- Offer Profile

- Racking and Storage

Systems

We swear by solid walled, hot-rolled standard steel. Especially when it gets heavy and awkward, the robust cantilever and pallet racks keep to their promises.

Contrary to conventional sheet metal shelves, the stacking systems from hot-rolled steel profiles have proven themselves as a safe and durable storage solution in all the industries.

The highest demands in quality and load bearing capacity are fulfilled without the least problem.

Cantilever racking

-

Robust and space-saving storage systems

Perfect racking solution for bulky storage goods

Cantilever racks are highly load-bearing storage systems intended for storage of long and/or bulky storage materials. Such goods include, for example timber, wooden boards, metal sheets, sections, beams or steel elements, building materials but also scrap cars and all kinds of heavy loads.

Cantilever racking by OHRA is distinguished from standard racks using solid steel sections for all load-bearing elements. Thanks to this slim construction of our racks a high storage capacity can be achieved across a small floor space.

Cantilever racking by OHRA – flexible and bespoke

There are specific types of cantilever racks for every product and for every industry. They differ based on requirements, height, useable depth, load-bearing capacity or section thickness. All cantilever racks are produced individually according to customer requirements; they are equipped with a high-quality powder coat or hot-dip galvanised for outdoor storage. OHRA cantilever racks are available in different variants ranging from small racks for light loads to complete rack clad buildings, where the rack uprights simultaneously function as the load bearing structure for the roof and walls. Versatile accessories, such as beams for continuous storage surfaces without cumbersome intermediate supports or inclined arms for storage and retrieval using cranes are part of the company’ standard services. Additional services, such as racking assembly, statics calculations or preparation of drawings complete the range of services.

OHRA cantilever racking – your benefits- Racking uprights and cantilever arms made of solid, hot-rolled IPE steel sections

- Clipped-in, height-adjustable arms

- High-quality powder coating

- In outdoor applications also incl. roof, back wall and rain gutter

- Hot-dip galvanised design for outdoor storage

Heavy duty cantilever racking

-

OHRA doesn’t give in. Heavy loads are a challenge for every type of rack but not for the OHRA cantilever racking. The product benefits of our racking system become even more distinct with higher load requirements. With standard arm loads of up to 2,500 kg and support loads of up to more than 10,000 kg the OHRA cantilever racks can easily handle even the heaviest burdens.

Whether its slabs, metal sheets, wood packages, coils or heavy long boards, regardless of indoor or outdoor storage, our experts will develop an ideal solution for your storage demands. OHRA racking meets your technical requirements and is in compliance with the applicable standards.

OHRA racking - more than 30 years of experience

Benefit from our long-term experience as a planning and manufacturing company of racking systems. OHRA’s more than 30 years of experience as a racking manufacturer acting all over Europe comes in handy. We provide solutions for complex storage situations by relying on a comprehensive range of accessories and/or by creating bespoke solutions, such as guiding rails in combination with very narrow aisle trucks.

With an OHRA cantilever arm rack, each of your products can be directly accessed and is easily stored and retrieved either by crane, forklift truck, VNA truck or stacker crane. With full capacity utilisation, OHRA racks remain permanently stable and ensure a high degree of safety for your staff and your customers.

OHRA cantilever racking for heavy loads – your benefits- Racking uprights and cantilever arms made of robust, solid, hot-rolled IPE steel sections

- Clipped-in, height-adjustable arms

- Bespoke solutions based on 30 years of experience

- Permanently stable and safe

Light duty cantilever racking

-

Light duty cantilever racks are different in truck-operated racks or manually operated racks. In the aluminium or plastics trade, the loads moved and stored are very light. However, as with heavy duty racking, the requirements frequently are for optimum space utilisation and ideal technical solutions. This may be implemented by means of conventional cantilever racking but also by means of VNA warehouses, automated warehouses or paternosters/mobile racking. The decisive factor are the objectives that you want to achieve with your project.

Manually operated cantilever racking by OHRA

Racks that are operated or moved by hand are mainly found in carpenters’ and woodworkers’ shops but also in the drywall construction and metal processing industries. Light duty cantilever racks are required for such purposes, for picking individual plates or sections, for keeping the rack tidy and in order, and for supporting the production process. Rack height, rack depth and arm loads can be optionally configured. However, for manually operated cantilever racking, the most frequently used heights are 2,000 or 2,500 mm and the useable depths are mostly 600 or 800 mm. Upon request, we can also equip racks with a trolley base, casters and/or shelves to be used as mobile solution for transport within the company/factory. You can choose from our entire range of standard accessories. All racking is delivered including all mounting and fixing elements, as well as floor anchors.

OHRA cantilever racking for light loads – your benefits- Customised adjustment to all requirements

- Clipped-in, height-adjustable arms

- Easy handling

- Large selection of standard accessories

Roofed cantilever racking

-

In outdoor areas cantilever racking with a roof is the right choice for your long goods that do not necessarily need storage in a warehouse. In the static calculation of the storage system we consider the additional loads due to wind and snow in your region and dimension the rack sections and the rack roof accordingly. We advise and inform you from the beginning - from planning to roof covering. In addition, we provide help and support for obtaining building permits; if required, including drawings and static calculations.

OHRA roofed racking - functional storage in outdoor areas

For outdoor applications, the cantilever racking is supplied with a roof, the racking materials are made of high-quality hot-dip galvanised or of powder-coated materials, according to your requirements. As an additional weather protection element, we have various back and side wall designs made of metal sheets or wood boards, weather protection nets or roller shutter systems. Roofing and water drainage is also included in our range of services but may also be provided by the customer. The inclination of the roof can be individually adjusted according to the drainage system and the forklift truck properties. The combination of our robust cantilever racks and our comprehensive knowledge for racks with roof and/or walls, means we will find the perfect solution, for your new warehouse. Make use of your outdoor space to store long goods or heavy loads.

OHRA roofed cantilever racking – your benefits- Racking uprights and cantilever arms made of solid, hot-rolled IPE steel sections

- Clipped-in, height-adjustable arms

- In outdoor applications also available incl. roof, walls and water drainage system

- Hot-dip galvanised standard design for outdoor storage

- Statics calculations can be provided for obtaining building permits

Mobile cantilever racks

-

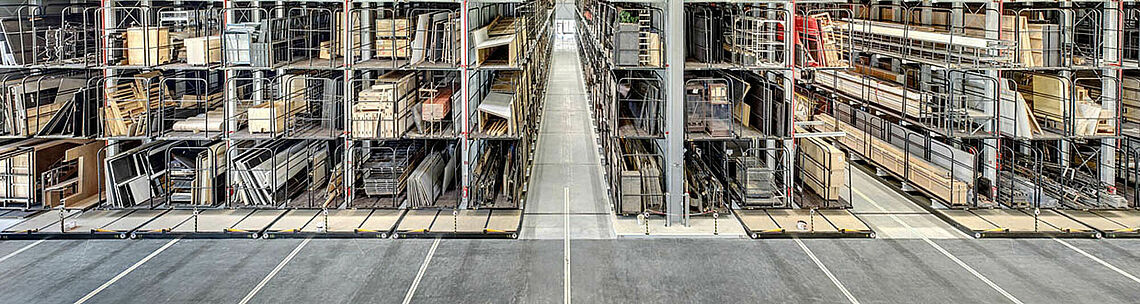

Mobile cantilever racks allow for most efficient utilisation of space within your warehouse. Depending on the selected design, the storage capacity may be increased by up to 100%. Mobile racking is ideal for bulky storage goods with a low access frequency. For that purpose, the racks are mounted on beds, which may be designed with up to 70 metres length. The beds can be moved apart either manually or by radio remote control so that the required aisle is opened.

