CG

- Offer Profile

- CG, a leading electrical

engineering corporation, offers its customers end-to-end solutions in the

effective use of electrical power. CG has more than 75 years of experience

in the engineering and manufacturing of cost efficient electrical equipment

from transformers, switchgear, motors, drives and personal electrical

appliances. CG is a fully listed company part of the Avantha group. CG

employs more than 10.000 people in 21 countries. CG is organized in three

Business Units focusing on the key electrical market segments: CG Power

Systems focusing on Transmission and Distribution as well as Smart Grid

solutions and Renewable Energy integration, CG Industrial Systems focusing

on motors and drives solutions and CG Consumer Products focusing on

electrical appliances and equipment for personal comfort.

For more information, please visit: www.cgglobal.com.

Product Portfolio

Power Systems

- Power System includes the business area related to transformers, switchgear, circuit breakers, vacuum interrupters, network protection & control gear, as well as design, execution and servicing of turnkey T&D as well as substation projects and solutions including complete end to end Renewable projects. This is the largest business which is now well entrenched throughout the world.

Transformers & Reactors

- We are among the top 10 transformer manufacturers

in the world, and one of the very few companies worldwide that designs

and manufactures a wide range of power & distribution transformers and

reactors.

The range of Power Transformers offered is from 25 kVA to 600 MVA, and 11 kV to 765 kV class, and Reactors from 10 MVAr to 125 MVAr, and 33 kV to 765 kV class. These products are conforming to IEC, ANSI, IS, BS and other international standards. It has recently made a foray in the manufacture of 765 kV transformers with the execution of its maiden order for Power Grid Corporation of India. We emerged as a large supplier of a wide range of transformers and reactors for all critical applications. Our products are used in industries such as power utilities, process industries, railways, mines, electricity boards, industrial users, etc. in global markets.

We have pioneered the technology for manufacture of compact, reliable SLIM® transformers with high overload capacity in collaboration with Dupont’s Nomex® thermal insulating technology, rendering it a world leader in wind farm installations, where these transformers have extensive utility. Its Hungarian plant has over 125 years of experience in the production of power transformers.

Power Transformers

- CG offers a complete range of Power Transformers. These transformers are manufactured at our facilities in Belgium, Canada, Hungary, India, Indonesia and USA. Some of these units also offer customised HVDC Converter Transformers, Mobile Transformers, Regulating Transformers and Reactors.

Distribution Transformers

- CG offers an extensive range of Distribution Transformers to meet the requirements of power distribution, wind farm energy, utilities and industries. These transformers are manufactured at our units in Belgium, India, Ireland and USA.

Special Transformers

- Our special category transformers include customised trackside and loco transformers for the Railways and furnace transformers for Steel manufacturing plants. These transformers are manufactured at our own facilities in Belgium, Hungary and India.

Distribution Unit Substations

- CG offers Distribution Unit Substations, including Mini and Micro type. These substations are manufactured at our facilities in India and Ireland.

Switchgear Products- MV / HV / EHV / UHV

- CG manufactures the widest range of Medium to Ultra High Voltage(UHV) switchgear products to meet the requirements of power generation and distribution substations in utilities and industries. Our products are in service for several years in many countries. We also export Low Voltage Panel Products from our India based export house.

Vacuum Circuit Breakers

- Power distribution arena has been one of the

strongholds for CG Medium Voltage (MV) Switchgear Division since its

inception in 1985. We pioneered the arrival of vacuum technology in

India with vacuum interrupters.

CG is the largest manufacturer of indoor vacuum circuit breakers (VCB) as well as outdoor porcelain clad VCBs in India. We also offer outdoor metal clad VCBs (KIOSK).

Gas Circuit Breakers

- CG is one of the leading manufacturers of SF6 gas circuit breakers (GCB) in the world. We manufacture GCBs ranging from 24 kV to 765 kV. We developed 800 kV 3150 A, 50 kA GCB with Spring-Pneumatic Mechanism indigenously with our R & D efforts. We have also developed breakers for 40 Deg application and 60 Hz frequency requirement. Our manufacturing units are certified with ISO 9001, ISO 14000 for environment control and OSHAS 18000.

Ring Main Units

- CG Lucy Switchgear Ltd is a joint venture company of Crompton Greaves Ltd, India and W. Lucy and Co. Ltd, UK. Established in 1994, the factory is situated at Nasik, India. Within a short span, the company became the leading manufacturer for Ring Main Units (RMUs) in India. With 30000 sq.feet of area, the facility has modern and automated equipments like robotic welding, shot blasting and zinc spray. All major testing facilities are available in-house to guarantee quality products to customers. CG Lucy is an ISO 9001:2000 certified company.

Disconnectors

- CG has been a name to reckon with in the global

electrical arena. We bring all our products with leading edge technology

which supplement the existing CG range of switchgear products in order

to complete the scope of the substation equipment such as outdoor off

load disconnector.

We started manufacture and supply of the isolators from the year 2005 and within a short span of time we have made our presence felt worldwide. We are exporting disconnector products to almost 32 countries.

