- Offer Profile

- Coherent Corp. is a global leader in materials, networking, and lasers for the industrial, communications, electronics, and instrumentation markets. The company is headquartered in Saxonburg, Pennsylvania. It was founded in 1971 to manufacture high-quality materials and optics for industrial lasers. Today, the company operates in more than 20 countries around the world.

Coherent is focused on delivering innovations that fuel market megatrends while pursuing our mission of enabling the world to be safer, healthier, closer, and more efficient. Coherent empowers market innovators to define the future through breakthrough technologies, from materials to systems

CO2 LASERS

-

Family of sealed CO2 and CO Lasers, with power from Watts to Kilowatts for processing materials ranging from paper to metal. Coherent offers the broadest portfolio of completely sealed CO2 and CO laser products in the market.

This family of sealed lasers is available in a wide range of models, with output powers ranging from 20W to 1000W. Their no-maintenance design makes them a robust and highly reliable ‘laser engine’. And, with market-proven Designed in Reliability at its foundation, Coherent’s CO2 and CO lasers offer the best power/performance/size ratio for a sealed laser.

In addition to standard products, Coherent develops customized high and lower power CO2 and CO laser solutions for commercial, industrial, and military applications. With the extensive system and subsystem design and development capability, Coherent offers complete subsystem solutions to select customers. These solutions can include lasers, embedded controls, remote telemetry and diagnostics, as well as extensive optical, electronic and mechanical design expertise.

Diamond 5 μm CO Laser

-

Get breakthrough technology for 5 µm output that delivers the same reliability, stability, and beam quality as traditional CO2 lasers to enable new applications.

This laser's unique wavelength can increase processing efficiency with certain plastic films, polymers, and water, plus some of the dielectrics and copper oxides used in PCBs, and also enables smaller focused spot sizes to yield higher resolution.

Diamond C/Cx Series

-

Cut, slit, engrave, score, and mark a wide variety of materials, including wood, cloth, leather, paper, films, plastics, die boards, and even glass.

These low power (<150 W) CO2 lasers combine superior optical performance with high reliability, exceptional stability, long operational lifetimes, and a modular design for easy serviceability, making them a worry-free, cost-effective choice for OEMs.

Diamond J-1000 Series

-

Use 1 kW of power for converting, cutting, engraving, and drilling of paper, thin films, plastics, glass, carbon composites, textiles, wood, and even thin metals.

This laser offers a unique blend of compact size, exceptional output characteristics (high peak power, fast rise/fall times, 200 kHz repetition rate), and numerous features for easy field service that make it an ideal choice for systems integrators.

DIAMOND J-Series

-

Cut, drill, engrave, scribe and mark a wide variety of materials including plastics, metals, composites, PCBs, flex circuits, wood, die boards, paper, and cardboard.

Combines power, excellent beam quality, and nearly square wave pulses for high processing efficiency and speed. With small heat affected zone, plus compact, fully sealed, slab discharge construction for enhanced reliability and low cost-of-ownership.

DC Series

-

Cut, weld and perform surface treatment of metals, plastics, and organics with high speed and consistency with these diffusion-cooled, low-maintenance, highly stable CO2 slab lasers.

CO2 slab lasers deliver greater reliability, higher output consistency, and minimal gas consumption due to diffusion cooling compared to the fast flow construction traditionally utilized in Multi-kW CO2 lasers.

Industrial Fiber & Diode Lasers

- The HighLight Series of direct-diode systems and fiber lasers are robust and easy-to-use. These systems have a proven track record in industrial materials processing applications.

HighLight FL Series

-

See our cost-effective, industrial, multi-kW fiber lasers for many common welding tasks  maximizing operational flexibility with detachable process fibers.

The HighLight FL series employs a unique multi-stage back reflection immunity system to enhance reliability and lifetime, and enables safe processing of highly reflective materials, including brass, copper, and aluminum.

