- Offer Profile

- Since the last four decades Unitechnik Systems GmbH is considered to be among the leading suppliers of industry automation and informatics. We plan and realize tailored systems for the in-house logistics and production.

We operate on a worldwide scale. Our solutions endow the customers with long term benefits: efficient, durable and operator friendly. In this process, our professional project management lays the foundation for the project success.

We aim at long term business relations based on partnership. This applies to both suppliers and customers. We consider the expert support for the realized systems by our service department as very important.

Logistic Systems

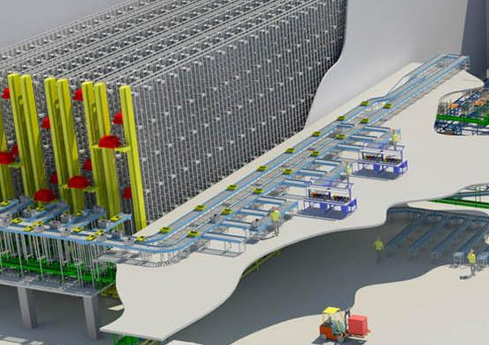

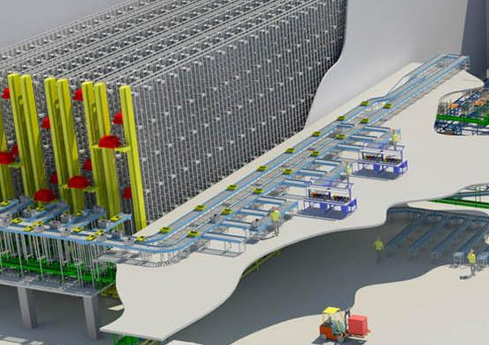

- Turnkey overall solutions for intralogistics

Thinking it out in detail, then acting purposefully. This is the philosophy which Unitechnik as general contractor consistently realizes in the intralogistics on a worldwide scale. The result: tailored logistics systems, which achieve a high measure of efficiency through automation and system integration. With an experience of more than 40 years our engineers know how customer specific solutions can be realized with high cost efficiency.

Unitechnik always considers intralogistics as a whole. In a governing overall concept we perfectly and mutually coordinate warehouse and transport systems, the control technique, as well as the warehouse management system. Your decisive advantage: when selecting individual components, we advice manufacturer independently. In this way, tailored logistics systems arise under the responsibility of an experienced general contractor.

A relationship with the customer based on partnership, committed project management and personal support lay the foundation for the success of our logistics projects. In our offers we describe your requirements in detail and think a step further. This way we show you what is technically possible for your intralogistics and makes economic sense. In doing so, we draw on our wealth of experience in different sectors with a variety of different system solutions.

Our expertise for tailored logistics systems includes:- System integration

- Warehouse technique

- Transport systems

- Automation technique and electrical equipment

- Warehouse management software

- Retrofit / modernization

- Energy efficiency

Systemintegration - Tailored logistics center

-

As experienced general contractor Unitechnik takes over the total responsibility for your logistics center. To this end, we analyze your individual process operations and show you optimization potentials. In our offer we describe a tailored logistics center, which will meet your requirements.

With the selection of the system components we advice manufacturer independently.

Our team of experts accompanies you from the beginning of the planning phase up to the productive operation of the logistics systems. As general contractor with an experience of more than 40 years, Unitechnik is focused on the overall project at all times. In a functional specification document we show you already from the beginning of the construction all the steps and arrange these chronologically in order. For the comprehensive automation of your logistics center we mutually coordinate warehouse technique, process control and warehouse management system.

Our performances for the system integration include:- Potential analysis

- Planning

- Selection of system components

- Simulation

- Overall project management

- System test and emulation

- Assembly and start-up procedure

- Maintenance and servic

- Electrical equipment

- Process control

- Warehouse management syste

Storage systems - High bay warehouse

-

High rack warehouse for efficient space utilization

High rack warehouses enable an optimal space utilization and offer with a height of up to 50 meters a maximum of warehouse capacity. Automated pallet warehouses guarantee efficient storage and distribution of goods – also of heavy and large-volume goods.

The selection of the appropriate solution for a demand-based high rack warehouse is challenging:

Which components are useful?

Which manufacturers are best suited?

Silo structure or freestanding multi-tiered shelving system – what is more economical?

Single- or multiple-deep storage – what is suitable for us?

Which factors are ideal?

Unitechnik advises competently and objectively when selecting suppliers and integrates your pallet warehouse in an intelligent overall system. That is to say: We plan your high rack warehouse in such a way, that is perfectly connected to the further stations of the logistics center.

The delivery of Unitechnik includes all components from rack up to the racking storage and retrieval vehicle. We equip the stacker cranes with our own control technique, so as to guarantee an ideal control of the pallet warehouse.

Storage systems - Small parts warehouse

-

Automatic small parts storage - dynamic and flexible

An automatic small parts storage enables high stock rotation and a quick access to the stored goods. With just in time or just in sequence production processes, an automatic small parts storage serves the reliable provision of work places and buffer storage. The stored items are stockpiled in small volume loading aids such as plastic containers and trays.

Unitechnik realizes dynamic and flexible automatic small parts storages, which optimally meet the requirements of your material flows. For this purpose, we integrate the automatic small parts storage in the total warehouse technique and achieve the ideal storage density and space efficiency for your logistics center.

An extensive analysis of the specific processes, an intelligent setup of small parts storage and the selection of the right components, is the basis for the tailored Unitechnik solution: We establish a multiple deep storage, which is exactly oriented towards the frequency of access of the individual goods. Demand based racking storage and retrieval vehicles or shuttle-systems are equipped with a control technique from Unitechnik. „UniWare" – the modular LVS software from the house Unitechnik - takes over the warehouse management with complete visualization of the stock and material flows.

An extensive service such as the electrical and mechanical maintenance of your automatic small parts storage, complete the range of services of Unitechnik.

Storage systems - Special warehouse

-

Special storage – a solution for specialized assignments

In more than 40 years Unitechnik has realized a multitude of complex special storages. Coil storage, lengthy load storage, air cargo containers, theatre sceneries or automatic parking garages – the solution competence of our engineers is without limits. Thanks to the extensive expertise within the experienced Unitechnik team we develop for every special request and for every storage type the fitting, tailored solution.

Particularly for the specific requirements from the metal industry, we have arranged precisely fitting concepts. In the coil storage the individual coils have been stowed away compactly and safely – and yet available at any moment. A lengthy load storage creates room for every type of steel profile and similar individual parts. Heavy duty pallet warehouses even sustain the weight of large sized stacks of steel sheet.

Moreover, Unitechnik uses its automation and process control knowledge also for extraordinary storage solutions. E.g. we have realized scenery warehouses for the continuous theatre performance and automatic parking garages.