VACUUM INTERRUPTERS

- Crompton Greaves (CG) is pioneer in introducing Vacuum Interrupters (VI) and Vacuum Technology in India. In Technical collaboration with then Westinghouse, USA, CG started Vacuum Interrupter manufacturing way back in 1985-86 at its State of the art manufacturing facility at Aurangabad in Maharashtra State. After the technical collaboration period, CG extended its range from 1kV to 72.5kV today to cover all applications with a dedication and continuous Research and Development activity. Since last 30 years, CG has continuously invested in adding the manufacturing capacity to take its annual capacity today to manufacture more than 170,000 Nos. of Vacuum Interrupters. CG is market leader in India & more than 1.5 Million Vacuum Interrupters are in service in & outside India. CG is a regular supplier of VIs to all small & major switchgear manufacturers in India and also an exporter to USA, Europe, Middle East and South East Asia countries.

Vacuum Contactor

- As a Value addition to its Vacuum Interrupters, CG

started manufacturing of indoor and outdoor Vacuum Contactors at

Aurangabad. Today , CG is one of the leading manufacturer and supplier

of indoor and outdoor Vacuum contactors to various industries and

utilities across India.

CG Offers following Vacuum Contactors

1. Outdoor Vacuum Contactors (Fully Automatic Capacitor Switch)

2. LT & MV Vacuum Contatcors

Surge Arresters

- CG surge arresters incorporate ZE elements (Zn0 elements) with superior non-linear voltage-current characteristics, high quality and reliability. Metal oxide type surge arresters offer special features inherent in gap-less structure such as quick response to surge voltage, high energy dissipation capability, safe operation, compact / lightweight and freedom from pollution. Surge arresters are applied for various systems including substation equipment, rolling stock and power distribution units from 3.3 kV to 420 kV system. These surge arresters demonstrate excellent protection properties.

Gas Insulated Switchgear

- As the world is moving towards highly compact and

reliable power Transmission and Distribution equipment, GIS is emerging

as the best solution for Power Transmission and Distribution.

CG offers latest technology GIS.They are now found affordable in place of AIS.

The Product comes with flexible SF6 gas insulated modules of various Equipment to suit different network configurations.

Instrument Transformers -MV / HV / EHV / UHV

- CG range of instrument transformers includes

Current Transformers, Inductive Voltage Transformers and Capacitive

Voltage Transformers. Our Instrument transformers have significantly

contributed to the electricity boards and utilities across the globe.

Several thousands of EHV Instrument Transformers have been put into

service in various environments in over 60 countries since 1984 and

operating satisfactorily.

With the support of our global R & D, we have developed 1200 kV Capacitor Voltage Transformer ( CVT ), which has been successfully type tested.

Our EHV range of instrument transformers uses (Oil Impregnated Paper) OIP as the main insulation system. Napthene based mineral insulating oil (free from inhibitors) is used in the equipment manufactured. This oil is highly stable against oxidation as well as chemical and electrical aging. The capacitor technology used in capacitor voltage transformers and coupling capacitors is all paper or paper plus film (mixed dielectric).

We also offer Medium Voltage Dry Type Instrument Transformers, since 1995. More than 60,000 units of Dry Type Polycrete® Outdoor Instrument Transformers are in operation globally.

Our Instrument Transformer manufacturing units in India also offer Condenser Bushings for power & distribution transformers.

Current Transformers- HV

- A large number of CG Current Transformers upto 550 kV

have been put into service in various environments in over 60 countries

since 1984 where they are operating satisfactorily. Type CT and Type

IOSK, CTs are of live tank type with rated voltage of 72.5 to 550 kV.

All our Current Transformers (72.5 to 550 kV) adhere to the requirements of the international quality standards. Our quality systems, environment management systems, safety management systems are certified to ISO 9001–2008, ISO 14001 and ISO 18001 respectively.

Inductive Voltage Transformers- HV

- CG has manufactured and supplied thousands of quality

electrical products for the past six decades which have excelled in

various test and service environments around the world. Nearly 5000

Inductive Voltage Transformers, type IVT/VEOT/VEOC, have been supplied

all over the world since 1986 and their performance and reliability has

proven to be one of the best.

All our Voltage Transformers (72.5 to 420 kV) adhere to the requirements of the quality standards and our quality system, environment management system, safety management system are certified to ISO 9001-2008, ISO 14001 and ISO 18001 respectively.

Capacitive Voltage Transformers- HV

- More than 15000 CG's Capacitive Voltage Transformers

(CVT's) upto 550 kV have been put into service in various environments

in over 60 countries all over the world since 1984 where they are

operating satisfactorily.

Our CVTs adhere to the requirements of the international quality standards and our quality and environment management system, safety management system are certified to ISO 9001–2008, ISO 14001 and ISO 18001 respectively.

MEDIUM VOLTAGE CURRENT AND VOLTAGE TRANSFORMERS

- CG commenced manufacturing of Polycrete CTs & VTs in

the year 1994-95. The Polycrete application for electrical products has

been patented by CG in the year 1995. Since 1994-95 , more than 50000

products have been manufactured & supplied to Indian & International

Customers. The CTs & VTs manufactured using Polycrete are in the kV

Range of 11kV to 33kV.

