- Offer Profile

-

SCHMITT as a facilitator

We LOVE to play a part in making sure that everything goes well for you!

That is why we listen to you carefully from the very beginning. After all, we want to understand exactly what you need. Only then can we offer you the perfect pump. We prevent problems right from the start through clever planning. And if something still doesn't work properly, we'll step into the breach for you. And we don't stop there with our knowledge. Instead, we put it at your service at all times.

SCHMITT as a facilitator

-

We LOVE to play a part in making sure that everything goes well for you!

That is why we listen to you carefully from the very beginning. After all, we want to understand exactly what you need. Only then can we offer you the perfect pump. We prevent problems right from the start through clever planning. And if something still doesn't work properly, we'll step into the breach for you. And we don't stop there with our knowledge. Instead, we put it at your service at all times.

NEOLUTION NHM

-

Normal-priming centrifugal pumps made of PDF or PP with magnetic coupling

- Housing and impeller materials: PVDF, PP

- Elastomers: EPDM, FKM (e.g. Viton®), FEP, FFKM (e.g. Kalrez®)

- Slide bearing materials: SiC/SiC (silicon carbide) or carbon/SiC

The all-new NEOLUTION pump is the first of its kind. With its legendary energy efficiency, it sets standards in this class. Made of individually selectable, chemical-resistant high-performance materials, the NEOLUTION NHM is uncompromisingly geared to your needs. Discover this world premiere!

Advantages:

- Up to 76 % efficiency and thus extremely energy-efficient

- Wear-free, maintenance-free and long-lasting due to the unique bearings

- Hermetically sealed due to contactless magnetic drive, thus absolutely leakage-free

Solid particles up to 3 mm in size and 10% by volume can also be handled. Viscosity may be up to 150 mas; maximum medium temperature is 95°C. All sizes are also available in ATEX-certified versions for use in ATEX Zones 1 and 2.

2-Way ball valve

-

Small innovation, big effect!

With our new KGH, our chemical-resistant ball valve made of PP or PVDF, we open up new possibilities for you. Because it is specially designed for use with our high-quality centrifugal pumps. This also means that the Schmitt KGH ball valve meets the highest industrial requirements and safety standards. And that it is as individually adaptable to your needs as all our products.

Your advantages at a glance:

- Rely on absolute operational safety thanks to the unique locking device, even under vibration and thermal loads

- The two-piece ball seat carrier increases the service life of the seals

- Mechanical resistance is extremely high, thanks to the high quality of the surface. The double sealed stem and a double groove connection to the ball are also important for this

