IMAO Corporation

Videos

Loading the player ...

- Offer Profile

-

Since 1967 when we were the first in the industry to introduce standard machine elements in Japan, we have pursued the development of unique standard machine elements with superior functionality.

In 1983 we started manufacturing and selling our first standard fixture components "Block Jig System". Since then, we have been expanding our lineup with creative fixture components to contribute to improving productivity for our customers engaged in manufacture.

Now we are one of the most well-recognized and appreciated manufacturers of fixtures and clamping components among global customers. We, as a professional supplier of standard fixture components, will continue contributing to our customers' manufacturing.

Product Portfolio

QUICK RELEASE FASTENERS

Quick Release One Touch Fasteners

- One-Touch Fasteners are quick release fasteners for frequent changeover of machinery or fixture.

Quick and easy tool-less clamping reduces setup time in changeover.

IMAO's quick release fasteners are available in various clamping styles, quarter turn fasteners, ball locking fasteners and pin holding fasteners.

Pneumatic Clamping Fasteners

- Pneumatic Clamping Fasteners are automated quick fasteners with air for quick change applications. Instant pneumatic clamping slashes setup time in multiple-parts holding and frequent changeover of machinery or fixture.

Flex Locators

- One Touch Flex Locators are mechanical clamping locators for quick change applications.

Positioning and clamping in an easy single operation reduces set up time in fixture change.

Tapered surface contact provides precise locating repeatability of 0.01 mm.

Cam or ball lock clamping produces heavy duty clamping up to 4500 N.

Pneumatic Flex Locators

- IMAO's pneumatic fasteners provide quick change solution for frequent changeover of automation machinery.

Quick clamping and locating with 0.003mm repeatability eliminates set up time in frequent changeover of plates, toolings and fixtures.

These automated fasteners are quick, simple and secure changeover solution to increase your productivity.

SLIDING LOCKS

One Touch Push Lock Clamps

- One Touch Push Lock Clamps are quick locks that provide easy, tool-less locking with a 90-degree turn for slide and angle adjustment. The internal spring keeps the clamping force constant to prevent over/under tightening. The indication line and touch of a click allow any user a secure and reliable operation. These locks are versatile enough to clamp various objects such as flat bars, round shafts and linear rails in many sizes. IMAO's One Touch Push Lock Clamps reduce setup time and increase productivity.

One Touch Sliding Locks

- One Touch Sliding Locks are quick locks for slide adjustment. Quick and secure clamping with a quarter turn reduces setup time and increases reliability in sliding applications for position change. These sliding locks are ideal for slide position adjustment with a sliding bar or a slotted hole.

One-Touch Indexing Clamps

- One-Touch Indexing Clamps are quick fasteners with precise locating for position adjustment by sliding or rotation. Tapered surface contact provides +/- 0.05 repeatability and ON/OFF marking and click eliminate human error.

One-Touch Locking Knob

- One-Touch Locking Knob enables secure locking of spindle with one-touch action. Perfect for radial feeding applications (e.g. rack and pinion) and thrust feeding applications (e.g. lead screw).

QUICK SHAFT CLAMPS

One Touch Push Lock Clamps

- One Touch Push Lock Clamps are quick locks that provide easy, tool-less locking with a 90-degree turn for slide and angle adjustment.

The internal spring keeps the clamping force constant to prevent over/under tightening. The indication line and touch of a click allow any user a secure and reliable operation.

These locks are versatile enough to clamp various objects such as flat bars, round shafts and linear rails in many sizes.

IMAO's One Touch Push Lock Clamps reduce setup time and increase productivity.

One-Touch Shaft Clamps

- One-Touch shaft clamps are quick and secure locks for shafts and spindles used in sliding position adjustment. Easy, tool-less operation and visible clamping position eliminate over/under tightening. One-Touch shaft clamps can be used in smaller spaces than conventional shaft collars, offering much better workability as there is no need to tighten levers or screws.

Pneumatic Shaft Locking Clamps

- Pneumatic Shaft-Locking Clamps are automated quick locks with air for machine changeover.

Perfect for secure clamping of sliding shaft and spindle after position adjustment of parts and units in the machinery.

