- Offer Profile

-

EROWA is known worldwide for clamping systems - our great competence lies in consulting for process automation.

The legendary "Flexible Manufacturing Concept" forms the basis for the modern automated production of small series and individual parts.

Our experts in manufacturing automation will also find a profitable solution for your production.

Contact us for further advice, an EROWA representative is close to you.

EROWA MTS

-

The versatile datum-point tooling system

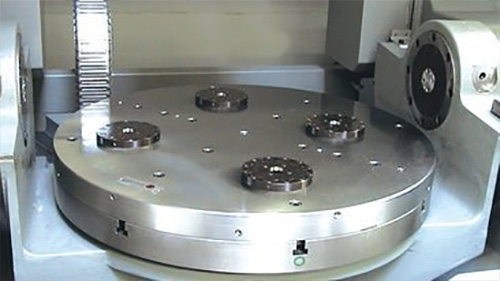

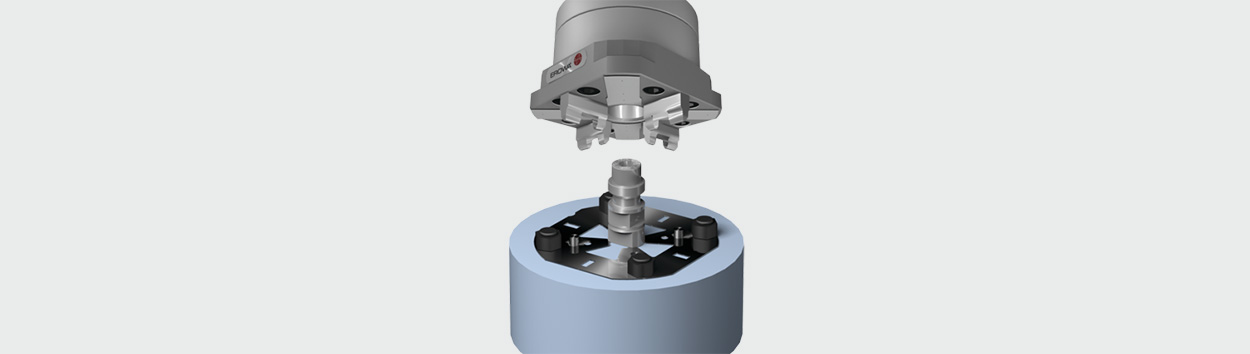

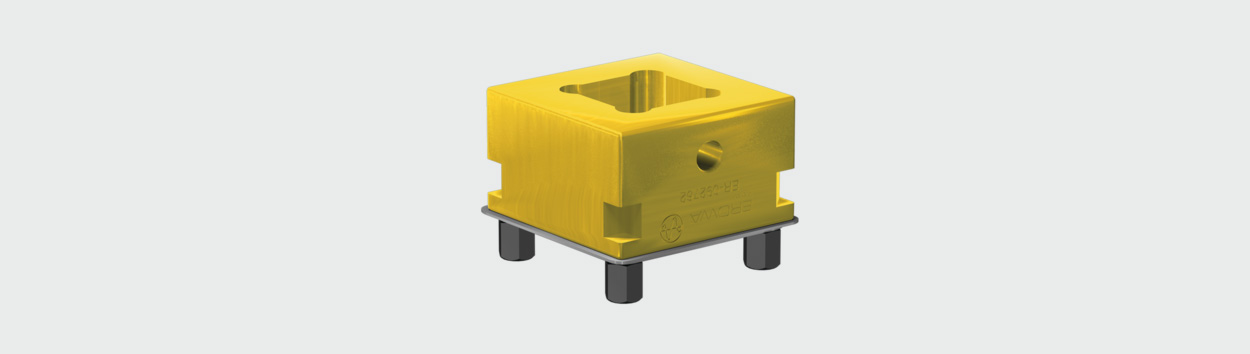

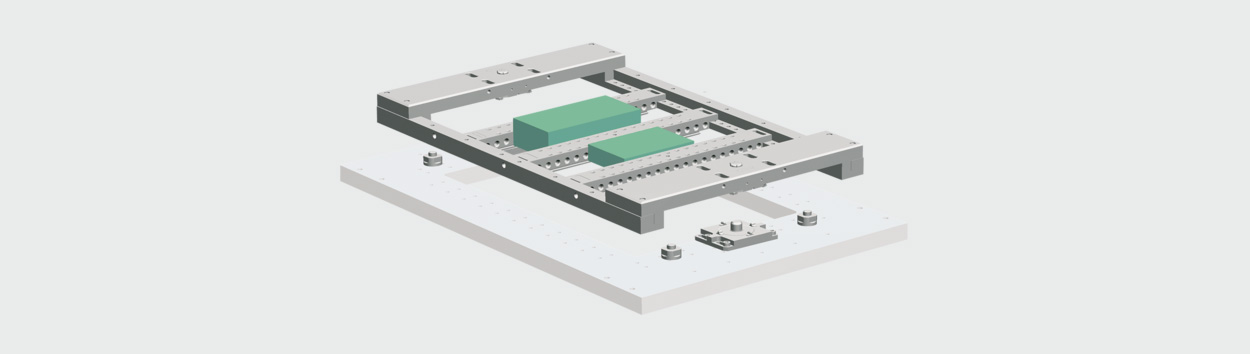

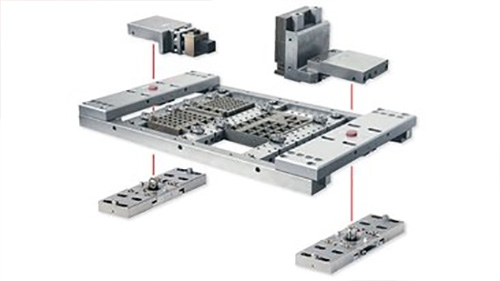

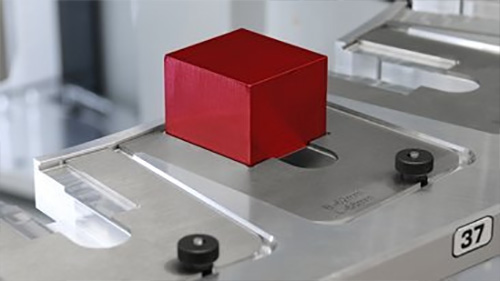

The EROWA MTS (Modular Tooling System) is a flexible tooling system. The maximum workpiece size is exclusively determined by the machine capacity.Whether you require single palletization with an MTS chuck or multiple palletization with several MTS chucks or base plates – all combinations are possible.

Modular and universal clamping

-

MTS base plates are the flexible and precise interface for single or multiple palletization.

MTS base plates are available in various versions – with 1, 2, 4, 6 or 8 MTS chucks, depending on the model. We would also like to advise you on customized versions.

Minimizing setting-up times

-

Workpieces and fixtures are palletized so that they can placed on the machine when required without any further setting up. On the machine, the MTS palletizing system holds them in position with precision and stability.

Further jobs are prepared outside the machine.