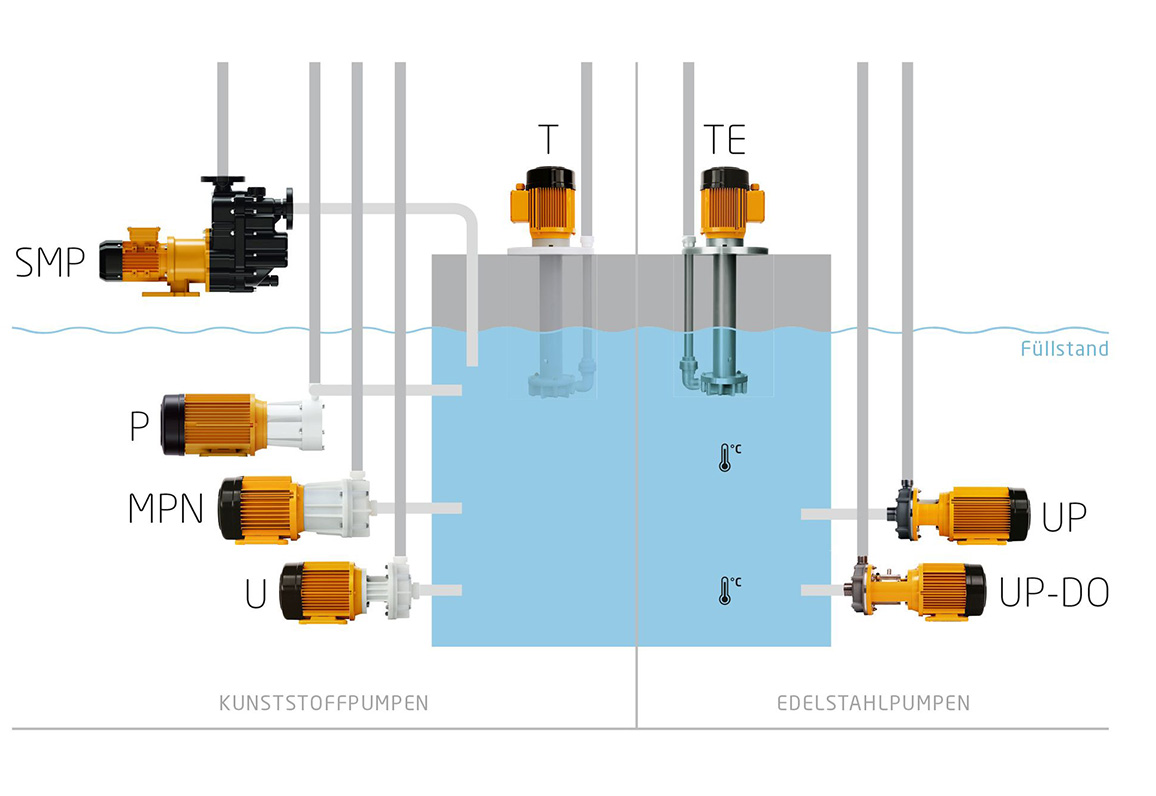

Centifugal, Submersible and Peripheral Pumps

Horizontal centrifugal pumps non-metallic

P series

-

Thanks to magnetic coupling, these pumps operate contact-free and wear-free. This is ideal for toxic, environmentally hazardous or aggressive media. They are designed for high pressures and can be controlled very precisely.

The P series can pump media up to a temperature of 60 °C. Under the designation P-EX, we also offer an ATEX-certified version for use in ATEX zone 2.

Special features of the P Series:- Very precise pump control due to linear pump curve

- Hermetically sealed and absolutely leak-free (no mechanical seal)

- Particularly suited for toxic, environmentally harmful and corrosive media

- Very suitable for pumping low-boiling liquids

Features:

- Hermetically sealed and absolutely leak-free (no mechanical seal)

- Powerful magnetic drive with neodymium magnets

- Practically maintenance-free in normal operation due to extra-large slide bearings

- Runs in partial dry run conditions due to large diameter PTFE slide bearings – design without impeller shaft Features

- All wet parts made of high-quality, corrosion-resistant plastics (PVDF or PP)

- Threaded connections (ISO 228-1) as standard

- Universally applicable, low-noise and compact close-coupled design

- Approved for use in explosive atmospheres ATEX zones 2

- Corrosion-resistant paint finish

- All stainless steel screws in 1.4571 (316Ti)

- FDA-certified materials (PVDF versions)

Operating conditions:

- Max. flow rate: up to 4.5 m³/h

- Max. delivery head: up to 45 m

- Liquid temperature: 0 to 60°C (PVDF, PP)

- Ambient temperature: -10 to 40°C, higher temperatures on request

- Pumps can be adapted to high-density liquids (up to 1.3)

