BioConstruct

Videos

Loading the player ...

- Offer Profile

- We are bioconstruct. We are an owner- and family-held business that stands for stability and reliability. This is a principle that we apply in all areas consistently, be it our accounting policies or our stainless-steel screws. In all cases, we work for the benefit of our customers, employees and business partners.

#mission

What we do

Clean water and air, biodiversity, healthy ecosystems and peaceful human coexistence are the most-precious things we have. We seek to contribute a significant part in preserving these.#vision

Why we do what we do

We firmly believe that by establishing a focus on sustainability we can achieve a harmony between the economy and our environment allowing us not to live at the expense of future generations.

Product Portfolio

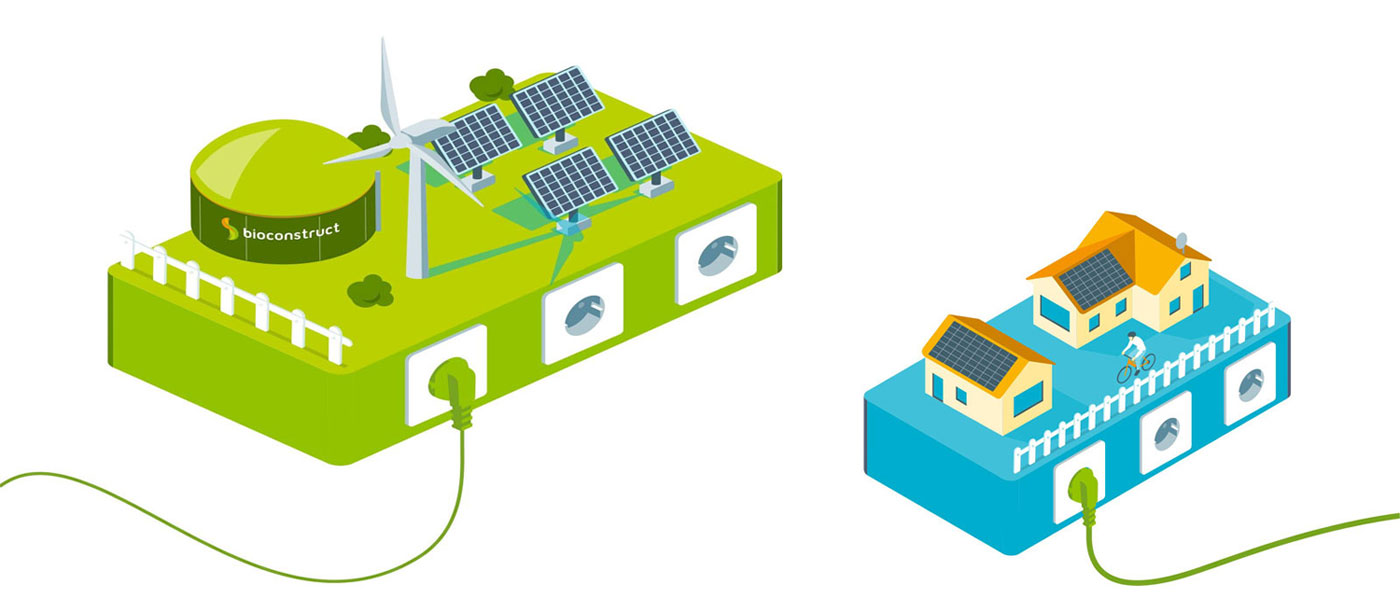

Green energy

What we do

The range of services offered by bioconstruct is unique. There’s no other company that offers a full suite of planning, construction and operation services for solar, wind energy and biogas projects, all under the one roof. We’re your one-stop shop for comprehensive solutions for the most-important sectors of the renewable-energies business. And with over 20 years of experience on top of that, too.Biogas

Biogas is created by fermentation of organic substances. In nature, this fermentation happens in places such as the bottom of a body of water, in bogs and in the stomachs of ‘ruminant’ animals (e.g. cattle or sheep). Such fermentation process is happening in a controlled environment in the digesters of a biogas plant. The electrical output of a biogas plant ranges from roughly 75 kW up to many megawatts.Wind energy

A wind turbine transforms wind energy into electricity. The electricity is fed into the power grid and distributed to end consumers. The rated power of an onshore wind turbine averages between 3 and 6 megawatts, while a more-costly offshore system has a significantly higher capacity of 6 to 10 megawatts.Solar energy

The sun is the planet’s most-important source of energy. This gigantic, natural power plant at the centre of our solar system will remain available for billions of years to come. Solar photovoltaic systems use the sun to generate electricity and heat, so any kind of raw-material shortages won’t be an issue for them in the long run.Biogas

Certainty for planning

We know from experience how things go

Based on the experience we’ve gained from many biogas projects we’ve developed ourselves, we possess the entire toolkit needed for successful project development: knowledge of agriculture, state-of-the-art planning software, precise contract templates, a sound knowledge of commercial law, excellent contacts with banking and financing partners and, last but not least, best-practice experience in relation to plant operation. With us you can be assured of having partnered with someone being able to provide you “everything” from one single source at an affordable price, from the greenfield site ultimately to a complete project.Investments

Long-lasting security for everyone’s capital

bioconstruct operates over 20 biogas plants either alone, in conjunction with agribusinesses or with its known investors, friends & family. Overall an investment of more than €80 million has been realized by such partnership schemes which allows everyone involved to play out their strengths and thus creating advantages for all involved. If you have a fantastic project but lack capital, we’d be happy to join as an a (co-)investor subject to a positive project check.

Why is biogas important?

- Renewable energies are continuously gaining importance. An increasing number of countries alongside Germany are turning towards sustainable fuel, energy and heat generation using biomass. Many countries are supporting the expansion and use of renewable energy by passing corresponding laws such include funding and subsidies for the construction and operation of biogas plants.

How does a biogas plant actually work?

-

Biogas is created by fermentation of organic substances. In nature, this fermentation can happen at the bottom of bodies of water or in bogs, for example, or even in the stomachs of ‘ruminant’ animals (e.g. cattle or sheep). At a biogas plant, the controlled fermentation process takes place in fermentation tanks known as ‘digesters’. These large tanks contain the organic substrate, which is decomposed by methane bacteria. This process, called anaerobic digestion, produces a mixture of gases. Roughly 55% of it is methane, an energy-rich biogas. The digestate, that is left over after digestion, can also be fully reused as a natural, nutrient-rich fertiliser.

