ISCAR

Videos

Loading the player ...

- Offer Profile

- Now in its 40th year in the U.K., ISCAR has successfully developed a major presence in the metalworking industry by helping customers to improve their productivity through the application of our innovative leading edge technologies and unique cutting tools.

Product Portfolio

Parting & Grooving

Parting

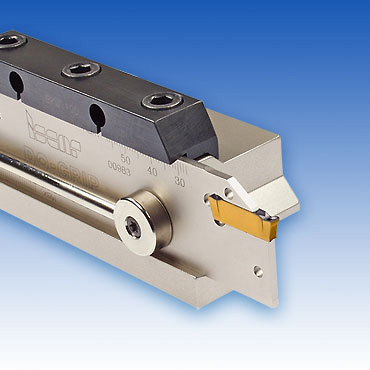

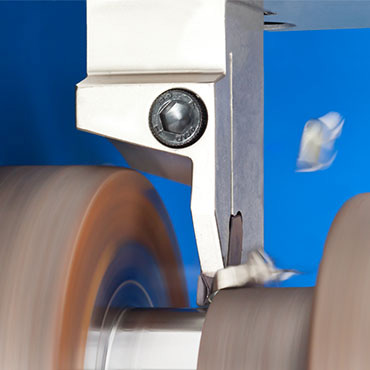

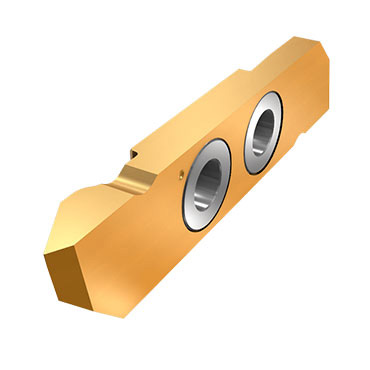

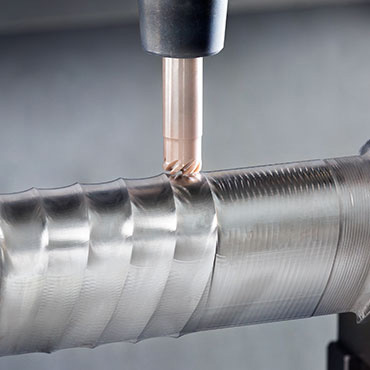

MULTI-F-GRIP HOLDER

- Parting System Designed for Increased Productivity

The revolutionary LOGIQFGRIP parting system was designed to achieve extra stability and high productivity in parting and grooving operations. The highly engineered LOGIQFGRIP is an assembled tool block that comprises a unique durable holder and a high-stiffness quad blade with pockets for mounting inserts.

Features:- Outstanding stability enables vibration-free grooving and parting - especially when parting large diameter workpieces.

- Significantly improves roughness and straightness for material reduction and prolonged insert life.

- High-vibration resistance enables cutting width reduction.

- User-friendly and easy-to-operate system.

- The quad blade design saves setup time after pocket replacement.

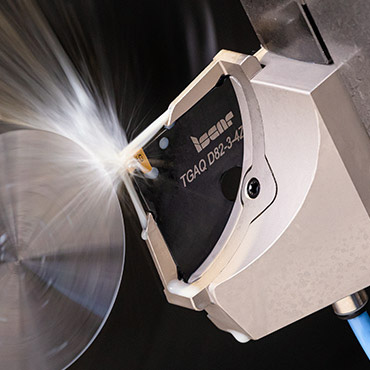

JET-CROWN

- Significantly improves insert tool life

A highly advanced parting system for square TANG-GRIP (TGAQ ) adapters that fit onto a unique crown clamping mechanism with a single screw for fast clamping and indexing.

Features:- Two coolant through tools with top and bottom outlets for output pressure of up to 340 bars.

Significantly improves insert tool life. - Quick, change fast and easy adapter indexing. User-friendly with a single clamping screw.

- No set-up time after blade or pocket indexing.

- Can be used next to the spindle or next to a shoulder as the square adapter and tool shank align with no protrusions.

- Economical adapters with 4 pockets for TANG-GRIP 2,3- and 4-mm width inserts.

- Suitable for all TANG-GRIP inserts including high feed inserts. Designed for higher productivity.

- Extremely stable system improves surface quality and part straightness.

- Several adapters can be clamped on one tool block.

Requires a separate crown for each insert width. (Crown to be ordered separately.) - Available for parting up to an 82 mm bar diameter.

- Two coolant through tools with top and bottom outlets for output pressure of up to 340 bars.

LogIQ_5_GripTANG-5-GRIP

- 5 Pockets

ISCAR introduces the world’s narrowest 0.8mm insert for parting and grooving, combined with an innovative and economical 5 pocket blade featuring extended tool life. The interchangeable blade is assembled on a toolholder which indexes SLIMGRIP inserts. The blade features high stability and repeatability, and the narrow chipformer on the inserts allows free chip evacuation. A new family of tools and economical 5 pocket adapters for existing TANG-GRIP inserts in sizes of 2 and 3mm. These new adapters will allow parting applications of bar diameters up to Ø45mm.

TANG5GRIP Features:- Economical adapters with 5 pockets for TANG-GRIP inserts

- Up to 45mm bar diameter - TANG-GRIP insert 2-3 mm width

- Up to 22mm bar diameter - TANG-GRIP insert 0.8-1.6 mm width

- No setup time after pocket replacement

- Unique product, door opener for parting applications

- The back of the adapters is designed with “V” shape geometry (wedge effect) to ensure maximum clamping forces and tool stability

- Several adapters can be clamped on one holder

- High pressure coolant. The tools and adapters are designed for JET-CUT cooling up to 340 Bar

TANG-GRIP IQ

-

Additional Pocket Advantages

ISCAR has upgraded the 3 mm and 4 mm TGSU blades and integral shank tools, by doubling their number of insert pockets.

The new blades feature the same general dimensions as the current, with the addition of two extra pockets. The new tools offer an additional pocket. This provides the advantage of half the price per pocket when compared with the current tools and blades.

Economic advantages of the TGSU 4-pocket blades and 2-pocket tools include:- High rigidity - capable of bearing heavy tooth load (high feed)

- No chip obstruction under any possible machining conditions

- Free chip flow provides excellent surface finish

- Excellent surface straightness due to high blade rigidity

- Can be used for deep grooving and parting applications (the 35 mm high blades are 30 mm longer than any other standard blade)

- Unique design

- Most economical price per pocket

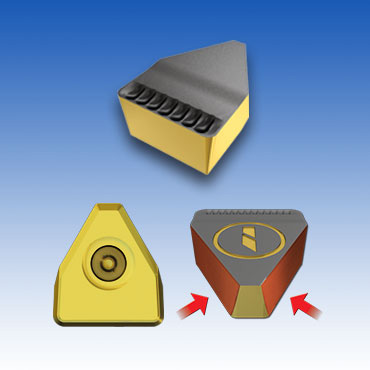

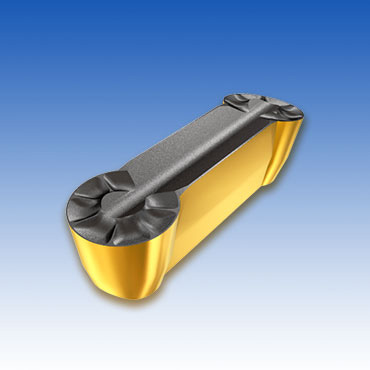

PENTA IQ GRIP

- Deeper Grooving

ISCAR is introducing the PENTAIQGRIP line for parting and grooving operations with a 5-edged insert for much deeper grooving and parting applications, compared with currently available pentagonal inserts.

PENTAIQGRIP has an innovative dovetail clamping structure that ensures a face contact of the insert, which means that the insert is very rigid in the pocket and therefore capable of recessing and holding side forces.

All these characteristics ensure excellent straightness and surface finish for parting applications.

A new user-friendly clamping mechanism enables easy and quick cutting edge and insert indexing. Three insert sizes are available for parting 22, 32 and 40 mm diameters.

DO-GRIP

-

Blocks and Double-ended Adapters

In addition to highly efficient parting inserts in single and double-ended conventional configurations, ISCAR offers a unique double-ended twisted geometry for unlimited depth of penetration. The DO-GRIP ranges also include the largest choice of parting widths available in today's market, covering all applications. ISCAR offers a wide variety of chipformers and the most advanced grades to ensure unbeatable performance and extended tool life.

TANG-GRIP

-

Improved Clamping Method

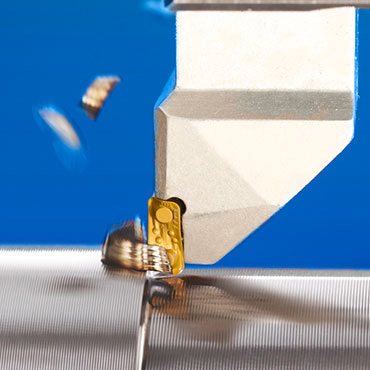

ISCAR's single-ended insert for parting, with an improved clamping method.

TAG Insert Features- Very rigid clamping in a tangentially oriented pocket.

- Enables machining at very high feed rates and provides excellent straightness and surface finish.

- Recommended for parting large diameter parts and for interrupted cuts.

- Offers a free, unobstructed chip flow, as there is no upper jaw like in other clamping systems (very important in deep grooving and parting applications).

- The combination of tangential clamping and free chip flow results in improved tool and pocket life.

- Provides a solution to the problem of inserts being pulled out during retraction.

PENTA-CUT

- 5 Cutting Edge Insert for Economical Grooving, Parting and Recessing

ISCAR’s 5 cutting edge PENTACUT 24 and 34 inserts are designed for multifunction applications including grooving, parting, recessing and chamfering.

This cost effective insert is designed to perform grooving operations and parting off solid bars up to 20 mm in diameter. Each cutting edge on the pentagonal shaped insert is equipped with a unique J and C-type chipformer to achieve excellent chip control in grooving, parting and recessing (light side turning) applications.

PENTACUT also has the ability to perform threading applications. Full profile inserts are available in the following thread standards: ISO, UN, Whitworth, BSPT and NPT. Partial profile inserts are available in 600 (MT) and 550 (WT) profiles.

The insert is tangentially mounted on a side of the holder, positioned against two peripheral contact surfaces to ensure accuracy of center height. Clamping of the insert is by a side torx screw. The torx screw can be activated from either side of the holder to enable insert indexing (rotation) without having to remove the holder from the machine turret. The short head of the holder ensures minimal overhang and high stability. The PENTACUT tools can be mounted on any type of lathe.

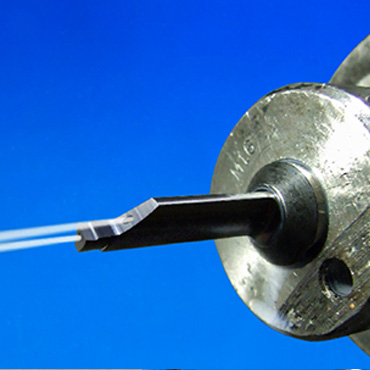

JET-CUT

-

A New Parting Insert with Direct Jet Cooling

ISCAR has upgraded the DO-GRIP parting insert.

