NKE

Videos

Loading the player ...

- Offer Profile

- NKE AUSTRIA develops and

manufactures premium quality rolling bearings for a wide spectrum of

industrial applications.

The uncompromising pursuit of quality is our highest priority and a cornerstone of our success. This quality process starts with engineering and commercial service, where customers’ requirements are analyzed and implemented.

Product Portfolio

Reliable bearings and competent service for wind energy applications

- Keeping your wind turbines turning

The operating conditions of wind turbines are complex and demanding; hence the bearings must work efficiently and offer supreme reliability. NKE supplies a wide range of bearings to specialised industries, including the following commonly used types for wind energy application

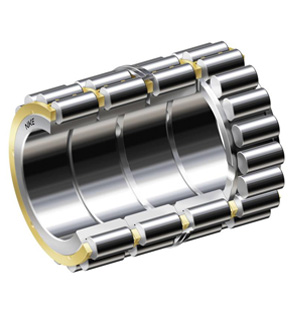

Cylindrical roller bearings

-

- Suitable for high radial loads

- Multi-row and full complement versions available for even higher radial loads

- Special specifications (optimised geometry) and customised designs available

- Modular system allows for standardisation of planet wheel bearings

- Special coatings for enhanced tribological properties

- For both gear boxes and generators

Tapered roller bearings

-

- Suitable for high radial and thrust loads

- Able to take up tilting moments

- When paired, can take up thrust loads in both directions

- Usually custom designs and for gear boxes

Spherical roller bearings

-

- Suitable for large radial loads and low to medium speeds

- Allows compensation for misalignment

- Usually for main shafts and gear boxes

our-point contact ball bearings

-

- Able to take up thrust and limited radial loads

- Easy mounting due to split inner rings

- Standard cage material: solid, one-piece brass cage (MPA)

- Usually for output shaft

Deep groove ball bearings

-

- Suitable for very high rotating speeds

- Well suited for medium high radial and axial loads in one or both directions

- Numerous clearance and tolerance classes available for different operating conditions

- Mainly for generators and gearboxes

Electrically insulated bearings

-

- Preventing damages caused by passage of electric currents

- 100% interchangeable with standard bearings

- Depending on size and type of bearings, several versions available:

- insulation coating (oxide ceramic) on outer or inner ring

- hybrid bearings with oxide ceramic rolling elements - More information about electrically insulated bearings

Standard Bearings

- Standard bearings are internationally standardized bearing types to cover most requirements in various industries. NKE offers more than 6,000 items from stock and additional items with short production lead-times. Our finished product inventory has a total value of more than ten million euro as of January 2009 and has been expanding to ensure availability.

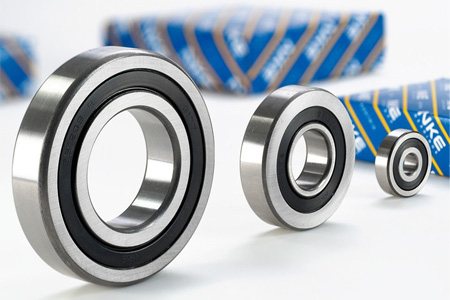

Deep groove ball bearings

- Deep groove ball bearings are the simplest yet the most popular bearing:

- Suitable for very high rotating speeds

- Well suited for medium high radial and axial loads in one or both directions

- Various seals and grease variants available for different operating conditions

- Numerous clearance and tolerance classes available for different operating conditions

- Standard: DIN 625

- Series: 600, 6000, 6200, 6300, 6400, 1600; Thin-ring: 61800, 61900

- Application examples: electrical motors, general machinery, industrial gearboxes, pumps, agricultural machinery, etc.

NKE POP range of single row deep groove ball bearings

- The NKE POP range of single row deep groove ball bearings covers the most frequently used types and sizes. The range features the following technical advantages:

- Newly developed seals (double-lip labyrinth RS2): Improved protection against contamination with low friction, better grease retention

- New, special low-noise lubricant: Lower starting torque over a wide range of temperatures

- Superior surface finish on raceways: Reduced friction, lower operating temperature

- Closer grade balls: More uniform running and lower noise

- Reduced running noise: Through 100% noise testing with stringent limit values

Angular contact ball bearings

- Angular contact ball bearings are available in single row and double row configurations.

- Able to accommodate both radial and thrust loads

- Suitable for high speed operation

- Open and sealed versions available

- Highly rigid

- Standard: DIN 616, DIN 628

- Series:

- single row: 7200, 7300

- double row: 3200, 3300, 5200, 5300 - Application examples: reduction gearboxes, agricultural machinery, pumps, etc.