Automating

-

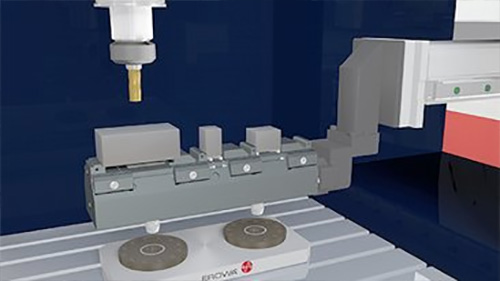

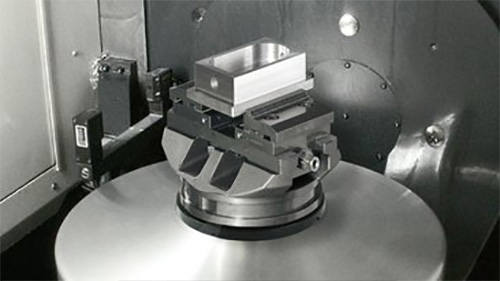

The MTS system is ideally suitable for automated pallet change.

When workpieces are changed, the contact surfaces of the chucks and chucking spigots are cleaned automatically. The MTS pallets are positioned neatly and with precision.

Low construction height

-

The low construction height of the EROWA MTS tooling system leaves a great deal of space for workpieces.

MTS chucks are fitted to the machine table or directly integrated in it.

Making use of existing equipment

- Existing vises, gauges and fixtures are equipped with chucking spigots or palletized. This immediately makes them universally integrated in the MTS system.

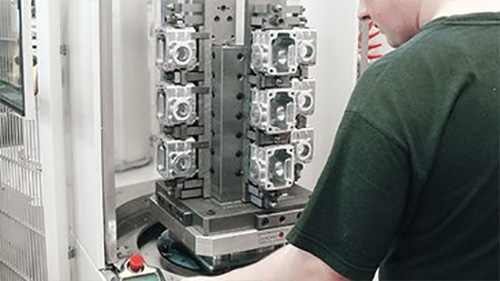

Making optimal use of working space

- The EROWA mineral cast tombstone provides a great deal of space for the simultaneous setting up of different workpieces. The entire working space of the machine is optimally exploited through the use of a tombstone.

The various EROWA MTS palletizing systems at a glance

EROWA MTS 81 – small construction size, high degree of clamping power

- MTS 81 is used wherever space is limited. Precise positioning of the pallets and high clamping force included.

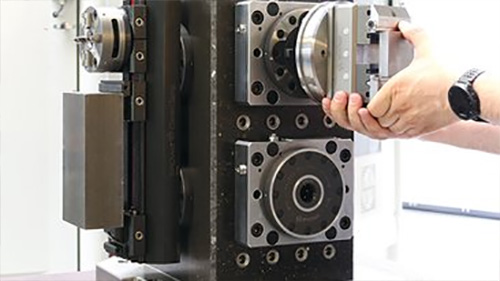

EROWA MTS – the universal interface

- The proven and versatile datum-point tooling system enables the pallet carriers to be changed within seconds with a repeat accuracy of < 0.005 mm.

The modular construction of the clamping components allows an almost unlimited combination of all components.

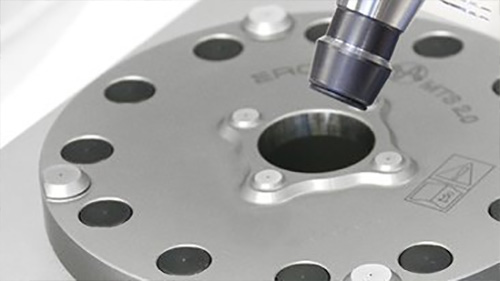

EROWA MTS 2.0 – to meet the toughest requirements

- The zero point clamping system with forward-looking functions. Ready for Industrial 4.0. Status display in real time with highest process reliability.

The centering and compensation pins position and center the workpiece carrier with < 0.003 mm precisely in the MTS 2.0 chucks.

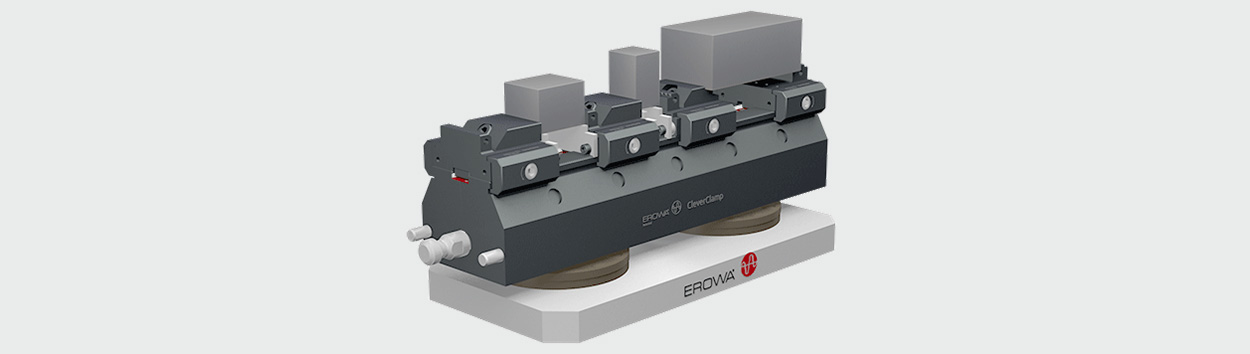

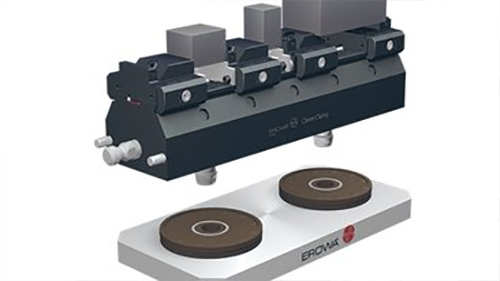

EROWA CleverClamp System

-

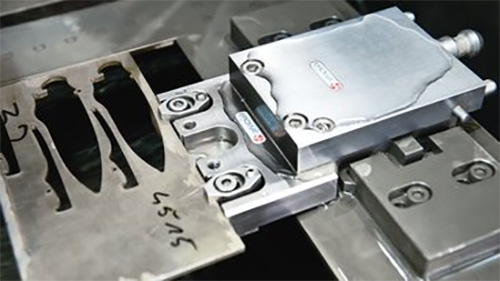

Clever clamping

The EROWA CleverClamp System is the modular and universal workpiece clamping system that is tailored to the production of one-off parts and small series.

It is simple to handle and versatile to use. Setting-up times are reduced, machine operating times increase and productivity is enhanced.

Modular and universal clamping

- Thanks to the standardized EROWA UPC or MTS interface, the CleverClamp workpiece carriers can be positioned on the machine with speed and precision, and they can be used universally.

