Linde Hydraulics

Videos

Loading the player ...

- Offer Profile

- Linde Hydraulics

founded in 1904, Germany develops, produces and globally supply modular drive systems consisting of hydraulics, power transmissions and electronics. As a leading technology provider in the field of high pressure hydraulics, the systems produced by us set the standard in terms of significantly reducing fuel consumption and CO2 emissions.

Our product range comprises hydraulic pumps and motors, valves, electronic controls and peripheral devices. We are a development partner and supplier of a number of reputable manufacturers of mobile work machinery, including construction, mining, agricultural, forestry and municipal utility machines, as well as manufacturers of industrial machinery.

Product Portfolio

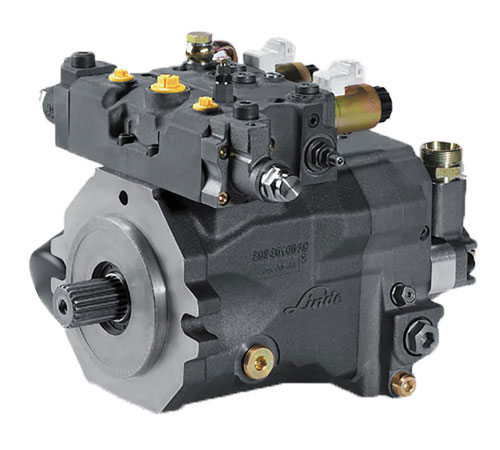

PUMPS

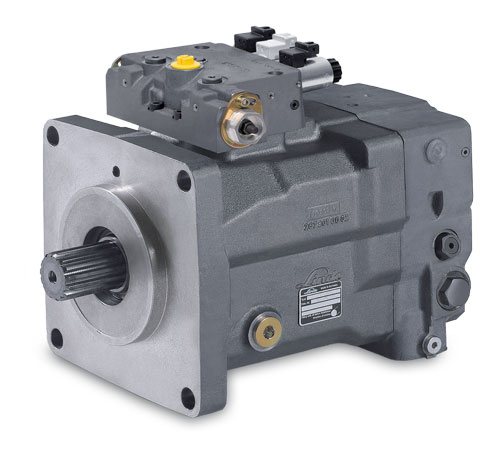

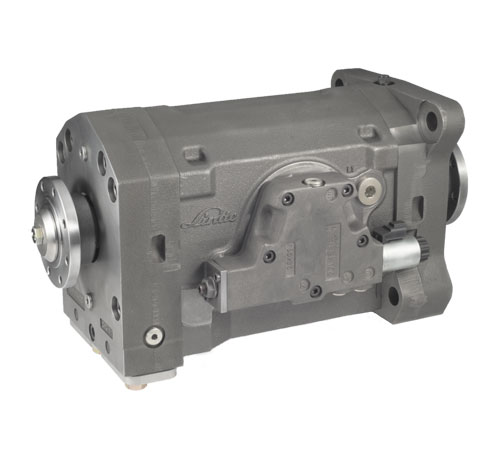

HPV-02

- Displacement size from 55 to 280 cc

Variable displacement pumps for closed circuit operation

All the controls used in the Series 02 are based on a load-independent control mechanism. No matter which control is used: identical commands always result in the same response in the machine. The sensitive and precise machine control makes work easier and increases productivity. Various customer system options for mechanical, hydraulic and electric input solutions are available. Further special regulating features like torque control and pressure cut-off are also available. The reliable control of the pump can easily be integrated into any kind of vehicle management control system.

Advantages- compact design

- high power density

- dynamic response

- high reliability

- long service life

- noise-optimized

- precise and load-independent

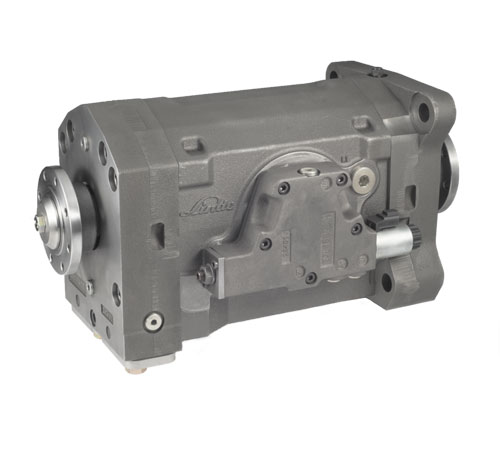

HPR-02

- Displacement size from 55 to 165D cc

Self-regulating pump for open circuit operation

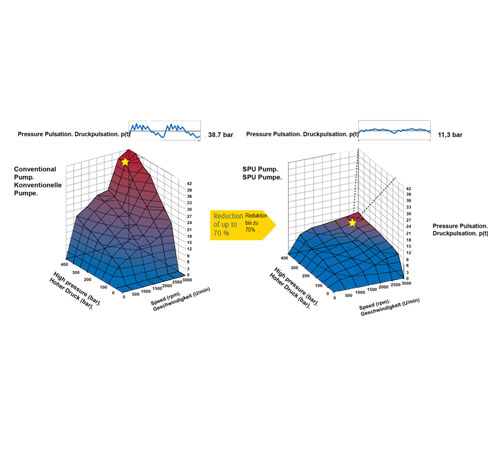

Legal emission regulations force manufacturers of mobile machinery to optimize the noise emission of their products. Since secondary measures tend to be expensive and less efficient Linde Hydraulics prefers to fight the noise where it is generated: by optimally connecting an additional volume directly next to the commutation of the HPR-02 pump, Linde Hydraulics invented the SPU silencer. The adaptive SPU reduces pressure pulsations in the regulating pump over the entire range of operation – without loss of power.

Advantages- optimum interaction with Linde LSC control valves and LinTronic

- energy saving operation by ‘flow on demand’-control

- dynamic response

- excellent suction up to rated speed

- noise optimization over the whole range of operation

- compact design

- high power density

- high reliability

- long working life

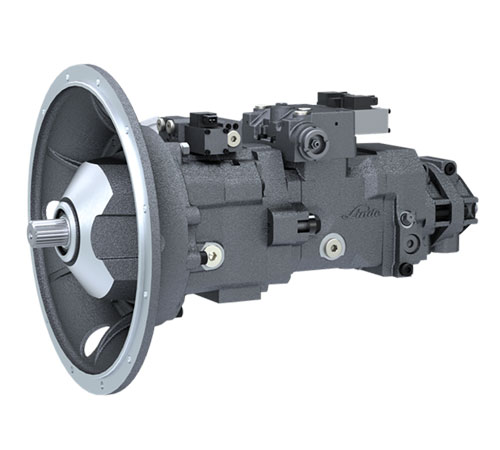

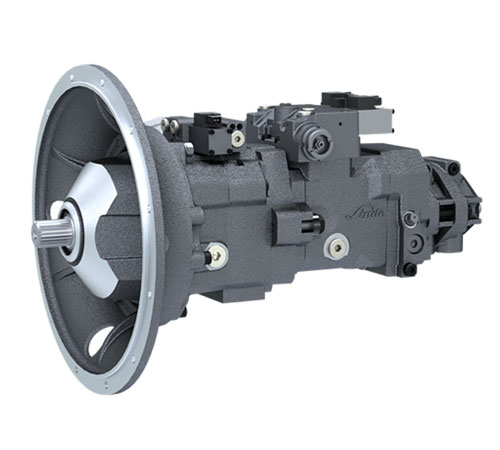

K-02

- Integrated Pump / Motor Drive Units

Stepless for optimum performance

Precise transmission control for simple operation without interrupting tractive effort. From stand still to maximum speed. Stepless. Together with the customer Linde Hydraulics defines new standards in technology. Advanced modular drive technology, realised in hydrostatic variators for variable speed transmission, form the core of power split gearboxes. Compact units with a hollow shaft are available for mounting to conventional gearboxes in smaller machines. These compact units are used as fully hydrostatic systems with PTO drive. With customer-specific developments, Linde Hydraulics supports the change from power shift to continuous variable transmission technology.

Advantages- accurate control of volume flow

- exact gear shift without interrupting tractive effort

- dynamic response

- standstill control

- sensitive start-upprecise crawling speed

- high efficiency

- low fuel consumption over entire operating range

- compact design

- high reliability

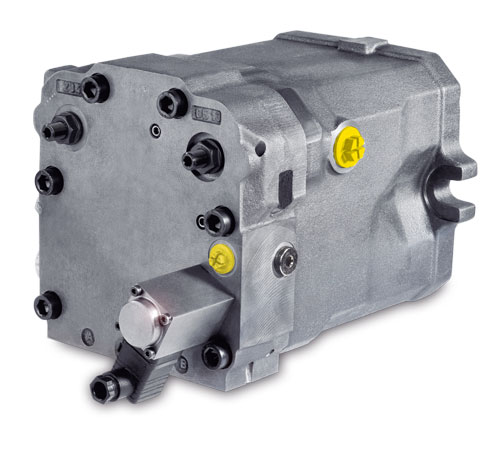

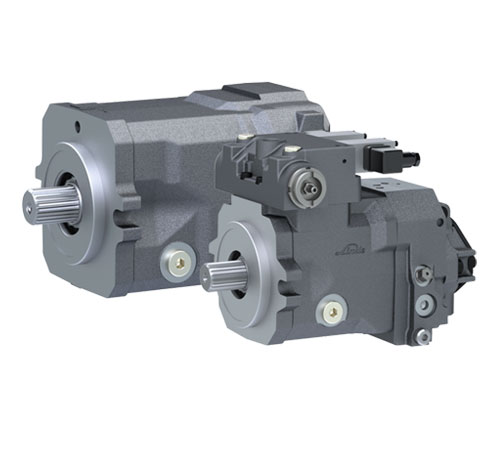

Multiple Units

- Displacement size from 55 to 280 cc per unit

Double, tandem and multiple pumps for open and closed loop operation

Set up by combining our variable displacement pumps and self-regulating pumps. They can either supply larger volume flows or feed different circuits.

