Starrett

Videos

Loading the player ...

- Offer Profile

- The L.S. Starrett Company, founded in 1880, manufactures more than 5,000 variations of Precision Tools, Gages, Measuring Instruments and Saw Blades for industrial, professional and consumer markets worldwide.

Starrett, a leader who has set the standard for fine precision tools in industry for over 140 years, has rightfully earned the title, "World's Greatest Toolmakers".

"Like all businesses, however large or complex, this one started with a man and an idea. The man was Laroy S. Starrett; his idea was 'to invent something useful that people would want.' Countless others have had a similar idea, the difference here was in the quality of the man. L.S. Starrett’s outstanding characteristic was confidence in himself; he was a man who in spite of one setback after another refused to admit defeat. He had unusual ability, vision and enterprise, but without his high courage this story of the foundation and growth of 'the world’s greatest toolmakers' could never have been written..."

Product Portfolio

Precision Measuring Tools

Precision Hand Tools

- Starrett Precision Hand Tools have been the standard for high quality dimensional measuring tools since 1880.

Gage Blocks

- Choose from a complete range of globally recognized Starrett-Webber gage blocks includes: High-grade steel gage blocks for shop floor use, longer-lasting and non-corroding ceramic blocks. Top-of-the-line croblox® Chromium Carbide, are very stable, non-corrosive and have excellent wringability. A variety of sets are available in square- and rectangular-block versions. Individual replacement blocks and a range of related accessories are also available.

Surface Plates

- Products and services range from standard surface plates and metrology accessories to engineering collaboration for unique solutions and complex assemblies. Skilled technicians build your product in our state-of-the-art, environmentally controlled manufacturing facility.

Saws

- Starrett saws and hand tools combine exceptional quality and innovative product offerings. With strict quality control, state-of-the-art equipment and an ongoing commitment to producing superior tools, the thousands of products in today’s Starrett line continue to be the most accurate, robust and durable tools available.

Band Saw Blades

- Starrett band saw blades provide the best solutions for cutting a variety of materials including hard, abrasive materials, ferrous and non-ferrous metals, wood, and food. Starrett band saws fulfill all cutting needs, economic or high production, and fit all types of band saw machines.

PTA & Hand Saw Blades

- Starrett Power Tool Accessories and Hand Saw blades: Starrett strives to improve blade life and performance through improved tooth geometry, edge materials and material processing technologies. At Starrett, we are driven by research and development of what we learn from listening to our customers and supported by complete metallurgical laboratories and sawing experts.

Metrology Equipment

- With the unbeatable combination of precision mechanics, powerful and intuitive software, and support from the most respected name in measurement, Starrett Metrology Systems take video-based and multi-sensor measuring systems to the next level. Our broad range of metrology systems are ideal for use in QC labs, research, engineering, and manufacturing environments where small to large scale high-precision measurement is critical. Starrett Metrology Systems provide quick Return-On-Investment through increased product quality, user time savings and alternative equipment reduction.

Vision Systems

- Starrett vision systems combine high-resolution images with robust, precision mechanical metrology platforms to deliver superb accuracy and repeatable measurement results for a wide range of measurement applications. Systems are available with a choice of MetLogix™ or Quadra-Chek® software.

Optical Systems

- Manufactured without compromise, Starrett optical comparators provide time tested, cost effective solutions for non-contact measurement. At the heart of these systems are precision optics, superb lighting and a highly accurate workstage. They combine to ensure bright, sharp images and exceptional accuracy. With a vast selection of styles, sizes, stages, lenses and other accessories, Starrett has a comparator for most any application.

Laser Measurement Systems

- Starrett laser-based, non-contact, dimensional measurement systems are employed on the factory floor for quality monitoring, process control and inspection. Our products have measurement accuracy and precision, system reliability, easy to use software. Starrett-Bytewise offers laser-based measurement systems that are employed on the factory floor for quality monitoring, process control and inspection. We are a vertical technology company with in-house resources for designing sensors, systems and software. We deliver products through our own sales and service network. Starrett-Bytewise is based in Columbus Georgia, USA, with offices in Europe and China, and is supported by independent sales and service representatives around the world.

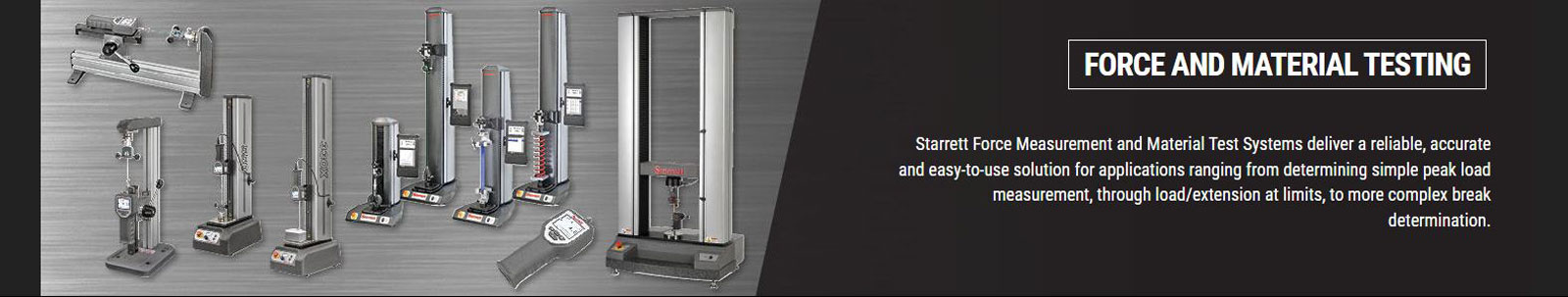

Force and Material Testing

- Starrett Force and Material test solutions range from simple hand-held measurements to highly advanced applications with extreme accuracy.