MECHANICAL LINEAR UNITS

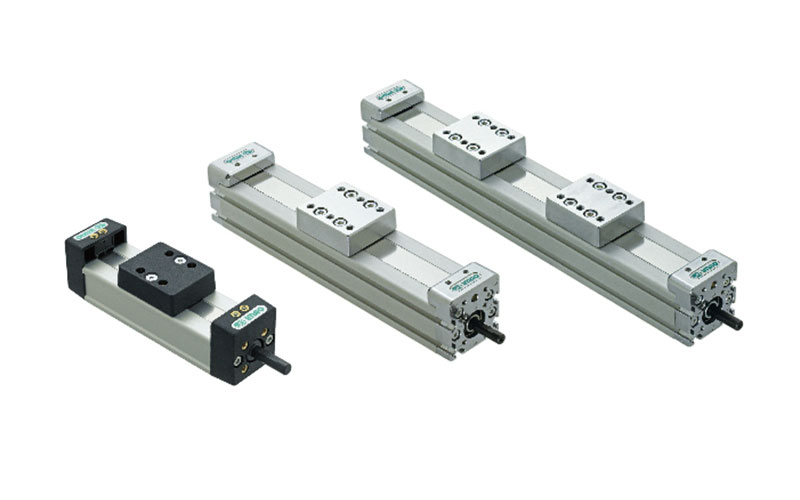

Mechanical Linear Actuators

- Imao's Mechanical Linear Actuator is a completed manual linear unit with lead screw and guide.

The lead screw is built into the aluminum profile body and protected with a dust cover.

The unitized design reduces design cost by eliminating time for parts selection and assembly.

These ready-to-use actuators are in-stock to ensure better availability and quicker delivery.

Mechanical Linear Actuators offer improvement in quick position adjustments on printing machines, material feeders, packaging machines, and conveyors.

TORQUE LIMITING KNOBS & HANDLES

Torque Limiting Knobs and Handles

- Torque limiting knobs and handles provide constant tightening force with the specified torque.

These functional knobs and handles prevent over / under tightening by clicking when reaching the desired torque.

The knobs come with preset torque of 2 or 3 Nm and the handles have adjustable torque range of 1 - 8 Nm.

Cam handles

- Cam handles and cam levers provide quick clamping for position adjustment or part changing in machine changeover.

The clamping force is applied by pushing down the handle, and it is released by lifting up.

Tool-free fast tightening with cam handles reduces setup time and eliminates the need for turning a screw or a knob many times.

IMAO's cam levers are available in many styles, sizes and materials to meet the requirement in various applications.

BEARING GUIDE ROLLERS

Bearing Guide Rollers

- Imao's guide rollers with built-in bearings are ready-to-use, and save your time and effort in product design.

All guide rollers are in-stock to ensure better availability and quicker delivery.

Imao offers a wide variety of shapes, sizes, and materials for various applications such as conveyor lines and material handling.

These standard rollers contribute to cost reduction by eliminating designing and manufacturing your own rollers.

MECHANICAL CLAMPS

One-Touch Clamps

- One-Touch Clamps are mechanical quick clamps developed for machining fixture.

Quick and easy clamping by turning the handle slashes workpiece setup time and spiral cam mechanism provides high clamping force.

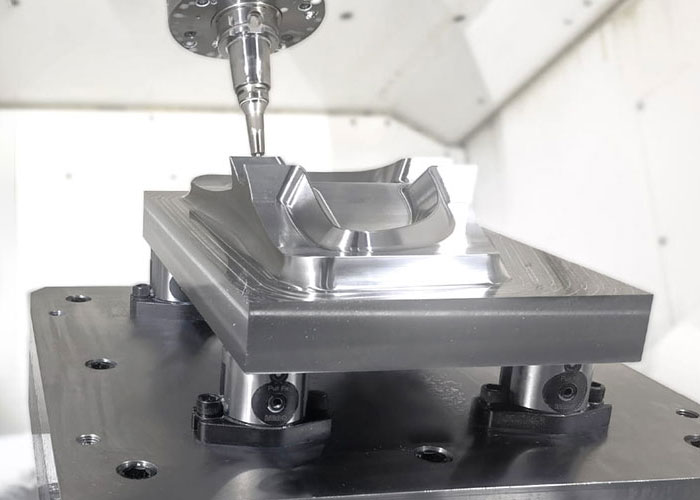

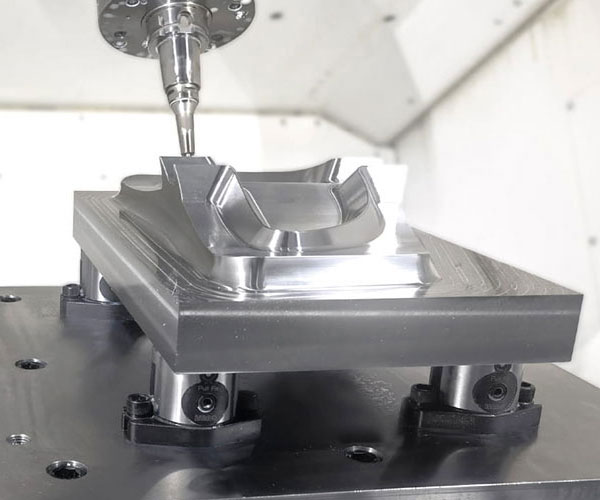

Modular Pull Clamping System

- IMAO's Modular Pull Clamping System is a workholding system for 5-axis machining with precise locating repeatability of 0.005mm.