The rated size and the type of the pump for open or closed circuits are variable. The sequential arrangement is determined by the maximum torque which can be transferred.

Due to their swashplate design our motors can also be combined to form double and tandem motors.

Advantages

Double, tandem and multiple pumps- only one drive shaft required

- no splitter box required for the pumps

- compact design

- individual control of each single pump

- no adverse influence on functionality of the single rotating groups

- advantages such as high dynamics and precise control remain in full

MOTORS

HMV-02

- Displacement size from 55 to 280 cc

Variable discplacement motors for open and closed circuit operation

Standard hydraulic motors at low speeds in their starting phase cannot generate the necessary torque. Therefore, the power of the fast spinning hydraulic motors has to be reduced by means of several step gearboxes down to the speed needed on the wheel. Somewhat higher windage losses and poorer mechanical efficiency are benevolently accepted in this context. Quite the opposite holds true for the motors by Linde Hydraulics: The motors of the Series 02 are capable of transmitting the required torque even at low speed and make it possible to start smoothly and sensitively.

Advantages- jerk-free low speed

- high starting torque

- large conversion range

- zero angle possible

- dynamic response

- PTO through-drive motor

- compact design

- high power density

- high reliability

- long service life

Multiple Units

- Displacement size from 55 to 280 cc per unit

Double, tandem and multiple pumps for open and closed loop operation

Set up by combining our variable displacement pumps and self-regulating pumps. They can either supply larger volume flows or feed different circuits.

The rated size and the type of the pump for open or closed circuits are variable. The sequential arrangement is determined by the maximum torque which can be transferred.

Due to their swashplate design our motors can also be combined to form double and tandem motors.

Advantages

Double, tandem and multiple pumps- only one drive shaft required

- no splitter box required for the pumps

- compact design

- individual control of each single pump

- no adverse influence on functionality of the single rotating groups

- advantages such as high dynamics and precise control remain in full

HMV-02 D

- Discplacement sizes 105D and 165D cc

Variable displacement double motor for open and closed circuit operation

This new axial piston motor has been developed by Linde Hydraulics to achieve maximum speeds higher than conventional swash plate designs. Additionally, a large displacement volume in a compact design means wider transmission speed ranges, normally achieved with modular transmissions, are possible. The HMV-02 D is about 30 % lighter than a motor combined with transfer gear box, and has a smaller footprint. The increased power density was achieved through the innovative design of two in-line swash plate rotating groups in a "face-to-face" arrangement. As a result, only one control is needed to adjust the displacement volume of the two motors. The inner lateral forces are compensated so that only one drive shaft and two (instead of four) bearings are required for both rotating groups.

Advantages- High power density

- High starting torque

- High speed capability

- Compact dimensions

- Low weight

- Increased average efficiency

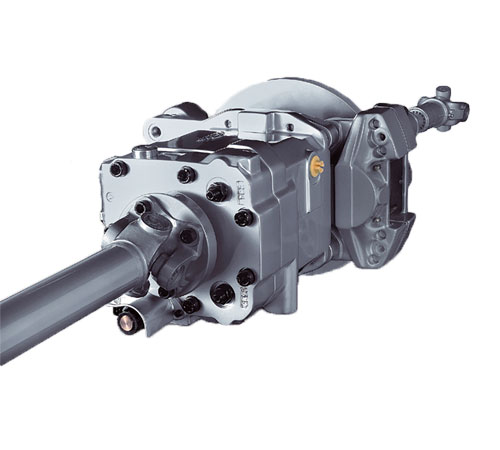

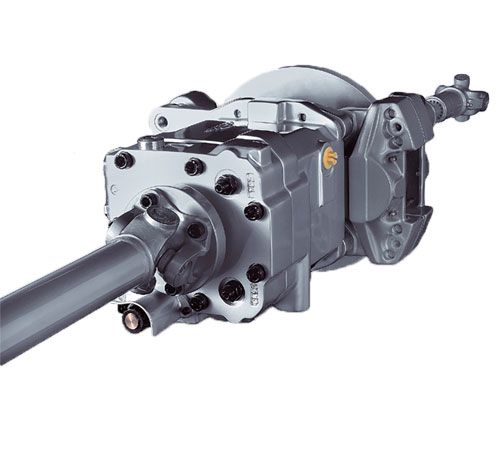

HMV-02 PTO

- Displacement size from 105 -165D cc

PTO - Through-drive motor for open and closed circuit operation

In conventional drives the torque of the hydraulic motor can be transmitted to the cardan shaft only by means of a dropbox. For further optimization of the drive train Linde Hydraulics developed the PTO Through-Drive Motor. Based on the standard hydraulic motor of the Series 02 with just one shaft end, the PTO Through-Drive Motor offers two shaft ends to transmit the torque. Hence the machine designer can conceive the hydraulic motor to fit directly and immediately into the drive train thus saving mounting space. The dropbox usually needed in a conventional propulsion drive can be saved. This reduces both noise emission and fabrication cost of the entire vehicle while overall efficiency increases.

As all Linde motors they are able to provide the required torque even at low speeds and make it possible to start smoothly and sensitively.Therefore, additional gear ratios for rpm reduction are not necessary. This reduces the amout of parts going into the component and also increases the overall mechanical efficiency, minimizes windage losses as well as the noize level of the machine.

The HMV-02D double axial piston hydraulic motor is with a shaft flange also PTO-capable. Advantages- Two shaft-ends

- Drop-box eliminated

- Smaller cooler

- Simplified drive line design (components, part numbers)

- Fits directly into the drive line

- No interruption of tractive effort, stepless driving

- Increased tractive effort / direct drive

- Improved transmission efficiency

- Lower overall costLess fuel consumption

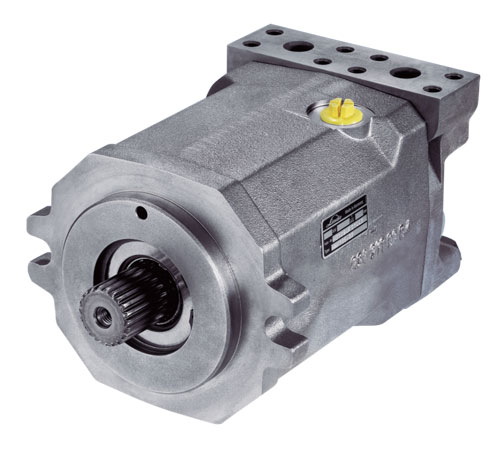

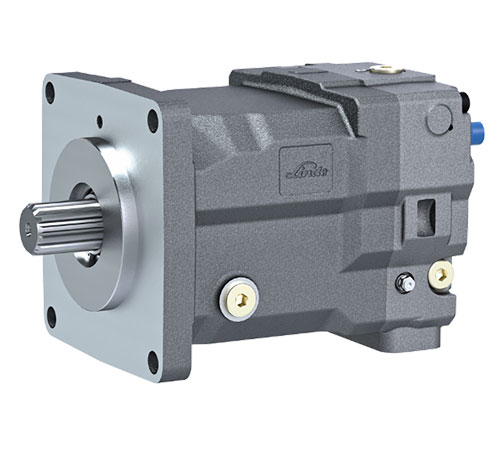

HMF-02/HMA-02

- Displacement size from 35 to 135 cc

Fixed displacement motors for open and closed circuits

Series 02 motors from Linde Hydraulics are different from those common in the market. They are able to provide the required torque even at low speeds and make it possible to start smoothly and sensitively. Therefore, additional gear ratios for rpm reduction are not necessary. This reduces the amout of parts going into the component and also increases the overall mechanical efficiency, minimizes windage losses as well as the noize level of the machine.

Advantages- steady low speed

- high starting torque

- compact design

- high power density

- high reliability

- long service life

CMV

- Displacement size from 60 to 215 cc

Variable displacement bent axis motors for closed and open loops

With the next generation of the bent axis motors, Linde Hydraulics expands its customer oriented portfolio of highquality components for hydraulic systems. Due to their standardized interfaces, e.g. the plug-in flange according to ISO, the CMV and CMF fit a high variety of applications, without the need of adaptors. The motors enable a more cost effective operation of the respective applications thanks to low windage losses and lighter weight.

Advantages- high power density

- high speedslow wind

- age losses

CMF

- Displacement size 80 cc

Fixed displacement bent axis motors for open and closed circuits

With the next generation of the bent axis motors, Linde Hydraulics expands its customer oriented portfolio of high-quality components for hydraulic systems. The fixed displacement motor CMF is characterized by its high external load and speed capacity. Due to its standardized interfaces, e.g. the plug-in flange according to ISO, the CMF fits a high variety of applications, without the need of adaptors. Low windage losses in combination with the low weight of the motor support the cost-effective operation of the application.