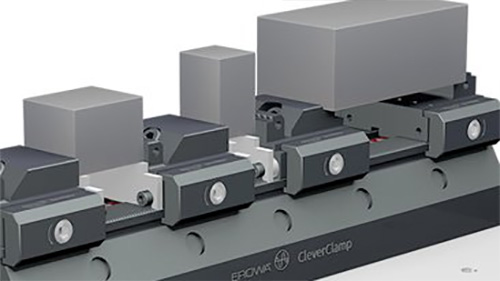

Faster set-up times

- Everything fits – the large and well-thought-out selection of various clamping and stop elements keeps the widest variety of workpiece shapes in any position you like with flexibility and precision.

Reliable base

-

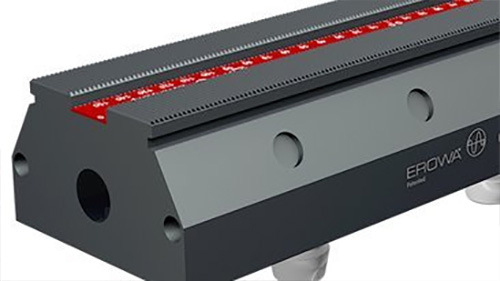

The base rails constitute the foundation of the CleverClamp workpiece clamping system. They can be used horizontally or vertically.

The matching clamping and stop elements can be positioned quickly with the help of the 2mm position toothing system.

Easy to handle

- Setting up and resetting with only a few simple steps: position and attach the clamping and stop element, then clamp the workpiece.

Various types of clamping surface

-

Depending on the material and workpiece, you can select the properties of the clamping surface.

The clamping surface with stamp contours is ideally suited for the clamping of blanks at a minimum clamping height and of parts with angular errors.

Can be automated directly

-

The CleverClamp base rail can be automated directly. The robot places the workpiece carrier on the machine with precision and speed.

The EWIS™ identification system provides you with a safe overviw of magazine positions and pallets.

EROWA Blank Vise

-

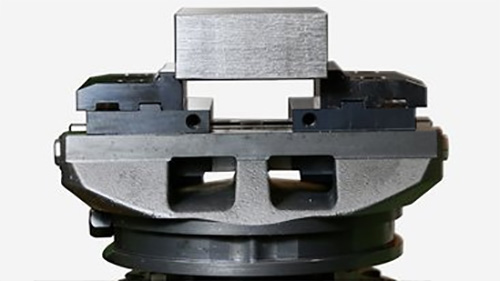

The strong connection

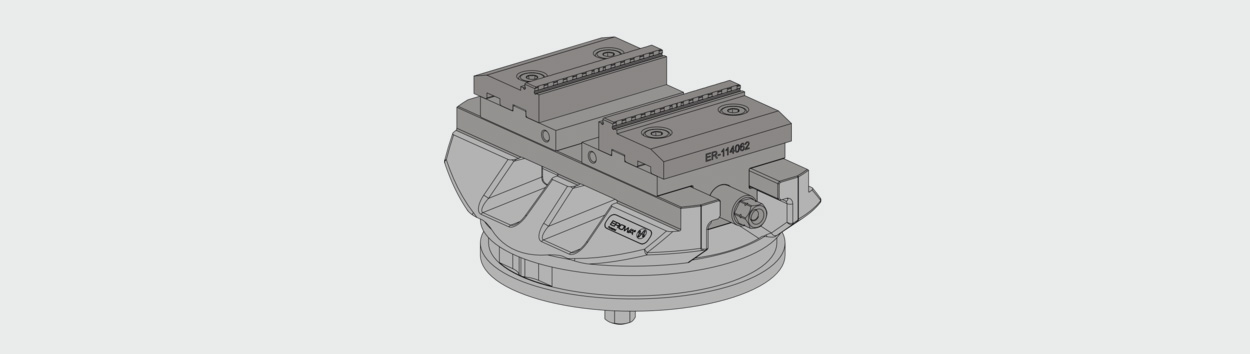

5-axis machining provides great advantages when it comes to machining workpieces as completely and economically as possible in one clamping position. Errors due to reclamping are avoided, and non-productive times are distinctly reduced.

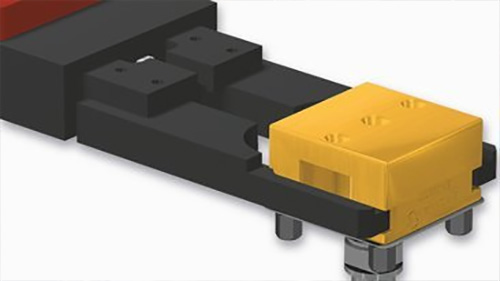

The new EROWA blank vise safely clamps workpieces with a high degree of clamping power at minimum height. The vise is characterized by a compact and robust, but still lightweight design. The individually usable jaws enable a wide variety of workpiece sizes to be clamped.

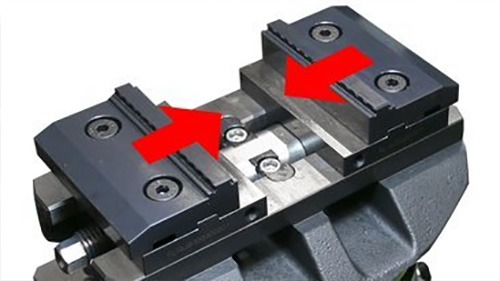

Practical design

-

The blank vise has a compact and robust design and as a workpiece carrier provides the machine-tool with optimal accessibility to the workpiece.

A height of only 100mm leaves a great deal of space for machining – even for larger workpieces.

High degree of clamping power

- The blank vise enables blanks to be clamped powerfully and reliably (up to 35kN) without prestamping and at a minimum clamping height of only 3mm.

Stamping jaw

-

The blank is stamped when clamped for the first time.

This makes prestamping on the stamping unit unnecessary. Set-up times and costs are reduced.

Automatically in the center

- The blank vise is characterized by a high degree of centering precision and repeatability. The workpiece can be centrically clamped with bolts on both sides.

Flexible clamping

- Clamping jaws that can be changed according to requirements result in a flexible clamping range of up to 165mm.

Versatile

-

An integrated interface enables the blank vise to be clamped into the following EROWA chucks: PowerChuck P, ProductionChuck 210 Combi and MTS Single Chuck.

The blank vise can be used in manual or automated operation.

EROWA EDM Tooling System

-

The tooling system for EDM and milling

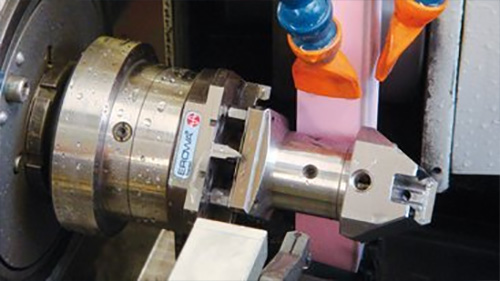

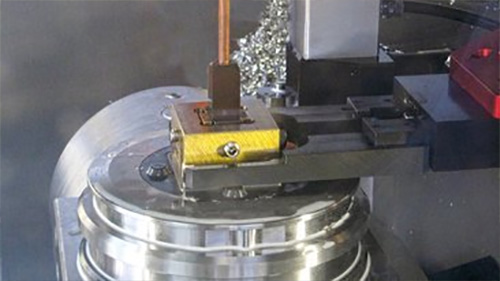

Fast and precise resetting in tool-making and in light chip removal: save time and money by using the EROWA EDM Tooling System. The basis of this workpiece clamping system is constituted by the EROWA ITS chucks, which can be fitted and aligned on the machine table or on the machine quill. Workpiece and electrodes are fitted to and set up on system carriers such as pallets, electrode holders, centering plates, etc. and production can start.

