- Offer Profile

- PIONEERED AND PERFECTED FOR 40 YEARS

In 1981 the first Winergy gearbox for wind turbines was built and since then the technical and qualitative concepts have been constantly worked on. Setting the standard in the industry for combined helical and planetary stages as well as super-finishing of gears.PIONEERED AND PERFECTED FOR 40 YEARS

In 1981 the first Winergy gearbox for wind turbines was built and since then the technical and qualitative concepts have been constantly worked on. Setting the standard in the industry for combined helical and planetary stages as well as super-finishing of gears.

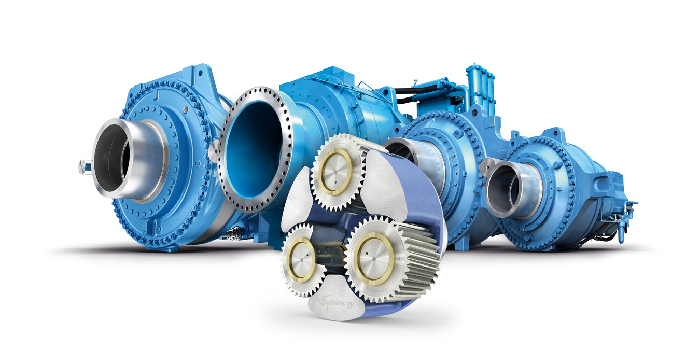

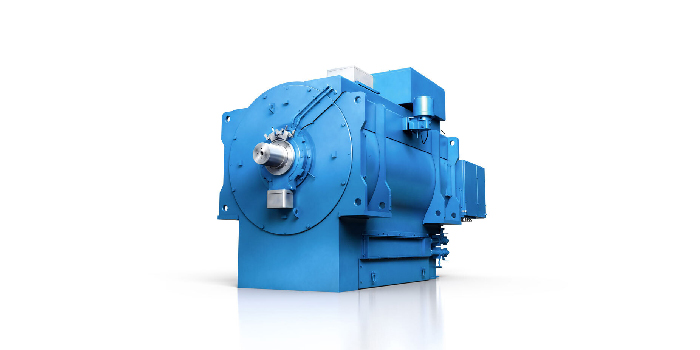

HYBRID DRIVE

-

THE POWERHOUSE FOR WIND TURBINES

The HybridDrive is Winergy's response to the challenge of further reducing the costs of energy generation. With the direct connection of a three-stage planetary gearbox and a permanent-magnet synchronous generator, a medium-speed drive has been designed ensuring the highest efficiency. The compact design makes the drive system shorter by more than 50%, and the efficiency is outstanding among all other technologies

BENEFITS

- High system efficiency

- Compact and flexible for different concepts

- Space-saving due to 50% shorter design

- Durable and easy to maintain

- Resource-saving design

GEARBOXS

HIGH DENSITY

-

THE NEXT GENERATION OF GEARBOX.

Our gearbox concept High Densityx unites power density, reliability and efficiency on a new level. The concept set new market standards by increasing torque density by more than 25 percent up to 200 Nm/kg while relying on our proven gearbox design.

The increase in power density results from a significant weight reduction and multiple planets in three planetary stages for balanced ratio distribution. High Densityx covers the full portfolio from low wind turbines to large offshore machines.

Benefit from the increased power density and optimized space requirements with the High Densityx.

BENEFITS

- Multiple planets in planetary stages for balanced ratio distribution

- Increased gearload capacity

- Topology optimized structures

- Increase in torque density by more than 25 percent to 200 Nm/kg

JOURNAL BEARING

-

JOURNAL BEARING TECHNOLOGY

By introducing the journal bearing technology for its gearboxes Winergy sets another milestone for the wind turbine drive technology. Bearings belong to the critical wear parts of wind gearboxes as they are exposed to high loads in operation and therefore have a significant impact on the overall gearbox reliability. As journal bearings have proven their advantages in several other heavy industries, Winergy developed the technology as an Alternative to common roller bearings.

The journal bearing technology is available for High speed gearboxes the HybridDrive.

