- Offer Profile

- Under the brand marsoflex® we produce hose assemblies for the safe

transport of liquid,

gaseous and solid media.

Our products provide specialized solutions for all industrial applications. This includes, among others, the chemical and petrochemical industry; refineries; the pharmaceutical industry; carriers and tank storage; the foodstuffs industry; all areas of mechanical engineering; plant manufacturing and industrial engineering as well as the steel industry and foundries.

MARKERT GRUPPE

Hoses

- From the correct PTFE liner for the medium to be transported, the correct pressure carrier for the operating pressure, the suitable hose cover for the intended application and a stainless steel spiral for vacuum use, we make you the best possible product for your conditions of use – always with the required conductivity. Whether it’s for loading and unloading tankers or for blood plasma applications in a pharmaceutical industry clean room, we will find the perfect hose for you.

PTFE hoses

Silicone hoses

Elastomer hoses

Composite hoses

Food hoses

Tanker and bunker hoses

Operating media hoses

Stainless-steel corrugated tube hoses

Custom components

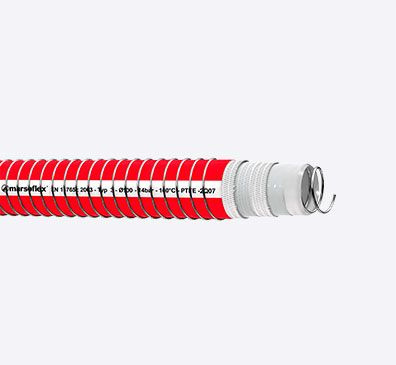

PTFE hoses

- The high quality of our marsoflex® PTFE hoses is shown by their flexibility and high resistance against almost all chemicals.

Type CA - PTFE - corrugated hose, black

- Highly flexible PTFE hose with the highest level of resistance against aggressive media. Thanks to the black, conductive tube, suitable for all explosive zones.

Type C - PTFE - corrugated hose, white

- Resistance against chemicals, acids, steam and pharmaceutical products.

Type 50 HW PTFE premium chemical hose

- Universal and premium chemical hose with black, conductive and ultra-smooth PTFE tube. Suitable for all explosive zones.

SIL 300 PTFE for the pharmaceutical industry

- The tube of this innovative hose consists of high-quality PTFE. This material allows it to be used for almost all pharmaceutical and chemical applications. The hose also impresses thanks to its high flexibility and temperature resistance. The smooth silicone cover also has FDA approval. If you wish, we can supply the hose with an extractable study.

Smooth hose type GA, black with spiral

- High-quality, flexible PTFE smooth hose with vacuum spiral. The smooth tube prevents the formation of dust pockets. Thanks to the black, conductive PTFE, it is suitable for all explosive zones.

Smooth hose type G

- High-pressure PTFE smooth hose with a high chemical resistance for chemical, pharmaceutical and foodstuff applications.

Smooth hose type GC, white with spiral

- Can be used for applications where a smooth hose with a high degree of flexibility is required. Suitable for highly purified media.

Type SIL 350 PTFE for the pharmaceutical industry

- Highly flexible and extremely durable silicone hose with conductive PTFE tube.

Highly innovative and unique in this design.

Polypropylene braid

- Pressure carrier for various application.

Polypropylene braid B6 electrically conductive

- Pressure carrier for various application, can be used in Ex-zones.

Stainless steel braid with rubber lining

- Pressure carrier for various applications

Silicone hoses

- The durable marsoflex® silicone hoses are used where hygiene and cleanliness are top priority.

SIL 300 PTFE for the pharmaceutical industry

- The tube of this innovative hose consists of high-quality PTFE. This material allows it to be used for almost all pharmaceutical and chemical applications. The hose also impresses thanks to its high flexibility and temperature resistance. The smooth silicone cover also has FDA approval. If you wish, we can supply the hose with an extractable study.

Type SIL 350 PTFE for the pharmaceutical industry

- Highly flexible and extremely durable silicone hose with conductive PTFE tube.

Highly innovative and unique in this design.