There are four stages during the biogas formation process. During hydrolysis or the liquefaction stage, the starting materials (fats, carbohydrates and proteins) are split into their fundamental chemical elements (such as fatty acids, monosaccharides and amino acids). During acidogenesis or the acidification stage, the hydrolysed materials are broken down into organic acids. The third stage, acetogenesis or acetic-acid production, sees the microorganisms transform these materials into hydrogen, carbon and acetic acid, the precursor materials to biogas.

Methanogenesis, or methane production, forms the final stage of the process. Without oxygen( ‘anaerobic’ conditions), the methane bacteria first turn the acetic acid into carbon dioxide, hydrogen and methane. The carbon dioxide and hydrogen subsequently become water and methane. Then, before further use, the biogas is desulphurised, purified and upgraded to the relevant plant demands. If you’d like to find out more about modern biogas plant construction and biogas technology, then we would be delighted to explain the details to you in a comprehensive information and consultation session.

Why do biogas plants use so much maize?

- In Germany, roughly 900,000 hectares of maize is farmed for biogas plants, which is about equivalent to the amount of land used for maize farming in the late 1980s. Maize grows to be very tall right before it is harvested. It’s difficult to oversee and hence is seen as something “quite dominant”, though its size also offers a benefit: maize produces more biomass per hectare than almost any other crop. What’s more, it requires little water and fertiliser, and yet still forms a great amount of gas during fermentation. The farming of bioenergy crops has also had a significant part in stabilising incomes in the agricultural sector. Farmers benefit from higher profits when they sell their harvest, while biogas plants offer many farmers a secure foundation for generating income in times when milk and meat prices are low. (Source: Fachverband Biogas e.V.)

How are plants planned, approved and financed?

-

Producing biogas requires a permit. If you wish to operate a biogas plant, you need to be familiar with the legal requirements and complete all the necessary formalities before starting construction. We’re happy to support our clients with their applications for permits. We can boast over 20 years of knowledge from applying and developing these systems, so we’re closely familiar with the individual steps and processes. We clear a path through the administration & government jungle of forms so that your biogas plant is fully compliant with applicable law and you can take full advantage of all potential funding and subsidies granted by the state and the nation.

Once the preparations are complete, you can get started building your biogas plant at your intended location. We perform all the required inspections and professional acceptance testing before putting it into routine operation. If desired, we can also make a separate arrangement to guarantee a specific electricity, gas or heat yield from your plant, giving you full certainty for your planning and finances.

Which biogas plant suits my needs?

- Using our modern process control system, BioControl, we ensure that biogas plants always perform at their best potential and at an optimal profitability. The software was developed by experienced bioconstruct technology specialists and can also be retrofitted to older biogas plants. It can help you to configure your plant perfectly to your needs (e.g. for an on-demand-based electricity generation) and enjoy a precise overview of individual operational processes at all times.

How do you turn manure into fuel for lorries or carbon dioxide for soft drink?

- Unfortunately, animal waste and slurry can’t be put straight into vehicle fuel tanks (just yet). Nevertheless, there’s an alternative that’s just as genius: our biogas plants digest slurry and manure and produce biogas from them. The main products created from this are carbon dioxide and methane. These two are separated from each other and purified using biogas upgrading systems. The carbon dioxide is then purified again and compressed. The end product is ready to dispense into bottles and be transported to soft drink bottling lines to carbonate beverages. Alternatively, it’s also possible to make dry ice – which is already done at our Crofthead biogas plant (see our testimonials).

The methane embarks on an even-longer journey. It’s usually fed into the gas network at the same location as the biogas plant. Then, at any other point in the gas network, an equivalent amount is extracted back out of the network and conveyed to a liquefaction facility that turns the biomethane into bio-LNG (liquefied natural gas). Heavy goods vehicles can use this as fuel and drive up to 1,000 km per tank of it (compared to roughly 1,500 km on diesel), making it an excellent alternative to diesel. The best part is that both the carbon dioxide and LNG can be produced in an environmentally friendly way, while generating and marketing them together with CO2 certificates provides for great profits. This creates a perfect synergy between economy and environment.

What does bioconstruct offer?

- bioconstruct plans, builds and maintains plants for farms, medium-sized plants for community use and waste-to-energy plants for industrial use. We have the right technical solution ready for any type of input material or we can create a solution together with our partners. When it comes to utilising biogas, we offer cogeneration and ORC plants as well as biomethane upgrading plants and technology for further processing of the gas. Accordingly, we can generate valuable fuels such as CNG or LNG out of biomethane and even make good use of the carbon dioxide from biogas.

Wind energy

Networking for wind

A strong network for successful wind power projects

Since it was founded in 2001, bioconstruct has worked on the construction of plants and turbines and on supervising projects for the use of renewable energies. The first bioconstruct wind energy projects were completed in 2001. Since then, we have earned lots of experience, , have continuously expanded it and kept it up to date. bioconstruct has planned, built and successfully commissioned more than 55 wind turbines in six of Germany’s states. Moreover, bioconstruct is involved in a network of companies which have completed wind energy projects worth over €500 million around the world.Investments

Public involvement and security for everyone’s capital

We have a considerable financial stake in every project that we develop. We’ve already invested €12 million of equity in our projects and used that to attract a total investment amount of over €100 million. We believe it’s important to get all project stakeholders involved and not just invest by ourselves. In our wind energy projects, for example, it’s not only the property owners who gain a stake.The local residents get involved as well. Back in 2001, we launched our first community-owned energy project, called Region Regenerativ Melle – Energie aus der Heimat (‘Melle Renewable Region – Energy from the Community’). We are proud to still manage this investment today.

Why do wind turbines stand idle despite the wind blowing?

- People often assume that a wind turbine stands idle because the turbine has been erected at a place where there is not sufficient wind. In reality, though, there are a variety of reasons why wind turbines do temporarily stand still. As the name of the technology suggests, wind turbines by their nature depend on wind. Measurements of the local wind conditions ensure that wind turbines are built in the right places so when the blades stop turning, it is mostly due to other reasons.