The insert features a coolant hole that passes through the insert, with an outlet near the cutting edge. The DGNC inserts have been designed for parting and grooving on stainless steel and high temperature alloys.

When machining stainless steel or high temperature alloys, the temperature near the cutting edge becomes very high.

These materials tend to adhere to the cutting edge, causing built-up edge. This phenomenon can be reduced or even eliminated, by efficient cooling of the cutting edge.

In grooving and parting applications, there is a problem that the chip prevents the coolant from reaching the cutting edge.

The DGNC inserts represent an ideal solution, as they have a coolant hole through the insert with an outlet near the cutting edge.

The coolant reaches the cutting edge and the insert body is internally cooled.

SELF-GRIP

-

For Deep Grooving and Large Diameters

F-type- Single-ended insert

- For deep grooving and large diameters

- With a stopper for high radial accuracy

- Single-ended insert

- The original SELF-GRIP design

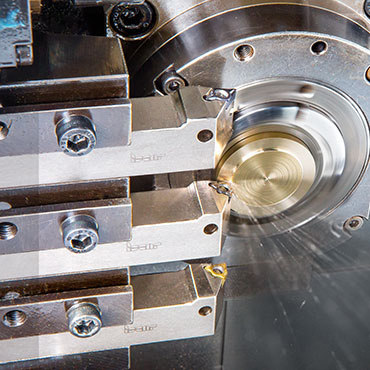

JET-HP-LINE

-

High Pressure Coolant with Parting Tools

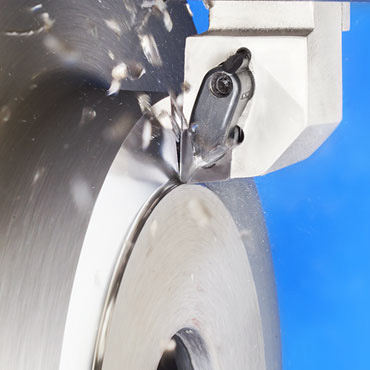

In grooving and parting operations, applying high pressure coolant provides excellent chip breaking results on all materials.

On exotic alloys such as Inconel and titanium, it is usually impossible to break the chips with standard external coolant pressure. Applying high coolant pressure resolves this issue successfully.

On some alloyed and stainless steel, especially when low feeds are applied, high pressure coolant may solve chip breaking problems.

High pressure coolant reduces or even eliminates built-up edge phenomenon, especially when machining stainless steel and high temperature alloys.

CHIPFORMERS

- For Various Workpiece MaterialsMain Chipformers for Steel Parting and Grooving (ISO P)

- C-Type

- W-Type

- JT-Type

- J-Type

- Z-Type

- UA/UT-Type

- P-Type

Groove Turn

DOVE IQ GRIP

- Heavy Duty

Grooving System

New line for deep heavy grooving with a unique frontal locking mechanism.

Features- Very rigid dovetail clamping

- User-friendly locking mechanism with frontal access, just a half-turn to clamp / unclamp the insert

- No need to fully extract the screw (means no falling parts)

- Unobstructed chip flow - no upper jaw or screw cavity

- Wide variety of standard sizes in the range of 10 to 20 mm

- The new blades carry a cartridge system that provides additional security for the blades

Groove Turn - General Information

- Multifunction Turning Tools

The GROOVE-TURN tools are multifunction turning tools, able to operate in a sequence of grooving and turning modes. Moving from turning to grooving requires consideration of the basic GRIP principle, thereby eliminating the possibility of insert breakage. In this situation one must release the side deflection which is necessary in turning, but not recommended in grooving.

CUT-GRIP

-

Insert Variety

The CUT-GRIP family has more variety than any other Groove-Turn product family in the market.

In addition to the large variety of general use precision ground and utility inserts, there is a huge variety of inserts for specific applications and materials.

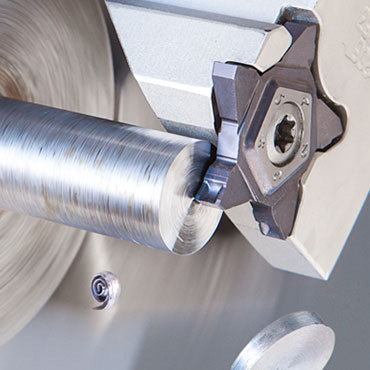

HELI-GRIP

- 1 Insert 8 Different Applications

Due to the twisted concept, HELI-GRIP inserts are the only double-ended inserts in the market that can groove deeper than the inserts’ length.

(see video)

Only 1 insert – 8 different applications:- External and internal grooving and turning

- Face grooving and turning

- Parting off

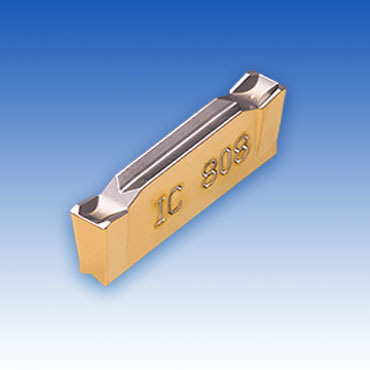

SUMO-GRIP-HEVY-DUTY

- Heavy Duty Groove- Turn Applications

ISCAR's single-ended insert for heavy grooving and turning applications is based on the very successful TANG-GRIP family.

Features- Tangentially oriented pocket creates a very rigid and secure clamping.

- Very strong insert design enables machining at very high feed rates of up to 1.0 mm/rev.

- Free, unobstructed chip flow, since there is no upper jaw as in the other clamping systems.

- Recommended for machining large diameter parts and heavy interrupted cuts

The TAGB inserts are available in widths of 6-14 mm, full radius and straight frontal edge with 0.8 mm corner radii. They are available in the most advanced SUMO-TEC grades IC808 and IC8250.

PENTACUT

- 5 Cutting Edge Insert for Economical Grooving, Parting and Recessing

ISCAR’s 5 cutting edge PENTACUT 24 and 34 inserts are designed for multifunction applications including grooving, parting, recessing and chamfering.

This cost effective insert is designed to perform grooving operations and parting off solid bars up to 20 mm in diameter. Each cutting edge on the pentagonal shaped insert is equipped with a unique J and C-type chipformer to achieve excellent chip control in grooving, parting and recessing (light side turning) applications.

PENTACUT also has the ability to perform threading applications. Full profile inserts are available in the following thread standards: ISO, UN, Whitworth, BSPT and NPT. Partial profile inserts are available in 600 (MT) and 550 (WT) profiles.

PENTA-CUT-24

- Variety of Chipformers

Following the successful market penetration of the PENTA 24 inserts, ISCAR is expanding the line by adding the following:- A C-type chipformer for higher feeds and tougher applications. It should be considered as the first choice for grooving and parting of hard materials and tough applications. The C-type chipformer features a positive rake, negative land and shoulders that provide extra cuttingedge strength.

- The PENTA 24-C inserts are available in straight and full radii configurations for grooving and parting applications and in slanted frontal edge (right- and left-hand) for parting applications, when a reduced center burr size is required.

- New wider inserts to the PENTA 24N-J family (up to 4.23 mm).

- New IC30N cermet grade inserts to the PENTA 24N-PF/P family. Grade IC30N can be applied on a wide variety of materials. It can run at high cutting speeds, providing high surface finish and price advantage.

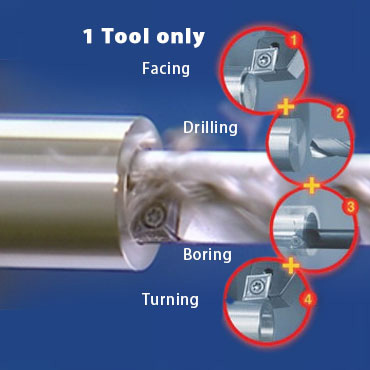

MULTIFUNCTION TOOLS

- Expanded for Internal Grooving

ISCAR’s very popular multifunction DR-MF tools family is being upgraded by new DRG-MF tools which can carry the XCMT-MF inserts and also a new insert type, XCMT-MG, designed for internal grooving.

The new tools and inserts extend the application range of the current DR-MF tools by adding a grooving capability to drilling, internal turning/boring, external turning, and face turning applications. The new DRG-MF tools differ from the current DRMF tools by a new pocket design, which features a rear groove intended to accommodate the second cutting edge.

The new XCMT-MG inserts with two cutting edges are made from grade IC808G, which is a submicron substrate TiAlN multilayer coating. This coating provides a high degree of reliability for cutting operations and a most competitive long edge life.

The new grooving inserts can be used only on righthand tools.

The new tools further enhance the reduction of customer inventory costs.

Whisperline Anti vibration

- Anti-vibration Blades

ISCAR anti-vibration blades are designed to eliminate vibrations in deep grooving applications. WHISPERLINE blades are designed for deep grooving and parting operations.

The damping unit is located under the insert pocket and consists of two plates situated in a rhombic frame, connected by a screw that pushes the plates against the walls through an O-ring.

Camfix

- ISCAR is adding a complete range of CAMFIX holders suitable for internal CUT-GRIP adapters

ISCAR is expanding its range of solutions for internal groove-turn applications and adding new holders for internal CUT-GRIP adapters and blades with CAMFIX shanks.

The standard line will include holders with CAMFIX shank sizes C3, C4, C5 & C6.

Left hand holders – upon request

SWISS-CUT

- Cam fix Modular holder

Tool Features:- The insert can be clamped from the back and the front end of the tool, providing inventory savings related to tools

- The insert can be extracted from the front end of the tool if the sides are blocked

- Features compact tool design which enables passing through the envelope of a Swiss machine magazine

- The second cutting edge of the insert can be used if the first cutting edge is broken

CUT-GRIP

- Extra Long

Overview

Following the development of new anti-vibration boring bars, round boring bars and CAMFIX holders with serrated type connections, ISCAR is expanding its range of solutions for groove-turn applications by adding suitable interchangeable heads.

Main Features- Interchangeable heads for Ø32 and 40 mm serrated type connection suitable for GIPI/GINI/GIFI/TIPI type inserts.

- Interchangeable heads for Ø16, 20 and 25 mm serrated type connection suitable for GEPI/GEMI type inserts.

- Interchangeable heads for Ø32 and 40 mm serrated type connection suitable for clamping internal single ended blades.

- All heads feature internal coolant system.

CUT-GRIP

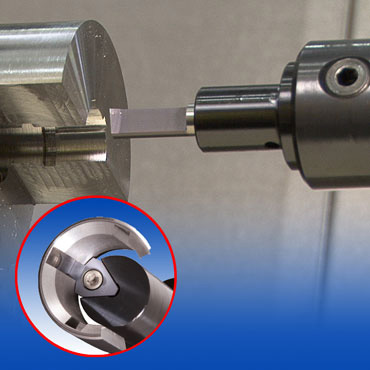

- A line of tools and inserts for broaching keyway grooves by using lathe / milling machines

ISCAR had developed a line of products for broaching applications. ISCAR’s broaching tools were designed for lathes and have many advantages, when compared to the process of typical dedicated broaching machines.

Advantages of Broaching on Lathe / Milling Machine- Full machining process in a single clamping – In order to machine a complete part that includes a broaching operation, several clamping processes are needed. ISCAR’s broaching line enables machining of the whole part in one single clamping process and saves precious lead time.