Advantages- high power density

- high speedslow wind

- age losses

CVT

K-02

- Integrated Pump / Motor Drive Units

Stepless for optimum performance

Precise transmission control for simple operation without interrupting tractive effort. From stand still to maximum speed. Stepless. Together with the customer Linde Hydraulics defines new standards in technology. Advanced modular drive technology, realised in hydrostatic variators for variable speed transmission, form the core of power split gearboxes. Compact units with a hollow shaft are available for mounting to conventional gearboxes in smaller machines. These compact units are used as fully hydrostatic systems with PTO drive. With customer-specific developments, Linde Hydraulics supports the change from power shift to continuous variable transmission technology.

Advantages- accurate control of volume flow

- exact gear shift without interrupting tractive effort

- dynamic response

- standstill control

- sensitive start-upprecise crawling speed

- high efficiency

- low fuel consumption over entire operating range

- compact design

- high reliability

VALVES

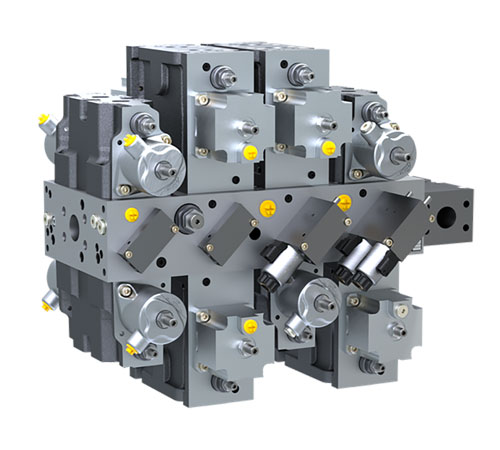

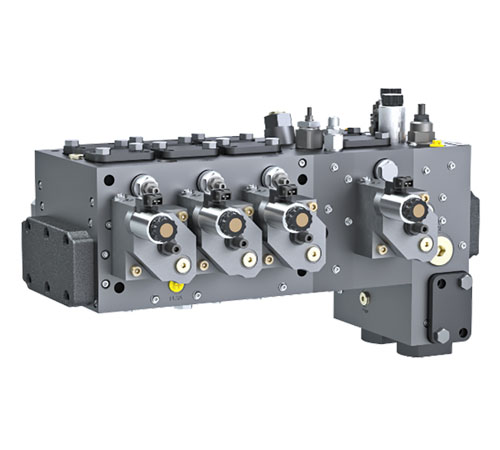

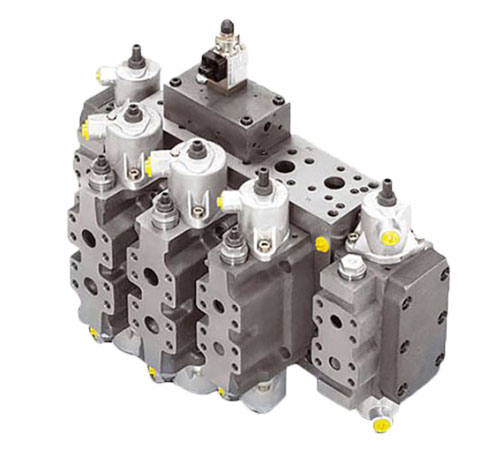

VT Modular

- Nominal sizes 25 and 30

Main control valve for load sensing systems in modular design

Manifold valve plates of series VT modular are made up of individual components of a modular building block system. This is why manifold valve plates can be configured to optimally match any application with one up to eight actuators.

Advantages- simple configuration

- quick availability

- modular design for the configuration of valve plates for 1-8 actuators

- follows up to 600 l/min per actuator

- hydraulic or electric piloting with identical machine response

- low warehouse costs and high serviceability due to high proportion of identical parts for various manifold valve plate configurations

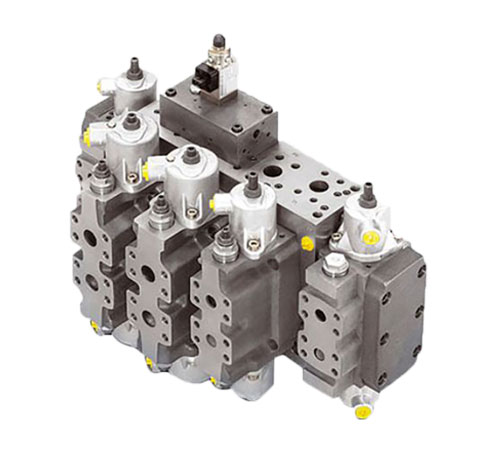

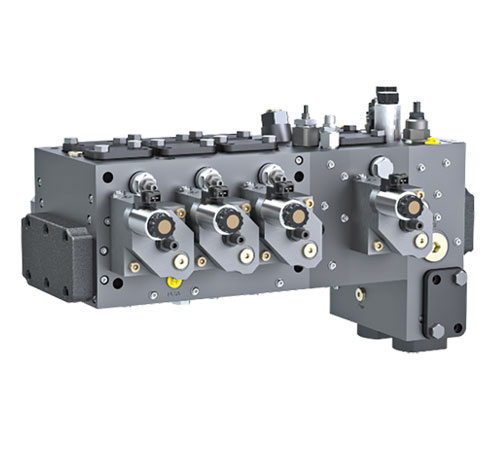

Monoblock

- Nominal sizes 30, 25 and 18

Main control valve for load sensing systems in monoblock design

Three directional control valves in a common housing form the base of the manifold valve plate in monoblock design. This results in the most compact package.

Design characteristics

basic block: three directional control valves of identical nominal size in one cast housingdesigned for the Linde Synchron Control (LSC)-Load Sensing Systemnominal sizes 30, 25 and 18flows up to 600 l/min (size 30)broad dimensioned diameters and flow-optimized design of the supply channelsextendable with directional control valves in sandwich design, in identical or differing nominal sizepressure cut-off and additional functions integrated in connection platespecial functions via intermediate platesoptionally with hydraulic or electric piloting

Linde Synchron Control (LSC)

- Load sensing directional control valve

Intelligent oil distribution

LSC stands for high handling performance due to load-independent and sensitive machine conduct. Fast and direct.

The Linde Synchron Control System, in open loop circuits, converts the commands of the machine driver into direct signals to the actuators. The easy control of all components supports efficient fatigue-free working. Simultaneous load-independent movements and a pump control ”on demand” are preconditions for fast working cycles with at the same time low operation cost. Safety and optimum exploitation of the machine are, apart from power regulation and high pressure relief, provided by the optional priority selection. Even with synchronous control of several functions the priority mode guarantees preferential operation of predominant actuators.

Advantages- excellent control with all flows

- load independent

- precision metering

- dynamic response for fast working cycles

- energy saving

- integral

- simple sensitive operation

- high reliability

ELECTRONICS

iCon®

- Electronic control unit

Electronic control unit for open and closed circuit operations

Linde electronic control units of the iCon series feature high mechanic and electric robustness.

Core components are a function controller and a safety control. Due to the redundant design, the unit can provide safety functions up to performance level d (DIN EN ISO 13849-1) and thus is able to meet global legal standards for on-road machinery. iCon controls are used individually or combined, for hydraulic and electric drives, as well as combinations of both. Additionally to the drive components, the combustion engine, as well as components such as sensors, joysticks and pedals can be integrated in the control system. Upon delivery, the control is preconfigured with the desired functions, machine characteristics and vehicle data. Single parameters can be configured easily and without programming know-how via the diagnosis software LinDiag and iDIAG. The control can thus be adapted to different power-classes and equipment of a machine or to comply with the specific legal requirements of different countries.

Advantages- optimum cooperation with hydraulic Series 02 components and electric drive components from Linde

- high availability and reliability

- advanced safety level due to parallel safety controller and redundant architecture

- complete drive train management by just one electronic control unit with additional definable digital and proportional inputs and outputs

- individually adaptable machine behaviour

- CAN bus

- easy parameterization and diagnosis own diagnostic tool (LinDiag, iDIAG)

Sensors

- Advantages of the CAN-Bus technology

LinTronic

Electronic controls of the LinTronic Program take advantage of the most modern CAN-Bus technology. In conjunction with Linde hydraulic components and peripheral equipment the LINC electronic control units offer an optimum vehicle management in mobile hydraulics for the most diversified fields of application. By choosing economical modes of operation and increased user-friendliness they provide better exploitation of performance and at the same time reduce emissions.

Potentiometer CEH 05- redundant potentiometer for mounting on MMi devices, with return spring, stabilized supply voltage 5 V–15 V.

Speed Sensor CEH 10- speed sensor for electric motor, gearbox and axle, two channels for detection of rotational direction, hall sensor up to 15 kHz.

Pressure sensor CEH 50- for high pressure detection, pressure range 0-600 bar, analogue output signal 0.5V - 4.5V, stabilized supply voltage 10V - 32V or 5V.

Swash Angle Sensor CEH 07- linear Hall-effect angle sensor with spring reset force for HPV-02.

Speed Sensor CEH-11- passive, inductive speed sensor with two-port connector for measuring the diesel speed.

Temperature sensor CEH-08- single channel temperature sensor ins NTC, KTY or PT1000 design for measuring the temperature at Linde’s electric drives.

Solenoid CEA-2x- 37mm-type solenoid in proportional or on/off version. For electromechanical valve control of pumps, motors, proportional valves and directional control valves. Magnetic force up to 55N.

LinDiag®

- Software for set up and diagnostics.

Modern machines benefit from the advantages provided by an intelligent electronic control: Increased comfort, machine variants realised by software instead of differing components and a further reduction of fuel consumption and emissions. Linde Hydraulics accompanies this development from the very beginning and complements the components of the power-train with electronic products of the iCon® family, in the accustomed quality and reliability.