Polycrete means Polymer Concrete & is a Solid Insulating Material. The main composition of Polycrete is Polyester Resin , Silica Flour & various chemicals used as binders. The mixing of the components is carried out under Vacuum to achieve void free castings. The Polycrete is Hydrophobic & thus ideal for Outdoor applications. The electrical application of Polycrete was established after thorough research and validation on samples & products at our Global R&D located in Kanjur Marg , Mumbai.

CONDENSER BUSHING

- CG commenced manufacturing of condenser bushing at Nasik in 1986-87.In 2009, the condenser bushing manufacturing unit for 72.5kV was transferred to Aurangabad.

Current & Voltage Transformers - Dry Type MV

- CG commenced manufacturing of Polycrete CTs & VTs in

1994-95. The Polycrete application for electrical products was patented

in the year 1995. Since then, more than 50000 products have been

manufactured and supplied to Indian and international customers. The CTs

& VTs manufactured using Polycrete are in the range of 11kV to 33kV.

Polycrete means Polymer Concrete and is a solid insulating material. The main composition of Polycrete is Polyester Resin, Silica Flour and various chemicals used as binders.

T & D Systems / Engineering Solutions

- CG is a specialist in turnkey substation projects

up to 765 kV. These projects are carried out for large industrial

customers as well as for major electricity utilities.We have built up an

important reference list in the turnkey construction of both AIS and GIS

substations in many countries around the world. Beside this we completed

several rural electrification projects as well as HV transmission lines

which came along with some of the turnkey substation projects.

Client Services- Provision of highly experienced engineers to undertake the client engineer’s role.

- Design evaluation & tender appraisal, including full technical & financial review.

- Complete project management & delivery including site management & CDM.

- Expertise in finalising project scope documentation & provision of project sanction paperwork.

- Undertake Principal Contractor role with full co-ordination of project & site sub-contractor.

Mobile Substations

- Mobile substations are fully equipped electrical substations mounted on semi-trailers. Rapid integration into the network and the ability to use them at various locations are the most important advantages of these mobile substations. Mobile substations are used in emergency situations, as a temporary solution for the supply of electric power or as substitutes for air insulated or gas insulated substations. In combination with the application of Hybrid or Nomex® insulation in the mobile transformer, the mobile substation is able to handle power ratings up to 80 MVA and 245 kV.

Mobile Circuit Breakers or Switchers

- Mobile circuit breakers or mobile circuit switchers

are employed in emergency situations, sometimes in combination with

mobile transformers. Mobile circuit breakers can also play a role in

rapidly changing networks. In North America, Mobile Circuit Switchers

are used for similar purposes.

Mobile Capacitor Banks

- Mobile capacitor banks are used in networks with a

temporary demand for reactive power compensation. The compensation is

required where the networks are affected due to rapidly changing

infrastructure and also in changing networks as a result of

deregulation. Semi-trailers can be equipped with capacitors, HV circuit

breakers, HV disconnectors, voltage transformers and control panel.

AIS Substations

- CG is a specialist in turnkey substation projects up

to 500 kV. These projects are carried out for large industrial customers

as well as for major electricity utilities. CG Systems Division has

built up an important reference list in the turnkey construction of both

AIS and GIS substations in many countries around the world. Besides this

CG has completed several rural electrification projects as well as HV

transmission lines which came along with some of the turnkey substation

projects.

GIS Substations

- CG is a specialist in turnkey substation projects up to 500 kV. These projects are carried out for large industrial customers as well as for major electricity utilities.CG Systems Division has built up an important reference list in the turnkey construction of both AIS and GIS substations in many countries around the world. Beside this CG Systems Division completed several rural electrification projects as well as HV transmission lines which came along with some of the turnkey substation projects.

Modular Substations

- Modular substation concepts in the transmission and

distribution systems from CG consist of three separate modules: high

voltage equipment, power transformer and medium voltage equipment.

Each module is mounted on skids. The modules are designed to allow easy transportation and quick installation times. These units are preassembled at the CG manufacturing facilities. Prior to leaving the factory, the entire substation is subjected to the necessary routine tests. Pre-assembled control cables with multi-plug connectors further reduce the installation time.

WindSub onshore

- Space and time are at a premium in wind farms while economics dictate that grid connections be installed on the smallest possible footprint within the shortest possible time and at the lowest possible prices. CG contracting division meets these challenges by building a modular substation ideally suited to the needs of the wind energy industry. The WindSub substation either of AIS or GIS type, allows multiple turbines to be connected to the electricity grid within the shortest possible time. We have been categorized as a full range supplier to the renewable energy sector with the development of WindSub solution.

Turnkey Solutions

- CG Transmission and distribution systems group has

extensive experience in the supply of total solutions packages in the

field. Customer requirements and demands are converted into engineering

and design, planning and scheduling, project management, delivery,

erection as well as installation and commissioning of equipment. These

solutions can include the civil works as well.