Type SIL – W

- Wire-reinforced silicone hose, ready for use in cleanrooms, with complete vacuum resistance. Does not transfer smells or tastes.

Type SIL – R

- Textile-reinforced silicone hose for high flexible and applications with a high eapplications.

Type SIL - C

- Flexible silicone hose, ready for use in cleanrooms, for the highest cleanliness and hygiene requirements.

Type SIL 100

- The type SIL 100 is resistant to extreme temperatures, ozone, radiation, moisture, compression, and weather and chemical influences.

Type SIL 200

- The textile-reinforced silicone hose type SIL 200 has high pressure resistance and can be used in the cosmetics and pharmaceutical industry, as well as in biotechnology.

Type SIL 300

- This wire-reinforced silicone hose can be used for vacuum and pressurised processes.

Elastomer hoses

- Our marsoflex® elastomer hoses can be used universally and ensure the safe transportation of your medium.

Type L suction and pressure hose NBR

- The foodstuff suction and pressure hose is suitable for products containing oils, fruit juices and alcoholic drinks with a low alcohol content.

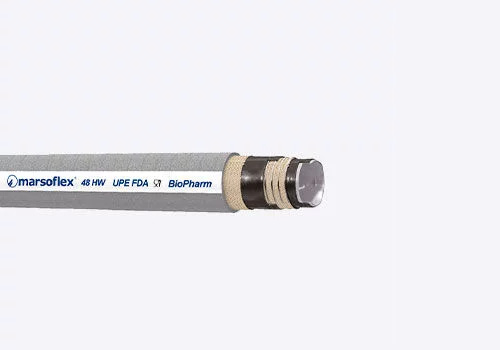

Type 48 HW chemical and pharmaceutical hose Biopharm

- The 48 HW with a conductive, highly pure UPE tube can be used universally in all applications in the pharmaceutical and foodstuffs industries.

Type 50 HW PTFE premium chemical hose

- Universal and premium chemical hose with black, conductive and ultra-smooth PTFE tube. Suitable for all explosive zones.

Type 44 HW suction and pressure hose FEP

- Our suction and pressure hose with a white FEP tube and black cover is perfectly suited to the suction and pressure transportation of almost all aggressive chemicals.

Type 45 HW suction and pressure hose UPE

- Universal chemical hose with black, conductive UPE tube. Suitable for approx. 95% of all media occurring in the chemical industry, as well as for all explosive zones.

Type LTW-UPE light suction and pressure hose

- The LTW-UPE can be used wherever low bending forces are required, and is resistant against chemicals, ozone and weather influences.

Type 40 HW suction and pressure hose EPDM

- EPDM suction and pressure hose for transporting many solvents and chemicals.s

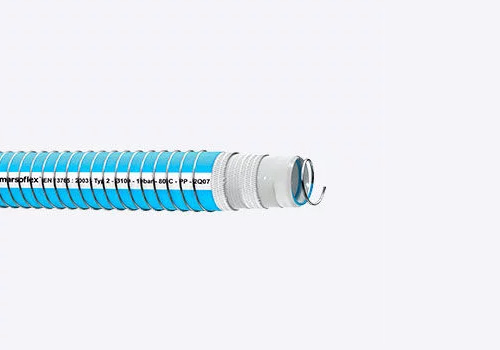

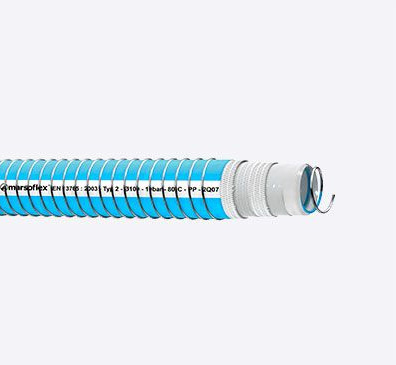

Composite hoses

- marsoflex® composite hoses offer excellent chemical resistance and have a high degree of flexibility regardless of temperature.

Type 1421 foil-wrapped hose

- The foil-wrapped hose type 1015 offers a high degree of flexibility and low bend radii regardless of temperature. It also has a high chemical resistance.