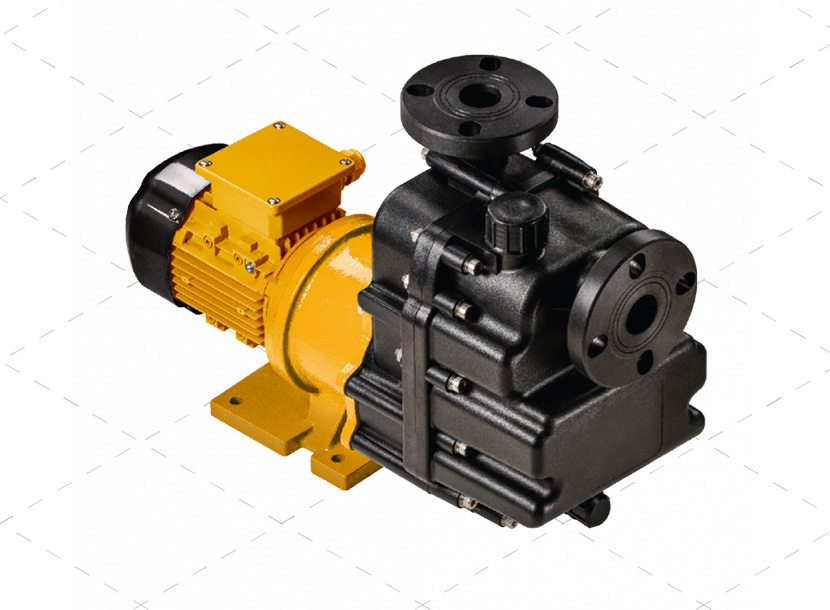

SMP series

-

These pumps operate without a shaft seal and with a contactless, wear-free magnetic coupling. They are absolutely tight, leakage-free and suitable for toxic, environmentally hazardous or aggressive media.

In addition, these pumps can automatically vent pipes. They are capable of drawing media from tanks located up to 7 meters below ground. Their absolute reliability and stability also contributes to safety.

Special features of the SMP Series :- Suction heights up to 7 m (depending on the size)

- Hermetically sealed and absolutely leak-free (no mechanical seal)

- Particularly suited for toxic, environmentally harmful and corrosive media

Features:

- Hermetically sealed and absolutely leak-free (no mechanical seal)

- Contact-free magnetic drive system

- All wet parts made of high-quality, corrosion-resistant plastics or PP

- Flanges and threaded connections as standard

- Universally applicable, low-noise and compact close-coupled design

- Corrosion-resistant paint finish

- All stainless steel screws in 1.4571 (316Ti)

Operating conditions:

- Max. flow rate: up to 23 m³/h

- Max. delivery head: up to 24 m

- Liquid temperature: 0 to 80°C (PP)

- Ambient temperature: -10 to 40°C, higher temperatures on request

- Pumps can be adapted to high-density liquids (up to 2.0)

U series

-

As an entry-level model, these normal priming plastic centrifugal pumps with single mechanical seal are perfect for aggressive media and weak/medium strength acids with metallic particles.

With this closed-coupled pump, the power of the motor is directly applied to the impeller by a shaft. Therefore it works without slippage. A single mechanical seal ensures the leakproofness of the U series. Overall, these centrifugal pumps can be used almost everywhere. The variety of materials available means that we can adapt them to almost all pumping media and conditions. As with the MPN series, all sizes of the U series are also available in ATEX-certified versions. This means that they can also be used in ATEX Zone 2. These versions have the designation U-EX.

Special features of the U Series :- Suction heights up to 7 m (depending on the size)

- Hermetically sealed and absolutely leak-free (no mechanical seal)

- Particularly suited for toxic, environmentally harmful and corrosive media

Features:

- Economic and robust alternative to magnetic drive pumps

- Well-suited for solid-containing fluids due to spring-loaded mechanical seal

- Pumping of magnetic particles possible

- Low-maintenance-operation due to high-quality seal face materials

- All wet parts made of high-quality, corrosion-resistant materials

- Threaded connections (ISO 228-1) as standard

- Available with flange connections from size 130

- Universally applicable, low-noise and compact close-coupled design

Operating conditions:

- Max. flow rate: up to 30 m³/h

- Max. delivery head: up to 40 m

- Liquid temperature: -5 to 95 °C (PVDF)

- Ambient temperature: -10 to 40 °C, higher temperatures on request

- Pumps can be adapted to high-density liquids (up to 2.0)

MPN series

-

SCHMITT MPN centrifugal pumps are normal priming, single-stage plastic centrifugal pumps with magnetic coupling. They are particularly chemical resistant.

