- Offer Profile

- Gems Sensors & Controls is a

leading manufacturer of level switch products, pressure switches, pressure

transducers, flow switches, miniature solenoid valves, proximity switches

and liquid level control units for use in a broad range of fluids across

industry.

Gems products feature an ever-expanding selection of fluidic and pressure sensing technologies.

SENSORS

LEVEL SENSORS & SWITCHES

-

Gems liquid level sensors and switches provide high-reliability monitoring and detection of a wide range of fluid media. Requirements can range anywhere from the sensing of cooking oil, to hydraulic fluids, to diesel fuel tanks (gas level indicator), to water and wastewater, to biohazards, to even deionized or potable water.

To effectively address such a wide variety of measurement challenges, Gems offers a broad range of contact, non-contact, and non-intrusive liquid level sensors and switches. These are available in multiple technology types, including magnetic reed switch-based floats, solid-state electro-optical, conductivity, capacitive, ultrasonic, and piezo-resonant. Multiple liquid level sensing technologies may also be incorporated within a single application. Sometimes, more than one “best fit” solution may also exist, with the ultimate decision simply a matter of customer preference.

Standard catalog products for liquid level sensing include single point level switches, continuous level transmitters, multi-point level switches, chemical vapor deposition (CVD) pressure transducers, coolant level sensors, and visual level indicators. Detailed specifications on these and other liquid level sensors and switches may be found in the links below.

Please consult our fully digital online standard product catalog for an up-to-date listing of available models for immediate customer shipment. Most Gems standard catalog products can be easily modified with alternate connectors and housings. Or, a custom solution can also be developed, many times delivered in OEM volumes with shorter lead times than most industry off-the-shelf solutions.

SINGLE POINT LEVEL SWITCHES

-

- Float Level Switches & Sensors with Magnetic Reed Switches

- Electro-Optic Level Switches

- Capacitive Level Sensors & Switches for Aqueous and Non-Aqueous Fluids

- Ultrasonic Level Sensor

- WIF-1250 Water in Fuel Single Point Level Sensor

MULTI-POINT LEVEL SWITCHES

-

- Float Level Switches

- UCL-510 Ultrasonic Water Level Sensor

CONTINUOUS LEVEL TRANSMITTERS

-

- Continuous Float Level Transmitters

- Ultrasonic Liquid Level Sensors & Transmitters

- CT-1000 Potentiometric Sensor

- XT-1000 Magnetostrictive Level Transmitter

CVD SENSING PRESSURE TRANSDUCER

-

- 1200/1600 Series Pressure Transducers

- 2200/2600 Series Pressure Transducers

- 6700 Series Pressure Transducer

VISUAL LIQUID LEVEL INDICATORS

-

- Suresite Visual Liquid Level Indicators

- DIPTAPE™ Oil Level Indicators & Oil Tank

- Gauges

- Receivers

WARRICK CONDUCTIVITY SENSORS

-

- Warrick® Liquid Level Controllers

- Warrick Fittings and Probes

- Warrick Panels, Alarms and Kits

- Low Water Cut-Off Boiler Controls

- Series M - Mechanical Tilt Level Sensor

FLOW SENSORS

-

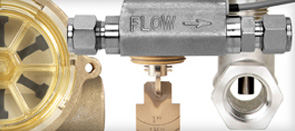

Gems designs and manufactures a complete range of flow sensors and switches for the reliable and effective measurements of both conductive and non-conductive fluids, as well as gases. At preset rates ranging from 50 cc/min to 100 GPM, rugged Gems flow switches will initiate alarm actuation or automatic system shutdown, making them a vital component of any predictive maintenance strategy. They are commonly specified for rotating equipment, conveyors, gas sampling and distilling, water purification systems, welders, semiconductor equipment, chemical processing, machine tool and robotics applications.

The complete Gems flow sensing portfolio is designed for versatility and performance. It is organized into five product types. Piston types are designed for low flow rates in gases and liquids from 50 cc/min to 20 GPM, with choice of alloy or plastic housings. Shuttle models are used with high flow rates from 0.5 GPM to 100.0 GPM. Paddle models are for larger line sizes, typically 1.25" and up. Thermal dispersion technologies feature no moving parts, making them ideal for applications where particulate matter is also a concern. Electronic flow switches encompass state-of-the-art electronics and positive visual indication.