Type 1015 foil-wrapped hose

-

The foil-wrapped hose type 1015 offers a high degree of flexibility and low bend radii regardless of temperature. It also has a high chemical resistance.

Food hoses

- The odourless and tasteless tube of the marsoflex® foodstuffs hoses are excellently suited to use in the food and drinks industry.

Type L suction and pressure hose NBR

-

Type L suction and pressure hose NBR

The foodstuff suction and pressure hose is suitable for products containing oils, fruit juices and alcoholic drinks with a low alcohol content.

Tanker and bunker hoses

- Easy to handle and the ideal transportation of your medium are the typical properties of our tanker and bunker hoses.

Type D pressure hose NBR1

-

Type D is suitable for the pressurised transportation of oil products with a benzene content of up to 50%.

Type S suction and pressure hose NBR1

- Suction and pressure hose for transporting oil products with a benzene content of up to 50%.

Type LTW light suction and pressure hose NBR1

- The light suction and pressure hose type LTW impresses with its easiness of use thanks to its high degree of flexibility and its light weight.

Operating media hoses

- Our robust marsoflex® operating media hoses have a long service life and are very versatile.

Type PR – compressed air hose SBR

- For transporting compressed air and water in extreme conditions.

Type 202 steam hose EPDM/CSM

- High-pressure steam hose made from EPDM/CSM suitable for transporting saturated steam or hot water. The special cover of the type 202 is oil resistant.

Type 205 steam hose EPDM

- High-pressure steam hose made from EPDM suitable for transporting saturated steam or hot water.

Type WH water hose

- The marsoflex® water hose is a robust all-purpose hose and is excellently suited to conducting water and water-based media.

Type 60 nitrogen hose EPDM

- Suitable for flushing and displacing explosive gases and their mixtures.

Type 80 multi-purpose hose NBR

- Multi-purpose hose for transporting air, water, oil, grease, petrol, nitrogen and various chemicals.

Type 60 operating media hose NBR

- The type 60 is resistant to oil and offers many possibilities of use.

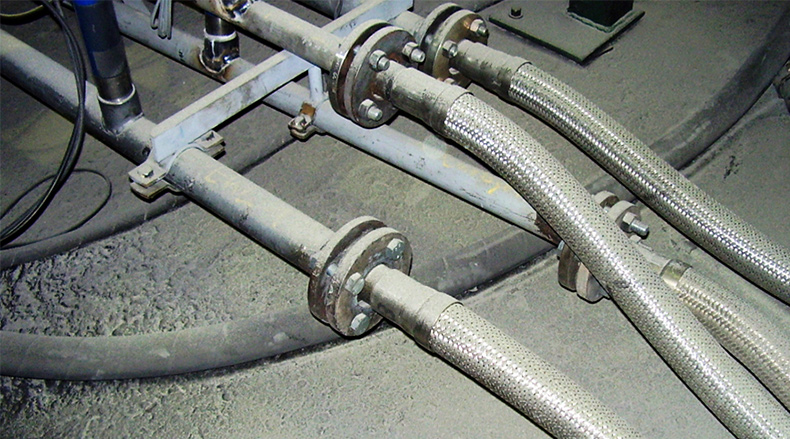

Stainless-steel corrugated tube hoses

- The marsoflex® stainless-steel corrugated tube hoses are resistant even to high temperatures, and are suitable for a wide range of applications.

Stainless-steel corrugated tube hose type EW

- Stainless-steel corrugated tube hose for high-temperature applications.

Custom components

- We can develop individual solutions for you and with you to guarantee that your production processes will continue.