HighLight FL-ARM Series

-

Go beyond what's possible with advanced fiber laser technology for effectively welding delicate or heat-sensitive materials, dissimilar materials, and even copper.

Coherent Adjustable Ring Mode (ARM) fiber lasers utilize a unique center/ring beam. Totally independent power and modulation control of these two beam components enables highly precise energy delivery for enhanced capabilities and improved results.

HighLight DD Series

-

Get up to 10 kW output power and a free space delivered beam with numerous shape options with these ideal tools for high-speed, large-area materials processing.

The high output power and large beam lengths of these lasers enable high-deposition rate cladding and additive manufacturing, plus heat treating.

HighLight DL Series

-

Use fiber-coupled, multi-kW diode lasers for efficient, cladding, additive manufacturing, heat-treatment, and laser assisted bonding.

These lasers combine high output power, the convenience of fiber delivery, and numerous optional accessories to make it easy to configure for specific tasks. Plus, their conduction-cooled diodes do not require deionized cooling water.

Compact Series

-

Deliver robust, modular, and physically compact sources with enough output power (50 to 1200 W) for materials processing of plastics, and metals.

Easily implement laser materials processing with our small, turnkey, fiber-coupled systems that integrate a diode source with all the required power and cooling equipment, featuring single-phase power requirements.

Laser Tools and Systems

-

From Turnkey Laser Tools to Complete Laser Machines

For decades Coherent has been developing not only laser sources but also specialized complete laser tools and laser systems for nearly every applications covering laser welding, laser cutting, laser marking & engraving, and various customized laser solutions.

With field proven success, all Coherent products are backed by a worldwide application development and support team, allowing customers to achieve greater productivity, improved results, and reduced operation cost.

Multi-Axis Universal Workstations

-

Versatile turnkey Universal Workstations for precision CNC laser processing of 2D and 3D parts, with a complete choice of nanosecond, USP or fiber laser sources.

UW workstations are flexible and economical multi-axis machines offered in either a closed (Class 1) format or open (Class 4) for very large parts. They are available in three footprints with options such as a rotary table and heavy (45 kg) part handling.

Manual Welding Systems

-

Offering manual and semi-automated tools that make the benefits of high-precision laser welding readily accessible.

These systems combine a Nd:YAG or fiber laser, laser-safe work chamber, microscope viewer, easy-to-use interface, and optional rotation or CNC axes into a compact package. They enable spot and seam welds to be produced quickly, at micron level precision, even by inexperienced users.

MPS Series

-

Modular and versatile integrated systems for laser welding, cutting, structuring and drilling, as well as for numerous high-precision USP laser-enabled applications.

Four MPS systems  Compact, Flexible, Rotary, Advanced  provide complete versatility with a choice of multiple different beam scanning modules and several multi-axis part motion options. Available with a broad range of laser types and power outputs

META Series

-

Get compact, flatbed CO2 laser machines for cutting, marking, and engraving of acrylic, wood, and other organic materials, plus metals, in sheets up to 1.25 m x 1.25 m.

META Series are complete, standalone tools offering a unique combination of small physical size, low operating cost, ease-of-use, exceptional reliability, and high operational versatility. Easy setup and fast cutting deliver economical production.

StarCut Tube Laser Cutting Systems

-

Fully-automated, multi-axis CNC machines for tubes and flat materials, including medical devices such as catheter shafts, stents, hypotubes, PTCA devices, TAVR, etc.

With a mineral cast cutting base, StarCut Tube L 600 and StarCut Tube SL offer the ultimate in precision, with contour cutting accuracies better than +/- 5 µm. A choice of fiber laser or the latest Monaco USP laser enables fine cutting of any polymer or metal.

Continuous Wave (CW) Solid-State Lasers

-

A complete portfolio of continuous wave lasers ranging in wavelength from the deep UV to the far IR, and power levels from a few mW’s up to to multiple Watts.

- OBIS Lasers - Compact UV, visible, and near-IR lasers with modulation features.

