- Offer Profile

- Years of experience for highest quality

Since 1957 we have specialised in the manufacture of agitators for biogas, slurry and waste water. With our range of pumps, we offer a perfectly matched system of agitator and pump. We concentrate our knowledge and decades of experience on the quality of our products. And that is what makes us experts. Set your operation on course for the future - with advanced technology that meets your exact requirements and allows you to work economically.

We support you with individual solutions and indicate new possibilities. Excellent quality, high performance, long service life of our mixers and pumps as well as accommodating service are our principles. Demand them and rely on them!

SUMA - Together for our environment

As a farmer & plant operator, you work with and for nature. Today, this is more important than ever. We protect our environment just like you do: In addition to economic focus, the consideration of ecological criteria is decisive. For SUMA, this means: the right choice of materials, a healthy production environment as well as manufacturing processes that contribute to the preservation of resources.

Agitators

-

Our agitators are used in the sewage industry, tunnel construction, cement industry, food industry, chemical & petrochemical industry, paper and pulp industry, aquaculture or fish farming, as well as in many other industrial sectors.

No matter whether drilling or sewage sludge, cement, water or waste water - we take on every stirring challenge! SUMA has a wide range of rod agitators and submersible motors for industrial use.

As a specialist with more than 60 years of experience in the construction of agitators, we have the necessary know-how to offer the right industrial mixer for a wide range of industries and applications.Our Agitatirs are used in:

- Closed Tank

- Tank Concrete Top

- Open Tank

- Steel Tank

- Open Lagoon

- Closed Lagoon

- Container

Agitators Wastewater and Water

- SUMA mixers ensure effective wastewater treatment in municipal, communal and urban sewage treatment plants. Submersible and long-axis agitators for water and wastewater management are designed for flow generation and maintenance in retention, denitrification or aeration tanks. Additionally, our agitators are used for energy generation from fermentation gases of sewage sludge. The homogenization of the digested sludge releases gases which are converted into electricity in combined heat and power plants (CHP) or used for direct feeding into the gas network. SUMA agitators are also used in various areas of water management, preventing the water from freezing by circulation providing the necessary circulation of cooling water.

Agitators Construction Industry

- SUMA agitators are designed for a wide variety of construction applications. The range of agitating technology for the construction industry includes solutions for homogenizing sludge and dissolving sedimentation and floating layers, as required in mining, digging and removal of sediments, tunneling, road construction and civil engineering.

Agitators Chemistry and Petrochemistry

Agitators Food Recycling

- Residual materials, waste and co-formulants from the food industry, generated during the production of edible oils, such as palm and olive oil, can be used for further processing. Press residues from olives, citrus and other fruits and vegetables are also suitable for further processing, as well as food and slaughterhouse waste. Residues from milk production can also be utilized, for example to generate energy. Moreover, mash from beer brewing is used for further processing.

Agitators Paper and Pulp

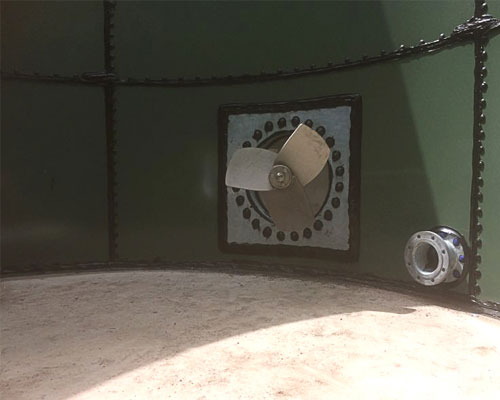

Agitators Biogas

-

Our agitators are especially designed for fermenters, secondary fermenters and end storages. We can provide you a optimal distribution of the temperature and nutrients within your digester. See for yourself what our products can do for you.

Thanks to our years of experience, as the first inventor and manufacturer of the electric agitator, we collect great knowhow and have the possibility to optimize our products throughout.

From the first electric agitator - the Rekordmix - in the 60's until today our product range has grown steadily. We find the perfect solutions for your requirements.

Agitators Agriculture

-

With our agitators for the agriculture area you can proper stir your slurry before application in the field. As manure agitator we offer automized solutions and as well PTO driven agitators. Find your perfect fitting product.

Wether slalom channel, concrete tank or lagoon - with us you can stir everywhere. Even for small buildungs or small openings - we have the solution.

The founding of our family buisness was to achieve, that for you as farmer, the work would be as easy as possible. Since 1957 we are working continously for your advantages.

Agitators

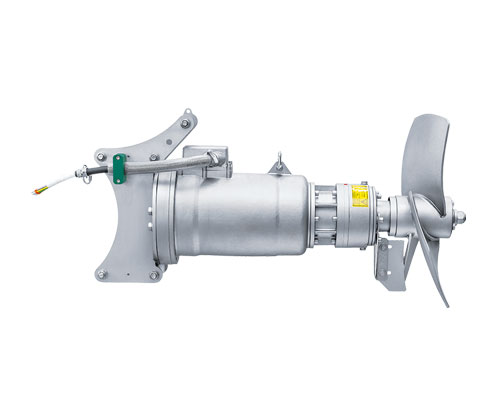

OPTIMIX 2A 15-720

- Fast-running agitator for aggressive media with low pH values

- Propeller in in ss304, optional in hardened ss304 or ss316

- Bearing flange with mechanical seal of SiC/SiC

- Guide mast support for 60 / 80 mm square mast

- Microbe resistant cable 2 separated oil chambers for motor and bearing housing Accessory: POM protection to minimize abrasion

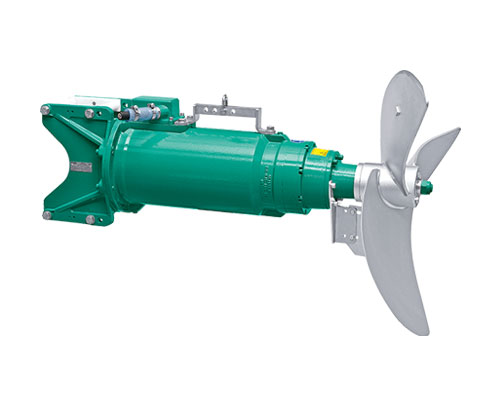

The submersible mixer 2A is specially designed for use in the industrial sector - in particular for water and waste water management. The Optimix 2A impresses with its solid stirring performance. The relatively high thrust forces with regard to the low nominal power of 0.8/1.5/2.2 kW demonstrate distinctly the know-how of the small submersible mixer. Due to the high rotation speed from 714 rpm up to 738 rpm, the compact agitator is ideally applicable for small to medium sized tanks with low dry matter content.