Cylindrical roller bearings

- Cylindrical roller bearings have the following key features:

- Single-row (design variants N, NJ, NU and NUP) and double-row (design variants NN and NNU) available

- Cage variants: brass (M6, MA6) and polyamide (TVP3)

- Suitable for high radial loads

- High speed ratings

- Simple mounting due to the possibility to fit inner and outer rings separately

- Full complement versions available for even higher radial loads

- Standards: DIN 616, DIN 5412 (part 1)

- Application examples: industrial gearboxes, mechanical presses, electrical motors, pumps and compressors, traction motors and axle boxes for railway vehicles, steel mills, etc

Self aligning ball bearings

- Self aligning ball bearings are non separable double-row radial bearings:

- Excellent alignment compensation due to the spherical outer ring raceway

- Suitable for low to medium radial loads and low thrust loads

- Available in open and sealed versions, as well as in tapered bore (suffix K)

- Standards: DIN 616, DIN 630

- Series: 1200, 1300, 2200, 2300, 11200, 11300

- Application examples: agricultural machinery, chemistry, pumps, etc.

Tapered roller bearings

- Single row tapered roller bearings are separable radial bearings:

- Suitable for high radial loads and thrust loads (in one direction)

- Take up tilting moments

- When paired, can take up thrust loads in both directions

- Standards: DIN 616, DIN 720

- Series: 30200, 30300, 31300, 32000, 32200, 32300, 33000, 33100, 33200

- Application examples: gear boxes, pumps, compressors, etc.

Spherical roller bearings

- Spherical roller bearings are non-separable double-row radial bearings, with barrel shaped rollers.

- Excellent alignment compensation

- Suitable for large radial loads

- Low to medium speed ratings

- Standards: DIN 616, DIN 635 (Part 2)

- Series: 21300, 22200, 22300, 23000, 23100, 23200, 23900, 24000, 24100

- Application examples: heavy machinery (e.g. construction and mining machines), rolling mills, gear boxes, shaker screens, etc.

Thrust ball bearings

- Thrust ball bearings are separable axial bearings

- Available in single direction and double direction designs

- Suitable for relatively high axial loads

- Low to medium speed ratings

- Standards: DIN 616, DIN 711, DIN 715

- Series: 51100, 51200, 51300, 51400

- Application examples: vertical shafts, etc.

Cylindrical roller thrust bearings

- Cylindrical roller thrust bearings are separable axial bearings

- Available in single direction as standard, double direction upon request

- Suitable for high axial loads

- Insensitive to shock loads

- Low to medium speed ratings

- Standards: DIN 616, DIN 722 Series: 81100, 81200

- Application examples: injection molding machines, presses, etc.

Spherical roller thrust bearings

- Spherical roller thrust bearings are separable single direction acting axial bearings

- Able to accommodate misalignment

- Suitable for high axial and some radial loads

- Relatively high speed ratings

- Standards: DIN 728

- Series: 29200, 29300, 29400

- Application examples: heavy vertical shafts, injection moulding machines, etc.

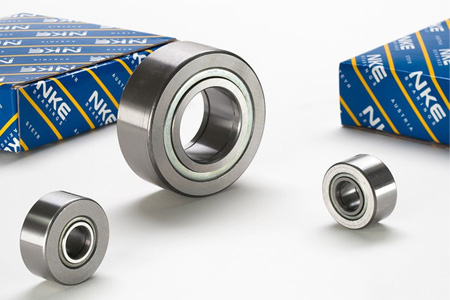

Cam rollers

-

Cam rollers are non-separable radial ball bearings with extra thick-walled outer rings

- Suitable for high radial loads, including shock loads

- Fitted with contacting seals (protection against contamination)

- Standards: DIN 616

- Series: 361200, 305700, 305800, 306700, 306800

- Application examples: cam drives, conveyor systems, etc.

Support rollers

-

Support rollers are either needle roller or cylindrical roller bearings with a thick-walled outer ring.

- Suitable for high radial loads, including shock loads

- Frequently with sphered outer rings to accommodate misalignments

- Standards: DIN 616

- Series: STO, RSTO, NA2200, RNA2200, NATR, NATV

- Application examples: cam drives, tracks, conveyor systems, etc.

Bearing units

- Bearing units consist of a housing and an insert bearing. NKE bearing units offer simple, effective and reliable technical solutions with the minimum design work requirements.

- Housing: cast iron or pressed steel

- Insert bearings: AY...NPPB, GAY...NPPB, GYE...NPPB, GE...KRRB, RAE...NPPB, GRAE...NPPB

- Application examples: iron and steel, heavy machinery, agricultural machinery, conveyors, etc.

