- Offer Profile

- Innovative and customer-oriented systems dictate tomorrow’s market. This is the principle which Universal Hydraulik has been following for more than thirty years in designing hydraulic systems, cooling systems, and heat exchangers which are used all over the world in all fields of application. We are at your service in Neu-Anspach in Germany, in Putim in the Czech Republic and in Perrysburg in USA. We distribute our products directly and work together with over twenty-five distributors to be present worldwide.

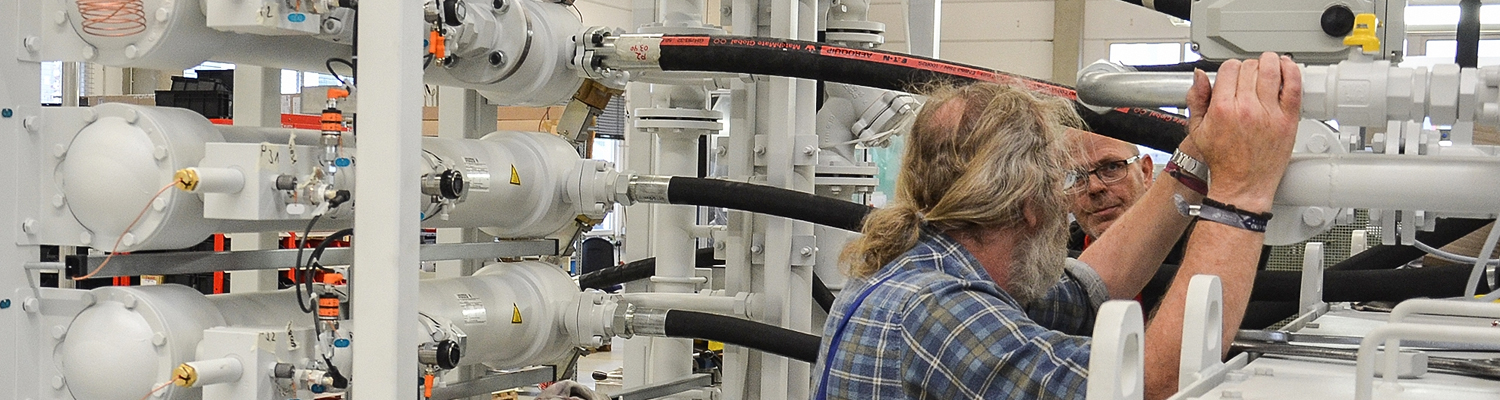

HYDRAULIC SOLUTIONS

-

OUR ORIGINS

Universal Hydraulik GmbH offer their customers over thirty years of experience in building hydraulic infrastructure. These units are planned and designed according to our customers’ individual requirements. We produce oil reservoirs from 10-10,000-liter and power from 0,25 to 160 kW. We only use pumps, valves, and electrical components from major international manufacturers.

We are Flexible

“Universal” means we offer a variety of customized solutions. Due to our long-term experience in hydraulics and our existing plant engineering, are we leading in developing cooling systems, hydraulic solutions and test benches.

Personal Consultation and Customer Support is standard

New developments and improvements of your hydraulic power units are part of our daily business. Your personal consultant in the hydraulic sector of Universal Hydraulik is there for you to meet your demands and requirements.

4.0 FLUID-MONITORING SYSTEMS:

-

INDUSTRY 4.0 WITH AGGREGATES OF UNIVERSAL HYDRAULIK

Universal Hydraulik 4.0 Fluid monitoring Systeme

Due to linkages of sensors on our hydraulic applications, we are now ready to provide Industry 4.0 applications. Focusing on the customer’s needs, we want to build and lead you through the fourth industrial revolution.

Leading Theme Predictive Maintenance

“Predictive Maintenance” is the new trend in mechanical engineering. The goal for the industry is clear, but the market fails to offer ready-made solutions and applications to lower the error rates (or increase the MTBF – Mean-Time-Between-Failure).

HYDRAULIC POWER UNITS

-

THE ORIGIN OF UNIVERSAL HYDRAULIK IS HYDRAULICS

Universal Hydraulik GmbH offers customers over thirty years of experience in building power units. These power units are planned and designed according to our customer requirements. We produce oil reservoirs from 10-10,000-liter and electrical power from 0,25 to 160 kW. We only use pumps, valves and electrical components from major international manufacturers.We are flexible

Universal means special solutions. Due to our long-time experience in hydraulics and our existing plant engineering are we leading in developing cooling systems, hydraulic solutions and test benches.

COOLING FILTER UNIT

-

COOLING AND HEATING

We produce cooling systems with our very efficient components (e.g. screw pump, heat exchanger, filter) according to our customer requirements. Viscosities of 5000 mm_/s (cst), heat transfers of 150 kW and oil volumes of 350 l/min are standard for us.

Please ask us also for more formidable applications or other components.