We are particularly proud of our MPN series. Because it is one of the most proven plastic magnetic pump in the world. It has been in use for decades. During this time, we have continuously developed it further. Today, tens of thousands of these pumps are used internationally in various branches of industry. With the MPN, the motor transmits its power without contact. A magnetic coupling is responsible for this, which acts through the closed housing wall (containment shell) on the impeller of the pump. All sizes are also available in ATEX-certified versions for use in ATEX zones 1 and 2. These versions are called MPN-EX.

Special features of the MPN Series:- Hermetically sealed and absolutely leak-free (no mechanical seal)

- Particularly suited for toxic, environmentally harmful and corrosive media

- Runs in partial dry run conditions due to large diameter slide bearings

Features:

- Hermetically sealed and absolutely leak-free (no mechanical seal)

- Powerful magnetic drive with neodymium magnets

- Practically maintenance-free in normal operation due to extra-large slide bearings

- Runs in partial dry run conditions due to large diameter PTFE slide bearings – design without impeller shaft Features

- All wet parts made of high-quality, corrosion-resistant plastics (PVDF or PP)

- Threaded connections (ISO 228-1) as standard

- Optionally available with flanges (from size 130)

- Universally applicable, low-noise and compact close-coupled design

- Approved for use in explosive atmospheres ATEX zones 1 and 2

- Optionally available with housing parts made of conductive plastic with approval for ATEX zone 1

- Corrosion-resistant paint finish

- All stainless steel screws in 1.4571 (316Ti)

- FDA-certified materials (PVDF versions)

Operating conditions:

- Max. flow rate: up to 35 m³/h

- Max. delivery head: up to 32 m

- Liquid temperature: -5 to 95 °C (PVDF), resp. 0 to 80 °C (PP)

- Ambient temperature: -10 to 40 °C, higher temperatures on request

- Pumps can be adapted to high-density liquids (up to 2.0)

- Depending on operating conditions and pump model, MPN pumps can run dry for certain amounts of time – up to several hours

Horizontal centrifugal pumps stainless steel

UP-DO Series

-

The UP-DO series is ideal for toxic or environmentally hazardous media up to 150 °C. Its double mechanical seal ensures maximum tightness and safety in back-to-back arrangement.

In these pumps, the power of the motor is transmitted directly to the impeller by a continuous shaft. In the UP-DO series, the mechanical seal is cooled by a sealing liquid. This is provided by a separate supply system. Seal faces and elastomers can be manufactured in various materials on request. Thus, there is hardly any limit to the use of these pumps.

Special features of the UP-DO Series :- Robust housing parts with high wall thickness

- Compact close-coupled design

- Easy installation

- Suitable for high temperatures

- Dry run safe in connection with a barrier fluid system

- No leakage of toxic or environmentally hazardous liquids

- Meets the requirements of TA Luft

Features:

- Robust housing parts with high wall thickness

- Well suited to fluids containing solid particles due to spring-loaded mechanical seal

- Pumping of magnetic particles possible

- Low-maintenance-operation due to high-quality seal face materials

- All wetted parts made of high-quality, corrosion-resistant stainless steel 1.4571 (AISI 316 Ti)

- Threaded connections as per ISO 228-1 as standard. Optionally available with flange connections (from size 130)

- Universally applicable, low-noise and compact close-coupled design

- Approved for use in explosive atmospheres (ATEX zone 1)

- Corrosion-resistant motor finish

Operating conditions:

- Max. flow rate: up to 30 m³/h

- Max. delivery head: up to 40 m

- Liquid temperature: -10 to 150 °C

- Ambient temperature: -10 to 40 °C, higher temperatures on request

- Pumps can be adapted to high-density liquids (up to 2.0)

UP series

-

These normal-priming centrifugal pumps in close-coupled design with single mechanical seal are robust, durable and solid. Designed for temperatures up to 150 °C, they also handle media with metallic particles.