The submersibel motor is completely made of stainless steel. It can therefore be easily used for stirring aggressive media with low pH values.

The propeller of the Optimix 2A, which was specially developed for the agitator, deserves special mention.

The 3-bladed self-cleaning stainless steel propeller is manufactured in a complex embossing process.

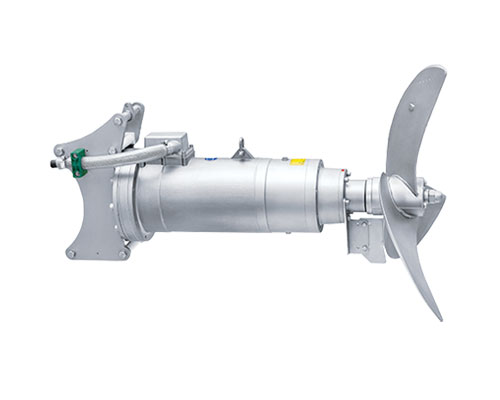

OPTIMIX 2A 3 / 4 KW

- Agitator for agressive media and low pH values

- Propeller ss304, optional hardened ss304 or ss316

- Mechanical SiC/SiC seal 2 separated oil chambers for motor and bearing housing

- Longlife-oil within the bearing housing

- Guide mast support with 4 rollers for 80 x 80 / 100 x 100 / 120 x 120 / 150 x 150 mm mast

- Galvanically insulated to the mast through ss316-rope

- The cable is restistant against biomass

Application:

The OPTIMIX 2A has an outer shell made entirely of 304 stainless steel for use in low pH and extremely aggressive environments.

Individual solutions:

Because of the unique SUMA modular design different motor performances, gears, propeller and mast sizes can be combined for an appropriate agitator for the customer.

Galvanical isolation:

The SUMA-guide mast support with 4 rollers and POM-slide rails guarantees a perfect sliding on the mast and furthermore a galvanical isolation between the mast and the agitator.

Optimum stirring result:

The 2 separated oil chambers for motor bearing housing ensure a proper stirring. Longlife oil with a longer oil changing interval is used for the bearing housing. The sealing is made through the mechanical seal SiC/SiC within the bearing housing. For the motor turbine oil is used for cooling.

Control box:

There are delta-star-operating-switches for a manually operation or time-controlled SUMA-soft start control available. All agitators can be managed over an external frequency converter.

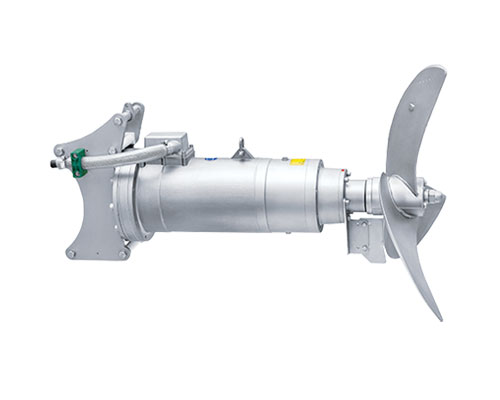

OPTIMIX 2A

- Agitator for agressive media and low pH environments

- Propeller in ss304, optional hardened ss304 or ss316

- Mechanical SiC/SiC seal

- 3 separated oil chambers for motor, gear and bearing housing Longlife-oil within the gear and bearing housing

- Guide mast suspension with 4 rollers

- Galvanically isolated to the mast and ss316-rope

- Biomass resistant jacket for electric cable

- Accessory: POM protection to minimize abrasion

Application:

The OPTIMIX 2A is available completely in stainless steel for substrates with low pH-values and operations in extreme aggressive media. This motor is certified for Ex-zone 1 or Ex-zone 2.

Customized solutions:

The SUMA modular design philosophy allows individualized combinations of motor performances, gears, propeller and mast sizes.

Galvanical isolation:

The SUMA-guide mast support with 4 rollers and POM-slide rails guarantees a perfect sliding on the mast and a galvanical isolation between the mast and the agitator.

Perfect stirring result:

The 3 separated oil chambers for motor, gear and bearing housing ensure a proper stirring. Longlife oil with longer oil changing intervals are used in transmission and the bearing. A mechanical SiC/SiC seal serves as separation to the bearing housing.

Control box:

Available are delta-star-operating-switches for manually operation or time-controlled SUMA-soft start controls. All agitators can be managed by an external drive controller.

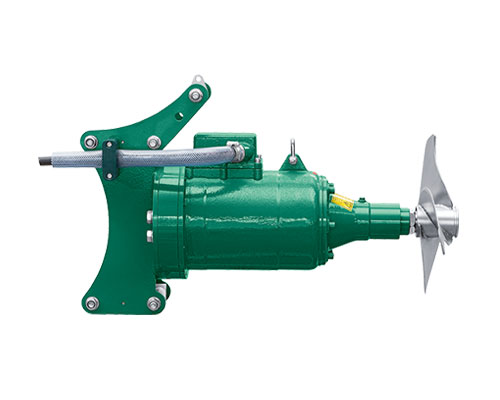

OPTIMIX 3A

- Your high performance agitator for agressive media an low pH values

- Propeller in ss304, optional gardened ss304 or ss316

- Mechanical seal SiC/SiC

- Separated iol chambers with longlife oil

- Guide mast support with 4 rollers for 120 x120 / 150 x 150 mm mast

- Galvanically isolated to the mast through ss316-rope

- The cable is restistant against biomass

- Accessory: POM protection to minimize abrasion

Application:

For substrates with low pH-values and operations in extreme agressive media the OPTIMIX 3A is available completely assembled in stainless steel.