Technical Specifications- Installed load : 3 kW

- RPM: 950 U/min

- Noise level : 65 dB(A)

- Type of oil : ISO VG 46

- Delivery rate : 93 l/min

- Operating pressure : 10 bar

- Pump safety device : 10 bar

- Max. pressure in-tank : 1 bar

- Cooling water demand : 96 l/min

- Cooling water temp inlet. : 30 °C

- Cooling capacity : 42 kW

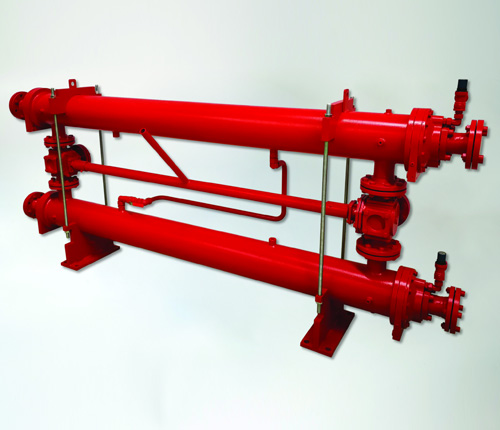

LUBRICATING OIL UNIT

-

FOR GEAR OIL LUBRICATION

We have extensive, long-standing experience in the market of gear oil lubrications, choosing the right components for your oil type even with high viscosities of 5000 cSt and higher. Ask us about our experience in the market. We are happy to assist you to select the right component for your application.

ELECTRICAL CONTROL SYSTEMS

-

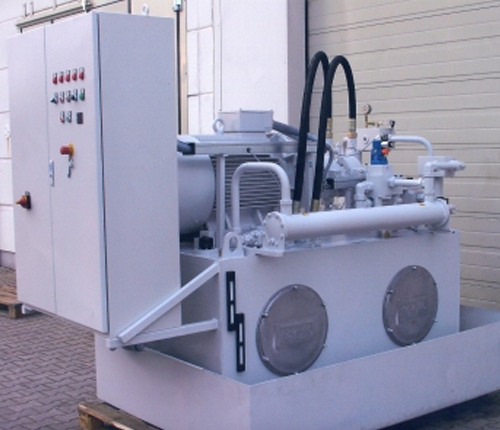

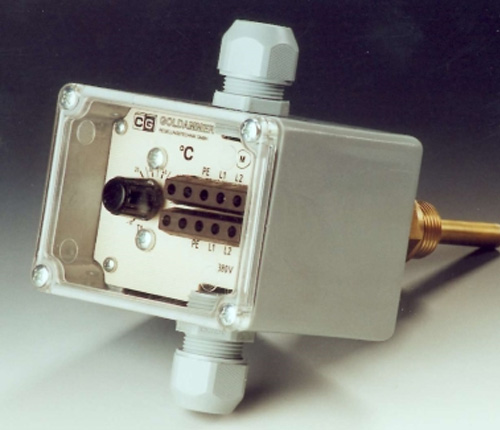

Electrical SPS control systems for your hydraulics or cooling/heating

We plan and engineer customized electrical control systems for test benches and hydraulic power units (HPU’s). We offer standardized and customized electrical control units for our heat exchangers. Through connecting the hydraulics sensors, industry 4.0 application are possible.

SYSTEM SOLUTION ATEX

- Hydraulic aggregates with ATEX from Universal Hydraulik

Universal Hydraulik GmbH now also develops and builds oil supply systems which can be used in potentially explosive environments. The systems comply with ATEX Directive 94/9/EC dated 23.03.1994 for machine group II, category 2. They can be used in zones 1 and 2.

Technical data:- Installed performance: 3 kW

- Rotation speed: 1.000 rpm

- Oil grade: ISO VG 150

- Flow-rate: 30 l/min

- Operating pressure: 10 bar

- Oil-in Temperature: 70°C

- Cooling performance heat exchanger: 17 kW

COOLING SYSTEMS

-

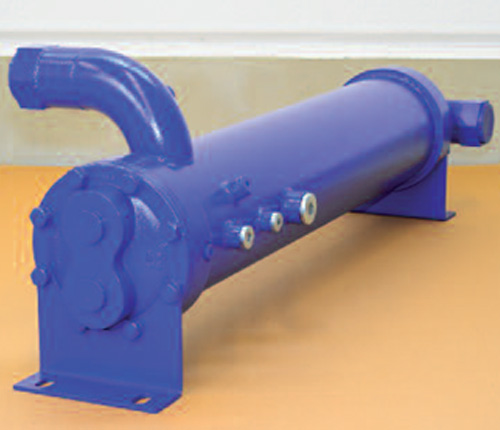

WE PRODUCE COOLING SYSTEMS ACCORDING TO OUR CUSTOMER SPECIFICATIONS.

We mount several coolers. If the biggest possible standard cooler does not comply with your needs, we mount them in a row or parallel, no matter if system is oil-air or oil-water cooling.

Additional requests for by-pass, noise reduction housings, single operations are as well possible as special voltages or special welding’s (e.g. ASME).

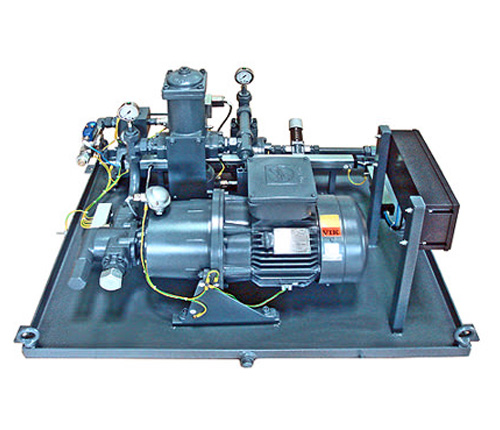

MOTOR-PUMP UNIT

-

ELECTRIC MOTOR WITH LOW-NOISE SCREW SPINDLE PUMP

We supply the driving unit as a complete component in the highest quality and delivery reliability.