- High accuracy – The use of a CNC lathe provides higher accuracy in comparison to the typical dedicated broaching machine.

- Better surface finish - The CNC machine’s high stability results in better surface finish received on the parts.

- Machining small batches – The ability to use a lathe machine eliminates dependency on subcontractors or on other machines, which is a significant advantage for small batches.

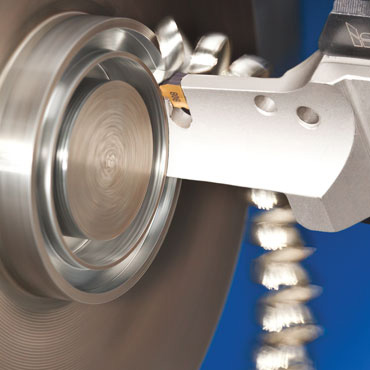

Face Grooving

- ISCAR offers a precision tooling range for face grooving and turning, with a wide variety of families including HELIFACE, CUT-GRIP, PENTACUT, MINCUT and PICCO.

The TANG-GRIP line of tangentially clamped single-ended inserts for face grooving includes single- and double-ended blades and inserts in 3 and 4 mm widths, in the most advanced IC808 SUMO TEC grade.

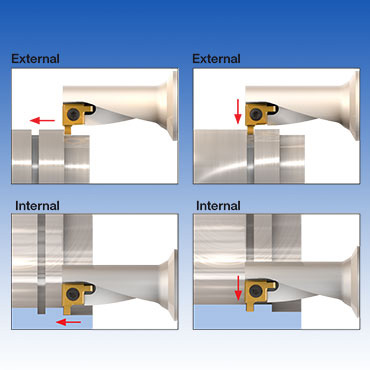

HELIFACE is a versatile screw-clamped insert system that provides a complete solution for face grooving and face turning.

HELIFACE chipformers are designed for optimal chip evacuation in face grooving, resulting in improved, trouble-free performance. Four types of adapters can be mounted on the same toolholder. External and internal face grooving and turning are possible with no limitation to widening the grooves after the initial pass. HELIFACE inserts feature twisted double-ended geometries for depth penetration greater than the insert length.

HELI-FACE

- HELIFACE is a versatile screw-clamped insert system that provides a complete solution for face grooving and face turning. The HELIFACE chipformers are designed for optimal chip evacuation in face grooving, resulting in improved, trouble-free performance. Four types of adapters can be mounted on the same toolholder. External and internal face grooving and turning are possible with no limitation to widening the grooves after the initial pass. HELIFACE inserts feature twisted double-ended geometries for depth penetration greater than the length of the insert.

CUT-GRIP

- The CUT-GRIP family has more variety than any other groove-turn product family in the market.

In addition to the large selection of general use precision ground and utility inserts, there is a wide range of face grooving applications and materials.

TANG-FACE

- System Features

- Very rigid clamping in a tangentially oriented pocket

- Designed for face grooving in 25 to 500 mm penetration diameter range

- Enables machining at very high feed rates and interrupted cuts, providing excellent surface finish

- Offers a free, unobstructed chip flow, since there is no upper jaw as in the other clamping systems (very important in deep grooving applications)

- The combination of tangential clamping and free chip flow results in very high reliability, improved tool and pocket life

- Provides a solution to the problem of inserts being pulled out during retraction

- The same insert can be used for both right- and left-hand tools

- The combination of the C-type chipformer and the SUMO TEC grade IC808 provides excellent performance on a wide range of materials and cutting conditions

- The new tools are equipped with a user-friendly clamping and extraction device

PENTA-CUT

- The PENTACUT 34F& 34FR/L..S 5 cutting edge insert is designed for face grooving and face turning applications.

This cost-effective insert is pentagonal shaped and is equipped with a unique C-type chipformer that provides excellent chip control in face grooving and face turning applications.

The insert is tangentially mounted on the side of the holder, and is positioned against two peripheral contact surfaces to ensure center height accuracy . The insert is clamped by means of a side torx screw. The torx screw can be activated from either side of the holder to enable insert indexing (rotation) without having to remove the holder from the machine turret. The short head of the holder ensures minimal overhang and high stability. The PENTACUT tools can be mounted on any type of lathe.

PICCO-FACE

- The growing demand for high accuracy and increased flexibility in clamping orientation inspired ISCAR to develop an advanced new range of PICCO insert holders. The innovative PICCOACE series features a unique patented clamping system that sets new standards in three highly important areas - accuracy, rigidity and flexibility of clamping orientation.

PICCOACE’s fast action and very secure clamping system increases machining efficiency by saving time when replacing an insert; it ensures rapid indexing and guarantees extremely high clamping repeatability of 0.005 mm.

The wide variety of Swiss-type machines currently available has increased the demand for multi-orientated clamping. Most of the existing available tools provide a single clamping orientation. In contrast, ISCAR’s PICCOACE offers a high-quality, universal solution that is suitable for all Swiss-type machines, enabling operators to install and remove an insert from any desired direction.

MIN-CUT

- The MINCUT line represents the largest variety of small diameter holders and inserts. The MINCUT 8 / 10 & 15 insert line can cover minimum diameters from 8 mm up to 60 mm and, in some cases, with no diameter limit. ISCAR has recently introduced a new family of MINCUT inserts for external face grooving and turning next to long shafts.

The MEFL 8… inserts are available in 1.5 to 2.2 mm widths with square and round edges for the diameter range of 8 to 20 mm and up to 5.5 mm grooving depth.

The MEFL 8… inserts are screw-clamped into the long pocket of the standard MIFHR 8... bars, with very rigid clamping, resulting in prolonged tool life and enabling high machining parameters

Turning

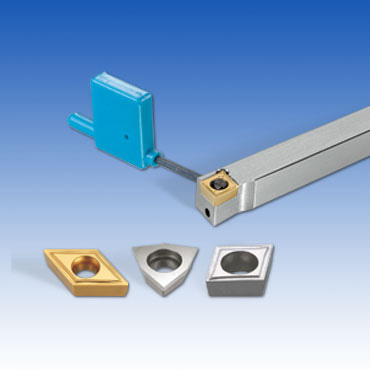

ISO Turning Tools

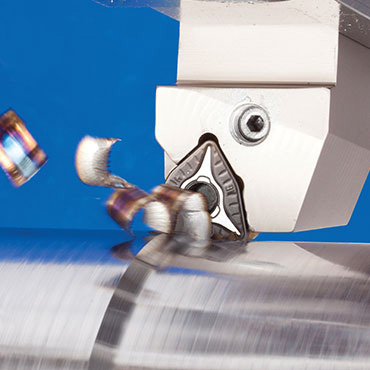

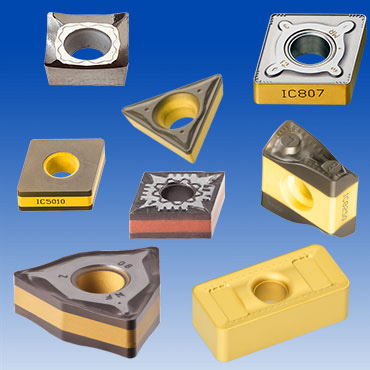

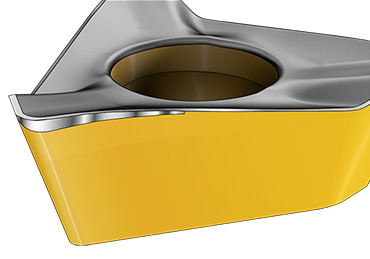

- ISO standard tools perform most of the metalworking industry's machining. The applications range from finishing to roughing. As a full-line supplier of metalworking tools, ISCAR provides a full ISO range of quality tools. All standard geometries are supplied, including the most popular trigon shape. These semi-triangular turning inserts are used for axial and face turning and feature three 80° corner cutting edges on each side of the insert. They replace the rhombic inserts that had only two cutting edges, thus saving production time and cost while maximizing insert life. ISCAR offers a variety of unique chipformers and grade combinations that provide solutions to most of modern industry's machining needs. ISCAR's ISO turning line provides a complete solution for all types of applications and materials, with innovative insert geometries combined with the world's leading carbide grades designed to meet high customer demands for tool life and productivity.

LOGIQ-F-TURN

- 4 Positive Cutting Edges

ISCAR doubles the cutting edges on positive rake inserts intended for general turning applications. This economical solution for 80 degree turning provides double-sided robust and positive 4 cutting-edged inserts that easily replace the positive 2 cutting edged inserts. Their dovetail shape fits into a unique pocket design, assuring better insert positioning and stability to guarantee longer insert tool life. The holders can be ordered with or without through-tool coolant channels.

DOVE IQ TURN

- FEEDTURN

ISCAR is introducing the PWXOL 3232P-10-TF-IQ lever lock 18.5° lead angle toolholders, for fast feed, up to 3 mm/rev and small, up to 2.8 mm D.O.C. longitudinal turning. The new tools carry WOMG 100716-T3P-IQ double-sided 10° negative flank trigon inserts, for high feed turning of steel.

Due to their ability to run at extremely high feeds, the new tools are used to reduce machining time and costs.

DOVE IQ TURN

- Innovative Clamping System

Rough turning is characterized by high D.O.C. (4-10 mm) and high feed rates (0.4-1.0 mm/rev).

Usually large single-sided inserts are used on top-clamp toolholders to withstand interrupted cut and high machining load. The current method of using single-sided inserts and top-clamp holders has the disadvantages of a small amount of cutting edges and interrupted chip flow due to the obstruction of the top clamp.

ISOTURN

- Swiss-Type External Tools

PWLNL …X-04S and PDJNR/L … S lever-lock tools are available in square-shanks. The clamping system enables indexing the insert by using the key from either free side of the tool without removing it from the machine, thus reducing machine idle time. The new tools were designed for Swiss-type automatics and small CNC machines that are widely used in medical, aerospace, automotive, electronics and general metalworking – and for machining complex, precision parts with a length to diameter ratio that is subject to deflection in the turning process.

FLASH-TURN

- Economical and Small

In many turning applications people tend to use larger inserts than are actually required for the machining parameters being applied, Therefore, ISCAR is introducing a wide range of ISOTURN small size inserts, which provide an economical advantage regarding cost per cutting edge.

The new inserts are available in a wide range of geometries, corner radii, chipformers and the most advanced carbide grades. They are available in WNMG, CNMG, SNMG, DNMG and TNMG geometries. These inserts are thicker than the standard inserts of the same sizes, which provides higher durability.

- YNMG - Small Size Inserts

ISCAR has added a new geometry to its line of small economical inserts: YNMG 1604… This insert fits into the VNMG 1604… insert's standard pocket. The YNMG 1604… insert features a 25º corner angle. It was designed for turning of very narrow V-shaped grooves which cannot be machined by the standard 35º inserts.

T-LOCK

- Highly Rigid Profiling Tools for Accurate Contours

ISCAR is introducing the SDNCN 2525M-13-SL screw lock toolholder for 55° diamond inserts with a 7° clearance angle. A long groove on the pocket and a matching ridge at the insert bottom ensure high rigidity in profiling applications.

The new design ensures high edge location after indexing and no backlash when changing machining direction, as required in profiling applications.

