Navigation : EXPO21XX > QUALITY & TESTING 21XX >

H29: 3D Measurement

> Hexagon Manufacturing Intelligence

Hexagon Manufacturing Intelligence

Videos

Loading the player ...

- Offer Profile

- At Hexagon Manufacturing

Intelligence, we work with our customers to improve productivity by

embedding quality throughout the product lifecycle.

Our technology enables manufacturers to take control of quality at all the key stages of their process. Through an unparalleled portfolio of digital manufacturing technologies spanning CAE solutions for design and engineering, CAD CAM and complementary software for production applications, metrology hardware and software solutions, as well as data management and analytics tools, we empower technology users throughout the process with deep and actionable insight into product quality, ensuring that quality drives productivity.

Product Portfolio

Rethink Quality

Design and Engineering

-

Embed quality into product design and engineering to ensure component manufacturability and downstream production productivity.

Production

- Ensure that design intent is maintained through the production cycle to improve productivity and continuously deliver high-quality components.

Metrology

- Capture real-world quality data for measurement, positioning and inspection, and use actionable information gained by analysing the results to improve manufacturing processes.

Products

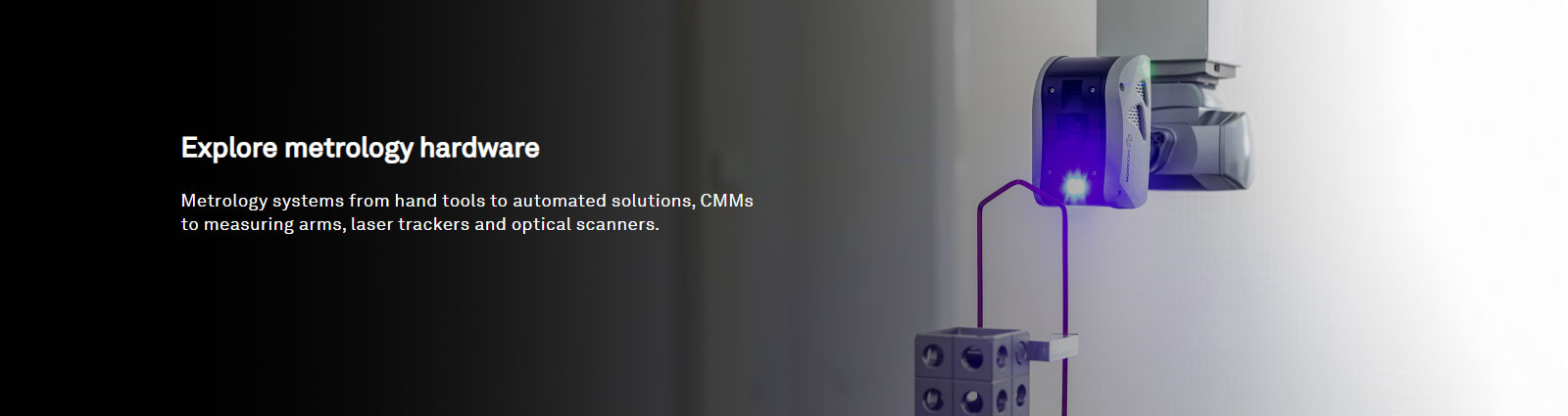

Metrology Hardware

- From hand tools to automated solutions, coordinate measuring machines (CMMs) to portable measuring arms, laser trackers and optical scanners, Hexagon Manufacturing Intelligence provides industrial metrology systems for when dimensional measurement matters.

Coordinate Measuring Machines (CMM)

- Whether you are looking for an entry-level model or already have experience with coordinate measurement systems and are now looking to improve quality assurance or increase inspection capacity - we have the products and expertise you require.

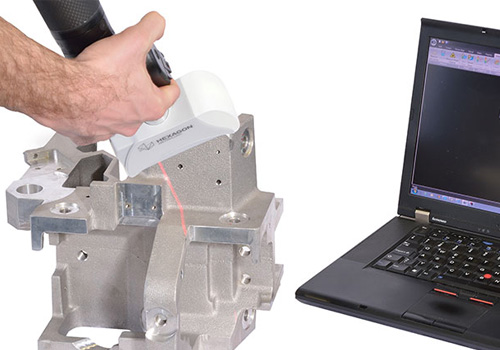

Portable Measuring Arms

- Portable measuring arms allow you to take measurements directly in the manufacturing environment, where process improvements are the most beneficial.