Advantages- optimum system usage by teach-in function

- error prevention through continual comparison and documentation of the variance

- user-friendly software up-dating (“flashing”)

- easy usage by self-explanatory user surface

- large letters and buttons offer optimum use even with the machine running

- self-adapting screen sizemulti-lingual, up to 10 languages can be programmed

- documentation exportable into MS Office

- practical-minded partition of control elements by functional groups

- modular set-up: individual functions can be added optionally later

SYSTEMS AND FUNCTIONS

HMV-02 D

- Discplacement sizes 105D and 165D cc

Variable displacement double motor for open and closed circuit operation

This new axial piston motor has been developed by Linde Hydraulics to achieve maximum speeds higher than conventional swash plate designs. Additionally, a large displacement volume in a compact design means wider transmission speed ranges, normally achieved with modular transmissions, are possible. The HMV-02 D is about 30 % lighter than a motor combined with transfer gear box, and has a smaller footprint. The increased power density was achieved through the innovative design of two in-line swash plate rotating groups in a "face-to-face" arrangement. As a result, only one control is needed to adjust the displacement volume of the two motors. The inner lateral forces are compensated so that only one drive shaft and two (instead of four) bearings are required for both rotating groups.

Advantages- High power density

- High starting torque

- High speed capability

- Compact dimensions

- Low weight

- Increased average efficiency

HMV-02 PTO

- Displacement size from 105 -165D cc

PTO - Through-drive motor for open and closed circuit operation

In conventional drives the torque of the hydraulic motor can be transmitted to the cardan shaft only by means of a dropbox. For further optimization of the drive train Linde Hydraulics developed the PTO Through-Drive Motor. Based on the standard hydraulic motor of the Series 02 with just one shaft end, the PTO Through-Drive Motor offers two shaft ends to transmit the torque. Hence the machine designer can conceive the hydraulic motor to fit directly and immediately into the drive train thus saving mounting space. The dropbox usually needed in a conventional propulsion drive can be saved. This reduces both noise emission and fabrication cost of the entire vehicle while overall efficiency increases. As all Linde motors they are able to provide the required torque even at low speeds and make it possible to start smoothly and sensitively.Therefore, additional gear ratios for rpm reduction are not necessary. This reduces the amout of parts going into the component and also increases the overall mechanical efficiency, minimizes windage losses as well as the noize level of the machine.

The HMV-02D double axial piston hydraulic motor is with a shaft flange also PTO-capable.

Advantages- Two shaft-ends

- Drop-box eliminated

- Smaller cooler

- Simplified drive line design (components, part numbers)

- Fits directly into the drive line

- No interruption of tractive effort, stepless driving

- Increased tractive effort / direct drive

- Improved transmission efficiency

- Lower overall cost

- Less fuel consumption

- Reduced noise emissions

HPV-02 + HMF/V-02

- Classic, hydrostatic drive system

Classic, hydrostatic drive system for closed circuit operation.

The connection of a hydraulic pump and a hydraulic motor provides the conditions for a stepless drive. By adding a pump to the diesel engine and a hydraulic motor to the gearbox the result is a simple but powerful solution CVT drive. Hydrostatic drives have already proven their advantages over converter drives several times in various applications. The hydrostatic drive also offers an unbeatable driving experience in terms of precision, dynamics and reliability.

Advantages- All the advantages of hydrostatic LinDrive® drives

- Wide conversion range of the hydraulic system

- Stepless, even in combination with a shift gearbox, for greater ranges of tractive effort and speed

- Various types of control

- Reliable, robust and extremely compact design

- PTO drive-through capability for pumps and motors

- Smooth and delicate machine operations; even at low speeds

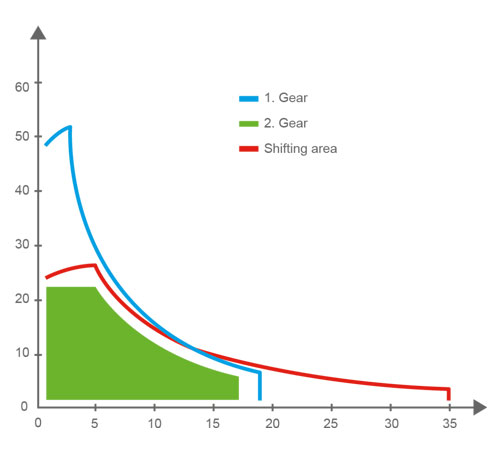

Shift in Motion

- Area of Application 40 - 300 kW

Hydrostatic Drive. Shift in Motion.

Shift in Motion enables shifting procedures in a moving machine, equipped with a manual transmission that is intended to be shifted at standstill by electro-hydraulically synchronising the drivetrain. This system is particularly suitable for vehicles that often change between transport and operation, i.e. vehicles that require both high tractive effort and a high top speed above 25 kilometres per hour.

The shifting procedure is load-free thanks to electro-hydraulically synchronised gears and the ability to adjust the drive component’s speed and torque. Thus there is no need for multi-disc clutches and mechanical synchronisation using synchronizer rings and moreover there’s less pinion engagement.

This makes the shifting procedures wear-free and also increases the transmission’s efficiency.

The shifting process can be initiated by driver request or automatically according to customer specifications. The criteria for its permissibility can be adapted to the specific vehicle and situation. The drive train is relieved by adjusting the pump and engine and the transmission is disengaged in neutral position. The hydraulic transmission ratio is then adapted to the new gear, afterwards the desired gear is engaged and the normal driving program is continued. The entire process takes only about half a second. Due to the quick and uncomplicated gear change, it is also worthwhile to design the transport gear for a higher than the desired final speed.

The actual top speed of the vehicle is thus achieved with reduced hydraulic motor and diesel engine speed. By operating the units at the more favorable operating point, both fuel consumption and noise emissions are reduced.

SPU

- SPU Noise Optimization

Legal emission regulations force manufacturers of mobile machinery to optimize the noise emission of their products. Since secondary measures tend to be expensive and less efficient Linde prefers to fight the noise where it is generated: by optimally connecting an additional volume directly next to the commutation of the HPR-02 pump, Linde Hydraulics invented the SPU silencer. The adaptive SPU reduces flow and pressure pulsations in the regulating pump over the entire range of operation – without loss of power. Compared to a customary variable pump, an HPR-02 with SPU reduces pulsation level by up to 70 %, independently of pressure, speed and temperature! The pulsations transmitted to system components and machine structure are significantly less, making the machine quieter.

Advantages- low noise level inside the cabin and outside: obvious relief for driver and environment

- self-adapting wide scale reduction of pulsation over the whole range of operation: independent of pressure, speed and temperature

- no need of costly measures for additional noise dampening

- significantly reduced noise peaks

- no effect on function and performance

- minor increase of weight and mounting space

- simple and robust design

- immediately usable, maintenance-free

Low Speed Concepts

- Low Speed Concepts for open and closed circuits

Standard hydraulic motors at low speeds in their starting phase cannot generate the necessary torque. Therefore, the power of the fast spinning hydraulic motors has to be reduced by means of several step gearboxes down to the speed needed on the wheel. Somewhat higher windage losses and poorer mechanical efficiency are benevolently accepted in this context.

Quite the opposite holds true for the motors by Linde Hydraulics: The motors of the Series 02 are capable of transmitting the required torque even at low speed and make it possible to start smoothly and sensitively. Therefore, additional gear ratios for rpm reduction are not necessary.

Advantages- jerk-free and steady low speed behaviour

- fuel saving in all operating situations

- elimination of mechanical gearboxes

- quieter through speed reductionless maintenance because of simplified drive concept

- increased service life of the transmission

Linde Synchron Control (LSC)

- Intelligent oil distribution

LSC stands for high handling performance due to load-independent and sensitive machine conduct. Fast and direct.

The Linde Synchron Control System, in open loop circuits, converts the commands of the machine driver into direct signals to the actuators. The easy control of all components supports efficient fatigue-free working. Simultaneous load-independent movements and a pump control ”on demand” are preconditions for fast working cycles with at the same time low operation cost. Safety and optimum exploitation of the machine are, apart from power regulation and high pressure relief, provided by the optional priority selection. Even with synchronous control of several functions the priority mode guarantees preferential operation of predominant actuators.

Advantages- excellent control with all flows

- load independent

- precision metering

- dynamic response for fast working cycles

- energy saving

- integralsimple sensitive operation

- high reliability

- long service life

LSC+

- Adaptive Electro-Hydraulic Control Valve (LSC+)

With its latest LSC generation, LSC+, Linde Hydraulics combines the design characteristics of the proven LSC system with the benefits of the electric control.

The powerful electronic control unit recognises the operator’s command by the amplitude and the speed with which the joysticks are being moved. It then sets the pump and the valves according to the dynamic demand. Due to the overlaid, classic load-sensing control mechanism, no sensors are needed. All components are provided by a single source and matched perfectly with each other. The operator can change the system’s behaviour electronically with regard to its dynamics and fine control, as well as its dependency or independency on the load.

This enables multi-purpose machines which can quickly be optimized to the specific use by the operator. With completely opened valves, the actuators can be controlled exclusively via the pump’s control to achieve the maximum possible efficiency.

Driving Control (CA)

- Simple, intuitive operation for optimum efficiency

The unbeatable driving experience for applications with engine speed control.

Precision, dynamics and reliability. These typical LinDrive® advantages feature in all our propel drive concepts. Linde Hydraulics has specially developed the HPV-02 CA for use in various applications like telehandlers, wheel loaders or dumpers. It enables engine-speed-dependent driving that is exactly coordinated with the pressure requirements of the driving status and the installed engine power.