ISO-TURN

- R3P Chipbreaker for Rough Machining

- Single-sided insert chipbreaker for rough machining of steel

- Reinforced cutting edge

- Positive rake angle for smooth cutting and reduced cutting forces

HEAVY-SUPER-DUTY

- For Heavy Industry

ISCAR is introducing the PLBOR/L 5050T-40 tools and LOMX 402224-H6P insert for very heavy turning applications.

The new tangentially clamped insert is made from the tough grade IC8250. It can machine at up to 35 mm depth of cut and up to 2 mm/rev feed. The insert is clamped on a very rigid lever lock pocket equipped with a protective seat.

The new tools were designed for use in heavy industry applications such as the power generation, marine and large automotive parts.

COMBI-D-LOCK

- Top Lever

ISCAR is introducing an upgraded lever lock to improve the clamping rigidity of the popular and user-friendly insert clamping system.

The new design actually combines the advantages of the current lever with the extra clamping rigidity of the top clamp method.

The current lever pushes the insert against the pocket, perpendicularly to the cutting force. This method sometimes fails during interrupted cut or heavy load applications, which causes the rear side of the insert to rise.

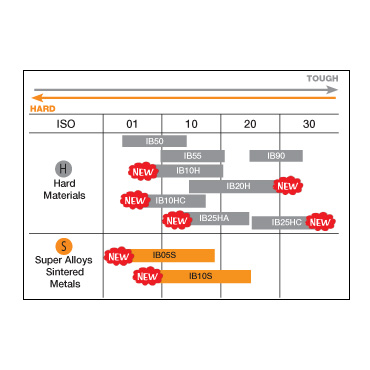

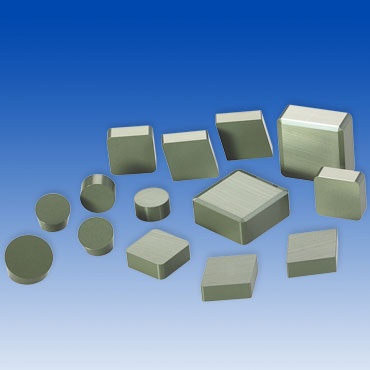

ISCAR-CBN-LINE

- CBN

Machining Hard Materials is Now Easy with ISCAR's CBN Grades

ISO-TURN

-

Insert for aluminium machining

- VCGT-AS

- CCGT-AS

- SCGT-AS

- TCGT-AS

- DCGT-AS

- RCGT-AS

- TNMS-12

- DNMS-12

- CNMS-12

- VNMS-12

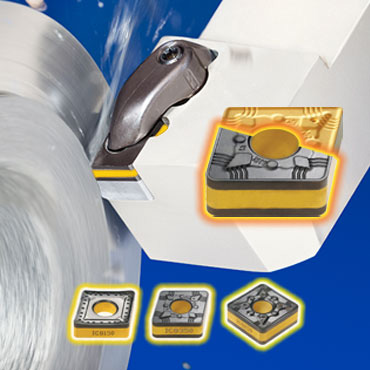

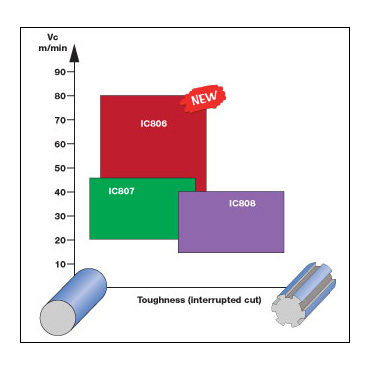

SUMO-TURN

- Expanding Line of ISO Standard Turning Tools

New rough turning tools and inserts have been added:- 80° rhombic inserts in 16, 19 and 25 mm cutting edge sizes and square inserts in 15, 19 and 25 mm cutting edge sizes.

The new inserts are available in single- and double-sided configurations.

They are made from ISCAR’s most advanced SUMO TEC PVD and CVD grades. - Two geometries, CNMG 190612-MR and CNMM 190616-MH in IC807 grade, were designed especially for machining stainless steel and high temperature alloys.

These are initial items and there will be more in the near future. - Two RCMX 25 and 32 mm round inserts, used mainly for railway wheel machining.

- 80° rhombic inserts in 16, 19 and 25 mm cutting edge sizes and square inserts in 15, 19 and 25 mm cutting edge sizes.

HELI-TURN-TG

- Fast Metal Removal (FMR) is essential especially in roughing applications where high removal rates are desired.

The HELITURN holder with its tangentially clamped insert and the unique helical shaped cutting edges provide an exceptional solution, enabling the use of very large depths of cut and high feeds.

The HELITURN SLANR/L-…TANG toolholder uses a unique tangentially clamped insert, LNMX 2210..R/L-HT. The double-sided insert, with its narrow curved rake face, is clamped into the toolholder on a corresponding seat using a conical head screw.

This design protects the toolholder from overload and insert damage.

The upper rake face of the insert is mounted at the same level as the holder body, thereby enabling the chips to flow without being disturbed by the tool body or any other element.

Depth of Cut up to 15 mm!

IS6 - New SiAlON ceramic garde

- The IS6 grade was developed in order to increase productivity in cast iron turning, as a complementary grade to the IS8 and IS80. IS6 can be used also for high productivity in rough turning of steel mill rolls composed of high-Cr steel, HSS (High Speed Steel) and adamite. The SiAlON material is characterized by high hardness, combined with moderate fracture toughness and excellent thermal resistance. These characteristics are achieved by a manufacturing technology of precisely-controlled alloy composition and a special sintering process that enables the IS6 grade to function at higher cutting speeds than the SiN-based ceramic grades.

IW7 - New Whisker Ceramic Grade

- The new IW7 grade is suitable for turning Ni-based super alloys (e.g. Inconel), Co-based super alloys (e.g. Stellite) and for roughing hard castings and hardened steel.

Main Advantages- High hardness (Hv 2,100)

- High fracture toughness due to SiC (silicon carbide) whisker

reinforced ceramics - Excellent thermal shock resistance, which enables using coolant

and interrupted cut machining - Excellent for roughing and semi-finishing operations at 8-10 times

faster cutting speeds when compared with carbide grades - Good oxidation resistance due to its alumina substrate

IC6025 (M20-M35)

- ISCAR's IC6025 grade covers the ISO application range (M20-35) and is used for roughing and interrupted cuts, as well as applications at medium to low cutting speeds. The IC6025 grade is composed of a cobalt-enriched outer layer substrate, with MT TiCN and alpha Al2O3 coating. The unique SUMOTEC CVD post coating treatment was developed for machining stainless steel. IC6025 provides substantially improved tool life, excellent edge performance and repeatability when compared to our current grades and competitor grades.

M3M Chipformer

- In addition to grade IC6025, ISCAR is offering an innovative chipformer under the designation of M3M.

The new chipformer was designed especially for machining stainless steel.

The M3M chipformer was designed with geometric features that improve the tool’s life due to a reinforced cutting edge at the area where VG (notch wear) wear tends to occur when machining stainless steel, causing poor surface finish and risk of edge breakage.

IC6015 (M10-M20)

- ISCAR's grade IC6015 is a complementary SUMO TEC CVD coated grade for high speed machining of stainless steel.

ISCAR also offers grade IC6025, which covers the application range of M15-35 used for roughing and interrupted cut applications at medium to low cutting speeds.

IC6015 (M10-M20)

A cobalt enriched outer layer substrate, with MT TiCN and alpha Al2O3 coating with a special post coating treatment, provides substantially improved tool life, and excellent edge performance and repeatability.

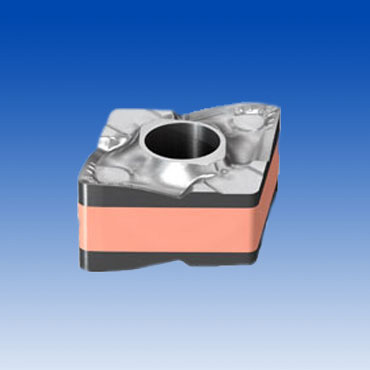

IC806 SUMOTEC PVD for Inconel 718

- PVD Coated Grade for Turning and Grooving High Temperature Alloys

ISCAR grade IC806 is a complementary SUMOTEC PVD coated grade for machining high temperature alloys, especially Inconel 718, a nickel based superalloy used extensively in the aerospace industry.

IC806 has a hard submicron substrate with PVD TiAlN coating and a special post coating treatment which provides substantially improved tool life and better reliability. IC806 is recommended for turning Inconel 718 at moderate to high cutting speeds, with stable to mildly unstable conditions.

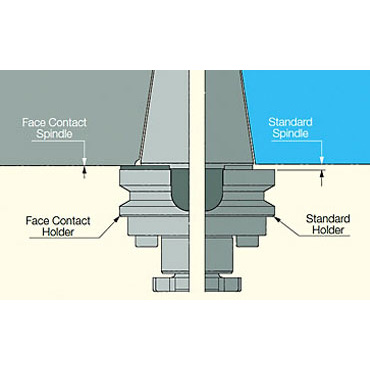

EXCHANGEBLE HEADS- for Turn-Mill Machines

- As a result of the increasing popularity of Turn-Mill machining centers, ISCAR has decided to expand the range of exchangeable head tools.

ISCAR has developed a range of HSK A63 WH toolholders and tool adapters for Turn-Mill machines. These holders comply with a new HSK standard interface, recently introduced under the ICTM standard - Interface Committee for Turn-Mill and Mill-Turn machines.

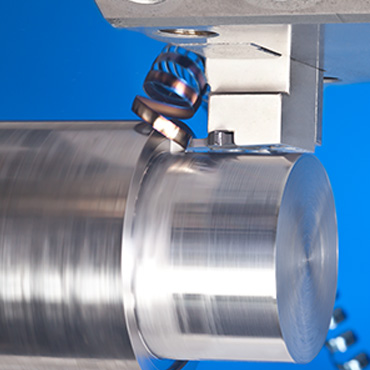

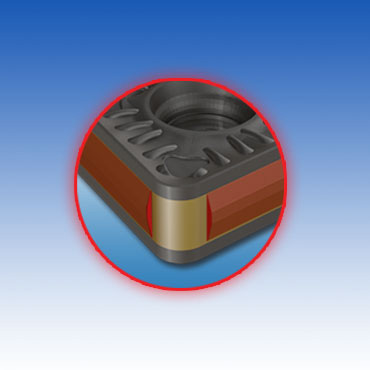

SUMOTURN/HELITURN/JETCUT

SUMOTURN

- The SUMOTURN line includes external and internal tools, as well as large sized inserts for roughing and heavy duty applications.. Rough and heavy duty turning applications feature relatively large depths of cut, high feed rates and rough, non-uniform surfaces to be machined. These applications require both tough carbide grades and specifically designed chipformers. The tools are equipped with a lever lock clamping system, which is recommended for large depths of cut and interrupted cut applications.

The SUMOTURN inserts are coated with ISCAR’s innovative SUMOTEC grades.

In order to assist customers in selecting the correct grade for their applications, ISCAR developed new coating processes for the SUMOTEC grades featuring different colors for easy identification. (The older SUMOTEC grades featured the same gold color.)