- Sapphire Lasers - Continuous wave lasers available from 458 nm to 594 nm and ultra-narrow line width versions.

- StingRay and BioRay Lasers - High-quality elliptical dot lasers or flat-top line generators.

- Genesis Lasers - Continuous wave lasers available from 355 nm to 1154 nm with powers up to 10W.

- Verdi Lasers - Powers up to 20W at 532 nm.

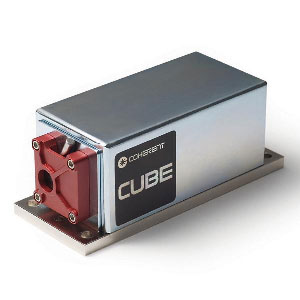

- CUBE Lasers - Compact UV and visible lasers with a footprint of 40 mm x 100 mm.

- Compass 115M - Continuous wave green lasers from 5 mW to 20 mW.

- Miniature Diode Laser Modules - High-quality elliptical or circular beams. Also available in line generators.

Genesis Lasers

-

CW lasers with industrial reliability, long lifetimes, and unmatched performance choices for lab or OEM use: wavelengths from 355 to 1154 nm and power from 40 mW to 10 W.

Genesis CX provides TEM00 output up to 10 W visible or 250 mW UV, for semiconductor inspection, holography, flow cytometry, and microscopy.

Genesis MX MTM provides low M2 output up to 10 W at wavelengths from 460 to 1154 nm, for medical applications, bio-instrumentation, and imaging.

Genesis MX STM and SLM provide TEM00 output up to 2 W of visible output, for semiconductor inspection, holography, and bio-instrumentation.

CUBE Lasers

-

Compact turnkey diode laser systems, including a laser head, power supply, cable, and control box, for use in flow cytometry, sequencing, microscopy, and more.

CUBE lasers are designed for easy setup and simplified use. CUBE deliver the most power, stability, and performance, together with the best value. They support analog, digital, and mixed modulation modes. Ideal for OEMs, plus CDRH safety features support laboratory use.

Sapphire Lasers

-

Providing industry-leading beam quality, reliability, and stability with up to 500 mW of low noise output for OEMs and end users. A choice of 9 visible wavelengths.

The leading choice for OEM instrumentation and lab use with >50,000 installed in the field. Applications include flow cytometry, confocal microscopy, DNA sequencing, high throughput screening, Raman spectroscopy, interferometry, inspection, metrology, and more.

Verdi Lasers

-

Providing high-stability TEM00 CW power up to 20 W at 532 nm, the Verdi is ideal for a wide range of applications including semiconductor inspection, annealing, holography, and Ti:Sapphire pumping.

The Verdi series features OPSL models ideal for semiconductor inspection, annealing, and Ti:S pumping. It also includes SLM single-longitudinal mode OPSL and DPSS lasers for interferometry/holography and ultra-low noise applications.

Excimer Lasers

Excimer Lasers

- With 50 years of experience in excimer lasers, we understand you get the best results with an excimer laser matched to your application. ThatÂs why we offer the widest selection of laser power and energy options, all with superior quality and performance.

The High-Power Ion Laser Leader since 1969.

-

Noble gas ion lasers are among most mature of all laser technologies. Coherent has been in the high-power ion laser business from the very dawn of the laser industry.

With technological maturity comes performance and reliability that was unheard of when ion lasers first made their name in applications as diverse as ophthalmologic photocoagulation, laser pumping and holography. From flow cytometry to laser light shows, and everything in between, Coherent ion lasers have been there. We are the acknowledged leader, with the market position and installed base to prove it. That is why ion lasers are still the light source of choice for mission-critical applications in the semiconductor and microelectronics industries worldwide. INNOVA Series

-

Offering the ion laser's unique capability for producing output at numerous wavelengths, including several high-power lines in the ultraviolet.

Coherent leverages over 50 years of experience in ion lasers to provide a range of systems that deliver long tube lifetime, high stability, and exceptional reliability, combined with automation capabilities for ease-of-use and enhanced productivity.

