Binsack Reedtechnik

- Offer Profile

- As an experienced manufacturer of Reed sensors, Reed relays, Float switches and Flow switches, Binsack Reedtechnik can provide the optimal sensor for your application. If you can not find a suitable solution in our standard product range, we can develop a fast and cost-effective solution. The production of customized products is one of our strengths.

Product Portfolio

Reed sensors

-

Application:

Reed sensors are so-called proximity switches, that work when a magnetic field approaches non-contact. They are often used for position sensing or monitoring in safety devices.

Advantages:- long life

- insensitive

- maintenance-free

- no standby power

- high insulation resistance

- very low contact resistance

Working principle:

Reed sensors, also known as proximity switches, toggle through the approach of a magnet. The inside of the sensor hermetically sealed reed switch reacts reliably and accurately to a magnetic field. It requires no power supply, is insensitive and has a high frequency and long life. The sensor is available as normally open or normally closed. The appropriate switching magnet, even in an assembling friendly housing, can be obtained from us as well.

Round shape

- with cable, screw or plug connection

Square shape

- with cable, screw, clamp or connector

Customized items

-

different shapes

we realize your wishes

Reed relays

-

Application:

The reed relay is used to switch small signals (NV) and very small currents (femto) to high voltages of 10kV. The reliability and low contact resistances are the deciding factor for many applications.

Advantages:- long life (up to 109 cycles)

- hermetically closed

- galvanic separation

- high insulation resistance (up to 1014 ohms)

- very low contact resistance (typ 100 milliohms)

- transport current up to 5 A

- switching time ca. 1 ms

- shock resistance up to 100 g possible

Working principle:

The reed relay operates with a built-in reed switch which is located within a magnet coil. When a reed switch, the switch contacts are hermetically enclosed in a glass body and thus protected from pollution and other environmental influences. This ensures a consistently low contact resistance for high reliability and long service life. Reed relays are available in various designs as normally open, normally closed, change-over or bistable.

Standard, Mini, Axial, Hg

- with different terminals

Hochspannung

- for switching voltages from (1 - 10) kV

SIL, DIL

- standard and customized

Hochisoliert

- insulation resistance (to 10^14 ohms)

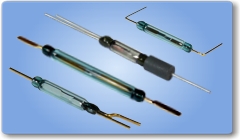

Reed switches

-

Applications:

The hermetically closed contact is used to switch electrical signals and loads. It is activated by an external magnet field.

Advantages:- high life expectancy (up to 109 switching cycles)

- high switching speed (up to 0,2 ms)

- hermetically closed

- maintenance-free

- inexpensive

- very high insulation resistance (up to 1014 Ohm)

- very low contact resistance (50 mOhm)

- switching voltage from a few nano-volt up to 10000 Volt

Working principle:

The reed switch is composed of two ferromagnetic blades that are sealed in a glass tube. The blades overlap slightly and have a distance of only a few micrometers. When approaching a magnetic field, they are attracted to each other and close. If the magnetic field weaks (by removing the magnet), the contacts reopen.

Standard

-

several sizes ( 5-50 ) mm

as NO-contact ( Form A )

or changeover contact ( Form C ),

as well as bistable and customized

High voltage

- switching voltage ( 2,5 - 10 ) kV

High insulated

- Insulation resistance up to 10^14 Ohm

Float switches

-

Application:

Float switches are used for level monitoring of liquids (e.g. detecting whether the container is full or empty, or any other defined level). They have one or more defined switching points.

Advantages:- low cost

- reliable

- durable and maintenance-free

- potential-free

- no standby power

- different types of installation

- very low contact resistance

Working principle:

The magnet, integrated in the float, switches one or more reed contacts without touching.

Vertical shape:

The float moves with the liquid level along the stem up and down and switches one or more reed contacts located inside the stem.

Horizontal shape:

At the so-called folding float switch the magnet is integrated in the hinged part and the reed switch in the fixed part. By turning the float switch, the switching function can easily be reversed (NC or NO).

Hints for selection:

Make sure that you choose the suitable float switch for your application. So that the functionality is preserved for many years and thus your device or application to work properly or not be damaged.

Important selection criteria:- type of liquid

- temperature range

- pressure conditions

- number of switching points

- output type (NO, NC, CO contact)

Horizontal mounting

- mounting from outside

Vertical mounting

- variant for dirty water

Customized

- variant with flush cover

Suction lances

-

Application:

Lances are used for filling and emptying of canisters or containers with liquids. Our items have a built-in float switch for level detection. Available in different lengths with a wide variety of fittings or plugs.

Advantages:- long life

- maintenance-free

- different lengths

- div. container threads

- no standby power

- built-in float switch

Working principle:

With the integrated float switch, you can monitor the level in your tank at the same time. The level switch requires no power in standby mode, is insensitive and has a long life. Optional our lances can also be equipped with a ball check valve and strainer.

Customized

- Our suction lances are available in various designs, optional with ball check valve and / or rinser.

Floats

-

Application:

The float with integrated magnet is used as a component for level measurement.

Advantages:- long life

- hermetically closed

- individual dimensions

Working principle:

The float is usually mounted on a stem. Depending on the level, it moves up and down. At a defined level, the integrated magnet switches the contact inside the stem.

Stainless steel

Plastic foamed

- NBR, PE, PP

Plastic hollow

- PP

Flow switches

-

Application:

The flow switch monitors in your application a minimum or maximum flow cost. Due to its compact size, it is universally applicable.

Advantages:- small and light

- low cost

- potential-free

- no standby power

Working principle:

The internal piston is moved against a spring, in relation to the flow rate. At a defined operating point, the integrated reed contact switches. With its return spring the flow switch operates mainly independent of position.

Standard and customized

-

size: 62 x 22 mm

weight: 11 grams

other connection types on request

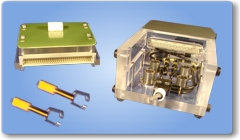

Testing tools

-

Test adapters and adapter carriers ( e.g. for relays ),

as well as Kelvin contacts for 4 pole measuring techniques.

Construction according to your requests.

Adapter / Kelvin contacts

- test engineering