This coating technology improves insert life by 5 to 12% compared to the previous coatings.

HELITURN

- The CNMX 1207..-HTW insert features a very positive radial, helical cutting edge and a positive rake angle - a combination which substantially reduces cutting forces. The insert's corner has a wiper configuration which produces high surface finish even at high feed conditions, which on many occasions can eliminate a finishing cut. The corner angle is 88°, which provides increased strength.

The CNMX inserts are designed for heavy machining applications. Their unique design ensures reliable, fast metal removal when using 80° rhombic inserts.

They can be mounted on any standard toolholder that carries standard CNMG inserts, but the seat has to be replaced with a special seat: TCH 4.

ISCAR's R-clamp toolholders are most recommended for heavy machining applications.

- ISCAR JETCUT tools offer the ultimate solution for utilizing high pressure coolant (HPC) in a multitude of turning operations.

With the availability of high speed machines which offer standard or optional 70-bar coolant systems and through-spindle delivery, HPC technology has grown much more accessible and ISCAR provides hundreds of special HPC turning tools for a wide range of applications. HPC has proven itself in dedicated turning applications on difficult-to-machine materials such as titanium and Inconel, at removal rates of up to three times more than that of the conventional flood coolant system. Users report elimination of chip jamming, faster cutting and much longer edge life in outer and inner diameter turning as well as grooving, parting and hole making. The advantages of ISCAR’s JETCUT line are also noticeable when machining steel parts, where the chips are more manageable and insert life is significantly improved.

Miniature

SWISS-GRIP

- Double-pocket

SELF-GRIP mini blade

Small size SWISS-GRIP tools were designed specifically for efficient parting and grooving on Swiss-type machines.

These operator-friendly tools comprise of holders and double-pocket SELF-GRIP mini blades mounted on the holders. Hence, the ability to clamp existing SELF-GRIP small size inserts.

Features:- Reliable and friendly-to-operate holders with a self-clamping mechanism for securing the insert.

- Double-pocket mini blades ensures high repeatability and position accuracy.

- Fast and easy blade indexing from both sides of a holder.

- Mini blades of different widths suitable for mounting in the same tool holder.

- Assures slim cuts to utilize the workpiece.

MULTI-MASTER SUMO-CHAM

- Mini-Diameter Tools

Technological advances in machine tool engineering have brought new opportunities to manufacturing and resulted in rethinking the manufacturing of various components, particularly small-size parts. Multi-tasking machines and driven-tool lathes enable different types of cutting operations to be performed on one machine. It was a significant step to enable the machining of a whole part in a single setup, which is especially relevant for producing small-size components where the cycle time is small.

ISCAR provides a wide range of products intended for highly efficient small-size part production on multi-tasking machines and driven-tool lathes. In addition to the traditionally used solid carbide tools, these solutions incorporate tools with a replaceable cutting head concept.

SWISS-CUT

- Innoval Line

- The same tool and insert can be used in both front and back clamping

- 50% less inventory

- Insert indexing without removing the screw

The new clamping design uses a special screw that can be accessed and operated from both tool sides. The screw has to be fully removed for insert indexing. As the clamping screw is small, it can easily fall and disappear inside the machine or on the floor. In the upgraded line, the insert can be indexed without the need to fully remove the screw. Therefore, there is no risk of falling parts and indexing is easier and faster.

SWISS-TURN

- Precision Ground Cutting Edges

ISCAR features a variety of ISO standard inserts, with small shank sizes. Also available are many standard geometry inserts with precision ground cutting edges and small radii for manufacturing small and thin parts.

ISCAR's toolholders with a unique clamping device, provide solutions for solving the main problems related to insert clamping and replacement on Swiss-type machines.

JET-CUT

- Coolant Hole Through the Insert

ISCAR is introducing a DO-GRIP parting insert with an internal coolant hole which passes through the insert, with an outlet near the cutting edge. This unique design is due to an advanced technology which was developed especially for these inserts.

The new DGNC inserts were designed for parting and grooving mainly on stainless steel and high temperature alloys.

JET-CUT TANG-5-GRIP

- 0.8mm insert for parting and grooving

ISCAR introduces the world’s narrowest 0.8mm insert for parting and grooving, combined with an innovative and economical 5 pocket blade featuring extended tool life. The interchangeable blade is assembled on a toolholder which indexes SLIMGRIP inserts. The blade features high stability and repeatability, and the narrow chipformer on the inserts allows free chip evacuation. A new family of tools and economical 5 pocket adapters for existing TANG-GRIP inserts in sizes of 2 and 3mm. These new adapters will allow parting applications of bar diameters up to Ø45mm.

PICCO-CUT

- Solid Carbide Mini Boring Bars

ISCAR has added more geometry types and sizes to the current PICCO mini-bar range:

A. Back boring and profiling mini-bars

Designed for back turning and profiling applications, may be used in a minimum bore of 3 mm. Available with shank sizes of 4 to 7 mm and fit our standard MG PCO.. and PICCO holders.

B. Mini-bars for 0.6 mm diameter boring

Boring and profiling mini-bars for as small as 0.6 mm diameter bore. The smallest PICCO mini-bar for miniature and tiny parts are supplied with 4 mm shank diameter and fit standard PICOO...4-5 holders.

MULTI-MASTER

- Indexable Solid Carbide Line

MULTI-MASTER is a family of tools with shanks and interchangeable heads for a variety of milling applications including ball nose, straight shoulder and slitting and slotting applications. This system features ISCAR’s unique threaded carbide heads for superior performance, short indexing time and improved economy.

As there is no setup time for head replacement, MULTI-MASTER can reduce your production costs through increased production efficiency.

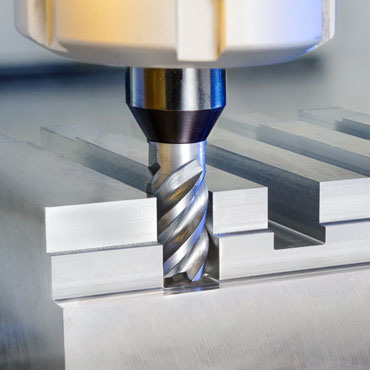

SOLID-MILL

- Solid Carbide Endmills Variety

Micrograin solid carbide endmills with extended tool life are a part of the ISCARMILL family.

These endmills have an improved design and are available with the most advanced TiCN or TiAIN PVD coatings, in a range of 2-20 mm.

Ball nose endmills are available in a diameter range of 3-20 mm.

SUMO-CHAMSUMO-CHAM

- Mini SUMOCHAM

Dia. 4-10mm

ISCAR's SUMOCHAM drill family is the next evolution of the very successful CHAMDRILL and CHAMDRILLJET families. The new family has similar features, with improved head and pocket design, no setup time, Fast Metal Removal and economical indexing.

The SUMOCHAM comprises a revolutionary clamping that enables improved productivity output rates, while enabling more insert indexes.

SOLID-DRILL

- Specially Tailored Drills

The unique requirements of the mass production industries make specially tailored drills essential for optimal performance.

ISCAR’s trained design engineers ensure that customers have the finest multifunction drilling tools for their required profiles.

MIN-CUT

- Mini Face Grooving

MINCUT is a family of internal face grooving and face turning tools for machining small diameters ranging between 8–17 mm (0.315–0.669”)- Inserts in widths of 1.5–3 mm (0.05 9–0.118”)

- Highly stable tangential clamping

- Highly efficient chip evacuation

- Tools with internal coolant

Dmin. 8 mm (0.315”)

Hole Making

Reamers

-

BAYO-T-REAM

- New Interchangeable Reaming Head System

The BAYO T-REAM high speed reaming system enables dramatic increases in speeds and feeds, particularly when compared to the conventional method.

This feature is most advantageous in mass production industries.

When large quantities of workpieces are involved, the savings in machining time, labor cost and productivity are multiplied greatly.

BAYO T-REAM consists of an interchangeable carbide reaming head with a quick-change bayonet mechanism, suitable for reaming applications of H7 hole tolerance range.

The reaming head is mounted on a HARD TOUCH steel shank (solid carbide or heavy metal shanks are available on request).

The reaming head is attached to the shank by a bayonet screw and a special wrench is used to clamp and release it.

The reamer has been designed with internal coolant holes directed on each cutting edge for the most efficient head lubrication and extremely long tool life.

Advantages- High speed/high production

- No setup time while indexing

- Low runout (maximum 3µm)

- Versatile modular system (one shank can be used for a range of hole diameters and various types of cutting edges)

- Durable, due to the combination of a carbide head and steel shank

- Internal coolant directed optimally to the cutting edges

SOLID-H-REAM

- Solid Carbide Reamers for Conventional and Fast Reaming

SOLID H-REAM reamers are high quality tools, manufactured in accordance with the requirements of the DIN 1420 standard. This ensures that, when using these tools, the reamed hole is within the respective tolerance range and the reamer can be used to its full economic potential.

Additional factors that may affect the tolerance of a reamed hole are: cutting and lead angles of the reamer, chucking force of the tool, pre-drilled hole size, machine stability and lubrication type.

Advantages- Durable (produced from submicron fine carbide grain)

- Good solution for old machines

- Suitable for low cutting speeds and feeds

- Economical for small production batches

- Easily regrindable

- Mostly used with floating adapters

- Coated for high cutting speeds (upon request)

- With internal coolant supply (upon request)

- PCD - for nonferrous materials (upon request)

- CBN - for hard materials (upon request)

- Cermet - for superior performance in steel (upon request)

- Combined and stepped reamers (upon request)

- Integral and modular (upon request)

- Special diameter range 1 mm (.039) and up

INDEX-H-REAMINDEX-H-REAM

- Single Edged Reamers

A high speed reaming system with internal coolant supply, INDEXH-REAM standard line covers reaming applications of 8-32 mm (.315-1.25") hole diameters.

The indexable cutting insert has two cutting corners with 4 lead angle options and 3 rake angle variations, covering most workpiece material types. The INDEXH-REAM single indexable insert with carbide pads provides a combination of economical and high precision results on a very wide range of materials.