Laser Diode Modules

-

Lasers that transform the familiar laser dot into a wide range of structured light patterns for alignment, inspection and machine vision applications.

Coherent Structured Light Lasers offer the Machine Vision market the highest quality performance with the proven reliability.- Exceptional line uniformity

- Unique beam shaping capabilities

- Unmatched power ranges from 1 mW to 7 W

- Widest range for standard options

- Largest installed base of Machine Vision Lasers

- Highest reliability and best industry warranty - 24 months.

- Uniformity – Down to +/- 1%

- Straightness <= 0.1% of line length

- Relative Illumination limits >= 75% of normalized intensity

- Boresight <= 3 mrad, Pointing <= 10 urad/C

StingRay and BioRay

-

StingRay and BioRay deliver power and control to your application with high-quality glass optics and sophisticated electronics to improve SNR and measurement speed.

StingRay is a high-performance top-hat-profile laser with a choice of fan angles to create the line you need. BioRay is a Stingray with an included heat sink and mounting plate for life science applications, with an elliptical beam output and adjustable focus.

Ultra-Low Noise (ULN) and Visible Laser Modules (VLM)

-

OEM laser modules offering ultra-low noise or extreme miniaturization, with circular, elliptical, or fan line output for use in inspection, alignment, and instrumentation.

The tiny VLM style modules are fully featured robust systems. The head includes precision aligned, high-quality glass optics, plus a photodiode and feedback electronics to control the power. The ULN modules eliminate mode-hops and deliver

SureLock

-

Single-frequency or narrowed linewidth lasers with stabilized temperature operation and high efficiency, that are ideal for Raman spectroscopy and metrology.

SureLock diode laser modules deliver superior optical stability. They enable affordable, portable, instrument-quality performance for diverse applications. They are available in a wide range of wavelengths, power levels, and form factors.

CUBE

-

Compact turnkey diode laser systems, including a laser head, power supply, cable, and control box, for use in flow cytometry, sequencing, microscopy, and more.

CUBE lasers are designed for easy setup and simplified use. CUBE deliver the most power, stability, and performance, together with the best value. They support analog, digital, and mixed modulation modes. Ideal for OEMs, plus CDRH safety features support laboratory use.

Industrial Ultra Short-Pulse Lasers

-

Short-pulsed industrial lasers from nanosecond lasers with up to 1 Joule pulse energy, through picosecond lasers with up to 80 MHz repetition rates, to femtosecond lasers with up to 900 fs pulse widths.

Nanosecond Lasers - With pulsewidths of 10’s of nanoseconds and high power output, nanosecond lasers perform precision processing with excellent material removal rates for microelectronics, materials processing, solar and medical device manufacturing

Picosecond Lasers - With pulse durations typically around 10 ps, picosecond lasers offer the best mix of high quality results and reasonable process throughput for a wide range of precision processing applications, including cutting, drilling and marking.

Femtosecond Lasers - The ultrafast pulses delivered by femtosecond lasers enable the most demanding, high precision micro-structuring tasks in industrial and ophthalmic applications, and are employed when quality is of utmost importance.

Chameleon Discovery NX

-

Addressing the most demanding requirements in two-photon imaging and spectroscopy by delivering industry leading power levels and tunablity.

Deepest excitation of all fluorescent probes & label-free modalities. Phase-locked second beam and octave spanning (660 to 1320 nm) tuning range benefit Raman techniques and ultra-fast spectroscopy applications. Built-in Fast Power Control (TPC) available.

HyperRapid NXT

-

Maximize throughput and minimize cost-per-part with this high-power picosecond laser. Its wide operational range makes it suitable for use on nearly any material.

Tasks as diverse as cutting and drilling of metals, semiconductors, plastics, organics, glass, sapphire, ceramics, and composites all benefit from the output characteristics, pulse control capabilities, reliability, and stability of this laser.