A suitable variant for every job

-

The applications of ITS chucks are as many-faceted as the challenges presented by jobs in precision mechanics and tool- and mold-making.

Depending on workpiece size, we offer a considerable range of different suitable chuck variants.

Quick resetting

-

Fixed reference positions: the chucking spigot and the centering plate guarantee precise positioning in the chuck and powerful clamping of electrode holders.

The next job is prepared while the machine is productive. Then, there is a quick resetting operation, without loss of time through re-alignment and re-positioning of the electrode holder.

Universal interface

-

EROWA ITS chucks can be used universally on all machines.

Workpieces and electrodes pass through the entire production chain (turning, milling, grinding, EDM, WEDM, and measuring and presetting stations) palletized on the same system carrier.

Precise

-

Precision and reliability in the machine tank and on the quill of the EDM machine.

Workpiece holders are divisible 4 x 90°.

The repeatability of 0.002mm guarantees universal and precise positioning.

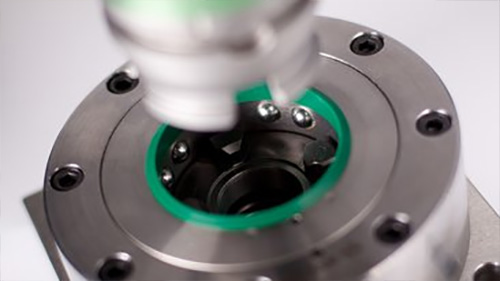

Safe and sealed

-

The sealing plate of the EROWA ITS 50 Holder C and the sealing ring provide a form-fit seal.

This ensures that the chuck is optimally protected against contamination and the penetration of liquids.

Automation

-

Automatic loading by an EROWA robot provides the CNC machine with unforeseen autonomy. Marginal and night hours are used productively, and throughput times are reduced.

The entire EDM tooling system can be automated. A large selection of EROWA loading devices supplies an appropriate solution to every application.

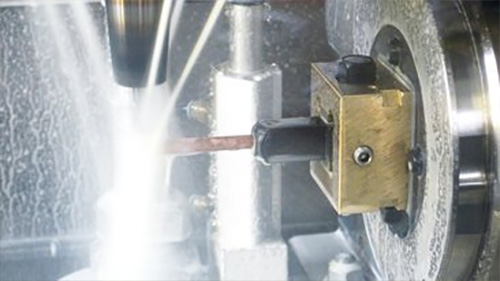

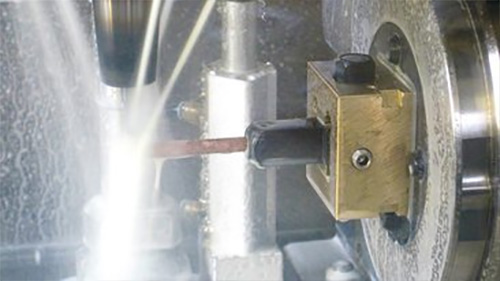

EROWA ITS 50 Electrode Holder C

Completely sealed

The demand for a high degree of reliability and quality in automated production makes great demands on the equipment. The use of the new EROWA ITS 50 electrode holder C provides maximum protection against the contamination of EROWA chucks during production. Whether there are copper chips, graphite dust or fine HSC chips the functionality of the chucks will be guaranteed.

Universally usable

- EROWA ITS 50 holders C can be universally used for most machining technologies.

Patented safety

-

The sealing plate of the EROWA ITS 50 holder C and the sealing ring constitute a positive-locking seal.

This provides the chuck with maximum protection against contamination.

Sealed

-

Seals are available to fit all EROWA chucks.

The sealing ring is put over the chuck on the machine table.

Retrofit existing holders

-

Existing ITS 50 holders of the first generation can simply be retrofitted and put to continued use.

Fit the sealing plate (with new or existing centering plates and supports) to the existing holder.

Automating

- The new ITS 50 holders C are prepared for automated handling with an EROWA robot. They have a gripper slot at the circumference.

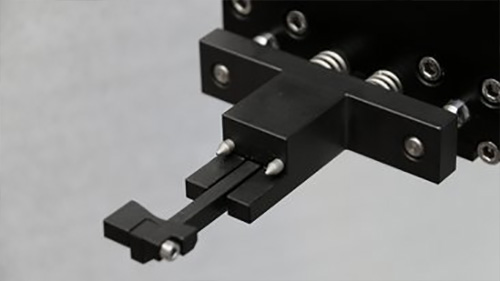

Suitable gripper

-

The holders can be moved by a robot with a model ITS 50 C gripper.

This particular gripper fits all current EROWA robots.

EROWA Wire EDM Tooling System

-

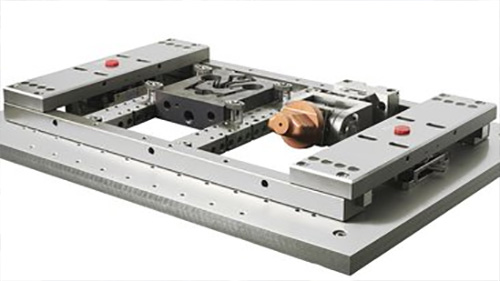

The modular tooling system for WEDM

The EROWA Wire EDM tooling system frees up your valuable WEDM machines from unproductive setting-up and preparation times.

The well-thought-out combination of vises, clamping elements and clamping beams enables you to clamp all conceivable workpieces in an appropriate manner.

The repeatability of the Wire EDM tooling system allows for presetting outside the machine and for safe automatic loading operations.

The right equipment for every application

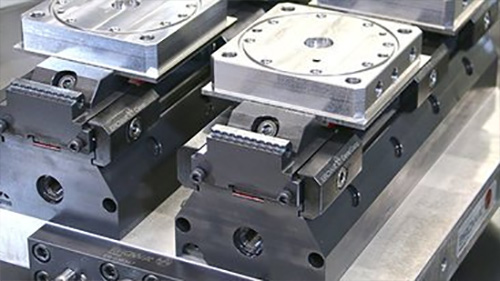

-

The EROWA flat chucks on the machine table constitute the flexible interface with the workpiece carriers.

The EROWA Wire EDM tooling system is suitable for single palletization or multiple palletization in a clamping frame.

Everything fits

-

There are suitable and flexible clamping elements for every size and type of workpiece.

The workpiece to be machined is attached to the clamping elements with brackets.