The following special warehouses provide you with an overview:- Coil and collar storage

- Lengthy good storage

- Heavy duty pallet storage

- Air cargo container storage

- Theatre scenery warehouse

- Automatic parking garages

Transport systems

-

Intelligent transport systems for optimal material flow

A transport technique developed by Unitechnik ensures efficient material flow in your logistics center. In an ideal way it connects the function areas goods input, storage, order picking, packaging and loading area, and goods output with one another. Intelligent, reliable and route optimized. The advanced process knowledge of the Unitechnik engineers is the basis for a systematic transport technique.

A whole range of automated transport systems can be chosen from: chain conveyors, wheel conveyors, belt conveyors, electric monorails, sometimes lifts and elevators. The experts from Unitechnik can determine which transport technique can be used efficiently for your specific material flow. Objectively and manufacturer independently. In this we measure efficiency according to the criteria of energy consumption, transport performance and usage costs.

The selection of the suitable vehicle systems takes place in an equally practiced and process oriented way. Whether route trains, transport systems without driver, or an electric monorail - decisive is the optimization of your material flow. In this, Unitechnik sees the transport technique as part of the whole. Also, we integrate the company own control technique (SPS level) in a total system. The cooperation of UniWare and SPS is our strength - and ultimately to your benefit. As a result the best performances of the transport systems can be realized. As general contractor we care for the total service regarding your transport systems.

Possible transport systems for an automated material flow, are:- Chain conveyor

- Wheel conveyor

- Belt conveyor

- Electric monorails

- Lifts and elevators

- Transport systems without drivers

Driverless transport systems

-

Custom material flow solutions with driverless transport systems

Driverless transport systems and driverless transport vehicles are important elements of networked Logistics 4.0. They transport a wide variety of goods autonomously and with flexible routing. Driverless transport vehicles can drive right up to processing machines, depending on the material flow concept. This makes it possible to supply production according to the respective requirements, without stationary materials handling systems.

Driverless transport systems are suitable for a wide variety of logistics tasks thanks to their great flexibility. They are easy to integrate into existing structures and are individually scalable. Additional transport systems can be integrated quickly depending on utilization and the internal material traffic.

Unitechnik designs solutions to meet the respective requirements for the deployment of autonomous transport systems, and also supplies the vehicles on request. We determine the individual need for driverless transport systems and develop ideal routes during a comprehensive analysis of the material flows and movement of goods.

Driverless transport systems are fully integrated into our UniWare warehouse management system. It supports order management and vehicle routing. Our system visualization consistently provides you with an overview of which vehicle is transporting what order and where it currently is.

Picking systems

-

Many order picking systems – one expert for the realization

Order picking means making available a partial quantity from a total quantity present in the logistics center. Either by customer order or for production requirement.

Unitechnik advises with the selection of the fitting order picking systems. Moreover, we take care of the perfect integration of the order picking zones in your intralogistical processes. The order picking is an integral part of our warehouse management system „UniWare". The highly developed warehouse management system supports all current order picking procedures.

Meanwhile there is a multitude of order picking systems, which can be classified according to one of two basic principles „stock-to-person" or „person-to-stock". With automated, paperless systems like „pick-by-voice" and „pick-by-light" for instance, the error rates are reduced to a minimum. The adaptation of the order picking system to the individual logistics processes of our customers is an important step within the framework of our overall projects.

The most important order picking systems at a single glance:

Pick-by-light

a light signal shows the storage compartment and the number of the items to be picked. The picker confirms the picking of the ordered quantity form the storage compartment.

Pick-to-light

mostly in combination with the „stock-to-person" principle. Several orders are picked at the same time. The light signal shows the order for which the next item is destined.

Pick-by-voice

a voice-guided order picking system. The picker receives the orders through computer voices through a headphone and he can also confirm by voice.

Pick-by-vision

a special innovative form of order picking. The picker receives the necessary information through a pair of data glasses directly shown in his field of vision. The signals through the glasses guide him via the best possible route to the next position.

Pick per handheld

the picker accesses his orders onto the display of his mobile data terminal, which he holds in his hand. The taking of the goods is confirmed by scan.

Pick & pack

a procedure, through which the taken items are placed directly into the transport packaging. Typical for the fast order picking in the mail order business.

Multistage order picking

the total order quantity of all orders for a particular processing time is obtained in one go. Only then, in a second processing step, an allocation to the individual orders takes place. Typical for large order volumes such as in e-commerce.

Multi-order-picking

several orders are picked together constantly. The picker saves time and can work along the most optimal route.

Automatic order picking

if requested, the order picking can also be automated extensively, e.g. through robots or automats.The experts of Unitechnik would be pleased to advise you.

Warehouse management system UniWare

-

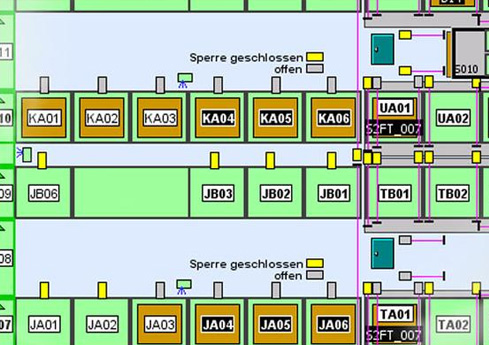

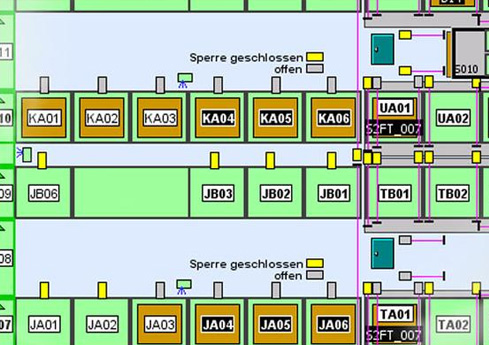

Warehouse management system UniWare - maximum transparency for your warehouse

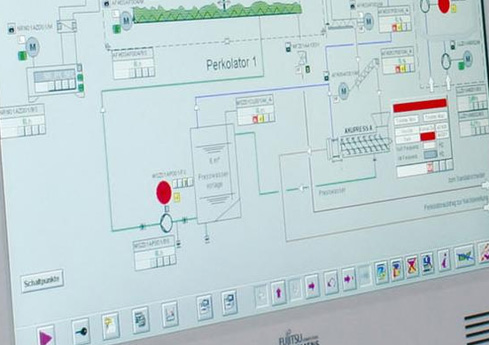

UniWare is a modular warehouse management system, which ensures maximum transparency in your logistics center. The system, which can be used platform independently and in all industries, manages your warehouse stock, optimizes your storage resources and guarantees an efficient order picking.