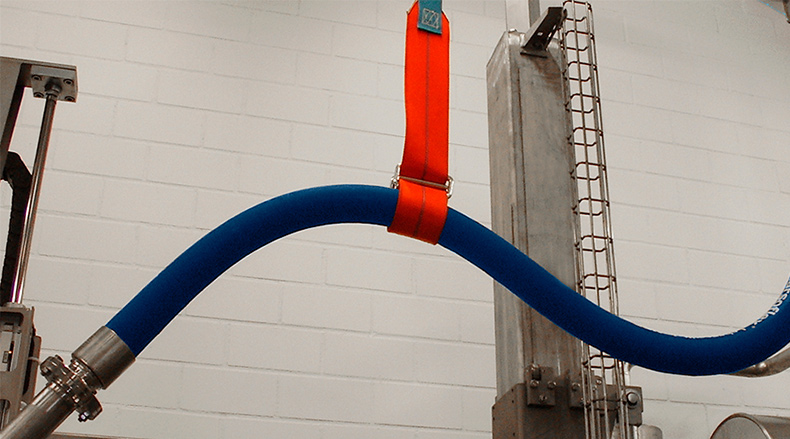

Heating hoses

- Our marsoflex® heating hoses are heating the medium up to the desired temperature or prevent a flowable product from crystallising out or curing.

Rubber Kink Protection Plus

- In cooperation with leading customers and our R&D department, we developed the Rubber Kink Protection Plus.

PTFE protector

- PTFE protectors for hoses have become indispensable within the industry.

Type 46 HW pipeline hose

- Flexible conveyor hose system for transporting abrasive and chemically aggressive materials.

Special hose systems

- In addition to standard designs of marsoflex® products, we also produce hoses for special applications.

Couplings & connections

-

If a hose is integrated with fittings, this creates what is known as a hose assembly. The variety of materials and designs for hoses is immense, but is dwarfed by the greater variety when it comes to fittings and connections.

The correct binding technology must be used to connect the hose and fitting. Regardless of whether it's clamp collars, press fittings or PTFE lining: as a manufacturer of hose assemblies, Markert has decades of experience so that every connection proves safe and reliable in use.

In addition to the fittings and connections listed below, Markert offers a wide range of special connections that can be used to reproduce any plant situation. If necessary, we also manufacture fittings from Hastelloy, for example, or we can create customised designs: we will be happy to advise you.

Quick couplings

Linings and coatings

Safety couplings

Hose connections

Seals

Areas of application

- Regardless of the physical state, marsoflex® hose systems can transport any medium safely to it’s destination. You will find our products in refineries, open pit mining, in the chemical industry, in plant and mechanical engineering as well as in filling and dosing systems and for sure in the pharmaceutical industry.

Pharmaceutical industry

-

Cleanliness and precision are the priorities for pharmaceutical industry processes. In spite of the strict requirements, marsoflex® pharmaceutical hoses can guarantee the hygienic and safe transportation of your medium. Our products are fulfilling the highest standards.

examples of usage:

The manufacture of drugs and medications.

Chemical industry

-

You need to be careful when working with chemicals. marsoflex® chemical hoses prevent hazardous materials from leaking out and make a big contribution to protecting your employees.

examples of usage:

Loading and unloading tanker lorries, tanker trucks and tanker ships, and equipping machinery, systems and instrumentsLoading and unloading tanker lorries, tanker trucks and tanker ships, and equipping machinery, systems and instruments

Food

-

There are precise regulations for contact with foodstuffs which we fulfil conscientiously with our marsoflex® products with regard to the materials used and their process integration.

examples of usage:

Filling of liquid and solid food products such as flour, sugar, wine, beer, juice, milk, oil and alcohol up to 96%.

Heavy industry

The development of the heavy industry is important for the economy of numerous countries. Due to the high mechanical stress, efficient hoses are required in this area of application. With our marsoflex® stainless-steel corrugated tube hoses, we can ensure that the processes run smoothly.

According to the requirements, they are manufactured ready to be integrated with welded hose connections.

Our marsoflex® pyro heat protection products offer effective protection for cables and hoses.

examples of usage:

Foundries, steelworks and roller mills

Transport

-

Our marsoflex® hoses offer safe transportation of numerous liquid or solid media. To do this, hoses are used which have been adapted to suit the medium being transported, including application-specific connections and couplings.

examples of usage:

Examples of use: Loading and unloading tanker lorries, rail tankers and tanker ships.