, bench & DIN rail mountable versions

LoadSense Handheld Receiver

- The wireless LoadSense HandHeld Receiver Display is used in conjunction with the wireless Load Sensor. It provides the user with an easy way to receive and view data from the Load Sensor.

Up to 9 Load Sensors can be selected from the HandHeld Receiver and individually displayed. These Load Sensors can be named by plugging the Load Sensor into a PC via USB and using the Load Sensor software.

They can then be easily distinguished on the display, which will show the current name of the Load Sensor being read.

The display shows the name of the current Load Sensor, the load, battery status of readout and Load Sensor and signal strength. By using the menu tree on the readout the user can select which Load Sensor to read, what units to be displayed, tare the data, display peak value and many more functions.

A 9 way D connector is provided to output data via RS232 / RS422 and a USB mini B to charge the battery and output data to a PC.

Key Benefits:- Reads multiple Load Sensors

- Receives data up to a distance of 100m

- Receives data at 10 times a second

- Connect to PC via USB for user setup

- Output data via RS232 / RS422 / USB Ruggedized rubber case with back stand

- Long life rechargeable battery powered

LoadSense Cabin Display

- The LoadSense Cabin Display is a small, lightweight, cabin / window mounted unit which is used in conjunction with our LoadSense Wireless Load Sensors to display the reading from the load sensor. Our range of Load Sensors are shown in datasheet WLS3625R.

Using the 2.4GHz licence free band to receive the Load Sensor signal, it can display the load value in several views which are user selectable. It also allows the user to tare off any equipment weight to display just the load value of the cargo.

The system can operate from its rechargeable battery and does not need to be hard wired, enabling the equipment to be easily transferred between installations. The display can be operated and charged from a 28V supply.

Key Benefits:- Reflective, sunlight readable LCD display

- Optional analog output for cirscale meters

- External antenna

- Units displayed: Tonne, Kg , lbs

- RAM® 1″ ball mount. Base options on request

- Multiple display views. Digital, Analog Bar

- Tare function to zero out weight of equipment

LoadSense Receiver Interface

- The wireless receiver is used in conjunction with the wireless Load Sensor. It provides the user with an easy way to receive and output data from the Load Sensor. Enclosed in a hardwearing aluminium box, the receiver can be installed into environments where it may be subjected to harsh conditions.

The receiver is easy to install as it only requires DC power to be supplied to the unit. An SMA connector allows the use of an external antenna. It outputs a string of data from the Load Sensor which includes: Serial number, full scale, Load, Temperature, RSSI and battery voltage.

The data is constantly outputted from the receiver straight from “power on” as long as the Load Sensor is in range. The output can be provided as either RS232, RS422, USB or Analog. This provides the functionality of being able to send the data over a longer distance if the receiver was to be in a remote location.

The interface is suitable for applications where no user interaction is needed and data is fed into a data logger or remote display. An internal memory with real time clock is available for stand alone applications which may be interrogated from a PC.

Key Benefits:- Small Footprint (133mm x 67mm x 43.5mm)

- Receives data up to a distance of 100M

- Receives data at 10 times a second

- Minimal startup time

- Very simple installation

- Operates on 2.4GHz licence free band

Technology

- The technology behind our rotary torque transducers and wireless load measurement sensors.

How it Work - Torque Transducer

-

The SGR510/520 and SGR530/540 series transducers operate using a four-element strain gauge wheatstone bridge, which is connected to a miniature shaft mounted analog to digital converter and microcontroller. The microcontroller conditions and measures the strain gauge bridge output as close to the gauges as possible, eliminating any possible external noise pick up in the gauge wiring.

The shaft mounted electronic module is wirelessly powered by a radio frequency source which drives a stator coil, the output of which is received by a rotor coil on the shaft thus making the system completely contactless. This eliminates the need for slip rings and their associated wear and noise problems.

The shaft microcontroller outputs a digital serial stream that is transferred back from rotor to stator by modulating the impedance of the rotor coil and detecting the impedance changes at the stator coil. A secondary high-performance microcontroller receives the serial stream from the shaft microcontroller, which then performs calibration and temperature compensation before outputting the results digitally via RS232, CAN bus or USB. A 16-bit digital to analog converter also outputs the sensors data as a fully calibrated and compensated analog voltage or current.