In pumps of the UP series, we transmit the motor power directly to the pump impeller by a fixed shaft. Therefore these pumps operate without slippage. The mechanical seal is lubricated and cooled by the pumped medium. All seal rings and elastomers are available for the UP in various materials. This allows us to easily adapt them to different applications. The spring of the pump is made of Hastelloy C4. The UP series is also available as UP-EX variants if required. Thus, its use is also possible in ATEX zones 1 and 2.

Special features of the UP Series :- Robust housing parts with high wall thickness

- Compact close-coupled design

- Easy installation

- Suitable for high temperatures

Features:

- Robust housing parts with high wall thickness

- Well suited to fluids containing solid particles due to spring-loaded mechanical seal

- Pumping of magnetic particles possible

- Low-maintenance-operation due to high-quality seal face materials

- All wetted parts made of high-quality, corrosion-resistant stainless steel 1.4571 (AISI 316 Ti)

- Threaded connections as per ISO 228-1 as standard. Optionally available with flange connections (from size 130)

- Universally applicable, low-noise and compact close-coupled design

- Approved for use in explosive atmospheres (ATEX zone 1)

- Corrosion-resistant motor finish

Operating conditions:

- Max. flow rate: up to 30 m³/h

- Max. delivery head: up to 40 m

- Liquid temperature: -10 to 150 °C

- Ambient temperature: -10 to 40 °C, higher temperatures on request

- Pumps can be adapted to high-density liquids (up to 2.0)

Vertical centrifugal pumps

T Series

-

These durable and chemically resistant vertical plastic immersion pumps work in the standard version without seals and up to 95 °C. Optionally also available with shaft seal as vapour barrier.

The T series features a vertical shaft extension that directly drives the impeller. The rotating shaft runs completely contact- and abrasion-free inside the housing (“cantilever” design). This design concept eliminates the need for shaft seals and additional bearings.

Special features of the T Series :- Absolutely dry run safe because of contact-free shaft and impeller rotation

- No abrasion into the fluid, therefore well-suited for high-purity applications

- Maintenance-free operation as no wearing parts such as slide bearings or mechanical seals

Features:

- Absolutely dry run safe because of contact-free shaft and impeller rotation

- Maintenance-free operation as no wearing parts such as slide bearings or mechanical seals

- Available with extension tubes in different lenghts to individually adjust the immersion depth

- Available with inlet strainer to prevent rough dirt and objects from entering the pump housing

- All wetted parts made of high-quality, corrosion-resistant plastics (PVDF or PP)

- Threaded connections (ISO 228-1) as standard

- Optionally available with flange connections (from size 130)

- Universally applicable, low-noise and compact close-coupled design

- Corrosion resistant motor finish

Operating conditions:

- Max. flow rate: up to 30 m³/h

- Max. delivery head: up to 28 m

- Liquid temperature: -5 to 95 °C (PVDF), resp. 0 to 80 °C (PP)

- Ambient temperature: -10 to 40 °C, higher temperatures on request

- Pumps can be adapted to high-density liquids (up to 2.0)

- T series pumps can run dry for unlimited time (except special versions with shaft seals)

Motors & Accessories

Motors

-

A pump is only as reliable as the motor that drives it. That's why we focus on uncompromising quality in this area as well. We equip our pumps with asynchronous three-phase motors as standard.