In terms of functional quality, comfort and safety the HPV-02 CA is at the level of electro-hydraulic actuation. Precise power control settings enable full utilisation of the available power. The torque control and performance limiter can be variably defined. In this way, the HPV-02 CA ensures individual driving characteristics adjusted to your requirements.

Advantages

Precision

Continuously variable selection of driving and operating speed via the accelerator pedal through the integrated charge pump for hydrostatic speed sensing.- temperature independent

- pressure compensated

- performance optimised

- low noise level

Actuator

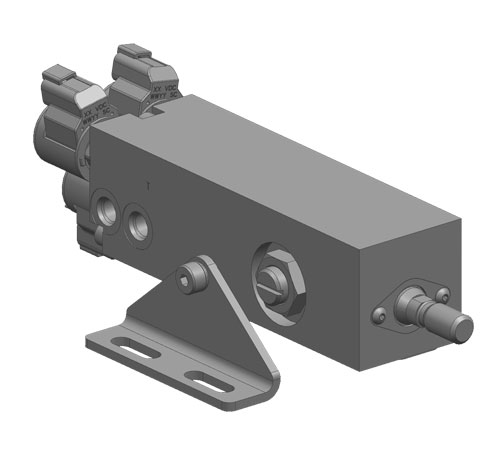

- Shift Actuator for Shift in Motion

The use of hydraulic cylinders for shifting gears requires not only fast and precise shifting processes, but also defined and electronically sensable rest positions as well as a defined behavior in case of system failure. The actuator from Linde Hydraulics combines all these properties and accommodates them in a robust and compact housing.

Together with the shift rod, which is prepared to accommodate conventional connections, all requirements for easy implementation are met. More information can be found on the "Shift in Motion" page.

Advantages- Defined and exact switching operations

- Easy implementation in conventional gearboxes

- Small space requirement and high reliability

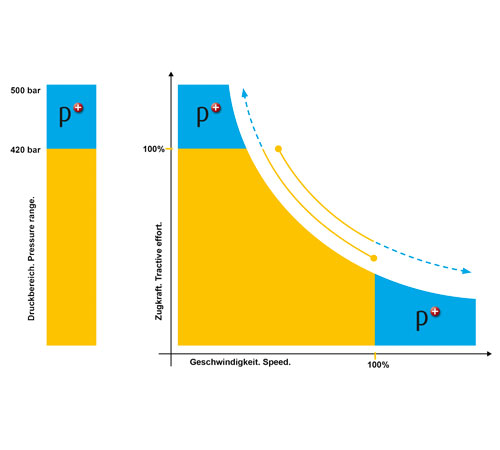

P+

- Higher power density for hydrostatic propel drives

Pressure increase for series 02 enables greater output and downsizing of drives. Raise the performance limit of your machine. A higher pressure level generates more torque from the same size of hydrostat. Extensive testing has demonstrated the durability of the 02 Series, even at working pressures of up to 500 bar. The Plus for your driving performance. The benefits this higher pressure range of the hydrostatic drive now offers for both the construction equipment manufacturer and the operator are quite obvious. The additional pressure can be utilized to achieve higher travel speeds. This only requires the use of a longer gear ratio in the working and road travel gear. Or one uses the 20% torque increase to provide the driver with a 20% higher tractive effort and thus higher power reserves. This increases the productivity of construction equipment. As an example, the tractive effort of a wheel loader equipped with a combination of HPV 75-02 CA (pump) and HMV 135-02 (motor) can be increased from 50 kN to 60 kN - without any extra costs and additional weight. Another example: A telescopic handler with hydrostatic propel drive consisting of a pump HPV 55-02 and a motor HMV 165-02. In this case only the transmission ratio needs to be adapted to be able to increase the travel speed from 32 to 40 km/h. Such improvements can always be achieved with high energy efficiency. Utilizing this higher pressure range increases the power density of hydrostatic equipment while nominal sizes remain unchanged. This is why the p+-concept is an excellent choice also under the aspects of fuel economy and environmental protection.

APPLICATIONS

AGRICULTURE

Forage Harvester

- Harvesting performance up to 400 tonnes an hour, even when used 24 hours a day throughout the entire harvesting season. High performance and availability of a unit is independent of its type of control. Whether mechanically, hydraulically or electrically actuated, all Linde Hydraulics controls operate with absolute precision and reliability.

Intelligent electronic controls offer an extended range of sophisticated comfort-, application- and safety features. The controls ensure that the diesel engine, variable-displacement pump and -motor are perfectly matched to each other in every situation. Utilisation of the installed power is optimised, and the fuel is used efficiently. The electronics themselves offer an impressively high level of safety – in both concept and design. If, however, external circumstances cause the control signals to fail, the hydraulic units set their swash plate angles back to minimum volume. The machine decelerates moderately until standstill, without over-revving the diesel engine.

The powerful CMV 115 hydraulic motors enable speeds of up to 40 kph on the road. The harvesting gear covers a speed range up to 15 kph, which makes shifting gears unnecessary on the field. The optimum speed is pre-selected in each case, and is reliably maintained thanks to the automatic regulation; after turning round, it is rapidly regained.

An additional hydraulic motor can be activated at the rear axle. The two axles can be controlled independently of each other, and the axles are not mechanically coupled. The tractive effort is distributed to the front and rear axles to suit the situation so that the traction limit is reached on both axles simultaneously. The mechanical decoupling of the two axles protects the soil, even when driving in tight curves. Reducing the effective torque to zero ensures that the vehicle retains full steering properties at all times, even when decelerating sharply.

Sprayer

- Application of fertiliser, plant protection agents or just plain water. Self-propelled sprayers are well established in agriculture. Not just in regions where several harvests are gathered during the year and sowing machines follow directly in line behind harvesting machines – in Europe too, they help to make the most of time-frames.

The use of hydraulic drives permits great freedom in configuring the machine so as to achieve uniform weight distribution across all the tyres. This helps to minimise the pressure on the ground and the compacting vibrations. Hydrostatic systems from Linde Hydraulics ensure that the machine always travels exactly in accordance with the position of the accelerator, irrespective of the quantity remaining in the tank and of the steepness and difficulty of the terrain. The sprayer travels completely evenly, and the spraying result is uniform across the entire field.

The example shows a machine with a contemporary design, featuring a large high-pressure pump and individual wheel motors. This configuration allows for a more creative machine design and allows for variable ground clearance depending on the application. Moreover, this configuration does not require a

manual gearbox and offers a high level of tractive effort and high top speeds for the road. Separate control of the individual motors enables the drive power of the individual wheels to be adapted to changing load and traction conditions.

Other control systems and designs, for instance layouts with portal axes or PTO motor, are also available. The wide product range from Linde Hydraulics allows machines of different sizes and power classes to be optimally equipped – all with the same familiar operating controls.

Feed Mixer

- The use of hydrostatic drives for auxiliary and propelling functions is illustrated by this example of a self-propelled feed-mixer. The chopping unit at the leading end of the conveying channel is driven by an HMF 55-02 fixed-displacement motor of compact dimensions. This is supplied with oil by an HPV 105-02 variable displacement pump as required. It could also be used to drive the conveyor belt, which can be within the channel or arranged in other configurations.

The driver has a perfect overview of the chopping process and can move the machine sensitively and precisely. The reason for this is the hydraulic rear-wheel drive. This consists of two variable motors, which are connected directly to the wheels via wheel gears.

The hydraulic motors can be switched between two displacements and therefore take over the function of a mechanical shift gearbox. The machine can be moved sensitively by means of the second HPV 105-02.

The variable speed of this unit is controlled by a electric control signal, which is determined by the operator’s accelerator pedal. Thanks to the PTO capability of the Series 02 units, the pumps for the drive and auxiliary circuits can be connected one directly behind the other. There is no need for a pump splitter gearbox.

Feller-Buncher

- Linde Hydraulics components are robust, field-tested and designed for a long service life even in heavy duty applications. The example design depicts the propel drive system in a closed circuit, which provides precise, controlled directional stability and wear-free steering, especially with regard to soil protection. The saw is driven by a separate drive in an open circuit. The other machine functions are realized using a LSC valve block which distributes exactly the demanded flows.

Thanks to the parallel architecture of the LSC System and the block's modular design, based upon infrastructure modules and sub plate-mounted valves, one MCV provides a common basis for differently equipped machines. In a machine with an open circuit drive system design the other components do not change greatly: The MCV block can simply be extended with the required valve sections and pump fittings if necessary. The rest of the components remain the same, which simplifies storage and reduces the training requirements of service personnel.

Beyond that, the modular design offers the ability to customise machines even in the field. Thanks to the LSC system, no actuator stops unexpectedly or reacts unpredictably when the system's demand exceeds the diesel motor power. Keeping the actuator responses proportionally identical makes the machine safe to control in any situation. LSC also prevents open circuit propel drive systems from unforeseen turning due to obstacles such as tree stumps. If an obstacle causes the system pressure on the drive side to increase, the oil does not flow to the other side - both drivetrains continue running at the same speed.

A layer-brazed valve block distributes the volume flows in the processing head. It is characterised by an extremely compact design and excellent electro-hydraulic actuation behaviour. Linde Hydraulics is also the perfect partner for other forestry machines, as well as wood processing and handling machines.