The two most-significant obstacles for a more-efficient use of the wind energy are the delayed power grid development in Germany and an oversupply of conventional electricity. Occasionally, wind turbines need to be shut down at times when they could theoretically be working at their peak efficiency, for example when strong winds feed a lot of power into the power grid. This will happen on fewer occasions in the future due to two reasons. First: an optimised, high-performance power grid will be capable to absorb more wind power and establish a better balance between supply and demand. The rapid expansion of the grids will ensure that renewable energies have the largest proportion in Europe’s long-term energy mix. Second: If we’re to take climate protection seriously, coal and lignite power plants must be shut down consistently over the next few years. They have little flexibility which results them blocking the power grids with climate harming power – and that clogging leads to the shut-down of flexible wind turbines. In the power system of the future, which will be reliant on wind energy, other renewables and flexible gas power plants, there will be no longer the need for coal-fired power plants.

In addition to the above, there are a number of additional reasons why wind turbines stand still despite good winds. Maintenance and repairs as well as the protection of birds and bats during breeding season or other activity times. Turbines are also temporally shut down to protect local residents if the sun is low and the turbines cast a shadow on neighbouring houses for longer than 30 minutes a day. (Source: Bundesverband WindEnergie e.V., 2021)

Can wind turbines be recycled?

- Wind turbines are demanding high-tech components. Despite that, dismantling them and recycling their components has now become a routine matter, as companies in the waste industry can confirm. There are companies that offer straightforward solutions for a cost efficient recycling of wind turbines.

Modern wind turbines are almost fully reused, with 80 to 90 per cent of the components in terms of its weight being recyclable. This is due steel and concrete making up over 80 per cent of a wind turbine. The concrete parts of the foundation can be processed and be used as recycled concrete for new roads. The steel segments are returned to the steelwork factories as a secondary material. Recycling the rotor blades is probably the most-difficult part due to their composition out of fibreglass, carbon fibres and other plastics. If they can’t find another life cycle in a secondary market – usually outside of Europe – they are incinerated by specialised companies and processed for use as a secondary material.

The incineration process involves the rotor blades being crushed, metal parts such as lightning arresters being removed and the leftover product then being burned. The remaining ash, which is less than 30 per cent of the volume of the original material, can be used as a substitute for other raw materials in the cement industry. Processing 1,000 tonnes of fibreglass – the same type used in the automotive, shipping and aviation industries – in the manner just described above, can prevent the consumption of about 450 tonnes of coal, 200 tonnes of chalk and 200 tonnes of sand. This is overall a recognised process: Bremen-based company neocomp GmbH, for instance, recently received the GreenTech Award for this process.

The manufacturers of wind turbines have also set zero-emissions targets for themselves and are endeavouring for an European-wide circular economy. They are continuously investing in research projects and in the optimisation of production and recycling processes. The results are documented in publicly available sustainability reports. (Source: Bundesverband WindEnergie e.V., 2021)

Do wind turbines affect people’s health?

- People are surrounded by modern technologies each and every day, not only in towns and cities, but also in their private households and working environments. However, wind energy is one of those technologies that have a highly visible presence in the landscape. This is why people who live nearby wind turbines ask – quite understandably – if wind turbines near residential areas have an impact on people’s health.

There are various studies and reports that debunk these fears. Studies by Germany’s Nature and Biodiversity Conservation Union and various state environment agencies prove that noise in the direct vicinity of wind turbines does not reach a level which is anywhere near concerning for people’s health. Just like choppy wind, surf from the ocean or passing cars, wind turbines also emit noise at very low frequencies, referred to as ‘infrasound’. This infrasound consists of very low tones with a frequency of less than 20 hertz (Hz). Humans cannot normally perceive such frequencies, though some neighbouring residents fear that they can be harmed by infrasound exposure.

Nevertheless, long-term studies show that only a small portion (5 per cent) of people who live in the direct vicinity of wind turbines report symptoms such as headache or sleep disruption. A long-term study by the VTT Technical Research Centre of Finland concluded by saying ‘No evidence of health effects of wind turbine infrasound was found’. To explain the allegedly frequent occurrence of symptoms nearby the wind turbines, the study suggested that they were the result of a ‘nocebo effect’ (analogous to a placebo effect), where influences that are not actually harmful to the human body end up having a negative effect on people’s health because these people think the influences have a negative effect. Symptoms caused by other things can also be incorrectly associated with wind turbines. The infrasound from wind turbines can be contrasted against the infrasound levels found in day-to-day situations, such as inside a saloon car driving at 130 km/h. Such level is much higher than those of a wind turbine 150 metres away. The studies are backed up by a judgement made by the Würzburg administrative court in a case regarding the harmlessness of noise emissions from wind turbines. (Source: Bundesverband WindEnergie e.V., 2021)

Why are wind turbines getting taller and taller?

- Many wind energy projects attract criticism because the wind turbines are getting bigger and taller. Fifteen years ago, the maximum height of a turbine has been 100 metres. These days, they reach up to 250 metres. The simple fact is that there is more wind at greater heights, with the yield increasing by 1 per cent (approximately) for each additional metre that the hub rises. The higher yields from the wind turbines not only benefit their operator, but also helps to protect our nature and benefits our society as a whole. That’s because the operator can sell its power at significantly more-affordable prices thanks to the increased yields from its turbines, and that means the financial support needed for a wind turbine is reduced to a minimum. Furthermore, the higher yields allow the turbines to be shut down for longer periods to minimize affection of local residents by noise and shadow flicker. Wind turbines are even shut down during breeding seasons to protect sensitive bird species such as storks, buzzards and red kites, reducing the risk of collision significantly. These things wouldn’t be possible without the financial buffer provided by a tall wind turbine.

How much power can a wind turbine deliver?

- Today’s wind turbines feature a direct connection to the power grid; the electrical energy produced is transferred and fed onwards using power electronics. The peak power of a contemporary onshore wind turbine averages between 3 to 6 megawatts. Offshore turbines are significantly bigger at 6 to 10 megawatts, however these plants are way more expensive to build.

How economical is wind energy in comparison?

- Wind turbines are a catalyst for the energy revolution, with many countries supporting their construction and operation through feed-in tariffs and legally mandated targets for wind energy development. The electricity generation costs are an important factor when comparing solar photovoltaic systems, biogas plants and wind turbines. These costs include all the expenses for generating power from the renewable source of energy, for example the costs to build a system and operate it. Put in context with the power produced by the system, the electricity generation costs say a lot about a system’s cost-effectiveness. The latest studies show that renewable energies have become competitive. A new solar system or wind turbine, positioned at the right location and backed with a carefully planned financing concept, will already operate more economically today than a new power station fired by fossil fuels- without harming the environment!