But we also have many other options for you :

- AC motors 115 V or 230 V, 1-phase (up to 1.1 kW)

- PTC thermistor chain and phase insulation for use on frequency converter

- Integrated frequency converter

- Special and multi-range voltages

- Special frequencies

- ATEX versions, e.g. T3 and T4

- UL, CSA, NEMA, CCC versions

- Direct current motors (DC or BLDC)

- Other versions are available as special requests

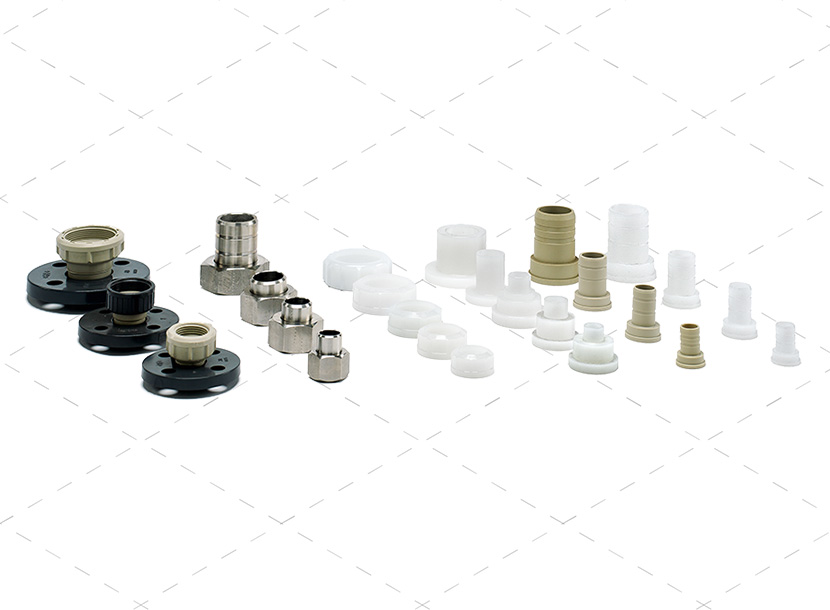

Accessories

-

A SCHMITT pump is only perfect if you can easily work with it in everyday life. Therefore we provide you with a range of accessories. Above all, this involves adapters and connections - after all, what use is the best pump if it does not fit fully into your system?

We offer you as standard: :

Let us advise you on this!- Flange adapter

- Hose connections

- Weld-on connecting pieces for stainless steel piping

- Reduction and extension adapter

- Screw adapter to NPT thread

- Strainers for submersible pumps

- Extension tubes for submersible pumps

Industries

Semiconductor & Solar Cell Industry

-

More safety, absolute purity: SCHMITT centrifugal pumps are ideal for etching, rinsing and cleaning processes. They are also suitable for the production of raw silicon.

High purity, safe production

High-purity silicon is the most important basic material for the manufacture of microelectronic components such as ICs, microprocessors and memory chips. SCHMITT pumps are already used here in the production of the raw silicon. They are also used in etching and rinsing processes in the production of wafers made of pulled monocrystalline silicon single crystals.SCHMITT pumps also reliably convey, circulate and prepare the aggressive liquids required in the further manufacturing process of the microchips for metallizing, developing, etching and cleaning.

Some applications of our centrifugal pumps are:

The pumps must not contaminate the media to be conveyed. Because absolute purity is simply essential for process stability.

A further area of application in the semiconductor industry: SCHMITT pumps also convey the cleaning fluid from thermal scrubbers with which exhaust gases produced during chip production are cleaned.- Production of high purity polysilicon

- Cleaning and etching of monocrystalline wafers

- Wet chemical processes: Developing, spray etching, immersion etching, rinsing

- Supply of used liquids for treatment

More safety, absolute purity: SCHMITT centrifugal pumps are ideal for etching, rinsing and cleaning processes. They are also suitable for the production of raw silicon.

High purity, safe production

High-purity silicon is the most important basic material for the manufacture of microelectronic components such as ICs, microprocessors and memory chips. SCHMITT pumps are already used here in the production of the raw silicon. They are also used in etching and rinsing processes in the production of wafers made of pulled monocrystalline silicon single crystals.SCHMITT pumps also reliably convey, circulate and prepare the aggressive liquids required in the further manufacturing process of the microchips for metallizing, developing, etching and cleaning.