Galvanical isolation:

The SUMA-guide mast support with 4 rollers and POM-slide rails guarantees a perfect sliding on the mast and furthermore a galvanical isolation between the mast and the agitator.

Optimum stirring result:

Longlife oil with a longer oil changing interval is used for the gear and the bearing housing. The sealing is made through the mechanical seal SiC/SiC within the bearing housing.

Control box:

There are delta-star-operating-switches for a manually operation or time-controlled SUMA-soft start control available. All agitators can be managed over an external frequency converter.

OPTIMIX 2G 3 / 4 KW

- Agitator for smaller tanks with low dry matter content

- Propeller in hardened steel,galvanized, ss304 or ss316

- Mechanical seal SiC/SiC

- 2 separated oil chambers for motor and bearing housing

- Longlife-oil within the bearing housing

- Guide mast support with 4 rollers for 80 x 80 / 100 x 100 / 120 x 120 mm mast

- Galvanically insulated to the mast through ss316-rope

Application:

The OPTIMIX 2G with 3.0 or 4.0 kW is especially designed for smaller containers or tanks and substrates with a low dry matter content of up to 8%.

Galvanical isolation:

The SUMA-guide mast support with 4 rollers and POM-slide rails guarantees a perfect sliding on the mast and furthermore a galvanical isolation between the mast and the agitator.

Optimum stirring result:

The 2 separated oil chambers for motor bearing housing ensure a proper stirring. Longlife oil with a longer oil changing interval is used for the bearing housing. The sealing is made through the mechanical seal SiC/SiC within the bearing housing. For the motor turbine oil is used for cooling.

Control box:

There are delta-star-operating-switches for a manually operation or time-controlled SUMA-soft start control available. All agitators can be managed over an external frequency converter.

OPTIMIX 2G

- Your fluidically optimized submersible motor

- Propeller in hardened steel, optional galvanized or ss304

- Mechanical seal of SiC/SiC

- 3 separated oil chambers for motor, gear and bearing housing

- Longlife-oil within the gear and bearing housing

- Guide mast support with 4 rollers for 80 x 80 / 100 x 100 / 120 x120 / 150 x 150 mm masts

- Galvanically isolated to the mast through ss316-rope (V4A)

- The cable is restistant against biomass

- Accessory: POM protection to minimize abrasion

Individual solutions:

The fluidically optimized submersible motor Optimix 2G is available with 4 / 9 and 15 kW and different rotational speed of the propeller.

Because of the unique SUMA modular design differend motor performances, gears, propeller and mast sizes can be combined for an appropriate agitator for the customer.

Galvanical isolation:

The SUMA-guide mast support with 4 rollers and POM-slide rails guarantee a perfect sliding on the mast and furthermore a galvanical isolation between the mast and the agitator.

Optimum stirring result:

The 3 separated oil chambers for motor, gear and bearing housing ensure a proper stirring. Longlife oil with a longer oil changing interval is used for the gear and the bearing housing. The sealing is made through the mechanical seal SiC/SiC within the bearing housing.

Control box:

There are delta-star-operating-switches for a manually operation or time-controlled SUMA-soft start control available. All agitators can be managed over an external frequency converter.

OPTIMIX 2G 90-75

- For the reliable stirring operation and maintaining the stream

- Propeller in hardened steel, optional galvanized, ss304 or ss316

- Mechanical seal of SiC/SiC

- separated oil chambers for motor, gear and bearing housing

- Longlife-oil within the gear and bearing housing

- Guide mast support with 4 rollers for 100 x 100 / 120 x120 / 150 x 150 mm masts

- Galvanically isolated to the mast through ss316-rope (V4A)

- The cable is restistant against biomass

Application:

The streamlined design ensures better heat dissipation and a range of application up to 55°C is possible.

Flow preservation:

Because of the slow propeller speed and the greater propeller diameter this submersible motor is mainly for the flow preservation.

Gear:

The resilient planetary gear has its own oil circuit with turbine-oil and an oil change interval of 12,000 operation hours.

Galvanic isolation:

The SUMA 4-roller guide system avoids the direct contact to the guiding mast and gives a galvanic isolation. The ss316 rope is also isolated to the submersible motor through a special socket.

Guiding system:

Through cable clips the connection cable is guided behind the mast that there is no possibility for the cable to reach the propeller and a safe stirring operation can be ensured.

Propeller:

The propeller is a 3-bladed LT 1400 propeller. For different substrates are galvanized propellers, stainless steel propellers or hardened steel propellers available. Thanks to a great propeller diameter a high thrust is achieved. The propeller is coated with 2K-Epoxy lacquer.

OPTIMIX 2G 150-275

- Suitable for an installation with a substrate temperature up to 55°C

- Propeller in hardened steel, optional galvanized or ss304

- Mechanical seal of SiC/SiC

- separated oil chambers for motor, gear and bearing housing

- Longlife-oil within the gear and bearing housing

- Guide mast support with 4 rollers for 120 x120 / 150 x 150 mm masts

- Galvanically isolated to the mast through ss316-rope (V4A)

- The cable is restistant against biomass

- Accessory: POM protection to minimize abrasion

Application:

The streamlined design ensures better heat dissipation and a range of application up to 55°C is possible.

Galvanic isolation:

The SUMA 4-roller guide system avoids the direct contact to the guiding mast and gives a galvanic isolation. The ss316 rope is also isolated to the submersible motor through a special socket.

Guiding system:

Through cable clips the connection cable is guided behind the mast that there is no possibility for the cable to reach the propeller and a safe stirring operation can be ensured.

Propeller:

The propeller is a 3-bladed HD+ propeller and gets delivered in balanced condition for smooth running of the agitator. For different substrates are galvanized propellers, stainless steel propellers or hardened steel propellers available. Thanks to a great propeller diameter a high thrust is achieved. The propeller is coated with 2K-Epoxy lacquer.

Gear:

The resilient planetary gear has its own oil circuit with Longlife-oil and an oil change interval of 8,000 operation hours.