Advantages- Economical system (2 cutting edges)

- Wear compensation mechanism

- Maximum precision

- Designed to achieve IT5 tolerance

- For extremely fine surface finish, roundness and cylindricity (due to the burnishing action caused by the tough guiding pads)

- For high concentricity in interrupted applications (due to the smooth and continuous cut)

- Relatively high reaming speeds (modern coating technology and strong substrate)

- Effective chip evacuation

- Optimally directed internal coolant supply, for long tool life

Drilling

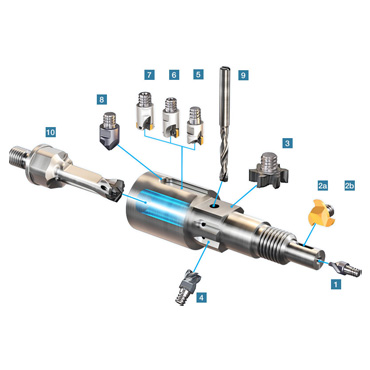

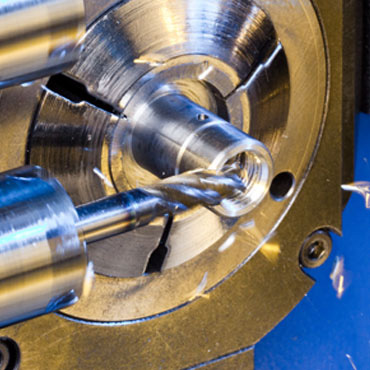

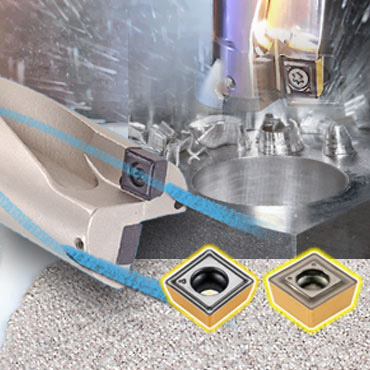

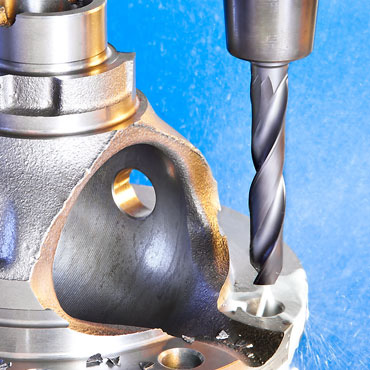

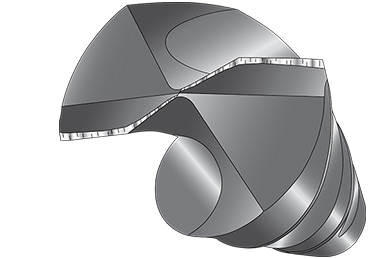

SUMOCHAM

- ISCAR's SUMOCHAM drill family is the next evolution of the very successful CHAMDRILL and CHAMDRILLJET families. The family has similar features, with improved head and pocket design, no setup time, fast metal removal and economical indexing. The SUMOCHAM comprises a revolutionary clamping system that enables improved productivity output rates, while enabling more insert indexes. The shank itself is designed with twisted nozzles and exhibits a durable and stably constructed body. The indexable heads are available in four different standard geometries, designed for drilling steel, exotic materials, cast iron or aluminum. The unique pocket design of the SUMOCHAM takes good advantage of the cutting forces, which are mechanically exerted upon the tool. These forces are then converted into gripping forces that are used for tightening the insert towards the back of the pocket - the more cutting forces applied, the better gripping forces obtained. In addition, the clamping forces around the connection area generate little strain, preventing any potential plastic deformation and providing at least triple the amount of head indexes. The most important attribute of the clamping design is therefore a very substantial increase in productivity. All of these features provide the most productive and most profitable solution for the hole making industry.

CHAMIQDRILL

- ISCAR is introducing the CHAM IQDRILL drill family for the drilling range of 33 to 40 mm with 1.5, 3, 5 and 8 length to diameter ratios.

The CHAM IQDRILL features a unique design, utilizing the carbide flexibility for self-locking; eliminating the need for clamping accessories. The robust structure of the drill with the concave cutting edge design enables drilling at high feed rate, providing very accurate IT8 – IT9 hole tolerance.

The new design body is produced from special steel for high durability and a special stopper prevents the drilling head from being extracted upwards from the pocket. Long stoppers provide high resistance to cutting forces, enabling applications under very high cutting conditions.

High flute helix and polished flute surfaces provide a smooth and easy chip evacuation process.

An internal coolant supply provides efficient cooling and lubrication during the drilling process.

The HFP-IQ Drilling Heads have unique self-centering geometry enables using up to 8xD long overhang without the need for a pilot hole operation

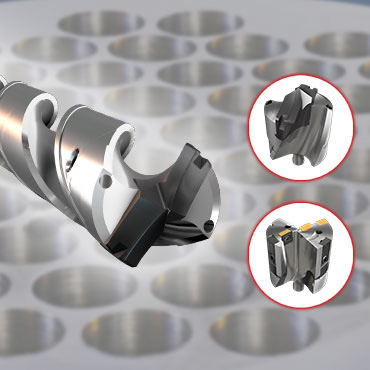

LOGIQ3CHAM

- LOGIQ3CHAM, a new family of assembled drills carrying exchangeable carbide heads with three effective cutting edges. This family of drills was designed by utilizing highly advanced technologies based on ISCAR’s successful SUMOCHAM drill family. LOGIQ3CHAM drills increase productivity by up to 50% when compared with a common two-flute drill with exchangeable heads.

Features:- General cutting geometry provides effective machining of various engineering materials.

- Concave cutting edges enable smooth penetration into material, excellent centering, and stable drilling.

- Extremely robust and precise chisel edge to withstand high loading during cutting.

- Corner chamfering to increase wear resistance and strengthen the outer corners.

- Dovetail clamping prevents the drilling head from being extracted from the drill pocket during retraction.

- A durable drill body carrying a carbide head made from hard, high-strength steel grade for better wear resistance.

- Three polished flute surfaces to ensure smooth and easy chip evacuation.

- Variable flute angle design results in a durable body structure to sustain high axial forces.

- Internal coolant channels supply efficient cooling and lubrication during the drilling process.

- Available in several drilling depth to diameter ratios (1.5, 3 etc.).

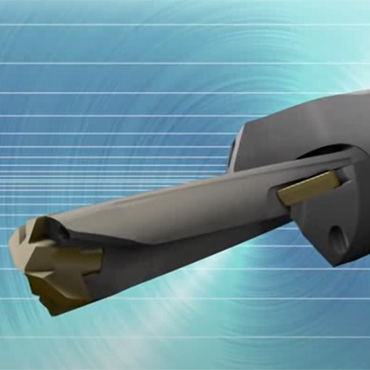

COMBICHAM

- ISCAR is introducing COMBICHAM - Large diameter indexable drills with an integral pilot drilling head and one flat shank.

The new drill provides an excellent solution for drilling 26-50 mm diameter holes in a drilling depth of up to 8xD. The COMBICHAM features a pilot SUMOCHAM drilling head and standard SOGX/SOGT square inserts in various sizes, made from IC808 SUMO TEC PVD coated grade.

As the drill is fully effective, it enables high feed drilling, providing high drilling rates, and high accuracy and surface finish.

The COMBICHAM is compatible with MQL coolant type and features two peripheral coolant nozzles to provide high coolant flow directly to the cutting zone. The precise ground self-centering geometry of the leading SUMOCHAM head provides high penetration rates and eliminates the need for making a pre-hole prior to using the COMBICHAM.

MODUDRILL

- The new MODUDRILL family uses only two drill bodies to cover the full range: one for 33-36 mm and the other for 37-40 mm. Each drill body can carry any one of the two head types. The two available drilling heads were designed for different applications - cutting conditions, required hole accuracy and surface finish.

DR-TWIST

- The DR line of hole making tools is designed to provide an economical solution, suitable for all types of materials.

These tools are designed primarily for semi-finishing operations and exhibit a high level of accuracy, even when subjected to interrupted cut machining conditions, or while drilling stacks or sloped surfaces.

Furthermore, with the right edge geometry these tools can easily perform angular penetration holemaking operation, drilling into the material and exiting with flat burr-free exit.

These tools are known to be less susceptible to unstable machining conditions, making them ideal for unbalanced holemaking operations associated with vibration.

DR-BIG

- New Large Diameter DR-TWIST Drills

ISCAR's new family of 61 to 80 mm large diameter drills expands the existing 14 to 60 mm range.

This family features a drill body with a 50 mm Weldon shank that carries cartridges with square inserts (4 cutting edges) in 10, 11 and 12 mm sizes. The inserts are available with two chipformer types and in the following grades: IC808/908 for low alloy steel, stainless steel and high temperature alloys. IC8080 which is recommended for high speed drilling of cast iron and steel, should be used for the peripheral insert.

Advantages- Each drill is supplied with a set of shim plates used to change the drill’s diameter.

- The new PVD IC808 and CVD IC8080 carbide grades which are used on external inserts, provide a smooth cut and a very competitive prolonged edge life when compared with any throwaway drilling insert.

- The IC08 submicron substrate provides increased hardness and toughness, for both external and internal inserts.

- The new DR-TWIST drills are available in whole metric sizes.

- Can be used for intermediate hole sizes on lathes by offsetting the machine’s X-axis to obtain the desired hole diameter.

- Can be used as boring tools to enlarge existing holes.

- The same insert may be used for both internal and external drill pockets, which reduces inventory.

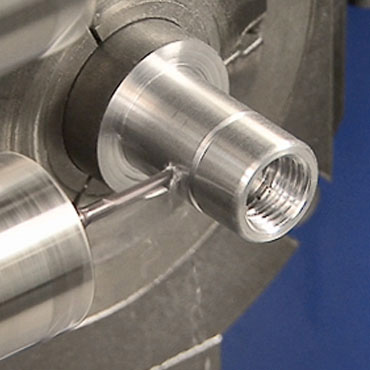

Pre-Threading - DCNT

- DCNS

Modular drills for chamfering holder.

The SUMO UNICHAM, a drill without a flange for chamfering operations by using the standard CHAMRING modular chamfering drill holders.

Diameter range of 7.5 to 25.9 mm and L/D ratio of 3XD and 5XD.

Pre-Threading - SUMO-UNICHAM

- DCNS

Modular drills for chamfering holder.

The SUMO UNICHAM, a drill without a flange for chamfering operations by using the standard CHAMRING modular chamfering drill holders.

Diameter range of 7.5 to 25.9 mm and L/D ratio of 3XD and 5XD.

Multifunction Tools

-

- Much machine idle time is saved due to limited tool exchange - chip to chip time, thus no wasted unproductive time.

- Further cost savings on tools, inventory management and storage.

- In many cases solve problems associated with limited space on the turret.

- Ideal for automatic machines (Swiss type).

Solid Carbide Drills

-

- Range of 3-20 mm in length to diameter ratio of 3xD, 5xD, 8XD.

- Range of 0.8-2.9 mm in length to diameter ratio of 4D & 6D.

- Right-hand cut with and without internal coolant nozzles.

- IC08 submicron substrate.

- Most advanced TiAlN coating for best hole quality, high performance reliability and economical output.

The new solid carbide drills were designed and produced according to DIN 6537 standard. There are two new designations for easy product identification: SCD … (Solid Carbide Drill) SCDR … (Solid Carbide Drill Reamer)

Special Tailored Tools

- Drilling Tools Upon Request

Special toolholders are an integral part of our business. In addition to standard tools, ISCAR also designs and manufactures special tools. Each of our special tools is designed to conform strictly to the customer's parameters and specifications, meeting demands for performance, tool life, cost and ease of use. ISCAR's engineers work together with the customer to ensure that the tool manufactured will be the most suitable for the required application and machining process and will provide optimum output for the client.

ISCAR operates numerous manufacturing facilities around the globe to answer to the demand for special inserts and tools.

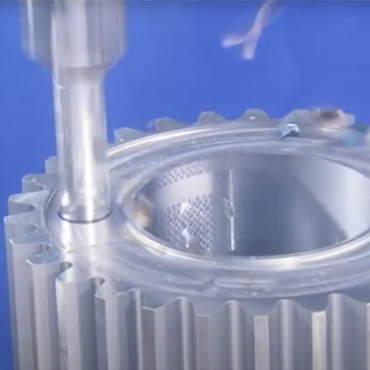

Dedicated Industry Solutions

- ISCAR dedicates its resources in order to boost its customers’ productivity.