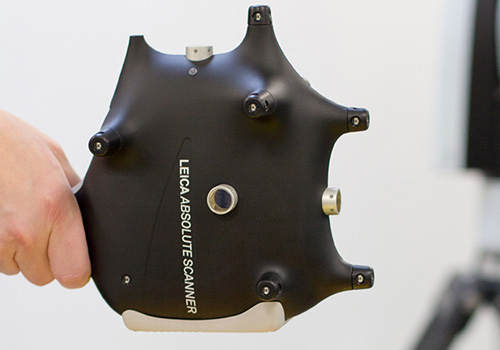

Industrial 3D Laser Scanners

- Laser scanners play a key role in quality assurance. 3D digital capture of shapes and surfaces using lasers is an effortless and precise process. The industry uses laser scanners primarily for the quality control of geometries and surface, but also for reverse engineering, fit and finish, and assembly applications.

Laser Tracker Systems

- A long-term standard in industrial metrology: Laser Tracker Systems lead the field in terms of the accuracy, reliability and durability of portable coordinate measuring machines.

Industrial Theodolites & Laser Stations

- Cost-efficient measurement with absolute reliability – industrial theodolites and laser stations meet the highest standards even under tough conditions. The extreme measurement volume of over 500 m makes a total station the first choice for the inspection and assembly of very large components.

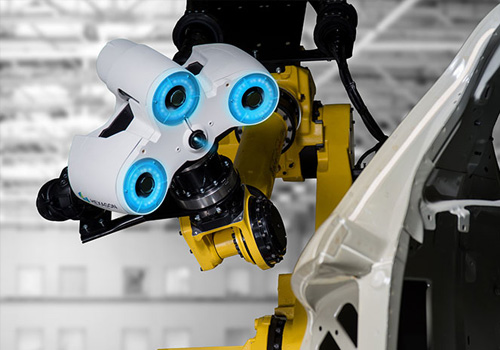

Robotics and Automation

- The factory of tomorrow will be smart and digital with a data driven understanding of assembly processes. Automation will play a significant role across any industrial sector. Hexagon Manufacturing Intelligence offers the right solution for fully automated measurement and process control already today.

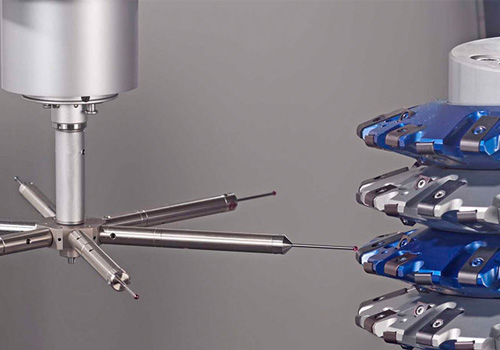

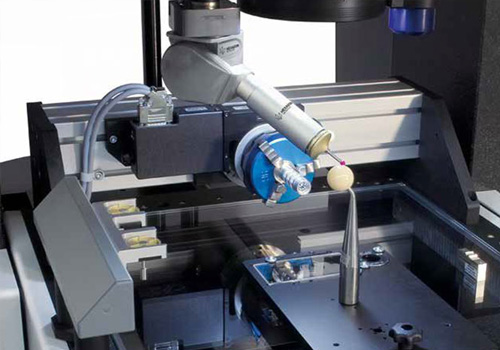

Multisensor and Optical CMMs

- Flexibility is the key issue for multisensor technology. Flexibility in the world of metrology means having the freedom of choice between contact and optical measurement – with only one measuring system. A single system is therefore sufficient for the contact and optical measurement of all inspection features on a workpiece.

Structured light scanners

- Structured light scanner systems are comprehensive 3D optical measurement solutions that deliver high-accuracy data capture at high-speed for small-to-medium sized parts.

Micrometers, Calipers, Gauges

- Precision instruments for dimensional measurement

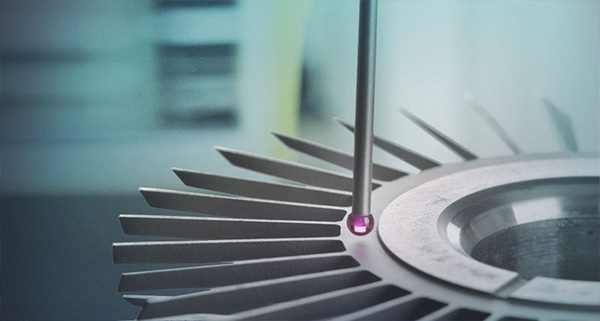

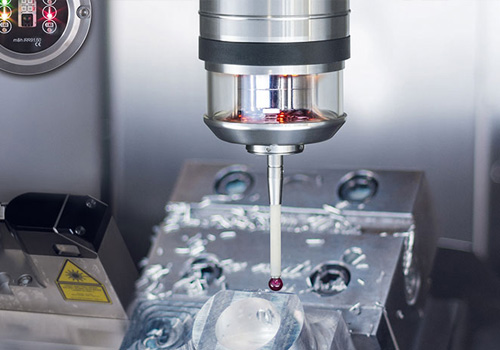

Machine Tool Measurement

- High-precision, high-quality, process-reliable probe systems especially for use in machine tools.