What does bioconstruct offer?

- When it comes to wind turbines, our focus is on project development, planning, providing the infrastructure (cabling, earthworks and foundations) and financing. We’ll be at your side for the entire journey, from the initial idea and getting permits and funding to managing the wind turbine’s profitable operation. We’ll answer your questions about the opportunities of a given site, for financial support and feasability assessments. We’ll help you to develop a profitable new wind energy project as well as to optimise existing turbines and wind farms. When you come to us, you can rest assured that we’ll remain your point of contact even after construction is finished. For instance, we still administer the very first community-owned wind farm we built back in 2001- with over 150 satisfied invested locals.

Get in touch with us to on-board a team of dedicated experts for your project development and transform your idea and planning into a successful and sustainable result. We’d be happy to set up a phone call or personal meeting so we can explain to you all the details surrounding site analysis, turbine construction, engineering and modern wind power financing.

Solar energy

Forecast: boom!

Solar power is a hot investment

Solar photovoltaics is a popular, entry-level solution for renewable energies. Why? The prices have dropped by 90% in recent years. The affordable investment costs are complemented by relatively low operating and maintenance costs, with solar photovoltaic energy able to be produced for less than €0.05 per kWh. For this reason, we’re expecting solar photovoltaics to boom very soon, both in sunbathed areas such as southern Europe as well as in places that consume lots of electricity, like densely populated Germany for example.Investments

Public involvement and security for everyone’s capital

Over the last 15 years, the bioconstruct Group has set in motion over €120 million for renewable-energy systems thanks to the dedicated funding it has sourced. Our core duties are structuring financing and attracting loans and equity needed for it. We have contributed ourselves approximately 30 per cent of the equity required for our projects, giving us a long-term involvement tothem. This creates trust and confidence from our partners. After all, the best construction company of plantsis the2 one that invests in its technology itself!

Why is solar energy important?

- The sun is the planet’s most-important source of energy. This gigantic, natural power plant at the centre of our solar system will remain available to us for billions of years to come. Photovoltaic systems use exactly this source to generate electricity, so raw-material shortages won’t be an issue– even in the long run.

Do photovoltaic systems reduce the amount of available agricultural area?

- When solar photovoltaic systems are built in open spaces, it’s usually in such areas that are designated as ‘unfavourable’ land. Unfavourable might be, for example, low-yield areas with poor soil or not enough rain. Even in good spaces, system owners might build ‘agrivoltaic’ systems, which consist of panels in a vertical angle that allows farmers to continue using the land , e.g. as a pasture.

What is the future potential of photovoltaic ?

- Photovoltaics (PV) , is planned to become a key pillar of the energy revolution. It offers massive potential, and not only because with rooftops and open areas huge amounts of space are suitable for solar PV systems. The main argument to make even more use of solar photovoltaics is that this technology has become enormously more cost-effective.

Can solar photovoltaic systems in open spaces be integrated in a nature friendly manner?

- Yes, they can! Flowering plants and herbs can be grown between panels to provide an ideal habitat for bees and other insects. At some of our photovoltaic sites, there are even sheep that graze in these spaces. The animals are happy and content to graze beneath the panels when it’s windy or hot outside, which has a pleasant side effect of stopping the vegetation around the system from growing too tall.

How much do solar photovoltaic panels cost?

- The prices for solar PV panels decreased by 90 per cent (!) between 2010 and 2021. The nowadays attractive investment costs, coupled with relatively low operating and maintenance costs, have resulted in solar power being able to be generated for less than €0.05 per kWh. This is cheaper than any conventional power plant if you consider carbon emissions in your calculations.

For this reason, we’re expecting a solar-power boom over the next decade. Not only in sunbathed areas such as southern Europe, but also and especially in places that consume lots of electricity, like densely populated Germany for example.

Is solar photovoltaics more efficient than biogas?

- Farmers and community representatives often ask if it would be better to use a hectare of farmland to install a solar photovoltaic system rather than growing plants like maize for biogas. There’s good reason to ask this, as a solar PV system produces 32 times as much power per hectare compared to biogas. However, such a figure is only half of the truth. In addition to power, biogas plants produce an equal amount of heat. Accordingly, the energy yield from a solar PV system is only 16 times greater than biogas. This is still a very large yield and would make you think that solar power is much better than biogas. Yet for as long as there isn’t an affordable method for storing solar PV power, we need to use the electricity from solar PV systems at the time it’s produced, which is usually around midday during summer. Biogas power, on the other hand, is always available and can even be generated on a demand-based basis, i.e. whenever supply is running low and there are clouds in the sky (or at night). This is what makes biogas power so valuable and suggests that the two forms of energy are equally important. The power from PV is cheap but not reliable, whereas the power from biogas is reliable and therefore extremely valuable!

What does bioconstruct offer?

- bioconstruct concentrates on planning, constructing and overseeing large systems on commercial rooftops and open, non-built-up areas. The ideal open spaces are meadows and fields beside motorways and railway tracks as well as farming areas that have low yields when used for food or feed production. Unused industrial estates and former airports are also ideal for conversion.

Great cases

Where we’re active

Success stories from A to Z – from the village of Ahe to the village of Zens (both in Germany). All our testimonial projects make great case studies as we work on them jointly to achieve the best of the biogas plant, wind turbine or solar photovoltaic system. We guide our clients and partners from the planning and permit application process through to the ongoing operations and system management. Below you can find some of our GREAT CASES:

Biogas plant Saumur

-

Place: Saumur Since: 2020

The biogas plant project “Saumur” was developed and is operated by the French company “Saumur Energie Vertes” in cooperation with “Agriopale Service” which is acting in the field of composting. bioconstruct was chosen for the delivery and installation of the whole fermentation line technology including pretreatment and feeding of substrates, fermentation and digestate treatment. The construction of the plant was started in May 2019 and the first injection of biomethane into the gas grid has been released in September 2020. The plant is located in the industrial area of Chacé, which is part of the agglomeration of Saumur in Loire region and is surrounded with the famous vineyard of Saumur Champigny.