The company’s products are designed with special emphasis on dedicated solutions for the industry. There are no two industries alike and each one has its own needs and requirements. ISCAR has acquired knowledge and developed solutions dedicated to every industry, following a thorough analysis and study.

ISCAR responds to industry needs by providing solutions that not only emphasize flexibility, efficiency, durability, reduction of production costs, but most of all increase productivity.

ISCAR has developed dedicated solutions for "difficult to machine" materials, taking into consideration enormous workpieces, stability abrasiveness and high temperature issues.

The constant need to respond to industry needs made ISCAR more receptive for easily responding to special needs and requirements that the industry set as targets.

Deep Drilling

- Deep holes are defined by a ratio between the hole depth and the hole diameter.

Deep hole ratio depths are more than 10x the diameter and up to 150x the diameter ratio.

There are 3 types of deep drilling methods:

Gundrills

STS (Single tube system)

DTS (Double tube system)

NEO-GUN

- Gundrills that Minimize Machine Downtim

NEOGUN is a family of indexable Gundrills with No Setup Time for minimizing machine downtime and ensuring high productivity and excellent surface finish.

Features:- An assembled steel drill body carrying a replaceable insert made of cemented carbide.

- A uniquely designed insert combined with a cutting edge, supporting pad and guide pad, provides precision for high drill performance and reliability.

- Suitable for rotating and nonrotating applications on all types of machine tools.

SUMO-GUNSUMO-GUN

- High Table Feeds

ISCAR's SUMOGUN line has been developed for deep drilling applications of a diameter range of 12 to 25 mm (total length of 1000 mm).

SUMOGUN enables replacement of the drilling head inside the machine – there is no need to remove the drill for head indexing.

A polyamide plastic key is available for clamping and removing the SUMOGUN head.

The SUMOGUN features two straight flutes carrying the standard SUMOCHAM drilling heads.

The SUMOCHAM drilling heads are fully effective, which enables drilling at much higher table feed rates, when compared to most other gundrills available in the market.

GundrillGUN-DRILLS

- Single Flute Gundrill

ISCAR's gundrill consists of a single piece carbide head, a streamlined shank and a driver through which coolant flows to the working end where it is most needed. Chips are evacuated along the V-shaped external flute.

1. The Drilling Head

The carbide head is tapered on its length to reduce friction. The taper angle depends on the type of material to be drilled. For high precision drilling, the taper should be reduced to a minimum. Note that when the head is resharpened, the diameter of the drill changes, affecting the hole tolerance.

2. The Shank

The cross-section of the shank is V-shaped with coolant holes. It is made of hardened steel that is highly resistant to twisting. This cross-section provides the optimal conditions for twist resistance, coolant flow and chip evacuation.

3. The Driver

The driver ensures the connection between the gundrill and the machine tool. ISCAR’s advanced gundrill technology provides superior geometric and dimensional quality for both deep and shallow drilling. The drills are available in the range of 2.5 to 32 mm in 0.1 mm increment diameters. Larger diameters, between 32 and 40 mm, are available upon request. In addition, any other drilling head configuration or coated drilling head can be produced upon request.

ISCARDEEPDRILLISCAR-DEEP-DRILL

- Deep Hole Drilling Index

Single Tube System (STS)

Cooling fluid is induced through the gap between the drill and the hole, conveying the chips through the tube. Requires the usage of dedicated machines.

Double Tube System (DTS)

Cooling fluid is induced between the coaxial tubes, conveying the chips through the inner tube and can be applied for standard machines.

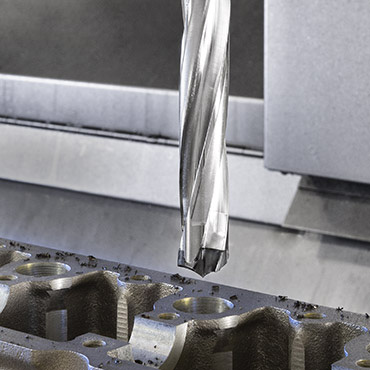

ISCAR-DR-DHISCAR-DR-DH

- Deep Drills for Milling Centers and Lathe Machines

ISCAR is introducing long drills for a drilling depth-to-diameter ratio of 7XD and up, to be used on standard horizontal milling centers, turning, and multi-task machines. Use of supplementary machine and setup can be avoided.

The new drills will be available as semi-standard items in the diameter range of 25.4 to 69.5 mm (1.00 - 2.73”).

Drill Features- High feed drilling: up to 0.35 mm/rev for high productivity

- Excellent surface quality: Ra = 0.6 – 2.0 [μm]

- Good hole cylindricity: 50-80 [μm]

- Hole tolerance: IT10

- Large drilling depth: L=5xD and higher – up to 800 mm

- Carries standard SOMX/SOMT indexable inserts with 4 cutting edges

- No dedicated machine or extra setup needed

- Standard coolant pressure as used in general drilling

- Standard indexable, double ended guiding pads

- Used for steel (ISO P) and cast iron (ISO K) materials

TRIDEEPTRI-DEEP

- TRIDEEP Gundrills and Deep Drilling Heads

The TOGT inserts feature 3 chip splitting cutting edges, a positive rake chip breaker and a wiper for high hole surface quality. The new inserts are available in 5 sizes, made from IC908, a versatile PVD coated grade.

Features- The only deep drills with a 3 cutting edged insert (other manufacturers only offer inserts with 1 or 2 cutting edges)

- Highly accurate peripherally ground insert, provides high hole diameter accuracy of IT10

- The chip splitter produces narrow chips for efficient chip evacuation, enabling higher feed rates compared to other drills available in the market

- A wiper on the insert provides extra fine surface finish

- Direct insert mount - no adjustment needed for accurate hole diameter

- The drills can carry the new economic solid carbide or the brazed guide pads

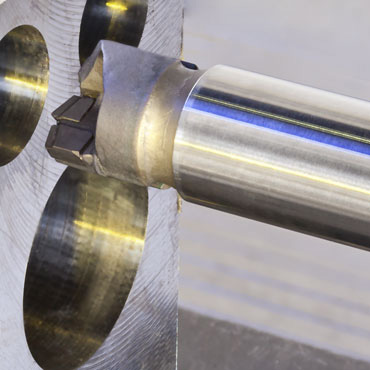

Boring

ITS-BORE

- High Precision Modular Toolholder System

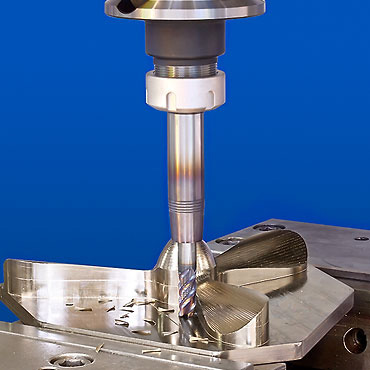

ITSBORE is a high precision modular toolholder system for boring, milling, drilling and tapping applications that provides an extremely high degree of rigidity.

The system's flexibility and simplicity make it suitable for machine tools, machining centers and flexible manufacturing systems.

It uses a unique cylindrical-conical coupling and radial expansion pin to ensure maximum rigidity and concentricity.

For applications that require machining to strict tolerances with a superior surface finish, ITSBORE is an excellent solution.

ITSBOR

- Modular Boring System

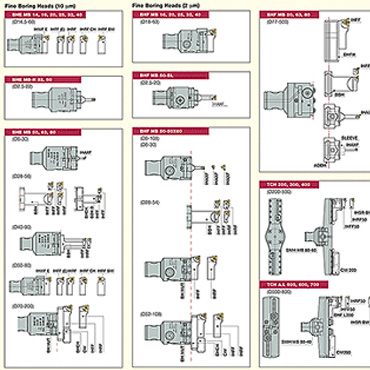

ITS-BORE

- Fine Boring Head

Due to market demand, especially from the heavy duty industry which is characterized by high power machines, ISCAR–ETM is expanding the ITSBORE system by adding MB110 adapters, to be used on large shanks.

The new adapters will enable using the MB boring system also for heavy duty machining by the heavy industries, such as power generation.

MB110 will be available with the following combinations:- SKA 50/60, BT 50/60

- Extensions

- Reducers

- Shell mill holders

- Blanks

Milling

Profiling

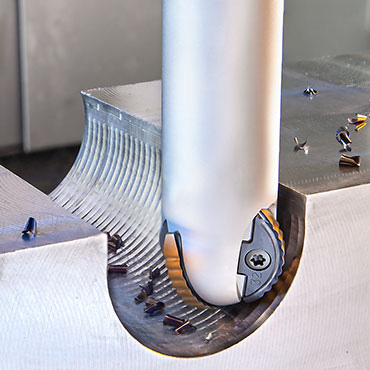

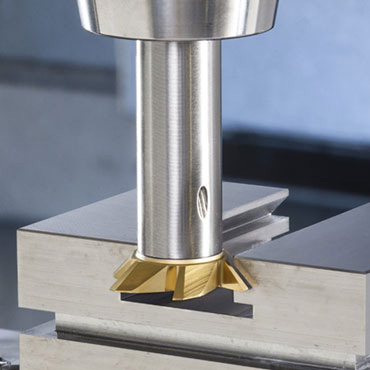

TOR-6-MILL

- Multifunction Indexable Cutters

TOR6MILL is a family of multifunction indexable cutters featuring different insert geometries.

The cutters are designed in the following configurations:

TR6 ER - Endmills in a diameter range of 16-32 mm ( .625 - 1.250”)

TR6 ER-M – Interchangeable milling heads with FLEXFIT adaptation in a diameter range of 16 – 35 mm ( .63 – 1.38”)

TR6 FR - Face mills in 52, 66 and 80 mm (1.500, 2.000, 2.500 and 3.000” ) diameters

Cutter Features:- Tool diameter remains constant for all insert corner radii

- Tool design enables undercutting

- The coolant holes for coolant supply are directed to each cutting edge

- The cutter body has a special protective coating for uninterrupted chip flow and protection from corrosion and wear

HELIDO Round 606

- Precise Round Profile Insert with 6 Cutting Edges

The HELIDO H606 line is an economical tool and insert system which features a double-sided precise round profile insert with 6 cutting edges.

Main Features- 6 mm radii with 90° vertical cutting edge

- Very positive rake angle to reduce power consumption

- Dovetail rigid clamping

- AXT chipformer for steel and cast iron

- AXMP chipformer, suitable for austenitic stainless steel and high temperature alloys

HELIDO Round H400

- Excellent for Semi-Finish Applications

The HELIDO round H400 product line features a double-sided round shaped insert. The insert has a unique design that is not completely circular. This allows placement of an additional insert on the cutters, which provides higher productivity.

Features- Screw clamping

- 4 cutting edges of radius 5, 6, 8 x 120°

- Dovetail clamping

- Excellent for semi-finish applications

MILL-SHREAD-ROUND

- Reduction of Cutting Forces

The MILLSHRED round family comprises a wide range of chip splitter inserts for a wide range of applications.