OHRA racking – movable on beds

The beds for the movable racking are operated on rails, which have been previously installed in the floor. Subsequent installation of rails and beds for your existing OHRA cantilever racking in the existing storage spaces is also possible. At the end of the working day, the racks are positioned in the night position so that unwanted access by forklift trucks is prevented. We attach equally great importance to reliable safety and tried standards for mobile racking as for our standard racking. The OHRA cantilever racking on beds comply with the provisions of Regulation BGR 234 of the German employers’ liability association and the CE standards.

OHRA mobile racking – your benefits- Increase of storage capacity of up to 100%

- Operation via radio remote control

- Subsequent installation of rails in existing buildings is possible

- Safety as per BGR 234 and CE

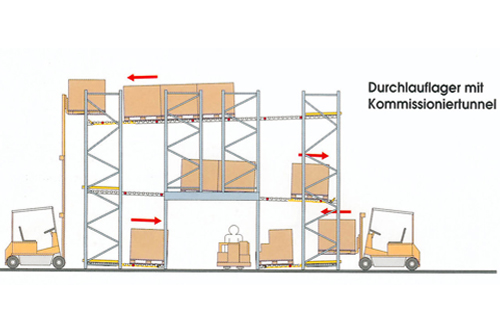

Cantilever rack mezzanine floors

-

The combination of robust OHRA cantilever racks, and space-saving, multi-level storage platforms, results in a perfect storage system that can be used as an order-picking level, a sales area or workplace. Thanks to the flexible racking solutions by OHRA your stored material remains directly accessible and can be efficiently processed without long and time-consuming transport routes.

Using OHRA cantilever racking for a mezzanine floor

The cantilever racks are used as the support structure and carriers for the mezzanine floor, regardless whether it is a top-mounted mezzanine or an in-rack intermediate mezzanine. Benefit from this flexibility of OHRA cantilever racking to utilise space from the floor to the ceiling and create ideal storage conditions. We offer complete services for your OHRA rack as a one-stop shop, ranging from statics to installation.

OHRA racking on trolleys – your benefits- Racking uprights and cantilever arms made of solid, hot-rolled IPE steel sections

- Perfect solutions for long goods picking warehouse

- Full utilisation of the space

- Clippwd-in, height-adjustable arms

Cantilever racking with inclined arm racks

-

Another option for storing long materials using a crane, are the versatile inclined arm racks. With this type of OHRA racking the cantilever arms are manufactured with a 20° inclination and provide load-bearing capacities per arm of up to 800 kg. The long materials will easily slide into the intended bay. Individual batch sizes can be picked by what is referred to as locking pins and then be transported by forklift truck or crane.

OHRA inclined arm racking – your benefits- Racking uprights and cantilever arms made of solid, hot-rolled IPE steel sections

- Robust, hooked-in inclined arms

- Locking pins for picking and shelves as standard accessories

Complete tiles presentation rack

-

In the DIY industry or in hardware stores OHRA cantilever racks are used as presentation and storage racking for tiles or laminate and parquet flooring. Their robust design and the easily assembled 20° display panels ensure permanent, perfect product presentation. The overall standard height is 2,650 mm the rack length is 2,800 mm so that exactly 3 Euro-pallets can be positioned in a row.

OHRA tapered racking – your benefits- Racking uprights and cantilever arms made of solid, hot-rolled IPE steel sections

- Clipped-in 20° display area

- High-quality powder coating

Pallet rack

-

Pallet racking for bespoke solutions

Pallet racks are by far the most widely used storage systems for many applications. In addition to conventional storage of goods on different types of pallets (e.g. Euro or industrial pallets) these racks are also suitable for accommodating other storage aids such as pallet cages or heavy tools. Pallet racks are used in many sectors and industries, for example in the building materials trade, haulage and transport companies, in dispatching warehouses or as a single storage system for heavy goods.

OHRA pallet racking – many application options

The sturdy pallet racks by OHRA are made of hot-rolled high-quality steel sections for high load capacities and safe handling. The beams have a 100mm pitch. For light and medium loads, we offer the P5 pallet rack, a cold rolled pallet rack system made of optimised steel sheets with IPG profile beams. A special offer of OHRA are hot-dip galvanised pallet racks for outdoor storage. These storage systems can be supplied either with or without a roof. All pallet racks are quick and easy to assemble and can be optionally extended at any time.

OHRA pallet racking – your benefits- Customised adjustment to your warehouse configuration

- Easy and fast assembly

- Large safety tolerances in all systems

- System accessories for individual configuration of the racks

- Outdoor application including roof and/or walls in galvanised design is possible

- Suitable for all types of sectors and industries – Made in Germany

Heavy duty pallet racking

-

The robust P3 pallet racks by OHRA provide an ideal storage system for heavy and bulky loads. With these racks, you will find a place for a large number of goods, such as raw materials, semi-finished products and other products stored on pallets. The combination of solid, hot-rolled steel sections for the uprights and beams allows for bay loads of more than 31,500 kg and beam loads of more than 6,000 kg. The rack heights can be specified to the available space. The beam levels have a 100mm pitch and can be moved without the need of tools. We supply hot-dip galvanised design for outdoor areas. Supplied with a roof and wall(s) upon request.

OHRA racking – highest load-bearing capacities

The hot-rolled steel of our racks ensures stability and provides many benefits in terms of high vertical load-bearing capacities. Other pallet racks are made of cold-rolled steel with a thickness of 2 mm, which is rather rigid even with comparably light impacts so that it is prone to kinking or bending and loose its load-bearing capacities. To ensure optimum load-bearing capacities of the racks when supporting pallets with heavy loads, we have opted for hot-rolled steel for both the uprights and beams.

OHRA pallet racking for heavy loads – your benefits- Individually configurable pallet rack for heavy loads

- Particularly suitable for building materials, raw material pallets and machine components

- Bay loads up to 32,500 kg

- Beam loads up to 6,000 kg

- Optionally extendable, easy assembly

- For outdoor application, available incl. roof and in hot-dip galvanised design

Medium and light duty pallet racking

-

For light and medium loads (up to 3,000 kg beam loads) OHRA offers the P5 range of pallet racks, with is more favourably priced. In configurations where for forklift trucks are rail-guided, the requirements for robust uprights in the racks are lower. Our P5 rack uprights made of optimised steel sheets as well as the matching beams comply with the requirements for a safe and versatile pallet rack.

OHRA racking for light loads – high-quality production

Standard rack structures are screw-fixed but OHRA will also provide welded rack structures upon request. The beams are made of IPG sections and connected to the uprights by means of hanging brackets. The racks have a 50mm pitch, and adjustment of the beams can be made without the use of tools. The OHRA P5 pallet rack offers beam loads of up to 3,000 kg and bay loads of up to 18,000 kg. As standard, the uprights are supplied galvanised, and the beams are painted in RAL 7035 (light grey).