Inch size (imperial) bearings

- Inch sized (imperial) bearings are manufactured according to various British Standards in the following product groups:

- Deep groove ball bearings

- Angular contact ball bearings

- Cylindrical roller bearings

Special bearings for your special requirements

-

If your application requires special sizes, load or speed ratings,

we can provide you with rapid, practical and creative custom-made

solutions. Our experienced engineering team has developed special

bearings and systems for numerous industries, such as:

- Pumps

- Agricultural machinery

- Wind energy

- Heavy machinery

- Iron and steel

- Railway vehicles

- General machinery

- Industria gearboxes

- etc.

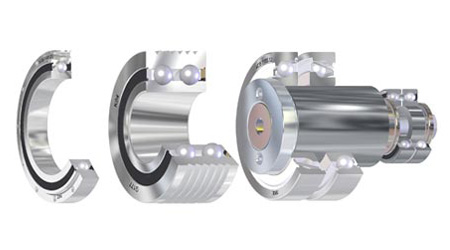

NKE electrically insulated rolling bearings

-

Advantages

- Higher operational reliability through optimum protection

against electrical corrosion

- More economic than, for example, insulation on housings or

shafts

- Interchangeable: Same key dimensions and technical properties as

conventional bearings

- Coating resistant to damage if correctly handled

Typical applications

Electric motors, generators, etc.

NKE electrically insulated rolling bearings - Optimum protection against bearing damage caused by the passage of currents

-

NKE electrically insulated rolling bearings reliably prevent current

discharge. Three versions are available:

- Bearings with oxide ceramic insulating layers on outer ring (SQ77) or inner ring (SQ77E) – Applied with plasma technology, the insulation has a guaranteed dielectric strength of at least 1000 V AC or DC.

- SQ77B (hybrid bearing): Rolling bearing with oxide ceramic rolling elements. Resistance of insulation theoretically ∞.

- SQ77(insulated outer ring)

Cylindrical roller bearings - Design variants: NJ, NU, NUP;

Dimension series: 210-230, 310-330; Cages: brass and polyamide; Radial clearance groups: C0, C3, C4

Deep groove ball bearings - Dimension series: 6212-6226; 6312-6326; Cages: brass; Radial clearance groups: C3, C4 - Other types and SQ77E (insulated inner ring) as well as SQ77B (hybrid) upon request

NKE bearings for your applications

-

Whether you want to increase the performance of your equipment or to reduce the life cycle costs to increase profitability, you can benefit from NKE’s professional advice and technical expertise. We have developed effective solutions in a wide spectrum of industries, for example:

- Pumps

- Gearboxes

- Railways

- Agricultural machinery

- Electrical motors

- Wind energy

- Construction and heavy machinery

- Iron and steel

- General machinery

- Others

- General machinery

- Industrial gearboxes

- etc.

Bearing solutions for pumps

-

NKE offers comprehensive bearing solutions for high performance pumps. Our products are used in numerous industries, such as the petrochemical, food, water supply, and chemical industries.

Standard bearings – commonly used bearing types for pump applications:- Cylindrical roller bearings

- Angular contact ball bearings

- Spherical roller bearings

- Tapered roller bearings

- Deep groove ball bearing

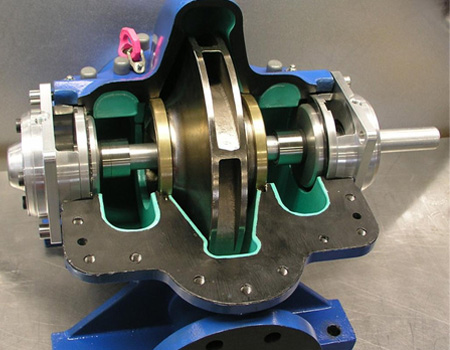

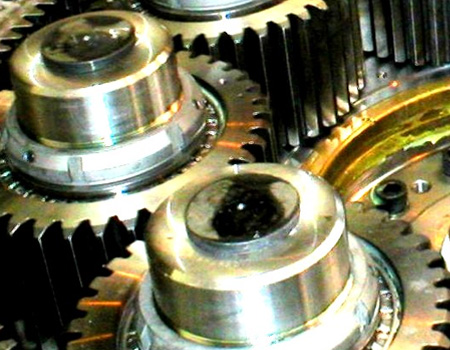

Bearing solutions for gearboxes

-

NKE offers comprehensive bearing solutions for industrial gearboxes. NKE bearings are used in general machinery, material handling, iron and steel processing, gearboxes for windmills and many more.

Standard bearings – commonly used bearing types for gearbox applications:

- Cylindrical roller bearings

- Spherical roller bearings

- Tapered roller bearings

- Angular contact ball bearings

- Deep groove ball bearing

NKE bearings for traction motors and railway gearboxes: Always on the right track

-

Over the years, NKE AUSTRIA has successfully gained approval from numerous renowned companies in the railway industries, including railway operators, service companies and OEM manufacturers.