WindSub offshore

- Reliability and reduced offshore maintenance are important factors to take into account when designing offshore wind farms. The CG Systems Division meets these challenges by introducing a new concept: an AC-connection to link an offshore wind park to the electricity grid (patent pending). This offshore WindSub development more than ever categorizes CG Systems Division as a full-line supplier to the renewable energy sector. The CG Systems Division offers you a turnkey solution for connecting the offshore windpark to an onshore utility grid. The CG Systems Division selects the most suitable partners, each an expert in the different specific fields which are applicable in the offshore industry.

Substation Engineering Services

- CG Engineering Projects Division has successfully

completed several substation projects, including railway

electrification, in India and other countries. The projects covered Air

Insulated Substations from 11kV up to 765kV & Gas Insulated Substations

from 33kV to 400kV. Many of these projects have been executed with

complete Substation Automation Solution.

The projects deployed equipment like Transformers, Reactors, Circuit Breakers, Instrument Transformers, Isolators, Insulators, Lightening Arrestors, etc.

Transmission Engineering Services

- CG Power Solutions' transmission line projects, ranging from 12 kV to 500 kV, have been implemented geographically across the US. The project teams are currently working for several utility companies on projects as diverse as new EHV transmission lines, voltage upgrades and conductor replacements on existing lines, tower and pole analysis for upgrade projects. Our projects have ranged from engineering only projects to full EPC projects where we take total responsibility for the entire project.

Testing & Commissioning

- We can do complete substation equipment testing and complete functional relay & controls testing. We have a full suite of modern test equipment that enables us to do following tests: 10kV Insulation PF, 5kV Insulation Resistance, Ground Grid, Ductor, CT Ratio/Polarity, Breaker Motion Analysis, Transformer Turns Ratio and Protective Relay.

Project Management

- CG typically organizes and executes each contract on

a project by project basis. A project manager is assigned for the

duration of the project. The project team remains together for the life

of the project and project information, both technical and

administrative is routed through the project manager to and from the

client.

We provides a formidable combination of field proven reliability, project proven project engineering, management & execution experience, expertise and reasonable cost. We specialize in fast track projects and we have a reputation for on-time delivery.

EPC Services

- CG Power Solutions combines multiple aspects of our

considerable resources to provide our clients with a complete EPC scope.

The advantages we provide with the EPC model are:

- Shorter project cycle

- Single point of responsibility

- Reduced cost

- Lower exposure to additional costs such as change orders

Procurement

- CG Power Solutions has a dedicated procurement department where we work with blanket orders. Our strong relationship with vendors in the industry provides us competitive prices and lead times. Please contact our Procurement Department to get more information.

SAP Operations

-

- Client Services for T & D Systems

Protection, Control & Automation

- The CG Substation Automation platform has been

designed to facilitate the automation of T&D apparatus by collecting,

processing and distributing data within the hostile electrical

environment of high voltage substations.

The XCell RTS offers the latest in processing power and communications options built into a fully distributed architecture. The software products are designed to fully utilize the capabilities of the XCell RTS to perform automation functions ranging from simple to the most complex. Our engineering services and technical support offers a complete solution for every customer’s requirement.

Total Substation Automation Solutions

- CG delivers highly reliable and flexible turnkey substation automation solutions worldwide. Whether upgrading existing substations or delivering complete protection and automation solutions for new greenfield sites, we provide cost effective solutions based on open standards to simplify future expansions, maintain and minimise lifetime costs. Our solutions range from complete IEC 61850 based systems to non-IEC 61850 IEDs and combinations of both, allowing utilities to move to new technologies without discarding current investments. We provide a full range of services including: control, protection and communications design, system build, installation, grading settings, commissioning and support.

Services for Automation & Controls

-

- Control and Protection Design

- Protocol Development

- Power System Analysis

- IED integration

Protection Relays & IED

- CG numerical communicable relays are indigenously

developed products whose design is based on microprocessor technology

using DSP. The products are designed with focus on accuracy and speed of

operation, complying with the latest IEC standards.

- Multifunction Relay Platform

- Over current and earth fault relay

- Under voltage and over voltage relay

- Self powered relay

- Circuit breaker manager

Distribution Automation

-

- Primary Distribution Automation

- Secondary Distribution Automation

Products for Automation & Controls

-

- Substation Automation System

- Bay Control Unit

- Remote Telemetry Unit

- Substation Gateway

- Distribution Automation Controllers

- Switchgear Actuators

- Vision SCADA

- Master Station - Control Room

- Feeder Automation

- Substation Automation

- Customer Support Services

- Capacitor Controllers

- Power Line Carrier Systems Monitor & control downline devices beyond the

- Distributed Remote Terminal Unit (DRT) Series

- Sentinel-21 Software Products

- Substation Terminal Node Series

- EPAQ Multifunction Gateway Series

Protection & Control Panels

- CG Power Solutions UK manufactures a range of panels,

including control and protection relay panels, marshalling kiosks, pilot

termination boxes, metering panels etc. Utilising a well-appointed

workshop facility in Glasgow, CG Power Solutions UK can define and

supply our clients’ complete requirements. All panels are fully tested

to rigorous procedures before being delivered to site.

The types of services we offere and the sectors we operate in are detailed below.