OHRA pallet racking for light loads – your benefits- Low investment costs, favourably priced solution for storage of pallets

- Quick assembly

- Optionally extendable

- Surface finish in high-quality powder coating

Roofed pallet racking

-

Roofed pallet racks are a special product by OHRA. There is no better alternative for weather-resistant goods that can be stored in outdoor racks. The roofed OHRA racks are particularly suitable for businesses with a garden centre product range or for building materials trade where finished concrete parts, bagged goods on pallets or timber elements are stored in outdoor areas.

OHRA rack with a roof – versatile designs

The multiple roofing options as well as different wall designs complement the racking system and thus protect the stored goods from any type of weather. Trapezoidal sheets or light panels may be used for roofing, for example: for wall panels, use trapezoidal sheets or sandwich panels. Everything load-bearing such as uprights and beams are available either in hot-dip galvanised or powder-coated finish. With roofed racks, the regional snow and wind loads are determined and considered when selecting the correct sections. Considering these statics conditions ensures that your OHRA pallet racking with a roof withstands all weather conditions.

OHRA roofed pallet racking – your benefits- Utilisation of the entire outdoor area; thus, saving valuable space inside the warehouse

- High bearing loads, considering the weather effects

- Durable structure – sustainable investment in storage

- Favourable prices due to low number of different components

- Different roof designs available for selection

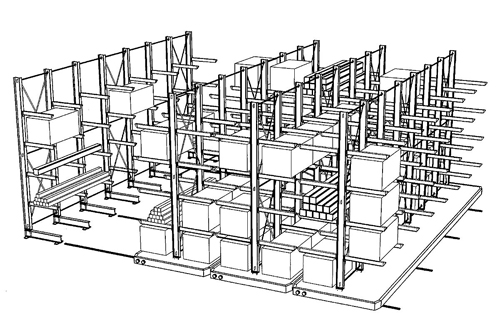

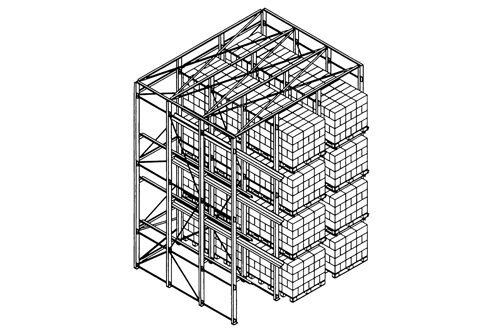

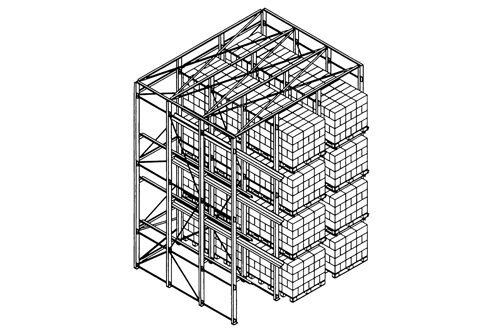

Pallet racks on trolleys

-

Movable pallet racks are dynamic racking systems and are suitable for palletised goods that require compact storage with a low footprint. With this storage system, the robust pallet racks are installed on torsion-resistant moving trolleys. The complete rack is moved as a single racking unit by means of either electronic or manual control. The trolleys are moved on rails, which can be implemented both in new systems and retrospectively in existing floors. In this way, only one active aisle is required per rack run of the pallet rack. This results in a high degree of utilisation of the available space since only one aisle is open, i.e. in the position where goods are stored into or retrieved from the rack.

OHRA racking - optimum utilisation of space due to trolleys

Movable racks ensure low-noise movement and are pushed together without any gaps. Outside the operating hours, the racking system can be switched to “night position”. In that case, the individual racks of the pallet racking system are opened at equal distances, which are so narrow that none of the aisles can be accessed with a forklift truck. In this way, the movable racks also provide efficient theft protection.

OHRA pallet racking on trolleys – your benefits- Very compact system for storage of large amounts with a small footprint

- Very efficient utilisation of space

- Increased storage capacity

- Protection of valuable goods from theft due to “Night position” of the rack blocks

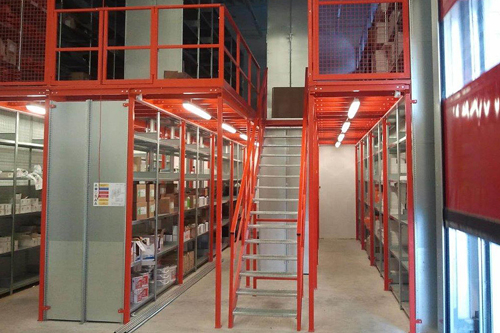

Pallet rack mezzanine floors

-

Pallet rack mezzanine floors by OHRA are storage levels based on OHRA pallet racks used as the substructure. The individual runs of the pallet racking are horizontally connected with steel sections covered with the required flooring material (metal sheets or chipboard panels) so that a structural supporting area is created between the racks. In this way, every inch of the warehouse space is utilised and no space is wasted. With this method, several mezzanine levels can be implemented within the racking system.

OHRA rack used as mezzanine floor – new options

The fusion of rack and mezzanine floor creates customised and versatile storage options, i.e. a combination of order-picking and a working zone with direct storage options. Thanks to the strong, hot-rolled steel sections used by OHRA for the pallet racks, several levels of mezzanine floors within one racking system are no problem, at all.

OHRA pallet racking mezzanines – your benefits- Optimum space utilisation by exploiting the entire height of the building

- Direct proximity of storage and order-picking zones

- Saving transit time thanks to intermediate mezzanines directly integrated in the storage area

- Expansion of the useable area due to complete utilisation of the height of the warehouse

Drive-in racks

-

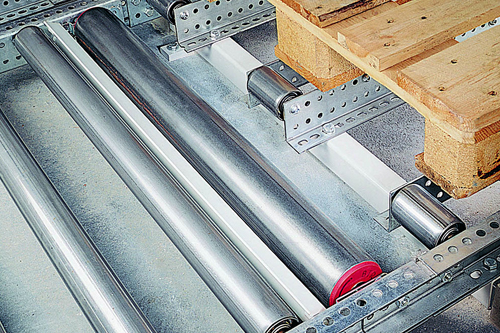

Drive-in racks combine the advantages of block stacking and rack storage: compact space utilisation combined with large storage heights. They are particularly suited for storage of large quantities of equal products and for pressure-sensitive goods that cannot be stacked. These include washing agents, catalogues, motor oil, toilet paper or tinned food with long best before dates.

OHRA drive in rack – storage system with one end open

Storage of goods in the rack is performed from one side only. The forklift truck moves into the rack channel and deposits the pallets on laterally installed shuttle units. The drive-in rack has only one open end and operation is performed from that side only. The pallet stored last is retrieved first. Thus, storage is performed according to the LIFO principle (last-in-first-out). The uprights of the OHRA drive-in racks are made of IPE or U sections, depending on the requirements. This is to implement several rack channels above one another and to protect the rack from accidental impacts by the forklift truck. The shuttle units installed at the sides of the rack channels have extreme load-bearing capacities and sliding properties. For additional protection of the uprights in the entry areas, OHRA recommends using collision guards.