Special workpiece mount

- The Prisma clamping element for cylindrical parts: fitted to the pendulum holder, the workpiece can then be adjusted in three axes.

Clamping frames for different workpieces

-

Multiple palletization in a clamping frame: the workpieces to be machined are fitted to the clamping beams, which are individually arranged in the clamping frame.

In this way, workpieces of different dimensions are positioned in the same clamping frame, and various jobs can be completed in the same clamping frame.

The machine remains productive

-

While the next job is prepared, the machine remains productive. The set-up work is carried out in optimal surroundings and without any time pressure.

Throughput times are substantially reduced since no set-up work is done on the machine.

Automation

-

Since WEDM machines are loaded automatically, the share of productive hours is substantially increased.

An EROWA robot places the workpiece carrier on the machine with speed and precision.

We would like to advise you about an appropriate automation solution.

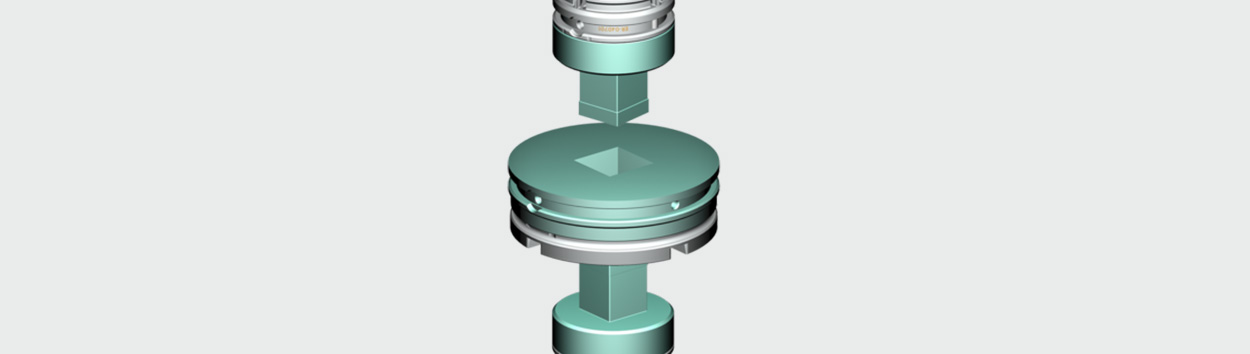

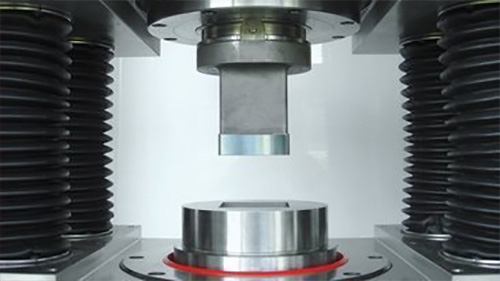

EROWA PM Tooling System

-

The rapid-change tooling system for powder presses

As a consequence of variable part forms and different part sizes, powder press adapters must be reset flexibly and quickly. A rapid-change tooling system makes a crucial contribution to a distinct reduction in resetting times.

EROWA’s PM Tooling System constitutes the precise interface between punch, die plate and powder press.

Systematic clamping

- The PM Tooling chucks are directly integrated into the powder press or into the press adapter and constitute the precise and universal basis for the press tools.

Quick change of press tools

-

Consequently, press tools such as punches and die plates can be clamped and exchanged quickly and with precision.

The 4x90° pallets are divisible; repeatability is <0.002 mm.

Retrofitting existing equipment

- Punches and die plates that are already in use can be adapted to PM Tooling pallets and aligned with precision. After this, they can be used throughout the system.

Aligning punches

-

With the EROWA PM Tooling aligning system, bottom and top punch chucks can be aligned with precision on the powder press.

Sensors or gauges serve to align the chuck positions according to requirements.

Different system sizes

-

Different PM Tooling system sizes can be adapted together in order to manufacture small and big parts on one and the same powder press. Thus resetting on the press becomes even more economical.

EROWA’s PM Tooling System is extremely flexible and provides various adaptation options for refined combinations of different system sizes.

PM Tooling center pin chuck

-

The positioning and clamping of center pins on powder presses is substantially simplified by the use of the EROWA CPC center pin tooling system.

Center pins can be clamped in the fixed or swimming position according to requirements. Palletized center pins and the correspondingly prepared bottom punch are preassembled outside the press and placed and clamped in the planned positions as units.

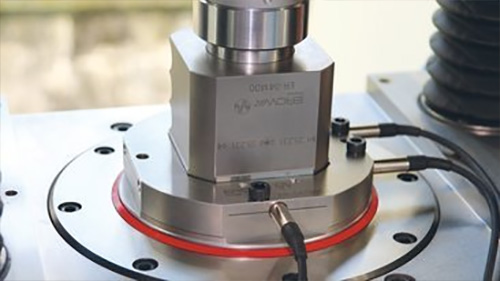

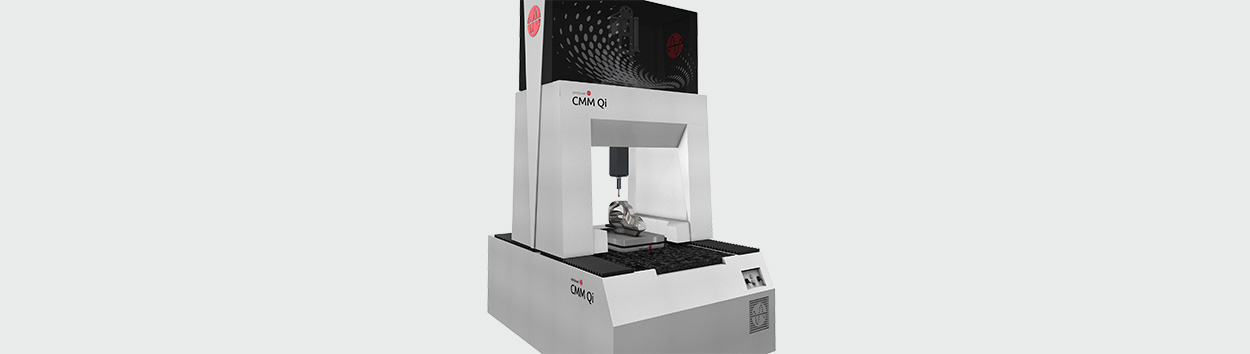

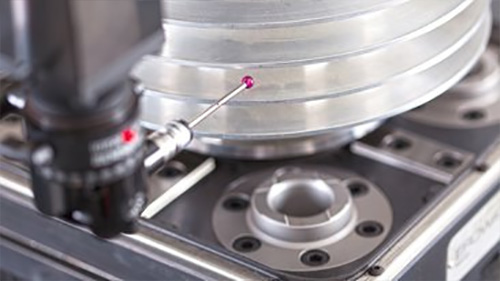

EROWA CMM Qi

-

Quality measurement of the highest precision

The EROWA CMM Qi portal measuring machine provides the highest mechanical accuracy for the efficient completion of any presetting jobs, as well as quality measurements.