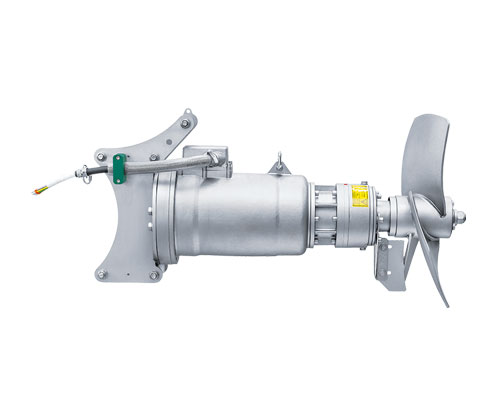

OPTIMIX 3G

- Submersible motor for higher performance requirements

- Propeller in hardened steel, galvanized, ss304 or ss316

- Mechanical seal SiC/SiC

- 3 separated oil chambers for motor, gear and bearing housing

- Longlife-oil within the gear and bearing housing

- Guide mast support with 4 rollers for 120 x120 / 150 x 150 mm mast

- Galvanically isolated to the mast through ss316-rope (V4A)

- The cable is restistant against biomass

- Accessory: POM protection to minimize abrasion

We offer the OPTIMIX 3G with 25 kW for higher performance requirements with maximun thrust.

Application:

For substrates with low pH-values and operations in extreme agressive media the OPTIMIX is available completely assembled in stainless steel.

Galvanical isolation:

The SUMA-guide mast support with 4 rollers and POM-slide rails guarantee a perfect sliding on the mast and furthermore a galvanical isolation between the mast and the agitator.

Optimum stirring result:

The 3 separated oil chambers for motor, gear and bearing housing ensure a proper stirring. Longlife oil with a longer oil changing interval is used for the gear and the bearing housing.

Sealing system:

The sealing is made through the mechanical seal SiC/SiC within the bearing housing.

Control box:

There are delta-star-operating-switches for a manually operation or time-controlled SUMA-soft start control available. All agitators can be managed over an external frequency converter.

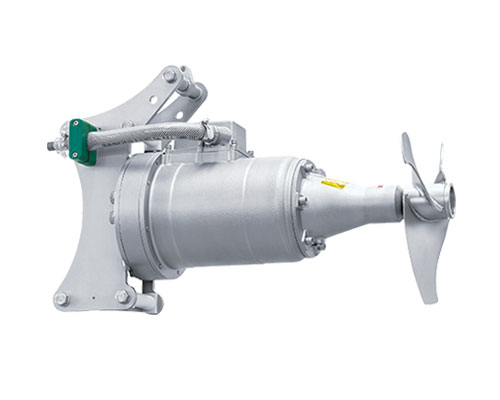

OPTIMIX 4G 150-150

- Submersible mixer with high thrust and for high dry matter content

- For dry matter content up to 14 %

- Propeller in hardened steel or ss304, optional galvanized

- Guide mast support with 4 rollers for 150 x 150 mm masts

- POM protection to minimize abrasion

The submersible mixer Optimix 4G convinces with its high thrust of 6.5 kN. The agitator easily masters a dry matter content of up to 14 %. This makes it the ideal mixer for use in biogas plants and various industrial applications as well as in the agricultural sector. The submersible motor has an output of 15.0 kW at 150 rotations per minute. The high efficiency of the IE4 motor ensures energy-efficient operation. A robust 2-stage planetary gear assures a long service life. The agitator is equipped with a three-blade XT agitator blade with a diameter of 1,200 mm. The Optimix 4G is approved for explosion protection zone 2. The agitator is equipped with the proven POM protection from SUMA. This offers additional protection against long-fibre foreign matter and effectively prevents damage caused by abrasion under the agitator blade bush.

SUSPENSION MOUNTING FRAME EV3 LIGHT

- For open concrete tanks up to 7 m tank height

- Suitable for tank depths up to 6 m

- Lateral rotation ± 60°

- Mast: 60 x 60 mm in ss316, 80 x 80 mm in ss302 or ss316

- Base frame and wall support in ss304

- For dowelling to the tank wall

Application:

Suspension mounting frame for open concrete tanks (not gastight).

Installation depth:

The EV3 light is suitable for tanks with up to 7 m height.

Adjustment:

The optimal stirring depth can be adjusted by the stainless steel cable winch.

In addition, the agitator can be swivelled laterally up to ± 60° at any height.

Guiding system:

The ss316 guide mast is available in the size 60 mm or 80 mm (ss304 or ss316).

Easy maintenance:

By pulling up the agitator, quick and easy maintenance is possible. The substrate does not need to be drained separately. It is also not necessary to enter the tank.

Optional:

The cable winch is also available in a ss304 version with a maximum strain relief of 900 kg.

The suspension mounting frame EV3 light ist suitable for the OPTIMIX 2A 8-720 / 2A 15-720 / 2A 22-720 series.

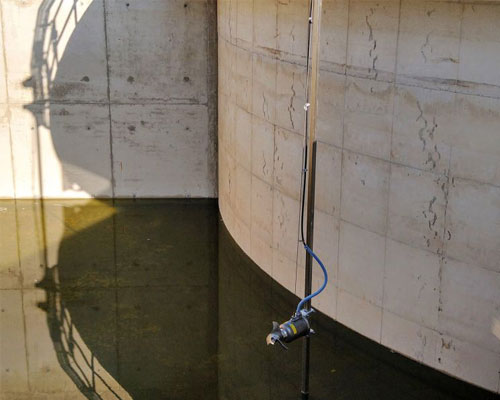

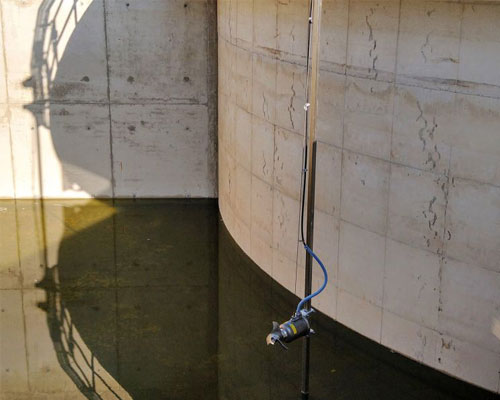

SUSPENSION MOUNTING FRAME EV3

- For plugging onto the wall and for a 4 - 12 m container height

- Suitable for tank depths up to 12 m

- For mounting onto the tank wall

- Lateral rotation +/- 60°

- Incl. SUMA cable winch

- Optional with SUMA-height indication

Application:

For open and closed tanks are different mounting devices available.