OHRA drive-in racks – your benefits- Particularly space-saving due to high compaction of the warehouse

- High degree of utilisation of the available floor area/space

- Gentle storage of sensitive goods

- Cost savings due to particularly compact storage of pallets

Rack-Clad Warehouse

-

Rack-clad buildings as combined solutions

Rack-clad buildings by OHRA are the perfect fusion of building and warehouse system. In contrast to conventional warehouse structures, the uprights of the racking system serve as load-bearing substructure for the roof in addition to their actual function as a storage system, and can also be optionally used for attachment of the side walls of the storage building. In this way, significant cost advantage is achieved in comparison with conventional warehouse structures with additional racks installed.

Rack-clad buildings using OHRA racks for all requirements

Rack-clad buildings may be based on cantilever racks or pallet racks. A combination of the two rack types as the load-bearing structure is also possible. Depending on the intended use and requirements, rack-clad buildings may be designed as an open or closed construction. Closed buildings are completely enclosed with panels and equipped with doors or rolling gates. The design and construction of the roof and walls of rack-clad buildings are very varied. Trapezoidal sheets or light panels may be used for roofing, for example. The substructure may be designed either as lean-to roof or as saddle roof. For wall cladding, either trapezoidal sheets, sheet piling or sandwich panels are used. There are many design variants and warehouse types that can be realised using the OHRA racks.

OHRA rack-clad buildings – your benefits- Combination of building and racks

- Large span lengths possible due to strong steel sections in the substructure

- Increased space savings, higher flexibility and considerable cost benefits

- Customer’s contribution possible, e.g. roofing

- Experience gained from more than 1,000 rack-clad buildings realised

- Determination of sections, drawings and assembly plans are included services

- Statics calculation for approval can be provided

- Large range of accessories for individual design

- Consideration of CI when selecting the colours for the roof and walls

Cantilever rack-clad buildings

-

With this building type, the tops of the vertical uprights of the cantilever racks are cut at an angle, depending on the shape of the roof and are equipped with plates or rafter brackets. On top of that, the roof structure for the cantilever rack-clad building is build. For wall cladding, trapezoidal sheets, ISO sound insulation panels or weather-protection systems can be attached to the rear side of the rack.

OHRA rack-clad buildings – robust storage solutions

The uprights of the cantilever racks are made of hot-rolled IPE steel sections. They provide high load-bearing capacity and are very elastic. Depending on requirements and intended use of the building, the uprights of the racks are appropriately prepared for assembly and support of the roof. In general, rack-clad buildings are built with a lean-to or saddle roof. The punched rear of the uprights is also used for attachment of the wall cladding. Upon request, a rain gutter may also be included with the roofing structure, also made by OHRA. In this way, we deliver your cantilever rack-clad building as a one-stop shop.

OHRA cantilever rack-clad building – your benefits- Weather-protected storage of long and bulky goods

- High bearing loads of the IPE sections verified by static calculations

- Cost reduction, space saving and flexibility

- Customer’s contributions possible

- Different roof shapes can be realised, depending on the plot of land and rain drainage conditions

Pallet rack-clad buildings

-

Like cantilever rack-clad buildings, the rack uprights of the pallet racks are made of hot-rolled U sections and bear the loads of the roof and wall structures. For roofing, the uprights of the racks are cut at an angle at the top and subsequently connected with the roof sections. Depending on the geographical situation, the local snow and wind loads, but also earthquake zones, for example, are taken into account to ensure optimum anchorage in the ground.

OHRA rack-clad buildings – customised design

The pallet rack-clad buildings can be designed either as open or completely closed halls including doors and gates. The punched uprights of the pallet racks are also used for attachment of the wall cladding of the hall. Upon request, not only the wall cladding but also roofing, including water drainage, may be performed by OHRA.

OHRA pallet rack-clad building – your benefits- Cost-effective storage option compared to conventional hall structures

- Saving of costs due to customer’s contributions for roofing and wall cladding

- Determination of sections, drawings and assembly plans are included services

- Consulting, planning, production and assembly - all from the same company

- Large range of accessories for individual design options

Mezzanine floors

Mezzanine floors

-

Mezzanine floors by OHRA increase the existing storage area without the need of extensions or reconstruction measures. The additional floor space generated by the mezzanine floor can be cost-effectively and variedly used, e.g. as office area or workspace, as production or exhibition area or as an additional storage unit.

OHRA mezzanine floors as flexible storage extension

All OHRA mezzanine floors can be configured for a variety of requirements and loads, e.g. by means of different upright sections, beams and rafters (e.g. made of solid steel sections or optimised Sigma sections). Obstacles such as pipelines and power supply lines or windows and doors are taken into account. OHRA can easily design and build mezzanine floors with up to 5 levels. The centre-to-centre distance of the mezzanine uprights is between 3.5 and 8.5 m as standard. The bearing loads range between 250 and 2,000 kg/m². Greater centre-to-centre dimensions and bearing loads can be designed upon request. The mezzanine floors are completed by stairs with grating or wooden steps, screw-fixed bannisters, including hand rail and knee rail. Transfer stations in various designs and options are also available. The flooring material to be used on the mezzanine is plastic-coated chipboard panels or flooring with anti-skid coating.

OHRA mezzanine floors – your benefits- Optimisation of storage areas by storage in on two or more floors

- Combination of storage and working place in one area

- Strong steel sections ensure large span lengths below the mezzanine floor

- Up to 5 levels and bearing loads of up to 2 t/m² can be realised

- Economically optimised price-performance ratio

- Different flooring designs available

- Self-bearing structure

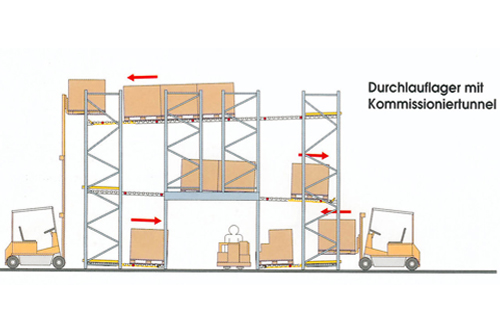

Dynamic racking systems

-

Dynamic racking systems are modular rack systems which, in comparison with static racking systems, can achieve increases in storage capacities due to their type and technical components and thus accelerate the order-picking process.

OHRA dynamic rack systems – sustainable investment

In comparison with conventional racking, the initial purchase costs of a dynamic rack system are slightly higher. However, in the long run and with correct operation, the significantly higher economic benefits that the rack provides will pay off these investment costs. OHRA provides all typical systems, ranging from a cardboard flow racking to heavy-load pallet flow racking to cater for any different fields of application and investment budgets.