The measuring machine has been prepared for automatic loading and can therefore be integrated into automatic production without any problems.

The very best material

-

Only choice components were used for the construction of the measuring machine.

The solid granite table and the specially cast portal constitute the basis for the precision of the measuring portal and the selected tooling systems.

Mechanical quality

- The stable axes are moved on high-precision rails with air bearings. In combination with the centrally arranged drives, mechanical accuracy is quite remarkable even with fluctuating temperatures.

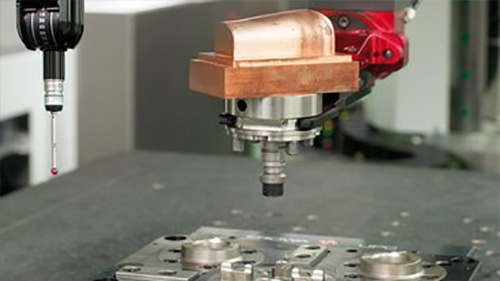

Prepared for EROWA tooling systems

-

Thanks to the standard hole pattern, one or more EROWA tooling systems can be directly fitted to the granite table, depending on requirements.

EROWA FrameSet, MTS, UPC or ITS – all the variants are supported.

Renishaw probe systems

- The high-precision Renishaw measuring probe systems provide the highest degree of flexibility.

Software

- An extensive software package for presetting, quality measurement and automation supplies a suitable measuring program for every application.

Automated quality measuring

-

The measuring machine has been prepared for automatic loading and can therefore be integrated into automatic production without any problems.

With a suitable EROWA robot and the manufacturing control system, we provide you with the overall solution from one single source.

EROWA PreSet 3D CNC

-

The all-rounder measuring machine

Machine tools must be relieved of unproductive work to the greatest possible extent. Every resetting process on a machine loses valuable productive time.

Presetting and measuring workpieces are processes that can be completed substantially more efficiently on a measuring machine.

EROWA’s PreSet 3D CNC measuring machine is an appliance that is optimally equipped for such work. The EROWA PreSet 3D CNC is ideally suited for efficient presetting and serial measurements.

Presetting simply and quickly

-

An extremely user-friendly software is available on the measuring machine.

Macros are selected visually. Graphic user guidance helps the operator execute the measuring cycles correctly.

Subsequently, the data recorded by the computer will be unequivocally allocated to the current workpiece.

Joystick control

-

The operator profits from the simple and practical user guidance with a precise joystick control.

You will be able to regulate all the axes precisely with the control level.

Prepared for all EROWA tooling systems

-

The high-precision work plate of black granite constitutes the basis for all EROWA tooling systems.

The integrated mounting hole configuration is prepared for each EROWA chuck to be fitted.

Versatile

-

PreSet 3D CNC measuring machine based on an EROWA CTS chucking spigot exchange system.

The ideally suited, precise measuring station for reliable quality checks and process safety in the watchmaking industry.

A suitable probing system for every occasion

- From favorably priced probing systems for simple point measurements to high-precision tactile scanning solutions and efficient laser scanners, every solution can be used on the PreSet 3D CNC.

Automating

-

Thanks to the full integration in our control systems and the standardized interfaces, the PreSet 3D measuring machine can be automated simply and is therefore also available to you in marginal hours and at night.

Process safety is substantially increased. The measuring machine is used to better capacity and is therefore more profitable.

EROWA Robot Compact 80

-

High performance on little space

The EROWA Robot Compact 80 provides the optimal ratio between a large number of magazine positions and a small amount of floor space.

The tall and lean design of the Robot is suitable for optimal floor space use in the workshop. With a transfer weight capacity of up to 80kg, it can serve one or two machine tools.

Two machines – one Robot

-

One production cell with two machines and one EROWA Robot Compact 80 requires only little space: productivity set up on a mere 2m² of floor space.

The Robot provides the machines with a great deal of autonomy.

80kg transfer weight

- Even large UPC 320 pallets of up to 80kg in weight can be transferred to the machine with precision.

Moving it out of the way

-

The Robot is lifted pneumatically and can be shifted out of the way on a rail system, which frees up access to the machine.

The shifting system is a retrofitting option.

Variable magazine levels for different pallet sizes

-

The EROWA Robot Compact 80 is able to move up to 11 different EROWA pallet sizes for varying workpiece sizes.

The magazine levels can be set up precisely to meet requirements.

The loading station

-

The integrated loading station (option) makes it easy for big and heavy workpieces to be positioned in the magazine at an ergonomically correct height.

While this is taking place, the Robot keeps on working without any problems.

User-friendly

- Extendable magazine levels allow for a comfortable loading/unloading process. The extension of the magazine levels is triggered through the integrated handle positions.

Blank handling made easy

Various jobs

- Load the machine in mixed operation with blanks, clamping vises for the blanks or palletized workpieces.

For round and square parts

- The magazine-levels with configurable positioning aid can be set up quickly and easily, depending on the size and shape of the workpiece.

Quickly customize

- The blank part gripper can be quickly and easily configured for other workpiece sizes.

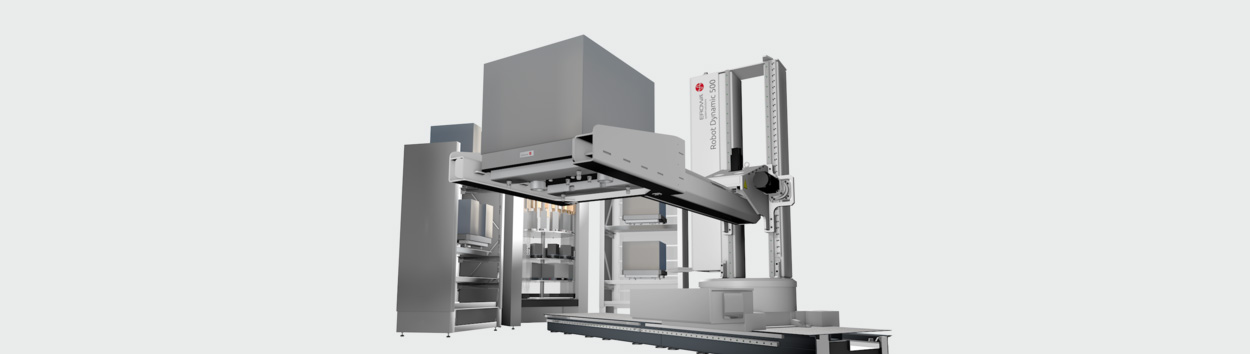

EROWA Robot Dynamic 150L

-

More for less

Automation according to your requirements, precisely as much as necessary: this is the concept of the ERD 150L. You acquire exactly as much automation as makes sense at the present time. If demands on production capacity change, the Robot system can be modularly extended at any time.

The loading robot was uncompromisingly geared to the requirements of Industry 4.0: a high degree of functional density with the simplest operability.

More modularity

-

Thanks to the almost unlimited possibilities and thanks to our product configurator, we can create precisely THE production cell that satisfies your requirements.