Installation depth:

The EV3 is suitable for plugging onto the wall and for a 4 - 12 m container height.

Adjustment:

Through the rope winch the optimised stirring depth can be adjusted fast and easy. Also, the agitator can be horizontally adjusted up to 120°.

Guiding system:

The guide mast is available in the sizes 80/ 100 / 120 and 150mm and in V2A (ss304).

Long service life:

The EV3 is completely in V2A, except the rope winch.

Easy maintenance:

Through hoisting of the agitator, a fast and easy maintenance is possible because the substrate don't need to get drained off and no one needs to decend into the tank.

Option:

The height indication for the exact determination of the agitator height within the tank.

The whole OPTIMIX series are suitable for the EV3.

SUSPENSION MOUNTING FRAME EV4

- For closed container with a height of 4 - 12 m

- Suitable for tank depths up to 12 m

- For mounting onto the concrete ceiling

- Vertically rotation +/- 60°

- Incl. SUMA cable winch

- Optional with SUMA-height indication

Application:

For open and closed tanks are different mounting devices available.

Installation depth:

The EV4 is suitable for closed container (not gas tight) with a height of 4 - 12 m.

Guiding system:

The guide mast is available in the sizes 80/100/120/150 mm and in V2A (ss304).

Long service life:

The EV4 is completely made of V2A, except the rope winch.

Easy maintenance:

Through hoisting of the agitator, a fast and easy maintenance is possible because the substrate don't need to get drained off and no one needs to decend into the tank.

Optional:

Height indication for the exact determination of the agitator height within the tank.

The whole OPTIMIX series are suitable for the EV4.

SUSPENSION MOUNTING FRAME EV5

- For plugging to the wall of a container with 4 - 12 m height

- Suitable for tank depths up to 12 m

- Guiding mast: onto the inside tank wall

- Lifting gallow: onto the outside tank wall

- Incl. SUMA cable winch

- Optional with SUMA-height indication

Application:

For open and closed tanks are different mounting devices available.

Installation depth:

The EV5 is suitable for plugging to the wall of a container with 4 - 12 m height.

Adjustment:

Through the rope winch the optimised stirring depth can be adjusted fast and easy. Also, the agitator can be horizontally adjusted up to +/- 60°.

Guiding system:

The guide mast is available in the sizes 80/100/120 and 150 mm and in V2A (ss304).

Long service life:

Also the EV5 is completely in V2A, except the rope winch.

Easy maintenance:

Through hoisting of the agitator, a fast and easy maintenance is possible because the substrate doesn't need to get drained off and no one needs to decend into the tank.

Optional:

Height indication to determine the exact height of the agitator within the tank.

The whole OPTIMIX series are suitable for the EV5.

MAST GASTIGHT WALL LEAD THROUGH MGD

- Maximum adjustment and gastightness

- For biogas tanks up to 14 m

- External vertically rotation 210°

- Adjustable in height through cable winch

- Mast up to 120 cm distance to the wall within the tank

- Optional: Height indication & angular display

Application:

The guide mast with base frame is suitable for tanks with a depths of 14 m.

Adjustment:

The vertically adjustment (+/- 105°) is made through the external handwheel.

Cable guidance:

The cable guidance is behind the mast on a Ø 30 mm ss316 guide tube through cable clips.

Long service life:

The MGD is completely manufactured of ss304 and within the gas area of ss316.

High gas-tightness:

Also in the space of the rope lead through thanks to the SUMA grease cartridge out of POM and special grease.

Delivery scope:

Wall support inside and outside the tank, gastight cable- and rope lead throughs, external rope winch with a Ø 8 mm ss316 rope and a handwheel for the vertically adjustment of the agitator.

The robust device is delivered with a wideness of 60 cm to the mast (steel tank) or 120 cm to the mast (concrete tank).

Optional:

A height indication for the exact display of the agitator-height and the angle display for the exact determination of the angle position of the agitator can be delivered.

GASTIGHT CEILING LEAD THROUGH GDD

- For a gas tightness of nearly 100 %

- For biogas tanks up to 14 m

- Optional with maintenance hatch

- 360° tilt adjustment

- Adjustable in height through cable winch

- SUMA-height indication

Application:

The gas tight ceiling lead through is a developed product by SUMA with guaranteed serviceability and optimised for biogas tanks with concrete top or big lagoons with concrete bridge.

Adjustment:

The easy adjustment of the horizontal rotation direction is an unique advantage of the GDD.

High gastightness:

For a gas tightness of nearly 100 % a new seal bushing for the rope lead through was developed which is lubricated with special grease at the installation point. Also important by the development was the gas tightness of the service box.

Easy maintenance:

The service box of the GDD simplifies the maintenance of the propeller of the submersible motors without shut down the whole plant. A special highlight is the optional available access cover which closes automatically when sliding the agitator to the top. This mechanism reduces the loss of gas while maintenance is in progress and simplifies the installation work. The maintenance unit can be adapted accordingly to the tank ceiling opening.

Long service life:

The GDD is manufactured completely in ss316 (V4A) and is suitable for guide masts of 100 / 120 / 150 mm.

Monitoring:

In Addition to the mounted sight glass a hight indication for the exact display of the hight of the agitator will be delivered.

REKORDMIX B1

- Especially for lagoons

- Motor power of 4 kW

- Tube Ø 70 mm, ss304

- Tube lengths 3.75 or 4.25 m

- Propeller Ø 320 mm

- Available with foil clamp unit

Application:

The Rekordmix B1 has been specially developed for biogas plants built around a large covered lagoon. Retro-fitting is also possible.

Adjustment:

Vertical adjustment is possible through upper link.

Gas-tightness:

A rubber sealing membrane, secured by a metal ring fastened to the membrane ensures a gas-tight installation. Through the rubber seal, the agitator unit is mechanically separated from the gas membrane to prevent ripping and tearing of the membrane.