Services for Power Systems

- CG has been acknowledged the world over for a full

range of after-sales services. These are provided by our own Service

Divisions. This is an expert set up with divisions in India, Charleroi,

Belgium, United Kingdom and a subdivision in Hungary. These divisions

cater to the installation, maintenance, refurbishing and repair of

transformers, tap-changers and AIS - GIS switchgear products and

substations worldwide.

The Service Divisions are ISO quality-certified and have been awarded the VCA / LSC safety label as well as EDF / CNPE certificate required to be held by suppliers to the French nuclear industry. Services for Transformers

- CG Services Division offers full-service maintenance,

whether on - site or at the central service centre. With a large inventory

of spare parts on hand, repairs can be carried out quickly and with minimal

disruption to operations. In the event of a product defect, CG service

engineers rely on electrical measurements and oil analysis, as well as other

diagnostic tools, to diagnose the problem. At the same time, they explore

the possibility of making adaptations and performance enhancements, which

are carried out according customer requests.

Services for GIS, AIS Circuit Breakers

- CG provides services like Installation & commissioning,

Repair & Refurbishment, Overhauling, Spare parts, Condition monitoring &

maintenance for GIS and AIS.

Transformer & Switchgear Components

On-load tap changers

- CG is one of the first companies to manufacture OLTC

since 60`s. The product started with "F" series tapchangers in

collaboration with M/s.Fuller Electric Co - UK.These tapchangers were

based on latest technology of their time and still satisfy the needs of

present customers. Even today, the F33 & F66 are highly familiar names

in the OLTC market.

Over the years, the product has undergone various design upgradations satisfying the new challenges and requirements of the customers. The product, a high speed resistor type is designed for use with 3 ph distribution substation transformer. It can be bolted directly to a port flange on the transformer.

Condenser Bushings

- Our Instrument Transformer manufacturing units in

India produce EHV condenser bushings transformers. These bushing are

also supplied to meet the replacement requirements. Since 1985, more

than 25000, air to oil type condenser bushings up to 420kV have been

supplied .

Our units are ISO9001 certified since 1993. Our SixSigma Quality drive, which uses the "measure – analyze – improve – control" methodology, has resulted in achieving breakthrough quality at design, component & process level, thereby establishing failsafe designs with large margins on power frequency withstand voltage.

Industrial Systems

- CG’s Industrial Systems is engaged in the business

of power conversion equipment a wider spectrum of High and Low Voltage

rotating machines (motors and alternators), stampings, as well as

railway transportation and signalling products. Industrial Systems is

largely India focused with a very strong market presence and market

leadership position in many segments. It also caters to foreign markets

through its facilities in Hungary and exports. Its product portfolio

includes motors and generators ranging from 100W to 100MW. CG enjoys a

market leadership for AC Motors and the second position in AC Generators

and DC Motors in India. CG is the largest manufacturer of Low Tension

motors in India offering a range of AC and DC motors, ranging from

0.18kW to 450kW in various standard and customized configurations to

respond to the exacting demands of the industry. To ensure the highest

levels of customer satisfaction, the latest designs have been

incorporated for its range of product offerings, to achieve better

performance as well as versatility in mechanical features. The products

of this business have received many international certifications

including CSA, UL, CE and Flame Proof Gas Group IIA and IIB

certifications. The customer emphasis for this business group has been

the textile, cement, sponge iron and large steel plants sectors, which

are growing segments

Services For Industrial Systems

- Complete site establishment and erection,

- Site erection of our own products,

- Retrofit and maintenance regular or occasional electrical checks, measurements and diagnostics of industrial electrical systems,

- Service, maintenance works, repair of rotating machines, and other electrical apparatus (made by our factory or other origin); regular or occasional electrical checks, measurements and diagnostics.

Motors; High / Low Voltage AC & DC.

High Voltage Motors

- CG offers both Squirrel Cage (TPC & FTC Range) and

Slip Ring (TPR & FTA Range) motors in horizontal (IMB3), vertical (IMV1)

and inclined (IMB5, IMV5) mounting options to suit every customer

requirement.

Built in accordance with IEC 60034-1 / IS 325 standards, we offer customized, energy efficient and intelligent motors for various applications in IP23 & IP55 enclosures. We offer a wide range of cooling systems ranging from Self Circulation type (IC611) to independent forced circulation circuits (C616) and Tube Ventilated (IC511) to fin cooled (IC411) types.

The motors offered ranging from Open Air Circuit (IC01) and Closed Air Circuit (IC611) to independent externally fed air circuit (IC616). These are designed for optimum performance in adherence with application and site requirements of performance and space.

Low Voltage Motors

- CG has an exemplary facility with an established

manufacturing range of low voltage motors. All the manufacturing units

are well supported by robust infrastructure. With world class

infrastructure, we are satisfactorily meeting the client’s expectations.

We have employed the most sophisticated and inclusive range of equipment

and machinerys to carry out the bulk or customized order in most

hassle-free and timely manner. Our core competencies lie in our

manufacturing facility conforming to the international quality

standards.

Low Voltage (LV) AC motors range cast iron and aluminium motors conforming to IEC and NEMA MG 1 Standards.