All Gems flow switches feature high-quality, corrosion-resistant materials, ensuring their continued performance within challenging environments. Material choices, ranging from stainless steel to Ryton, further offer vast chemical compatibility. In addition, models are offered with fixed or adjustable actuation settings; viscosity compensation or high pressures; media compatibility with slurries and particulates; as well as in-line models and designs to satisfy any mounting or space requirement.

FLOW SWITCHES - GAS FLOW & LIQUID FLOW SWITCH

-

- FS-600 - No-Moving-Parts - Thermal Dispersion Flow Switch

- Piston Type Flow Switches

- Shuttle Type Flow Switches - Piston Flow Switches

- Paddle Type Flow Switches

ELECTRONIC FLOW SENSORS - FLOW INDICATOR

-

- RotorFlow Sensors

- Turbine Flow Sensors - Low Flow Mete

PRESSURE SENSORS

-

Industrial Pressure Sensors, Transducers, Switches

Gems offers a wide range of industrial pressure sensors, transducers, and switches. Each is ruggedly designed to address customer measurement challenges in hydraulics and pneumatics; water and wastewater; HVAC; OEM compressors and pumps; refrigeration systems; oil and gas; off-highway; machine tooling; medical gases; in-process control; and other applications.

Industrial pressure transducers are available with ratiometric output for continuous real-time monitoring. They are also offered in gauge, absolute, differential, vacuum and compound types, and in standard ranges from vacuum to 10,000 PSI. High-temperature and submersible versions are also available.

The Gems portfolio includes chemical vapor deposition (CVD), sputtered thin film, capacitance, and micromachined silicon (MMS) pressure transducers. These technologies support a diverse range of requirements. Capacitance-based pressure transducers, for example, are ideal for higher volume use. Sputtered thin film pressure transducers are specified where the highest possible measurement accuracy must be achieved.

Rugged industrial pressure switches from Gems provide basic “On/Off” functionality, either factory set point or adjustable, for a broad range of price and performance compatibility. Depending upon selection, units can offer over 1 million cycles of reliable service. Repeatability ranges are typically from 0.25 percent to 5 percent of the set point. The unique design of Gems pressure switches incorporates a special diaphragm/piston mechanism. This feature combines the benefits of high proof pressure piston technology with high repeatability, along with added resistance to vibration, pressure spikes, and temperature variations. For especially tough environments, Gems further offers a CVD-based solid state pressure switch with a field-proven ASIC design. A full family of water pressure switches is also available, with high-reliability over a standard range of 2 to 6000 PSI.

Available pressure switch enclosure options include aluminum, stainless steel, brass, reinforced plastic and zinc-plated steel. Wetted parts include choice of Buna-n, Teflon® coated Kapton®, stainless steel, PTFE, EPDM or Viton® diaphragm. Standard pressure port options include stainless steel, brass, zinc or aluminum. Extended ranges or other features are available upon request.

PRESSURE SWITCHES & SENSORS

-

- Pressure Switches - Gems™ Sensors

Adjustable Air Compressor Pressure Switch for hydraulic pumps and Other Applications - Vacuum Pressure Switches and Sensors

- Solid State Pressure Switches

- Pressure Switches - Gems™ Sensors

PRESSURE TRANSDUCER & OIL PRESSURE SENSORS

-

- CVD Pressure Sensors

- Thin Film Pressure Sensors

- Capacitance Low Pressure Transducers

- MMS Pressure Transducers

- Digital Pressure Gauge & Transducers - 9000 Series

QWIK SHIP PRESSURE SENSORS

-

- Pressure Switches

- Pressure Transducers

PROXIMITY SENSORS

General Purpose Proximity Sensors

-

- PRX-300 Series Proximity Sensor

- Heavy Duty Proximity Sensor

Compact Proximity Sensors

CONTROLS

MINIATURE SOLENOID VALVES

-

Electromechanical solenoid valves provide effective automatic fluid flow control of liquid or gas, as well as air, water, or steam. They are widely specified within medical equipment, food processing, industrial, automotive, water transfer systems, oil and gas, analytical instrumentation, clinical chemistry, HVAC, printing, environmental test chamber, semiconductor manufacturing, and larger pneumatic valve control applications.

