- Offer Profile

- Carl Zeiss Industrial Metrology is a leader in CNC coordinate measuring machines and complete solutions for multidimensional metrology in the metrology lab and production. The company is a recognized partner to the automotive industry and its suppliers. 2.400 employees from manufacturing sites in four countries and more than 100 sales and service centers supply customers around the world.

Systems

- Measuring technology from the leader

Reliable, high-quality measuring technology consists primarily of the coordinate measuring machine, well-engineered software and customer service and support. At Carl Zeiss, these elements interact in perfect harmony. We are your one-stop provider of metrology solutions. Bridge CMMs

- Bridge Coordinate Measuring Machines

Faster, more precise measurements

Industrial measuring technology from ZEISS is a well-balanced system: from the measuring machine, to the sensors and software, all the way up to service. All single components, as well as the entire system are designed to deliver the best possible results as quickly as possible.

SPECTRUM Family

- Upgrade to trusted measuring results.

Your companies production plan needs to be fullfilled? Growth ratios performed? No time for complaints and lowered productivity - caused by missed error detection of defective parts?

With ZEISS SPECTRUM Family you will enter the next level of certainty and productivity. Trust your parts due to more reliability in the measurement results. Upgrade to trusted measuring results.

MICURA

- Maximum Precision for Small Parts

Despite its small size, ZEISS MICURA makes no compromises when it comes to accuracy. ZEISS MICURA comes standard with the VAST XT gold scanning sensor from ZEISS and navigator technology.

CONTURA

- The Reference Machine in the Compact Class

ZEISS CONTURA enables you to be prepared today for the measurement requirements of tomorrow: The new generation is equipped with the mass technology and, thanks to a common interface, enables simple switching between different sensor technologies in just a few simple steps. In addition to innovative options such as measuring in four axes using a flexible rotary table, an automated probe changing system or the HTG option (for larger temperature ranges), the device also stands for first-class performance, ergonomics and future security.

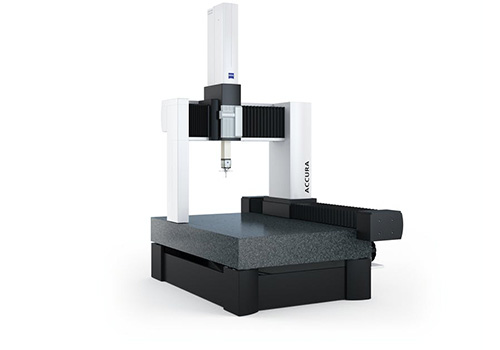

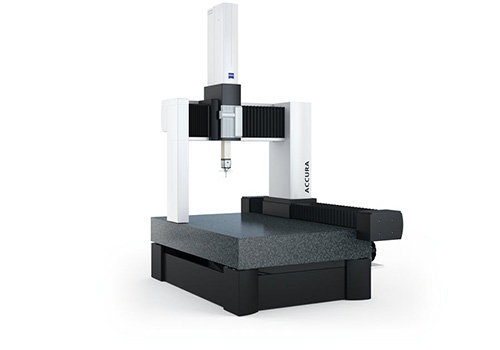

ACCURA

- Tailored to your Needs

Are performance and precision your top priorities? With its wide range of configurations, the ZEISS ACCURA measuring machine can be tailored to your needs and budget.