Thanks to the integrated material flow computer and the standardized PLC interface, the warehouse management system enables the usage of all current storage and transport technique components and creates maximum transparency in the storage management. All stocks and material movements can be visualized at any time for the total facility. Mobile and stationary. UniWare has a multiple client capability, can be used with several languages and can be applied at group level. It maps out both the standardized and the individual business processes.

The warehouse management software UniWare is predestined for automated logistics centers. However, also manual warehouses can be included simply and flexibly. It has interfaces to all current ERP systems and facilitates the operation by an intuitive user surface. The visualization of warehouse management, material flow and control technique happens completely in an on-screen form. Because of its modular structure the warehouse management system validated by Fraunhofer IML, can be used flexibly and is a safe investment.

The advantages of the warehouse management system UniWare in an overview:- Modular warehouse management system with integrated material flow computer

- Platform independent and in all industries

- Interface to most current ERP systems

- Integrated material flow visualization

- User friendly operator interfaces

- Operation with stationary and mobile devices

- Multilingual, useable at group level and multiple client capability

- Ideal for corporations and medium sized companies in industry, trade and logistics services

Retrofit

-

Retrofit - Increase performance. Save costs.

Logistics systems become more efficient and economical all the time. You can benefit from this - also without new construction. Unitechnik ascertains for your existing logistics center the most effective retrofit and works out a comprehensive concept for modernization. For example, we take your intralogistics to the state of the art and restructure your material flow.

As specialist in the automation of logistics centers, we are predestined for an efficient retrofit. With a know-how of more than 40 years of experience we deliver within the framework of the modernization a tailored solution. Geared to your ideal process operations.

Unitechnik offers you a free of charge stocktaking and first analysis. In a first concept we will demonstrate optimization and savings potentials through an expert retrofit. In a joint planning we design for you a changeover scenario. Most measures for modernization can be realized during running operation. In our test laboratory we already put the new system into operation. This extensive system test guarantees that the change over from the old to the new system runs smoothly. Moreover, in this virtual logistics center the warehouse staff can already be trained.

The support during the whole project and a comprehensive service also after commissioning, are for Unitechnik self-evident.

The steps for your cost efficient retrofit in an overview:- stocktaking without obligation

- advice with a first concept

- extensive offer

- award of contract at fixed price

- joint planning of the changeover scenario

- system test in the laboratory

- training of the employees in the new system

- realization in one or several steps

- support during the startup phase

- after sales service

Energy Efficiency

-

Green Logistics - energy efficiency in the logistics center

Green Logistics and energy efficiency are in times when resources are becoming increasingly scarce, and with rising costs for heating, power, gas, oil and water, by now more than just fashion topics. Industrial enterprises are more and more faced with the challenge to use energy as efficiently as possible and environmentally friendly.

Precisely with automated intralogistics systems the potential to save energy is particularly high. In order to enhance the energy efficiency, Unitechnik uses the most diverse technologies and methods from the use of energy saving drives via energy recovery and energy compensation, up to route optimized storage and retrieval strategies and a reduction of the standby energy consumption of the facilities.

Energy efficiency also means the regular check and optimization of the power consumption in the warehouse. Unitechnik advices and accompanies with the conception and introduction of an energy management system. A monitoring system constantly monitors the energy consumption of your intralogistics facility, in a breakdown by as many part segments as you desire. The building and further facilities can be integrated without any problems. We plan and integrate our hard and software directly into your infrastructure.

Unitechnik has extensive references in the area of Green Logistics. Moreover, we are preferred Siemens Solution Partner for „Automation" and „PowerManagement".

Airport Logistics

-

The Unitechnik Group is expert in material flow solutions at airports.

In the areas of cargo, Unitechnik delivers equipment for handling air cargo. The spectrum reaches from highly automated air cargo terminals to manual solutions for the flexible handling of air cargo containers.

Catering includes the material flow inside flight kitchens, the so-called In-Flight-Catering. Here it is all about transporting the narrow wheel containers through the spacious facility, as well as storing cutlery and crockery.

Air Cargo Handling Systems

-

Under the brand name ACUNIS, Unitechnik Systems and AMOVA combine their know-how in the area of air cargo handling systems. The spectrum ranges from fully-automated air cargo terminals to special vehicles for IATA-compliant handling of ULDs. ACUNIS combines decades of experience of the companies ICM Airport Technics, Unitechnik, SHS, SMS Logistiksysteme, and AMOVA. They profit from more than 40 years of experience in the planning and realization of air cargo terminals.

Turnkey air cargo terminalsYou receive all services from one source:

- Feasibility studies

- Planning, including simulation

- ULD high rack warehouse

- Racking storage and retrieval vehicles

- Transfer carriages, transport technique

- Work stations

- Cooling technology

- X-ray systems

- Control technique

- Facility visualization

- Material flow computer

- Warehouse management system UniWare

Airline Catering

- Unitechnik is specialist for automated flight kitchens. These catering companies have the task to equip every aircraft that takes off from the airport, with carts. These are narrow containers on wheels, which the stewardess pushes through the aisles of the plane. The carts are filled with food, drinks, duty free items, blankets, headphones and much more. The carts of the landed planes are emptied, cleaned and filled again - each time individually for every new aircraft. This way, every day 120,000 meals are provided.

Big flight kitchens are equipped with an automatic transport system for the carts. The carts are transported on hangers through the spacious facility.

In order to be able to manage the great multitude and quantity of cutlery and crockery parts, the automatic small parts storage is used. Through transport technique the containers of the food distribution are supplied.

Uniware monitors the whole material flow and storage management system with integrated installation visualization. Through the connection with external devices UniWare becomes the control station of the whole facility.

Production automation / robotics

- Production automation, robotics, and machine safety from one source

Our economical automation solutions offer maximum flexibility in compliance with the highest safety standards. We provide services ranging from material feeding to highly automated, linked, integrated solutions. In doing so, we control materials handling technology, machines, and robots.

An in-depth process analysis forms the basis for successful production automation. This supports the ideal modeling of production requirements while simultaneously maximizing plant safety. That is why Unitechnik offers a complete package including conceptual studies and risk assessments according to the machinery directive in addition to the automation technology. Our tailor-made plant safety concepts help minimize the risks of human/machine interaction.

For new construction or retrofitting, turnkey systems or specialized solutions – Unitechnik in close coordination with the customer develops suitable solutions for all production automation problems. We are an automation specialist and system-neutral, full-range supplier with competent project management. This approach makes us a reliable partner for mechanical engineering and plant construction firms as well as end customers in the production industry.

