- Offer Profile

-

Telemecanique Sensors specializes in sensors and sensor-related technology.

Telemecanique Sensors is a global player, present in more than 20 countries, with products distributed worldwide through a broad network of partners. As a global leader in the sensors business, we help our customers select the right technology to get the best performance and reliability from their machines. Focused on 3 core values – Simplicity, Proximity and Expertise – we have become experts in factory automation sensors as well as specialists in demanding applications, making our customers’ lives "simply easy!"

Limit Switches

-

Boasting a rich history of limit switch innovation dating back to the early 1900s, we now carry the broadest line of mechanical limit switches available in the industry.

Whether your machine application calls for an IEC, NEMA, safety, wireless, or battery-less limit switch, Telemecanique Sensors unparalleled selection of mechanical limit switches and connector options make it easy to find the perfect solution for your machine design.

Our limit switches come in standard, heavy duty, compact, miniature, safety, and application-specific models and our wireless and battery-less limit switches are revolutionizing the industry.

The wireless and battery-less limit switches have transformed an electronic signal previously traveling through a cable into internet data which can be easily documented and analyzed for maximum efficiency identification.

Application-specific Limit Switches

-

INDUSTRIAL APPLICATION-SPECIFIC LIMIT SWITCH MODELS

Unique applications demand unique limit switch solutions; and Telemecanique Sensors has been addressing unique machine applications all over the globe for the past 90 years.This range of application-specific IEC limit switches with special formats (formerly known as OsiSense), are dedicated tospecific applications such as hoisting, Mining, Minerals & Metals or belt conveying.

The whole range is designed for easy product selection, installation and maintenance.

XC2 VERY SEVERE DUTY APPLICATIONS

XC1 VERY SEVERE DUTY FOR MATERIAL HANDLING APPLICATIONS

XCR / XCK*R CROSS LIMIT SWITCHES FOR HOISTING APPLICATIONS

XCRT FOR CONVEYOR BELT APPLICATIONS

XEP* / XC0 MICROSWITCHES

NEMA Limit Switches

THE INDUSTRY STANDARD FOR RELIABLE LIMIT SWITCH PERFORMANCE SINCE 1924

Since 1924, Telemecanique Sensors brand limit switch has been synonymous with quality and dependability, firmly establishing itself as the industry leader. The 9007 series limit switches are designed to withstand harsh industrial environments and are available in a wide range of options. Some of the variations include

9007 AW HEAVY DUTY PRECISION LIMIT SWITCHES

L100 / L300 SEVERE DUTY MILL AND FOUNDRY WITH EXTENDED CONTACT SEQUENCES

9007 T/FT SEVERE DUTY MILL AND FOUNDRY LIMIT SWITCHES

9007 MS/ML HEAVY DUTY MINIATURE LIMIT SWITCH

9007 C HEAVY DUTY COMPACT LIMIT SWITCHES

9007 AO/CO SNAP LIMIT SWITCHES

L525 BELT CONVEYOR SWITCHES WITHOUT LEVER

L140 / L2153 ROPE PULL SWITCHES

Standard Limit Switches

-

THE WORLDWIDE LIMIT SWITCH STANDARD FOR INDUSTRIAL APPLICATIONS

As market leader, Telemecanique Sensors offers a comprehensive range of IEC limit switches (formerly known as OsiSense), with proven robustness and reliability for more than 90 years.The whole range is designed for easy product selection, installation and maintenance..

Inductive Sensors & Capacitive Sensors

-

BEST-IN-CLASS QUALITY AND IMMUNITY TO HARSH INDUSTRIAL ENVIRONMENTS

Regardless of the material you need to detect - without contacting it, Telemecanique Sensors has you covered with a full range of high quality and high performance inductive and capacitive sensors. For detecting metal objects up to 60mm, our range of inductive sensors feature the latest in high performance technology. For non-contact detection of any other type of material up to 20mm, our capacitive sensors match that same top level of performance.A summary of these two best-in-class non-contact detection options appear below

Inductive proximity sensors - XS range

Our inductive proximity sensors (formerly known as OsiSense XS) are solely for the detection of metal objects up to 60mm. They basically comprise an oscillator whose windings constitute the sensing face. An alternating magnetic field is generated in front of these windings. When a metal object is placed within the magnetic field generated by the sensor, the resulting currents induced form an additional load and the oscillations cease. This causes the output driver to operate and, depending on the sensor type, a normally open (NO) or normally closed (NC) output signal is produced. Our inductive sensors come in flush and non-flush versions (shielded / non-shielded), short and long body versions, PNP and NPN versions to be compatible with all PLCs and controllers worldwide. 2 wires DC, AC, or AC/DC versions are also available to be installed in your application as a limit switch.