Photogrammetry

- Photogrammetry solutions from Hexagon Manufacturing Intelligence offer speed and flexibility across a wide range of measurement-related applications in industrial production. From testing, inspection and positioning tasks to deformation analysis and tracking applications, our camera-based 3D optical metrology systems deliver unmatched high-speed geometric data collection.

Profile and Surface Measurement

- Offering dedicated non-contact systems for profile measurement and 3D surface inspection, Hexagon Manufacturing Intelligence’s profile and surface measurement range supports a number of manufacturing quality needs from product development through production and into service life.

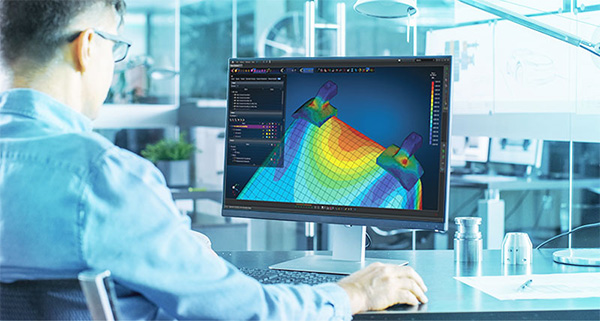

3D Metrology Software

- Hexagon Manufacturing Intelligence is the largest software developer in the metrology industry and offers a wide range of in-house developed, individually-customisable software packages that deliver intelligent and effective data acquisition, analysis and evaluation as well as powerful data management and reporting tools.

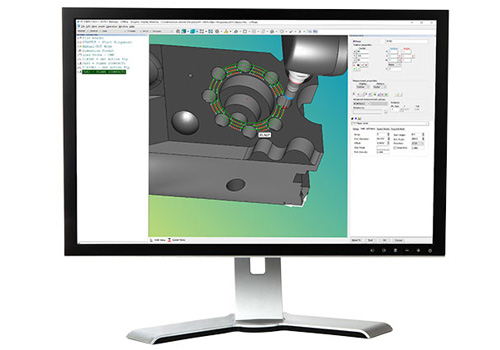

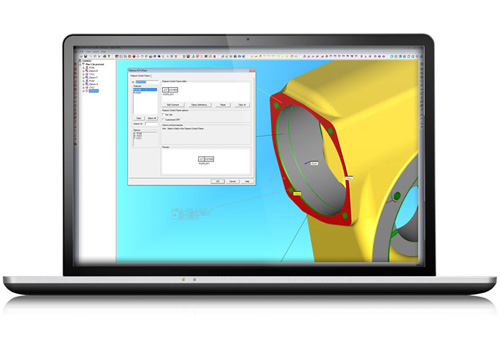

PC-DMIS

- PC-DMIS is the world’s leading measurement software, with over 70,000 seats in place worldwide. Its powerful capabilities enable users to measure everything from simple prismatic parts to the most complex aerospace and automotive components.

QUINDOS

- QUINDOS is the ideal software for coordinate measuring machines, gear inspection centers and all applications.

I++ Simulator

- Online Simulation in the Virtual Laboratory.

SpatialAnalyzer

- Powerful, traceable and easy-to-use metrology and analysis software

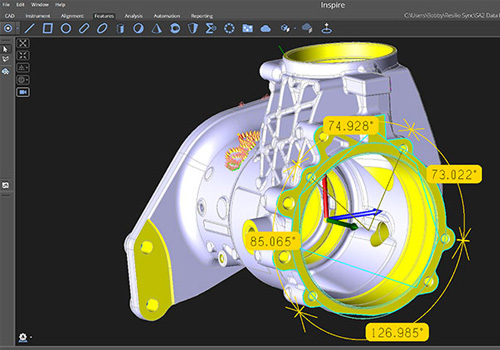

Inspire

- User-Friendly Measurement Software for Portable Probing and Scanning

Software for CMMs

- Whichever the part that needs to be measured: with the right software, measurement is effortless.