Production logistics

-

Production logistics - optimal material flow

Unitechnik offers automated system solutions for the production logistics. Whether tablet packages or aluminum coil, ¬Unitechnik takes care of the handling, transport and storage. We interlink your production.

Unitechnik realizes for you tailored intralogistics solutions for pallets, containers, panels, cartons, bottles, coils, bodies etc. Depending on the task, our solutions consist of stationary transport technique, driverless transport systems, stacking terminals, handling systems, as well as manual or automatic storage systems.

Our software system UniWare coordinates and visualizes the material flow and the storage management. With the selection of the transport technique components we are manufacturer independent. This way, we plan and realize a material flow system, which is optimally attuned to the requirements of your production.

Unitechnik bears the responsibility for the entire system - at the time of the realization and in terms of service. 24 hours a day, 7 days a week.

Production Control

-

Controlling production efficiently

Unitechnik plans and realizes production management systems, machine controls and optical systems for your production.

Our production management systems are specialized in the automatic production of unique items, or customer specifically adapted series products. Keywords in this connection are: order administration, production control, work schedules, CAD data, waste optimization, installation visualization, product tracking, information management, etc.

We create machine controls at the highest level. Operation and visualization are carried out via modern touch screens. Portal and buckling arm robots are operated on individual target coordinates (no teach mode). With this, 7 axes are highly dynamically accessed. We have experience with complex metering tasks, vibration technique and bending machines.

Optical systems: We use projection lasers for the positioning assistance. Moreover, the image processing systems for the measuring of work pieces and for the quality assurance are used.

Robotics

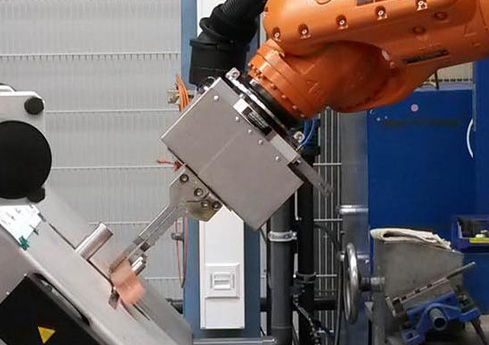

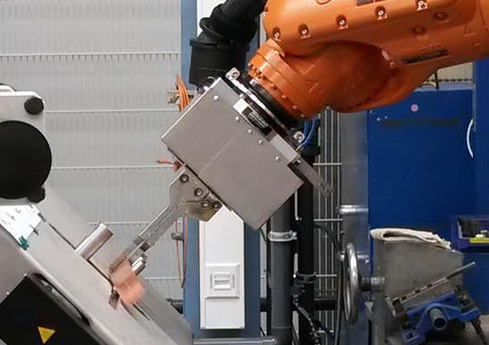

- In the current production landscape, systems interlinked with robots play an increasingly important role. Unitechnik has extensive know-how regarding the integration of these highly complex systems in the current industrial landscapes.

In this we are system neutral and use six to eight axle robots of different renowned manufacturers. In this connection, we do not consider the robots independent of the process, but also „care" about the upstream and downstream systems. A demanding image processing in connection with the parts to be moved by the robots, belongs to the scope of delivery.

In doing so, Unitechnik offers a total package, from concept studies via the layout planning up to safety concepts, which will satisfy you as demanding customer.

References such as e.g. a robot supported high-end installation for the automatic flight baggage loading, or a worldwide unique system for the fully automatic slag removal in the metal processing industry, offer you as customer the possibility to convince yourself of the performance capability of our company.

Whether new construction or retrofit, whether turnkey installations including trade-spanning project management or special solutions for the enhancement of productivity and efficiency - Unitechnik is the perfect partner both for the demanding machine and installation builder, and for the final customer in the manufacturing area.

Robotics - Automated baggage loading

-

Unipack - Automated flight baggage loading

Modern airports have an automatic baggage transport installation at their disposal, which transports the pieces of baggage from the check-in desk to the baggage loading belt of the aircraft. On the way there, the pieces of baggage are automatically X-rayed, temporarily stored and sorted. However, with the loading a manual and physically demanding work begins. Usually, the pieces of baggage are manually stacked into a flight container (ULD), or onto a baggage cart (ramp cart). Doing this, a worker will move approx. 16 tons of weight per shift.

The automated baggage loading cell Unipack accomplishes this step of the procedure through a buckling arm robot. The special feature here is the patented „gripper" of the robot. It consists of a telescopable surface with an end stop. As a result, the telescopic surface adapts itself precisely to the piece of baggage. This amongst other things works out beneficially for the actual loading procedure, as the maneuverability inside the container - particularly behind the spaces which are not accessible from the front - is increased substantially. The robot moves with its load precisely above the pre-estimated spot in the container. The robot gripper retracts its telescopic surface very quickly and the baggage piece is placed down on the desired spot (gravity principle). The patented system meets the requirements, which are worldwide placed on future-proof baggage logistics in view of safety, performance and ergonomics.

Functional principle

Loading of the flight baggage by means of a conveyor belt

Determination of position and contour of the piece of baggage to be loaded through a scanner and an image processing system

3D measurement of the inside space of the flight container for the assessment of the current loading state

Calculation of the optimal spot for the next piece of baggage

Picking the piece of baggage from the conveyor belt by the robot and placing it on the calculated target spot in the container. This procedure (duration approx. 10 - 15 sec.) repeats itself for every piece of baggage, until the container has been filled.

Advantages of the system- Relieving the workers from physically exerting work

- Enhancement of flight security through prevention of human intervention

- Tracking until inside the aircraft

- Quality improvement of the loading

- Modular system, adaptable and adjustable to the most diverse customer's requirements

- Higher degree of filling through patented picking unit

- Simple handling, also of excessively heavy pieces of baggage

- Reduction of baggage damage

Robotics - Handling systems

-

Handling systems

Flexible handling in the most limited space! The handling systems of the company Unitechnik Automatisierungs GmbH have always been able to cope with the modern requirements of an effective handling of components, work pieces and raw material. Through innovative concepts we realize in the most limited space short cycle times. Depending on the requirement or desire of our customers, with our handling systems we integrate already existing components, or we develop and realize complete new solutions. At the same time, we always endeavor to plan the technically and economically best solutions for the customers, so as to make their processes even more efficient. Unitechnik Automatisierungs GmbH offers a complete service from the planning, development and construction via the programming and installation of individual industrial robots, up to the linkage of complex robot systems.

Robotics - Slag skimmer

-

Slag skimmer

For the improvement of the productivity and work safety, the company Unitechnik Automatisierungs GmbH has developed a procedure for the automatic skimming of slag at the zinc coating line. With this procedure, slag is continuously skimmed from the zinc bath's surface and temporarily stored in a special tank. Depending on the filling level, the tank is emptied and the slag recycled. Specifically for this, Unitechnik has constructed a skimming tool and the corresponding movement strategies to gently skim the zinc dross. The control of such installations can be integrated in the existing installation control, or be realized independently with the corresponding interfaces.