Gems Sensors & Controls designs and manufactures a complete range of 2-way normally open/closed, 2-way normally closed, and 3-way directional miniature solenoid valves, available in general purpose, cryogenic (-320 °F) and isolation types. Their rugged construction incorporates a bubble tight plunger for reliable operation over millions of cycles without failure, making them ideal for use within demanding environments.

Please consult the Gems standard product catalog for a comprehensive listing of available solenoid valves for immediate customer shipment. Customers can also choose from among a variety of standard and custom product modifications, including choice of body materials, orifice sizes, wattages, and coil construction, as well as MOPD and CV range options.

For more complex applications, Gems can integrate multiple solenoid valves, switches, sensors and other components into a single custom control module. Custom manifolds can also be designed and manufactured in OEM volumes with short lead times.

GENERAL PURPOSE SOLENOID VALVES

-

- A Series Solenoid Valve - General Purpose Solenoid Valves

- BL Series Latching Valve

- B Series Solenoid Valve

- C Series Solenoid Valve

- D Series - High Flow Solenoid Valves

- E & EH Series Solenoid Valve

- G & GH Series Solenoid Valve

- M Series - Miniature Solenoid Valves

- Humidifier Solenoid Valve

CRYOGENIC SOLENOID VALVES

-

- Cryogenic Solenoid Valves

- B-Cryo Series Solenoid Valve - Cryogenic Valve Design

- D-Cryo Series - Cryogenic Solenoid Valve

ISOLATION SOLENOID VALVES

-

- AS Series Solenoid Valve

- BS Series Solenoid Valve

- KS Series Isolation Solenoid Valve

- KM/KL Series Solenoid Valve

- KV/KW Series Solenoid Valve

- PM/PL Series Solenoid Valve

ELECTRONIC RELAYS & BARRIERS

Intrinsically-Safe Relays

Electronic Solid-State Relays

Intrinsically Safe Zener Barriers

Markets & Applications

- Your Solution Partner

Gems™ Sensors & Controls is a leading manufacturer of a broad portfolio of liquid level, flow and pressure sensors, miniature solenoid valves, solid-state electronics and fluidic systems. Decades of application engineering experience has given Gems the knowledge required to deliver tailored products that measure up to today's most sophisticated and critical applications. Working around the world with global resources, and to exact customer application and manufacturing requirements, products from Gems Sensors & Controls are used in almost every industry from medical to waste water treatment, semiconductor fabrication to off-highway vehicles and HVACR to food and beverage. Alternative Energy - Pressure and Level Sensors For Hydraulic Systems In Wind Turbine

- Hydraulic systems play a crucial role in wind turbines

by controlling blade pitch and yaw to maximize the amount of power generated

under any wind condition while protecting the wind turbine from damage.

Monitoring these and other hydraulic systems is critical to the performance

and durability of wind turbines. Leading edge pressure switches and

transducers from Gems™ Sensors & Controls deliver the accuracy and

reliability needed to help meet the rapidly growing demand for economical

and reliable wind energy. Gems has provided sensor packages for thousands of

wind turbines currently in the field with on time delivery and competitive

pricing.

Importance of hydraulic systems

In most turbines, the angle of a wind turbine blade is pitched at a specific angle in order to optimize its power output at any given wind speed. Leading wind turbine manufacturers use hydraulic pitch control because a hydraulic system uses fewer components than a mechanical system making it easier to maintain.

Boiler Control - A Closer Look at Component-level Approvals that Help Ensure System Integrity

- The selection process for incorporating electronic

controls into a boiler system can be daunting and can vary depending on the

application. For the simplest of applications a basic safety relay may be

all that is needed. For more complex applications, feature rich controllers

that can assist the end user in troubleshooting the heating system are a

necessity. No matter what your application, specifying and designing in a

controller that meets local and federal regulations is a must. Gems Sensors

& Controls, manufacturer of the industry respected Warrick Line of boiler

controls, developed this article to help those within the boiler industry

understand the codes that cover boiler safety controls.