If or when your requirements change, functions, interfaces and magazine positions can be extended at will. Existing investments remain in use, and further investment costs are calculable.

More machines

-

Up to seven machines from various manufacturers and with varying machining technologies can be combined into a flexible production cell with the EROWA Robot Dynamic 150L, whose transfer weight capacity is up to 150kg.

With the easy-to-operate process control system, jobs from batch size 1 can be automated in a profitable manner.

More magazine capacity

-

Various magazine sizes also allow for the optimal exploitation of limited space. The magazines provide space for an almost unlimited number of pallets and workpiece holders.

Thanks to the autonomously loadable rack magazines, no down times occur. While the operator is loading the magazines, the Robot continues to work in the background without any interruption.

More ergonomics

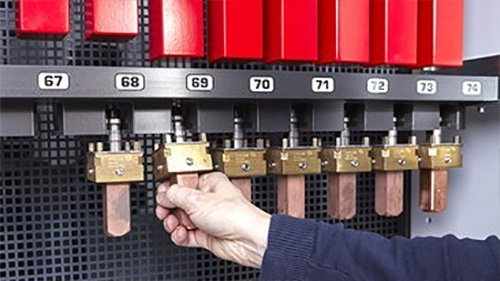

-

User-friendly operation – the extendable magazine levels create the highest degree of ergonomics for the loading/unloading process of pallets.

Equally, the plug-in magazine slots offer an ingenious solution for the rapid loading of electrode holders.

More safety

-

Thanks to the integrated safety system, the production cell requires only one single access protection facility.

The barriers are modularly extendable and favorably priced.

More control

-

The whole cell can be supervised at a glance on the large touchscreen with the progressive and clear user concept.

The operator can see quickly what jobs have already been completed or how much production time is still left.

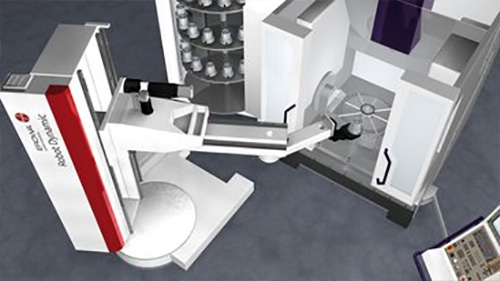

EROWA Robot Dynamic

-

For large and small workpieces

The EROWA Robot Dynamic is the flexible and extendable handling system for economical loading of machining centers.

The robot automates as a stand-alone model, one machine, or up to eight machines running on rails.

Various pallet sizes

-

One of the important features for automated manufacturing of single parts and small batches is that the system can switch automatically between different pallet sizes.

The Robot Dynamic is suitable for loading large and small workpieces. Each magazine position and each pallet is continuously monitored. The EWIS™ Rapid identification system ensures a clear view.

Extendable at any time

-

The EROWA Robot Dynamic is always adaptable and upgradeable to the current requirements. The basic investment is protected.

The robust linear rail is extended in segments to the appropriate length (up to 20 meters). Element by element in 2 meters' steps.

High transfer weight

-

The Robot Dynamic changes pallets with a total weight up to 250 kg reliably on to the machine. Also small and light workpieces.

The right gripper for each tooling system size is stored in the GripperDock and can automatically replaced when needed.

Long range

- Depending on the type of X-axis, there are three configurations to choose from, the arm of the Robot Dynamic has a range of up to 2350 mm.

Optimal loading through the front door

-

The Robot Dynamic is located laterally offset from the machine. The combined swivel axis allows to load the machine through the front door.

The operator area in front of the machine thus remains accessible for manual operation.

2D scanner for access safety

-

An 2D scanner continuously monitors the operator area.

If a person is located in the area, pallet changes are not allowed. If the area is free, the Robot Dynamic loads the machine as planned.

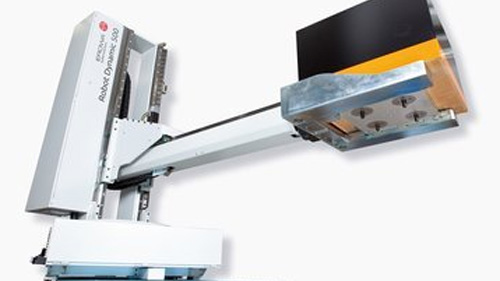

EROWA Robot Dynamic 500

-

To load large workpieces precisely onto the machine

The EROWA Robot Dynamic 500 is a flexible loading device for serve processing machines with large and heavy as well as small and light workpieces.

The transfer unit can be equipped with one or more magazines; and on a rail up to 20 m long it becomes the "EROWA Robot Dynamic 500 Linear" and loads up to eight machines.

Up to 500 kg transfer weight

-

Palletized workpieces of up to 500kg in weight and, for instance, 800×800×500mm in size can be loaded onto the machine tool safely and with precision.

Besides the focus on heavy workpieces, the robot can also reliably transport lightweight pallets.

Exchange gripper system

-

The EROWA Robot Dynamic 500 has an exchange gripper system with which almost all EROWA pallet and system sizes can be handled.

The robot switches to the relevant system according to the jobs it has been assigned. This means that there are no obstacles in the way of mixed and flexible manufacture.

Modularly extendable at any time

-

Do you need more magazine positions? Do you want to serve a second machine? Do you want to integrate a measuring machine or a loading station?

No problem: the robot system can be adapted to current requirements at any time and be modularly extended to a rail length of 20m.

Suitable magazine positions

-

Magazines are available as rack and rotary versions which can be configured for almost all EROWA tooling system pallets.

While rack magazines are suitable for large and heavy pallets, rotary magazines provide very many storage positions for smaller workpieces in the same space.

Practical loading station

-

A loading station is avaiable to simplify setting up and the preparation of heavy and large workpieces.

This is where the palletized workpieces are prepared for the next job: the operator has the robot collect the prepared job by pressing a button and placing it on a free position in the magazine.

Cell management

-

EROWA's JMS 4.0 process control system provides the machine operator with all the relevant information and various planning aids, updated and online, at all times.

This is one of the requirements for the flexible and automatic manufacture of small series and one-off parts.

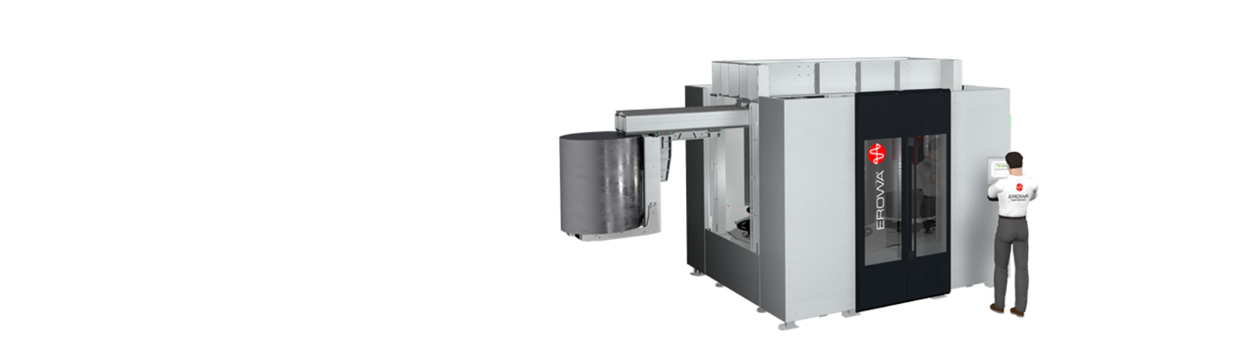

EROWA Robot Easy 800

-

The compact loading device for large workpieces

The Robot Easy 800 is impressive with its compact design, high degree of configurability and a transfer capacity of up to 800 kg. This turns a CNC machine into an automated manufacturing cell at reasonable cost.