Compact Tractor

- The variants available for tractor drives are almost as diverse as their possible applications. In addition to the conventional hydraulic drive concepts, Linde Hydraulics has a special option on the market: the compact K-02 unit. The variable-displacement pump and the motor are mounted back-to-back within a common housing, thus eliminating the need for hoses.

The K-02 Series from Linde Hydraulics is available in two basic variants: as a fully hydrostatic drive, combined in a single unit, or as the hydrostatic branch of a power-split mechanical CVT gearbox. The inline design, featuring a hollow shaft, enables direct torque transmission from the prime mover to the PTO shaft. For compact tractors, the K 75-02 therefore offers stepless drive technology for the propel drive and direct power transmission for auxiliary drives.

Combine Harvester

- A harvesting machine which is reliably available throughout the entire harvesting season, which is built on robust technology and whose operation is intuitive and easy to learn, even for varying operators – in many places, this is exactly what is needed.

The design example shows such a combine harvester, driven by a 155 kW diesel engine with an HPV 105-02 pump with a mechanical hydraulic controller. It delivers oil to a fixed-displacement motor with 105 cc displacement, mounted to a 3-speed gearbox with varying gear ratios for harvesting, field travel and road travel.

A Bowden cable provides a mechanical link between the control lever in the operator's cabin and the controller of the variable displacement pump. The machine response is completely in the driver‘s hands. He can virtually ignore the load on the machine and the steepness of the terrain. Like all Linde Hydraulics controls, the M1R mechanical hydraulic control operates independently of the load. The same lever position produces the same machine response. The machine is operated intuitively.

Beet Harvester

- It’s all about high-performance harvesting. Multi-purpose harvesting machines, with and without bunkers, quickly and efficiently perform what used to be arduous manual work. For the farmer, the number of rows, the bunker volume, the harvesting and turn-round speeds are important. It’s essential at all times to ensure good harvesting quality and to avoid compacting the ground, irrespective of how quickly the machine progresses.

Machine manufacturers need hydraulic drives which enable the enormous performance of the machine and help to relieve stress on the driver. Thanks to the wide range of pumps and motors, hydrostatic systems from Linde are suitable for equipping each and every type of harvesting machine. The drive concept is optimised in each case to suit the numbers of harvesting rows, axles and wheels, and the engine power class of the machine.

The design example shows an HPV 280-02 driving three HMV- 02 variable motors in parallel. Two of these, each with 165 cc maximum displacement transmit the torque via the gearbox directly to the propulsion wheels. The third motor with 135 maximum displacement drives the twin tyres, which are offset within the travel path, via a T-axle. The motors can be controlled independently of each other. This allows tight turning circles, without any of the wheels spinning.

Beet Loader

- Highly specialised self-propelled machines are firmly established in beet harvesting operations. Harvesting and transport are increasingly treated as separate operations and optimised in their own right.

Self-propelled loading machines compact the ground less than towed transfer trailers, and have plenty of reserves in traction and power – especially on difficult terrain. Where towed trailers often exceed the permissible axle loads for road transport, self-propelled transfer machines allow beet to be loaded directly onto the transport vehicle from the field. The beet harvester machine can meanwhile take the ideal line across the field, with no accompanying tractor, and can then pile the beet at the end of the field.

Self-propelled transfer machines with Linde Hydraulics propel drives are characterised by their ability to go into the stack at high power and maintain precise movement at creep speed. The operating speeds of the cleaning and loading devices are precisely tuned at all times. The design example shows a double motor supplied with oil by a HPV 135-02. Like all Linde Hydraulics motors of the series 02, it is characterised by its precise low-speed behaviour. Both motor units are set parallel and have a combined oil flow of 330 cc.

Tractor

- The example on the right shows the K 75-02 as a component of a powersplit gearbox.

It is fitted directly within the gearbox casing. The power of the diesel engine is split at the input. One part is linked by a direct mechanical connection to the annular gear of a planetary gearbox. The K-02 is positioned in the second path as a variable unit and drives the sun gear as required. The power is transmitted as required; the speed can be precisely controlled. The sensitive hydrostatic system keeps the tractor under control on hills, preventing inadvertent rolling away and permitting smooth and gentle starting. The high conversion capability ensures that virtually any load situation can be mastered at low diesel engine speed.

Telehandler

- The key feature of the telehandler configuration shown here is the hydraulic mechanical drive with our innovative double motor. This delivers maximum tractive effort even at minimal diesel speeds.

Thanks to the through drive shaft, it can be installed if required between the cardan shafts or with one side directly towards the drive axle. The immediate power transmission ensures excellent drive and allows fast reversing, fine-touch driving, and precise shunting. Smooth at all times, even when heavily loaded. The lack of a gearbox reduces costs, increases overall efficiency, allows a smaller radiator and eliminates gear noises. The driver is free at all times to give his full attention to the load being moved.

The axial piston double motor design offers higher maximum speeds and hence a bigger transmission ratio spread of oil volume flow into rotary motion than conventional swash plate motor designs. The HMV 105D is about 30 percent lighter than a motor withtransfer gear box and is shorter than other modular approaches. This is achieved through innovative design of two in-line swash plate rotating groups in "face-to-face" arrangement. This means that only one swash plate is needed to adjust the displacement volume of the two motors, and additionally inner lateral forces are compensated so that only one drive shaft and only two (instead of four) bearings are required for both rotating groups. Apart from the weight and size advantages, the double motor also offers cost reductions in the drive-train with full power take-off capability.

Sugar Cane Harvester

- Tracked harvesting machines offer advantages over wheeled variants in terms of stability, traction and soil protection, especially in difficult terrain comprising soft, wet soil such as on rice, soya and sugar cane plantations.

The sugar cane harvester drive depicted here is based on Linde Hydraulics' many years of experience in equipping construction machines. The dual circuit concept depicted sets standards for tracked machines and operates without a splitter gearbox. This special solution comprising standard components is characterised by an impressive level of durability and robustness, as well as low fuel consumption levels. It is also particularly gentle on soil — either when driving in straight lines or in curves. All this combined with outstanding ease of operation.

Controlled directional stability is just one example. The hydrostatic units can be easily integrated into the overall design of the machine and enable optimum interaction between driving speed, crop intake, shredding and transportation.

Furthermore, the hydrostatic system is always powerful enough to drive continuously through dense crops. They are also extremely rugged, allowing the machines to make it right through the harvesting season with a low amount of planned maintenance time. The result: many tonnes of crops harvested in line with specifications and using little fuel.

CONSTRUCTION

Drilling Machine

- Endless auger drilling, double-head drilling, vibrating, hammering or dry mixing - the applications of a drilling rig are manifold. Linde Hydraulics components are up to these different challenges. In the upper carriage, as feed of the drill drive or in the drill drive directly, we offer you the right solutions for the entire working hydraulics.

In this application example, the drill head is driven by an HMV-02. Particularly with different types of rock, extreme loads can occur in the hydraulic motor in the drill drive due to high angular accelerations. Our swash plate motor withstands these impacts thanks to its outstanding robustness.

Optionally, the drill head can also be powered by a CMV. This is especially beneficial when particularly high speed capabilities are required in the drill drive.

Both designs from the Linde Hydraulics portfolio - swashplate or bent axis motors - offer added value for your machine. We will find the solution to suit your requirements.

Due to its unbeatable low-speed performance, the HMF-02 in the winch function enables a smooth feed of the drill drive.

Our LSC system is powerful and adaptable. Machines with LSC are not only intuitive, easy to operate and versatile, but also extremely powerful, as this application example shows. The double pump in the design example provides a total volume flow of 700 l/min for the machine and can be used as a single- or dual-circuit pump. Basic machines for drilling work are characterized by another feature of LSC technology: the parallel architecture. The compact design of the manifold also allows additional functions to be added at a later date.

Sandwich valves with different nominal sizes can be added to the existing sections or replaced. The real advantage, however, is that there is no need to recalibrate the system or replace the manifolds.

Concrete Pump

- High and steady concrete flow characterizes a premium concrete pump. It benefits from the smooth running behaviour of the Linde components, which help to reduce mast vibrations and noise emissions to a minimum. The assembly realizes up to 36 conveying cycles per minute which results in an almost constant concrete flow.

The two conveying cylinders are driven by two HPV variable displacement pumps, which operate in a push-pull mode. Each pump features 210 cc/rev displacement and is optimized to this application. This is done by an optimized signal flow and an increased control pressure of 40 bar which enables the pumps to swivel between the two displacement maxima in only 210 ms. This makes them one of the fastest pumps on the market in this scale.

By operating in a closed hydraulic circuit, the system only needs a small amount of circulating oil. Like every controller available for the HPV, the E1P type represented here is working independent of the load. Since the control signal for the pump is always the same, there is no need to change the software in order to adapt the machine to different conveyor heights or different concrete textures.

The other components of the open hydraulic circuit are fed by a HPR 55-02 self-regulating pump which is also very silent due to its pulsation damping SPU unit.

Road Paver

- Millimetre-precision work across long distances and under changing conditions. Road-surfacing machinery of all types present significant challenges to the drive unit. Linde Hydraulics meets these challenges, delivering drive units that fulfil the toughest requirements.

Two identical drivetrains consisting of a variable displacement pump and a variable motor each supply one side of the surfacing machine. The specific dimensions of the machine with its tight spaces require a special motor version. The solution is a variable motor with a plug-in design, which even includes a speed sensor in its compact housing. This continuously monitors the speed and reports it to the electronic control unit, which permanently adjusts all drive components, ensuring an even surface. Not only does it control the components of the drivetrain to achieve a perfect line and defined curves, but it also adjusts other drives such as the scraper belt and distributor auger to suit the situation.