Energy Efficient Motors

- Efficient use of energy enables commercial and

industrial facilities to minimize production costs, increase profits,

and stay competitive. The majority of electrical energy consumed in most

industrial facilities is used to run electric motors. Energy-efficient

motors now available are typically from 2 to 6 percent more efficient

than their standard counterparts. This efficiency Improvement translates

into substantial energy and money savings.

CG offers an entire range of energy efficient motors as per the latest IEC, IS & NEMA standards and also complies with the efficiency norms of each geographies.

Motors for Hazardous Areas (HV)

- CG is fully geared to manufacture and supply a

complete range of hazardous low voltage motors designed to suit the

ignitable atmospheres present in hazardous Locations such as Zone1, Zone

2 or Class1 Div 1 and 2. The motors are tested in nationally and

internationally affiliated Laboratories and are approved by BASEEFA for

ATEX, CSA for IEC and Ex Div 2 and DGMS / CCO for complete range of low

voltage hazardous motors.

We are the first manufacturers in India to develop motors complying with the requirements suitable for Group IIC (For Hydrogen Gas). With the advantage of meeting all the technical standards applicable for Oil and Gas industry, we cater efficiently to all the Oil companies for their Off-Shore Platforms and Refineries projects.

Motors for Hazardous Area (LV)

- CG has the largest manufacturing range of low voltage motors suitable for hazardous area. These motors are designed to suit the ignitable atmospheres present in hazardous locations such as Zone1, Zone 2 or Class1 Div 1 and 2. Motors are suitable for various temperature classes & gas groups. CG manufactures Ex’e’ , Ex’nA’ & Ex’d’ enclosure motors. The motors are licensed by BASEEFA for ATEX, CSA for IEC and Ex Div 2 and DGMS / CCO for complete range of low voltage hazardous motors.

DC Motors

- CG is an established name synonymous with rotating

machines. Today, we are in a position to offer an ENTIRE RANGE of world

Class DC Motors. We offer laminated Yoke DC Motors in IEC frame up to

710, for various applications for constant and variable speed

requirements.

Applications:

Plastic extruders, Printing machines, Steel Rolling Mills, Wire Rod Mills, Apron Feeder, etc.

Special Application Motors

- We manufacture motors for special applications. Some of them include Double Cage Motor for Cement Mill, GD Series Brake Motor, Oil Well Pump Motor and Re-rolling Mill motor.

Generators / Alternators; AC & DC

- CG offers a wide range of AC & DC generators (alternators), both brushless and slip ring type. Our single phase alternators are designed to meet the customer requirements in remote as well as urban areas for uninterrupted power supply. Our AC Brushless generators incorporate advanced European technology and are designed for optimum performance. Our compact Slip Ring alternators are popular in agro industries. We also offer laminated yoke DC Generators up to 2000 kW.

1 Phase Brushless Generator - LV

- CG AC Generators are state-of-the-art, self-excited,

self-regulated and dependable source of power.

These generators incorporate advanced technology and are designed for optimum performance using high-end software solutions. With well-qualified engineers and technocrats, backed by a strong R & D team, We have fully harnessed long experience in design and software to offer a range of innovative, reliable and efficient AC Generators.

3 Phase Brushless Generator - LV

- CG AC Generators are state-of-the-art, self-excited,

self-regulated and dependable source of power.

These generators incorporate advanced technology and are designed for optimum performance using high-end software solutions. With well-qualified engineers and technocrats, backed by a strong R & D Team, We have fully harnessed long experience in design and software to offer a range of innovative, reliable and efficient AC Generators.

Synchronous Generators - HV

- CG manufactures state of the art, self excited, self regulated and dependable generators which are reliable sources of power by deploying superior techniques and processes in each specialized field of design, material specifications, procurement, testing and packing. We offer salient pole and cylindrical pole generators, which are custom built and find applications in various industries like steel, cement, fertilizer, chemical, textile, float glass, etc. for captive power generation using, steam, gas and hydro turbines.

Single Phase Alternator

- CG single phase alternators are designed to meet the customer requirements in remote as well as urban areas where there is requirement of uninterrupted power supply. Robust rolled thick steel body with reliable slip ring type construction and efficient design provides power at Unity power factor. An electronic circuit is used for the load regulation.

1 Phase Slip ring Generator - LV

- CG also manufactures Compact Series of Slip Ring Alternators for agro industries. These alternators have a high Motor Starting Capacity. Due to the use of High Grade Carbon Brush Holder Assembly in these units, the alternators have a longer durability even while operating in continuously adverse conditions.

3 Phase Slip ring Generator - LV

- CG also manufactures Compact Series of Slip Ring Alternators for Agro industries. These alternators have a high Motor Starting Capacity. Due to the use of High Grade Carbon Brush Holder Assembly for these units, the alternators have a longer durability even while operating in continuously adverse conditions.

DC Generator

- CG manufactures state of the art, self excited, self regulated and dependable generators which are reliable sources of power by deploying superior techniques and processes in each specialized field of design, material specifications, procurement, testing and packing. We offer salient pole and cylindrical pole generators, which are custom built and find applications in various industries like steel, cement, fertilizer, chemical, textile, float glass, etc. for captive power generation using, steam, gas and hydro turbines.