Retrofit

-

Retrofit - Rejuvenation for your production

Unitechnik brings your production and your material flow at the level of state-of-the-art technology.

Often it is the discontinuation of electrical components, which gives the push to a modernization. However, the advantages for the operator of the installation, go a lot further than just guaranteeing the provision of spare parts. Unitechnik has extensive experience in the retrofitting of long-serving installation technique. Our automation competence and the professional project management take care of short retrofit times and a process secure restart of the installation.

Your advantages:- Minimum downtime with retrofit

- Using available machines and transport technique

- Higher productivity

- Higher availability

- Newest safety technique

- Intuitive and multilingual operation

- Top information management

- Safe supply of spare parts

- Reduced energy consumption

- Integration into an energy management system

Precast Concrete Technology

- Automation and IT-Systems for precast concrete plants

We automate production installations for the manufacturing of ceilings and walls. Modern plants of concrete components produce tailored elements and this way provide the architect all degrees of freedom in the planning of his buildings. The CAD program calculates the required concrete components based on the building plan. On the basis of these data, the concrete component plant will produce the required elements and makes these available in accordance with the assembly order.

Products which are typically manufactured in automated installations:- Ceiling elements

- Solid ceilings

- Double walls

- Insulated double walls

- Solid walls

- Sandwich walls

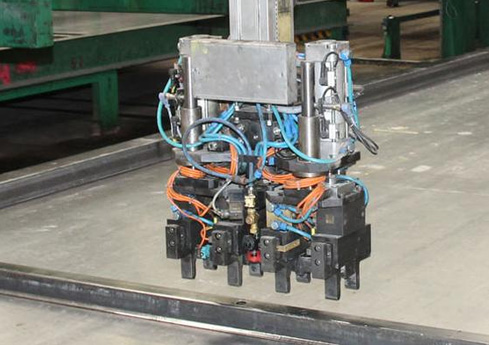

Automation

-

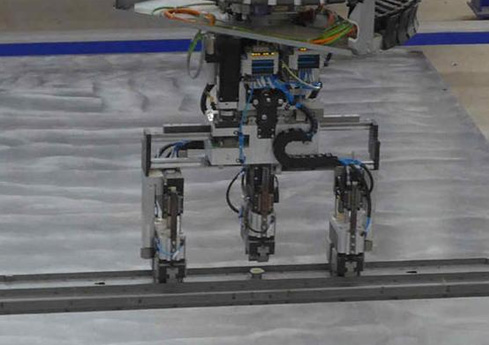

Automation in the precast concrete plant

With the automated concrete component plants it usually concerns pallet circulation installations. One produces on steel pallets up to 18m long. These pallets are moved in a circular method from one work station to the next. Work stations are e.g.: cleaning, molding, installation parts, reinforcement, insulation, pouring concrete, compressing, hardening, smoothing and lifting off. These work stations can be operated fully automatically, half automatically, or manually. Typical machines are molding robots, concrete dispensers and stacker cranes.

In essence the automation system consists of the control technique UniControl and the production management system UniCAM.

UniControl

-

UniControl - Automation technique at the highest level

With UniControl we provide you with control and safety technique from a single source. We exclusively use industrial components of major manufacturers. Designed by experienced electrical design engineers and produced in our own switch gear and control gear construction, control systems come about, which distinguish themselves through high availability and maintenance friendliness.

More than 20 years of experience in the concrete component industry enables us to build the software for these control systems very efficiently. Many experienced standard modules release us from routine activities and provide us with the opportunity to realize the individual requirements of the installation concerned.

The control system can be divided into the circulation control, the robot/robots, the concrete dispenser and other machines. The circulation shows the logistics of the plant. Pallets must be at the right place at the right time. Essential success parameters in this are: safety, operator friendliness and energy efficiency. Through language switchable and graphics oriented touch screen operation, familiarization times can be significantly reduced and faulty operations prevented.

Contrary to this, the molding and demolding robots have very different requirements. Here it is about the highly dynamic and extremely accurate control of up to 7 axes. For the demolding the pallets are measured accurately to the millimeter. In all cases, in addition to the accuracy, the shortest possible cycle time is important.

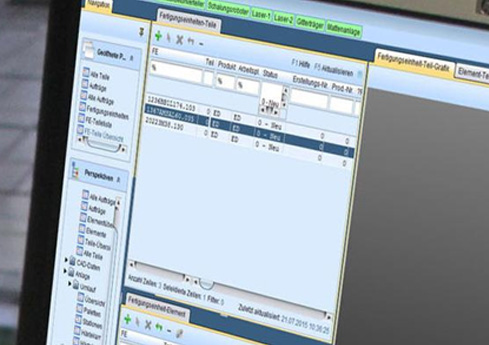

UniCam

-

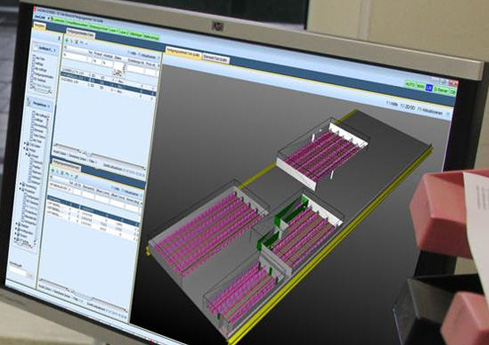

UniCAM master computer

Unitechnik has indruduced its the new master computer UniCAM.10 at the bauma. In the meantime the usage has been proven in the practice. The completely redeveloped master computer UniCAM.10 allows users to increase their productivity during the production of precast concrete components. Additional advantages include the intuitive usability across all modern devices and long-term future proofing through advanced software technology. Via the new user interface which can be individually configured, all production processes can be controlled centrally and visualized in detail. As an additional newly developed feature the control computer allows simulating the entire concrete plant at the PC and to visualize it in 3D. This feature is beneficial to users for example during the design of a new plant, during the optimization of existing facilities and during training of operators in the virtual concrete plant.