BENEFITS

- High reliability

- Low noise and vibration

- Optimized efficiency at lower costs

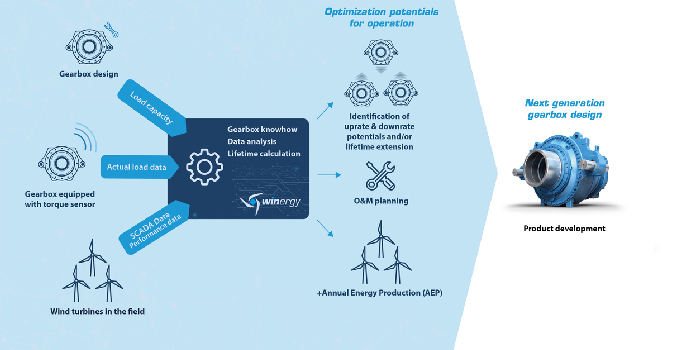

DIGITAL GEARBOX

-

Digital Gearbox by Winergy increases the efficiency of wind turbine gearboxes. Our gearboxes can be run with optimum torque and rotation rate by digitalizing and analyzing their operating data including real measured torque. As a result, either the power output or the gearbox service life can be increased. The turbine operator is aware in which phase of the product lifecycle his gearboxes are in and is able to optimize the lifetime according to his needs.

BENEFITS

- Minimized Levelized Cost of Energy production (LCoE)

- Torque measurement with 99.7% accuracy

- Digital detection and predictive maintenance of gearboxes without being on site

GENERATORS

-

GENERATORS FOR ALL CASES

For wind turbines with gearboxes, our specialized generator systems up to 20 MW offer the perfect combination of performance and quality for onshore and offshore applications. Benefit from a generator customized to your individual system type and get to know the wide variety of products on offer.

SQUIRREL-CAGE INDUCTION GENERATOR

-

Compact and rugged.

Our squirrel-cage induction generators are durable, reliable, and easy to maintain. Due to a simple mechanical and electrical design without brushes and slip rings, they are extremely compact and lightweight despite their high performance. The construction and the technical design of the generator therefore have exactly the characteristics that are required in wind power industry.

The generator is completely decoupled from the grid via the frequency converter and can be controlled over a wide speed range. The usual grid fluctuations cannot influence the operation of the generator and the drive train of the wind turbine. The turbine can be optimally adapted to the current wind conditions, resulting in a positive annual value.

BENEFITS

- Use in on- and offshore turbines

- Reliable and low-maintenance: troublefree operation in any climate zones also under severe conditions

- Global and flexible application: available as version 50 Hz, 60 Hz or combined 50/60 Hz

- Designed for large maintenance intervals

- Flexibility thanks to cooling options: open cooling IP34, air-/air- or air-/water-cooling

DOUBLE-FED INDUCTION GENERATOR

-

One generator for all cases

The double-fed asynchronous generators have proven themselves thousands of times over worldwide. A rotor fed by the converter is used for speed control. Together, the generator and converter meet all current grid codes. Due to the small size of the rotor converter and the converter losses from the rotor circuit, the system features a high efficiency and low investment costs.

Only about 30% of the generator's rated power is fed into the grid via the converter. In addition to the high efficiency of the generator, this allows an added increase in the efficiency of the system. Come and see our lifetime-optimized and monitored brush slip ring designs.

BENEFITS

- Use in on- and offshore turbines

- Compatible with directives regulating the connection to the grid network

- Custom-designed to turbine and converter requirements

- Cost-optimized system configuration with adaptation by the converter

- Available as versions 50 Hz, 60 Hz or combined 50/60 Hz

- Simple connection to the grid network and frequency regulation with full-converter solution

- Flexibility thanks to cooling options: open cooling IP34, air-/air- or air-/water-cooling

PERMANENT-MAGNET SYNCHRONOUS GENERATORS

-

Thousands of times in operation worldwide

Synchronous generators using permanent magnet technology are common in the wind industry. The full converter concept offers advantages, such as optimized yield because of the wide speed control range. This is complemented by the benefits of the permanent magnet technology. These include low maintenance and reliability, as no electrical excitation equipment is required. They bear a high efficiency and ultimately ensure a high total energy yield.

We designed these generators with high ruggedness in mind. The magnets are completely protected against corrosion and are short-circuit proof. Further, they set themselves apart as a result of their modularity: They are available in water-cooled and air-cooled versions, for low voltage and medium voltage designs.

The result: They can be optimally adapted to every turbine type.

BENEFITS

- Use in onshore and offshore applications

- Corrosion-resistant components

- Maintenance-friendly design and high spare parts availability

- Maximum energy yield and high efficiencies

- Easy connection to the grid and frequency control with a full converter solution

DIRECT DRIVE

-

IN HARSH CONDITIONS THEY NEED TO BE HIGHLY EFFICIENT

The gearless Direct Drive wind generator is a multi-pole synchronous machine, usually equipped with permanent magnet technology. Winergy offers you custom-made stators in segmented design for your Direct Drive wind generator.