Specification:

Shaft unit with electric motor, shaft tube with bearing and sealing unit of low-maintenance modular construction. To protect the gas storage membrane inside the bay, the propeller is fitted with a protective ring. An oil reservoir serves the lubrication and the maintenance indicator. A mounting bracket for securing the unit to the foundation is included within the scope of delivery. Height of the unit is set at the frame.

Optimize the biological process: preventing floating and sinking substrate layers ensuring that the substrate maintains an equal temperature throughout distributing nutrients for the biological process homogeneously enabling more efficient gas flow out of the substrate mass

GIANTMIX BG2

- Espacially designed for biogas lagoons

- Motor power: 10 kW

- Tube Ø 101,6 mm, ss304 or ss316

- Tube lengths 4 / 5 m

- Propeller Ø 560 / 750 mm

- Available with foil clamp unit

Application:

The Giantmix BG2 has been specially developed for biogas plants built around a large covered lagoon.

Retro-fitting is also possible.

Adjustment:

The vertical adjustment is possible through upper link.

Gas-tightness:

A rubber sealing membrane, secured by a metal ring fastened to the membrane ensures a gas-tight installation. Through the rubber seal, the agitator unit is mechanically separated from the gas membrane to prevent ripping and tearing of the membrane.

Construction:

Shaft unit with electric motor, shaft tube with bearing and sealing unit of low-maintenance modular construction. To protect the gas storage membrane inside the bay, the propeller is fitted with a protective ring. An oil reservoir serves the lubrication and the maintenance indicator. A mounting bracket for securing the unit to the foundation is included within the scope of delivery. Height of the unit is set at the frame.

The Giantmix BG2 optimizes the biological process:

Preventing floating and sinking substrate layers. Ensuring that the substrate maintains an equal temperature throughout. Distributing nutrients for the biological process homogeneously. Enabling more efficient gas flow out of the substrate mass.

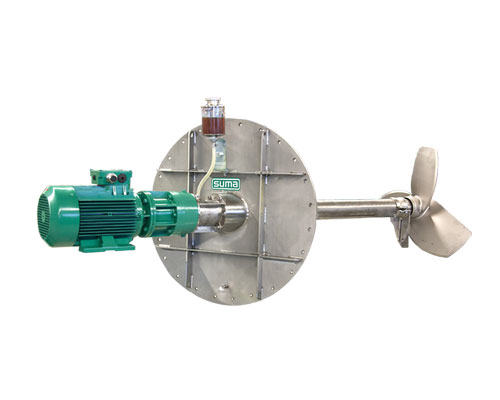

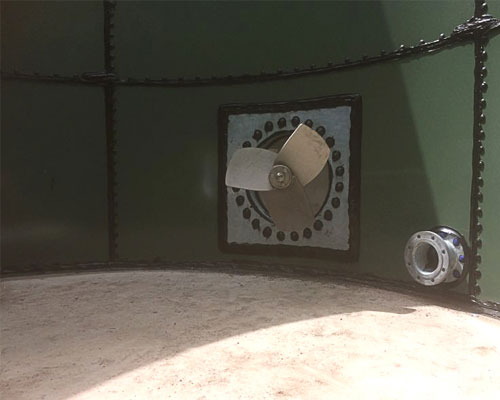

GIANTMIX BG2 - VERTICAL MOUNT VERSION

- Designed for installation on top of the tank

- Motor power: 4.0 / 7.5 / 10.0 kW

- Tube Ø 101,6 mm, ss304 or ss316

- Tube lengths 4.0 / 5.0 m

- Propeller Ø 520 - 750 mm

- For installation on top of the tank

- POM protection to minimize abrasion

Application:

The Giantmix BG2 has been developed for installation on top of the tank. The rod agitator can be used for mixing substrates of dry matter content up to 12% and pH values between 6.5 to 8.2.

Technical Information:

With motor powers of 4.0, 7.5 or 10.0 kW (400V, 50 Hz) the BG2 is the right choice for many applications in the biogas and industrial sector. The Giantmix BG2 is available with tube lenghts of 4.0 or 5.0 m. Other lenghts on request. The tube and the propeller are made from 304 stainless steel. The SUMA POM protection which is included in the scope of delivery provides additional safety.

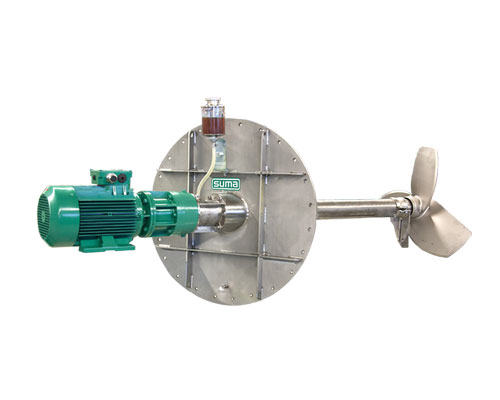

GIANTMIX FR LIGHT

- Gigantic can be so compact

- Ex-motors of rated output 4.0 kW (6-poles / 945 rpm) / 7.5 kW (1.440 rpm)

- Tube-Ø 101.6 mm, ss304 or ss316

- Installation depth up to 6 m beneath substrate level

- Authorized for ex-Zone 1 within the tank

- ss304-stainless steel version of tube and sealing plate, optional ss316

- Fast installation outside the tank - also afterwards

- POM protection to minimize abrasion

Application:

The Giantmix FR Light has been specially designed for concrete- or steel tanks to optimize the biological processes in fermenter and end storages with nearly constant substrate levels.

Easy maintenance:

One advantage of the design of the Giantmix is that almost all of maintenance duties can be carried out from the outside, which means that opening the fermenter or dismounting the unit is not necessary.

The drive side with the electric motor and transmission is accessible from the outside, only the shaft tube and propeller are within the fermenter and in an optimal position for proper mixing.