New functions in UniCAM.10:- Configurable and scalable user interface

- Use of any stationary or mobile device

- Plant visualisation with infinite zoom

- Dashboard for mobile devices with the key performance figures

- Integrated simulation of the actual plant

- Optimised, automatic pallet assignment

- More efficient machine routeings

- Form removal function: Faster measurement

- Self-learning cycle time homogenisation

- New CAD-CAM viewer – UniCADView

- UXML interface

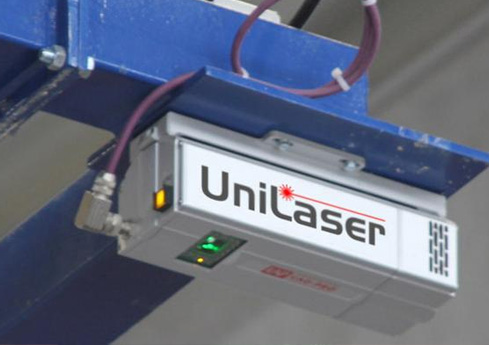

UniLaser

-

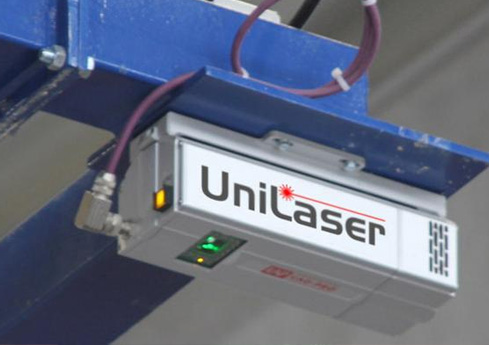

UniLaser - Enhancement of productivity and quality in your concrete component production

The laser projections system UniLaser is an efficient tool for the accurately size placing of the parts onto the production pallet. By integration into the master computer, UniCAM can adapt UniLaser to the individual production process. For example, if a part of the mouldings was already placed by means of robots, then the UniLaser will only still project the remaining moulding length. Advantage: no disturbing reflection, no flickering lines. If a window frame must be positioned, it may be more useful to mark the topside of the frame. Advantage: none of the lines are shaded by the frame. The projection at freely definable heights is particularly advantageous in case of multilayered, resp. three dimensional elements.

A further application area of UniLaser is the quality assurance. Before the pouring of concrete, all dimensions can be checked. While doing so the projection height is determined automatically from the CAD data. With the production of double walls, the lattice girders of the first mould are projected, so as to exclude later collisions when bringing them in.

UniLaser is integral part of the process control technique of the company Unitechnik. You will benefit from smooth startup operations and professional service, including a hotline and remote maintenance.

Retrofit

-

Retrofit - Rejuvenation for your precast concrete component plant

High-quality production installations run for several decades. Especially with good maintenance. However, in spite of flawless function, after years one or the other problem arises. Certain control components are discontinued by the manufacturer, the computer is no longer compatible with the new USB devices and so on. One can kick the can down the road for a while by a skillful spare part provisioning. However, eventually there comes a point where the availability of the installation is jeopardized ...

Unitechnik offers the modernization of the process control technique of precast concrete component plants. In this, it is irrelevant whether the plant was automated originally by Unitechnik. We offer you an evaluation of the situation and advice without obligation. In case you would find our service of interest, we offer you this at a fixed price. The great experience of countless modernization projects and the professional project management guarantee a short reconstruction time, so that production downtime is minimized.

The renewal of the control technique ensures that current provisions are complied with, the installation runs steadily and that support as well as spare parts are available. Moreover, through the upgrading of a modern manufacturing execution system, many new functions become accessible to the plant.

Procedure of a modernization project:- Evaluation of the situation free of charge

- Extensive offer

- Award of contract at fixed price

- Electrical construction and if need be construction of control cabinet

- Software building on the basis of UniControl and UniCAM (no conversion of the old software)

- In-house system test at Unitechnik

- Preparatory measures in the plant parallel to the running production

- Interrupting production (if need be during the plant shut-down)

- Conversion of the controls, control points and computer systems

- Restart of the installation with the new software

- Parallel with that restart of the production

- Production monitoring

- Service and hotline

CAD-CAM-Interface

-

UXML – the new communication standard for precast concrete plants

The open "Unitechnik CAD-CAM interface" has formed the basis for the free exchange of information within a precast concrete plant for 25 years. This interface is now available in the contemporary XML format. UXML is going to be the future standard for precast concrete plants.

Unitechnik presents the interface description "Unitechnik CAD-CAM interface XML 7.0.1“ - short UXML 7.0.1 - at the bauma. It is available in a English and German version. This interface has been implemented by some CAD manufacturers. In the leading position is Tekla Structures who will present a UXML compatible version of their software at the bauma.

As in the past all software and equipment manufacturers can incorporate this interface in future versions. In this way, Unitechnik is addressing the trend toward manufacturer-specific interfaces and supports continued free competition within the industry.

Advantages of the UXML interface compared to the conventional Unitechnik CAD-CAM Interface:- Can be displayed in any browser

- Hierarchy levels can be shown and hidden

- Easy to implement in modern software systems

- Tunneling of additional information from CAD to subsystems without having to modify the control system.

- Support for variable field lengths

- Ability to transmit binary data (images, PDF, printing data)

- Capability for validation against XML schema definition

- Ability to reference objects via GUID

Metallurgy

-

Metallurgy

Unitechnik offers well-engineered solutions and has the most modern know-how for a complete metallurgic cycle from fluid metal via rolling mills of all types, through to complex treatment and packaging installations.

Whether new construction or retrofit, whether turnkey installation including trade-spanning project management or special solutions for the enhancement of productivity and efficiency - Unitechnik is the perfect partner both for the demanding machine and installation builder, and for the end customer in the manufacturing area.

Raw material conveyance

-

Basis of the raw iron and steel production are the necessary primary raw materials such as iron ore, fuels and aggregates.

Installation types:

Installations for the transport, loading and storage of these raw materials are automated by us. To this end we have a wide array of realized installations - from simple conveyor controls via wagon tipplers to complex loading installations.- Conveyor installations

- Fuel conveyance

- Ore and coke storage

- Loading installations

- Defrosting halls

- Wagon tipplers

- Conveyor controls

- Burner controls

- Fan controls

- Loading bridges

- Crane installations

- Three-phase drive technology

- Safety technique

Liquid metal

-

For the area of fluid metal, we deliver tailored solutions for electrical systems and automation. This way we guarantee a high product quality, flexibility and productivity with new installations and modernizations. We have extensive experience with electrical systems and automation of steel degassing installations, desulfurization installations for crude iron, exhaust filter installations for the steelmaking and with conditioning facilities for the casting preparation of steel.