Pull-down clamping allows clear tool access and enables machining from five sides, leading to better machining accuracy with a single setup.

This simple mechanical system provides easy & precise positioning and clamping for 5-axis machining.

Side Clamps

- IMAO's manual side clamps grip the side of a workpiece to keep the top free of obstructions in machining fixture.

Strong downward clamping prevents workpiece from lifting upward.

Spring Clamps

- Imao Spring Clamps are mechanical tool-less clamps with constant clamping force by spring pressure.

The handle clicks at its clamping end, leading to error-free secure clamping.

The clamping force generated by a spring is always constant, preventing over/under tightening and workpiece damages.

The compact design allows integration to a limited space where toggle clamps cannot be used.

MACHINABLE COLLET CLAMPS

Machinable Collet Clamps

- Machinable collet clamps hold any external shape of workpieces by a single tightening.

Ideal for machining small, thin, complex and irregularly shaped workpieces on machining centers or turning lathes.

The collet is divided into up to 8 sections and distributes the clamping force over the external contour to prevent workpiece deformation.

Compact body allows mounting multiple clamps on the fixture plate.

Simple workholding with Machinable collet clamps saves your time in fixture design.

Form Holding Clamps

- Form Holding Clamps with a machinable jaw are perfect for irregular-shaped workpieces.

Simple workholding on external/internal form eliminates the need for custom fixtures.

CLAMPING AUTOMATION

Pneumatic Clamps

- IMAO's Pneumatic Clamps are automated machining clamps with our unique clamping mechanism. The combination of mechanical and pneumatic clamping technology generates a fivefold higher clamping force than pneumatic cylinders of the same size. IMAO offers a wide variety of compact pneumatic clamps including swing, hold-down, pull-down and OD-holding clamping styles, to provide an ideal clamping solution for your automated application.

Nutrunner Clamps

- Clamping automation by Imao's Nutrunner Clamps serves as alternatives to hydraulic clamps. Tightening with nut runner installed on a robot actuates Nutrunner clamps to hold workpieces with high clamping force in machining and assembly line. Mechanical design does not require hydraulic piping and simplifies fixture design and maintenance. IMAO's robotic clamps achieve automated workpiece clamping with shorter fixture preparation time and lower fixturing cost than hydraulic clamps.

5-AXIS CLAMPING SYSTEM

Centering Clamps

- IMAO's Centering Clamps are mechanical self centering vises for raw workpiece clamping on 5-axis machining centers. Highest 20 kN clamping force allows rigid clamping of raw part without stamping process. The low profile and compact design offers best accessibility to workpieces for 5-sided machining. These self centering vises are adaptable with our quick change plate, leading to reducing setup times in fixture changeover.

Flex Zero Bases

- Flex Zero Base is a quick change plate with 0.005 mm repeatability and 12 kN clamping force. 4-point clamping by only one actuation screw drastically shortens machine down time during fixture change operations. Compact body is perfect for quick change on small 5-axis machining centers and vertical machining centers.

Modular Pull Clamping System

- IMAO's Modular Pull Clamping System is a workholding system for 5-axis machining with precise locating repeatability of 0.005mm. Pull-down clamping allows clear tool access and enables machining from five sides, leading to better machining accuracy with a single setup. This simple mechanical system provides easy & precise positioning and clamping for 5-axis machining.

QUICK CHANGE ZERO POINT SYSTEM

Pneumatic Flex Locators

- IMAO's pneumatic fasteners provide quick change solution for frequent changeover of automation machinery. Quick clamping and locating with 0.003mm repeatability eliminates set up time in frequent changeover of plates, toolings and fixtures. These automated fasteners are quick, simple and secure changeover solution to increase your productivity.

Modular Pull Clamping System

- Modular Pull Clamping System allows quick change fixturing with 0.005mm locating repeatability on CNC machining centers. Quick locating and clamping reduce fixture set up time by eliminating operations such as positioning, centering and fixing with screws. This mechanical zero point clamping system holds fixture plates in different sizes by changing the mounting position.

Flex Locators

- One Touch Flex Locators are mechanical clamping locators for quick change applications. Positioning and clamping is an easy single operation reduces set up time in fixture change. Tapered surface contact provides precise locating repeatability of 0.01 mm. Cam or ball lock clamping reduces heavy duty clamping up to 4500 N.

Flex Zero Bases

- Flex Zero Base is a quick change plate with 0.005 mm repeatability and 12 kN clamping force. 4-point clamping by only one actuation screw drastically shortens machine down time during fixture change operations. Compact body is perfect for quick change on small 5-axis machining centers and vertical machining centers.

WORK SUPPORTS

Work Supports

- Spring loaded work supports provide better machining accuracy by reducing workpiece deflection and vibration during machining operations. The support plunger is automatically compressed to the proper height and locked mechanically or pneumatically. These workpiece supports provide quick and secure workpiece setup compared to conventional screw jacks.