Main applications

- Railway

- Mobile equipment

- Lifts & Escalators

- Hoisting

- Material handling / Conveying / Logistics

- Material working / Machine tools

- Packaging

- Food and Beverage

- Robotics

Photoelectric Sensors

-

THE WORLDWIDE LIMIT SWITCH STANDARD FOR INDUSTRIAL APPLICATIONS

For over 45 years, Telemecanique Sensors has been setting industry standards in photoelectric proximity sensors with innovative design solutions like the XUY roller conveyor sensor. Telemecanique Sensors XU range offers a full line of photoelectric proximity sensors dedicated to material handling, packaging, labeling, assembly, lift & escalators or food & beverage industries. This range offers many functionalities such as Diffuse mode, Background Suppression (BGS), polarized reflex, laser reflex & through-beam or through-beam, available in the 4 most popular formats worldwide. The XU range is divided into 4 sub ranges for general purpose, lasers, forks and frames, and specific applications' sensors.

Advantages

- Medium sensing distance (up to 15 m).

- Precise detection.

- Only one unit to be wired.

- Detection not affected by colour of object or by position angle

- Visible red beam transmission

GENERAL PURPOSE

GENERAL PURPOSE LASERS

FORKS AND FRAMES

APPLICATION

Ultrasonic Sensors

-

MATERIAL DETECTION REGARDLESS OF LIGHT, SHAPE, COLOR, DUST, OR DENSITY

XX Ultrasonic Sensors (formerly known as OsiSense) perform contactless, reliable, and high-performance detection regardless of the target’s shape, texture, color, or transparency. Capable of withstanding even the harshest industrial environments, XX Ultrasonic Sensors operate in diffuse, reflex, and thru-beam modes.This range of sensors even includes long distance detection models. The integral connector and the available cabling and fixing accessories make these ultrasonic sensors extremely easy to install. Our most recent XX Ultrasonic Sensors line include:

High immunity to electromagnetic interference

XX Ultrasonic Sensors are E2-certified for mobile equipment. This entails a higher immunity to electromagnetic interference even in the most demanding applications.

Pressure sensors

- For over 70 years, Telemecanique Sensors has been setting the standard for pressure switch innovation and reliability, with our Pumptrol brand clearly establishing itself as the #1 pressure switch in the industry. Using the same spirit that created the Pumptrol legacy, we have taken pressure control to the next level, integrating today’s advanced pressure control features into high performance sensors that are as reliable as they are easy-to-use. Installation and set-up are a snap and quickly put you in complete control of your machine pressure.

Pressure Sensors and Switches

-

INNOVATIVE, PRECISION PRESSURE MEASUREMENT FOR MULTIPLE CONFIGURATIONS

The line of XM Pressure Sensors and Switches (formerly known as OsiSense) combine the latest in pressure sensing technology with adaptability to virtually any configuration. Whether your pressure switch is positioned in a convenient, accessible location or in an area that is hidden from view, Telemecanique Sensors has a solution to help you easily monitor its activity.

The XMLR from Telemecanique Sensors incorporates a monitoring interface as a part of the pressure switch for applications when the switch can be easily viewed. Our ZMLP monitor can be used to connect to our XMLP pressures switch when the switch is going to be hidden from view.

Ideal for pumping, hydraulic, HVAC, and machine tool applications, these pressure monitoring solutions are easy to set up and easy to maintain. Choose from 3 available options detailed below.