The input for the biogas plant is organic waste from different kind of sources like horse dung, cattle slurry, cereal crop, onion scraps and waste from different kind of industrial processes or agricultural waste. The total input amount of 23.500 t/a represents a production of 185 Nm3/h of biomethane. The produced biomethane is purified by an upgrading unit and fed into the local gas grid. A CNG station has been built in Saumur in addition to the biogas plant to provide green fuel to the customers.

The technology feature of this biogas plant is the combination of the feeding container and mixing pump with a buffer tank. This allows two different ways of feeding the biogas plant: either feeding directly into the digesters or to go through the buffer tank where a hydrolysis of substrates is achieved. At the same time the substrates in the buffer tank can be pumped to the digesters which enables an autonomy in particular for the week-end. This buffer tank is also gas tight so that eventually produced biogas won’t be lost at such stage.

The main portion of the biogas is produced in the two digesters. After the fermentation, the digestate is transported to a separation unit where the material is separated into a liquid and solid phase which furthermore can be used for fertilizing purposes in the agriculture sector again.

Biogas plant Charpentier

- Place: Chailly-en-Brie Since: 2021

The biogas plant project “Charpentier” was developed and is operated by the French company “CPL Biogaz” especially by his managing director Baptiste Charpentier who is active in the field of agricultural production and logistics . BioConstruct was chosen for the delivery and installation of the whole fermentation line including feeding technology, fermentation and storing of digestate. The biogas plant was built in cooperation with the French engineering office SAS ASTECA. The construction of the plant was started in August 2020 and the commissioning of the gas purification unit was realized in June 2021. The location of this project is the village Chailly en Brie which is based in the eastern part of Paris (France).

The inputs for the biogas plant are basically agricultural residual products like sugar beet pulp, cereal waste and energy crops like rye whole plant silage and maize silage. The total input amount of 17.000 t/a represents a capacity of approx. 180 Nm³/h biomethane. Therefore the produced biogas is upgraded by a gas purification unit to biomethane. The biomethane is then fed into the local gas grid.

The technology feature of this biogas plant is the special feeding technology which consists of one solid feeder dosing unit including a hydraulic pushing floor and mixing screw. This dosing unit can be filled up with different kind of substrates like whole plant silage; cattle manure; sugar beet pulp etc. The substrate are all mixed up by the mixing screw and afterwards forwarded to a mixing pump including shredding unit, which is able to cut bigger lumps into small particles and in addition to mix up the solid substrate with liquids. This technology also enables to separate heavy artificial parts like stones. After this process, the homogenous mixture is directly pumped into the fermenter tank. This technology enables a flexible feeding with different kind of substrates and also reduces the own consumption costs of the biogas plant because of less mixing time in the fermenter tank. For the reception of liquid manure or comparable, a separate slurry store is available at the biogas plant. From this tank the liquids are automatically pumped into the fermenter tanks. After the fermentation process, the digestate is pumped into the storage tank and is available for fertilizing purposes in the fields again.

Lübesse-Sülte-Uelitz I wind farm

- Place: Lübesse Since: 2004 Quantity: 17 wind turbines / WEA-Typ: NORDEX

The largest wind farm developed by bioconstruct and its affiliate EEG Energie Expertise GmbH is located in Mecklenburg-Western Pomerania. After years of development and planning work, a total of seventeen NORDEX wind turbines were set up in 2004.

Gehrde wind farm

- Place: Gehrde Since: 2014 Quantity: 4 wind turbines / WEA-Typ: ENERCON E-115

Project development, construction

The district of Osnabrück has big plans: A regional planning program in 2014 designated more than 150 locations for wind power plants, many of which the district itself would like to run. bioconstruct GmbH is also taking part in the projects in collaboration with Landvolkverband Osnabrück and other partners. In this powerful team, bioconstruct is responsible for supplying ready-to-use infrastructure and for project assurance. Cable routes, road construction, license agreements, permits – all from a one-stop-shop! The Gehrde wind farm with four ENERCON E-115 wind turbines is the first in this series.

Region Regenerativ Melle

- Place: Melle Since: 2001

“Half the electricity for households in Melle from renewable sources of energy, and all produced locally!” This slogan was hard for many people to believe in 2001, since it seemed almost impossible to cover the electricity needs of nearly 25,000 people from local sources. At that time, bioconstruct GmbH put its ambitious project, with a total of six wind power plants, a biogas plant and a photovoltaic installation, into the focus of public attention with a great deal of élan and pioneering spirit, then developed and completed the project. The local residents were so delighted that a total of more than 150 limited partners could be attracted to the operating companies, which are still being managed by Mr. Borgmeyer. Everyone talks about civic involvement – bioconstruct put this successfully into practice fifteen years ago!

Frotheim/Isenstedt wind farm

- Place: Espelkamp Since: 2003 Quantity: 2 wind turbines / WEA-Typ: SÃDWIND S-70

In 2003, bioconstruct set up three SÃDWIND S-70 wind turbines with a hub height of 65 meters in Espelkamp in North Rhine‑Westphalia. bioconstruct supplied the entire infrastructure for the project (cable routes, road construction, foundations). One of the three turbines is still owned by partner Reiner Borgmeyer.

PV installation Salzwedel

- Place: Salzwedel Since: 2012 Capacity: 2,1 MWp

In mid-2012, an installation with an output of 2.1 MWp was able to be set up on a general contractor basis within only six weeks on the empty grounds of a former chemical works, which had been remediated at great cost for this purpose. bioconstruct managed and was responsible for all the earth work, the complex pile driving work and for mounting the modules, connecting them to the grid and commissioning. In addition, bioconstruct is not only the supplier of the photovoltaic installation, but also its owner and operator.

PV installation Fonte Cupa

- Place: Gualdo Cattaneo (PG) Since: 2011 Capacity: 650 kWp

In the rolling hills of Umbria, bioconstruct set up a ready-to-use, ground-mounted photovoltaic installation in 2011. This was preceded by intense planning and project development with local partners. The commissioning of the installation, with 650 kWp of installed output, was successfully initiated in a final spurt about three hours before the then effective Conto Energia III development program terminated. Since then, the installation has been yielding performing excellently! In 2013 the installation was sold to a medium-sized electricity supplier in Rome which specializes in renewable energy.