GIANTMIX FR 30°

- For an optimized biological process by almost constant substrate level

- Ex-motors of rated output 7.5/11/15/18.5 at 200 - 400 rpm (3-phase 50 cycles)

- Tube Ø 101.6 mm, ss304 or ss316

- Suitable up to 1.5 m beneath substrate level. Higher immersion depths on request

- Authorized for ex-zone 1 within the tank and ex-zone 2 outside the tank ss304 version of tube and sealing plate, optional ss316

- Sealing through maintenance-free sealing membrane EPDM 60

- Inclination adjustment by upper control arm, toothed rack with winch or hydraulic drive

- Fast installation outside the tank - also afterwards

- POM protection to minimize abrasion

- Giantmix FR HY only with PTO drive and without motor possible

Application:

The Giantmix FR 30° has been specially designed to optimize the biological processes in primary and secondary fermenters with nearly constant substrate levels.

Easy maintenance:

One advantage of the design of the Giantmix is that almost all of maintenance duties can be carried out from the outside, which means that opening the digester or dismounting the unit is not necessary.

The drive side with the electric motor and transmission is accessible from the outside, only the shaft tube and propeller are within the fermenter and in an optimal position for thorough mixing.

Optional PTO drive: The Giantmix FR can be ordered with an optional protective device and PTO connection.

GIANTMIX FR SP

- Agitator which is vertically adjustable up to +/- 30°

- Suitable up to 8 m beneath substrate level. Deeper immersion depths on request

- Horizontally adjustable +/- 25° Vertically adjustable up to 30° through hydraulic cylinder or pinion

- Authorized for ex-zone 1 within the tank

- A 13,5 kW version is available for ex-zone 1 outside the tank

- Sealing plates 98 x 98 / 120 x 120 / 143 x 143 cm V2A (ss304) or V4A (ss316)

- Tube and sealing plate in ss304 or ss316

- Tube Ø 101,6, ss304 or ss316

- Propeller in hardened steel, ss304 or ss316

- POM protection to minimize abrasion

Application:

The Giantmix FR SP has been specially designed to optimize the biological processes in fermenter and end storages with nearly constant substrate levels.

Installation depth:

Because of the unique SUMA-sealing system, the installation depth of 8 m beneath substrate level but full swivel range is possible. Deeper immersion depths on request.

Sealing system:

The flexible tube leadthrough gets sealed with 2 EPDM sealing membranes (inside and outside) and a special sealing system of SUMA.

Easy maintenance:

One advantage of the design of the Giantmix is that almost all of maintenance duties can be carried out from the outside, which means that opening the fermenter or dismounting the unit is not necessary.The drive side with the electric motor and transmission is accessible from the outside; only the shaft tube and propeller are within the fermenter and in an optimal position for proper mixing.

Optional PTO drive:

The Giantmix FR can be ordered with an optional protective device and PTO connection.

GIANTMIX FR STATIONARY

- The stationary version of our Giantmix FR

- Motors of 11.0 - 18.5 kW

- Tube Ø 101.6 x 4.0 mm stainless steel ss304 / ss316

- Tube lengths of 2.0 - 3.0 m

- Propeller Ø 580 - 660 mm galvanized or ss304, ss316

- Installation up to 8.0 m below substrate level. Deeper immersion depths on request

- POM protection to minimize abrasion

- FR HY: For tractor power 70 - 130 kW

Application:

The long-axis agitator comes together with the model-specific installation console for the stationary installation.

Installation depth:

A rubber compression seal (Ø 200 mm) is approved for an installation depth of 8.0 m. Deeper immersion depths on request.

Monitoring:

An oil pressure equalization tank is used for leak monitoring of the bearing housing.

GIANTMIX FT

- The agitator which is horizontally and vertically adjustable up to +/- 30°

- Low-noise spur gear

- Bearing housing with mechanical seal of SiC/SiC Tube Ø 159 mm, ss304 or ss316 / wall thickness 5 mm

- Tube lengths from 4.0 / 5.0 / 5.5 / 6.0 m

- Sealing plates in 3 sizes in ss304 (V2A) or ss316 (V4A)

- Sealing membrane EPDM 60

- Oil expansion vessel for lubrication and monitoring of the seal

- Suitable up to 8 m beneath substrate level. Deeper depths on request

- Horizontally and vertically inclination adjustment of ± 30°

- Propeller diameters from 660 to 880 mm in ss304 (V2A) stainless or hardened steel

- Hydraulic inclination (optional cylinder support upwards)

- Stainless steel rain covers optional POM protection to minimize abrasion

- Giantmix FT HY only with PTO drive and without motor possible

The Giantmix FT is the advanced development of the Giantmix FR. Adjustment: The agitator is worldwide the only agitator which can be inclined horizontally and vertically by ± 30°. Therefore a high quality hydraulic unit and a hand spindle are provided as standard. Installation depth: Because of the unique sealing system the installation for immersion depths to 8 m below maximum substrate level and full swivelling range is possible. Deeper depths on request. The flexible tube leadthrough gets sealed by 2 EPDM sealing membranes (inside and outside) and the special SUMA sealing system. Optional PTO drive: The Giantmix FT can alternatively be tractor-driven by using an optional protective device. All agitators of the type Giantmix FT are available with PTO connection and without motor.

GIANTMIX FT - TOP MOUNT VERSION

- Long-axis agitator Giantmix FT - version for top mounting

- Bearing housing with mechanical seal of SiC/SiC

- Tube Ø 159 mm ss304 (V2A) or ss316 (V4A) / wall thickness 5 mm

- Tube lengths from 4.0 / 5.0 / 5.5 / 6.0 m

- Sealing plates in ss316 (V4A) and in three sizes

- Sealing membrane EPDM 60 Oil expansion vessel for lubrication and monitoring of the sea

- Propeller diameters from Ø 660 - 880 mm in ss304 (V2A) stainless or hardened steel

- Optional rain cover in ss304

- POM protection to minimize abrasion

The Giantmix FT top mounting version was especially developed for an installation on top of a concrete wall of a biogas or industry plant.

Adjustment:

The agitator is worldwide the only agitator which can be inclined horizontally and vertically by ± 30°. Therefore a high quality hydraulic unit and a hand spindle are provided as standard.