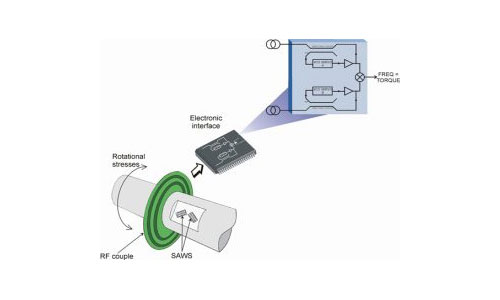

How it Works - Surface Acoustic Wave (SAW) Torque Measurement

-

The measurement technology for our ‘TorqSense’ RWT410/420, RWT430/440 and RWT450/460 Series Torque Transducers and torque meters is based on the patented technology of measuring the resonant frequency change of ‘Surface Acoustic Wave’ (SAW) devices in a non-contact manner when strain is applied to a shaft to which the SAWs are fixed. The applied torque causes a deformation of the quartz substrate of the SAW device, which in turn causes a change in its resonant frequency. Essentially the SAWs act as ‘frequency dependent’ strain gauges.

The frequency signal measuring the resonant frequency is coupled via a non-contact RF rotating couple from the shaft to a fixed pick-up and it is the analysis of the difference in resonant frequencies between the two SAW devices, with electronic processing and calibration, that gives a precise indication of the torque transmitted by the shaft. SAW devices have a high immunity to magnetic fields allowing their use in motors. For example, where other analog technologies are susceptible to electronic interference and are not suitable.

The use of this patented measurement technique results in a transducer being able to sense torque bi-directional, with fast mechanical and electrical responses. As the method is non-contact it has also complete freedom from brushes or complex electronics, which are often found in traditional torque measurement systems.

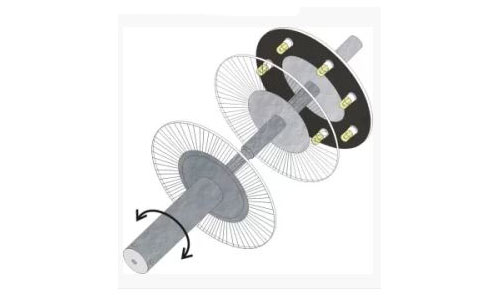

Optical Torque Measurement Technology

-

The technology for our Optical ORT230/240 Series Torque Transducers is based on an extensively proven and developed measurement principle whereby two discs with segmented gratings are positioned on the shaft so that the opaque sectors on one disc partially obscure the clear sectors on the other. Light passes through the sectors and is detected by photovoltaic detectors.

The intensity of light beams, which is constantly monitored, is modulated by the applied torque and produces an electrical output that is used to provide a precise indication of the torque transmitted by the shaft. The light intensity is automatically controlled within the transducer body by a monitor cell. Lamps used to provide the light source are selected to ensure they have a long life and high stability.

The use of this measurement technique results in a transducer being able to sense torque bi-directionally. Very high full-scale sensitivity can be achieved with fast electrical responses up to 50kHz and low inertia. As the measurement is non-contact it has also has complete freedom from brushes and complex electronics on the shaft, which are often found in traditional torque measurement systems.

Strain Gauge Technology

-

The SIT 105/110/120 torque transducers use modern wire foil strain gauge technology with the latest high performance stainless steel shafts. The SIT 105/110/120 strain gauge reaction transducers are designed for operation in any industrial environment.

The Strain Gauge torque transducers offer a range of outputs from mV/V outputs, to ratiometric voltage outputs, to digital data connection via RS232 or USB.

An option of a bench mount housing is available for torque wrench test and calibration.

How it Works - LoadSense Technology

- Wireless Load Measurement

The wireless LoadSense load measurement sensor is a strain gauge stainless steel tension type sensor currently available in 1 Ton to 25 Ton ranges, having an overload capability of more than 150%. It has the capability of wirelessly transmitting its data to one of our compatible displays or data recorders. Data is transmitted 10 times per second in the worldwide licence free 2.4GHz frequency band. A pair of rugged inbuilt antennae ensure the sensor will not get damaged in harsh operating environments. A transmission distance of 100 metres is achievable.