- Offer Profile

-

IdentPro has specialized on material tracking solutions in intralogistics. We help tracking work-in-progress items in industrial production and pallets, paper reels and similar in warehouses. Our 3D Inventory Tracking System identplus® makes barcode scanning in lift truck operated warehouses obsolete. Every pallet is precisely located indoors and out, no RFID involved! We are looking for partners around the world.

AUTOMATED TRACKING FOR INTRALOGISTICS 4.0

-

Everyone is talking about Industry 4.0, with most people thinking of digitized and networked production or predictive maintenance. But what about intralogistics?

EVERYTHING BECOMES DIGITAL. ALSO INTRALOGISTICS?

-

When thinking of a logistical process where a digital exchange of information would be helpful many people will name Supply Chain Management (SCM) first. However, Industry 4.0 works holistically only.

Everyone who still controls his warehouse processes and production supply via voice messages or with printouts has a need for action. Anyone who relies on digitization on the road or in production should consider whether in his warehouse paper lists, barcode scanning and logistics by calling are actually future-proof.

May we introduce our 3D Forklift Management System identplus®: Intralogistics 4.0 for your lift truck fleet.

ARE YOU STILL SCANNING, OR ARE YOU ALREADY 4.0?

-

Scanning barcodes by forklift drivers is also a no-no with Intralogistik 4.0. Expensive time is lost simply through the manual scanning process of barcodes.

The average duration of a barcode scan is at least 3 seconds. If you add this number up to the year, seconds add up to many days that are wasted destroying value. In addition to wasting time, manual scanning also generates corrupted data.

How much does it cost you to search for pallets and to correct errors resulting from inconsistencies in your warehouse management software (WMS)? And, BTW, how big is your safety stock?

Products: Tracking solutions for your intralogistics

-

Benefit from 100% visibility in your warehouse and in your production logistics.

3D Forklift Management System identplus®

Do you want your forklift drivers to simply transport more and not scan any barcodes? Do you want full transparency about your inventory at any time?

Then the 3D Forklift Management System identplus® is the right choice for you.Asset Management With finderbox®

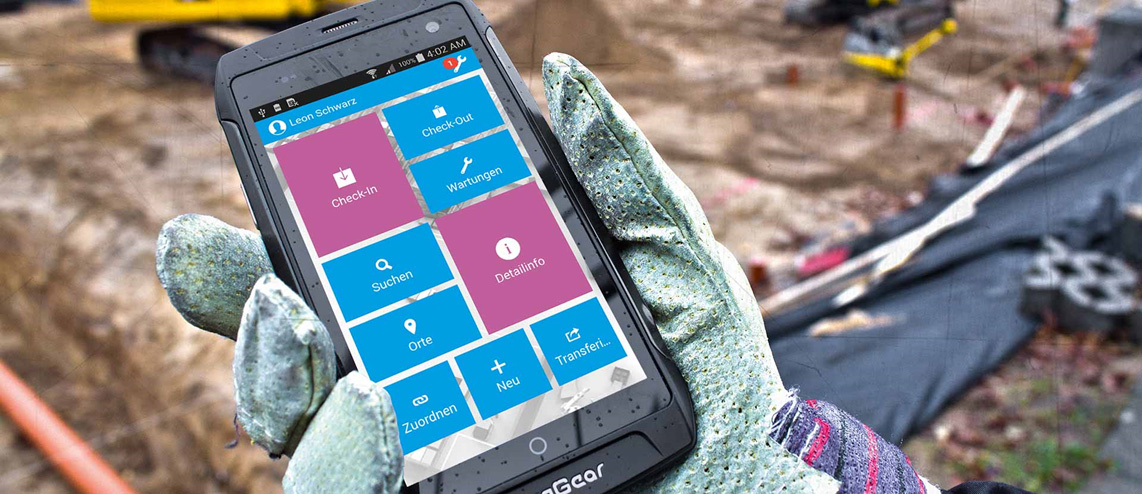

Do you want to manage your assets in a paperless, structured and centralized manner with access options independent of time and location?

Then the finderbox® is your first choice.RFID in Production (WIP)

Do you want more transparency in your production (WIP, work-in-process)?

We offer our RFID know-how for selected applications and would be happy to advise you in a workshop. 3D FORKLIFT MANAGEMENT SYSTEM IDENTPLUS®

-

With our 3D Forklift Management System identplus® you increase the productivity of your forklift fleet by up to 20% and more. Simultaneously, data and material flow are synchronized (digital shadow) – You benefit from automatic data acquisition (no scanning of barcodes!) and, when using a warehouse management system (WMS), from automatic completion confirmations. This means your lift truck fleet is fit for Industry 4.0.