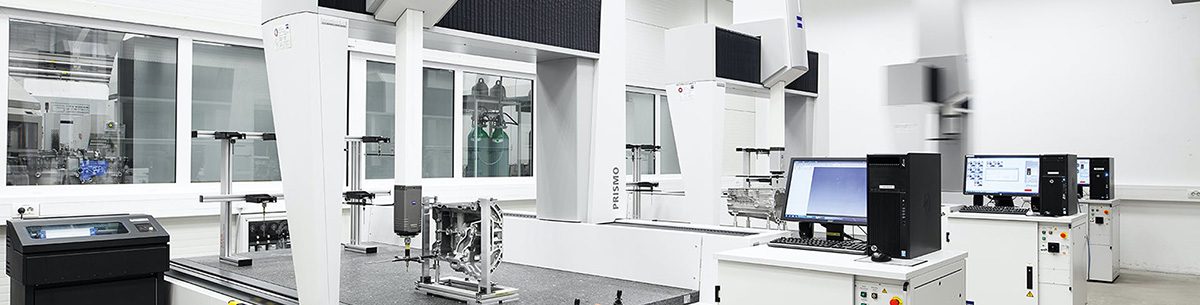

PRISMO Family

- When Precision Matters the Most

Over the last 25 years ZEISS PRISMO has become synonymous around the world for high-speed scanning and maximum accuracy in the measuring lab. PRISMO from ZEISS is a reference in precision measurement and follows the ISO quality standards entirely. An essential in a world where precision matters the most and compromises on accuracy are not acceptable.

XENOS

- The Reference

ZEISS XENOS is at home wherever maximum precision is demanded in the measuring labs of research institutes, the aerospace industry and the optical industry. The high-end machine combines precision at the limits of what is technically feasible with a measuring range of nearly one cubic meter.

Shop Floor CMMs

- Excellence in production

Quality assurance should be performed at the site of production. This is how manufacturing errors can best be identified and even avoided in the best case scenario. We not only provide the answer to this customer requirement with our MaxLine, but are continuing to enhance it.

DuraMax

- The right measuring equipment for the shopfloor.

ZEISS DuraMax eliminates the need for fixed gauges. Equipped with the VAST XXT scanning sensor from ZEISS, it can even be used to capture contours and freeform surfaces. A rough production environment? No match for ZEISS DuraMax.

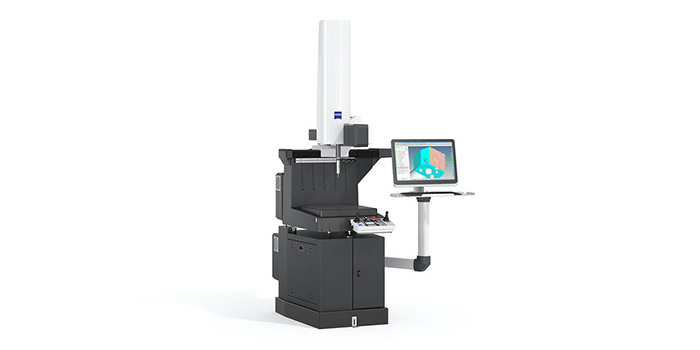

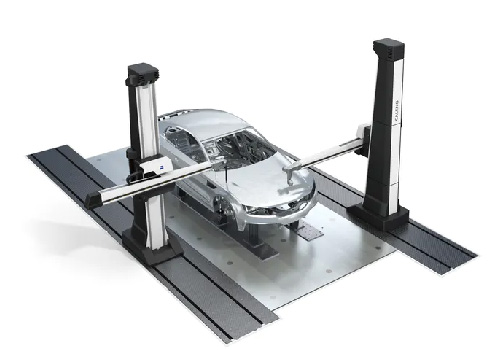

CenterMax navigator

- Unparalleled stability.

CenterMax navigator can be directly integrated into a production line. Vibrations from processing centers are effectively damped. Its variable workpiece base makes it ideal for automated loading.

Large CMMs

- Measure even the largest parts with highest precision with large CMMs

In the aerospace industry, in vehicle and mechanical engineering as well as in many other fields, coordinate measuring machines with a large measuring range are required so that there is no need to compromise when it comes to precision. This is why ZEISS offers a wide range of tabletop, bridge-type and gantry coordinate measuring machines in various sizes. Large coordinate measuring offered by ZEISS include ZEISS ACCURA and the entire ZEISS MMZ product family (MMZ T, MMZ M, MMZ G).

ACCURA

- The Bridge-Type Measuring Machine

Tailored to your needsAre performance and precision your top priorities? With its wide range of configurations, the ZEISS ACCURA measuring machine can be tailored to your needs and budget.

MMZ T

- Bridge-Type CMM with Large Measuring Range

The fascinating combination of measuring range and precision.With a measuring range of up to 14.8 m3, the ZEISS MMZ T offers the largest measuring range from amongst the table bridge-type measuring machines. For example: it enables the highly precise measurement of large gears directly on the shop floor.