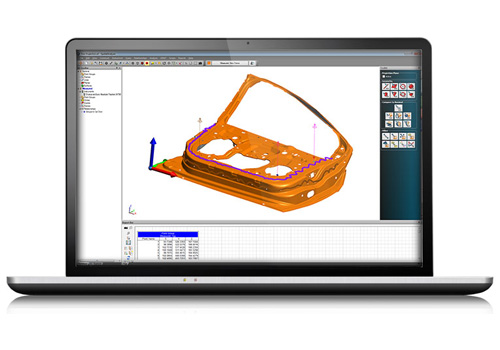

Software for Laser Scanners

- Software plays a crucial role in the use of laser scanners. Powerful programs support the use of scanners in combination with portable measuring arms, Laser Tracker Systems or fixed coordinate measuring machines.

Software for Laser Tracker Systems

- Hexagon Hexagon Manufacturing Intelligence and our specialist software partners know the customer's requirements and develop reliable, customized software solutions for use with Laser Tracker Systems.

Software for Multisensor & Optical Systems

- The quality of your products is best demonstrated with our software for optical and multisensor measuring systems. It reliably shows whether the parts are in tolerance. The proven PC-DMIS measuring program also provides the necessary in this case: as part of this software family, PC-DMIS Vision is specially designed for usage in combination with optical and multisensor measuring systems. The software integrates CAD directly into the measuring process. As a result the user can work on the 3D CAD model and develop, test and edit programs for the optical and multisensor measurement.

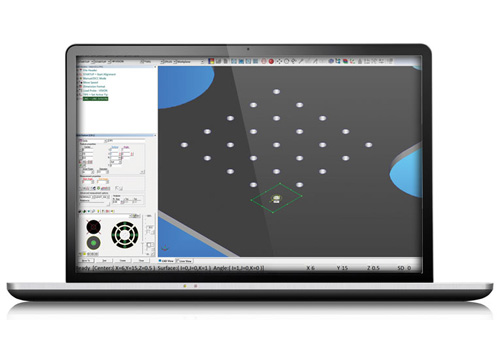

Software for 'On Machine Tool' Inspection

- PC-DMIS NC software products are advanced, process-internal measuring systems for CNC machines. They monitor all processes while the parts are still on the machine. As a result measuring in real-time becomes a reality and you can identify all weak spots very quickly.

Software for Portable Measuring Arms

- Portable measuring arms ease the task of monitoring manufacturing processes and help in the solution of problems before expensive reworking is called for.

Software for Theodolites & Laser Stations

- Industrial theodolites and laser stations from Hexagon Manufacturing Intelligence have open-system software architecture. 3D coordinates can be captured with PC support and stored offline using a PCMIA card. Any control and data processing software can be used. Open-system architecture allows simple connections to the software via Windows®.

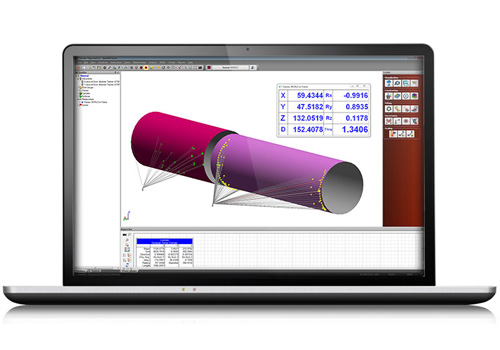

Software for Tube Inspection Systems

- Software solutions from Hexagon Manufacturing Intelligence are the byword for high user-friendliness, stability and minimum familiarization times. Hexagon Manufacturing Intelligence has developed a highly specialized application for measuring tubes that has the special ability to automatically set a variety different tube bending machines through customized interfaces.

Software for structured light scanners

- The Hexagon software suite for structured light scanner systems is comprised of various value-added software products and collaborative tools that enhance the benefits gained from using 3D optical measurement solutions.

Production Software

- Offering a range of CNC simulation software, factory automation solutions and computer-aided manufacturing (CAD CAM) packages specified for different production methods, Hexagon Manufacturing Intelligence’s production software solutions help manufacturers produce parts right first time.

CAD/CAM Software - Computer-Aided Design and Manufacturing

- Supporting the design and manufacture of products, Hexagon Manufacturing IntelligenceÂs CAD CAM (computer-aided design and computer-aided manufacturing) software portfolio includes specialised packages to generate, manage and optimise CNC machining toolpaths in a range of industry and material applications.