The days of temperamental boiler systems have all but passed. Nation-wide adoption of safe installation practices, regular maintenance and technological advancements are edging boilers into the category of set it – forget it. This is not to say that accidents have been wholly eliminated.

Marine Product Applications - MarineGrade™ Sensors: Built for Shipboard Demands

- Since 1955, Gems™ Sensors & Controls has earned a solid

reputation for accuracy and dependability in marine service. Gems™ marine

products are approved and qualified to MIL-L-23886, the military

specification for fluid level sensors. Other military qualifications include

MIL-S-901C, Shock Test High Impact Shipboard Machinery, Equipment and

Systems…MIL-STD-167, Mechanical Vibration of Shipboard Equipment

Vibration...Inclination, Bureau Veritas, Lloyds, ABS and USCG. Commercial

vessel approvals include UL, CSA, and FM.

Typical applications are ship-wide and include high, low and/or intermediate level alarms, automatic pump-up and pump-down control, single-point, multi-point and continuous level monitoring, flow confirmation, and pressure switch monitoring.

Off-Highway Vehicle Products - Don't just measure. Take control.

- For more than 50 years Gems™ Sensors & Controls has been

continuously improving the design and manufacturing process of fluid sensors

in the Off-Highway Vehicle (OHV) Industry. With decades of experience, Gems

has a unique understanding of the most sophisticated applications in OHV,

and delivers fluid sensors that measure up to today's - and tomorrow's -

critical requirements.

With a growing need for sophisticated systems to control fluids, Gems team of engineers has designed highly accurate and configurable products that provide improvements in fluid management, enhancing the overall efficiency of heavy equipment. These include level, flow, and pressure systems for hydraulic fluid, engine and transmission oil, coolant, urea, fuel, and brake fluid.

Medical - Were at the heart of fluid management technology for the medical sciences

- Gems Sensors and Controls products have been field-tested around the world and across industries for over 60 years – and in the Medical Industry for over 20 years.

From in vitro diagnostics to medical lasers and analytical instruments, we offer an extensive catalog of level, pressure and flow sensors, as well as miniature solenoid valves and customized fluid management systems to help you create your best design. We’re proud to help protect patients and prevent medical lasers from overheating with our flow switches, get every last drop with our ultra-low level sensors and reduce the footprint of medical equipment with our customized fluid management systems.

And, when you’re ready to make a purchase or manufacture a customized system, our four fully-equipped manufacturing sites located in North America, Asia, and Europe are all ISO certified (ISO 13485 certification at U.S. headquarters site).

Semicon Manufacturing - Fluid Control Sensors For Semicon Manufacturing

- When most people hear the word “semiconductor” they think of processing speed. When folks like us hear “semiconductor” we think of process purity. The microscopic topography of today’s silicon circuits demand the cleanest manufacturing facilities on earth. We know that, and we build liquid level, flow and pressure sensors to meet those stringent requirements. It’s because of these special requirements we have a special semiconductor sensor team at Gems™. These men and women are dedicated to making your manufacturing clean and simple.

Fluid Control Water and Wastewater - Clean or Waste, Gems Sensors Help Monitor and Control Water Processing

- Gems™ Sensors & Controls has earned a solid reputation

for accuracy and dependability in industries that require reliable

instrumentation products. Both the Water and Wastewater industries are no

exception. Gems manufactures an array of water level & flow sensors,

pressure switches, pressure transducers, and control devices in every area

of water and wastewater treatment plants.

Typical applications in treatment plants include automatic pump-up and pump-down control, single-point, multi-point and continuous level monitoring, flow confirmation, and pressure monitoring.

Selecting a Gems sensor offers easy installation, consistent accuracy, design flexibility, and fluid compatibility. Sensing technologies include Ultrasonic, Submersible Pressure Technology, Magnetically-actuated Reed Switches, Electro-Optic, and Conductance.