MMZ M

- Bridge-Type CMM for Complex Workpieces

For the most demanding precision requirementsPrecise measurements at favorable acquisition costs this was the goal when developing the ZEISS MMZ M. The coordinate measuring machine is ideal for checking complex workpieces, especially those with tight tolerances.

MMZ G

- Bridge-Type CMM for Large Workpieces

Unparalleled greatnessLarge bridge-type machines in the ZEISS MMZ G line meet the highest demands: they feature the largest measuring range of all measuring machines offered by ZEISS and offer you unparalleled accuracy. This makes the ZEISS MMZ G ideal for checking complex, extremely large workpieces, especially those with tight tolerances.

Horizontal Arm CMMs

- Top performance with a system

As a system provider, ZEISS offers just the solutions for the changing conditions of day-to-day measuring tasks with impressive accuracy, effectiveness, and above all, dependability. From the first consultation on the installation, to the maintenance of your measuring machines, ZEISS takes charge of your metrology. You get all the services and products from the same partner and all optimally matched to each other.

PRO T

- Fully Configurable for your Convenience

Tailored to your needsThe ZEISS PRO T is a modular horizontal arm measuring machine that is very easy to configure and available in two versions: PRO T advance and PRO T premium. This means that it can be ideally tailored to meet your cost efficiency and performance requirements.

CARMET

- Exclusive Features for a Wide Range

The standard for a wide range of tasksZEISS CARMET is an economical, all-inclusive package that leaves nothing to be desired and offers ZEISS quality throughout.

CALENO

- Multisensor horizontal arm machine

With its combination of high-performance optical and tactile sensors ZEISS CALENO ensures maximum productivity and precision.

Optical Metrology

- Simple and reliable: Optical measurements

Complex measurements can be performed quickly and easily with optical measuring solutions from ZEISS. With a high degree of automation and state-of-the-art sensors, they reduce operating errors and guarantee high measuring accuracy.

O-INSPECT

- The perfect symbiosis of seeing and touching

ZEISS O-INSPECT multi-sensor measuring machines enable to optimally measure each characteristic in compliance with ISO-10360 - optically or by contact.

Your advantages

- Large visual field with high image definition

- Quick and precise 3D tactile measurements

- Optical measurements for sensitive surfaces

- Increased reliability in less time

O-DETECT

- Entering the world of optical metrology

Intuitive operation, high-quality camera and flexible lighting for precise measurement in an instant. Suitable for a wide variety of components, but mainly for those that are best left touched. Discover the new generation of optical metrology: ZEISS O-DETECT.

Your advantages

- Excellent optics

- Versatile and easy to upgrade

- Simple part navigation and visualization

- Stable precision

- Intuitive and user-friendly software

- Professional and actionable reports

Form Testers

- Form testers and spindle form testers

The highly accurate rotary table machines and spindle form testers of the RONDCOM series can be used in many areas: production, measuring room and calibration lab.

RONDCOM TOUCH

- Compact Form Tester for Production

Accurate and effective with simple TOUCH operationDirect and uncomplicated measurement during the manufacturing process thanks to its easy operation this is no problem for RONDCOM TOUCH.

RONDCOM 31 - 43 Series

- Compact Form Tester for Extensive Analysis

Reliable, manual form tester with narrow tolerancesThe form testers of the RONDCOM 31 - 43 series are compact devices with top-class analysis functions, e.g. Fourier analysis. The form testers features a precise rotary table on air bearings for optimal radial runout properties and excellent measurement of even the most narrow tolerances.

RONDCOM NEX Series

- Highly Accurate for Form and Surface

Form tester with the highest accuracy in its classThe form testers of the RONDCOM NEX series enables precise measurements of roundness and roughness in the R, T and Z axes and features best-in-class rotational accuracy.

RONDCOM 60 Series

- Precise, Stable, Efficient

Excellent measurement of even the most narrow tolerancesHighest rotational accuracy for measuring the narrowest tolerances sets this stable form tester apart.