ELECTRONIC PRESSURE SENSORS FOR CONTROL CIRCUIT

ELECTROMECHANICAL PRESSURE SENSORS FOR CONTROL CIRCUIT

ELECTROMECHANICAL PRESSURE SENSORS FOR POWER CIRCUIT

NEMA Pressure Sensors and Switches

-

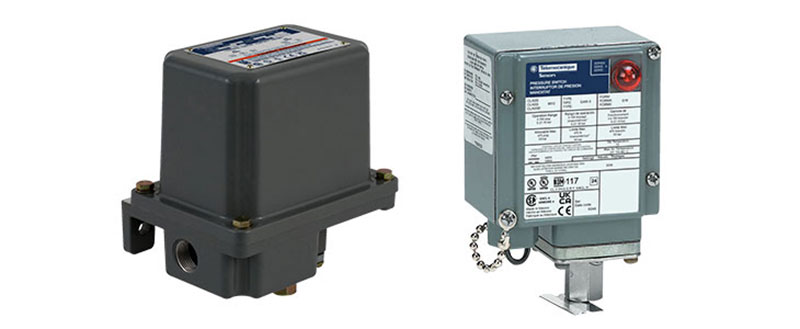

THE CLASSIC PUMPTROL BRAND PRESSURE SWITCH, VACUUM SWITCH, AND FLOAT SWITCHES

Consistently recognized as the #1 switch on the market, the century-old Pumptrol brand water pressure switch has expanded to an entire line of industry-leading Pressure Sensors and Switches. The trusted and reliable line includes pressure, vacuum, and float switches which meet most domestic and international standards, including NEMA, UL, CSA and CE. As an innovation leader with a long history of application success, our switches provide virtually unlimited flexibility and an unmatched level of reliability

9012 INDUSTRIAL PRESSURE SWITCHES

9013 POWER PRESSURE SWITCHES

9016 INDUSTRIAL & POWER VACUUM SWITCHES

9036/9037/9038 LEVEL CONTROL FLOAT SWITCHES

Safety sensors & switches

-

For over 90 years, Telemecanique Sensors has developed quality sensor products which help engineers ensure their machines are safe to operate and meet all the industry’s applicable safety standards.

Whether you need to secure a hazardous area, automate hazardous machinery shutdown when a restricted area is entered, or provide workers a readily available means to shut down hazardous machinery, Telemecanique Sensors’ line of Preventa safety products has you covered with a variety of machine safety solutions. The solutions include safety limit switches, safety interlock switches, contactless safety magnetic switches, contactless RFID safety sensors, safety light curtains, and emergency stop cable pull switches.

Securely lock the access to the machine. Automatically shut it down when a hazardous area close to it is breached. Provide employees a quick, easy way to shut it down.

Simple and Emergency Stop Safety Cable Pull Switches

-

PROVIDES MACHINE OPERATORS A QUICK WAY TO SHUT DOWN HAZARDOUS MACHINES

Preventa XY2 emergency stop cable pull switches from Telemecanique Sensors are an affordable, UL certified safety solution allowing personnel to react quickly, at any point along a conveyor, to shut down hazardous machines to protect themselves and the equipment.

Simple to use and set up, these Rope Pull Switches are compact and ergonomic to meet the requirements for performing emergency stops on hazardous machines.

The XY2 line of switches come in a robust metal enclosure so they can be used in severe environments and they conform to EN/ISO 13850, EN/IEC 60947-5-5.

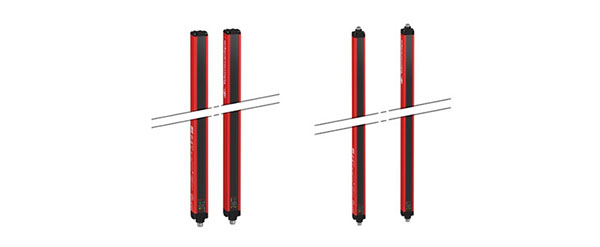

Safety Light Curtains

-

PROVIDES AUTOMATIC MACHINE SHUTDOWN WHEN A RESTRICTED AREA IS BREACHED

Preventa XUSL Safety Light Curtains from Telemecanique Sensors provide automatic machine shutdown when a restricted area is breached.

LIGHT CURTAINS

LIGHT CURTAINS IP69K

LIGHT CURTAINS XU2S

MUTING APPLICATION

ACCESSORIES FOR GENERAL PURPOSE

ACCESSORIES FOR MUTING

Hazardous dust environment Safety Sensors

-

EXPLOSIVE DUST ATMOSPHERE SAFETY SWITCHES AND SENSORS

The Telemecanique Sensors Preventa line of hazardous dust atmosphere sensors are compliant with the global international standard IECEx and the latest European ATEX directive. By choosing a Telemecanique Sensors product for your hazardous dust machine application, you are choosing a sensor that had been tested and certified to perform in a manner compliant with these prominent, established safety standards.