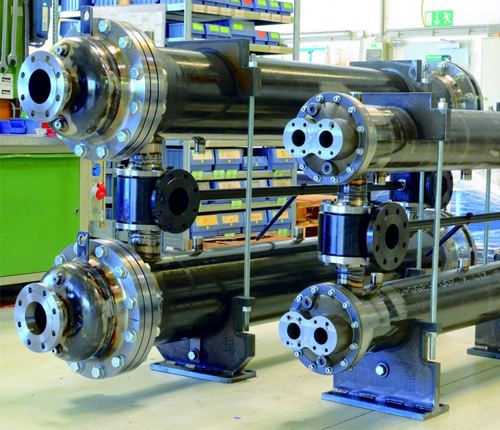

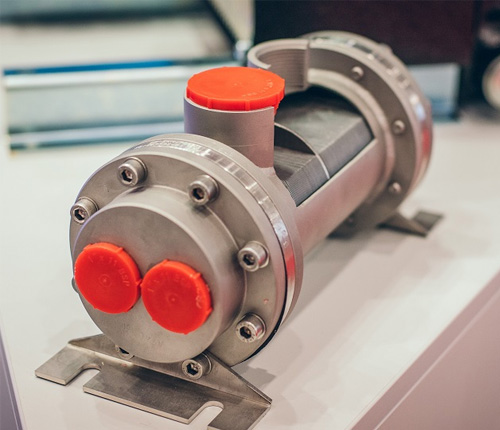

SHELL AND TUBE HEAT EXCHANGER

-

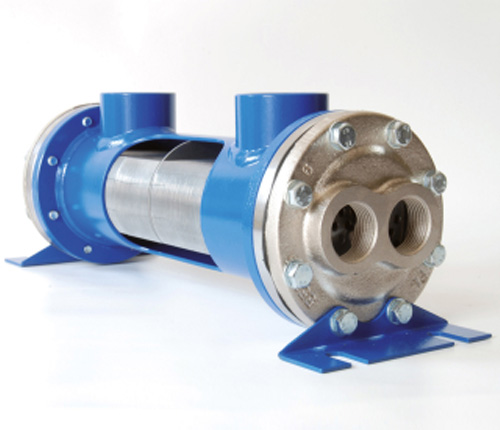

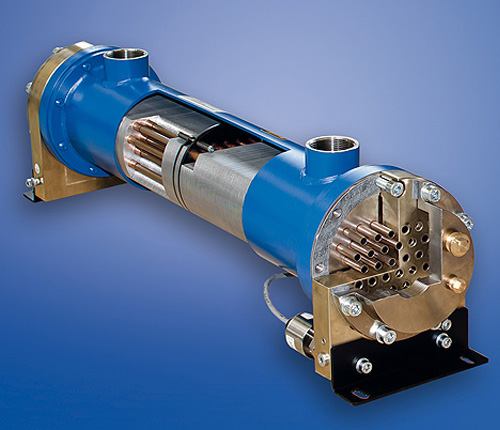

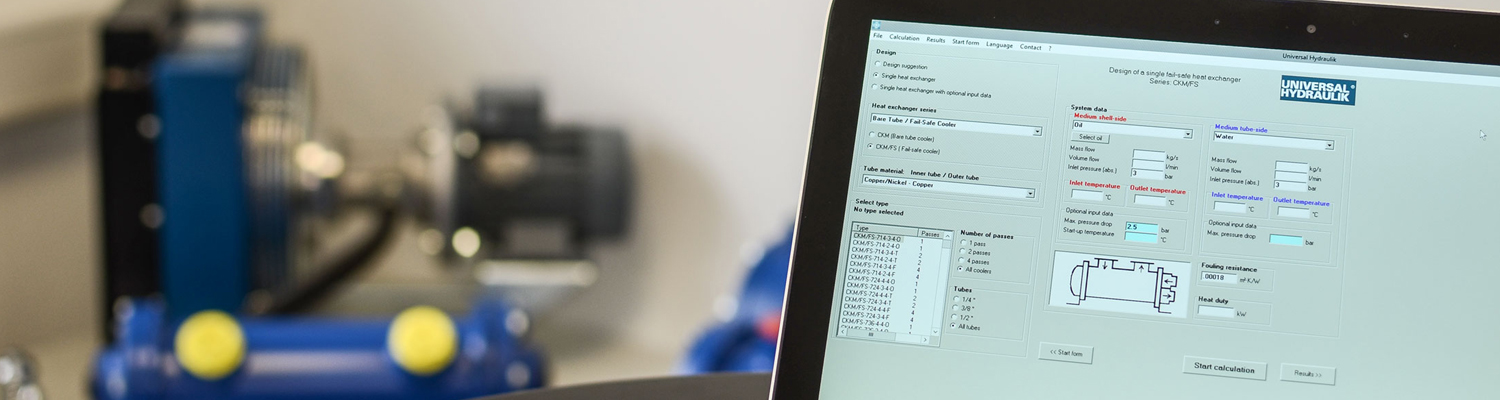

ROBUST – DURABLE – PROVEN QUALITY

Our Heat Exchangers are available as catalog products or designed per your special request. The calculation is done with precise calculation software. The drawing is available in 3-D. The products are tested up to five times during production. The cooling performance can be proofed on our own test stand.