Equipped with engineering know-how and manufacturing expertise, NKE can provide you with comprehensive bearing products and services.

Traction motor bearings

Traction motor bearings must demonstrate long service life. The most frequently used bearing types are:- Cylindrical roller bearings

- Deep groove ball bearings

- Electrically insulated bearings (coated outer ring or inner ring, hybrid)

Bearing solutions for agricultural machinery

-

Agricultural equipment often operates under rough conditions, such as contamination, rain, dust, shock loads or corrosion. NKE’s engineers have successfully developed solutions for numerous agricultural machinery manufacturers.

Standard bearings – commonly used bearing types in agricultural machinery:- Bearing units

- Deep groove ball bearings

- Angular contact ball bearings

- Tapered roller bearings

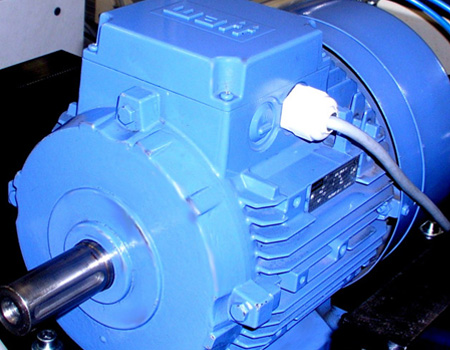

Bearing solutions for electrical motors

-

Bearings for electrical motors are required to have extremely low running noise, long service life, high load capacity, efficient seals, and cost effectiveness. NKE supplies a broad range of bearings for this industry.

Standard bearings – commonly used bearing types in electrical motors:- Deep groove ball bearings

- Cylindrical roller bearings

- Angular contact ball bearings

Reliable bearings and competent service for wind energy applications

-

The operating conditions of wind turbines are complex and demanding; hence the bearings must work efficiently and offer supreme reliability. NKE supplies a wide range of bearings to

specialized industries, including the following commonly used types for wind energy applications:

- Cylindrical roller bearings

- Tapered roller bearings

- Spherical roller bearings

- Four-point contact ball bearings

- Deep groove ball bearings

- Electrically insulated bearings

- Competent services

Bearing solutions for construction and heavy machinery

-

In heavy and construction machinery, bearings are sometimes exposed to extreme operating conditions – excessive loads, contaminated environments, rough weather, etc. NKE has extensive experience in this area.

Standard bearings – commonly used bearing types in construction and heavy machinery:- Spherical roller bearings

- Cylindrical roller bearings

- Tapered roller bearings

Bearing solutions for iron and steel

-

Operating conditions for bearings in iron and steel industries are extreme – excessive loads, often extremely high temperatures, vibrations and shocks, etc. NKE bearings have been used by many renowned customers in the industry.

Standard bearings – commonly used bearing types in iron and steel:- Spherical roller bearings

- Cylindrical roller bearings

- Tapered roller bearings

- Thrust ball bearings

- Angular contact ball bearings

- Bearing units

Bearing solutions for general machinery

-

Whether for injection molding machines, forklifts, compressors, or mechanical presses -NKE has the right bearing solution for you.

Standard bearings – Due to the diversity of general machinery, almost all types of standard bearings can be found in use. Please refer to the section "standard bearings"

Special bearings – If your application requires special sizes, load or speed ratings, we can provide you with rapid, practical and creative custom-made solutions.

Bearing solutions for YOUR applications

-

NKE develops and manufactures premium quality bearings for a wide spectrum of industries. Our technical team in Steyr has the experience and know-how to develop solutions for YOUR application too. In an uncomplicated and unbureaucratic way.

Just talk to us!

Production

- Manufacture on the Steyr Site

The strategic set-up of the manufacturing facilities in Steyr, Austria is based around flexibility and speed. State-of-the-art technologies enable the highest operating efficiency and precision.

Manufacture of components

Our flexible mechanical manufacturing units of the latest generation enable machining processes such as grinding and honing (superfinishing) of bearing inner and outer rings. Our machine park is configured for all bearing types, such as cylindrical roller bearings, deep groove ball bearings, tapered roller bearings and spherical roller bearings.

CNC machining unit

CNC grinding

Honing/superfinishing

Assembly Lines

- The assembly of components are carried out on four interlinked production lines. Currently, the assembly in Steyr is focussed on bearings of medium to larger diameters. This assembly range comprises more than 5,000 bearing types and is continuously expanding

Assembly lines of NKE in Steyr

Assembly of cylindrical roller bearings

Hot riveting of brass cages