Pumps

PRESSURA - Pumping is easy

With our range of pumps we offer a perfectly matched system of agitator and pump for stirring, mixing, homogenising, pumping and filling from one hand. In doing so, not only do we meet the requirements for reliable pump technology, but also set new standards. PRESSURA is available as a long-shaft pump and submersible pump. The slurry pumps are available in various designs. Thanks to the extensive range of accessories, you will find the right solution for your application.The SUMA among pumps

Innovation and the quest for the perfect solution: PRESSURA complements the existing portfolio optimally.

You can rely on:- Proven SUMA quality

- Maximum durability

- Easy handling

- Energy-efficient operation

- Perfectly matched system of pump and agitator from one hand

The PRESSURA pumps are available as long shaft pumps or submersible pumps. You can rely on the familiar SUMA quality, durability and easy handling.- Mixing

- Stirring

- Homogenising

- Pumping

PRESSURA LW

- Stirring, mixing, homogenising, pumping, filling

- Maximum pumping rate: 340 m3/h

- Maximum head: 23 m

- Motor: 15,0 kW

- Tube length: 1.5 - 8.0 m

- Flange connection: DN 125

- Available with or without nozzle

- Nozzle vertically and horizontally adjustable

The Pressura LW 150 long-shaft pump handles classic applications like stirring, mixing, homogenising, pumping over and filling with ease. The pump is designed for pit depths from 1.5 to 8.0 metres.

Motor

The long shaft pump LW 150 is available in three different motor versions, each with 15.0 kW. The energy-efficient IE3 or IE4 motors provide the required power.

Nozzle

The long shaft pump is available with or without nozzle. The nozzles allow stirring and mixing of the substrate and help dissolve floating and sinking layers. The agitator nozzle is vertically and horizontally adjustable, which makes it flexibly adaptable to the conditions and requirements. The height of the nozzle attachment is also variable.

Wall mount

Adjustable wall brackets are used for easy fixing to the tank wall, regardless of its geometry.

Accessories

The pump is also available with lifting frame for easy transport, lowering and lifting.

PRESSURA TP

- Stirring, mixing, homogenising, pumping, filling

- Maximum pumping rate: 340 m3/h

- Maximum head: 23 m

- Motor: 15,0 kW

- For pit depth from 1.5 - 8.0 m

- Flange connection DN 125

- Horizontally and vertically adjustable

Technology

Our Concept

- The SUMA concept - high vertical depth of production for maximum quality and customer satisfaction

Why can we promise our customers the highest level of quality? Because it's in our own hands.

SUMA has been designing purpose built mixers and agitators in the biogas, liquid manure and waste water treatment for years. Our concept is to make a low maintenance, high capacity agitator using the latest technology and innovation on the market. SUMA designs and manufactures the majority of our components in-house leveraging the highest quality and control of our products. In turn this allows us to offer additional customized solutions to fit your specific needs because we can conceptualize, design, construct and manufacture all of it in-house.

Thanks to our experience building agitators for decades, we have been able to build up a concept that can meet the demands of tomorrow.

Modular Technique

multi-purpose equipment options, simple installation, easy interchangeability

Bearing concept and smooth running

optimal power transmission, long-life service

Geometrically accurate propeller

for a high mixing performance

Construction

- SUMA has been designing purpose built mixers and agitators in the biogas, liquid manure and waste water treatment for years. Our concept is to make a low maintenance, high capacity agitator using the latest technology and innovation on the market. SUMA designs and manufactures the majority of our components in-house leveraging the highest quality and control of our products. In turn this allows us to offer additional customized solutions to fit your specific needs because we can conceptualize, design, construct and manufacture all of it in-house.

Thanks to our experience building agitators for decades, we have been able to build up a concept that can meet the demands of tomorrow.

SUMA has been designing purpose built mixers and agitators in the biogas, liquid manure and waste water treatment industry since 1957. Nearly all of our parts have been developed, designed and fabricated in-house with our sophisticated set of modern machinery.

At SUMA, we have been absolutely focused on product technology, quality and modularity that we even machine our own tools and devices for parts production. This allows us to adapt to new directions in the industry and continuously influence the direction of our product offering.

With decades of experience in water, manure, and other bio-waste agitation; we believe that we offer the best range of products to meet your specific agitation needs. Additionally, SUMA offers the flexibility to help solve difficult agitation problems with economical custom built solutions.

SUMA has developed a purpose built modular system to meet the demands of your business. Individual components of our product line can be easily replaced, upgraded, serviced or repaired for other SUMA components. Such as propellers, bearings, tubes, frames, drive shaft and seals; they are all part of our modular design.

With even the shortest notice, SUMA can respond to your businesses demands with a custom solution. This kind of forward thinking has also made yearly servicing our agitators extra easy on you and your business. Most of all, when you own and operate a SUMA mixer or agitator older models and components can be upgraded with newer components.

Propeller

- The exact propeller size and optimized, radius dependent angle of the blades are critically important for the performance of agitators.

To optimize the performance of its propellers, SUMA built a test basin, so that flow velocity, axial force and power consumption can be measured under real conditions. The measured values can then be compared with the results of CFD simulations, validating the model results.

Shorter agitation times and reduced power consumption can be realized by the optimization of the propeller blades.

The optimized and dynamically balanced SUMA propellers are also suitable for use on older SUMA mixers and these and can be upgraded on demand.

The high performance, push and suction propellers can be used depending on the application conditions and rotation direction and power requirements.- High performance propeller (HD+)

- Push propeller (D)

- Suction propeller (S)

Effective Protection to Reduce Abrasion

- Addititional protection

After a detailed test phase, SUMA offers POM protection as an additional safeguard against long-fibre materials. The protection effectively prevents abrasion damage under the bushing of the propeller.

Material

We use polyoxymethylene (POM), a material that has proven itself in the biogas sector for many years. Among other things, the material has already been successfully used in the slide rollers of our Optimix agitators. POM scores with very good gliding properties and a long service life, even when it comes to aggressive substrates.

Easy assembly

The protection clamp is available for many SUMA agitators and submersible mixers. It can be retrofitted to existing agitators. The POM protection is easy to install and can be mounted in just a few steps. The appropriate illustrated maintenance manual is enclosed.