The controller is CAN-bus compatible and can therefore communicate easily with additional functions such as an automated level regulation.

The motors stand out thanks to their excellent low speed behaviour. They move jolt-free and evenly, even at very slow speeds or where different speeds are required. Everything functions optimally combined with the series 02 high-pressure pumps, whose unique adjustments ensure precision supply even with minimal volume flows.

Crusher

- The key feature of Linde Hydraulics series 02 high-pressure motors is that they have a PTO drive shaft thanks to the swash plate design. This means that two or more motors can be combined in tandem. With an identical gearbox interface and the same rotating speeds, they offer twice the displacement and therefore twice the torque and power. Compared to individual motors with identical nominal sizes, they have smaller dimensions and higher potential speeds, even compared to bent-axis motors.

The rear motor also has a PTO option, which means the tandem motor can be directly integrated into the drivetrain or a speed sensor can be fitted. An electronic control unit actuates the motors and the pump and offers electronic maximum load regulation of the drive motor.

The crossover relief valve is the ideal supplement for the tandem motor. It allows rapid limitation of the high pressure in the motor, which reduces the load for the remaining hydraulics circuit. It offers additional ports for connecting the rear motor, which reduces the amount of piping in the machine.

Above all, the semi-stationary crusher shown here benefits from the robust design of the motors and the high torque. The result is continuously high crushing performance with long durability.

The hydraulic components are not only powerful and robust, but also allow fast, infinitely variable control. As such, the crusher can be adjusted perfectly to the required material, producing consistent results every time. The system can be reversed quickly if there is a blockage in the crushing chamber.

Mining Rail

- When used in the mining locomotive shown here, a drive unit in a closed hydraulic circuit with a diesel speed-dependent pump displacement CA is recommended. This offers a high safety standard for driving and stopping due to a reliable pump neutral position when idling and due to activation and shut-off of the control signal at defined diesel speeds.

The high setting forces in the pump controller ensure precise control in any operating mode. After smooth starting, the pump goes on stroke without delay and the drive accelerates the vehicle dynamically with optimum utilisation of the installed power. During deceleration, the drive is supported by the diesel, generating a continuous, moderate retardation through to standstill. In order to use slopes, the motors and the pump can be swivelled to zero. In the event of unwanted rolling back, even a minor speed increase returns the machine to a standstill and subsequent fine-touch driving. The configuration shown here uses several motors in order to set the hydraulic power in motion. These ensure high climbing capability with full loads and higher speeds with empty loads. A CAF block, which governs the diesel speed dependency of the pumps, can also control several pumps, which means that longer trains with multiple railcars or more motors are possible.

The choice of motor type depends on the required vehicle characteristics. Using regulating or variable motors with or without pressure regulation affects the drive characteristics accordingly. High levels of robustness and long service life are therefore guaranteed for each configuration thanks to the proven construction qualities and excellent qualities of the series 02.

Crawler Excavator

- The LSC system is high-performance and adjustable. Machines with LSC are not only intuitive, easy to use, and versatile, but are also extremely powerful, as this example of a tracked excavator shows.

The control plate in the monoblock design is impressively compact. The real benefits can be seen inside: optimised supply channels with large cross-sections supply the directional control valves, which each feed up to 600 liters of oil per minute to the actuators. For extreme demands, functions can also be fed by combining multiple valves. The regeneration function of the actuator, i.e. the back-flow of the oil from the piston side to the rod side of the boom, for example, is performed in the directional control valve itself with minimum deflection.

The double pump in the design example provides the hydraulic power for the machine with 700 liters of oil per minute and can be used as a single-circuit or double-circuit pump. As such, the bucket has impressively high tear-out force and the machine demonstrates high handling performance with the low consumption and excellent operation that typifies the LSC system. Not only can it move many cubic meters of material per hour, but also per liter of fuel spent.

Basic machines for demolition work stand out thanks to another feature of LSC technology: the parallel architecture. Despite the compact design of the monoblocks, these also allow additional functions to be added later. Sandwich valves with a range of nominal sizes can be inserted between the existing sections and the cover plate and use pump and tank channels as well as the LS signal. However, the real advantage is that the system does not need to be recalibrated neither the orifices need to be exchanged.

Material Handling

- Machines that rotate a lot in their day-to-day work, such as the material handling machine shown here, benefit from a slewing gear in a closed hydraulic circuit. This means the rest of the machine can be optimised to the work functions, regardless of the rotating mechanism performance.

The configuration shown uses two fixed displacement motors in combination with a variable displacement pump with torque control. This combines a hydraulic proportional flow characteristic with a torque control characteristic. During acceleration, the pump swivels quickly thanks to the volume control and increases the torque in direct proportion to the acceleration setting of the joystick. The torque characteristics of the control dominate the movement. The movement is dynamic but never jerky, even when re-accelerating out of a run-out phase.

The pump control forms the basis for load-independent, customisable run-out of the upper carriage in the neutral position of the joystick. Its position feedback control compensates for load influences.

The mechanically pre-set run-out behaviour of the upper-carriage when the joystick is in the neutral position is the same for every boom distance and clamshell load. During countercontrol, the run-out angle can be reduced additionally in a dosed manner. This transfers the core features of the Linde Hydraulics driving experience to the working hydraulics system: precision, dynamics and reliability with unrestricted machine control.

The system is supplemented by the open circuit as a dual circuit setup. As such, significant lifting power can be achieved regardless of the swing movement. A self-regulating pump tandem and two valve blocks efficiently serve the different energy levels of the remaining actuators. The result is a dynamic machine that is easy and sensitive to operate for very high material handling performance with minimal loss, which does not cause fatigue.

Dozer

- The robustness and durability of all series 02 components makes them a reliable drive technology solution for heavy machinery in the toughest conditions, as demonstrated by this example of a bulldozer. In addition, Linde Hydraulics components also help you to realise ambitious targets when it comes to fuel consumption and ease of operation, even at full load.

The machine operator simply sets the desired speed with the joystick and the electronic controller ensures even, straight travel. A control circuit has been developed for this purpose, as the following diagram shows. Two identical drivetrains consisting of a variable displacement pump and a variable motor each supply one side of the bulldozer. The speed of the motors is constantly monitored by speed sensors. If different ground conditions, obstacles, and other factors require an adjustment to the rotational speed or torque, the relevant units are controlled in relation to the current situation and the speeds of the two drivetrains are coordinated.

Individual control of the drivetrains also allows precise turning curves to be achieved, right through to turning on the spot without increased risk of wear to the brakes or chain.The motors are extremely robust when it comes to rapid angular acceleration, which makes them immune to tracks which skip a tooth on the sprocket.

Thanks to the large spread of the hydrostatic power train, there is no need for a manual gearbox and the machine can be driven stepless from standstill through to high speeds. The optimal traction means that thrust performance is always constantly high, even during cornering. Fuel consumption is comparatively low, even at full load. The high efficiency level of the hydrostatic drive units and an electronic power limit control ensure the diesel motor is working at favourable operating points all the time.

Wheel Loader

- Optimised components are often not enough to help realise ambitious targets when it comes to fuel savings and comfort. Real advantages can only be achieved if the system components are perfectly coordinated with each other and work as one overall system. The following sample of a wheel loader demonstrates this.

Linde Hydraulics has developed a system to receive considerable reduction of fuel consumption and noise emissions as well as lower initial and operating costs. This innovative system called Shift in Motion for hydrostatic drive consists of a variable displacement pump, a variable displacement motor, a shift actuator and an electronic control unit.

It enables shifting procedures in a moving machine, equipped with a manual transmission that is intended to be shifted at standstill by electro-hydraulically synchronising the drivetrain. This system is particularly suitable for vehicles that require both, high tractive effort and a high top speed above 25 km/h - for example for small and compact wheel loaders.

The shifting procedure is load-free thanks to electro-hydraulically synchronised gears and the ability to adjust the drive component's speed and torque. Thus there is no need for multi-disc clutches and mechanical synchronisation using synchronizer rings and moreover there's less pinion engagement. This makes the shifting procedures wear-free and also increases the transmission's efficiency.

Crawler Crane

- The crawler crane utilises the full benefits of LSC technology: the combined movement of individual functions without mutual interactions or influences in all load situations ensures perfect positioning. Furthermore, the crane also benefits from the smooth operation and no lowering of loads at the start of the movement.

This ensures excellent load capacity in all working conditions. The superb low speed behaviour and the smooth, even running characteristic of the Linde Hydraulics motors is particularly noticeable when it comes to lifting and lowering the hook.

The valve sections in the control block can be actuated fully hydraulically or electro-hydraulically. The two types of control can also be combined in one control block.

Thanks to the electronic controller, selected functions can also be operated by remote control or partially automated. Sophisticated safety systems are also possible, which can be implemented via locking mechanisms or through proportionally slower reactions from individual actuators in given situations. Even without the use of position sensors, the machine can be equipped with the functions of the LSC+ system.

In particular, this includes switching between rough control or fine control, or overriding the LS signal if load-dependent machine reactions are required. The maximum efficiency of single actuators is achieved, when they are controlled purely via the pump with fully open directional control valve pistons.

Telehandler

- The key feature of the telehandler configuration shown here is the hydraulic mechanical drive with our innovative double motor. This delivers maximum tractive effort even at minimal diesel speeds.