OHRA dynamic rack systems – your benefits- Modular standardised components

- Adjustment to storage goods and fields of application

- Wide range of products

- Optimisation of travel routes and order-picking times

Pallet flow racking

-

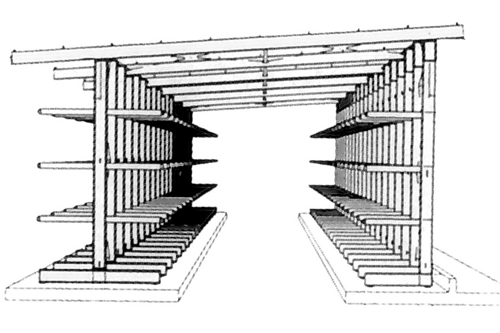

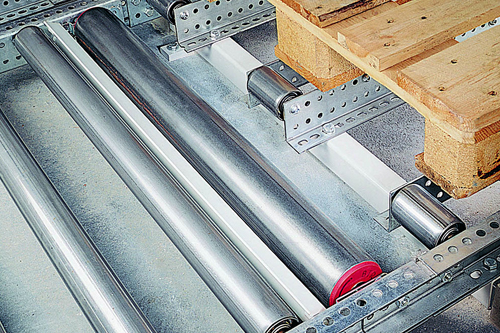

Pallet flow racks are among the most compact methods for storage and picking according to the first-in-first-out principle. Thanks to the channel formation, high utilisation of the surface area is generated and with uniform pallets, optimum degree of filling is achieved. The smooth roller system with integrated brake support rollers, the product’s own weight moves it to the removal position. The pallet separation unit on the removal side ensures safe handling.

OHRA pallet flow racking – your benefits- Modular standardised components

- High load-bearing capacities and durability

- Safe handling through pallet separation

- Suitable for all smooth-running surfaces

- FIFO principle - optimisation of transport routes and order-picking times

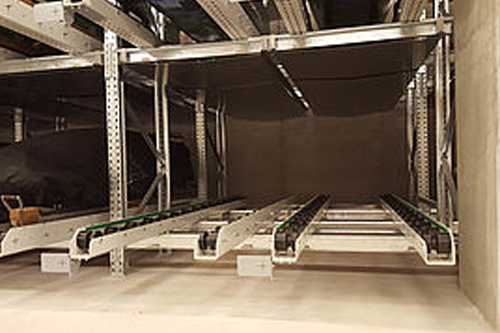

Order-picking flow racking

-

The order-picking flow racks are used in a similar way than the pallet flow racks, however, preferably for cardboard or plastic boxes that are suitable for transport on roller conveyors. Particularly for order-picking of products with regular turnover (medium-moving items) and with high turnover (fast-moving items), flow racks are the proper and most effective storage solution.

OHRA order-picking flow racking – optimised times

Thanks to the FIFO principle, the stored goods are transported to the removal position by their own weight and are then ready for order-picking. Work routes become shorter, picking times are optimised and refill aisles are separated. In planning of order-picking racks, ergonomics of the workplaces always has very high priority.

OHRA order-picking flow racking – your benefits- Modular standardised components

- Individual plastic rollers with steel shafts that can be loaded with up to 6 kg

- Suitable for cardboard and plastic boxes

- FIFO principle - optimisation of transport routes and order-picking times

Push-back racking – trolley systems

-

Push-back systems, also referred to as trolley systems provide a space-saving storage option based on the last-in-first-out principle. These racks are ideally suited for applications involving batches of the same types of articles.

OHRA push-back rack – contact-free storage on trolleys

With the push-back trolley system, the pallets are deposited on a rail system in the channel system, one after the other. Then, they are also removed from the same side: Stacking depths of up to 6 pallets are possible. Advantage over push-back racking with conventional gravity roller conveyors: During the storage process, the uppermost loaded trolley with pallet to be stored next is pushed back. This pallet is then deposited on the next free trolley. Direct contact with the goods is thus prevented.

OHRA push-back racking – your benefits- Modular standardised components

- Storage depths of up to 6 pallets possible

- Can be used with sensitive palletised goods - no contact of the pallets

- LIFO - optimisation of transport routes and order-picking times

Push-back racks – roller conveyor systems

-

The benefit of push-back racks with roller conveyor systems is in the quantity of goods that can be stored in the available depth. Up to 10 pallets in a row. In comparison with push-back racking with trolley systems, the building height is lower. Due to the high push forces required to move the pallets, push-back racks are particularly suitable for insensitive goods.

OHRA push-back racking – your benefits- Modular standardised components

- Storage depths of up to 10 pallets possible

- Can be used with insensitive goods

- Optimisation of travel routes and order-picking times

Vertical shelving systems

-

Vertical storage

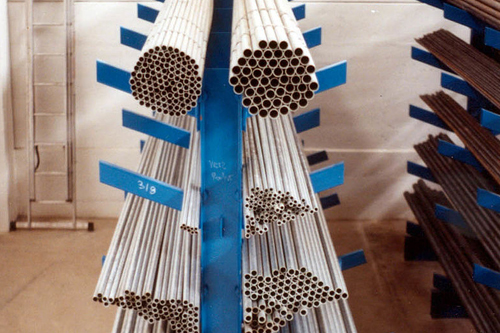

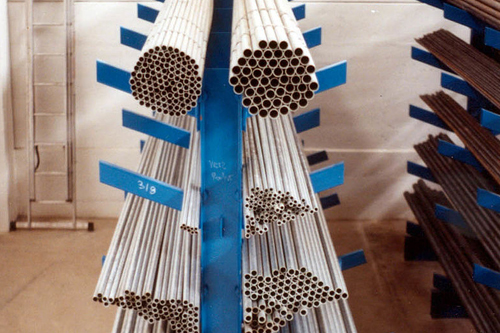

For vertical storage of long goods, such as sections, tubes, rods or strips, an OHRA vertical rack is the best solution. For vertical storage of chipboard sheets, the chipboard sheet rack is the first choice, particularly in cutting applications of wooden products. OHRA provides vertical racking systems for a large variety of applications and various industries. Vertical racks and chipboard sheet racks are an integral part of storage technology, particularly in carpenter’s and woodworker’s shops, as well as specialised wood shops and DIY shops.

OHRA vertical racks – optimum vertical storage

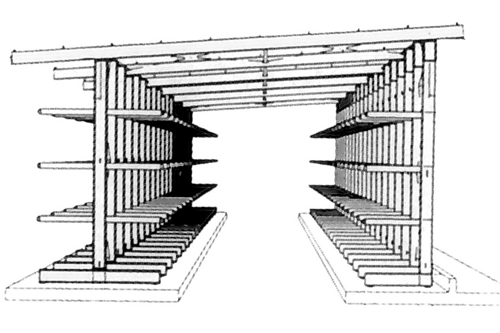

Vertical racks by OHRA are used in applications where different types of long goods, particularly strips or tube sections need to be stored in vertical position. These may be supply racks, directly at the workplace, but also presentation racks in showrooms where various designs, dimensions or colour options are to be presented in a customer-friendly manner. The robust design of the rack uprights and transverse beams in tried and tested steel structures are also intended for high loads and are not prone to tilting. Depending on the type of applications, the racks may be delivered either as single - or as double-sided racks. The standard heights of the vertical rack are 2,100, 2,700 and 3,300 mm. They are applied depending on the goods to be stored. The useable depths are 450, 650 and 850 mm, the standard bay widths supplied by OHRA are 1,500 or 2,000 mm. For other dimensions, please send us a request.

OHRA vertical racking - your benefits- Storage of long goods, such as tubes, strips, sections or rods, directly at the workplace

- Option for subdivision by means of separating brackets or separating arms for fast and direct access to the product

- Customer-friendly presentation in the sales area

- Delivery including fixing materials, foot and side cover panels, as well as anchorage options

- Good overview, compact storage, fast and easy access

Chipboard sheet racking

-

A special OHRA product is the sturdy chipboard rack for vertical storage of chipboard sheets and materials in various qualities and dimensions. The sturdy racking system guarantees high bearing loads and fast handling in the workshop.