RONDCOM 65 B

- Excellent Rotational Accuracy

The trend-setter among form testersA rotational accuracy of 10 nanometers makes the trend-setting RONDCOM 65 B form tester the best in its class. The system positions workpieces fully automatically in less than a minute.

RONDCOM 73 A and RONDCOM 76 A

- Large Measuring Range for Heavy Workpieces

Featuring high rotational accuracyThe working range of the RONDCOM 73 A and RONDCOM 76 A is exactly where other form testers reach their limits. The form measuring stations feature excellent rotational accuracy and a substantial measuring range in spite of its compact design.

Contour and Surface Measuring Machines

- Measuring machines for roughness and contour measurements

The contour and surface measuring machines from ZEISS offer different, sometimes combinable sensors for roughness measurements, contour measurements or both. The contact-free linear drive makes these machines highly efficient and low-maintenance.

SURFCOM NEX Series

- Profile Detection for Every Application

Full flexibility for your applicationThe contour and surface measuring machines from ZEISS offer different, sometimes combinable sensors for roughness measurements, contour measurements or both.

SURFCOM CREST

- Combined CNC Reference Machine for Contour and Surface Measurements

The flagship for contour and surface measuring technologySURFCOM CREST features high resolution and a laser-interferometric measuring system and is often used in calibration labs.

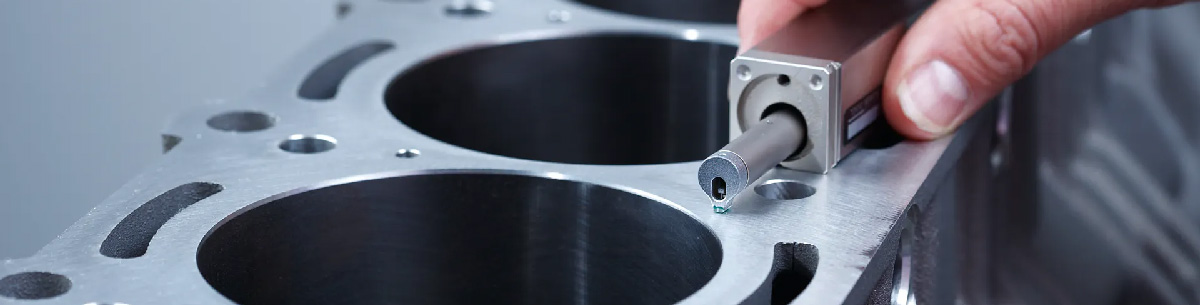

SURFCOM C5

- Fully Automated Surface Measurement

Automated quality assuranceDesigned for quality assurance in volume production, SURFCOM C5 is ideal for performing the fully automated surface measurement of engine components.

Mobile Surface Measuring

- Portable and multi-sensor

The mobile surface measuring instruments and analysis units from ZEISS are robust and easy to use. They are suitable for non-transportable workpieces.

SURFCOM TOUCH Series

- Intuitively Operated Surface Texture Measuring Instruments

Surface roughness solution for any measurement challengeOur intuitively operated surface texture measuring instruments allow easy roughness measurements of various types of workpieces.

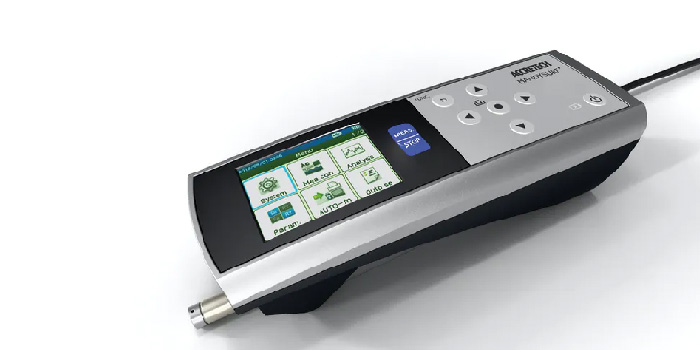

HANDYSURF +

- Mobile Surface Measuring Instrument Featuring an elegant Design

Simple quality assurance throughout the productionThe simple solution to measure, evaluate and document surface roughness from incoming goods to production all the way to final inspection.