One of the expansion tests involves subjecting the coolers to 100 bar on the waterside which puts the material under enormous stress and constitutes a test step which is without parallel elsewhere in the market.

Proved quality

Our customers are providing us constant positive feedback and are validating the high quality and reliability of our heat exchangers. PLATE HEAT EXCHANGER & ELECTRICAL OIL PRE-HEATER

SCREWED PLATE HEAT EXCHANGER

-

TL – SCREWED PLATE HEAT EXCHANGER

Despite the fact that the screwed plate heat exchanger produce high-pressure loss, they are still found in many applications.

Standard version- Screwed plate heat exchanger

- Modular system, thus great flexibility, subsequent adjustment possible by changing number of plates

- Easy to clean

BRAZED PLATE HEAT EXCHANGER

-

PWT – BRAZED PLATE HEAT EXCHANGER

Brazed plate heat exchange are most likely used for small cooling capacities. Because of the low-cost, it is not worthwhile to clean the heat exchanger at all. If it clogs, it will just be replaced.

Standard version- Brazed plate heat exchanger

- Plates and connection port in stainless steel 1.4401

ELECTRICAL OIL PRE-HEATER

-

Our EDH-Series Electrical Oil Pre-Heater

Standard Version- Heating capacity up to 90 kW

- Thermostat: Adjustable 0-90°C (except EDH-500)

- Temperature limiter: 100°C fixed (except EDH-500)

- Max. operating pressure 16 bar

- Surface loading 2W/cm²

- Voltage: 3 x 400V

- Material of housing: St-37

- Material of heating elements: Stainless Steel 1.4541 (AISI 321)

SHELL AND TUBE HEAT EXCHANGER

-

ROBUST – DURABLE – PROVEN QUALITY

Our Heat Exchangers are available as catalog products or designed per your special request. The calculation is done with precise calculation software. The drawing is available in 3-D. The products are tested up to five times during production. The cooling performance can be proofed on our own test stand.

One of the expansion tests involves subjecting the coolers to 100 bar on the waterside which puts the material under enormous stress and constitutes a test step which is without parallel elsewhere in the market.

Proved quality

Our customers are providing us constant positive feedback and are validating the high quality and reliability of our heat exchangers.

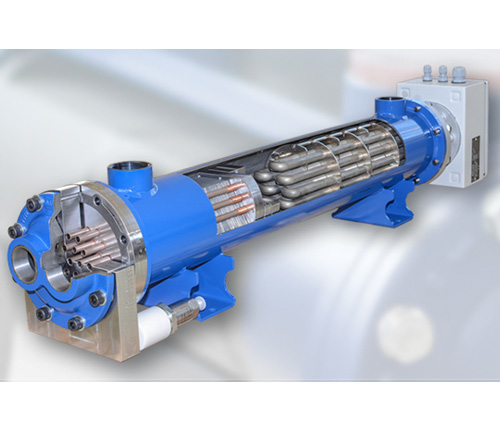

HYBRID HEAT EXCHANGER

-

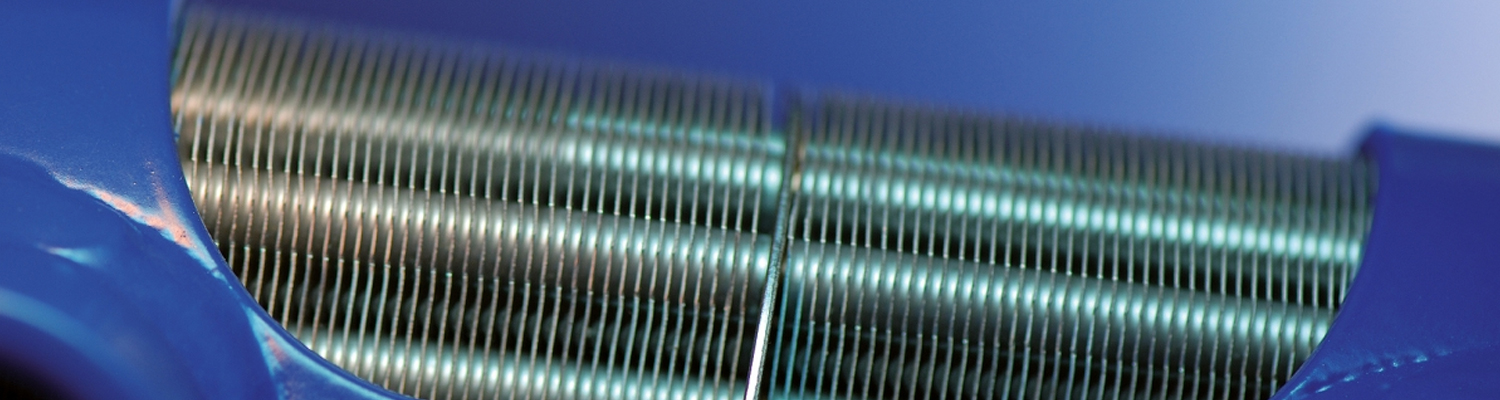

THE BEST OF BOTH WORLDS – ADVANCED QUALITY

The Hybrid Heat Exchanger produced by Universal Hydraulik combines the advantages of Shell & Tube- and Plate Heat Exchangers. A larger cooling surface through the hybrid-design and the easy to clean waterside allows us to manufacture heat exchangers in a smaller size with a better cooling capacity.