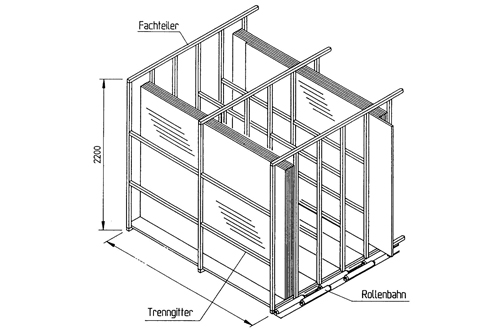

OHRA chipboard sheet racking – varied models

The OHRA chipboard rack is available in 3 different depths. 2,500 mm, 4,000 mm and 5,000 mm. The clear bay height is 2,200 mm. In this way, all conventional chipboard panel sizes can be vertically stored in the rack. The clear bay width is 400 mm. The rack can be ordered as a modular system comprising the base and attachment elements with either 2 or 3 bays. The surface finish is a high-quality powder coat. In addition, the top side of the chipboard plate rack can be covered with a chipboard plate, which can then be used as additional storage area with a surface load of up to 380 kg/m².

OHRA chipboard plate racking - your benefits- Fast and easy assembly due to modular design

- Subdivision in base and attachment fields for a large number of bay widths

- Top rack level can be used as storage area by using appropriate accessories

- Including roller conveyors in front of every bay for easy storage and removal

- Optionally extendable

- Optimum price-performance ratio

Mobile racking systems

-

Saving on racking aisles - More storage space

In the industrial warehouse dynamic or mobile racking systems are modern solutions for a compact warehouse. Single racks are mounted on traversing carriages, which can be pushed together by means of rails and rollers. For the stock storage and retrieval the required aisle is opened by an electronically controlled drive train. The result is a substantial decrease of transport routes and an increase in area of up to 100% compared to fixed racks.

- Compact storage on a small foot print

- Modern racking system for a wide range of applications

- High cost-efficiency and storage capacity thanks to optimal space utilization

- Effortless rail-wheel-system for quiet and durable operation

- Decrease of transport routes while simultaneously increasing the available storage area

Pallet racks on trolleys

-

Movable pallet racks are dynamic racking systems and are suitable for palletised goods that require compact storage with a low footprint. With this storage system, the robust pallet racks are installed on torsion-resistant moving trolleys. The complete rack is moved as a single racking unit by means of either electronic or manual control. The trolleys are moved on rails, which can be implemented both in new systems and retrospectively in existing floors. In this way, only one active aisle is required per rack run of the pallet rack. This results in a high degree of utilisation of the available space since only one aisle is open, i.e. in the position where goods are stored into or retrieved from the rack.

OHRA racking - optimum utilisation of space due to trolleys

Movable racks ensure low-noise movement and are pushed together without any gaps. Outside the operating hours, the racking system can be switched to “night position”. In that case, the individual racks of the pallet racking system are opened at equal distances, which are so narrow that none of the aisles can be accessed with a forklift truck. In this way, the movable racks also provide efficient theft protection.

OHRA pallet racking on trolleys – your benefits

- Very compact system for storage of large amounts with a small footprint

- Very efficient utilisation of space

- Increased storage capacity

- Protection of valuable goods from theft due to “Night position” of the rack blocks

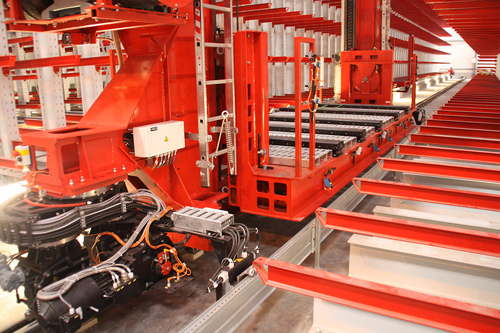

Automatic racking systems

-

Your warehouse needs to work properly to dispatch orders quickly and efficiently. It must be efficient and adapted to requirements: the only way companies stay flexible and competitive on today’s market. Warehouse automation has become such an important competition factor that it is now essential for modern companies.

- Maximum speed + safe handling saves time and money

- Optimal stock overview and perfect order processing on the warehouse management software

- Storage & retrieval machine with cornering technology to access several aisles with a single device

- Retrofitting from semi-automatic to fully-automatic operation at any time

The operating mode of the storage and retrieval machine (SRM) depends on the function of the warehouse. Choose between a semi-automatic or fully automatic warehouse.

Automated storage system - your advantages :

- Storage and equipment planning from a single source

- Warehouse management software available

- Wide range of equipment types

- Both curve-going and straight-running units possible

- Up to 8,000 kg load capacity

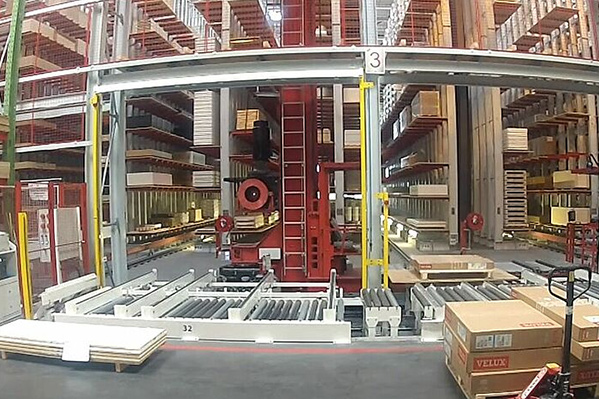

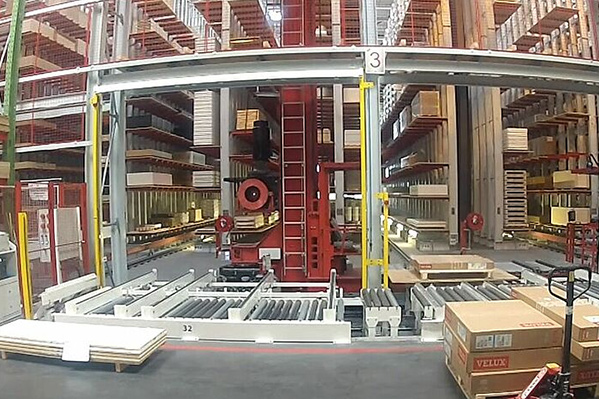

Semi-automatic warehouse

-

The semi-automatic warehouse is so named because the warehouse personnel work with the storage and retrieval machine for certain tasks and processes, such as order picking.

The SRM moves automatically to the racking position determined by the operator in advance. The precise positioning in front of the racking position is fully automatic, while the on- and offloading of e.g. wooden boards is controlled by the operator over a manual command. This is also the case for the raising and lowering of loads and for the direction of movement of the forks.