Based on its modular platform concept, the generator's stator is not manufactured as a whole but is composed of preassembled sub-segments. This offers especially advantages for the transport and erection and allows a customized adaptation to the respective performance requirements. The stator segments are integrated optimally into the drive train of the wind turbine using finite element calculations.

The stator segments are characterized by extreme mechanical accuracy, stability and highest efficiency and reliability of the electrical design. This makes the stator segments ideal for harsh offshore conditions in particular.

The many successfully installed Direct Drive offshore turbines worldwide featuring Winergy stator segments speak for our components' quality and reliability.BENEFITS

- Space-saving, compact design for use onshore and offshore

- Trouble-free and maintenance-free operation also under severe conditions

- Solutions according to customer's specifications, fully integrated in nacelle design

- Simple connection to the grid network by full converter

- Serial production and easy handling thanks to segmented design

ORIGINAL SERVICE

-

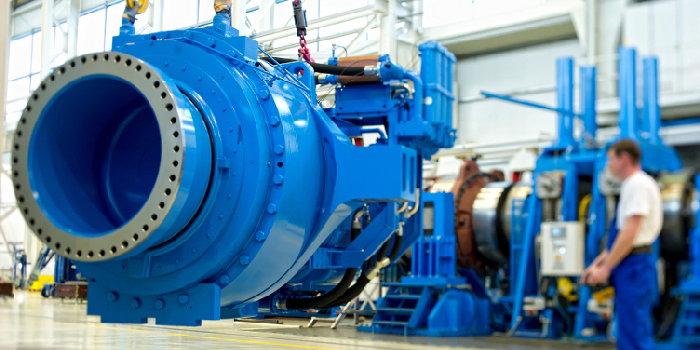

FIRST-CLASS SERVICE

More than 40 years of service experience can be felt at every point in our service program. We are just there - with words and deeds, competent and fast. This is ensured by a complete original documentation to provide a history-based service.

WORKSHOP SERVICE

-

HOW DO YOU COMBINE MAXIMUM SAFETY WITH COMFORT?

Winergy service performs gearbox and generator refurbishment according to the specific failure mode, condition, design status, and original scope of delivery.

FIELD SERVICES

-

WE ARE WHEREVER YOU NEED US

Fast and flexible on-site service solutions help Winergy customers to increase turbine availability and reduce their LCoE. With the right approach, a lot can be achieved up-tower.

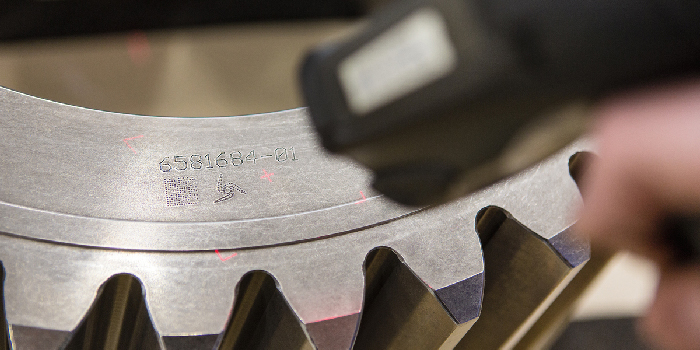

SPARE PARTS

-

ORIGINAL SPARE PARTS FOR WINDTURBINES.

With us as your service partner, you benefit from high-quality and immediately available spare parts straight from the manufacturer. We stock spare parts for all standard gearboxes and generators for service purposes.

Moreover, Winergy optimizes tooth geometry on the micron level. Spare parts that are not manufactured according to the original specifications can sustain significantly higher wear. Using original spare parts only means an increased lifespan for your wind turbines.

SPARE UNITS

-

ORIGINAL SPARE COMPONENTS FOR THE ENTIRE WINERGY PORTFOLIO

Should it ever happen that a gearbox or generator needs replacement whether as a preventive measure or in the event of damage it is essential to return the wind turbine to operation as soon as possible.

For this purpose, we have an immediately available stock of Winergy replacement components for all common wind turbine models in our exchange pool. We provide this service for series production as well as custom-built Winergy components. We apply the same strict quality requirements to these custom-built Winergy components as to our series production.

TRAININGS

-

CUSTOMER TRAININGS

As your original service partner we dont keep our expertise to ourselves, we pass it on in order to enable our customers to install Winergy Original Spare Parts on their own, professionally.