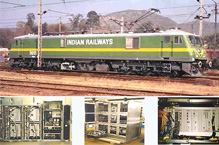

Traction Motors / Alternators / Control Electrics.

- CG is pioneer in Indian Railway Rolling Stock

business and offers the most comprehensive rail vehicle portfolio in

India. We are the leading manufacture all kinds of traction motors,

alternators and related control equipments.

More than 2000 traction motors are running in Indian railways, driving the most complex railway network in the world.

Traction Motors DC

- CG offers a wide range of DC motors for traction application with very high operational efficiency and power to weight ratio.

Traction Motors AC

- CG offers a wide range of AC motors for traction application with very high operational efficiency & power to weight ratio.

Traction Alternators

- CG manufactures a wide range of Traction Alternators (both Static & Brushless) for all Diesel Locomotives.

Control Electrics

- CG offers different types of Control Panel sets for controlling of various kinds of locomotives like JDCC (Jet Deflector Crane Car), DETC (Diesel Electric Tower Car), HHP-DEMU (High Horse Power–Diesel Electric Multiple Unit), etc.

FHP / Commercial Motors

- CG is pioneer in Indian Railway Rolling Stock

business and offers the most comprehensive rail vehicle portfolio in

India. We are the leading manufacture all kinds of traction motors,

alternators and related control equipments.

More than 2000 traction motors are running in Indian railways, driving the most complex railway network in the world.

Single Phase Motors

- Single Phase Motors are used in variety of applications in households and small industrial sectors, where three phase power supply is not available. Single Phase motors are classified based on the type of starting mechanism. Widely used starting mechanisms are SplitPhase, Capacitor Start and Run, Capacitor Start Induction Run & Capacitor Start Capacitor Run.

3 Phase Motors - Rolled Steel Body

- CG has Three phase general purpose motors in Rolled-sheet steel powder coated body in Drip Proof Fan Cooled(DPFC) construction in IEC(Metric) frame sizes of 80,90 and 100.These are most suitable for indoor environments.

Application Specific Motors

Railway Signaling & Coach Applications

- Railway signaling division is engaged in the

business of railway signaling equipment of wider applications of AC & DC

supply system.

Anticipating a future where the need of the railways for signaling equipment with quality & reliability will be very high, CG has set up a plant in 1988 for manufacturing of railway signaling equipment. The plant is situated in the central part of India, near Indore and well connected to all metros. In the past 22 years, the division has undergone a dramatic transformation in terms of the product portfolio and capabilities. With engineering & design excellence, we have a strong presence globally, and is the number One preferred source for Indian Railways.

Signaling Relays

- CG offers a wide range of Q SERIES RAILWAY SIGNALLING RELAYS to meet all types of Signaling Circuit Applications such as Route Relay Interlocking, Panel Interlocking, Automatic Signalling, Point Operation and Track Circuiting. Each individual type of relay undergoes extensive TYPE TESTING by Research Design and Standards Organization (R.D.S.O., Lucknow) of the Indian Railways and approved for use in Railway signalling circuits.

Data Logger

- Data logger is an electronic system; it has been specifically designed by CG to fulfill the needs of the Indian Railways.

Electric Point Machines

- CG`s Electric Point Machines are designed to fulfill requirements for operation of points. It is operated electrically and incorporates an internal point lock and detection mechanism. The machine can be provided with motor to operate on DC. In the event of a power failure or emergency the point can be moved to the full normal or reverse position by means of a crank handle

Coach Application Products

- CG R&D specially developed these products to fulfill the needs of Indian Railways (Brush Less Direct Current motor (BLDC) fans are operated by 110V dc. It used in the Railway coaches.

Drives & Automation

- More than seventy years of experience culminating into an extensive know-how, a structure thoroughly oriented to customer needs and continued investment in Research and Development, makes CG a natural leader in LT Motors. Going by the principles and practice to stay a step ahead, we have launched the Drives and Automation Division to provide Total Drive Technology Solutions to our esteemed customers. The guarantee for expert advice and most appropriate solutions for Drive System requirements makes our customers visit us for their needs. Our team of experts are geared to offer an ideally packaged solution tailor-made to the application needs of our clients. Naturally, our customers do not have to look beyond this well known brand in search of Drives & Automation Systems. They can enjoy all the benefits and advantages from a single reliable source with guaranteed solutions. The will to adopt the latest designs and manufacturing technology and an equally strong Research and Development back-up helps us to maintain our leadership in technology, quality, delivery as well as cost.

Industrial Drives

- An AC drive controls the application by continuously adjusting the motor speed. This results in reduced energy usage and prevents unnecessary wear of the equipment. CG offers a wide product range in the low voltage drives segment.

Softstarters

- CG Drives & Automation offers softstarters, designed for optimised start and stop of motor.

Shaft power monitors

- CG Drives & Automation shaft power monitors are deployed for detecting over or under load of motor therby providing early warning for preventive maintenance.

Heat exchanger drives

- CG Drives & Automation heat exchanger drive systems are specially designed for speed control of rotary heat exchangers.

Drive Specific Applications

- Knowing your process means we can offer optimized solutions, whether your need is for a single product or a complete system. We combine state-of-the-art technology for accurate motor control, with robust design and user-friendliness. Simple solutions to complicated challenges!