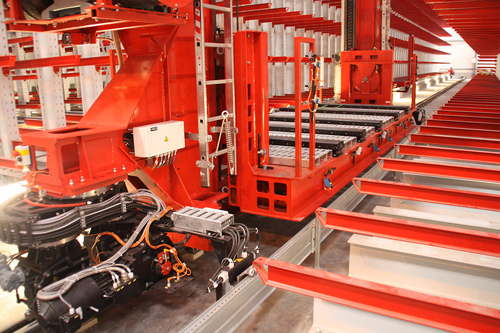

Fully automatic warehouse

-

In contrast to the semi-automatic warehouse, in the fully automatic warehouse mode, all processes are pre-set on the warehouse management software. All commands are transmitted automatically to the control unit of the storage and retrieval machine. All the steps involved, including start-up of the racking unit, exact positioning in front of the racking position, lifting and lowering of loads, and the journey to the pick-up station are fully automated, without any involvement by warehouse staff.

All the info at a glance:

- Very narrow aisle widths

- Connection to your warehouse management system

- Top storage level up to 20 metres high. Loads of up to 5 tonnes

- One storage and retrieval machine can serve several aisles

- Storage of products up to 8 metres long

Fully automatic order picking warehouse

- Storage and retrieval, picking and provision of the order-related packages are fully automated. This not only increases the efficiency of the entire storage and order picking process, but also enables a high area utilisation and reduces damage to the goods. The concept of using the advantages of two-stage picking is completely new: A storage and retrieval machine (SRM) handles the storage and retrieval of packages in the warehouse. If a shipping order requires the picking of different individual sheets, a vacuum manipulator has the corresponding articles ready for shipping, whereby several orders can be processed in parallel. Thus, two separate systems put the orders together very efficiently in the smallest of spaces.

Stacker cranes

-

With a load-bearing capacity of up to 8 tons, the device from this model range is particularly useful when handling heavy and large-volume goods in high-rise racks is required. This is particularly the case in the building materials, timber, slab or paper-processing industries.

OHRA two-mast stacker crane for long goods and heavy products

Thus, economic storage is possible with a small footprint. Using the “man at the goods” principle, the manual standard devices with standard platforms can be used for direct order-picking at the rack.

OHRA stacker cranes for long goods – your benefits

Particularly suited for long goods

Bearing loads of up to 8,000 kg

Device can be delivered with a platform for manual order-picking

Curve-operation - handling of several aisles possible

OHRA stacker crane for storage heights of up to 12 m

For automatic storage of Euro pallets and pallet cages in storage heights of up to 12 metres, OHRA provides a special stacker crane model as a true alternative of VNA trucks. The device can be curve-operated, is favourably priced and is based on a modular concept. Its special chassis also allows for direct driving on the hall floor.

OHRA stacker cranes for storage heights of up to 12 m – your benefits- Particularly suited for order-picking warehouses or automated buffer warehouses

- Building height of up to 12 m

- Alternative for very narrow aisle warehouses

- Curve-operation - handling of several aisles possible

OHRA stacker crane for storage heights of up to 25m

This OHRA stacker crane is intended for storage of pallets and pallet caged materials in high-rise racks of up to 25 metres and has successfully performed in the automation market for decades. Typically equipped with telescopic forks for single- or double-depth storage or alternatively with a shuttle system or special load-carrying device – with customised configuration depending on requirements. Fully automatic option or semi-automatic operation with complete driver’s cabin.

OHRA stacker cranes for high-rise racks – your benefits- Particularly suited for high-performance warehouses

- For pallets and pallet cages, building heights up to 25 m

- Curve-operation - handling of several aisles possible

Warehouse management software

-

The entire material flow of a warehouse or a production facility can be controlled fully automatically. Our strengths are especially in scenarios with new products, where the goal is to adjust the logistics system to your existing organisation structure, not the other way around(!). The basis for this is an initial analysis of the actual situation and a jointly deduced future forecast. Based on the data collected on item turnover and company structure, we will develop solution concepts together with your employees. These will later be used as a specification book for automated storage.

OHRA warehouse management software - digital automation

The WMS is a comprehensive and optionally configurable standard system. You can achieve fast and lasting cost savings through optimum deployment of employees and technical system and simultaneous improvement of the process quality and reduction of the storage volume.

OHRA warehouse management software- Analysis of the actual situation

- Solution development

- Presentation of results

- Compilation of the specifications book

- Optimisation of storage capacity

- Fifo-Lifo-BBD

- ABC classification

- Blocking of bays/stock

- Order-picking optimisation

Shelving rack

-

Shelf racking

OHRA shelf racks for storage of small parts and non-palletised storage goods. The galvanised plug-in sections are assembled without screw-fixings and is mainly used for manual removal of goods. The sturdy shelves are available in different widths and load-bearing capacities and are equipped with multiple chamfers.

OHRA shelf racks – flexible configuration

The shelf racks are available in 3 different heights: 2,000, 2,500 and 3,000 mm. The rack widths are optionally 400, 500 or 600 mm. The individual shelves can be supplied for bearing loads of either 150, 250 or 330 kg, depending on requirements. The bay load is max. 1,500 kg. All OHRA shelf racks have been tested according to the BGR regulations. The shelves can be adjusted in grid heights of 25 mm. Also, available as double racks.

OHRA shelf racks - your benefits- Clear and tidy storage of small parts

- Easy and fast assembly

- Height adjustable at a grid of 25 mm

- Favourably priced and flexible

- Also suitable for double-sided use

Large-span racking

-

Large-span racks differ from shelf racks by their larger bay widths and higher load-bearing capacities. Instead of shelves, horizontal beams are hooked in and optionally equipped with chipboard plates or steel panels. The ideal large bay rack for light and medium-heavy or large-volume and bulky goods, such as wall paper, foam panels, packaging or cardboard boxes.

OHRA large-span racking – spacious and load-bearing

Uprights and beams in galvanised design. All bay heights can be adjusted at a grid of 25 mm. Bay widths optionally available as 1,500, 2,000 and 2,500 mm with rack depths of 500, 600 or 800 mm. OHRA offers rack heights of 2,000, 2,500 and 3,000 mm. Other heights, depths and bay widths upon request. The individual bays may be loaded with up to 500 kg. Shelves are optionally made of chipboard panels with a thickness of 19 mm or of galvanised steel panels. The bay load is max. 2,500 kg.

OHRA large-span racking - your benefits- Robust, versatile rack, also suitable for small parts

- Flexible bay sizes and frame depths

- Ideally suited for bulky and high-volume storage items

- Easy and fast assembly

- Shelves design either as chipboard plate or as galvanised steel panel

Racks with roof

-

OHRA offers racking systems an externall outdoor warehouse, which not only create additional storage space, but also offer sufficient protection against the effects of the weather. The roofing of cantilever and pallet racks, for example for the storage of wood, ensures that the product remains dry and at the same time aerated.

OHRA offers various roof structures, all of which are statically calculated taking into account snow and wind loads. We supply Trapezoidal sheeting material fo the roof, we can also fit materials you supply.

OHRA racking systems - your advantages- Optimal utilization of the storage area outdoors

- Various roof structures avaiable

- Installation services including roofing

- On-site services possible

- Steel construction and foundational statistics available

- individual design according to requirement

- Optimized price-performance ratio

Roofed cantilever racking

-

In outdoor areas cantilever racking with a roof is the right choice for your long goods that do not necessarily need storage in a warehouse. In the static calculation of the storage system we consider the additional loads due to wind and snow in your region and dimension the rack sections and the rack roof accordingly. We advise and inform you from the beginning - from planning to roof covering. In addition if required, we can provide drawings and static calculations.