Biogas plant Vinni

- Place: Lääne-Virumaa Since: 2012 Capacity: 1 x 526 kW; 1 x 844 kW

And we are proud to have created this “lighthouse project” for the Baltic countries. It’s worth it to stay on the ball till the end.

In the process, the biggest challenges for us were of a technical nature. For example, temperatures of -25° C were not uncommon in the Estonian winters. We observed icicles forming on the biogas digesters that reached several meters long! But, all told, this enabled us to gather experience for perfecting plants in such extreme climates.

What else is there to say? For instance, fermenting slurry in biogas plants has a particular significance in light of climate change and protecting the environment. A not insignificant portion of the methane gas emissions (CH4) from animal farming originates from the slurry lagoons (approx. 10%). By using the slurry to produce power and heat in biogas plants, these CH4 emissions can be decreased up to 90%. And we think – since it’s impossible to turn everyone into a vegetarian – this is a good beginning.

We thank Mr. Pikk for his trust and collaboration and for his effort in arranging an Estonian photographer for us. The pictures are brilliant!

Biogas plant VettweiÃ

- Place: Vettweià Since: 2011 Capacity: 1 x 370 kW; 1 x 530 kW; 700 Nm³

Gas feed-in plant, Fermentation of sugar beets

The bio methane feed-in plant Vettweià (North Rhine-Westphalia) went operational in December 2012. Following the one in Neukammer (Havelland), it is the second largest feed-in plant we’ve built so far – and it’s the first one we operate ourselves. By doing so, we gain valuable expert knowledge for the construction of further plants. Expertise that each of our clients profits from.

We process bio gas into domestic gas quality and feed this so-called bio methane into the public gas network. This enables the highest possible efficiency in terms of raw material use, because while the bio methane is converted into electricity 100% of the resulting heat is also put use. The domestic gas grid works as a giant transport and storage facility and the biogas also adds stability to the energy grid. That’s because it can be converted into sustainable power whenever the wind doesn’t blow or the sun doesn’t shine.

The raw materials for the plant in Vettweià – namely sugar beets and corn – are supplied by over 40 farmers from the region. Speaking of which: We’d like to give them our warmest thanks for the good cooperation. We’d also like to thank the municipality of Vettweià as well as the gas grid operator RWE for their great contributions to the realisation of the project.

Postscript regarding the technology: The plant’s treatment capacity is 550 Nm³ per hour. Technology supplier for the pressure washer is the Swedish company Malmberg Water AB.

Biogas plant Schuby

- Place: Schuby Since: 2004 Capacity: 2 x 500 kW; 2 x 549 kW; 2 x 904 kW

Installation of an innovative mixing technology for homogenising slurry and energy crops before feeding the fermenter (Quickmix®), 2016 upgrade from 1.000 kWel to 3.906 kWel

In 2004 at the “Schuby” biogas plant, we installed for the first time an innovative mixing unit for the homogenisation of slurry and renewable raw materials before delivery to the fermenter. It was also our first system in Schleswig-Holstein, and at that time it ran at 500 kWel. Three years later we built a 500 kWel further system in Schuby, and in 2016 Mr Schwarten placed the order: even further expansion!

In the meantime we have installed a capacity of 4.406 kWel in Schuby, and the system is operating at optimum efficiency, thanks also to the diligence of the operator. It is extremely flexible and can react optimally to market conditions and to the requirements of the power grid operator. The farmhouse and the cowsheds are heated thanks to the biogas plant, with the feed of cattle slurry, maize silage, and sugar beets.

Biogas plant Randkanal Nord

- Place: Köln Since: 2012 Capacity: 1 x 1.200 kW

Heat use, Municipal utility company

We at bioconstruct are happy to be part on this coherent project by RheinEnergie AG.

The biogas plant Randkanal Nord feeds 1.2 MW of natural energy into the public power grid. This covers the power demand of 3,000 households. At the same time, the plant produces heat that supplies various facilities in the nearby town of Dormagen. Prior to the construction of the plant, the region was heated by fossil domestic gas. Now all raw materials come from the fields in close proximity of the plant. 16 farmers supply 20,000 tons of biomass generated from about 400 ha of land.

The use for the environment is great because the energy production from biomass is CO2-neutral. The reason: the burning of biogas emits only the amount of carbon dioxide that the plants have previously withdrawn from the atmosphere. Compared with fossil fuels, the biogas plant saves about 7,000 tons of carbon dioxide every year. In addition to that, the 17,000 tons of fermentation residue are used as high quality fertilizer which makes artificial fertilizers unnecessary.

Biogas plant Nonantola

- Place: Nonantola Since: 2013 Capacity: 1 x 1000 kW

Italy

Well, that’s one of the best compliments we could wish for. Thank you so much, Mr. Zobili. And we promise to remain a good and reliable partner while you expand your biogas activities as planned.

Lorenzo Zoboli is one of four partners in Nanatola, Italy (in the Emilia Romagna region) that have decided to invest in biogas. Their plant is mainly fed with liquid manure but also with flour and whole grain. It produces sustainable energy for over 1,500 households.

Biogas plant Lünen

- Place: Lünen Since: 2009 Capacity: 10 x 250 kW

Micro gas distribution system (length 6,5 km), 10 satellite-CHP units with 250 kWel each, enamelled Steel tanks, Operated by municipal utility company

The use of renewable energies leads to local added value.

The city of Lünen owns a district heat grid since quite some time that was earlier fired by ship generators amongst others. We included this existing heat grid in our planning and combined it with a micro gas distribution system of 6,5 km length. In this way we achieve a highly efficient utilization of the biogas from the plant.

The biogas plant Lünen with its two characteristic blue steel tanks is charged with 44.000 t of maize silage and 26.000 t of manure annually. A specialty is the separate filling and removal station securing the emission protection at the location within a commercial area.

Biogas plant Linne

- Place: Bissendorf Since: 2009 Capacity: 2 x 190 kW

Connection of barns and existing manure storages for input supply to the biogas plant, The biogas plant is almost solely operated with slurry.

The special circumstance in Linne is the big amount of slurry that is digested. The slurry of approx. 500 cows is around 90% of the input. Apart from that manure, fodder rests, green rye and grass silage are used. Approximately 75% of the produced gas comes from slurry and manure, which occur on the farm anyways.

We installed a pipe connection to the barn so the biogas plant is automatically supplied with 50-60 m³ of slurry per day.