Some applications of our centrifugal pumps are:

The pumps must not contaminate the media to be conveyed. Because absolute purity is simply essential for process stability.

A further area of application in the semiconductor industry: SCHMITT pumps also convey the cleaning fluid from thermal scrubbers with which exhaust gases produced during chip production are cleaned.- Production of high purity polysilicon

- Cleaning and etching of monocrystalline wafers

- Wet chemical processes: Developing, spray etching, immersion etching, rinsing

- Supply of used liquids for treatment

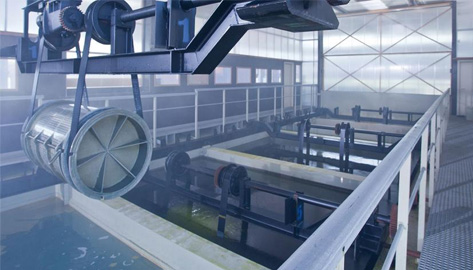

Electroplating & surface technology

-

Transporting aggressive media is our core competence - we also demonstrate this in electroplating and surface technology.

Chemical resistance and versatile use

Some applications of our centrifugal pumps are:

In surface technology, electrochemical, galvanic or electroless, wet-chemical processes are used to provide a wide variety of components, wires or sheets with durable, usually metallic coatings.

These coatings serve for example to protect against corrosion and wear. They are also applied for optical and design reasons. In the coating plants, the components pass successively through a series of dip tanks with various chemicals for cleaning, coating and rinsing. Various aggressive media are used, which is why the filling, circulation and emptying of the basins can only be done with pumps that are resistant to chemicals.

Our centrifugal pumps play their strengths to the full. They are resistant to the chemicals used and they work reliably. They also fit perfectly into the- Galvanic plants, circulation of galvanic baths

- Electroless chemical coatings, e.g. electroless nickel

- Pickling plants

- Degreasing plants

- Washing facilities

Environmental Technology

-

In the purification of exhaust gases, our pumps convince with their chemical resistance in gas scrubbers as well as in wet separators.

For the safe cleaning of gases and Co.

Some applications of our centrifugal pumps are:

In the most diverse industrial manufacturing and combustion processes, exhaust gases are produced that are contaminated with pollutants. Therefore, these exhaust gases must be cleaned or pollutants neutralized before exhaust gases can be released into the environment. Our customers use gas scrubbers or wet separators for this purpose. This is because they remove chemical and particulate impurities in the exhaust gases from the gas flow with the aid of suitable liquids.

Acids or alkalis are often used in this process. And the collected, contaminated liquid is treated in wastewater treatment plants. A robust pump is required for safe operation. This applies not only to chemical resistance. The pump used must also reliably supply the pressure required for continuous operation of the spray heads. Our pumps do both in many exhaust gas purification systems.- Vertical and horizontal gas scrubbers

- Wet separator

- absorber

- Counterflow scrubber

- Cross flow scrubber

- Neutralization of exhaust gases

Batteries & Energy Storage

-

Our pumps work reliably both when filling conventional batteries with electrolyte liquids and in energy storage solutions based on redox flow.

In conventional lead-acid batteries and the advanced gel, AGM and EFB batteries, sulfuric acid is usually used as the electrolyte. However, liquid electrolytes are also required in the production of lithium-ion cells, for example for electric mobility in cars and e-bikes or for cell phones. The challenge is here: These aggressive liquids must be pumped reliably and without contamination using durable pumps.

Some applications of our centrifugal pumps are:

This is a field that will certainly gain in importance in the future: Redox flow or flow batteries for storing large amounts of electrical energy. This is because they are suitable, for example, in combination with wind turbines or solar parks. Here the electrolyte fluids are stored in tanks and pumped through a galvanic cell at a defined pressure and volume flow to generate electricity. With our chemical-resistant plastic pumps, these systems function reliably and safely.- Production of lead-acid accumulators, gel and AGM batteries

- Production of lithium-ion cells

- Conveying of electrolytes in the battery filling

- Electrolyte feed pump in redox flow / flow cell batteries

Chemical industry

-

Filling and emptying tanks and containers with acids or alkalis, taking samples in laboratories and more: our pumps are versatile - and they will certainly fit your requirements exactly.