The Preventa line of hazardous dust atmosphere sensors include a wide range of products including limit switches, pressure switches, safety switches, inductive sensors, and speed monitoring sensors.

Safety Interlock Switches

-

FOR CONTROLLING THE SAFE OPENING AND INTERLOCKING OF GUARDS AND COVERS

When a running machine necessitates a door or guard remain closed and an idle machine means the machine should be accessible, there is no better solution than the Preventa XCS line of Safety Interlock Switches. The XCS line of Safety Interlock Switches is one of the most comprehensive catalogs of industrial safety switches on the market, providing a range of options for most machine applications.

RFID and Inductive Identification Systems

-

THE WORLDWIDE LIMIT SWITCH STANDARD FOR INDUSTRIAL APPLICATIONS

RFID (Radio Frequency IDentification) refers to radio frequency identification systems. These frequencies range between 50 kHz and 2.5 GHz. The most widely used is 13.56 MHz.

The RFID system makes it possible to perform traceability, object identification (tracking) and access control functions. The information is stored in a memory that can be accessed using a simple radio frequency link. This memory is in the form of an electronic tag, which contains an antenna and an integrated circuit. The tag contains the information associated with the object to which it is fixed. When a tag enters the field generated by the reader/smart antenna, it detects the signal and exchanges the data (read or write) between its memory and the reader/ smart antenna.

SMART ANTENNAS

ELECTRONIC TAGS

CONNECTION BOXES

ACCESSORIES

TERMINAL

Cloud Connected Sensor

-

THE "SIMPLY EASY!" SOLUTION TO MONITOR YOUR MOST UNREACHABLE ASSETS

The Internet of Things (IoT) is the extension of the Internet to connected devices. Telemecanique Sensors offers a wireless solution to collect data from remote equipment and use this data, via the Internet, on a PC or mobile device.

The XIOT Cloud Connected Sensor from Telemecanique Sensors is based on LPWAN (Low Power Wide Area Network) technology, operated by Sigfox. The Sigfox network covers is already very extensive in Europe and is being rapidly deployed in the US and Asia-Pacific.

It uses antennas with a range of around 50 km. The map on the Sigfox website shows exactly which areas are covered by the network. When the contacts on a switch (limit switch or pressure switch) installed on your site change state, the autonomous transmitter sends a message to the IoT network (LPWAN), which is then routed to our secure servers. This message is then delivered to one or more recipients as an alert on PC, tablet, or smartphone.

Hazardous dust location switches and sensors

-

SENSORS CERTIFIED FOR EXPLOSIVE DUST ATMOSPHERES

Some machine applications create potentially explosive atmospheres, making reliable detection even more critical. According to the European Directive, an explosive dust atmosphere is created when the air is mixed with a flammable dust which, in the event of combustion, would spread throughout the particles in the air which were not initially ignited.

Potentially explosive dust can be produced for a specific purpose (manufacturing flour or sugar, ...), generated when processing of solid materials (sawdust from cutting wood, ...) or result from the abrasion of solid material during transport (producing cereals, ...). All companies where such manufacturing is processed will face a risk of explosion.

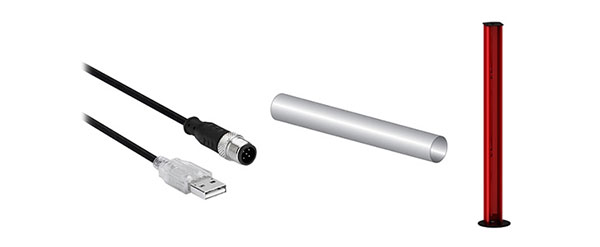

Cordsets and connectors

-

HIGH-PERFORMANCE, QUICK AND EASYCONNECTIONS TO ALL SENSORS

Reliable sensors need a reliable pathway to transmit the signals about their detection! This Telemecanique Sensors XZ range of machine cabling accessories (formerly known as OsiSense) include a wide range of cordsets, connectors and connection boxes. It has been designed for user-friendliness, a simple connection process, as well as quick and safe reference identification.