Standard version- Oil side: optimized performance by fin technology

- Water side: optimized durability due water tubes

- Small water tubes

- On-tank cooler

- Heat dissipation up to 1000 kW

- Flow rates up to 1500 l/min

- Cu-/CuNi-/SS- tubes

ASME HEAT EXCHANGER

-

ASME HEAT EXCHANGER IN HYBRID-DESIGN

The success of the model of the Hybrid Heat Exchanger is moving into new markets and gaining customers’ enthusiasm. We also provide you with a standard heat exchanger in accordance to ASME Boiler and Pressure Vessel Code: Section VIII, Division 1.

ASME Boiler and Pressure Vessel Code: Section VIII, Division 1

We calculate and build according to the latest ASME Boiler and Pressure Vessel Code: Section VIII, Division 1. Basis our Standard- or Hybrid-Heat Exchanger product lines. TEMA design possible by request.

SAFETY HEAT EXCHANGER

-

SAFETY FIRST!!!

The Safety Heat Exchanger from Universal Hydraulik is satisfying the highest quality demands for decades. Since then, it is avoiding application errors and the unintended mixing of two fluids.

Our new development (Hybrid-Safety Heat Exchanger, SCM/FS) in 2014 greatly improved performance for our customers – more affordable (costs) in terms of consistent safety.

Standard version- Version with/for double pipes

- 100% electronic monitoring

- Leak detector on request with ATEX Certificate

- Removable sealing cover for cleaning internal water pipes

SEA WATER HEAT EXCHANGER

-

SEA, AIR & SEA WATER: LEADING CAUSE OF CORROSION

The electrochemical process of corrosion is the biggest challenge of every marine application. That is the reason why we at Universal Hydraulik are choosing the most resistant materials for guaranteeing dependability and peace-of-mind.

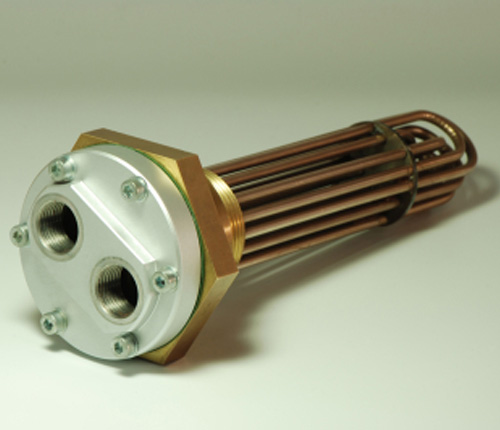

IN-TANK HEAT EXCHANGER

-

UKC-G IN TANK HEAT EXCHANGER

The UKC (cooling cartridge of UKM) is a possible solution for your cooling problem, if you are interested in maintaining the existing shell. With this, we can develop a compact design with no separate heat exchanger. We are happy to find a custom solution.

The UKC-G from Universal Hydraulik was developed for an in-tank solution to gear boxes. It can be easily attached to existing screw threads and offers a cost-effective cooling solution.

Standard version- Space saving

- Water side: optimized durability due water tubes

- Screw in cooler

BARE TUBE HEAT EXCHANGER

-

DESPITE HYBRID-DESIGN, AN IMPORTANT ALTERNATIVE

Depending on the customer’s application, a smooth pipe shell & tube heat exchanger from Universal Hydraulik is the better choice. High viscosities, or fluids with small particles, may clog the fins used for the hybrid-design.CKM-bare tube heat exchanger

With the same quality, Universal Hydraulik is manufacturing bare tube heat exchanger for the past several years. We can assist you with the decision if either a space-saving hybrid or a bare tube pipe heat exchanger is the best for your application.

Standard version- Water side: optimized durability due water tubes

- Small or large water tubes

- On-tank cooler

- Heat dissipation up to 900 kW

- Flow rates up to 2000 l/min

- Cu-/CuNi-/SS- tubes

STAINLESS STEEL HEAT EXCHANGER

-

THE ART OF WELDING STAINLESS STEEL

Stainless steel is non-corrosive and can tolerate external influences like lime, water, bacteria and dirt. Due to his low melting point and its stronger expansions after contact with heat, welding stainless steel needs highly-experienced workers with much experience.

EXHAUST GAS RECIRCULATION

-

ENERGY EFFICIENCY IS MORE IMPORTANT.

Energy saving and energy recovery are becoming more important today’s mechanical engineers. Universal Hydraulik contributes its part to the trend and is supplying in-tank exhaust gas recirculation heat exchanger (EGR) for MAN trucks.