Individually tailored to your needs

Here are some applications of our centrifugal pumps:

Many of our pumps are chemically extremely resistant and temperature-compatible up to 150 °C. This guarantees safety.

We already have the perfect solution for most requirements in our modular system. We adapt individual materials in the pumps - such as seals and elastomers or plain bearings - to your needs and specifications. Many of our centrifugal pumps can also meet maximum requirements for the purity of media. However, the most important thing is also here: SCHMITT pumps operate with a reliability that is second to none. Because we attach great importance to quality and to optimal advice.- Tank truck emptying of acids and alkalis

- Transfer of tanks and containers

- Filling and emptying of containers, IBC containers

- Sampling in the laboratory

Air conditioning, cooling & refrigeration technology

-

SCHMITT centrifugal pumps are also used under the toughest environmental conditions - for example in desert regions or in the Arctic. Embedded in cooling and preheating systems of electric drive systems and large diesel engines.

Created for all conditions, reliable in operation

Some applications of our centrifugal pumps are:

Our pumps are not only designed for extremely corrosive and aggressive liquids. SCHMITT's horizontal and vertical stainless steel pumps are also used as coolant pumps where the medium does not place particularly high demands on chemical resistance, but a wide temperature range must be covered in harsh environmental conditions.

Examples are cooling systems for frequency converters and transformers in oil and gas production plants in the Arctic, Saudi Arabia, Siberia and North Africa. In these regions, these systems have to cope with extreme cold, heat and other adverse environmental conditions.

As preheating pumps for large diesel engines, our products contribute to the reliability of the energy supply here. Our stainless steel pumps are equipped with very thick-walled parts and robust components. So they can easily withstand the extreme conditions mentioned above.- Circulation of coolants for transformers

- Circulation of coolants for cooling units on trains

- cooling of transformers, frequency converters, drive motors

- Preheating units for diesel drive engines and stationary power generators

Food & beverage industry

-

Hydrogen peroxide for sterility, detergents, but also lyes for the bakery industry can be easily transported with our pumps.

For the transport of cleaning agents and lyes

Here are some applications of our centrifugal pumps:

Our pumps are also suitable for use when foodstuffs in the production of baked goods are to be treated with brine. Especially important here: Our pumps have the necessary food approval to spray pretzels, for example, with caustic soda or brine in precise doses.- Equipment for bottle cleaning

- Conveying of acidic or basic cleaning agents for the disinfection of pipelines

- Disinfection of yoghurt cups

- Transportation of hydrogen peroxide (H2O2)

- Leaching of salt pretzels

Printed circuit board (PCB)

-

Metallizing, etching, stripping, cleaning and more ... In the production of printed circuit boards, our pumps sometimes convey very aggressive and corrosive media. Reliably, safely and always at the right pressure.

Ideal for wet and electrochemical processing

Some applications of our centrifugal pumps are:

Electronic devices such as computers, TVs, smartphones, tablets, smartwatches and more are not feasible without printed circuit boards (PCBs). So these are manufactured in large quantities in highly specialised production facilities all over the world. - Often in combination with SCHMITT pumps.

This is because special chemicals, some of which have very aggressive and corrosive properties, are used in various process steps during the manufacture of PCBs. SCHMITT pumps work here, for example, in systems for metallising, etching, stripping, cleaning and for other surface processes.

Our pumps operate spray nozzles, circulation, surge and rinsing baths in the various wet chemical and electrochemical production steps. And they are also used in the pumping and treatment of spent wastewater- Chemical metallisation

- Electrolytic metallisation

- Acid and alkaline etching

- Production of printed circuit boards and chip carriers

- Waste water treatment