IdentPro supplies visibility to companies who want to always be informed of the whereabouts and status of their goods and assets. We help you find your stuff.

We develop and implement standard solutions for automated identification and tracking of inventory in industry, production and intralogistics using auto-ID technologies like RFID, NFC, Barcode and our unique 3D Inventory Tracking System identplus® (RTLS). identplus® is based on laser technology (www.identplus.net).

Your benefits: better information quality, optimized processes, less error and reduced cost.

ASSET MANAGEMENT WITH FINDERBOX®

-

finderbox® is the easy to use asset management software in the cloud. finderbox® is extremely versatile: no matter what assets, you have everything under control. The cloud software supports RFID, NFC and barcode for tagging and identifying managed items. For mobile use there is an app available for Android smartphones (NFC and barcode) and for Apple iOS (barcode only).

- Linking tools and transponders

An NFC transponder is attached to each tool. - Scanning with the Smartphone

The employees book the tool on a construction site. - Always keeping the overview

The location and owner of your tools can be accessed anytime, anywhere. Whether with Smartphone, Tablet or PC. - enjoy th finderbox effect

Sit back and relax, you have everything under control from now on.

- Linking tools and transponders

RFID IN PRODUCTION (WORK IN PROCESS)

-

Is your production a black hole? For selected applications, we use RFID technology to bring light into the dark.

WHAT IS RFID?

-

UHF RFID is an established identification technique for optimizing selected processes and workflows. With RFID, previously manual data collection can be automated.

Where barcodes reach their limits, e.g. in harsh environments or inaccessible spaces, transparency may be achieved with RFID transponders.

The networkability of processes in the sense of Industry 4.0 or Smart Factory requires automatic data acquisition. However, a successful use of RFID requires the observance of system-immanent physical restrictions.

ADVANTAGES RFID OVER BAR CODE

-

RFID offers some decisive advantages compared to barcodes:

- Automatic data capture: Reading without line-of-sight simplifies the automated identification of objects

- Bulk-reading: Simultaneous acquisition of several objects, e.g. at goods receipt

- Security: RFID transponders are readable even when soiled

- Ruggedness: Can be used in harsh environments.

WHAT IDENTPRO OFFERS

-

For selected applications in production, such as the detection of objects at a conveyor line, IdentPro provides you with a complete solution consisting of hardware (RFID transponders, RFID readers), software and support during installation and commissioning.

Via our RFID Enterprise Server, the RFID infrastructure can be connected to any superordinate IT system, like a manufacturing execution system (MES) or similar.

DOES IT MAKE SENSE TO USE RFID TECHNOLOGY IN THE WAREHOUSE?

-

RFID can be useful for a point-by-point identification of objects in the warehouse, e.g. at goods receipt. Under certain conditions, several objects on a pallet (e.g. cartons) can be detected simultaneously as they pass through an RFID gate. Among other things, the objects to be identified must already be equipped with RFID transponders.

However, the biggest problem in many warehouses is the need to search for specific pallets. The question „Where to find what?“ occupies too many warehouse managers and the continuously required time and effort for searching reduces the productivity and thus the profit of a company.

RFID is an identification technology and therefore basically does no more than barcodes. RFID is unsuitable for locating pallets, containers, etc. In particular, RFID technology cannot provide continuous tracking of an object with high and repeatable precision. This applies in particular to bulk storage areas.

Radio waves cannot be controlled; they are attenuated, for example, in environments with liquids (beverage industry) and reflected or blocked uncontrollably in metallic environments. Also at high thermal loads RFID technology reaches its limits.

THE SOLUTION FOR YOUR WAREHOUSE: A FORKLIFT MANAFGEMENT SYSTEM INSTEAD OF RFID

-

Do you employ forklifts in your warehouse? The 3D Forklift Management System identplus® automatically tracks every movement of pallets, crates, paper rolls, etc. This gives you complete transparency about your inventory at all times: What is stored where, you know it!

identplus® is based on a laser localization solution developed by IdentPro and works without any RFID technology. Through the precise and repeatable localization of the forklifts, pallets etc. are automatically identified when they are picked up. Your forklift drivers are guided directly to any goods requested, no more searching for „lost pallets“. Furthermore, each transport order is checked for correct execution (source, product, sink). And an integrated optimizer ensures the best possible utilisation of your forklift fleet.