OHRA roofed racking - functional storage in outdoor areas

For outdoor applications, the cantilever racking is supplied with a roof, the racking materials are made of high-quality hot-dip galvanised or of powder-coated materials, according to your requirements. As an additional weather protection element, we have various back and side wall designs made of metal sheets or wood boards, weather protection nets or roller shutter systems. Roofing and water drainage is also included in our range of services but may also be provided by the customer. The inclination of the roof can be individually adjusted according to the drainage system and the forklift truck properties. The combination of our robust cantilever racks and our comprehensive knowledge for racks with roof and/or walls, means we will find the perfect solution, for your new warehouse. Make use of your outdoor space to store long goods or heavy loads.

OHRA roofed cantilever racking – your benefits- Racking uprights and cantilever arms made of solid, hot-rolled IPE steel sections

- Clipped-in, height-adjustable arms

- Outdoor applications also available with roof, walls and water drainage system

- Hot-dip galvanised standard design for outdoor storage

- Statics calculations can be provided for obtaining building permits

Roofed pallet racking

-

Roofed pallet racks are a special product fromOHRA. There is no better alternative for weather-resistant goods that can be stored in outdoor racks. The roofed OHRA racks are particularly suitable for businesses with a garden centre product range or for building materials trade where finished concrete parts, bagged goods on pallets or timber elements are stored in outdoor areas.

OHRA rack with a roof – versatile designs

The multiple roofing options as well as different wall designs complement the racking system and thus protect the stored goods from most types of weather. Trapezoidal sheets or light panels may be used for roofing, wall panels may use trapezoidal sheets or sandwich panels. Everything load-bearing such as uprights and beams are available either in hot-dip galvanised or powder-coated finish. With roofed racks, the regional snow and wind loads are determined and considered when selecting the correct sections. Considering these static conditions ensures that your OHRA pallet racking with a roof withstands adverse conditions.

OHRA roofed pallet racking – your benefits- Utilisation of the entire outdoor area; thus, saving valuable space inside the warehouse

- High bearing loads, considering the weather effects

- Durable structure – sustainable investment in storage

- Favourable prices due to low number of different components

- Different roof designs available for selection

INDUSTRIES

Alu-plastic

-

Plastics and Aluminium

For the storage of aluminum and plastic, cantilever racks are the ideal storage solution for long goods of any shape, length or quality. With this racking system, aluminum and plastic profiles, PVC pipes and panels, downpipes, window frames, guttering and miscellaneous long goods can be stored and removed in a particularly space-saving manner.

A wide range of accessories like dividers for the separation of material in one storage level, or identification plates for the marking of stored material, helps to realize individual storage possibilities. The most economical and compact storage of voluminous or bulky goods on a small base area.

Automobile recycler, wrecking services

-

The temporary storage of vehicles is a major challenge for towing services, local authorities and public service providers. Especially when it comes to car-friendly and space-saving storage, the possibilities are limited.

Uniform European guidelines for recycling and conditioning of old vehicles and spare parts, prescribe a certain and environmentally friendly storage of your products. The optimal warehouse technology for your business purpose must correspond to these guidelines. The default leads frequently to punishments and in emergency to denial of license. A further reason to choose the correct warehouse technology supplier.

Building materials

-

Building materials

The secure and efficient storage of your product range ensures greater customer satisfaction and is a critical factor for saving time and money in the warehouse. The storage and presentation of heavy products in particular represents a major challenge.

Many types of shelving systems quickly reach capacity. Here, OHRA racking systems prove to be robust, durable and reliable. They meet all conditions necessary for accommodating as much heavy building-material products as possible in less space. The high quality of the pallet and cantilever racking, made from hot-rolled steel profiles, ensures a durable and economical storage solution for your building materials storage.

Timber construction/ carpenter

-

Carpenters/Timber-frame constructions

Satisfying forever changing customer demands in terms of quality, individuality, cost, and delivery deadlines can create havoc with workshop workflow efficiency. OHRA storage systems for joinery and carpentry workshops provide valuable assistance to help cope with the strain of optimising your storage and working areas. Store your valuable woodworking materials close to hand and according to type and size:- Providing easy access to all material

- Space saving storage of all material sizes

- Save valuable workflow time

- Top quality – built to last

- Modular design

Timber trade

-

Timber Trade

For more than 40 years, OHRA characterises the technical development of economical and space-saving racking and storage solutions. OHRA invented and perfected the free movable arm, today a standard feature for carpentries.

Cantilever racking in particular is the ideal storage system for long, heavy and bulky materials in the timber trade. OHRA cantilever racking creates high density storage capacity on a small footprint thanks to the sturdy but slim hot-rolled steel profile construction. Continuous storage levels without interfering intermediate uprights enable various product sizes and assortments to be stored on one level. Flexible boltless height-adjustable cantilever arms protect product and racking from forklift truck impact damage. OHRA cantilever racking is made to order to fit your warehouse and product storage requirements

Furniture and timber industry

-

Industry-specific storage systems

For the furniture and timber industry, a special storage technology is an important feature to achieve an economic stock holding pallets and transport packages in a pallet rack, and primary material, timber and panels in a Cantilever rack. Due to the manufactured products and the applied material, voluminous goods should be stored in a space-saving and prompt commissioning friendly method.Industry-specific storage systems

For the furniture and timber industry, a special storage technology is an important feature to achieve an economic stock holding pallets and transport packages in a pallet rack, and primary material, timber and panels in a Cantilever rack. Due to the manufactured products and the applied material, voluminous goods should be stored in a space-saving and prompt commissioning friendly method.OHRA is a specialised company for this particular way of stock holding, and manufactures individual racking systems for the furniture and timber industry:

- Optimal utilization of existing surfaces

- Optimization of picking routes

- Highest quality ensures longevity

- Integration in the production flow

- Customized system technology

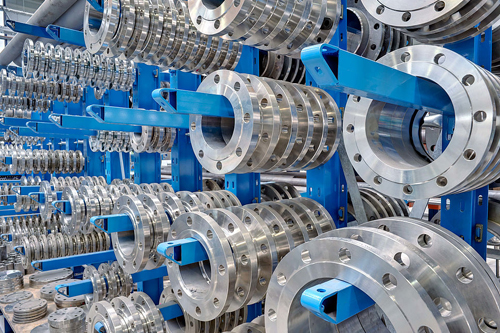

Engineering/ metal processors

-

Consultation meeting

The storage of steel and heavy metal products places high demands on a business. The selective access to different dimensions of goods, the optimal flow of materials, and the prompt commissioning of your customer orders must be coordinated and ensured at all times.

Depending on the type of forklift, our solutions can provide up to 30% optimization compared to conventional racking systems. Cantilever racks with inclined arms for pipes and long products are ideal for handling with an indoor crane. Double your storage space by using storage platforms.

Metal trade

-

Metal-Trade

The storage of steel and heavy metal products places high demands on a business. The selective access to different dimensions of goods, the optimal flow of materials, and the prompt commissioning of your customer orders must be coordinated and ensured always. Compared to conventional sheet metal shelving, OHRA shelving systems, made of hot-rolled steel profiles, have established themselves as a secure and long-lasting storage solution in the metal industry.

When things get heavy and unwieldy, the robust cantilever or pallet racking comes through. The highest demands for quality and loading are met without problem. Your products are securely stored, quickly accessible and easily sorted – all this in less space.