Basic automation:- Hydraulic systems

- Cooling systems

- Burner controls / exhaust gas system

- Wire feeding machines

- Conditioning facilities

- Direct current drive technology

- Three-phase current drive technology

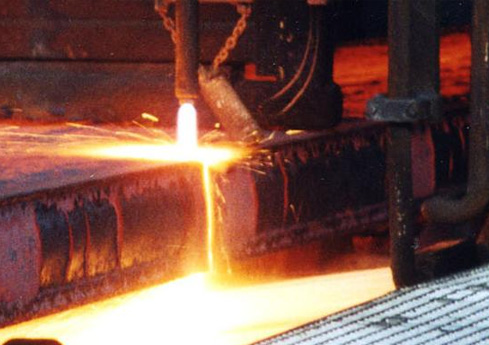

Casters

-

The operation of casters in continuous operation makes high demands on the automaton. Since many years, we develop automation solutions for the process management in casters - as innovations partner of renowned machine and installation builders. For the control of the casting procedure, from the ladle turret up to the exit roller conveyor, we offer well-engineered solutions - both for new installations, and for modernizations. Our strength lies in the system integration of the whole spectrum of electrical systems and automation.

Basic automation:- Hydraulic systems

- Cooling systems

- Longitudinal and lateral slitting lines

- Continuous casting plants

- Marking and stamping machines

- Emergency slides

- Direct current drive technology

- Three-phase drive technology

- Tracing of materials

- Load compensation control

- Oscillation control

Thermal treatment

-

We equip installations for the thermal treatment of slabs and coils with extensive automation technique. All areas of the basic automation, as well as the drive technology and the material tracking belong to our scope of delivery. Depending on our customers' desires, we develop fitting solutions for their applications. With this, we can draw on system components of the most diverse manufacturers.

Basic automation:- Hydraulic systems

- Cooling systems

- Burner controls / exhaust gas systems

- Input resp. output machines

- Electrical heating systems

- Transport systems

- Three-phase current drive technology

- Material tracking

- Control technique

- Safety technique

Rolling mill technique

-

Unitechnik has extensive experience and know-how in the area of cold and hot rolling technique. Both with electrical systems and automation equipment of new installations, and with the retrofit,

Basic automation:

already numerous projects have been realized worldwide. The scope of delivery and performance reaches from the engineering of hardware and software including the technological controls, via the manufacture of technical equipment and the assembly, through to the start-up and optimization of the installations.

Many years of experience and a close cooperation with operators of rolling mills form a solid basis for our technological know-how.- All auxiliary systems

- Stand movements

- Fully automatic roll replacement

- Direct current drive technology

- Three-phase drive technology

- Main drive, reel drive and auxiliary drive

- Adjustment controls

- Thickness controls

- Model based controls

Conveyor systems

-

In the area of conveyor systems we have been working with our automation solutions for auxiliary systems for years. In this connection, installations for the thermal and chemical

Basic automation:

zinc coating lines, the most diverse cleaning lines and coating installations belong to the spectrum of our automation. With

these installations we deliver the complete basic automation, the drive technology, as well as the conveyor imaging with Speedmaster and conveyor controls.- Hydraulic systems

- Cooling systems

- Burner controls

- Coater

- Straightening machines

- Brushing machines

- Shearing

- Skimming robots

- Direct current drive technology

- Three-phase drive technology

- Material tracking

- Conveyor imaging

- Speedmaster

- Conveyer run controls

- Safety technique

Auxiliary systems

-

The control and monitoring of larger auxiliary systems in the steel processing industry, is a demanding task. Since many years we develop and deliver solutions for the electric systems and automation of hydraulic installations, filter installations, gas grids and crane controls.

Basic automation:- Hydraulic systems

- Cooling systems

- Burner controls / exhaust gas systems

- Direct current drive technology

- Three-phase drive technology

Transport systems

-

Between the individual steps of the metallurgic products occur the most diverse transport tasks. For example, slabs or coils must be transported to all kinds of destinations. These tasks are carried out by manipulators or roller tables in different types. Unitechnik delivers the automation and drive technology for many installations of this type. Also the complete material tracking and storage management, is part of our scope of delivery.

Installation types:- Slab transport systems

- Slab storage

- Coil logistics

- Roller table controls

- Slab transport wagon

- Crane installations

- Three-phase current drive technology

- Direct current drive technology

- Control technique

- Material tracking

Retrofit

-

Unitechnik brings your production and material flow to the current technical state-of-the-art.

Often it is the discontinuation of electrical components, which gives the push to a modernization. However, the advantages the operator of the installation has, go a lot further than just safeguarding the provision of spare parts. Unitechnik has extensive experience in the conversion of long served installation technique. Our automation competence and the professional project management ensure short conversion times, and process secure restart of the installation.

Your advantages:- Minimum downtime with conversion

- Use of the available machines and materials handling technology

- Higher productivity

- Higher availability

- Newest safety technique

- Intuitive and multilingual operation

- First class information management

- Safe spare part provision

- Low energy consumption

- Integration into an energy management system

Process Engineering

-

Process technology

Unitechnik offers well thought out solutions in the demanding area of the process technology for different industries. For example, the power plant technology and installations in the water and sewage management can be mentioned.

Whether new construction or retrofit, or turnkey installations including trade spanning project management or special solutions for the enhancement of productivity and efficiency - Unitechnik is the perfect partner for both the demanding machine and installation builders, and the end customer in the manufacturing area.

Gas holders

-

Gasometers in the form of disk-type gas holders are used in the industry for the storage of bigger gas quantities. For the operation of these installations one needs extensive automation technique and complex safety provisions.

Since many years, Unitechnik plans, delivers and installs the necessary automation and safety technique for these disk-type gas holders.For the accessibility of these installations to all kinds of customers we develop the necessary gas management systems.

Installation types:- Disk-type gas holders

- Hydraulic systems

- Disk monitoring

- Electric heating of the disk holder

- Siphon control

- Three-phase current drive technology

- Gas management

- Control technique

- Safety technique

Water supply plants

-

Water supply plants as integral part of big industrial installations exist in all kinds of forms. These include for example the provision and disposal of water, open or closed cooling systems, as well as cleaning and purification installations. We deliver for these tasks our automation technique including our know-how.

Installation types:- Secondary and primary cooling water circuits

- Purification plants

- Flood control installations

- Weir systems

- Pump controls

- Cooling towers

- Dosages

- Three-phase current drive technology

- Control technique

- Analysis technique

Power plant technology

-

Several components of the power plant technology are automated by Unitechnik. Our know-how is based on years of experience with planning, construction and maintenance of these installations. We deliver amongst others burner controls, controls of boiler plants, necessary automation of the water and steam circulation systems, as well as the required safety technique for the operation of these installations.

Installation types:- Furnaces

- Boiler plants

- Biogas installations

- Communal power stations

- Compressor stations

- Burner controls

- Generator controls

- Remote control systems

- Three-phase current drive technology

- Control

Retrofit

-

Unitechnik brings your production and your material flow up to the latest state of the art.