GEAR BOX OIL COOLER – IN - TANK

- Standard cooler cartridge mounted inside of the gear box. It could be also a hybrid cooler cartridge or our standard cooler (UKC-G-series - screwed-in solution).

COMPRESSED-AIR COOLER

-

- Reduces coolers size by 50% !!

- Reduces air side pressure drop to 1/3 !!

- Individuelles design pro Kompressortyp

- Individual design per compressor size

HIGH-PRESSURE COOLER

-

HIGH PRESSURE DESIGNS ACCORDING TO INDIVIDUAL NEEDS

- Max. 50 - 100 - 500 bar possible

- Welded tubes

- Fully welded shell

SPECIAL SOLUTIONS

-

ADVANCED QUALITY, BECAUSE ONLY QUALITY REMAINS ON THE MARKET

Customized Designs

Universal Hydraulik GmbH is especially known for customized solutions with heat exchangers or cooling systems.

Customized solutions for heat exchangers is the challenge of Universal Hydraulik GmbH, when it comes to variance from the standard catalogue. One option is to use only components of the complete product, e.g. the customer provides the housing of the heat exchanger.

WRV - WATER REGULATING VALVE (TEMPERATURE CONTROLLED)

-

Function

The sensor internal pressure will increase as the temperature rises. This increase in pressure is transferred to the valve cone which then opens to allow the flow. The valves are pressure-relieved in such a way that any change in water pressure will not influence the valve setting. Apart from that, the valves operate independently from the ambient temperature. The universal filling ensures perfect valve operation, irrespective of whether or not the valve housing and corrugated pipe are warmer or colder than the sensor.

Cooler-Heater Unit

-

First heat up, then cool down - a new product of Industry 4.0.

Discover the new cooler – heater unit, the combination of hybrid - failsafe cooler and electrical oil pre-heater, that allows the temperature of the medium to be controlled in one device! It is not only multifunctional and ultra-compact, but also optional 100% failsafe!

- high pressure (500bar)

- high temperature

- compressor cooling

- etc.

Double Heat Exchangers with transfer valve (optional ASME etc.)

- For applications where uninterrupted operation is required, two heat exchangers with transfer valve are suitable. The cleaning or replacement of one heat exchanger can therefore be carried out without any problems at any time.

Additional requests such as bypasses, soundproofing hoods and transfer valve are possible, as are special voltages or special welds, such as ASME.

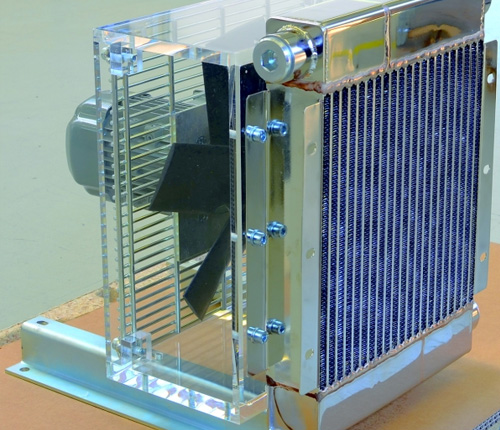

OIL AIR COOLER

OIL AIR HEAT EXCHANGER SERIES

-

OUR TASK IS 100% QUALITY

Every oil air cooler passes several test stands before delivery to keep cost-intensive quality defects to a minimum.

Standard version- Elektric motor

PARTIAL-FLOW-COOLING UNIT

-

HIGH QUALITY STANDARDS ARE OUR TASK

Partial-flow-cooling Units exist in many different models and are individually adjustable.

Standard version- Partial-flow-cooling unit

OIL-AIR COOLERS (MOBILE APPLICATIONS)

-

YOU MOVE, WE COOL

Hydraulic as part of mobile applications are often required. You will find our hydraulic as part of mobile oil/air coolers, municipal vehicles, concrete mixers and construction/agriculture machines.

Standard Version- Drive: 12 V-, 24 V- Motor

- Basis LKM Series

- individual designs of sizes and drives

SPECIAL OIL-AIR COOLER

-

OIL-AIR COOLER (LKI)

- Elektroncal control

- High-Temperature application

- Cooler and Housing in stainless steel

EQUIPMENT

-

TR-12 K TEMPERATURE CAPILLARY PIPE CONTROLLERS

Technical specifications:

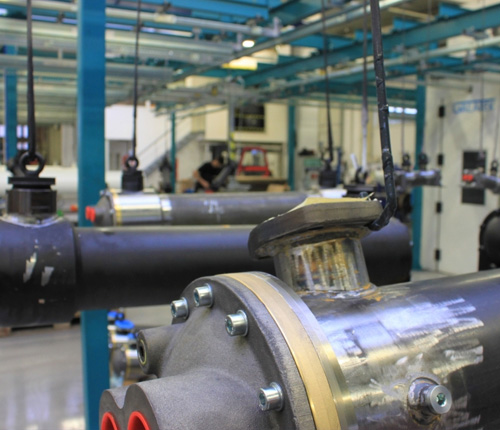

TEST STANDS

-

TRUST IS GOOD, CONTROL IS BETTER

We manufacture test benches for analysis, series and endurance tests, bursting pressure tests, as well as fatigue test benches. Areas of application in the automotive industry are gearbox test benches, engine and transmission mechatronics, ABS irritants as well as tire, wheel, shock-absorber and hose test bench Fields of application in industry are hydraulic, pneumatic and leakage test stands.