Traction Drives & Controls

- CG offers traction products and solutions for Indian Railways rolling stock requirements. These include state - of - the - art Converters / Inverters, Control Electronics (Train Management System) and integrated propulsion solutions. The products/solutions are designed by our strong R&D and engineering teams after closely interacting with customers and understanding their requirements. The integrated products/solutions are offered by teaming with the reputed world class European & other foreign technology partners.

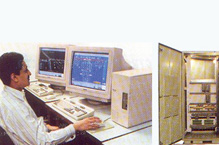

SCADA -Industrial & Railway

- Supervisory Control and Data Acquisition (SCADA) system

collects reliable field data through remote terminal units (RTUs) and

Intelligent Electric Devices (IEDs). The user interface or the man machine

interface (MMI) provides various options of data presentation according to

specific application and user needs.

Drives for Industries

- Knowing your process means we can offer optimized solutions, whether your need is for a single product or a complete system. We combine state-of-the-art technology for accurate motor control, with robust design and user-friendliness. Simple solutions to complicated challenges!

Drive Solutions

- We understand your needs, from power supply to process

Supplying the technical solution is one thing, making sure it works according to your requirements is another. That requires personal commitment and a true understanding of your process. Adding our engineering competence will help you improve efficiency. We can design complete drive solutions or deliver turn-key projects, including everything from engineering to commissioning.

OEM solutions

- Ready-to-run, with built-in intelligence

Add value to your offer by integrating intelligent control that will maximize output. We have developed tailored solutions for leading manufacturers of industrial equipment such as pumps, fans, cranes and crushers. Working with CG Drives & Automation means being a premium customer from day one, with direct connection to the core of the company and access to a worldwide service network.

Drives Case studies

- Customers around the world have saved energy, maintenance and downtime costs by controlling their electric motors with CG Drives & Automation products. Read their stories !

Stampings & Laminations

- CG started its unit for manufacturing electrical

laminations in the year 1976 at Mumbai to support all its divisions

manufacturing motors, fans, pumps and chokes. In order to meet the growth

expectations of the internal divisions as well as cater to the requirements

of outside industries, we started a new plant at M.I.D.C, Ahmednagar in

2004.

The stampings division of CG has:- Ultra modern tool room for in-house tool manufacturing allowing shorter lead time.

- The capability to offer various grades of high quality steel from imported and Indian sources both in fully processed and semi processed through In-house continuous roller hearth annealing furnace.

- The capability to manufacture through various processes: notching, blanking, gang slotting and progression and diameters ranging from 50 to 1250 mm in round and 1100 mm width segmental.

- The capability to offer welded, riveted, auto stacked, skewed packs and die cast rotors.

Stampings / Laminations

- At CG, we have manufactured laminations for use in

applications that have touched millions of lives, and are:

White consumer goods such as washing machine, air conditioners and mixers/grinders.

Domestic and industrial fans.

Domestic, agricultural and industrial pumps.

Low voltage to high voltage motors for varied applications

Traction motors for railways.

Alternators and generators for power generation.

Services For Industrial Systems

- The specialists of the Erection and Service Division

have wide international experiences and they offer the customers the

following:

The stampings division of CG has:- Complete site establishment and erection,

- Site erection of our own products,

- Retrofit and maintenance regular or occasional electrical checks, measurements and diagnostics of industrial electrical systems,

- Service, maintenance works, repair of rotating machines, and other electrical apparatus (made by our factory or other origin); regular or occasional electrical checks, measurements and diagnostics.

Service & Refurbishment of Large Rotating Machines

- We have several years of experience in production of

electric rotating equipment. These experiences we use to undertake winding

repairs of all kind and made of motors and generators.

TRACTION DRIVES & CONTROLS

- CG offers traction products and solutions for

Indian Railways rolling stock requirements. These include state - of -

the - art Converters / Inverters, Control Electronics (Train Management

System) and integrated propulsion solutions. The products/solutions are

designed by our strong R&D and engineering teams after closely

interacting with customers and understanding their requirements. The

integrated products/solutions are offered by teaming with the reputed

world class European & other foreign technology partners.

Traction products are manufactured with high quality standards from products reliability point of view at modern manufacturing facilities situated across India. The product life cycle service & spares support is provided from service centres located all over the nation.

POWER CONVERTER

- The propulsion system consists of Traction Transformer, Power Converter and Traction Motors. All the three products are manufactured by CGL for Indian railways. For better utilisation of power during traction and braking, power converter plays important role and works in 4-qurdrant throughout its operation range. The Power converter works with active front-end and can work nearer to unity power factor.

AUXILIARY CONVERTER

- Data logger is an electronic system; it has been specifically designed by CG to fulfill the needs of the Indian Railways.

CONTROL ELECTRONICS (TMS)

- Train Management System is a process-oriented, distributed control system, optimized for the application on electric traction vehicles. It consists of a number of devices for signal input/output and signal processing, communication systems to exchange data between propulsion equipment and auxiliary devices, a man- machine interface for the system operating as well as aids for planning, commissioning and maintenance of an installation.