Up to 800 kg transfer weight

-

Workpieces with a maximum weight of 800 kg and a size of ø 850 x 1,000 mm, for example, are loaded safely and reliably onto the production machine.

Plenty of magazine capacity

-

With the pallet size MTS 400, up to 12 magazine positions can be loaded with workpieces.

Long range

-

The stable transfer axis with fork gripper has a long reach of 2 meters from the outer edge of the robot. This also leaves enough space for manual work on the machine.

Comfortable preset

-

Rotatable magazine plates simplify setting-up and preparation. Pre-centering facilitates pallet positioning with crane and LiftGear.

Safe pallet handling

-

With the pillar-mounted boom crane (option) and the EROWA LiftGear MTS (option), palletized, heavy and large workpieces can be safely loaded and unloaded manually.

Ready for JMS 4.0

-

With the EROWA process control system JMS 4.0, the machine operator has all relevant information and various planning aids at his disposal at any time, up-to-date and online.

The system is controlled via the touchscreen user interface.

EROWA JMS 4.0 MoldLine

-

The universal process control system for tool- and mold-making

Within the overall concept of Industry 4.0, EROWA’s JMS® 4.0 MoldLine process control system occupies an important position. It maps a large part of the functionalities which fall under the heading of “smart factory”.

This provides users in tool- and mold-making with significant advantages: it is clear at all times which workpiece is engaged at which position in the process at what time.

The JMS® 4.0 MoldLine process control system links up all the data and controls the entire production process. Its software connects machines with the widest variety of manufacturing technologies without any problems.

Controlled data flow

-

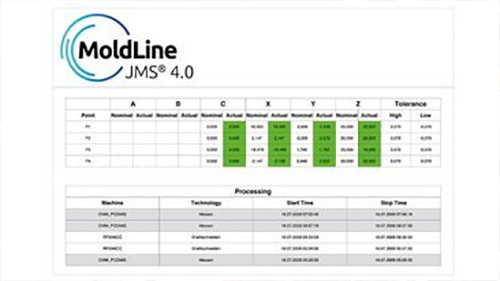

The JMS® 4.0 MoldLine process control system takes on the planning, controlling and monitoring functions of production plants.

The complete universality of the data allows for genuinely comprehensive control and process security.The JMS® 4.0 MoldLine system integrates machines with the widest variety of technologies without any problems. Its software is modular and can be extended according to requirements.

User-friendly and uncluttered

-

The JMS® 4.0 MoldLine system provides clarity and transparency.

The order list, priorities, CNC programs, tool management and the current status messages provide the operator with the relevant fact at a glance.

Even from a distance, the status of the production facility can be discerned clearly. Color signals clearly display what is going on.

Simple data import/export

-

The JMS® 4.0 MoldLine system is equipped with the widest variety of interfaces with order processing and production planning systems such as ERP, PPS, CAD, CAM, etc.

This means that direct imports, but also feedback, become substantially faster and more secure. And the current production status is recorded and displayed in real time.

Increased autonomy

-

The JMS 4.0 MoldLine system clearly states which workpiece occupies which position in the process at what time.

The pallets loaded with workpieces are unmistakably identified with a chip.

At every station in the production process, this unmistakable identification can be made by the EROWA EWIS™ system.

Universal identification

-

The JMS 4.0 MoldLine system clearly states which workpiece occupies which position in the process at what time.

The pallets loaded with workpieces are unmistakably identified with a chip.

At every station in the production process, this unmistakable identification can be made by the EROWA EWIS™ system.

Various pallet sizes

-

The traceability of all production processes is an integral component of all certification.

The use of the JMS® 4.0 MoldLine system takes this fact into account as early as when the data are generated. Defaults and evaluations are consistently allocated to workpieces and stored.

Specific protocols can be retrieved directly from JMS® 4.0 MoldLine.

EROWA JMS 4.0 ProductionLine

-

The universal production process control system for chip-cutting machining operations.

Within the overall concept of Industry 4.0, EROWA’s JMS® 4.0 ProductionLine production process control system occupies an important position. It maps a large part of the functionalities which fall under the heading of “smart factory”.

This provides users of chip-cutting production with significant advantages: it is clear at all times which workpiece is engaged at which position in the process at what time.

The JMS® 4.0 ProductionLine production process control system links up all the data and controls the entire production process. Its software connects machines with the widest variety of manufacturing technologies without any problems.

Controlled data flow

-

The JMS® 4.0 ProductionLine process control system takes on the planning, controlling and monitoring functions of production plants.

The complete universality of the data allows for genuinely comprehensive control and process security.The JMS® 4.0 ProductionLine system integrates machines with the widest variety of technologies without any problems. Its software is modular and can be extended according to requirements.

User-friendly and uncluttered

-

The JMS® 4.0 ProductionLine system provides clarity and transparency.

The order list, priorities, CNC programs, tool management and the current status messages provide the operator with the relevant facts at a glance.

Even from a distance, the status of the production facility can be discerned clearly. Color signals clearly display what is going on.

Simple data import/export

-

The JMS® 4.0 ProductionLine system is equipped with the widest variety of interfaces with order processing and production planning systems such as ERP, PPS, CAD, CAM, etc.

This means that direct imports, but also feedback, become substantially faster and more secure. And the current production status is recorded and displayed in real time.

Increased autonomy

-

The automation of production processes with the help of an EROWA robot generates manufacturing hours that have not been exploited before. During the third shift and at weekends, production becomes autonomous.

This requires precise yet flexible planning. The JMS® 4.0 ProductionLine system is configured precisely to satisfy specifications and requirements and provides exact data for every production step.

Universal identification

-

The JMS 4.0 ProductionLine system clearly states which workpiece occupies which position in the process at what time.

The pallets loaded with workpieces are unmistakably identified with a chip.

At every station in the production process, this unmistakable identification can be made by the EROWA EWIS™ system.

Tool life monitoring

-

Besides the workpieces and the NC programs, the appropriate tools must also be made available. Whether they are indeed ready and what life they still have can be read out of the machine’s own memory.

The JMS 4.0 ProductionLine control system provides a clear display of the tools on the machine, including status, tool life, tool breakage and a preview of the production time still available with the existing tools.