Thanks to the through drive shaft, it can be installed if required between the cardan shafts or with one side directly towards the drive axle. The immediate power transmission ensures excellent drive and allows fast reversing, fine-touch driving, and precise shunting. Smooth at all times, even when heavily loaded. The lack of a gearbox reduces costs, increases overall efficiency, allows a smaller radiator and eliminates gear noises. The driver is free at all times to give his full attention to the load being moved.

The axial piston double motor design offers higher maximum speeds and hence a bigger transmission ratio spread of oil volume flow into rotary motion than conventional swash plate motor designs. The HMV 105D is about 30 percent lighter than a motor withtransfer gear box and is shorter than other modular approaches. This is achieved through innovative design of two in-line swash plate rotating groups in "face-to-face" arrangement. This means that only one swash plate is needed to adjust the displacement volume of the two motors, and additionally inner lateral forces are compensated so that only one drive shaft and only two (instead of four) bearings are required for both rotating groups. Apart from the weight and size advantages, the double motor also offers cost reductions in the drive-train with full power take-off capability.

Walking Excavator

- Walking excavators – also known as spider excavators—are extremely specialized construction machines that move forward on four wheels, which are connected to the undercarriage by legs.

These legs can also be used to adjust the track width and the height of the vehicle over a wide range of dimensions, ensuring that the machine is highly flexible and can be adapted to the surrounding conditions, both in drive mode and work mode, when the stabilizers on the legs are extended. This means that they are ideally suited to work in locations such as very steep slopes or in mountain streams.

Exploiting this great degree of freedom in usage not only requires a very skilled and experienced driver, but also a powerful hydraulic system that can execute the often superimposed movements with the necessary dynamics or sensitivity.

The work hydraulics here are configured as a complete system of Linde Hydraulics components, including the electronic control unit.

Wheeled Excavator

- The LSC system is intuitive and efficient. All machines with LSC feature sensitive and intuitive operation. The excavator shown, which is versatile and suitable for use in different situations, greatly benefits from this technology. Thanks to the compensation of the load influences, the machine response is always the same, regardless of which functions are operated at the same time and even if the valves are not arranged on the same control plate, as shown in this example with a swing drive motor with integrated directional control valve.

A single LS signal is enough for all actuators. As such, the driver never has to make any post-adjustments and can always concentrate fully on the task at hand. The machine is highly sensitive with continuous movements and does not experience any jerking, even at the start of movements. The directional control valves do not open the paths until the pump pressure matches the load pressure. This means the load at the start of the function does not lower. Thanks to the social flow distribution, no actuators are stopped when the system is at full capacity.

As such, even challenging tasks can be completed without any post-adjusting or interruption of the movement sequence. High workloads are possible thanks to the system dynamics with fastresponse pumps. This does not compromise on efficiency because the LSC system saves fuel compared with other concepts, even in the partial load range.

The operation is not the only reason that working with the machine is a pleasure; one of the best features of the pump is the SPU silencer. This reduces pressure pulsations in the hydraulic system, thereby reducing the vibrations and noise emissions of the overall machine. This means that the excavator is comparatively quiet, which benefits not only the operator, but also the environment; something that is particularly useful in residential areas. Unlike other solutions, the SPU works across the entire typical speed range of the prime mover, reducing the pulsations of an open circuit almost to the level of a closed circuit.

Roller

- Even, jolt-free starting, driving and rolling set all Linde Hydraulics drive units apart. The key feature of the drive unit in the compactor in this example is the hydraulic traction control. The compactor boasts two hydraulic motors connected in parallel. One of these drives the rear axle, while another rotates the binding.

The system is able to complete its functions with very little input. Only a single pressure sensor monitors the drive pressure in the drive train. A tilt angle sensor is not necessary for the system to function. The more the drive resistance increases, either due to higher speeds, rougher terrain, or gradients, the more the pressure increases in the drive circuit of the machine. A pressure sensor detects this and reports the status to the electronic control unit, which sends a control signal to the motors.

When accelerating and driving on slopes, the transferable torque moves to the rear axle. The motors are adjusted accordingly and continuously shift a higher percentage of torque from the front to the rear axle – i.e. the axle with the better traction.

In coasting mode, the drive torque is distributed to the binding to benefit the front axle. This generates increased supporting torque, which allows the machine to move in a controlled manner. The drive on the rear axle is increasingly relaxed to maintain good steering properties.

Thanks to the rapid response time of the controller and motor, this all happens very evenly and without any interruption of tractive effort. The driving speed remains constant. The operator does not have to intervene manually and can concentrate fully on the task of achieving consistently high compacting quality.

This is further supported by the vibration drive for the binding. The strength and frequency can be set independently from the driving speed.

MINING

Crusher

- The key feature of Linde Hydraulics series 02 high-pressure motors is that they have a PTO drive shaft thanks to the swash plate design. This means that two or more motors can be combined in tandem. With an identical gearbox interface and the same rotating speeds, they offer twice the displacement and therefore twice the torque and power. Compared to individual motors with identical nominal sizes, they have smaller dimensions and higher potential speeds, even compared to bent-axis motors.

The rear motor also has a PTO option, which means the tandem motor can be directly integrated into the drivetrain or a speed sensor can be fitted. An electronic control unit actuates the motors and the pump and offers electronic maximum load regulation of the drive motor.

The crossover relief valve is the ideal supplement for the tandem motor. It allows rapid limitation of the high pressure in the motor, which reduces the load for the remaining hydraulics circuit. It offers additional ports for connecting the rear motor, which reduces the amount of piping in the machine.

Above all, the semi-stationary crusher shown here benefits from the robust design of the motors and the high torque. The result is continuously high crushing performance with long durability.

The hydraulic components are not only powerful and robust, but also allow fast, infinitely variable control. As such, the crusher can be adjusted perfectly to the required material, producing consistent results every time. The system can be reversed quickly if there is a blockage in the crushing chamber.

Mining Rail

- When used in the mining locomotive shown here, a drive unit in a closed hydraulic circuit with a diesel speed-dependent pump displacement CA is recommended. This offers a high safety standard for driving and stopping due to a reliable pump neutral position when idling and due to activation and shut-off of the control signal at defined diesel speeds.

The high setting forces in the pump controller ensure precise control in any operating mode. After smooth starting, the pump goes on stroke without delay and the drive accelerates the vehicle dynamically with optimum utilisation of the installed power. During deceleration, the drive is supported by the diesel, generating a continuous, moderate retardation through to standstill. In order to use slopes, the motors and the pump can be swivelled to zero. In the event of unwanted rolling back, even a minor speed increase returns the machine to a standstill and subsequent fine-touch driving. The configuration shown here uses several motors in order to set the hydraulic power in motion. These ensure high climbing capability with full loads and higher speeds with empty loads. A CAF block, which governs the diesel speed dependency of the pumps, can also control several pumps, which means that longer trains with multiple railcars or more motors are possible.

The choice of motor type depends on the required vehicle characteristics. Using regulating or variable motors with or without pressure regulation affects the drive characteristics accordingly. High levels of robustness and long service life are therefore guaranteed for each configuration thanks to the proven construction qualities and excellent qualities of the series 02.

FORESTRY

Feller-Buncher

- Linde Hydraulics components are robust, field-tested and designed for a long service life even in heavy duty applications. The example design depicts the propel drive system in a closed circuit, which provides precise, controlled directional stability and wear-free steering, especially with regard to soil protection. The saw is driven by a separate drive in an open circuit. The other machine functions are realized using a LSC valve block which distributes exactly the demanded flows.

Thanks to the parallel architecture of the LSC System and the block's modular design, based upon infrastructure modules and sub plate-mounted valves, one MCV provides a common basis for differently equipped machines. In a machine with an open circuit drive system design the other components do not change greatly: The MCV block can simply be extended with the required valve sections and pump fittings if necessary. The rest of the components remain the same, which simplifies storage and reduces the training requirements of service personnel.

Beyond that, the modular design offers the ability to customise machines even in the field. Thanks to the LSC system, no actuator stops unexpectedly or reacts unpredictably when the system's demand exceeds the diesel motor power. Keeping the actuator responses proportionally identical makes the machine safe to control in any situation. LSC also prevents open circuit propel drive systems from unforeseen turning due to obstacles such as tree stumps. If an obstacle causes the system pressure on the drive side to increase, the oil does not flow to the other side - both drivetrains continue running at the same speed.

A layer-brazed valve block distributes the volume flows in the processing head. It is characterised by an extremely compact design and excellent electro-hydraulic actuation behaviour. Linde Hydraulics is also the perfect partner for other forestry machines, as well as wood processing and handling machines.

Wheeled Harvester

- Benefitting from Linde Hydraulics, modern, mobile woodprocessing machines are both efficient and sustainable. The example design depicts a wheel-driven wood harvester with two high-performance yet compact hydraulic motors in a closed circuit. This design allows the machine to move safely and protect the soil, even on rough terrain.

The Linde Synchron Control (LSC) system is a load sensing system with downstream pressure compensators. It enables the work functions to operate in an open circuit without mutual interference. A main control valve distributes the oil flow to the consumers. Its monoblock design combines an extremely compact build with a very low level of flow loss.

The oil is provided by a high-pressure pump of type HPR-02, which operates at the noise level of a pump in a closed circuit thanks to the SPU silencer. The LEP controller enables volume flow regulation according to actual requirements, based on the load sensing signal. Using the electrical override, the displaced volume can also be limited or allocated according to application. Thanks to the hydraulically adjustable pressure cut-off, the hydraulic system is only operated at the defined pressure and securely protected from overloading.