CNC Simulation Software

- By virtually building the real-life machining environment prior to production, Hexagon Manufacturing Intelligence’s CNC simulation software helps manufacturers avoid errors, decrease setup times and switch CNC programs between machines to increase shop-floor productivity and reduce costs.

Factory Automation Software

- Providing a comprehensive software range to manage tooling and production resources, Hexagon Manufacturing Intelligence’s factory automation solutions give manufacturers greater visibility and traceability, enabling ongoing process optimisation for production efficiency.

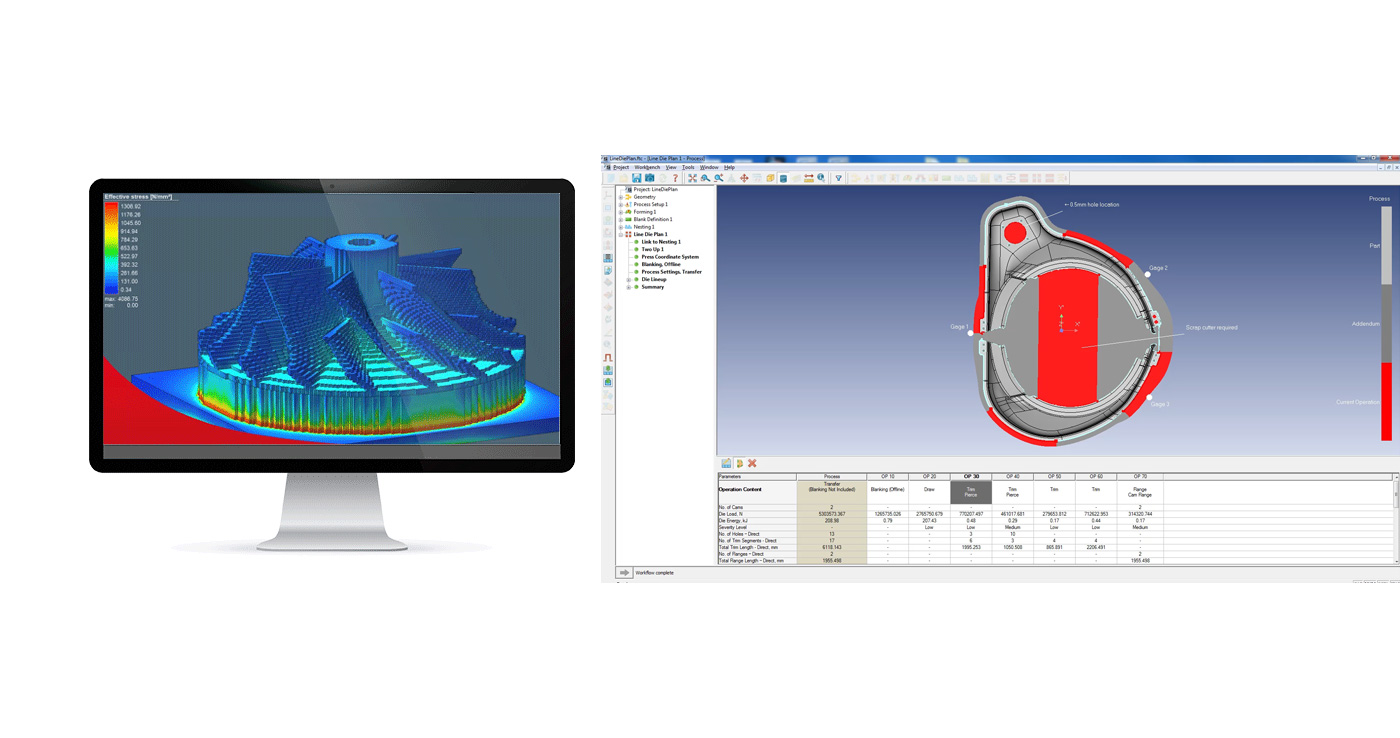

Design and Engineering Software

- Providing computer-aided engineering (CAE) software to simulate the behaviour of components, assemblies, materials, processes and environments, Hexagon Manufacturing Intelligence’s design and engineering software solutions give manufacturers the tools to design quality into components and ensure manufacturability before production begins.

Computer Aided Engineering Software (CAE Software)

- Hexagon Manufacturing IntelligenceÂs computer-aided engineering (CAE) software solutions enable designers, engineers and analysts to simulate product and process performance in finite element analysis (FEA), computational fluid dynamics (CFD) and multi-body dynamics (MBD), as well as providing cost estimation and design optimisation tools.