Very often it is the announcement of new electrical components that provides the incentive to carry out modernization. The advantages, which the operator of the system gets, go far beyond that of safeguarding future supplies of spare parts. Unitechnik has great experience

Your advantages:

in the converting and updating of long-serving systems. Our expertise in the area of automation together with our professional project management ensure short changeover times and smooth start-ups. In this way the risks for the customer are minimized.- Minimal downtimes at conversion

- Further utilization of existing machines and conveying systems

- Higher productivity

- Higher availability

- The latest safety systems

- Intuitive and multilingual operating

- Up-to-date information management

- Reliable supplying of spare parts

- Lower energy consumption

- Integration in an energy management system

Industrial Services

-

Buy special knowledge at attractive prices

Unitechnik offers a wide range of services for manufacturing companies. Partially, these services are used in conjunction with our projects. But they can be used completely independently of this.

Unitechnik offers services on the following topics:- Drive technology

- MSR technology

- Weighing technology

- Industrial radio and video systems

- Rail operations technique

- Profibus analysis

- Energy Management

- PLC Training

Drive technology

-

Advice and support for drive technology

Unitechnik has a high expertise in the drive technology. It concerns both drives in three-phase current technology (low voltage) and direct current. We install drive systems and start them up.

In the drive control we offer our support for digital and analog systems. We are specialized in the renewal of the drive control, e.g. the exchange of of analog control systems with digital frequency inverter.

Your advantages:- Advice with the drives planning

- Start-up of the drives

- Renewal of the drive control

MSR Technology

- Unitechnik has many years of experience and know-how in the area of demanding and complex systems for measurement and control including analysis technology.

In addition to the complete service (maintenance, repairs and testing of existing installations) we offer both the modernization and the new construction of the most diverse applications. In this, we use highly diverse sensors such as for example for pressure, temperature, filling level and flow rate, as well as analysis measuring technology and integrate this technique into overriding control and management systems.

Weighing technology

- Unitechnik has many years of experience and know-how in the area of weighing technology.

In addition to the complete service (maintenance, repairs and testing of existing installations) we offer both the modernization and the new construction of weighing technology for the most diverse applications.

Crane trucks in the heavy industry, coil cars in the metallurgic area and conveyor wagons in the raw material industry, are just a few applications, which Unitechnik has realized during the last few years at renowned customers.

The scope of delivery and service ranges from engineering of the hardware and software, via the production of equipment and the assembly, up to the start-up and optimization of the installations, including a process technical integration into overriding control and management systems.

Industrial radio and video systems

- Unitechnik has many years of experience and know-how in the area of industrial radio and video systems. Besides the complete service (maintenance, repairs and testing of existing installations) we offer both the modernization and the new construction of radio and video systems.

For radio controls we are listed service partners of renowned manufacturers such as for example the companies Laird Controls Europe and HBC radiomatic. The scope of delivery and service ranges from engineering of the hardware and software, via the production of equipment and the assembly, up to the start-up and optimization of the installations.

Rail operations technique

- Unitechnik has many years of experience and know-how in the area of industrial railways.

In addition to the complete service (maintenance, repairs and testing of existing installations), we offer both the modernization and the new construction construction of electrical and automation technical equipment for the area of industrial railways.

This concerns both signal controls including road crossings, and electrical and automation technique for switches.

Of course, our specialized personnel has the corresponding accreditations for these sensitive areas.

Profibus analysis

- The Profibus is in most industrial installations the communication technical backbone of the automation systems. A malfunction of the Profibus usually results in the breakdown of the entire control system. The analysis with traditional programming devices proves to be very difficult. Particularly unstable conditions on the bus, have already driven many a maintenance worker mad. That is why the Profibus measuring with our own projects is a fixed part of the start-up procedure.

We dispose of first class measuring devices, which recognize mains breakages, failing terminator resistances and faulty Profibus participants. Through recording the data on the Profibus, we sporadically get on the track of occurring faults. Finally, the physical and logical quality of the bus system can be determined. For example, one recognizes how many „reserves" the Profibus still has. Our staff, specially trained on the system, draw up measuring protocols, which are handed over to the customer. This way, the Profibus is no more an element of uncertainty, but a secure bank.

Your advantages:

- Reliable Profibus analysis

- Tracking sporadically occurring faults

- Statement on the bus quality

- Measuring protocol

- Excluding the Profibus as fault cause

- Correct dimensioning of the Profibus

Energy Management

-

Basic principles

Rapidly rising costs for heat, electricity, gas, oil, water and compressed air turn the energy consumption of an industrial enterprise more and more into a determining profitability factor.

Moreover, energy efficient and environmentally friendly production characterize the image in the market. Therefore, the sustainable establishment of an effective energy management will also impact the entrepreneurial success in the future.

Unitechnik advises and supports you with the conception and implementation of energy management. We plan and realize for you the system in hardware and software on the basis of the newest methods and technique. Our comprehensive competence in the industrial automation and automation and information technology enables us to realize the optimal integration in your infrastructure. Among other things, Unitechnik is Siemens Solution Partner in de areas of 'Automation' and 'Power Management'.

Concept

The energy management system can in essence be divided into three phases:

Transparency

Registration of the energy flows over time

Early recognition of anomalies, e.g. unnecessary peak loads or leakages

Allocation of the energy costs to cost centers and cost bearers

Basis for all savings and optimizations

Efficiency

Switching off idle users (temporarily)

Replacing or modernizing inefficient users

Reactive current compensation

Energy recovery system

Preventive maintenance

Load management

Avoidance of peak loads

Automated load dependent switching on of users

Organizational measures (altered pause times)

Reaction to electricity rates

Services

Unitechnik is your competent counterpart for the energy management.

Our services- Energy check

- Advice regarding advancement possibilities

- Manufacturer neutral conception of a measuring and evaluation system

- Realization and implementation of the energy management system

- Modernization of inefficient production and conveyor installations

- Realization of reactive current compensation and energy recovery

Switchgear construction

-

Switchgear construction

Unitechnik produces switchgear systems. Benefit from 40 years of experience in the international switchgear cabinet construction.

Our infrastructure:- 3.000 m2 production area

- CAD setup planning CNC processing center

- Spray booth

- Disk and print stations

- Test field for 100% testing and simulation

- Eplan workstations

Your advantages:

- High flexibility and short delivery time

- Highest quality standard

- Production according to all current standards, e.g. VDE, UL, NEMA, CSA, Norsk Veritas, also stainless steel or explosion proof version

- International documentation in accordance with sector and company standards

- Installation simulation / system test

- Engineering support

- Assembly and startup support

- 24h hotline service / spare parts service

- We advise you with the optimization of your switch gear cabinets, regarding costs, operation and maintenance friendliness, as well as energy efficiency, and the integration with an energy management system.