Force Testing REVOLUTIONIZED

- Starrett L1 Force Measurement Systems comprise our innovative, entry-level computer-based force testing solution. Optimized for production and quality control testing, they are easy to setup, operate and maintain. L1 Systems can be used to perform a wide variety of testing methods including Load Limit Testing, Distance Limit Testing, Break Limit Testing, Cyclic Count Testing, Cyclic Duration Testing, Constant Load Testing and Constant Distance Testing.

Advanced Force Measurement

- Starrett force measurement systems provide you with a reliable, accurate and easy-to-use solution for applications ranging from determining simple peak load measurement, load/extension at limits, or more complex break determination. Designed for professional use in production and engineering environments, Starrett L2 and S2 Force Systems are manufactured to provide high performance test frames and multiple levels of software capabilities to perform demanding force meaurement testing. Starrett systems are sleek and modern, and designed for high performanc, durability and consistency. The combination of frame, software and fixture options allows Starrett technicians to create a system specified to the needs of all engineering and quality personnel, research and design engineers, test technicians and more.

Material Testing

- Single and Dual Column Material Testers from Starrett offer high accuracy, flexibility and ease-of-use. L3 Systems are optimized for users involved with material testing and characterization- the research engineer, the design engineer, the quality control technician, the test technician and others.

Grips Fixtures

- Starrett offers a full range of test fixtures, grips and accessories. Test fixtures are compatible with all Starrett systems and test frames. Starrett can also engineer and supply custom test fixtures to your exact requirements.

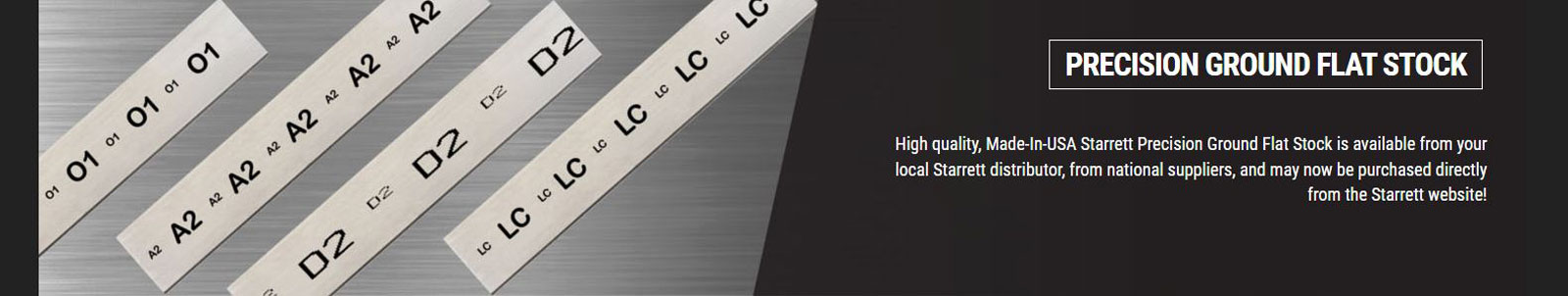

Precision Ground Flat Stock

- High quality, Precision Ground Flat Stock minimizes time consuming initial grinding to size in precision machining projects. Starrett Ground Flat Stock is of the highest quality - Used by Starrett in the production of many Precision Measuring Tools.

Flat Stock

- Starrett Ground Flat Stock is produced in Regular (+/-.001" Thickness & Square) and Oversized (+010/.015" Thickness & Square) in 18” 24” and 36” lengths out of the following materials O1, A2, D2, A6 tool steel and Low Carbon Steel with a surface finish down to 35 micro-inch. Specials are available upon request.

Jobsite & Shop Tools

- Starrett Jobsite and Workshop tools ensure exceptional quality and innovative products. With strict quality control, state-of-the-art equipment and an ongoing commitment to producing superior tools, the thousands of products in today’s Starrett line continue to be the most accurate, robust and durable tools available.

Hand Tools

- The Starrett hand tool range consists of exceptional quality and innovative products. With strict quality control, state-of-the-art equipment and an ongoing commitment to producing superior tools, the thousands of products in today’s Starrett line continue to be the most accurate, robust and durable tools available.

M1 Oil

- Starrett M1® industrial lubricant produces a micro-thin, airtight coating that simultaneously dries as it protects, avoiding dirt, grime, etc. It dries and will not attract dirt, dust or other contaminants as other leading lubricants do.

Features:- Silicone free

- Stands up to extreme temperatures

- Penetrates quickly to free frozen nuts, bolts and metal parts

- Removes grease, tar and grime from metal parts and painted surfaces

- Cleans and polishes for lasting protection

- Protects metal against rust and corrosion damage Instant lubrication properties that spread into hard-to-reach areas to stop squeaking and sticking

- Gets under moisture to lift it away from the surface

- Prevents short circuits in high moisture environments.