In this way we reduce environmentally relevant methane emissions and instead get the energy from the slurry. After the fermentation process the digestate which is high-quality fertiliser, is land applied and by that the use of mineral fertiliser is reduced. With their biogas plant in Linne the family Westrup therefore supplies climate friendly and sustainable energy with low substrate costs and without further increasing the competition for renting land.

Biogas plant Krukum (ATZ)

- Place: Melle Since: 2010 Capacity: 2 x 370 kW; 1 x 210 kW; 1 x 150 kW; 2 x 400 kW; 3 x 530 kW

Micro gas distribution system with satellite CHP unit, District heating grid (heating school, open-air pool, church institutions), Wood carburettor

Our plant in Krukum was Germany’s first demand-controlled biogas plant in 2010. We here produce electricity and heat whenever they are needed.

Biogas plant Ihausen

- Place: Westerstede Since: 2005 Capacity: 1 x 500 kW

The input consists of 85% grass silage, digestate separation, 2007: upgrade from 190 kWel to 500 kWel

We have to ungrudgingly acknowledge that you can find the major know-how in the matter of grass fermentation not at bioconstruct but in Ihausen. We’re very impressed by the way Mr. Geveke was able to optimise the grass fermentation in his biogas plant and we’re very pleased to be able to always draw upon his vast wealth of experience. After all we’ve been the ones who designed the solid basement for his key to success. “Small fermenter, big mixers, short ways”, is how Mr. Geveke describes it in the Biogasjournal 02/2008. Since commissioning in the last quarter of 2005 things have changed a lot. Today the Gevekes can intermittently digest up to 100% of grass silage with a capacity utilisation of 92%!

The thermal energy supplied by the biogas plant is used to heat two homes, the in-house work shop and to dry more than 2.500 m³ of high quality firewood. During the summer of 2010 another 15 mor homes will be connected to the heat supply. To get more redundancy and always be able to run the plant with 100% of grass silage a fourth fermenter will be built. Mr. Geveke is further planning a cooperationn with a nearby dairy farm. A manure pipeline from the farm to the biogas plant and the installation of several satellite CHP units at different heat sinks are in planning. In 2007 the plant has already been expanded from 190 to 500 kWel.

It’s good to know that plants from bioconstruct are designed for all future options right from the start.

Biogas plant Holterdorf

- Place: Melle Since: 2010 Capacity: 2 x 190 kW

approx. 40% solid manure, Micro gas distribution system with satellite CHP unit in 600 m distance

the high percentage of solid manure was indeed a challenge, but hey – anybody can do corn and slurry. We’re glad we could prove once again that whatever your preferred substrates are – we can build a suitable biogas plant.

The Holterdorf plant went online in 2010 with a power output of two times 190 kW. One of the two CHP units is situated 600 m away, where the heat output is used by a paint shop. Its drying cabins must be kept at a constant temperature of 65° C. By implementing this satellite cogeneration unit we were able to lower the paint shop’s heating costs by 25% while reducing CO2 emissions – meanding economics and ecology go hand in hand.

Biogas plant Götzberg

- Place: Henstedt Since: 2007 Capacity: 1 x 549 kW

Dry fermentation, Heating of greenhouses and pig barns

ur customers from Schleswig-Holstein are real northerners and therefore not very talkactive. So there wasn’t much more to get out of Mr. Mohr. Although he allowed us to quote what he said on another occasion: Mr. Mohr especially likes the down-to-earth character of the BioConstruct staff – none of them is aloof, the clever way the planning was carried out, that the bank could be persuaded and of course that it runs and runs and runs … In this case the picture says mors than a thousand words. Just click on it!

The biogas plant in Götzberg was commissioned in 2007. Since then it’s been running with an average utilisation of 99%. Do we have to say more?

Perhaps that it can be ruinous for women to visit this plant since it’s not just delivering heat to a pig breeding farm but also to one of the most beautiful plant nurseries in northern Germany. In any case the author of this text always has her trunk packed with shrubs and flowers when leaving Götzberg.

But let’s get back to the more relevant information: With an installed capacity of 549 kWel the biogas plant Götzberg produces electricity for approx. 1.100 households. With its dry fermentation it further supplies a heat equivalent of 439.000 l of heating oil. It uses an annual amount of 9.500 t of maize silage. Our scope of delivery included the permit and execution planning, the construction as EPC contractor and of course the commissioning and trial run.

Biogas plant Deblinghausen

- Place: Steyerberg Since: 2013 Capacity: 2 x 400 kW

Direct commercialisation, Dried chicken faeces, Domestic heating grid

The operator collective Deblinghausen knows exactly what it wants. Right from the start – the fist talks took place in late 2011 – there was a clear focus on direct sales. Although, actually the whole town of Deblinghausen knew what it wanted in 2011; after all, the heat concept was already a done deal when we were asked if we could secure the full supply. And of course we can!

We planned larger gas tanks, developed a two-engine concept and integrated an innovative gas management system. Nearly the whole town is now being supplied with heat from the biogas plant. And the customers can be sure their homes are always warm and cosy. Because even if both cogeneration plants should fail simultaneously, a biogas heating system would take over.

The houses in Deblinghausen have no more radiators in their basements. Heating oil and common domestic gas was replaced with “homemade” raw materials and we really like that!

Parallel to the heat, the plant also generates electricity, of course. And the maximum power output takes place whenever the heat demand is highest: at daytime in the winter. How fortunate that this is also when the demand for electricity is highest – meaning stock prices are up. In other words: It is consequent, market-conform and profitable to commercialise the electricity produced in Deblinghausen directly.

And so we can return the friendly compliment of Mrs Wehrs and her partners. Because we really love to work for smart clients.

* in addition to corn silage, the plant also ferments dried chicken faeces, pig manure and sugar beat leafs. Just bring it on!

Biogas plant Exeler

- Place: Rheine Since: 2015 Capacity: 2 x 530 kW; 1 x 250 kW

2017 upgrade from 780 kWel to 1.310 kWel

The trust that the Exeler family put into us – bioconstruct – from the very beginning could and was not disappointed in the end! It was from the outset a well-designed and smoothly handled building site, not least because of the open and honest communication and handling between the client and us. Thus, larger interfaces such as the built on-site solid storage area, which, at the same time, provides space for the 100 m³ solid feeding system as well as the separation unit, or the connection and integration of the on-site pre-storage tank within the barn via a 200 m long pressure line, could be handled easily.