Turnkey concept

We supply the test benches from the planning up to implementation on customer premise worldwide.

Long standing experience

Universal Hydraulik designed and built a large number of test stands for the entire industry since thirty years.

i.e. test benches:- leak/pressure tightness

- for pulse duration and burst pressure

- for the analyses of mechatronical systems

- for series of mechatronical systems

- test benches for tyre loads

- (also mobile to be able to test samples on real tracks)

- for pressure difference

- or arrangements for maintaining temperature in high-precision processes test stands for hydraulic components and systems

HYDRAULIC COMPONENTS

PUMPS

-

SCREW PUMPS

Screw pumps for industrial use series SSP (low pressure) and HSSP (high pressure)

Service

For all pumps Universal Hydraulik guarantee maintenance and repair.

VANE PUMPS

-

FOR MORE THAN THIRTY YEARS, UNIVERSAL HYDRAULIK IS THE EUROPEAN-DISTRIBUTOR OF RACINE/ BOSCH REXROTH PRODUCTS.

Universal Hydraulik have been the distributor for RACINE / BOSCH products throughout Europe for the last ten years. This includes, for example, self-controlling vane pumps (up to 210 bar) types

This type of pump, first developed by Racine in 1925 (since 1988 by BOSCH / RACINE), has been further developed and continues to set new standards worldwide.

Other RACINE / BOSCH types: gear pumps, radial and axial piston pumps

CYLINDER

-

HYDRAULIC CYLINDER

(UHD, UHSZ 100/ 160, UHSZ 250) In accordance with the currently valid ISO and DIN regulations.

In addition, we furnish cylinders up to 250 bar. In line with customer requirements, we also develop special cylinders according to individual specifications.

All cylinder versions can be produced as servo actuator with/without an integrated position measuring system.

CONTROL BLOCKS

-

ASSEMBLING OF CONTROL BLOCKS AS ONE COMPONENT

We assemble your control blocks and supply similar assemblies for your needs.

Industries & Applications

PLASTICS MACHINES

-

HIGH PRODUCTIVITY AND QUALITY ARE THE DEMANDS MADE BY MODERN PLASTICS-MACHINE TECHNOLOGY ON ITS PRODUCTS.

The hydraulic control of plastics machines is a domain inhabited by Universal Hydraulik GmbH.

Only products of the highest standard are used in order to be able to meet the constantly growing demands for improved product quality and evermore economical working processes.

TOOL MACHINES

-

FROM THE SMALLEST TO THE LARGEST APPLICATION

Hydraulic drive systems and components have traditionally been regarded as constituent parts of metal-cutting machine tools. First and foremost, Universal Hydraulik has been developing end-to-end system solutions for decades for a plurality of applications in the sector, e.g.:- Machining centres

- Transfer machines

- Turning centres

- Drilling machines

- Milling machines

- Grinding machines

- Honing machines Gear cutting machines

ROBOTIC

-

INNOVATIVE, A QUICK GROWING MARKET AND RAPID TECHNICAL DEVELOPMENTS

The Robotic Industry was growing constantly quicker and quicker and it did definitely not reach its all time high. For today’s manufactures, automated robots are indispensable.

Hydraulic is indispensable

This fast growing market needs quality, that is the reason why they often chose Universal Hydraulik as their partner for hydraulic solutions in robotic.

TEXTILE MACHINERY

-

RELIABLE PARTNER

Textile machines make a number of different products such as for woven and knitted fabrics, carpeting, and pile goods. In addition to clothing and automotive furnishings, there is increasing activity in industrial and medical textiles. Faced with this wide spectrum of products, machine manufacturers are required to develop solutions geared to specific applications in many cases.

GEAR MANUFACTURING

COMPRESSOR CONSTRUCTION

-

DURABLE & RELIABLE

Stationary screw compressors need long-lasting reliable products for their oil cooling and forced air cooling systems. Universal Hydraulik supplies standard and made-to-measure products for batch production in oil-free and oil-lubricated applications and for compressed air conditioning. They are also suitable for use in marine applications.

RUBBER TIRE INDUSTRY

-

LONG-ESTABLISHED EXPERIENCE

Whether it be vulcanised rubber compound technology or natural rubber technology, Universal Hydraulik has all products required by this sector: heat exchangers, pumps and end-to-end system solutions. Our products might, for example, be built into the following:- Hydraulic heating presses for tyre manufacture

- Mixers

- Mixing mills

- Strip cutters

- Twin screw extruders

- Single screw extrudersTyre construction machines

OFFSHORE INSTALLATIONS

-

IN ALL THE WORLD’S OCEANS – UNIVERSAL HYDRAULIK IN INVOLVED IN SHIPBUILDING AND OFF-SHORE APPLICATIONS

Modern-day seafaring is unimaginable without hydraulics, with essential functions and components on ships being hydraulically driven.

The harsh and inclement environment places particularly high demands on technology in terms of stability, reliability and durability. Nothing is better equipped to meet these expectations than the principle of hydraulics.

TEST STANDS

-

TRUST IS GOOD; CONTROL IS BETTER.