Features- Capable of milling with high overhang up to 10 times diameter

- Reduction of chip volume

- Reduction of cutting forces and machine power consumption

BALL-PLUS

- One Tool with 5 Insert Shapes

BALLPLUS is a multifunction system comprised of various shank options and 6 milling head types. Each shank has the ability to carry any one of the milling head types. Clamping and indexing of the milling heads is very simple. It can be done while the tool remains clamped on the machine - therefore no setup time is necessary after indexing. A unique pocket design enables a very firm insert clamping, edge position accuracy and no insert pullout problems. BALLPLUS is an ideal system for reducing tool inventory.

It is an attractive option for the die and mold industry and for any industry which uses many different endmills for its production applications.

Features- One tool with 6 insert shapes

- V-lock, high rigidity clamping mechanism

DROP-MILL

- High Depth of Cut

The DROPMILL product line is a ball nose type cutter with two indexable inserts that have

2 cutting corners each.

The round cutting edge of the insert continues with a 90° flat cutting edge, which provides higher depths of cut and finishing surface.

Features- Rectangular pocket seat for high accuracy

- 2 cutting edges per insert

- Strong rigid insert for rough operations

- Ground insert for semi-finishing (QT)

- Pressed insert with chip splitter for roughing (CS)

DROP-MILL

- Three Effective Flutes 240° Ball Nose

The lollipop-shaped ball nose cutters feature 240° spherical cutting edges and are available in the following tool configurations:- BLP Endmills – Endmills in the diameter range of 16 to 50 mm

- BLP-M - Milling heads in the diameter range of 16 to 40 mm with FLEXFIT adaptation

- BLP-Shell Mills - Arbor-type cutter in 50 mm diameter

The BLP- shell mill was designed to be mounted on face mill adapters with a 22 mm adaptation. A special screw, SR M10X20-10600, is supplied with the cutter.

This screw was designed to be used instead of the standard cutter’s frontal clamping screw. It serves as a retaining knob which pushes the cutter onto the adapter face by means of a screw situated on the cutter’s upper periphery.

Features- All three cutter teeth are fully effective

- 240° spherical cutting edge with chip-splitting action

- Center cutting

- Internal coolant holes directed to each cutting edge

SOLID CARBIDE ENDMILLS

- A full range of solid carbide endmills and MULTI-MASTER tools provides solutions for a wide range of applications, for rough or finish machining in any kind of material, to achieve superior performance and high productivity. The wide variety of our tools covers diameters of Ø1-20 mm in 1-6 L/D ratios. New innovative solutions designed especially for high tempered alloys and exotic materials are now available.

Solid Ceramic Endmills EC-E7 for Machining Superalloys

- ISCAR's new solid ceramic endmills were introduced recently to meet the growing demand for processing nickel-based high temperature superalloys (HTSA), such as various grades of Inconel, Incoloy, Haynes, etc. in the aerospace industry, and the demand to decrease production costs and increase productivity. The new tools enable increasing the cutting speed by up to 50 times when compared to carbide tools, thereby drastically saving machining hours and reducing production costs. The new endmills can also be successfully applied to productive roughing of cast iron and graphite.

Features:- 6 to 20 mm diameters

- There are 2 configurations:

E3 - with 3 flutes for shouldering applications

E7 - with 7 flutes, feed mill style for rough applications - Relieved neck diameter behind the effective cutting edge for machining next to shoulders

4 Flute Endmill EC-H4M for General Use

- The EC-H4M family includes 4 flute endmills with different helix and variable pitch for general use with high removal rates for rough and finish operations. Its unique design features optimal flutes and tooth geometries, delivering maximum metal removal rates, and enables large chip gullets for efficient chip evacuation and high productivity on most material types.

Features:- 6 to 20 mm diameters

- High removal rates

- 4 flute endmills with different helix and variable pitch

- Cylindrical and Weldon shanks

7 Flute Endmill EC-H7 for HSM (High Speed Machining)

- The EC-H7 family includes 7 flute endmills with different helix and variable pitch for high speed/trochoidal milling and semi-finish and finishing operations in L/D ratios of 2xD, 3xD, 4xD & 6xD. Its unique design features optimal flutes and tooth geometries, delivering maximum metal removal rates, and enables large chip gullets for efficient chip evacuation and high productivity on most material types.

Features:- 2 to 20 mm diameters

- 2xD, 3xD, 4xD & 6xD

7/9 Flute Endmill ECK-H7/9 for Machining Titanium

- The ECK-H7/9-CFR endmill family features 7 and 9 flute different helix and variable pitch configurations. This family was designed for finishing and high-speed machining applications.

Features:- Diameter range of 6 to 20 mm

- Each tool diameter is available with cylindrical and Weldon shanks

- Suitable for high speed milling of titanium

5 Flute Endmill ECY-S5 for Machining Stainless Steel

- CHATTERFREE ECY-S5 is a new family of solid carbide endmills with 5 flutes, sub-flutes and variable helix for milling austenitic, duplex, cast and precipitation hardening (PH) stainless steels (ISO M group of applications). The new ECY-S5 endmills are suitable for a wide range of milling operations, from rough to finish machining and including trochoidal milling. The new endmills feature a unique design that delays wear and significantly improves tool life.

Features:- 8 to 16 mm diameters in 2 mm increments

- Suitable for shoulder milling, milling full slot from solid and HSM/trochoidal milling

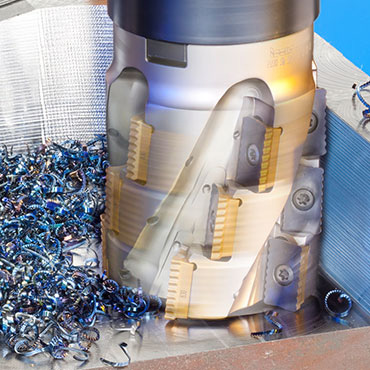

HPC - High Performance Cutting

- High Performance Cutting enables very high metal removal rates for rough milling, achieved by taking full advantage of the long edge and full immersion of the cutter. The overall depth can be up to two times the diameter and the width of cut can even be up to full diameter.

X-QUAD

- Extended Flute Milling Cutter for Machining Aerospace Components

The XQUAD extended flute milling cutter is designed for machining exotic materials. The 4 cutting edged insert is positioned on the cutter body to enable large volume metal removal. The distribution on the inserts and different helix angle enable quiet and chatter free operation and strong flushing capabilities provide the coolant pressure required.

Features- 90° extended flute shell mills carrying square inserts with 4 cutting edges.

- Designed for rough milling operations that require extremely high depth of cut, such as machining deep shoulders, cavities, high edges and full slots.

- Alternating rake angles are produced by different inserts mounted in the tool, which is combined with varying flute pitch to provide efficient chatter dampening, smooth progressive penetration into material and stable cutting action.

- Cutter design ensures that one cutting point is always in contact with the material during entrance and exit. This ensures optimal and steady harmonic oscillation, reduces power consumption and maximizes tool life.

- High material removal rates due to spacious chip gullet (flute) that enables uninterrupted chip flow.

- Coolant channels are directed to each insert cutting edge.

- The SDK …-HP cutters have coolant nozzles for high pressure coolant supply (HPC) through the cutter body. HPC dramatically improves effectiveness of chip evacuation and temperature stability in the cutting edge, significantly increases tool life.

MILL-SHREAD-P290

- Deep Cavities

The P290 - 90° shred milling tools line is based on unique inserts with serrated cutting edges. These tools can also carry regular straight edged inserts for finishing cuts.

When the tools are used with the serrated edged P290 ACKT…-FW inserts, very small chips are produced. They are an ideal solution for machining very deep cavities, as the chips can easily be removed from the machining zone, consequently enabling very effective chatter dampening abilities even when positioned at very long overhang positions.

The serrations on the cutting edges of the P290 inserts are designed to provide an overlapping effect between all adjacent tool pockets, providing a fully effective cutter configuration.

Unlike other milling tools carrying inserts with serrated cutting edge inserts that can be found in the market, the P290 line does not require special mounting instructions:

P290 ACKT...PDR-FW inserts can be clamped in any pocket. This feature simplifies tool assembly and eliminates insert indexing errors that can cause tool destruction.

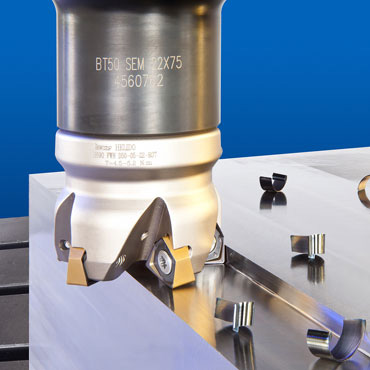

HELI-TANG-T490

- Extended Flute Cutters

HELITANG T490 Extended Flute Cutters Line with Tangentially Clamped Inserts for High Performance Cutting

Features- For shouldering and contouring

- Holes for internal coolant supply

- Suitable for all kinds of materials

- Recommended for rough milling deep shoulders

- Insert with chip splitting groove, for reduction of vibration and cutting forces

HELI-DO-490

- Double-Sided Inserts for Rough Milling of Deep Shoulders

HELIDO H490 Extended Flute Cutters with Double-Sided Inserts for Rough Milling of Deep Shoulders and High Edges

Features Tools- Positive cutting angles of the indexable insert geometry

- Coolant nozzles for insert

- Large variety of diameters and cutting lengths

- HARD TOUCH coated, providing better chip flow and protection from corrosion and wear

Shouldering

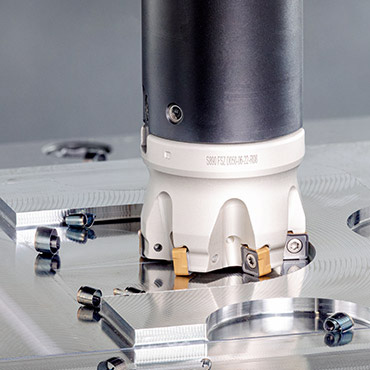

NEO-DO

- Square Double-sided Inserts with 8 Cutting Edges

NEODO is a family of 90° indexable milling cutters intended for roughing, semi-finishing, and shoulder milling, specifically for steel and cast-iron. These versatile cutters mount cost-effective square double-sided inserts with 8 cutting edges.

The advanced NEODO design combines a strong insert structure, a durable cutter body, secure mounting, and advanced carbide grades. This innovative solution enables face and shoulder milling, while providing an additional option for milling close to shoulders where there are workpiece or work holding fixture constraints.

HELI-DO-690

- Trigonal Inserts with 6 Helical Cutting Edges for 90° General

Use Applications

HELIDO Trigon Line H690-07 family is designed for productive rough to semi-finish milling, primarily on cast iron and steel components. The geometry generates positive radial and axial rake angles, that ensure smooth milling with soft entry to and exit from material.

The winning combination of effective geometry, innovative carbide grades and 6 cutting edges, enhances productivity and reduces operational machining costs.

Features- 90° milling cutters carrying trigon-shaped inserts

- Double-sided insert with 6 cutting edges

- Positive radial and axial rake angles

- Accurate 90° profile of machined square shoulder, with ramping down ability

- Highly economical solution for various milling applications.

NAN-MILL

- Triangular Miniature Inserts

with 3 Helical Cutting Edges

for 90° Shoulders