In order to feed the substrate mix which almost exclusively consists of solid materials without problems into the digesters, we decided to install a shredder unit prior to the liquid feeding pump, which was, at that time, newly introduced into the market by the manufacturer.

We recognized how passionate the Exeler family operated their agricultural business as well as their biogas plant, when, in 2017, we were contracted to expand their plant with two additional combined heat and power units to allow flexible operation. Such well-maintained plants and farms are not a matter of course.

Biogas plant Bukovec

- Place: Holýšov Since: 2009 Capacity: 1 x 600 kW

approx. 50% solid manure

The biogas plant in Bukovec with an electrical capacity of 600 kW was our first project in the Czech Republic. According to our claim of being “close to the customer” the control system is in Czech as well as the whole plant is labelled bilingual. A big help for the planning and construction of the plant was our Czech business partner.

The plant was commissioned by the end of 2009 and was on full load within four weeks. We achieved this although it’s running on 50% of solid manure! Our customer Mr. Šamberger paid special attention on having a plant that is flexible in terms of the use of different inputs and that it can be easily expanded in the future. And as you can see he is very relaxed and satisfied with his biogas plant. As EPC contractor we were again able to satisfy all our customer’s requests without disregarding the plants economic efficiency.

Biogas plant Dahlenburg

- Place: Dahlenburg Since: 2007 Capacity: 4 x 549 kW

Satellite CHP unit, Heat use, Municipal utility company

The biogas plant Dahlenburg is in mint condition although it already went on line by the end of 2007. During that time intelligent heat concepts were seldom implemented due to the fact that the feed-in tariff for electricity alone was enough for a good economic efficiency of the plant. But even back then the E-Werk Dahlenburg wanted more and together with them we installed a local heat grid and two heat sinks. To this grid all the surplus heat that is produced in the operation of the biogas plant is supplied. There is an on-site wood drying facility and a satellite CHP unit in 1,5 km distance supplying it’s thermal energy to greenhouses.

In total the biogas plant supplies three CHP units each with an installed electrical capacity of 549 kW covering the demand of 3.000 households. The produced heat equals an annual amount of 1.200.000 litres of heating oil. We’ve built two fermenter and two post fermenter with a volume of 2.200 m³ each and two additional digestate storage tanks of 5.800 m³ each.

Our scope of delivery included the permit and execution planning, the construction as EPC contractor and of course the commissioning and trial run.

Biogas plant Redefin

- Place: Redefin Since: 2008 Capacity: 2 x 250 kW; 1 x 550 kW; 3 x 630 kW

Micro gas distribution system (17km), approx. 30% solid manure

We are setting standards in terms of the management of your facilities; standards that even we can still learn from. Each of your staff is equipped with a mobile control unit. That makes site inspections extremely efficient and effective as your database is automatically fed with all important operational parameters. Together we’ll get even better and together we can make it to 100% sustainability.

Imperial Park AD plant

- Place: Middlesbrough Since: 2017 Capacity: 4.988 kW

This project was certainly a milestone in bioconstruct’s history. We were contracted to design, construct and commission the Imperial Park biogas/anaerobic digestion (AD) plant in 2015. We signed extensive guarantees for the plant’s technical availability which gave the investor sufficient financial security. The plant was designed for an electrical capacity of 5.1 megawatts and is situated in Middlesborough, England. Only 11 months (roughly) were needed for construction, after which the digester tanks were ready for their first fill with special substrate transferred from another plant. Since then, the plant has been operated and maintained by BioConstruct NewEnergy, our sister company in the UK.

bioconstruct designed the biogas plant with an aim of giving the operator as much flexibility as possible when choosing substrates so that it can be operated as economically as possible. This entailed, among other things, creating a generous pre-storage volume with multiple pre-storage and reception tanks, some of them heated, and enabling parallel infeed of solid and liquid substances. As a result, it’s easier to get through times when certain substrates have limited availability, while additional substrates can also be put in storage. The plant is able to process liquid substrates such as slurry, blood or fat and can mix them with solid feedstocks such as supermarket or restaurant waste before digestion using a special pump system. After mixing, they’re pumped into the digester tanks. Combining the two infeed lines makes the biogas plant able to process approximately 131,000 tonnes of organic waste per year and convert that into up to 5.1 megawatts of electrical energy plus approximately the same amount of thermal energy through the combined heat and power (CHP) systems.

bioconstruct installed a total of four GE Jenbacher CHP systems. To reduce the plant’s maintenance costs to the lowest amount possible, a choice was made to use high-quality components and process control systems right from the start. The external biological desulphurisation is a good example of this, as it keeps the costs for activated carbon and other expensive consumables as low as possible. Furthermore, the piping system – made fully of stainless steel – and the centrally stirred vertical digester tank – made of enamelled steel – help reduce the maintenance and operating costs as far as possible.

Chichester biogas plant

- Place: West Sussex Since: 2017 Capacity: 1.800 kW

This biogas plant in the south of England was built near Chichester in 2017. It generates electricity with a rated power of 1.8 megawatts using two Jenbacher CHP engines, and also produces an equivalent amount of thermal energy. At this plant, the thermal energy is converted into steam which is used for the pre-treatment and separation of wheat straw. This procedure improves the digestability of feedstock that contains fibres and enables the plant to process up to 7,000 tonnes of wheat straw per year. On top of that, there’s also approximately 20,000 tonnes of pig farm yard manure per year which results from an outdoor piggery operated by a neighbouring farmer. Due to the large proportion of feedstock that is biologically difficult to macerate, our client requested that we use innovative technology. This technology includes a cavitation system connected to the two digester tanks that keeps macerating the substrate by using different levels of pressure, making the substrate more viscous and therefore mixable. As a result, the plant is a pioneer in straw digestion in many ways and made use of innovative technology from the outset.

After digestion in the digester tanks, the substrate is hygienised at 70°C to make it possible to use as a premium fertiliser in accordance with England’s strict PAS110 regulations. Hygienisation is followed by mechanical separation into solid and liquid fractions before the liquid digestate is pumped into a digestate lagoon and stored there temporarily. This gives the local farmer the option of applying the nutrients from the fertiliser to the fields when the plants actually need them.