There is a wide range of different test stands. They analyses parts, measure series production, and test the burst pressure of parts. We produce test stands in the automotive sector for gear boxes, engine-and-gear box mechatronics, ABS-tests, wheels and shock absorbers. We also produce test stands in the industrial sector for hydraulic, pneumatic and leakage tests.

OIL & GAS

-

DEMAND IS INCREASING

Despite fluctuations in the market and renewable energies on the rise, we still see an increase in demand for fossil fuels constantly. Newest reports of the International Energy Agency showed that the age of fossil fuels is by no means at its ends.

oil & gas market in transformation

In the oil & gas market, manufacturers share, despite their area of specialty, several challenges: complicated processes preceded by long supply chains. Managing and monitoring those applications will be more efficient and predictable due to the huge amount of data that can be managed.

POWER PLANTS & HYDROELECTRIC POWER STATIONS

-

A longstanding and green method of renewable energy are hydroelectric power stations. With Hydraulic Solutions and cooling filter units from Universal Hydraulik, we guarantee safe operation of your plant.

Even though the trend is moving away from power plants, they are still indispensable for our energy generation. As a component manufacturer for heat exchanger, we are able to supply you with high-efficiency shell & tube heat exchangers. Our hybrid-design contains a larger surface on the tube side to increase efficiency.

WASTE DISPOSAL AND RECYCLING

-

UTILIZATION AND RECYCLING FOR THE ENVIRONMENT

The recycling market is a fast-moving business with many different materials and difficult conditions. For the efficient use of a baling press and the cutting of hard material, high-performance, precise components are indispensable.

Universal Hydraulik is supporting our customers with our oil air heat exchangers or our oil air partial-flow-cooling units, equipped with special filter mats for dusty environments. For water-cooled applications, we also developed robust shell & tube heat exchanger solutions, too.

MOBILE HYDRAULICS

-

CONSTRUCTION MACHINERY HAS ACCOUNTED FOR AN EVER-INCREASING PROPORTION OF OUR BUSINESS IN RECENT YEARS.

These applications depend on powerful heat exchangers boasting excellent standards of reliability and efficiency and with the strength and capability to endure heavy duty.

PAPER MACHINE

-

SAFETY FIRST

To ensure a flawless paper production, you need robust applications combined with absolute precision.

Universal Hydraulik is supporting the process safety with our safety heat exchanger, which is suitable with Industry 4.0, because of 100% electronic monitoring and provision for a default guarantee.

MINING

-

UNIVERSAL HYDRAULIK IS YOUR PARTNER

Whatever your plans and projects, whether it be mining to extract raw materials, tunneling, or extending pits, Universal Hydraulik is aware of the requirements in your industry and can supply tailor-made cooling systems for your plants and vehicles.

We know the demands.

The heat exchangers developed by Universal Hydraulik can adapt to the harsh service conditions below ground. We provide special materials, coatings, certificates of acceptance for your working conditions, and particularly robust products.

PRESS INDUSTRY

-

FORMING, CUTTING, BENDING – SHAPING METALS

Universal Hydraulik meets extreme demands in the press industry in terms of flow rates and cooling efficiency for the full range of presses, including press brakes and drawing presses.

Our objective is to select the ideal components from a wide range of standard products or to develop a customized solution which is designed to optimize the specific pressing application in terms of engineering and economic efficiency.

PRINTING MACHINES

- Universal Hydraulik supplies heat exchangers and pumps for this sector of industry. Our products cater to printing or processing requirements and range from cooling, filtering, and water regulation systems right through to motor pump drive systems for printing machines.

LIFT

-

THE HYDRAULIC LIFT LIVES ON.

Despite fierce competition, its use is still widespread and justifies its existence in family homes, large office buildings, and in the transportation of goods. The longevity of the hydraulic lift and its low maintenance requirements cannot be matched by cable lifts.

Universal Hydraulik has long been supplying a proven and optimized standard product for cooling hydraulic lifts and monitoring their temperature.

HOISTING AND CONVEYING TECHNOLOGY

-

MOVING HEAVY LOADS EASILY

Universal Hydraulik supplies customizes hydraulic units in the form of compact hydraulic drive assemblies as well as hydraulic cylinders with integrated position measuring systems for lifting functions on aerial work, platforms, or machines for bulk storage depots and blending beds.

We can solve your cooling problems and are particularly mindful of the need to factor in the high level of pollution in the operational environment.

CHEMICAL

-

THERE IS A WIDE AND DIVERSE RANGE OF REQUIREMENTS AND APPLICATIONS IN THE CHEMICAL INDUSTRY.

Universal Hydraulik supplies customized hydraulic units in the form of compact hydraulic drive assemblies as well as hydraulic systems which can be used in potentially explosive environments.

Furthermore, we supply a newly-developed hydraulic cylinder which can be used as a hydraulic/pneumatic closure system for pressure vessels and centrifuges of all kinds.

FOOD & BEVERAGE

-

HIGH QUALITY AND CLEAN PRODUCTION FOR THE FOOD INDUSTRY

Food industry customers pay increasingly more attention towards quality foods. For the optimized and hygienic processes of the products, the manufactures have high demands for the required technology. A perfectly-aligned cooling system for the medias is crucial and important for the following handling process.