ArcelorMittal in France submitted an order for a reversible 6-high cold-rolling mill from ANDRITZ

International technology group ANDRITZ has received an order from ArcelorMittal, France, to supply a reversible 6-high cold-rolling mill for processing high grade non-oriented silicon steel strip (NGO) for use in electric motors.

The mill is able to produce light-gauge strip, which is in high demand to produce more compact, lightweight, and energy-efficient traction motors for e-mobility. It will be an essential part of ArcelorMittal’s new production complex for electrical steels at its site in Mardyck, northern France.

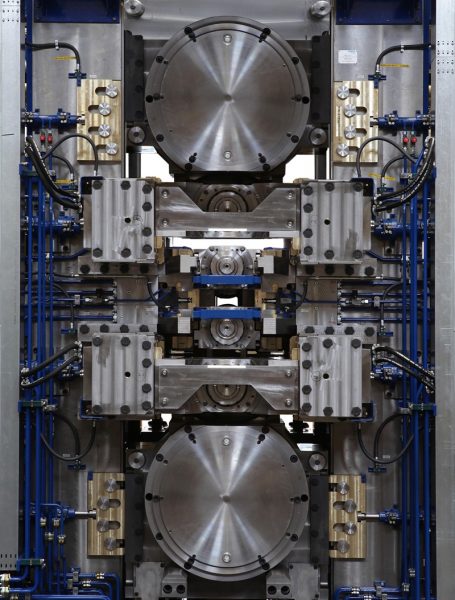

The ANDRITZ 6-high provides high roll force, roll torque, and bending forces at a relatively small work roll diameter. Along with the extensive process instrumentation and an exceptionally flexible cooling and strip-drying strategy, ArcelorMittal will receive the perfect solution to meet the challenging quality demands on the end product at a high production level.

The rolling mill will be capable of rolling up to 1,450 mm wide strip to a minimum finished material gauge of 0.2 mm.

The ANDRITZ scope comprises the design and supply of the complete mechanical and electrical equipment, as well as supervision of installation and start-up. The core equipment will be pre-assembled and tested at the ANDRITZ workshop in Hemer, Germany.

ArcelorMittal Europe – Flat Products is the largest producer of flat steel in Europe. All of ArcelorMittal Europe’s electrical steels for automotive applications will be produced at the newly planned complex in Mardyck and at the plant in Saint Chély.

For more information, please visit https://www.andritz.com.

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech